2.1.1. Particle Dynamics

Linear motion description for the NPK granular flow with spherical solid particles is modeled using the DEM since it extends the Lagrangian formulation to account for inter-particle interactions in the particle equations of motion, which are essential in highly loaded flows. The equation of conservation of linear momentum for a DEM particle of mass

is given by Equation (1), where

denotes the instantaneous particle velocity,

is the resultant of the forces acting on the surface particle, and

is the resultant of the body forces. These forces are also decomposed according to Equation (2), where

is the drag force,

is the pressure gradient force,

is the gravity force,

is the contact force from the DEM, and

is the force produced by the rotating reference frame.

For the solid-fluid interactions, the resultant

forces represent the momentum transfer from the continuous phase to the particle. The drag force is given by Equation (3), where

is the density of the continuous phase,

is the projected area of the particle,

is the particle slip velocity, and

is the drag coefficient of the particle given by the Schiller–Naumann correlation, which is suitable for spherical solid particles. The pressure gradient force

is defined according to Equation (4), where

is the volume of the particle and

is the gradient of the static pressure in the continuous phase.

For the particle body forces, the gravity force is given by Equation (5), where

is the gravitational acceleration vector. The contact force

represents inter-particle and particle-boundary interaction and is presented in Equation (6), where

is the contact force model. A modification of the linear spring contact model developed by Cundall and Strack was used [

20].

The normal and tangential forces are defined by Equation (7), where

is the normal spring constant,

is the tangential spring constant,

is the normal damping,

is the normal velocity component of the relative sphere surface velocity at the contact point,

is the static friction coefficient, and

and

are overlaps in the normal and tangential directions at contact points.

The normal and tangential spring stiffness is given by Equation (8).

,

, and

are the equivalent Young’s modulus, shear modulus, and radius of the interacting particles, and they are calculated according to Equation (9), where

and

are Young’s modulus of the particles,

, and

their Poisson’s ratios, and

and

their radii.

The normal and tangential damping is given by Equation (10), where

and

are the normal and tangential damping coefficient, and

is the equivalent particle mass. The normal and tangential coefficients and equivalent particle mass are given by Equation (11), where

and

are the normal and tangential coefficients of restitution defined by the physical properties of the material, and

and

the mass of each colliding particle.

The force produced by the moving reference frame is given by Equation (12), where

is the angular velocity vector of the rotating reference frame and

is the distance vector to the axis of rotation.

Rotational motion for DEM particles is described by orientations and, therefore, their angular momentum must also be conserved, and it is represented by Equation (13), where

is the particle moment of inertia described by a second-order tensor,

is the particle angular velocity,

is the drag torque, that is, the moment that acts on the particle due to rotational drag, and

is the total moment from contact forces.

The drag torque reduces the difference between a particle and the fluid in which it is immersed, and is defined by Equation (14), where

is the rotational drag coefficient.

is the relative angular velocity of the particle to the fluid and is given by Equation (15), where

is the fluid velocity, and

is the angular velocity of the particle. The rotational drag coefficient is defined by Equation (16) where

is the rotational Reynolds number defined by Equation (17).

The total moment from contact forces is defined according to Equation (18), where

is the position vector from the particle center of gravity to the contact point, and

is the moment that acts on the particle from rolling resistance. Rolling resistance was modeled with the proportional force method with a defined coefficient of rolling resistance

.

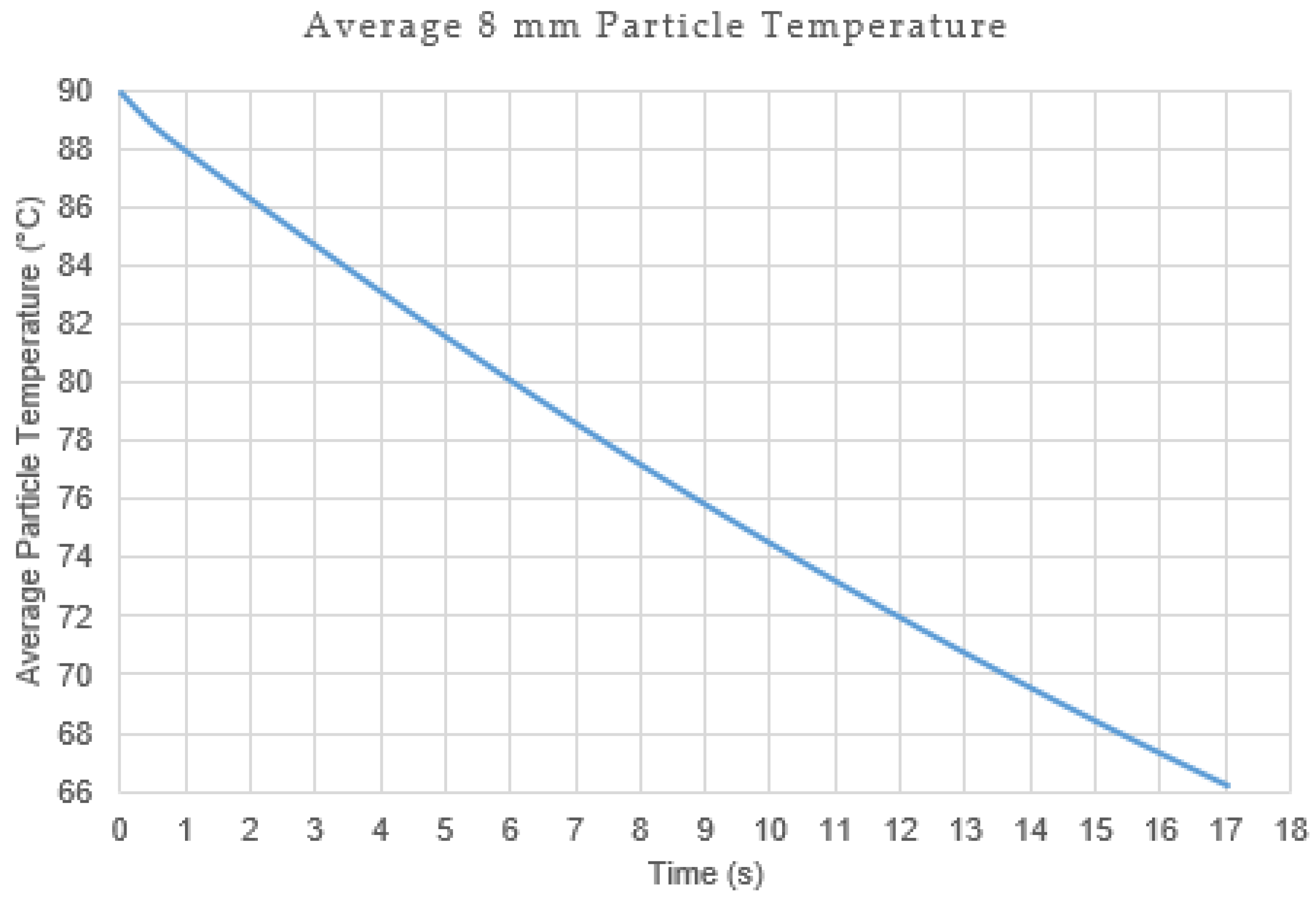

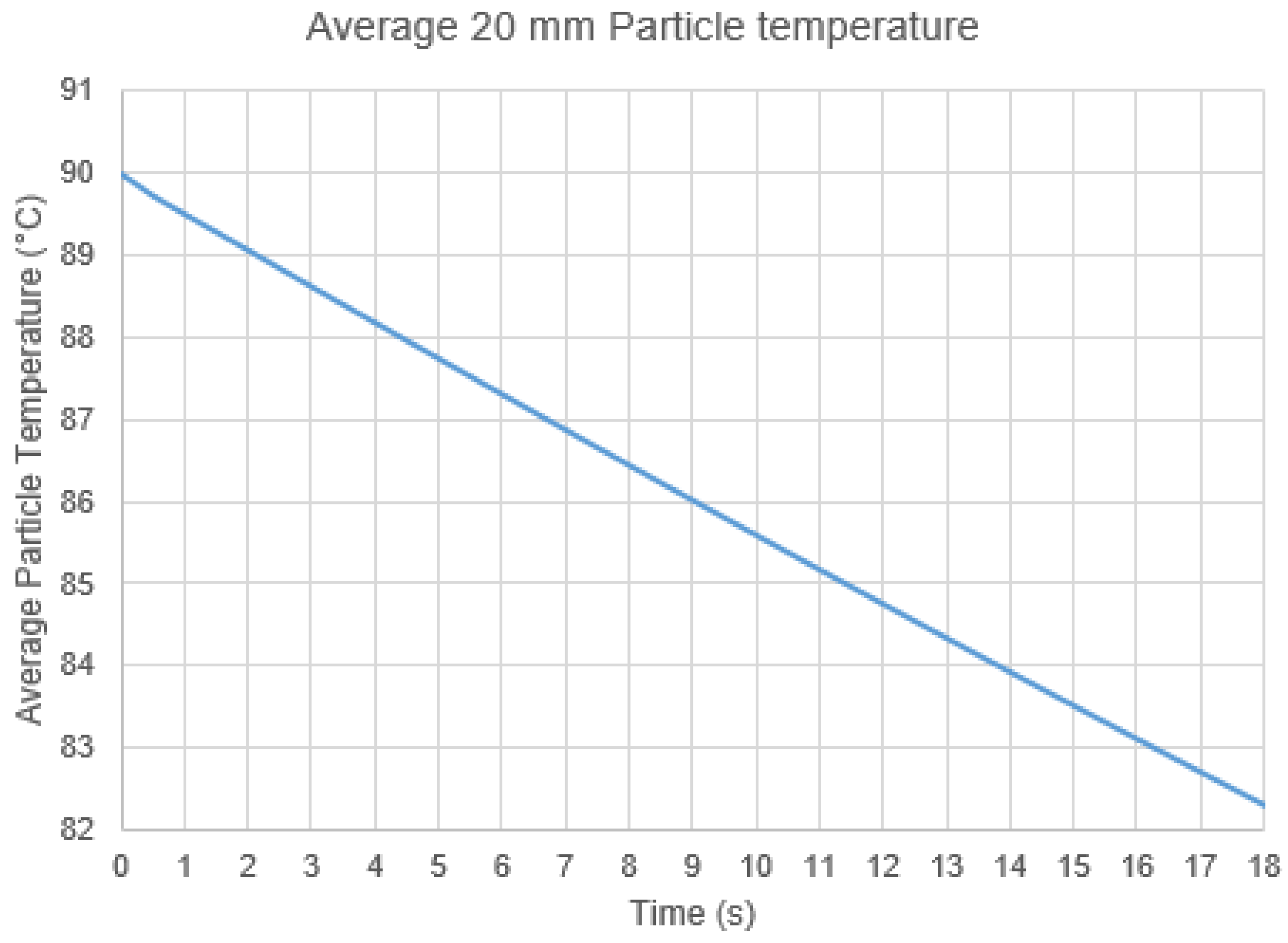

In order to study the heat and mass transfer process inside the cooling rotary drum, the solid-fluid heat transfer needs to be defined properly. The equation of conservation of mass of a material particle is given by Equation (19), where

is the rate of mass transfer to the particle. This term is zero since no evaporation occurs. The particle energy balance is shown in Equation (20), where

represents heat transfer by radiation and

represents heat transfer by other sources, and both of them are negligible in this process.

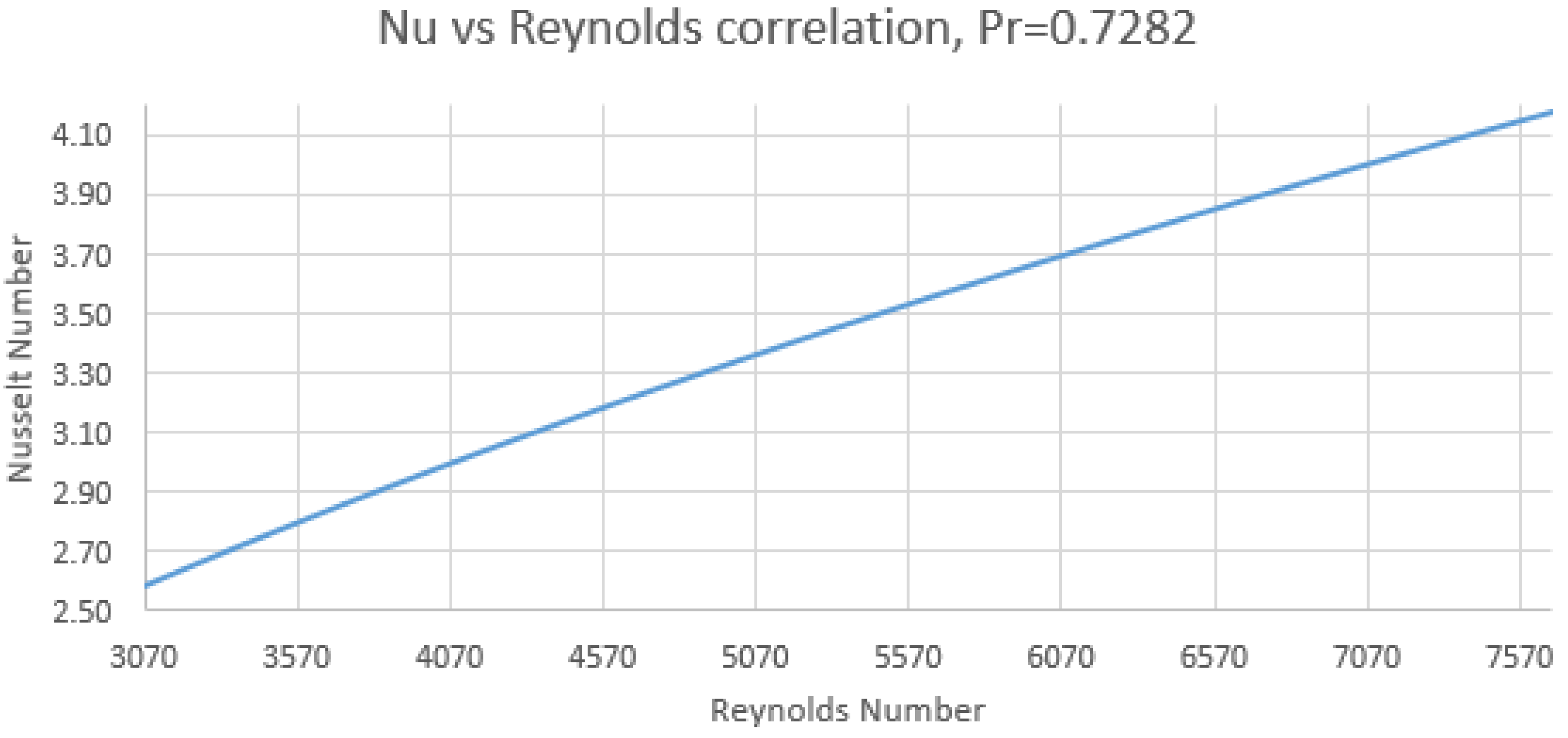

Convective heat transfer

is calculated according to Equation (21), where

is the heat transfer coefficient, and

is the particle surface area. The heat transfer coefficient was obtained from the particle Nusselt number presented in Equation (22), where

is the thermal conductivity of the fluid. Nusselt number was obtained using the Ranz–Marshall correlation defined by Equation (23), where

is the Prandtl number of the air.

The solid-solid heat transfer process is taken into consideration. When particles make contact with each other or with the wall, heat is transferred through conduction. In this work, the drum wall was considered adiabatic. Thus, conductive heat transfer was only considered between particles. Particle–particle heat transfer is given by Equation (24), where

is the contact radius and

is the equivalent thermal conductivity of the two particles and

the temperatures of particle i and j. The equivalent thermal conductivity is calculated according to Equation (25), where

and

are the thermal conductivities for particles

i and

j.

The impact heat model was employed for calculating the heat production that results from friction and damping in DEM particles. This model has a linear formulation given by Equation (26), where

and

are the fractions of frictional and damping work that are converted to heat,

and

are the frictional and damping forces on the particle, and

and

are the relative tangential and normal impact velocities.