Simulation-Based Design and Economic Evaluation of a Novel Internally Circulating Fluidized Bed Reactor for Power Production with Integrated CO2 Capture

Abstract

1. Introduction

2. Materials and Methods

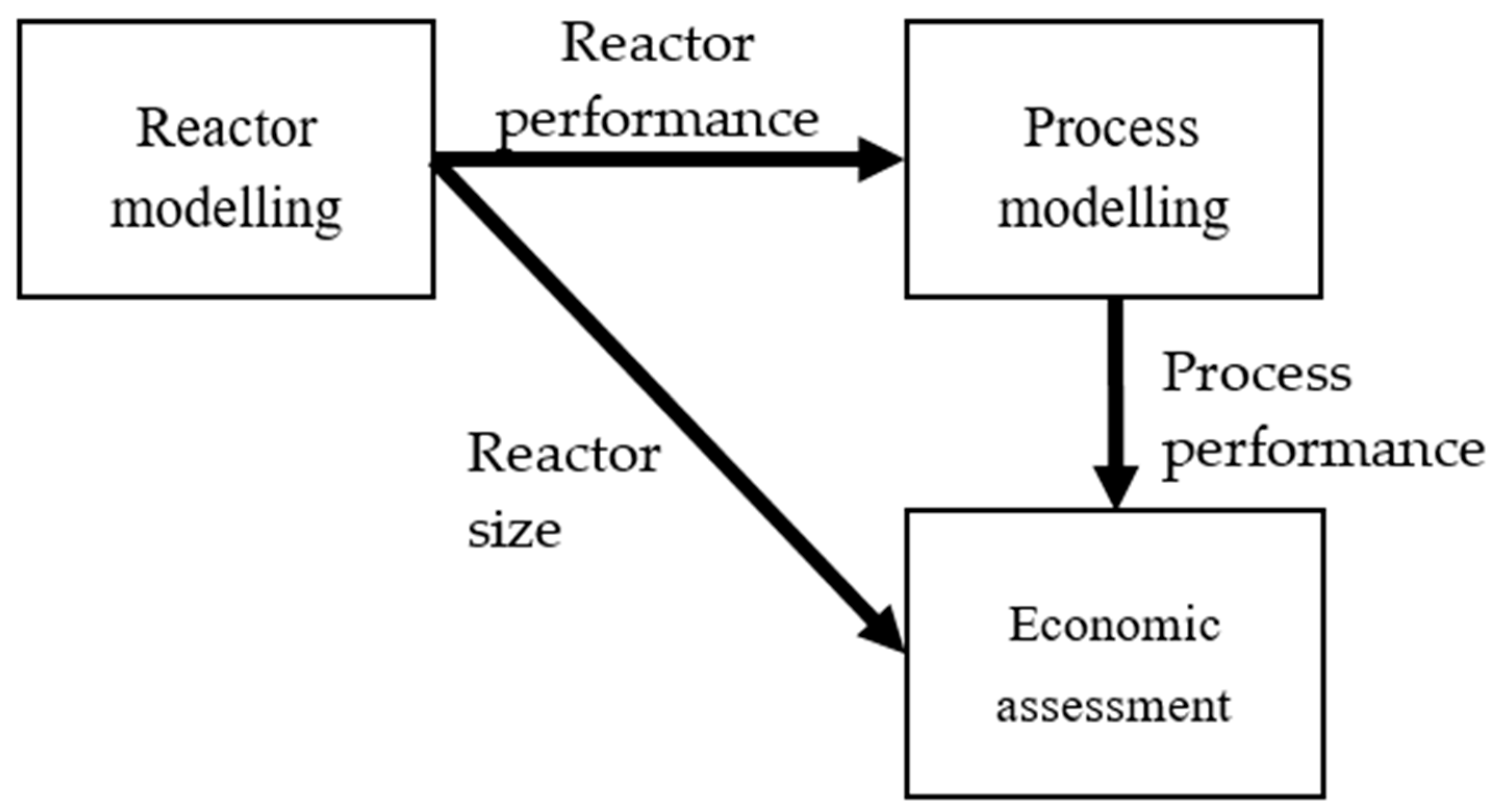

2.1. Reactor Modeling

2.1.1. The Filtered Two-Fluid Model (fTFM)

2.1.2. Reaction Modeling

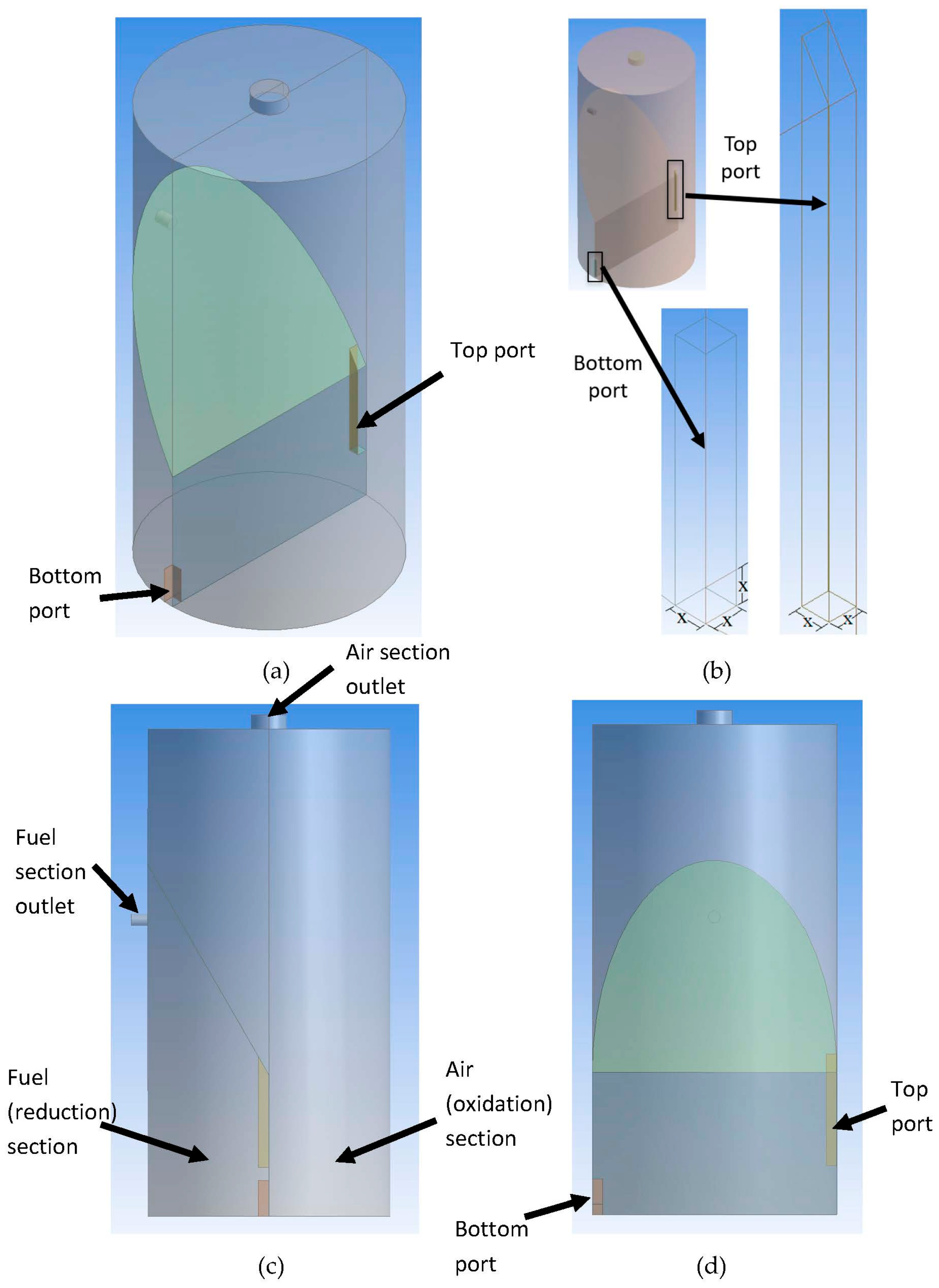

2.1.3. Simulation Geometry and Mesh

2.1.4. Reactor Operating Conditions

2.1.5. Solver

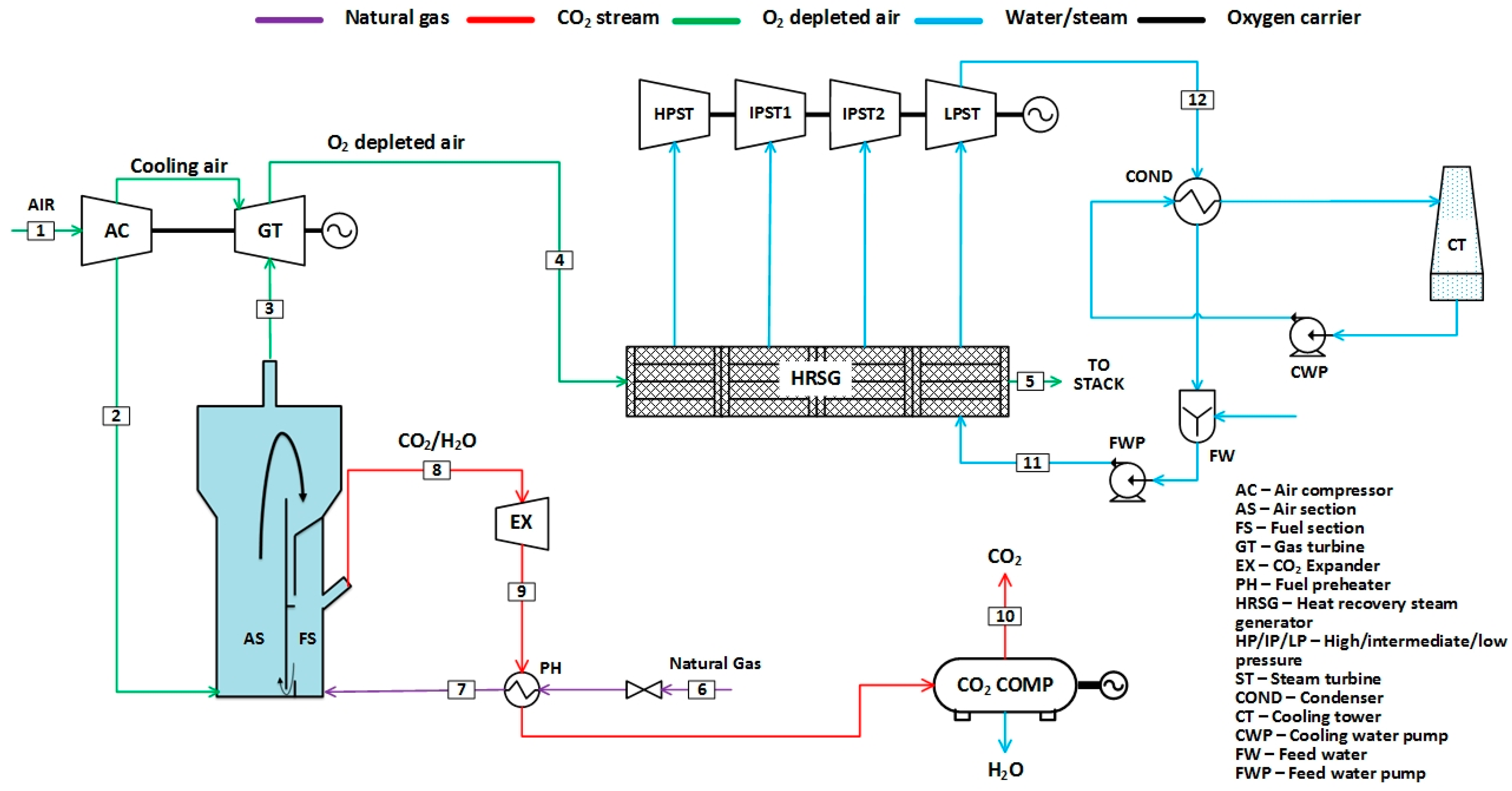

2.2. Process Modeling

2.3. Economic Assessment

3. Results

3.1. Reactor Optimization

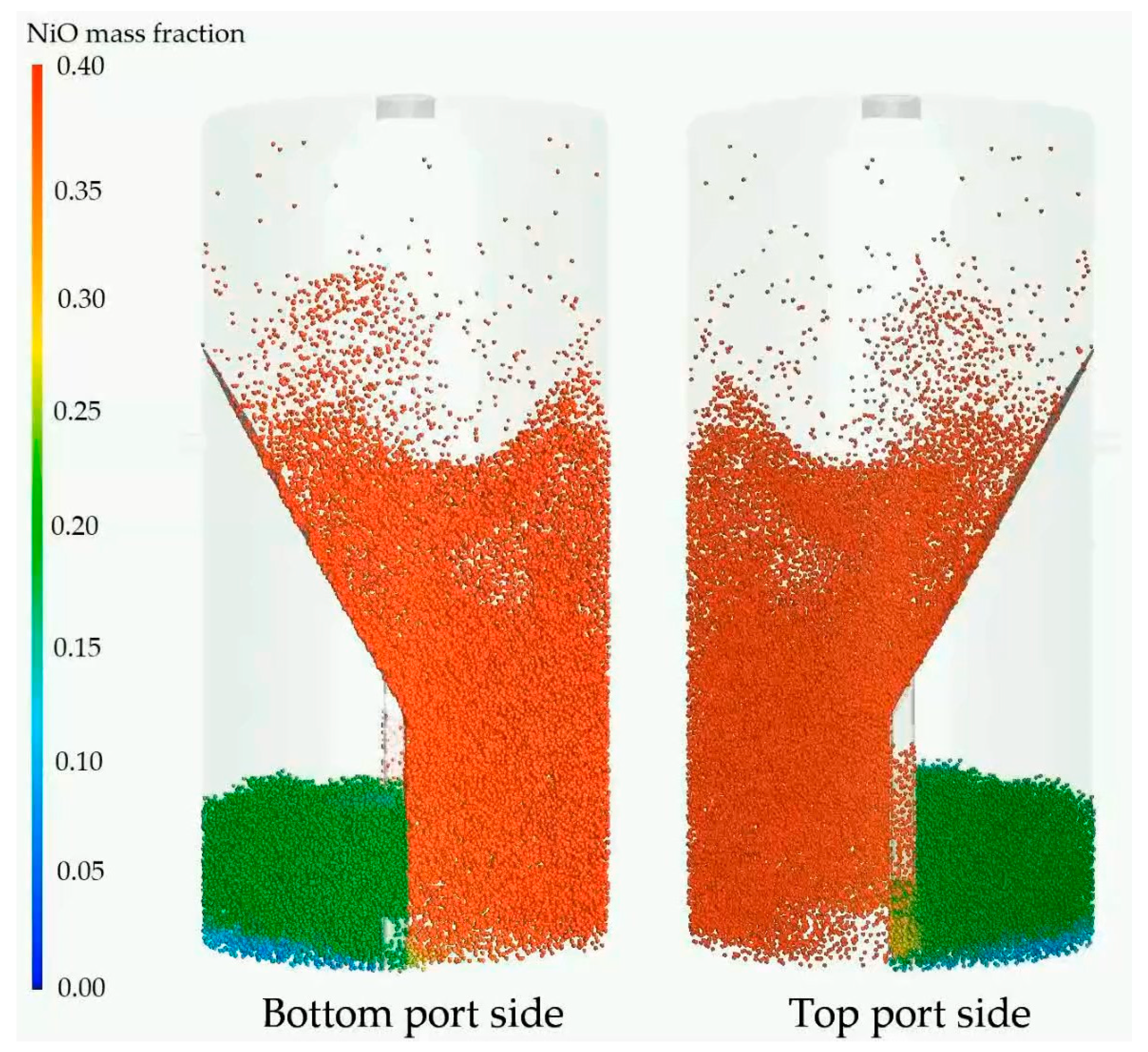

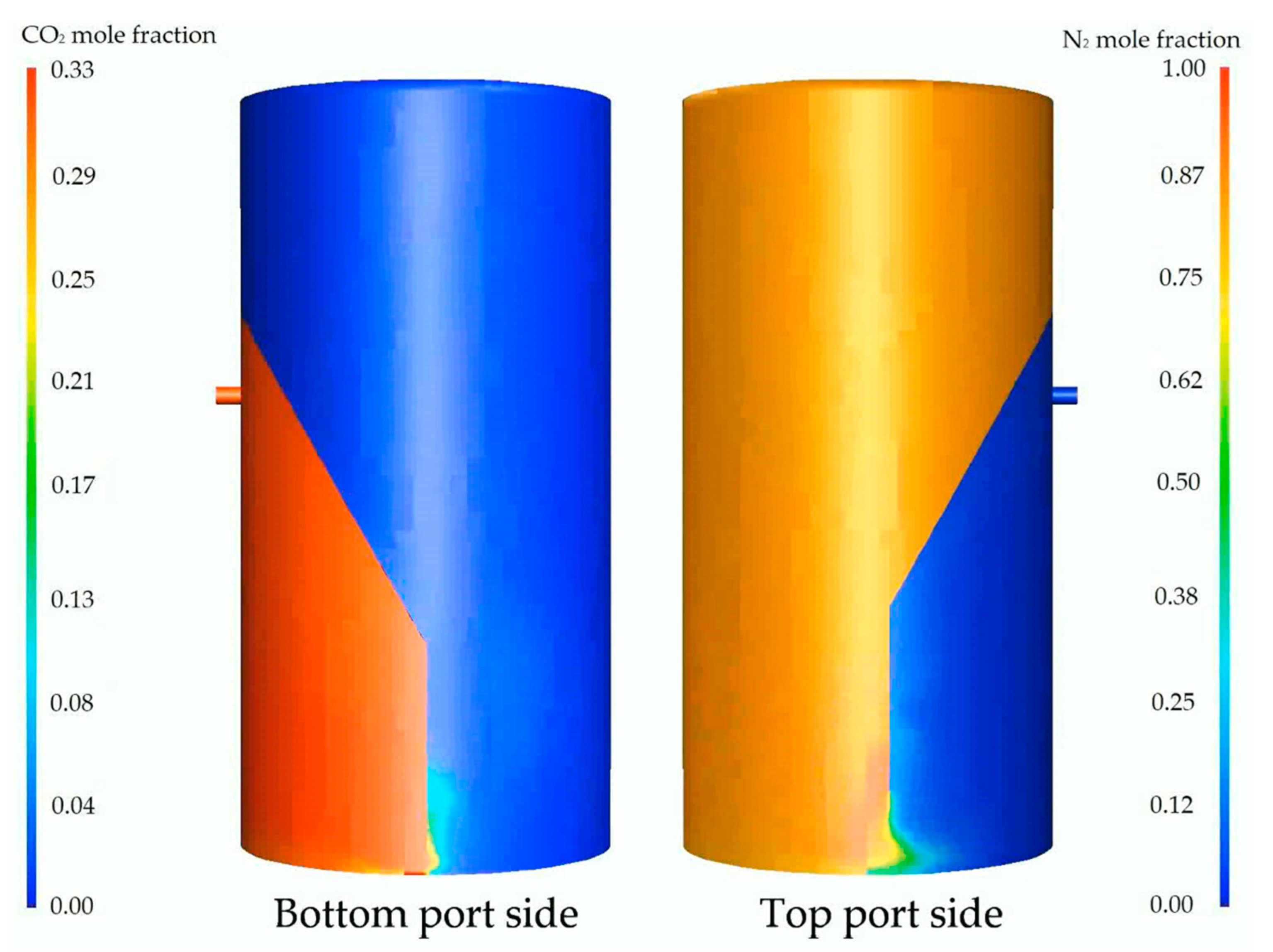

3.1.1. Characteristics of ICR Operation

- The pressure difference between the two reactor outlets, which can be used to control the solids distribution between the reactor sections, as well as the solids circulation.

- The size of the ports connecting the reactor sections, which can be sized to allow sufficient solids circulation while limiting undesired gas leakage.

- The overall reactor size, which primarily determines the amount of solids elutriation from the reactor.

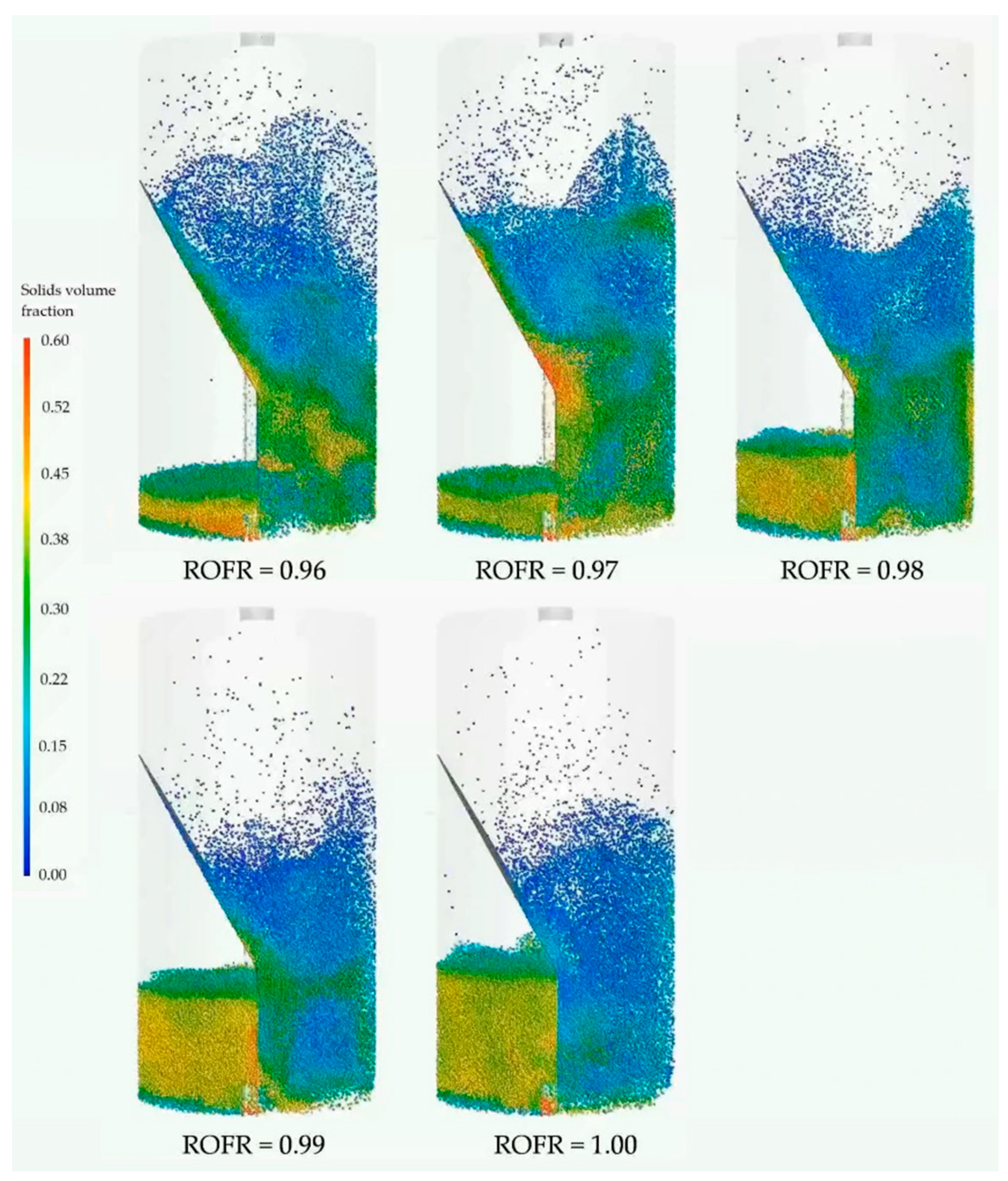

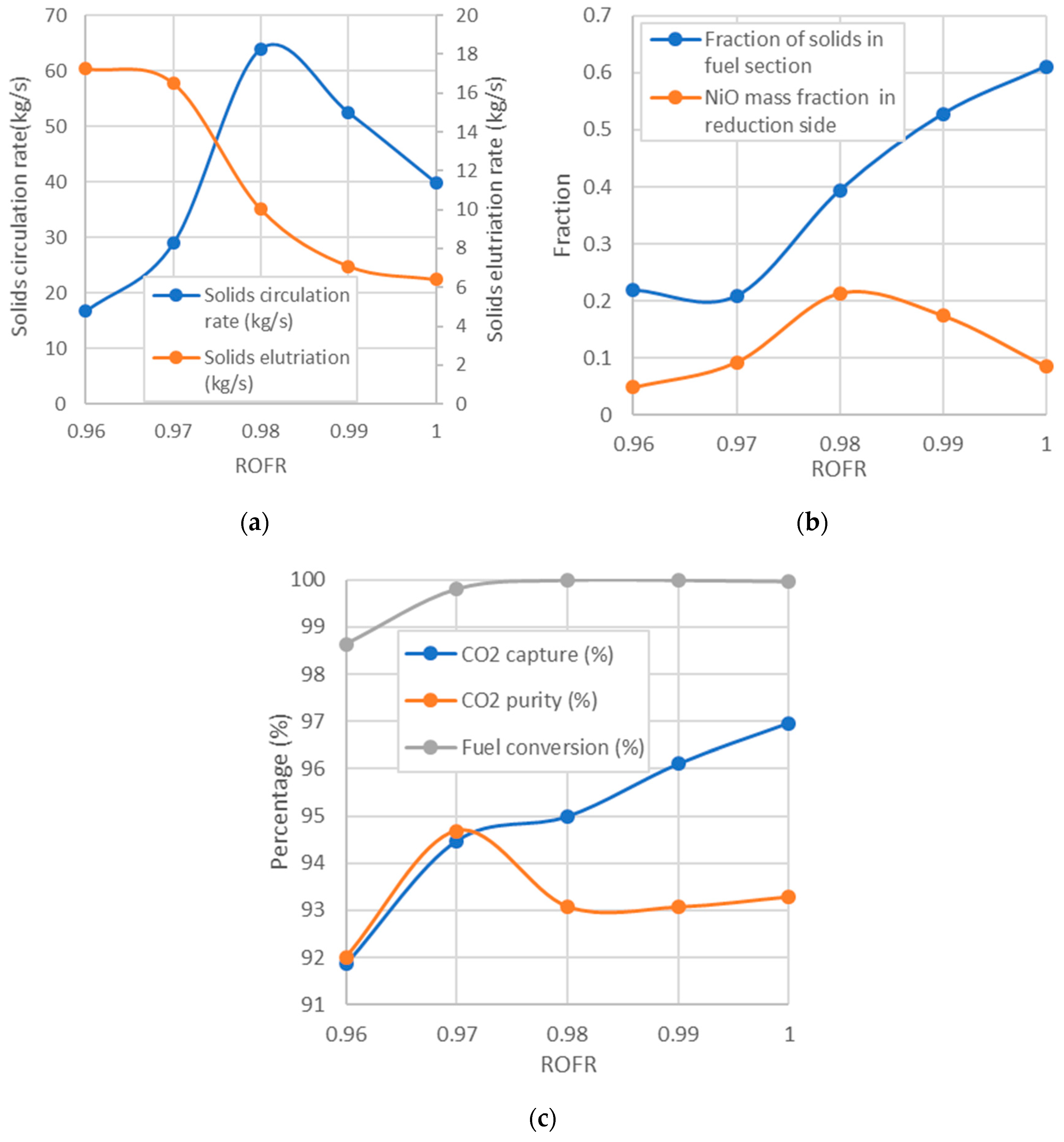

3.1.2. Reduction Section Overpressure

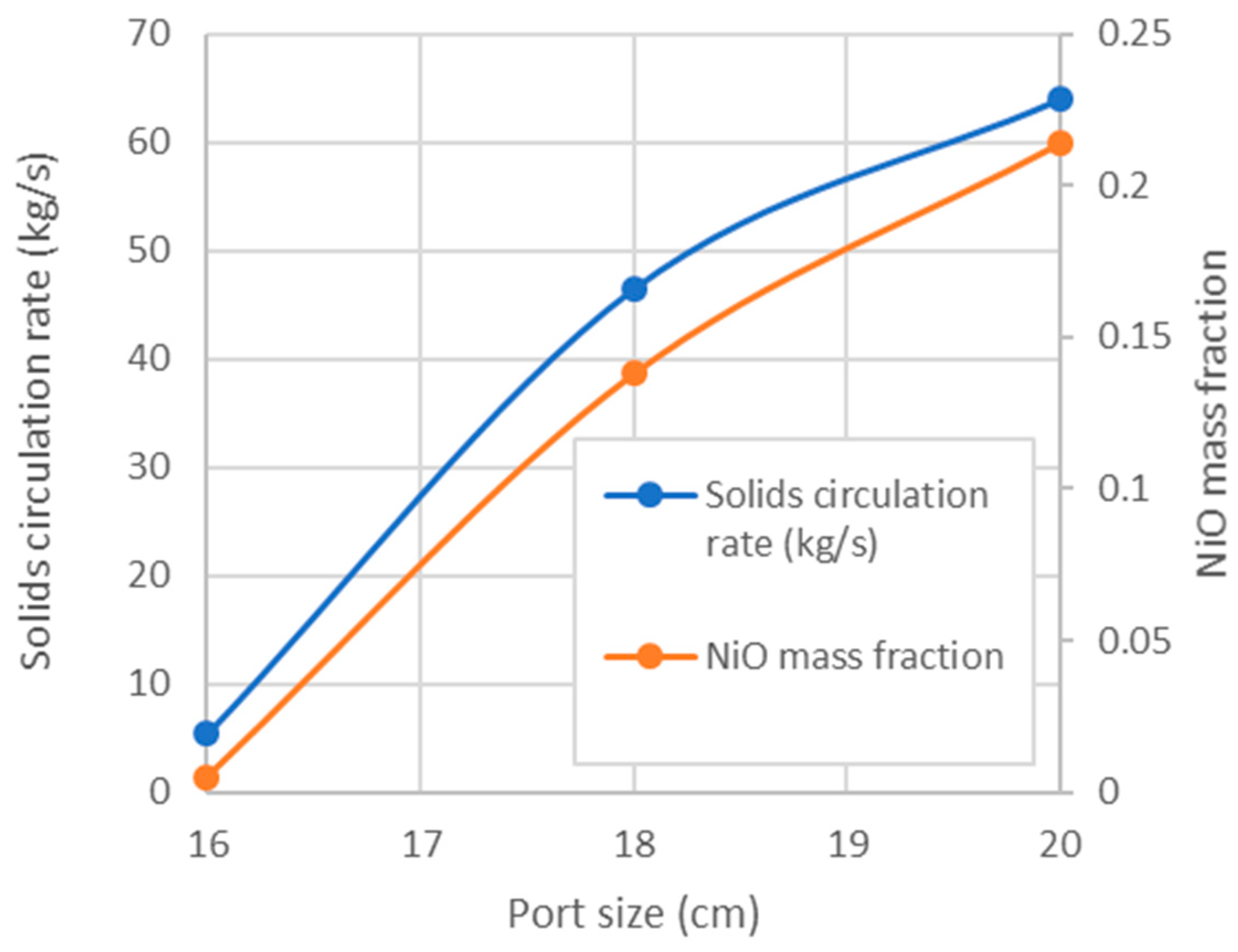

3.1.3. Port Size

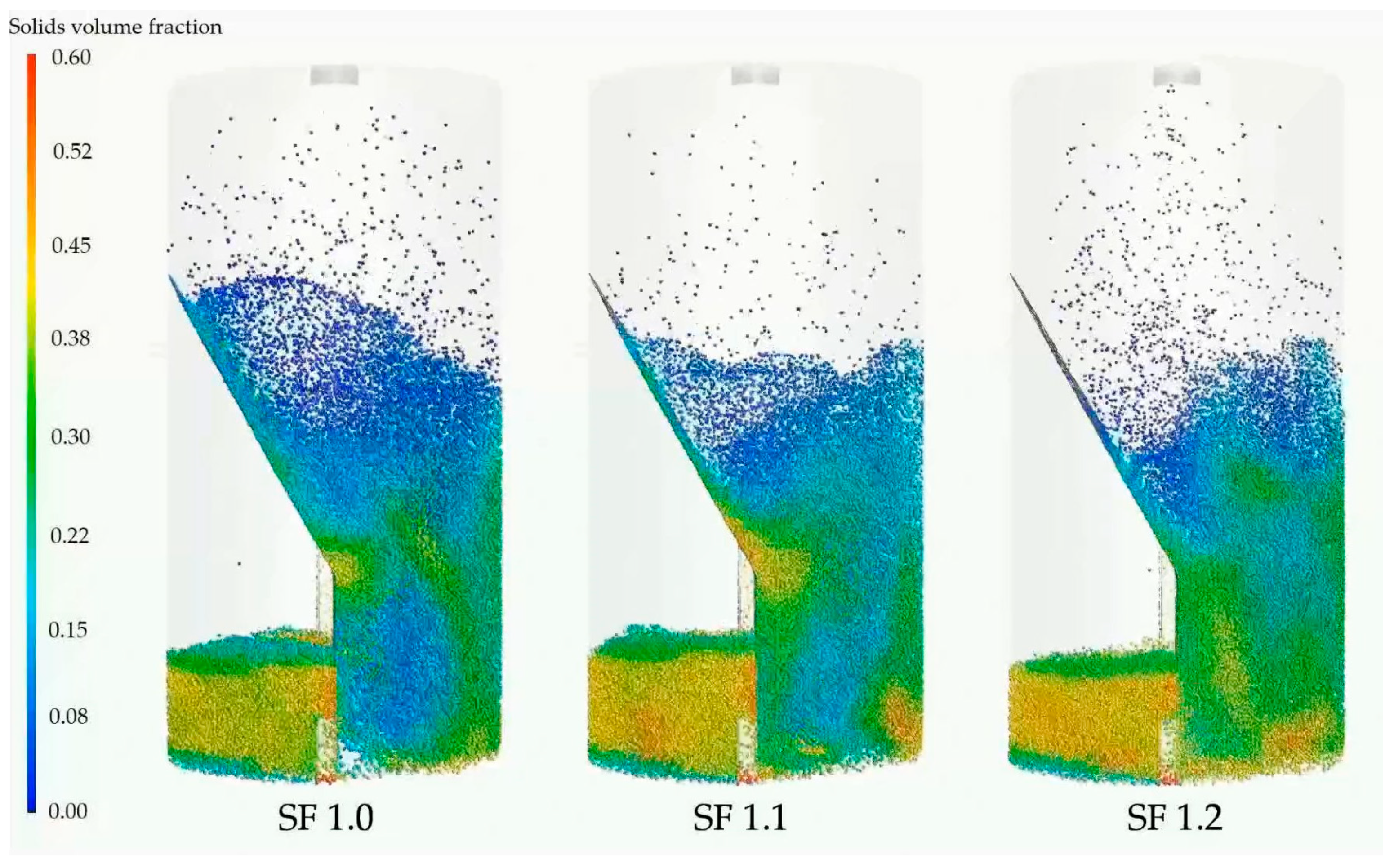

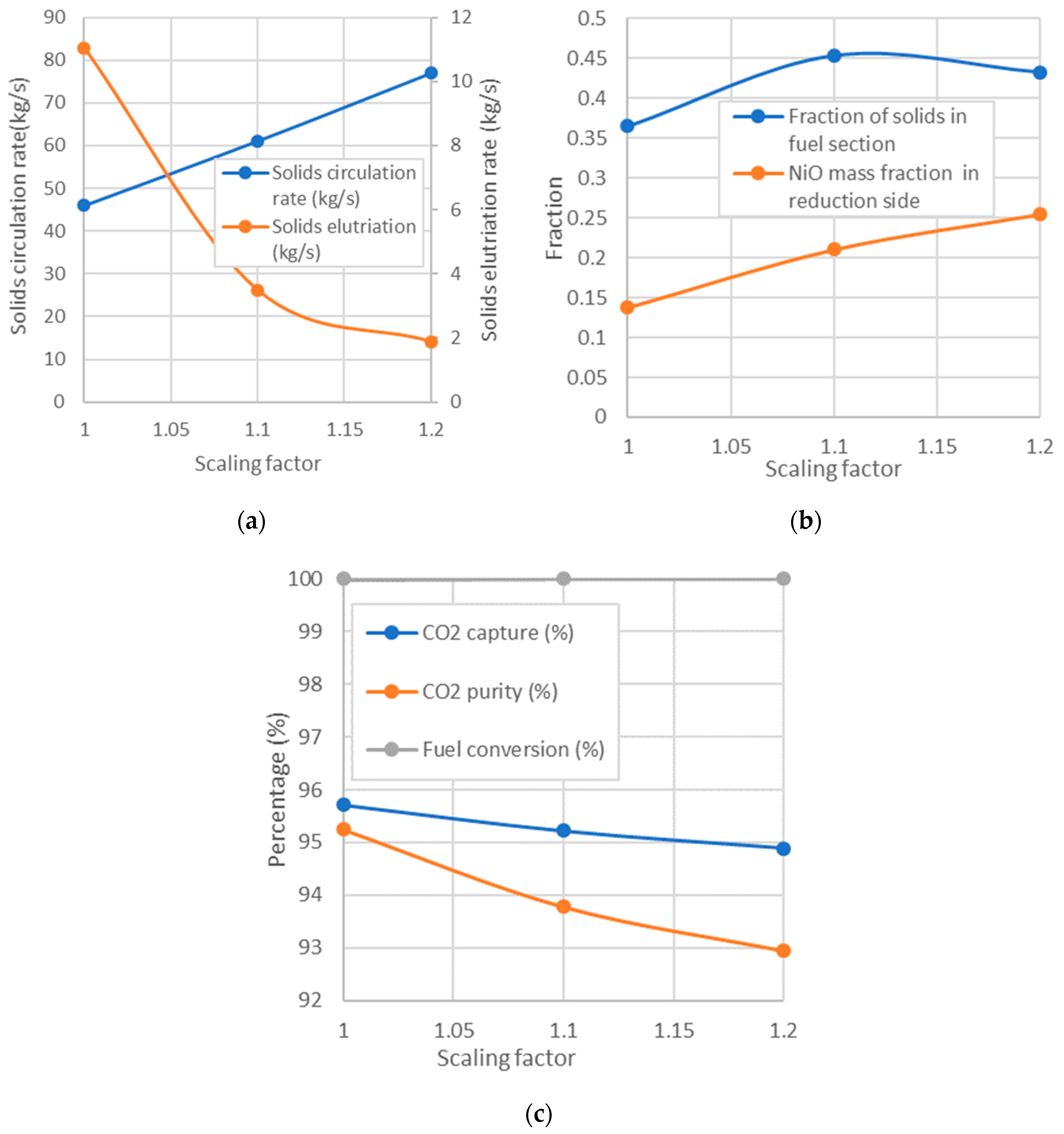

3.1.4. Reactor Size

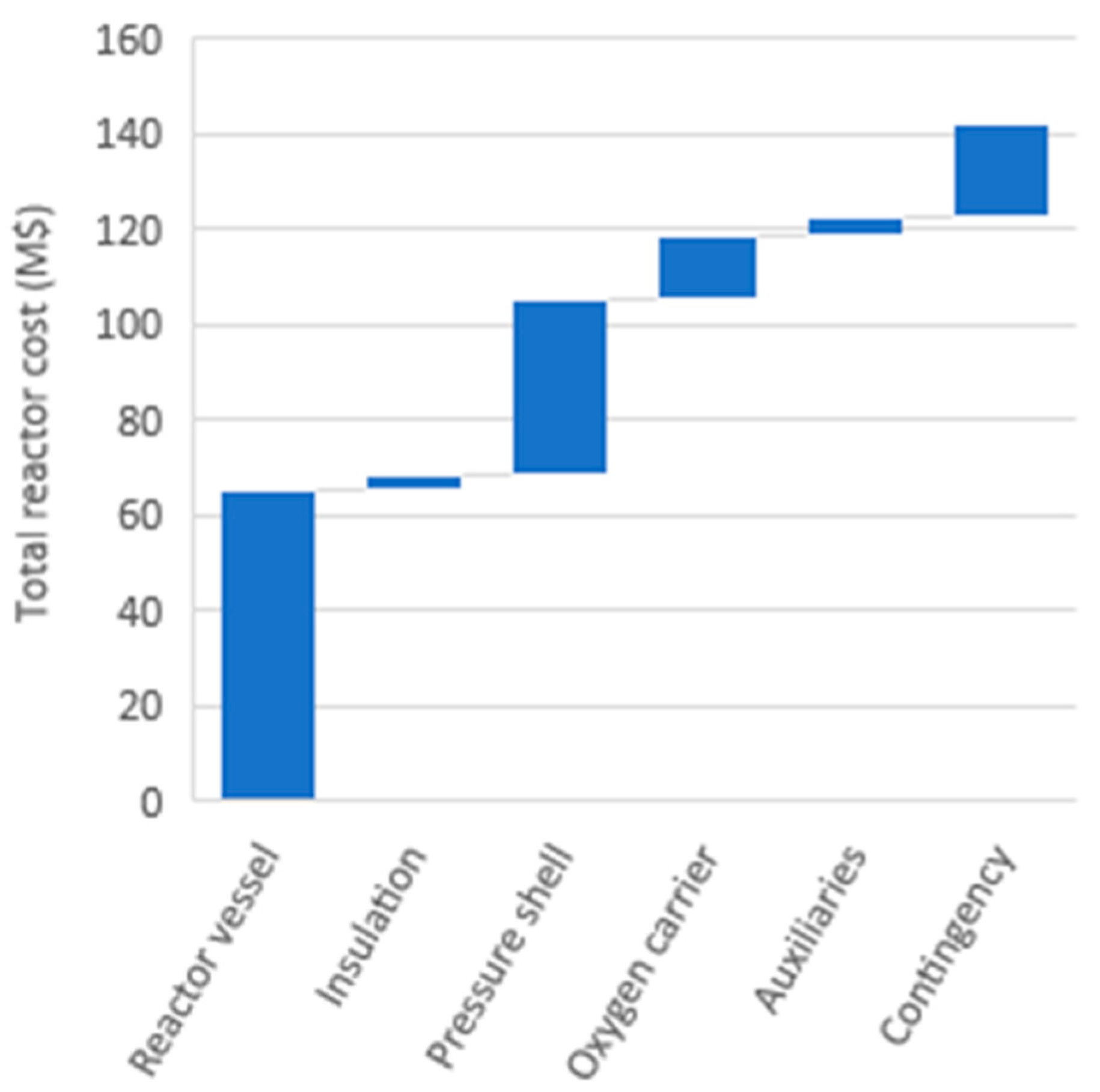

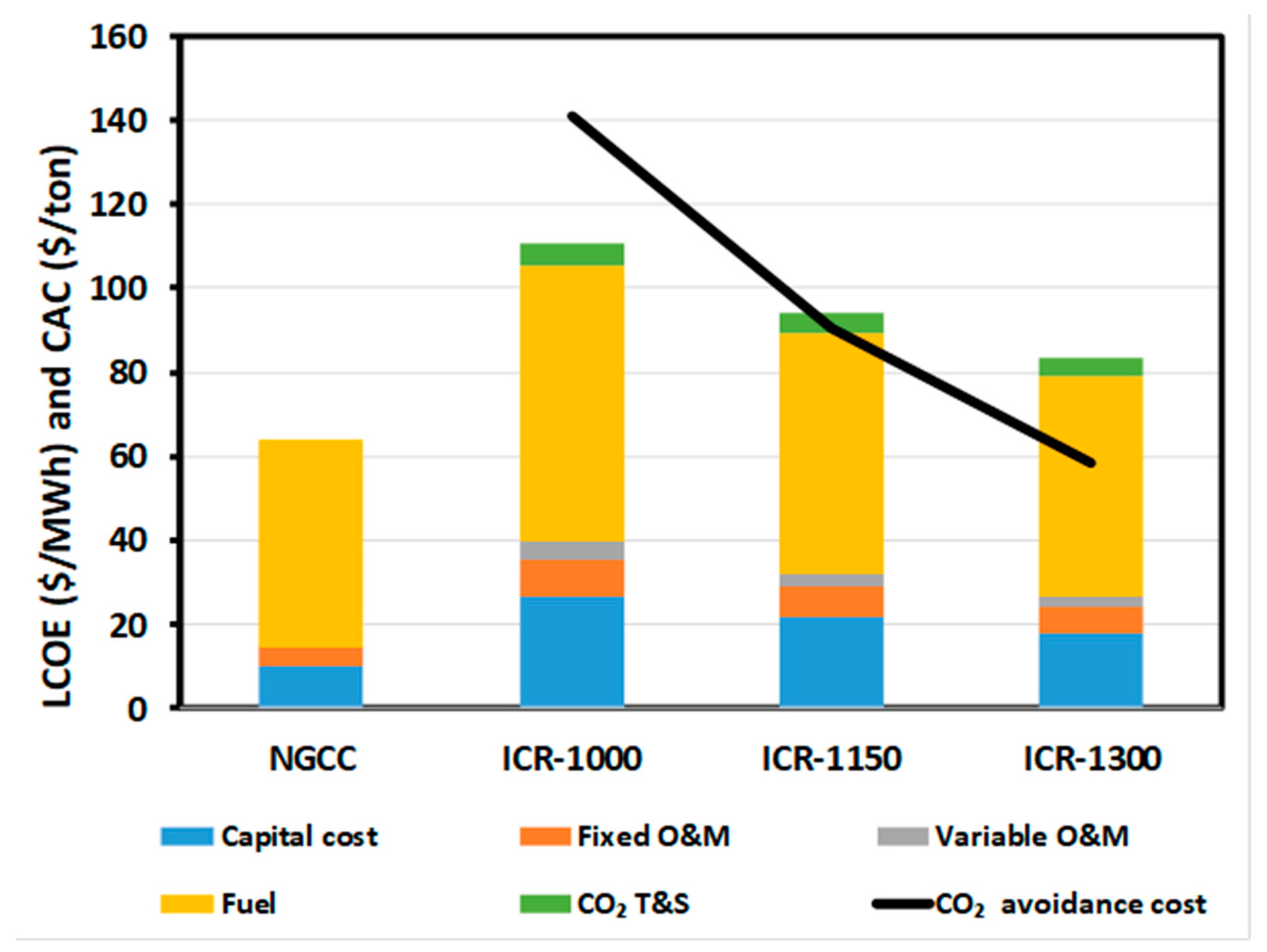

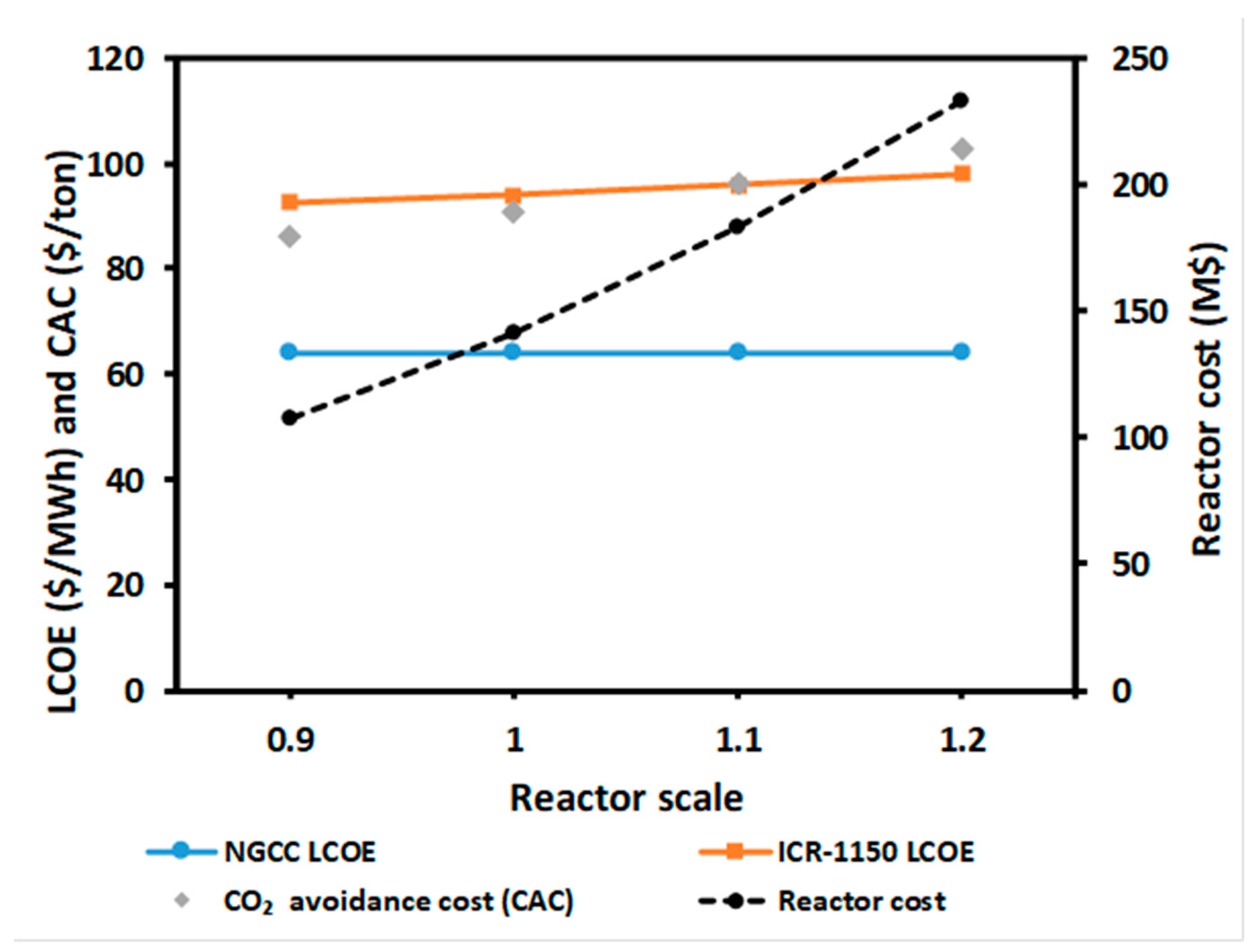

3.2. Economic Evaluation

4. Discussion

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Acronym Definitions | |||

| CCS | Carbon capture and storage | IEA | International Energy Agency |

| CEPCI | Chemical engineering plant cost index | LCOE | Levelized cost of electricity |

| CFB | Circulating fluidized bed | NGCC | Natural gas combined cycle |

| CFD | Computation fluid dynamics | OC | Oxygen carrier |

| CLC | Chemical looping combustion | O&M | Operating and maintenance |

| CAC | CO2 avoidance cost | ROFR | Reduction outlet flow ratio |

| fTFM | Filtered two-fluid model | T&S | Transport and storage |

| GPM | Gradient product marker | TFM | Two-fluid model |

| ICR | Internally circulating reactor | ||

| Main Symbol Definitions | |||

| Specific surface area (m2/kg) | Pressure exponent | ||

| Molar concentration (mol/m3) | Universal gas constant (J/(mol. K)) | ||

| Diffusion coefficient (m2/s) | Heterogenous reaction rate (mol/(m3.s)) | ||

| Particle diameter (m) | Mass transfer source term (kg/(m3.s)) | ||

| Activation energy (J/mol) | Discount rate | ||

| Plant specific emissions (ton/MWh) | Temperature (K) | ||

| Fuel expenditure ($/year) | Time (s) | ||

| Gravitational acceleration (m/s2) | Stoichiometric constant | ||

| Specific enthalpy (J/kg) | Species mass fraction | ||

| Investment expenditures ($/year) | Volume fraction | ||

| Interphase momentum exchange coefficient (kg/(m.s)) | Heat transfer coefficient (W/(m3.K)) | ||

| Pre-exponential factor | Heat of reaction (J/kg) | ||

| Reaction rate constant (m3n−3/moln−1s) | Filter size (m) | ||

| Reaction rate constant (m3n−2/moln−1s) | Effectiveness factor | ||

| Effective reaction rate constant (1/s) | Thermal conductivity (W/(m.K)) | ||

| Molecular weight (kg/mol) | Density (kg/m3) | ||

| O&M expenditures ($/year) | Stress tensor (Pa) | ||

| Plant economic lifetime (years) | Velocity (m/s) | ||

| Reaction order | Thiele modulus | ||

| Pressure (Pa) | Dimensionless cluster length-scale | ||

| Sub- and Superscript Definitions | |||

| Filter | Minimum | ||

| Gas | Particle | ||

| Species index | Reaction | ||

| Reaction index | Reference | ||

| Maximum | Solids | ||

| Sub- and Superscript Definitions | |||

| Algebraic volume average | Phase-weighted volume average | ||

| Fluctuation from mean (algebraic) | Scaled value | ||

| Fluctuation from mean (phase-weighted) | Vector quantity | ||

| Dimensionless value | |||

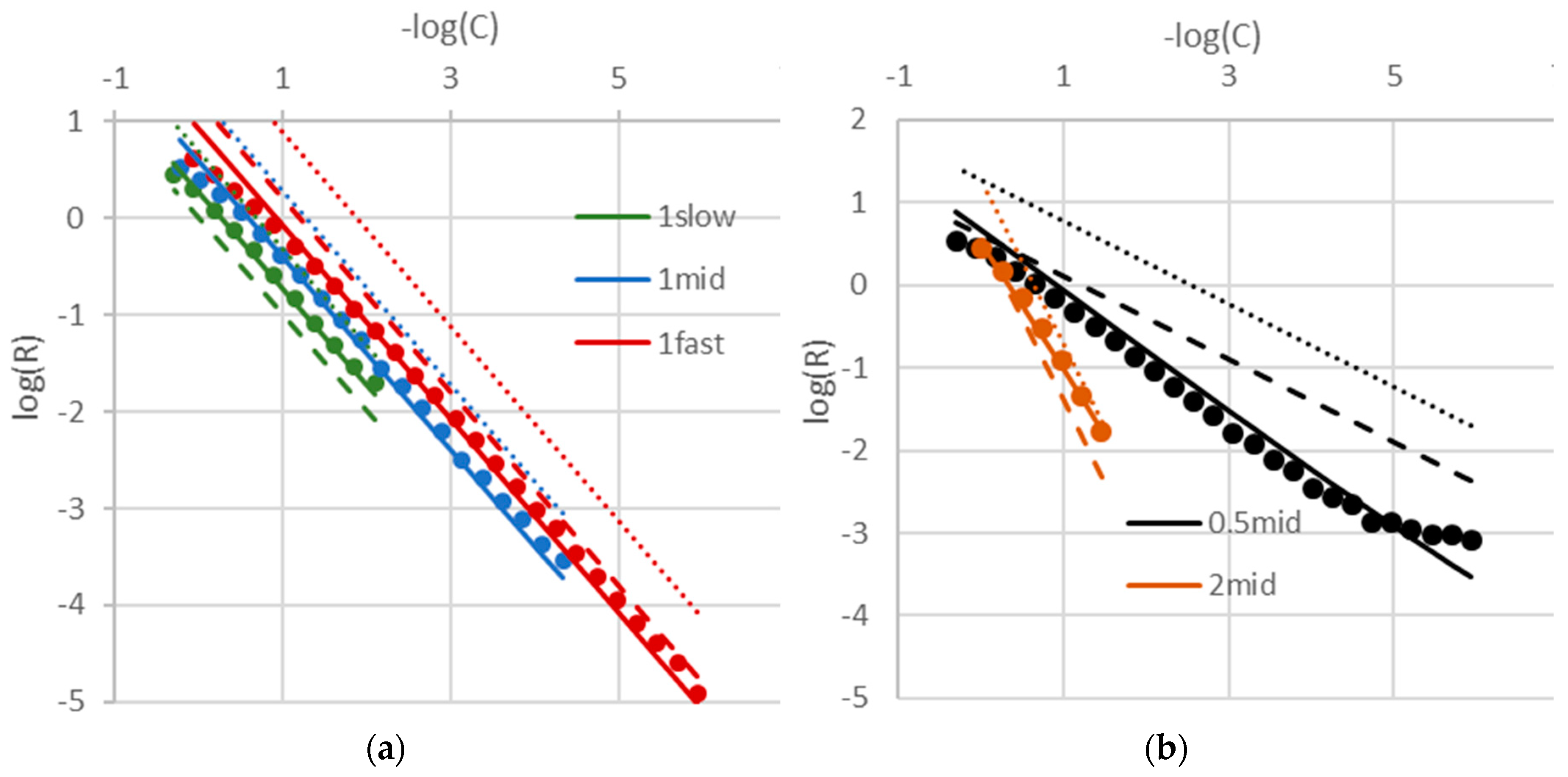

Appendix A. Reactive Closure Development

Appendix A.1. Resolved Two-Fluid Model (TFM) Simulations

| Abbreviation | —Reactant | —Product | ||

|---|---|---|---|---|

| 1 slow | A | B | ||

| 1 mid | C | D | ||

| 1 fast | E | F | ||

| 0.5 mid | G | H | ||

| 2 mid | I | J |

Appendix A.2. Closure Development

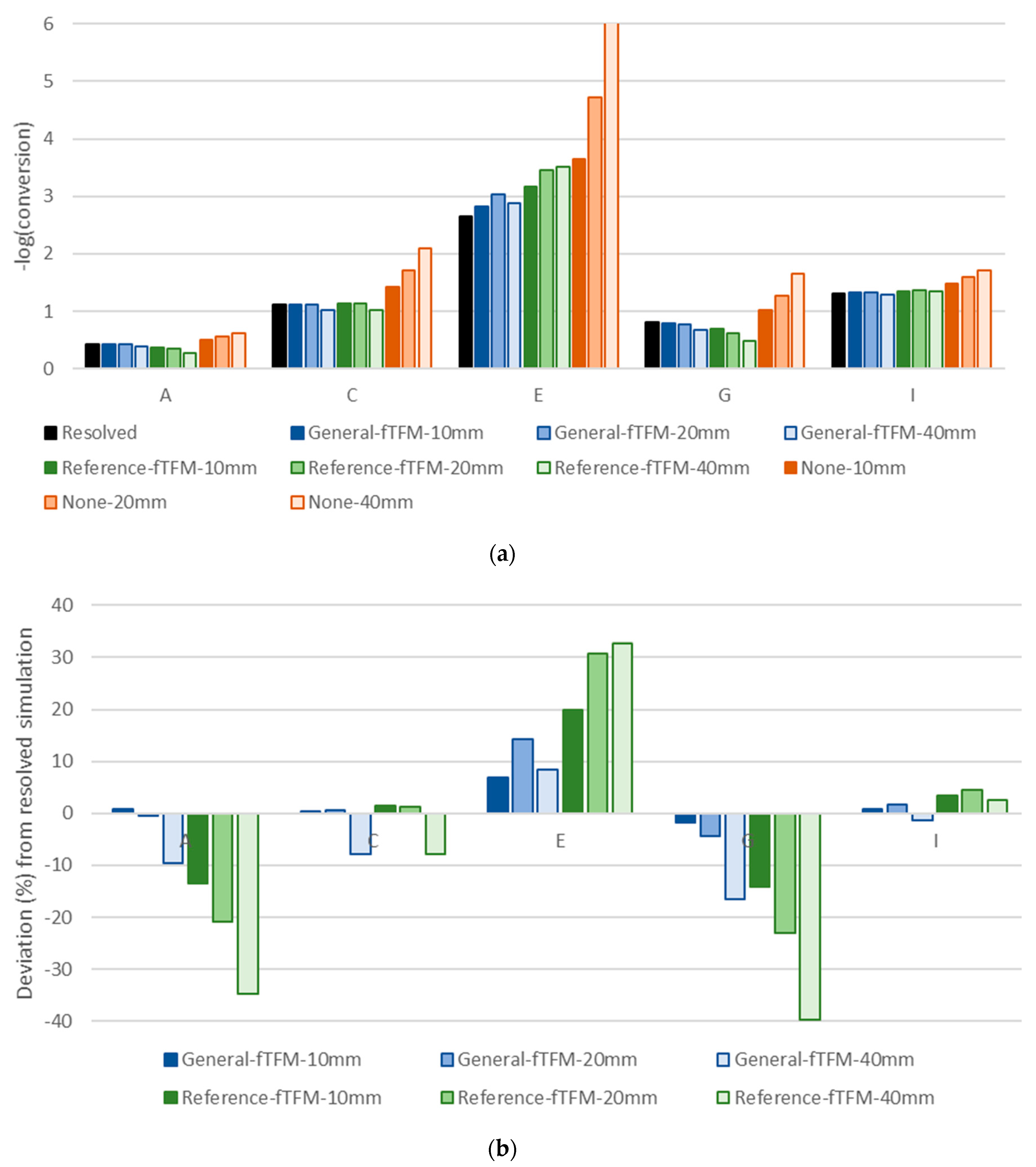

Appendix A.3. Closure Verification

References

- IPCC. Fifth Assessment Report: Mitigation of Climate Change; Intergovernmental Panel on Climate Change: Cambridge University Press: Cambridge, UK; New York, NY, USA, 2014. [Google Scholar]

- Bauer, N.; Calvin, K.; Emmerling, J.; Fricko, O.; Fujimori, S.; Hilaire, J.; Eom, J.; Krey, V.; Kriegler, E.; Mouratiadou, I.; et al. Shared Socio-Economic Pathways of the Energy Sector–Quantifying the Narratives. Glob. Environ. Chang. 2017, 42, 316–330. [Google Scholar] [CrossRef]

- IEAGHG. CCS in Energy and Climate Scenarios; IEA Greenhouse Gas R & D Programme: Cheltenham, UK, 2019. [Google Scholar]

- Ishida, M.; Zheng, D.; Akehata, T. Evaluation of a chemical-looping-combustion power-generation system by graphic exergy analysis. Energy 1987, 12, 147–154. [Google Scholar] [CrossRef]

- Arnaiz del Pozo, C.; Cloete, S.; Cloete, J.H.; Jiménez Álvaro, Á.; Amini, S. The potential of chemical looping combustion using the gas switching concept to eliminate the energy penalty of CO2 capture. Int. J. Greenh. Gas Control 2019, 83, 265–281. [Google Scholar] [CrossRef]

- Mattisson, T.; Keller, M.; Linderholm, C.; Moldenhauer, P.; Rydén, M.; Leion, H.; Lyngfelt, A. Chemical-looping technologies using circulating fluidized bed systems: Status of development. Fuel Process. Technol. 2018, 172, 1–12. [Google Scholar] [CrossRef]

- Zaabout, A.; Cloete, S.; Johansen, S.T.; van Sint Annaland, M.; Gallucci, F.; Amini, S. Experimental Demonstration of a Novel Gas Switching Combustion Reactor for Power Production with Integrated CO2 Capture. Ind. Eng. Chem. Res. 2013, 52, 14241–14250. [Google Scholar] [CrossRef]

- Cloete, S.; Romano, M.C.; Chiesa, P.; Lozza, G.; Amini, S. Integration of a Gas Switching Combustion (GSC) system in integrated gasification combined cycles. Int. J. Greenh. Gas Control 2015, 42, 340–356. [Google Scholar] [CrossRef]

- Håkonsen, S.F.; Blom, R. Chemical Looping Combustion in a Rotating Bed Reactor–Finding Optimal Process Conditions for Prototype Reactor. Environ. Sci. Technol. 2011, 45, 9619–9626. [Google Scholar] [CrossRef]

- Håkonsen, S.F.; Grande, C.A.; Blom, R. Rotating bed reactor for CLC: Bed characteristics dependencies on internal gas mixing. Appl. Energy 2014, 113, 1952–1957. [Google Scholar] [CrossRef]

- Noorman, S.; Gallucci, F.; van Sint Annaland, M.; Kuipers, J.A.M. Experimental Investigation of Chemical-Looping Combustion in Packed Beds: A Parametric Study. Ind. Eng. Chem. Res. 2011, 50, 1968–1980. [Google Scholar] [CrossRef]

- Spallina, V.; Gallucci, F.; Romano, M.C.; Chiesa, P.; Lozza, G.; van Sint Annaland, M. Investigation of heat management for CLC of syngas in packed bed reactors. Chem. Eng. J. 2013, 225, 174–191. [Google Scholar] [CrossRef]

- Zaabout, A.; Cloete, S.; Amini, S. Innovative Internally Circulating Reactor Concept for Chemical Looping-Based CO2 Capture Processes: Hydrodynamic Investigation. Chem. Eng. Technol. 2016, 39, 1413–1424. [Google Scholar] [CrossRef]

- Osman, M.; Zaabout, A.; Cloete, S.; Amini, S. Internally circulating fluidized-bed reactor for syngas production using chemical looping reforming. Chem. Eng. J. 2018. [Google Scholar] [CrossRef]

- Osman, M.; Zaabout, A.; Cloete, S.; Amini, S. Mapping the operating performance of a novel internally circulating fluidized bed reactor applied to chemical looping combustion. Fuel Process. Technol. 2020, 197, 106183. [Google Scholar] [CrossRef]

- IEA. World Energy Outlook; International Energy Agency: Paris, France, 2018. [Google Scholar]

- Ge, W.; Chang, Q.; Li, C.; Wang, J. Multiscale structures in particle–fluid systems: Characterization, modeling, and simulation. Chem. Eng. Sci. 2019, 198, 198–223. [Google Scholar] [CrossRef]

- Igci, Y.; Andrews, A.T.; Sundaresan, S.; Pannala, S.; O’Brien, T. Filtered two-fluid models for fluidized gas-particle suspensions. AIChE J. 2008, 54, 1431–1448. [Google Scholar] [CrossRef]

- Igci, Y.; Sundaresan, S. Constitutive Models for Filtered Two-Fluid Models of Fluidized Gas–Particle Flows. Ind. Eng. Chem. Res. 2011, 50, 13190–13201. [Google Scholar] [CrossRef]

- Sarkar, A.; Milioli, F.E.; Ozarkar, S.; Li, T.; Sun, X.; Sundaresan, S. Filtered sub-grid constitutive models for fluidized gas-particle flows constructed from 3-D simulations. Chem. Eng. Sci. 2016, 152, 443–456. [Google Scholar] [CrossRef]

- Ozel, A.; Fede, P.; Simonin, O. Development of filtered Euler–Euler two-phase model for circulating fluidised bed: High resolution simulation, formulation and a priori analyses. Int. J. Multiph. Flow 2013, 55, 43–63. [Google Scholar] [CrossRef]

- Ozel, A.; Gu, Y.; Milioli, C.C.; Kolehmainen, J.; Sundaresan, S. Towards filtered drag force model for non-cohesive and cohesive particle-gas flows. Phys. Fluids 2017, 29, 103308. [Google Scholar] [CrossRef]

- Jiang, Y.; Kolehmainen, J.; Gu, Y.; Kevrekidis, Y.G.; Ozel, A.; Sundaresan, S. Neural-network-based filtered drag model for gas-particle flows. Powder Technol. 2018. [Google Scholar] [CrossRef]

- Schneiderbauer, S. A spatially-averaged two-fluid model for dense large-scale gas-solid flows. AIChE J. 2017, 63, 3544–3562. [Google Scholar] [CrossRef]

- Schneiderbauer, S.; Saeedipour, M. Approximate deconvolution model for the simulation of turbulent gas-solid flows: An a priori analysis. Phys. Fluids 2018, 30, 023301. [Google Scholar] [CrossRef]

- Gao, X.; Li, T.; Sarkar, A.; Lu, L.; Rogers, W.A. Development and validation of an enhanced filtered drag model for simulating gas-solid fluidization of Geldart A particles in all flow regimes. Chem. Eng. Sci. 2018, 184, 33–51. [Google Scholar] [CrossRef]

- Cloete, J.H.; Cloete, S.; Radl, S.; Amini, S. On the choice of closure complexity in anisotropic drag closures for filtered Two Fluid Models. Chem. Eng. Sci. 2019, 207, 379–396. [Google Scholar] [CrossRef]

- Cloete, J.H.; Cloete, S.; Radl, S.; Amini, S. Verification of filtered Two Fluid Models for reactive gas-solid flows. In Proceedings of the CFD 2017, Trondheim, Norway, 30 May–1 June 2017. [Google Scholar]

- Cloete, J.H.; Cloete, S.; Radl, S.; Amini, S. Verification study of anisotropic filtered Two Fluid Model Closures. In Proceedings of the AIChE Annual Meeting, Minneapolis, MN, USA, 29 October–3 November 2017. [Google Scholar]

- Holloway, W.; Sundaresan, S. Filtered models for reacting gas–particle flows. Chem. Eng. Sci. 2012, 82, 132–143. [Google Scholar] [CrossRef]

- Agrawal, K.; Holloway, W.; Milioli, C.C.; Milioli, F.E.; Sundaresan, S. Filtered models for scalar transport in gas–particle flows. Chem. Eng. Sci. 2013, 95, 291–300. [Google Scholar] [CrossRef]

- Huang, Z.; Zhang, C.; Jiang, M.; Zhou, Q. Development of a Filtered Interphase Heat Transfer Model Based on Fine-Grid Simulations of Gas-Solid Flows. AIChE J. 2019. [Google Scholar] [CrossRef]

- Cloete, J.H.; Cloete, S.; Municchi, F.; Radl, S.; Amini, S. Development and verification of anisotropic drag closures for filtered Two Fluid Models. Chem. Eng. Sci. 2018, 192, 930–954. [Google Scholar] [CrossRef]

- Khan, M.N.; Cloete, S.; Amini, S. Efficiency Improvement of Chemical Looping Combustion Combined Cycle Power Plants. Energy Technol. 2019. in Press. [Google Scholar] [CrossRef]

- Gidaspow, D.; Bezburuah, R.; Ding, J. Hydrodynamics of Circulating Fluidized Beds, Kinetic Theory Approach. In Proceedings of the 7th Engineering Foundation Conference on Fluidization, Brisbane, Australia, 3–8 May 1992; pp. 75–82. [Google Scholar]

- Lun, C.K.K.; Savage, S.B.; Jeffrey, D.J.; Chepurniy, N. Kinetic Theories for Granular Flow: Inelastic Particles in Couette Flow and Slightly Inelastic Particles in a General Flow Field. J. Fluid Mech. 1984, 140, 223–256. [Google Scholar] [CrossRef]

- Cloete, J.H.; Cloete, S.; Municchi, F.; Radl, S.; Amini, S. The sensitivity of filtered Two Fluid Model to the underlying resolved simulation setup. Powder Technol. 2017, 316, 265–277. [Google Scholar] [CrossRef]

- Milioli, C.C.; Milioli, F.E.; Holloway, W.; Agrawal, K.; Sundaresan, S. Filtered two-fluid models of fluidized gas-particle flows: New constitutive relations. AIChE J. 2013, 59, 3265–3275. [Google Scholar] [CrossRef]

- Cloete, J.H.; Cloete, S.; Radl, S.; Amini, S. Development and verification of anisotropic solids stress closures for filtered Two Fluid Models. Chem. Eng. Sci. 2018, 192, 906–929. [Google Scholar] [CrossRef]

- Cloete, S.; Cloete, J.H.; Amini, S. Hydrodynamic validation study of filtered Two Fluid Models. Chem. Eng. Sci. 2018, 182, 93–107. [Google Scholar] [CrossRef]

- Cloete, J.H. Development of Anisotropic Filtered Two Fluid Model Closures. Ph.D. Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2018. [Google Scholar]

- Zhang, D.Z.; VanderHeyden, W.B. The effects of mesoscale structures on the macroscopic momentum equations for two-phase flows. Int. J. Multiph. Flow 2002, 28, 805–822. [Google Scholar] [CrossRef]

- Zaabout, A.; Cloete, S.; Amini, S. Autothermal operation of a pressurized Gas Switching Combustion with ilmenite ore. Int. J. Greenh. Gas Control 2017, 63, 175–183. [Google Scholar] [CrossRef]

- Kuusik, R.; Trikkel, A.; Lyngfelt, A.; Mattisson, T. High temperature behavior of NiO-based oxygen carriers for Chemical Looping Combustion. Energy Procedia 2009, 1, 3885–3892. [Google Scholar] [CrossRef]

- Abad, A.; Adánez, J.; García-Labiano, F.; de Diego, L.F.; Gayán, P.; Celaya, J. Mapping of the range of operational conditions for Cu-, Fe-, and Ni-based oxygen carriers in chemical-looping combustion. Chem. Eng. Sci. 2007, 62, 533–549. [Google Scholar] [CrossRef]

- Levenspiel, O. Chemical Reaction Engineering, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 1999. [Google Scholar]

- Thiele, E.W. Relation between Catalytic Activity and Size of Particle. Ind. Eng. Chem. 1939, 31, 916–920. [Google Scholar] [CrossRef]

- Yang, W.; Cloete, S.; Morud, J.; Amini, S. An Effective Reaction Rate Model for Gas-Solid Reactions with High Intra-Particle Diffusion Resistance. Int. J. Chem. React. Eng. 2016, 14, 331. [Google Scholar] [CrossRef]

- Rawlings, J.B.; Ekerdt, J.G. Chapter 7. In Chemical Reactor Analysis and Design Fundamentals; Nob Hill Publishing: Madison, WI, USA, 2002. [Google Scholar]

- Chevrier, S. Development of Subgrid Models for a Periodic Circulating Fluidized Bed of Binary Mixture of Particles. Ph.D. Thesis, Université de Toulouse, Toulouse, France, 2017. [Google Scholar]

- Naqvi, R.; Wolf, J.; Bolland, O. Part-load analysis of a chemical looping combustion (CLC) combined cycle with CO2 capture. Energy 2007, 32, 360–370. [Google Scholar] [CrossRef]

- EBTF. European Best Practice Guide for Assessment of CO2 Capture Technologies; European Benchmark Task Force, European Commission: Brussels, Belgium, 2011. [Google Scholar]

- Johnson, P.C.; Jackson, R. Frictional-Collisional Constitutive Relations for Granular Materials, with Application to Plane Shearing. J. Fluid Mech. 1987, 176, 67–93. [Google Scholar] [CrossRef]

- Patankar, S. Numerical Heat Transfer and Fluid Flow; Hemisphere Publishing Corporation: New York, NY, USA, 1980. [Google Scholar]

- Leonard, B.P.; Mokhtari, S. ULTRA-SHARP Nonoscillatory Convection Schemes for High-Speed Steady Multidimensional Flow; NASA Lewis Research Center: Cleveland, OH, USA, 1990. [Google Scholar]

- Gerdes, K.; Summers, W.M.; Wimer. Quality Guidelines for Energy System Studies: Cost Estimation Methodology for NETL Assessments of Power Plant Performance; DOE/NETL-2011/1455 United States 10.2172/1513278 NETL-IR English; NETL: Pittsburgh, PA, USA, 2011; p. Medium: ED.

- Turton, R.; Bailie, R.C.; Whiting, W.B.; Shaeiwitz, J.A.; Bhattacharyya, D. Appendix A. In Analysis, Synthesis and Design of Chemical Processes; Pearson Education: Upper Saddle River, NJ, USA, 2008. [Google Scholar]

- Peters, M.S.; Timmerhaus, K.D. Plant Design and Economics for Chemical Engineers; McGraw-Hill: New York, NY, USA, 1991. [Google Scholar] [CrossRef]

- Adanez, J.; Abad, A.; Garcia-Labiano, F.; Gayan, P.; de Diego, L.F. Progress in Chemical-Looping Combustion and Reforming technologies. Prog. Energy Combust. Sci. 2012, 38, 215–282. [Google Scholar] [CrossRef]

- Spallina, V.; Pandolfo, D.; Battistella, A.; Romano, M.C.; Van Sint Annaland, M.; Gallucci, F. Techno-economic assessment of membrane assisted fluidized bed reactors for pure H2 production with CO2 capture. Energy Convers. Manag. 2016, 120, 257–273. [Google Scholar] [CrossRef]

- IEAGHG. The Costs of CO2 Transport: Post-Demonstration CCS in the EU; European Technology Platform for Zero Emission Fossil Fuel Power Plants: Brussels, Belgium, 2011. [Google Scholar]

- IEAGHG. The Costs of CO2 Storage: Post-Demonstration CCS in the EU; European Technology Platform for Zero Emission Fossil Fuel Power Plants: Brussels, Belgium, 2011. [Google Scholar]

- Rubin, E.S.; Davison, J.E.; Herzog, H.J. The cost of CO2 capture and storage. Int. J. Greenh. Gas Control 2015, 40, 378–400. [Google Scholar] [CrossRef]

| Inlet | Oxidation | Reduction |

|---|---|---|

| Mass flow rate (kg/s) | 41.15 | 0.698 |

| Temperature (°C) | 422 | 434 |

| Composition | Air | Methane |

| Natural Gas | 8 $/GJ |

| Oxygen carrier (OC) | 15 $/kg |

| OC replacement period | 2 years |

| Process water | 2 $/m3 |

| Cooling water | 0.35 $/m3 |

| CO2 transport and storage costs | 12 $/ton CO2 |

| Plant | NGCC | ICR-1000 | ICR-1150 | ICR-1300 |

|---|---|---|---|---|

| Combustor/reactor outlet temperature (°C) | 1416 | 1000 | 1150 | 1300 |

| Thermal input (MW) | 765.0 | 697.5 | 697.5 | 697.5 |

| Gas turbine (MW) | 292.5 | 220.9 | 223.0 | 235.5 |

| Steam turbine (MW) | 161.6 | 84.3 | 106.9 | 121.5 |

| CO2 expander (MW) | 36.3 | 41.4 | 46.4 | |

| CO2 compressors (MW) | −15.9 | −15.7 | −15.5 | |

| Auxiliaries (MW) | −8.5 | −4.6 | −6.0 | −6.6 |

| Net power (MW) | 445.6 | 321.0 | 349.7 | 381.3 |

| Net electric efficiency (%) | 58.3 | 46.0 | 50.1 | 54.7 |

| CO2 intensity (kg/MWh) | 352.2 | 22.3 | 20.5 | 18.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cloete, J.H.; Khan, M.N.; Cloete, S.; Amini, S. Simulation-Based Design and Economic Evaluation of a Novel Internally Circulating Fluidized Bed Reactor for Power Production with Integrated CO2 Capture. Processes 2019, 7, 723. https://doi.org/10.3390/pr7100723

Cloete JH, Khan MN, Cloete S, Amini S. Simulation-Based Design and Economic Evaluation of a Novel Internally Circulating Fluidized Bed Reactor for Power Production with Integrated CO2 Capture. Processes. 2019; 7(10):723. https://doi.org/10.3390/pr7100723

Chicago/Turabian StyleCloete, Jan Hendrik, Mohammed N. Khan, Schalk Cloete, and Shahriar Amini. 2019. "Simulation-Based Design and Economic Evaluation of a Novel Internally Circulating Fluidized Bed Reactor for Power Production with Integrated CO2 Capture" Processes 7, no. 10: 723. https://doi.org/10.3390/pr7100723

APA StyleCloete, J. H., Khan, M. N., Cloete, S., & Amini, S. (2019). Simulation-Based Design and Economic Evaluation of a Novel Internally Circulating Fluidized Bed Reactor for Power Production with Integrated CO2 Capture. Processes, 7(10), 723. https://doi.org/10.3390/pr7100723