Comparison of the Economy and Controllability of Pressure Swing Distillation with Two Energy-Saving Modes for Separating a Binary Azeotrope Containing Lower Alcohols

Abstract

1. Introduction

2. Steady State Design and Optimization

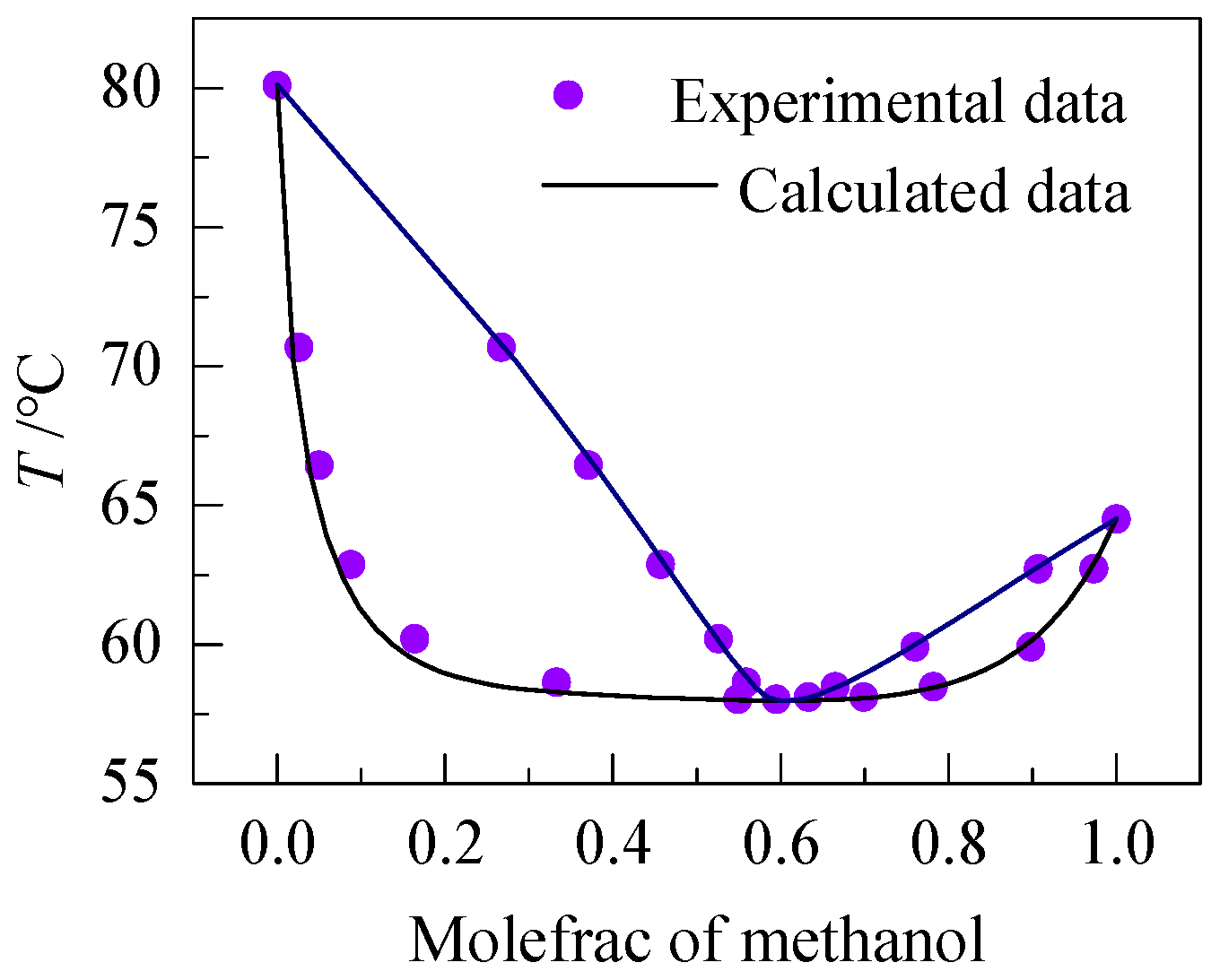

2.1. Property Method

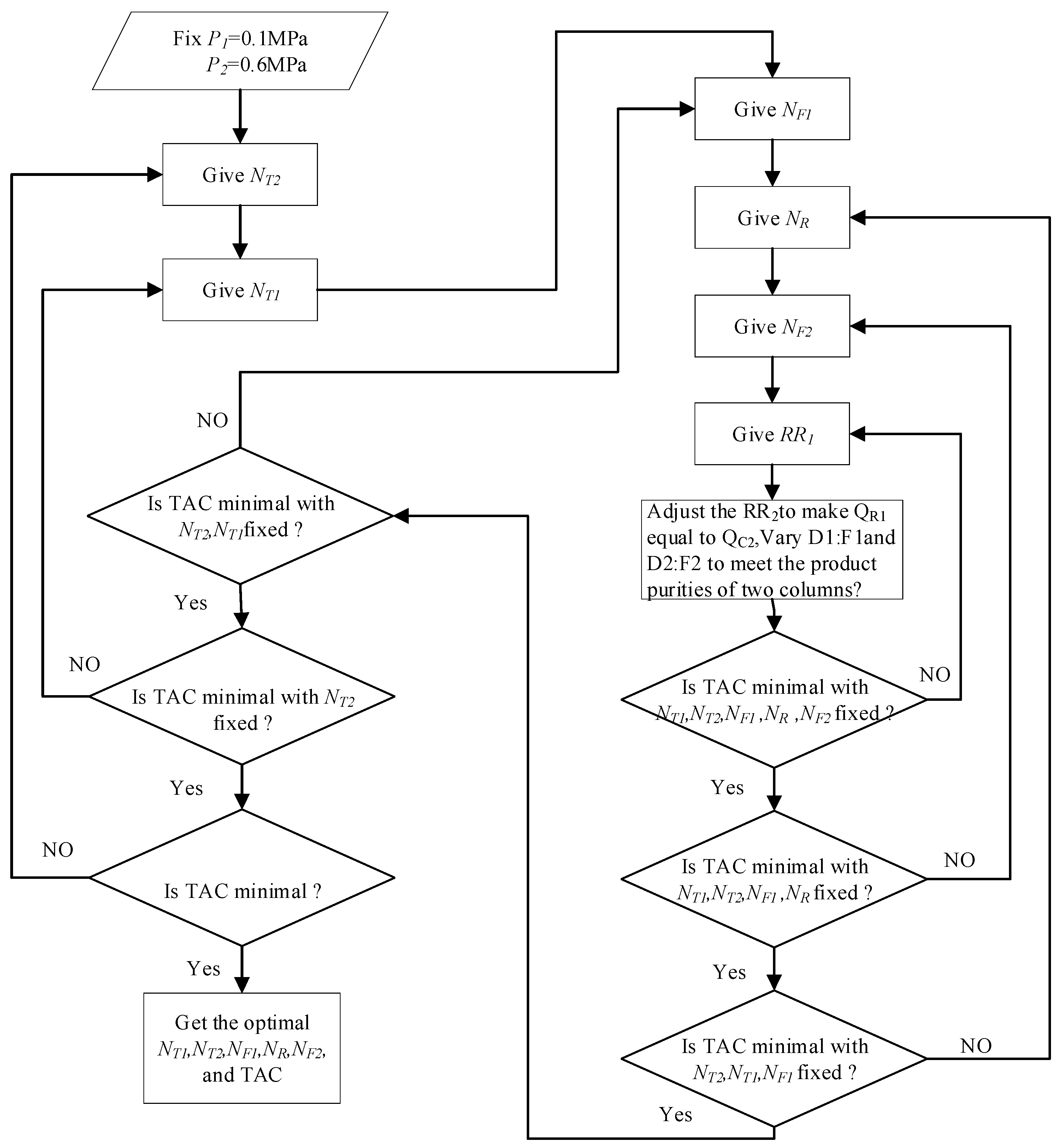

2.2. Optimization Method

2.3. Pressure Determination

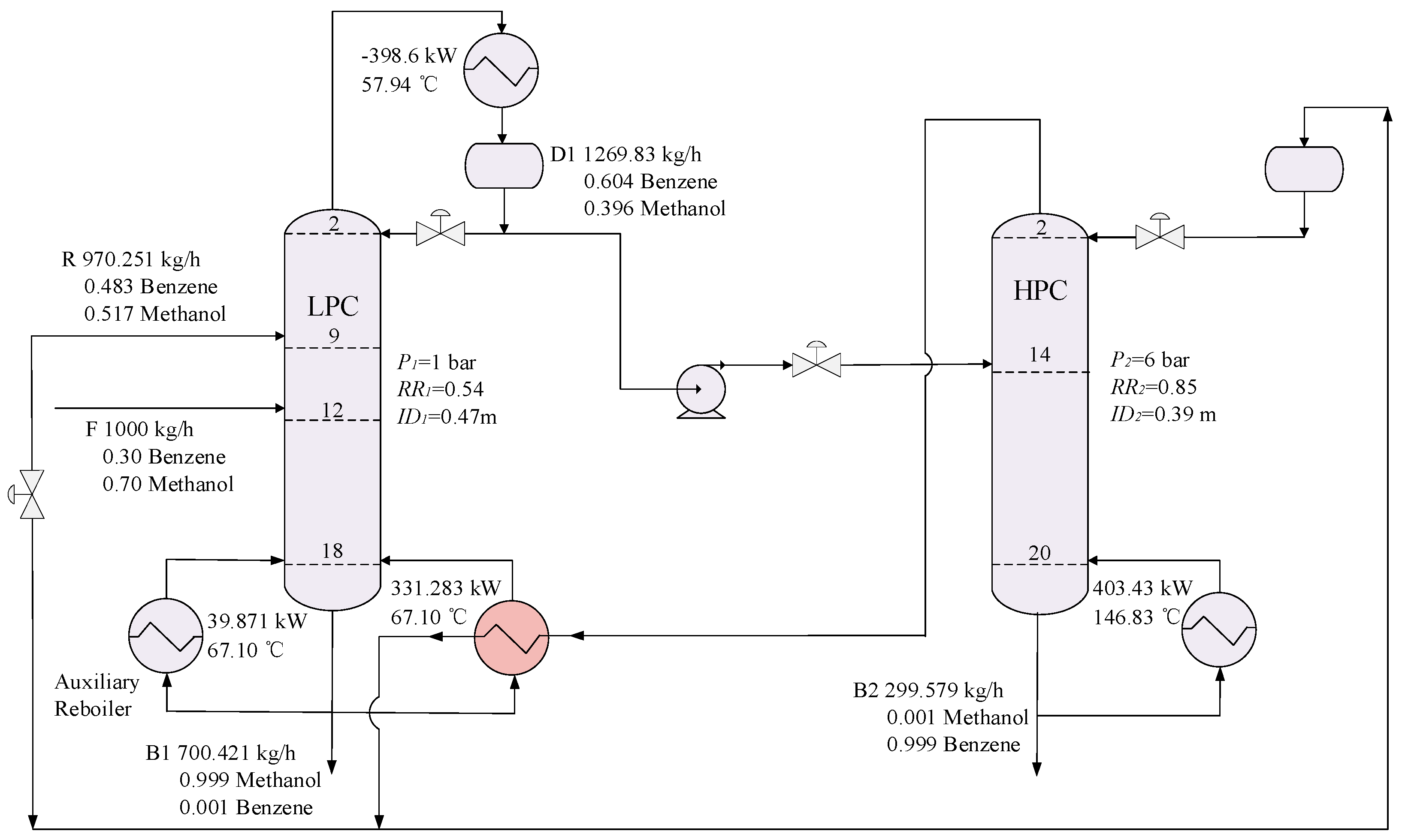

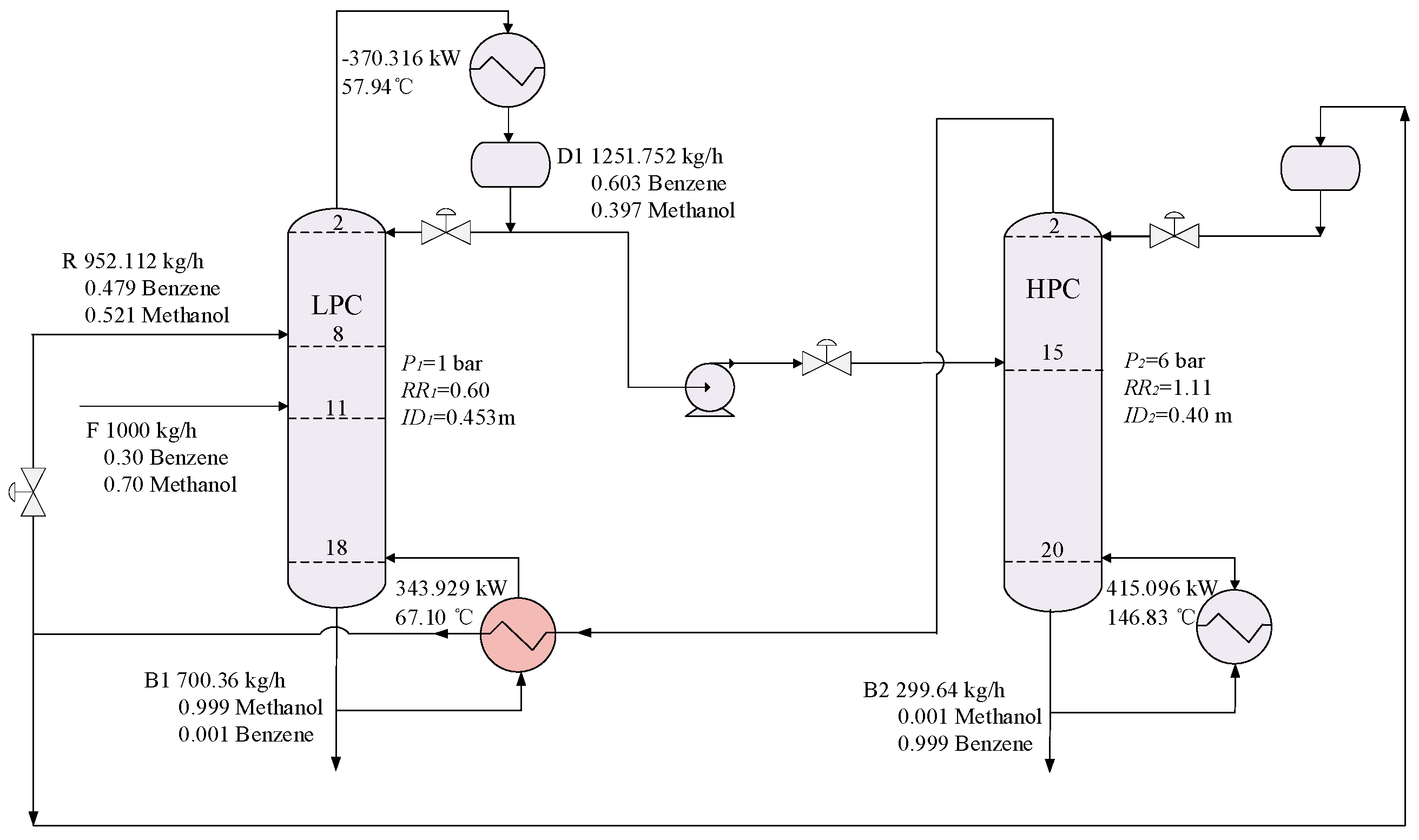

2.4. Optimization

2.4.1. Optimization of Distillation Sequence

2.4.2. Optimization of Operating Parameters

3. Control Structure Design

3.1. Selection of TCS

3.2. Control Strategies for Partial HIPSD Process

3.2.1. Control Structure CS1

3.2.2. Control Structure CS2

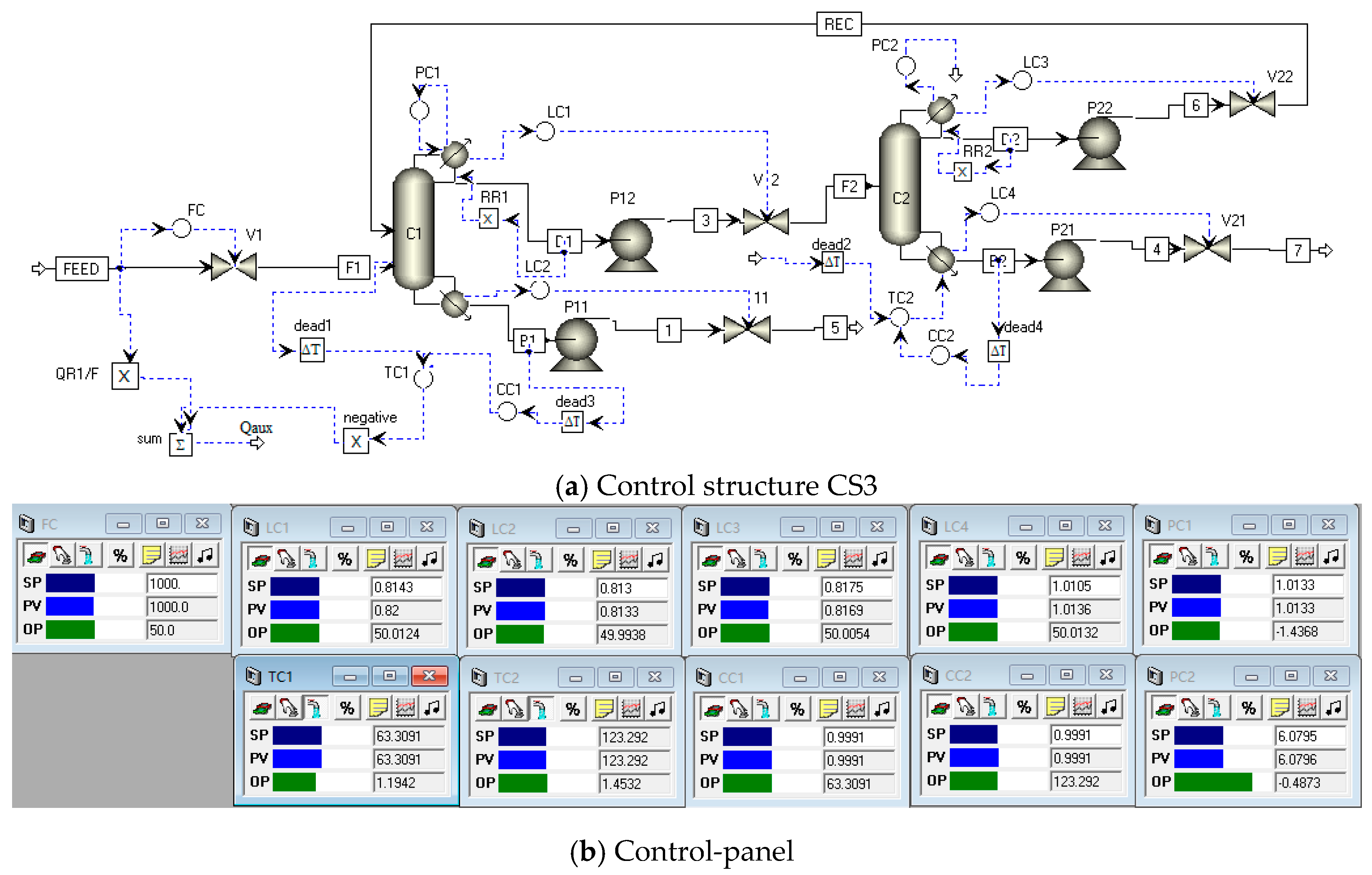

3.2.3. Control Structure CS3

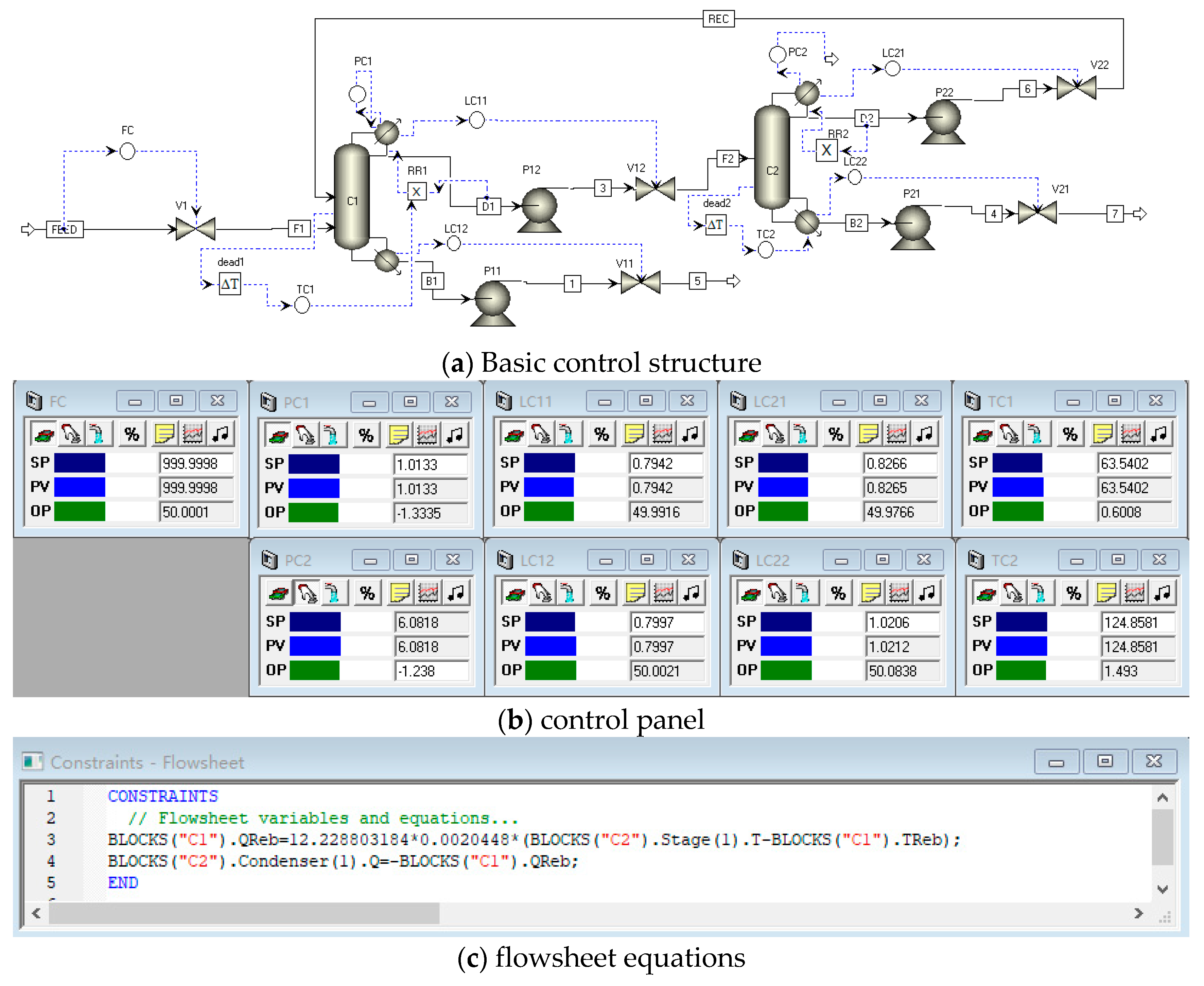

3.3. Control Strategies of Fully HIPSD Process

3.3.1. Control Structure CS1

3.3.2. Control Structure CS2

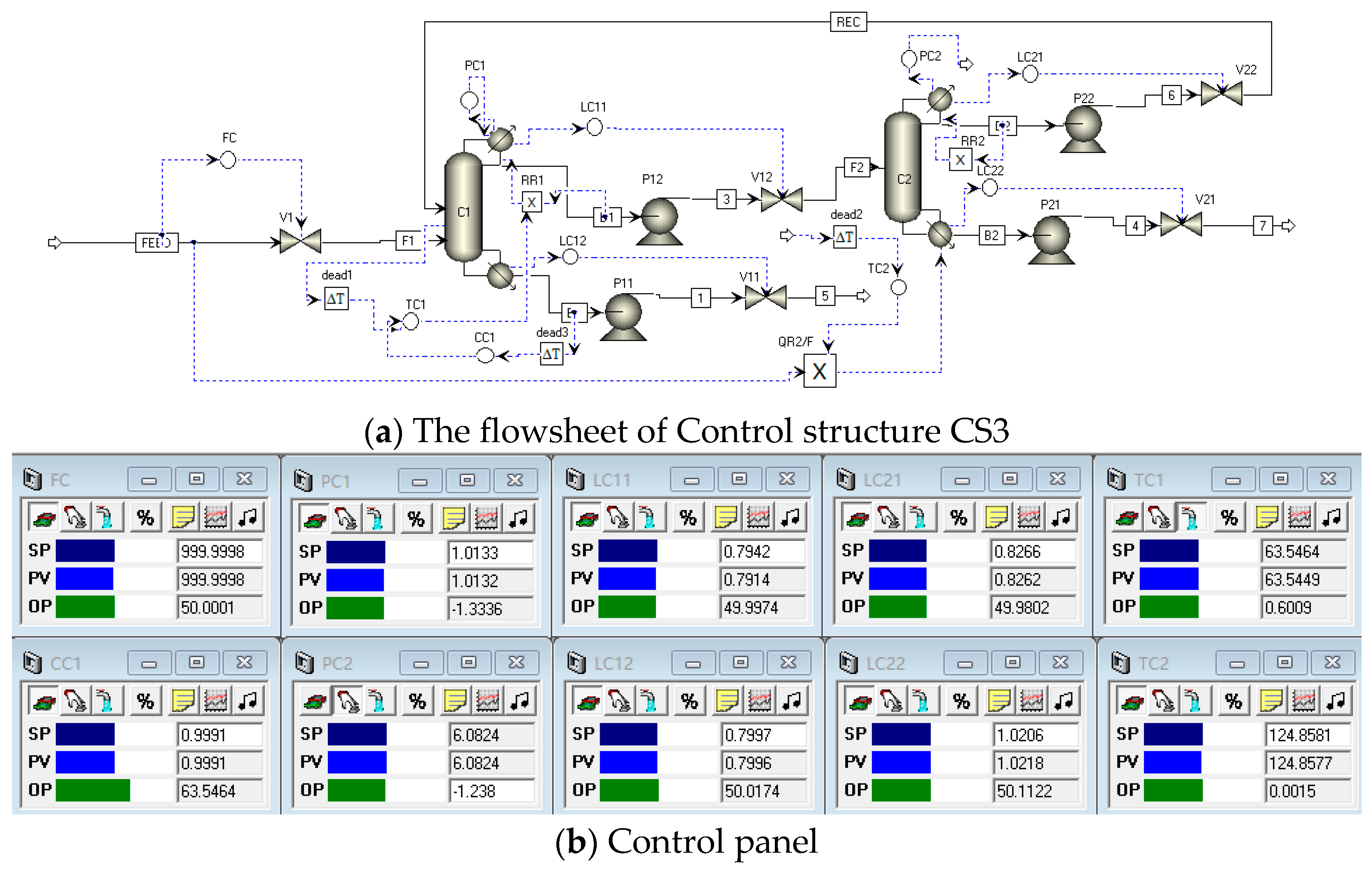

3.3.3. Control Structure CS3

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Luyben, W.L. Design and Control of a Fully Heat-Integrated Pressure-Swing Azeotropic Distillation System. Ind. Eng. Chem. Res. 2008, 47, 2681–2695. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Z.; Zhang, H.; Zhang, Q. Control of Heat Integrated Pressure-Swing-Distillation Process for Separating Azeotropic Mixture of Tetrahydrofuran and Methanol. Ind. Eng. Chem. Res. 2015, 54, 1646–1655. [Google Scholar] [CrossRef]

- Zhu, Z.; Wang, L.; Ma, Y.; Wang, W.; Wang, Y. Separating an Azeotropic Mixture of Toluene and Ethanol Via Heat Integration Pressure Swing Distillation. Comput. Chem. Eng. 2015, 76, 137–149. [Google Scholar] [CrossRef]

- Lv, L.Z.L.; Liu, H.; Li, H.; Sun, S. Comparison of Continuous Homogenous Azeotropic and Pressure-Swing Distillation for a Minimum Azeotropic System Ethyl Acetate N-Hexane Separation. Chin. J. Chem. Eng. 2018, 26, 2023–2033. [Google Scholar]

- Li, X.; Zhao, Y.; Qin, B.; Zhang, X.; Wang, Y.; Zhu, Z. Optimization of Pressure-Swing Batch Distillation with and without Heat Integration for Separating Dichloromethane/Methanol Azeotrope Based on Minimum Total Annual Cost. Ind. Eng. Chem. Res. 2017, 56, 4104–4112. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Q.; Li, G.; Liu, M.; Gao, J. Design and Control of Methyl Acetate-Methanol Separation Via Heat-Integrated Pressure-Swing Distillation. Chin. J. Chem. Eng. 2016, 24, 1584–1599. [Google Scholar] [CrossRef]

- Zhao, L.; Lyu, X.; Wang, W.; Shan, J.; Qiu, T. Comparison of Heterogeneous Azeotropic Distillation and Extractive Distillation Methods for Ternary Azeotrope Ethanol/Toluene/Water Separation. Comput. Chem. Eng. 2017, 100, 27–37. [Google Scholar] [CrossRef]

- Li, W.; Zhong, L.; He, Y.; Meng, J.; Yao, F.; Guo, Y.; Xu, C. Multiple Steady-States Analysis and Unstable Operating Point Stabilization in Homogeneous Azeotropic Distillation with Intermediate Entrainer. Ind. Eng. Chem. Res. 2015, 54, 7668–7686. [Google Scholar] [CrossRef]

- Lladosa, E.; Monton, J.B.; Burguet, M. Separation of di-N-Propyl ether and n-Propyl Alcohol by Extractive Distillation and Pressure-Swing Distillation: Computer Simulation and Economic Optimization. Chem. Eng. Process. Process Intensif. 2011, 50, 1266–1274. [Google Scholar] [CrossRef]

- Shen, W.; Benyounes, H.; Gerbaud, V. Extension of Thermodynamic Insights on Batch Extractive Distillation to Continuous Operation. 1. Azeotropic Mixtures with a Heavy Entrainer. Ind. Eng. Chem. Res. 2013, 52, 4606–4622. [Google Scholar] [CrossRef]

- Shen, W.; Dong, L.; Wei, S.A.; Li, J.; Benyounes, H.; You, X.; Gerbaud, V. Systematic Design of an Extractive Distillation for Maximum-Boiling Azeotropes with Heavy Entrainers. Aiche J. 2015, 61, 3898–3910. [Google Scholar] [CrossRef]

- Shen, W.; Benyounes, H.; Gerbaud, V. Extractive Distillation: Recent Advances in Operation Strategies. Rev. Chem. Eng. 2015, 31, 13–26. [Google Scholar] [CrossRef]

- Shirsat, S.P. Separation of Isobutyl Alcohol and Isobutyl Acetate by Extractive Distillation and Pressure-Swing Distillation: Simulation and Optimization. Sep. Purif. Technol. 2015, 154, 366. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, P.; Ma, Y.; Zhang, Z. Extractive Distillation and Pressure-Swing Distillation for THF/Ethanol Separation. J. Chem. Technol. Biotechnol. 2015, 90, 1463–1472. [Google Scholar] [CrossRef]

- Fulgueras, A.M.; Poudel, J.; Kim, D.S.; Cho, J. Optimization Study of Pressure-Swing Distillation for the Separation Process of a Maximum-Boiling Azeotropic System of Water-Ethylenediamine. Korean J. Chem. Eng. 2015, 33, 46–56. [Google Scholar] [CrossRef]

- Suo, X.; Ye, Q.; Li, R.; Dai, X.; Yu, H. The Partial Heat-Integrated Pressure-Swing Reactive Distillation Process for Transesterification of Methyl Acetate with Isopropanol. Chem Eng. Process. Process Intensif. 2016, 107, 42–57. [Google Scholar] [CrossRef]

- Luo, B.; Feng, H.; Sun, D.; Zhong, X. Control of Fully Heat-Integrated Pressure Swing Distillation for Separating Isobutyl Alcohol and Isobutyl Acetate. Chem. Eng. Process. Process Intensif. 2016, 110, 9–20. [Google Scholar] [CrossRef]

- Luyben, W.L. Methanol/Trimethoxysilane Azeotrope Separation Using Pressure-Swing Distillation. Ind. Eng. Chem. Res. 2014, 53, 5590–5597. [Google Scholar] [CrossRef]

- Wang, Y.; Cui, P.; Zhang, Z. Heat-Integrated Pressure-Swing-Distillation Process for Separation of Tetrahydrofuran/Methanol with Different Feed Compositions. Ind. Eng. Chem. Res. 2014, 53, 7186–7194. [Google Scholar] [CrossRef]

- Zhang, H. Heat Integration Process for Separating System of Toluene and N-Butyl Alcohol with Pressure Swing Distillation; University of Science and Technology: Qingdao, China, 2015. [Google Scholar]

- Zhang, Q. Dynamics and Control of Pressure Swing Distillation Process for Azeotropic Systems of Methanol/Ethanol-Tetrahydrofuran Qingdao; University of Science and Technology: Qingdao, China, 2015. [Google Scholar]

- Hosgor, E.; Kucuk, T.; Oksal, I.N.; Kaymak, D.B. Design and Control of Distillation Processes for Methanol–Chloroform Separation. Comput. Chem. Eng. 2014, 67, 166–177. [Google Scholar] [CrossRef]

- Zhang, Q.; Peng, J.; Zhang, K. Separation of an Azeotropic Mixture of Dimethyl Carbonate and Methanol Via Partial Heat Integration Pressure Swing Distillation. Asia Pac. J. Chem. Eng. 2017, 12, 50–64. [Google Scholar] [CrossRef]

- Luyben, W.L. Design and Control of Distillation Systems for Separating Azeotropes; John Wiley & Son: Hoboken, NJ, USA, 2008. [Google Scholar]

- Cao, Y.; Li, M.; Wang, Y.; Zhao, T.; Li, X.; Zhu, Z.; Wang, Y. Effect of Feed Temperature on Economics and Controllability of Pressure-Swing Distillation for Separating Binary Azeotrope. Chem. Eng. Process. Process Intensif. 2016, 110, 160–171. [Google Scholar] [CrossRef]

| Thermodynamic Models | Wilson | NRTL | UNIQUAC |

|---|---|---|---|

| Average relative error/% | 0.9295 | 2.247 | 1.8563 |

| Parameters | Data | |

|---|---|---|

| TAC | TAC = | |

| Payback period = 3 years | ||

| Total equipment cost | Distillation column cost | Equipment cost = 17,640 × (D, m)1.066 × (L, m)0.802 |

| Length: H = 1.2 × 0.61 × (NT − 2) | ||

| Condensers or Condenser/Reboiler | Equipment cost = 7296 × (Ac, m2)0.65 | |

| Heat-transfer coefficient (KC) = 0.852 kW/K·m2 | ||

| Heat transfer area: Ac = | ||

| Reboilers | Equipment cost = 7296 × (Ac, m2)0.65 | |

| Heat-transfer coefficient (KR) = 0.568 kW/K·m2 | ||

| Heat transfer area: Ac = | ||

| Annual operating cost | Annual stream cost | Annual stream cost = Q × CS × 8000 × 3600 |

| LP steam (6 bar, 160 °C): $7.78/GJ | ||

| MP steam (11 bar, 184 °C): $8.22/GJ | ||

| HP steam (42 bar, 254 °C): $9.88/GJ | ||

| Annual cooling water cost | Annual cooling water cost = Q × Cc × 8000 × 3600 | |

| Cooling water: $0.354/GJ | ||

| Variables | Case1 | Case2 | Case3 | Case4 | Case5 |

|---|---|---|---|---|---|

| P1 (bar) | 1 | 1 | 1 | 1 | 1 |

| P2 (bar) | 6 | 7 | 8 | 9 | 10 |

| NT1/NT2 | 20/20 | 20/20 | 20/20 | 20/20 | 20/20 |

| NF1/NR/NF2 | 10/6/14 | 10/10/10 | 11/7/12 | 9/10/15 | 10/10/10 |

| RR1/RR2 | 0.7/1 | 1.5/2 | 1.5/4 | 1.3/2 | 4/2 |

| ID1/ID2 | 0.437/0.394 | 0.539/0.461 | 0.529/0.538 | 0.512/0.424 | 0.623/0.260 |

| Rrec (kg/h) | 987.597 | 829.923 | 770.849 | 770.094 | 450.316 |

| QC1/QC2 | −404.579/0 | −532.573/0 | −524.103/−215.221 | −484.754/0 | −693.918/0 |

| QR1/QR2 | 39.144/410.218 | 69.3/510.74 | 0/789.316 | 32.111/504.469 | 439.747/307.238 |

| Equipment cost (105 $/y) | 3.27084 | 3.88473 | 4.31063 | 3.65064 | 3.87671 |

| Energy cost (105 $/y) | 1.04811 | 1.47438 | 1.92203 | 1.31563 | 1.78340 |

| TAC (105 $/y) | 2.14079 | 2.76929 | 3.35891 | 2.53251 | 3.07564 |

| Variables | Partial HIPSD | Fully HIPSD | ||

|---|---|---|---|---|

| LP-HP | HP-LP | LP-HP | HP-LP | |

| P1 (bar) | 1 | 6 | 1 | 6 |

| P2 (bar) | 6 | 1 | 6 | 1 |

| NT1/NT2 | 20/20 | 20/20 | 19/21 | 20/20 |

| NF1/NR/NF2 | 10/6/14 | 6/16/10 | 12/9/14 | 6/16/10 |

| RR1/RR2 | 0.7/1 | 2/1.5 | 0.61/1.097 | 2/3.768 |

| ID1/ID2 | 0.437/0.394 | 0.858/0.663 | 0.313/0.4 | 0.773/0.912 |

| Rrec (kg/h) | 987.597 | 1703.14 | 971.051 | 1664.69 |

| QC1/QC2 | −404.579/0 | −662.357/−784.539 | −376.467/−348.977 | −1320.5/−1462.78 |

| QR1/QR2 | 39.144/410.218 | 1494.72/662.357 | 348.977/421.276 | 1509.54/1320.51 |

| Equipment cost (105 $/y) | 3.27084 | 6.20901 | 2.53782 | 5.94179 |

| Energy cost (105 $/y) | 1.04811 | 3.49664 | 0.98231 | 3.09342 |

| TAC (105 $/y) | 2.14079 | 5.56631 | 1.82825 | 5.07401 |

| Equipment | Low Pressure Column | High Pressure Column | |

|---|---|---|---|

| Reflux tank | Volume flow (m3/s) | 0.000722942 | 0.00073135 |

| Volume (m3) | 0.434 | 0.439 | |

| Diameter/length (m) | 0.65/1.30 | 0.65/1.31 | |

| Sump | Volume flow (m3/s) | 0.000720035 | 0.00138284 |

| Volume (m3) | 0.432 | 0.830 | |

| Diameter/length (m) | 0.65/1.30 | 0.81/1.62 | |

| Parameter | TC1 | TC2 |

|---|---|---|

| Control variable | T1,13 | T2,20 |

| Operational variable | QAR1 | QR2 |

| Control variable range/°C | 0–126.62 | 0–248.89 |

| Operating variable range/GJ/h | 0–0.285 | 0–2.91 |

| Final gain/%/% | 15.36 | 10.02 |

| Final cycle/min | 3.6 | 3.6 |

| Gain/%/% | 4.80 | 3.13 |

| Integration time/min | 7.92 | 7.92 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, L.; Li, H.; Zhang, Z.; Huang, H. Comparison of the Economy and Controllability of Pressure Swing Distillation with Two Energy-Saving Modes for Separating a Binary Azeotrope Containing Lower Alcohols. Processes 2019, 7, 730. https://doi.org/10.3390/pr7100730

Lv L, Li H, Zhang Z, Huang H. Comparison of the Economy and Controllability of Pressure Swing Distillation with Two Energy-Saving Modes for Separating a Binary Azeotrope Containing Lower Alcohols. Processes. 2019; 7(10):730. https://doi.org/10.3390/pr7100730

Chicago/Turabian StyleLv, Liping, Hang Li, Zheng Zhang, and Huisheng Huang. 2019. "Comparison of the Economy and Controllability of Pressure Swing Distillation with Two Energy-Saving Modes for Separating a Binary Azeotrope Containing Lower Alcohols" Processes 7, no. 10: 730. https://doi.org/10.3390/pr7100730

APA StyleLv, L., Li, H., Zhang, Z., & Huang, H. (2019). Comparison of the Economy and Controllability of Pressure Swing Distillation with Two Energy-Saving Modes for Separating a Binary Azeotrope Containing Lower Alcohols. Processes, 7(10), 730. https://doi.org/10.3390/pr7100730