Lattice Strain Analysis of a Mn-Doped CdSe QD System Using Crystallography Techniques

Abstract

1. Introduction

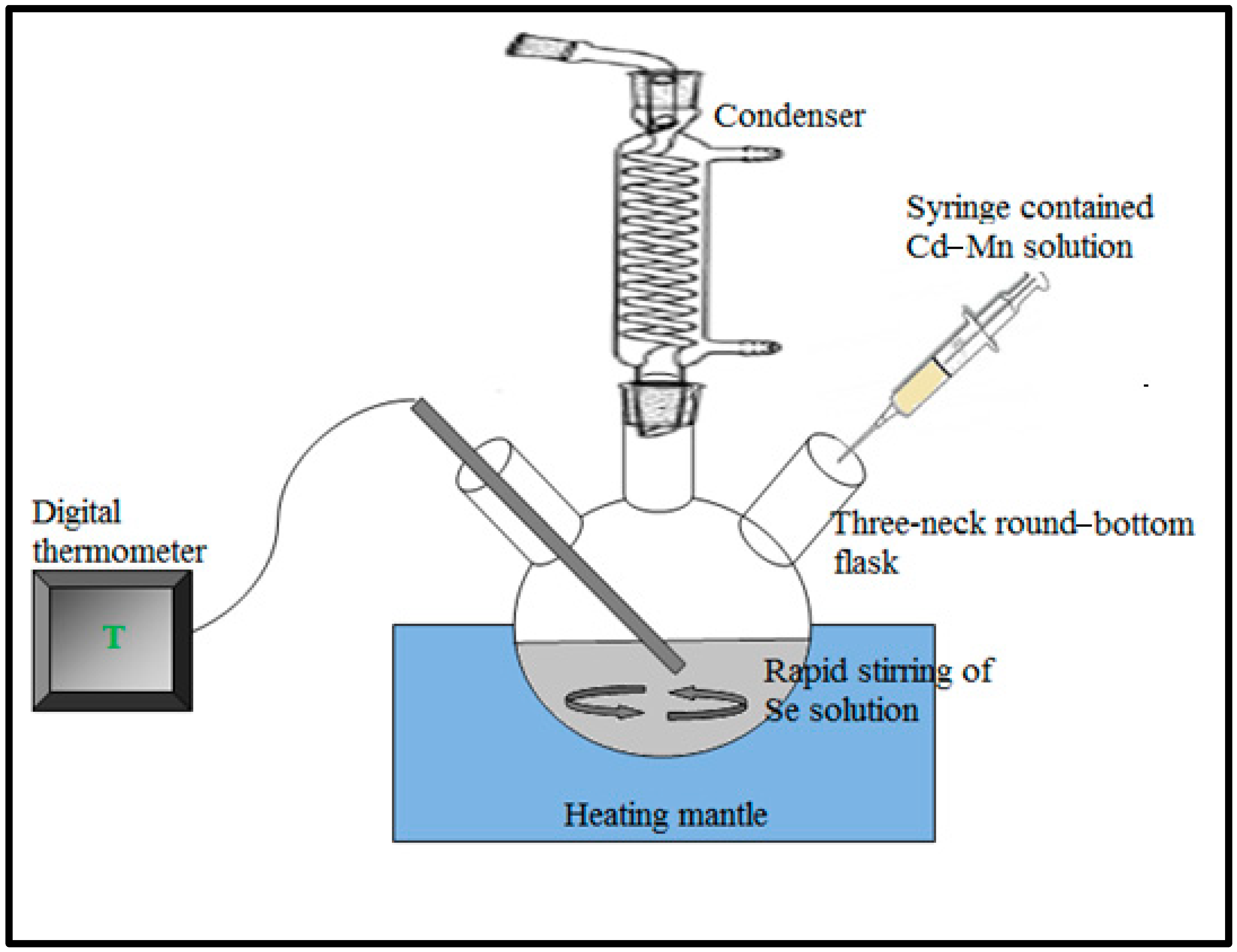

2. Experimental Procedure

Characterization Techniques

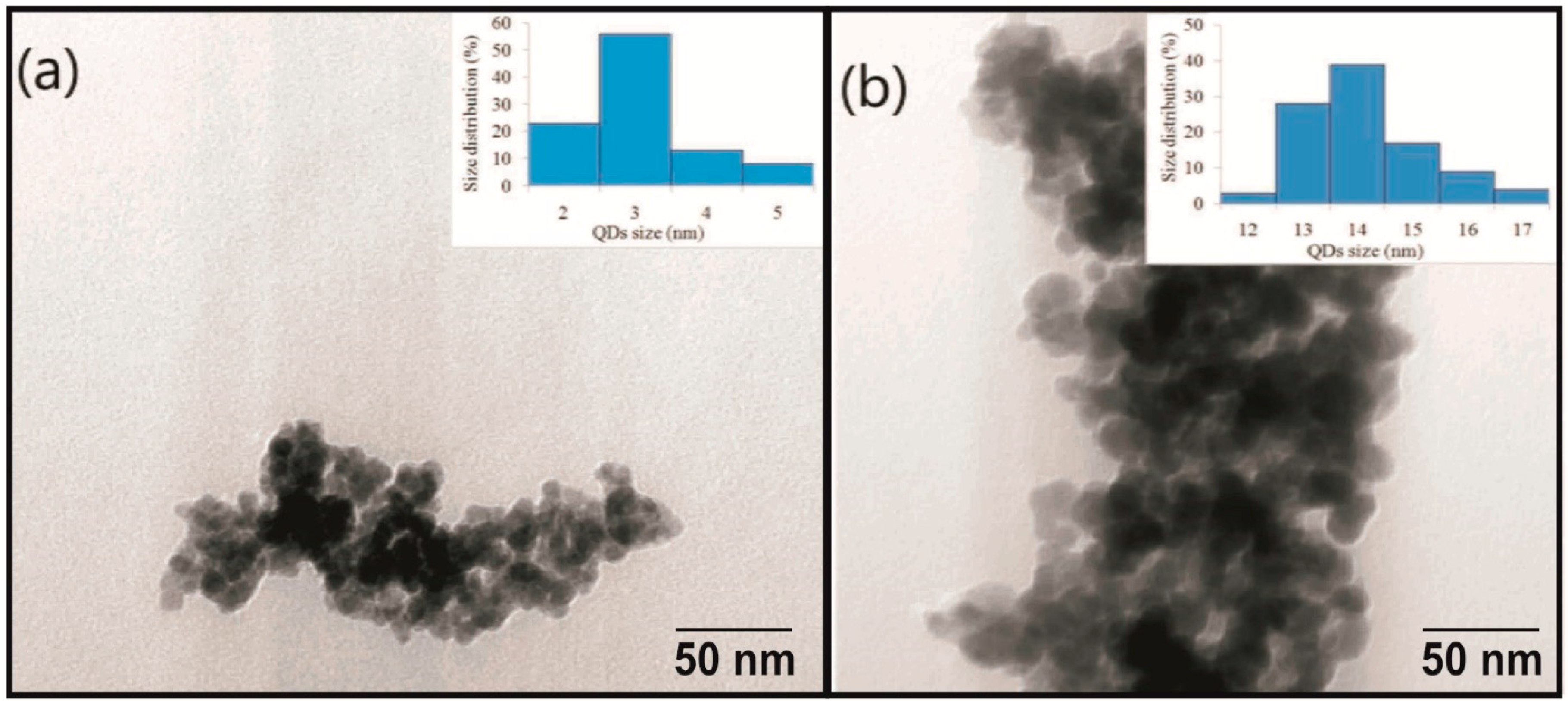

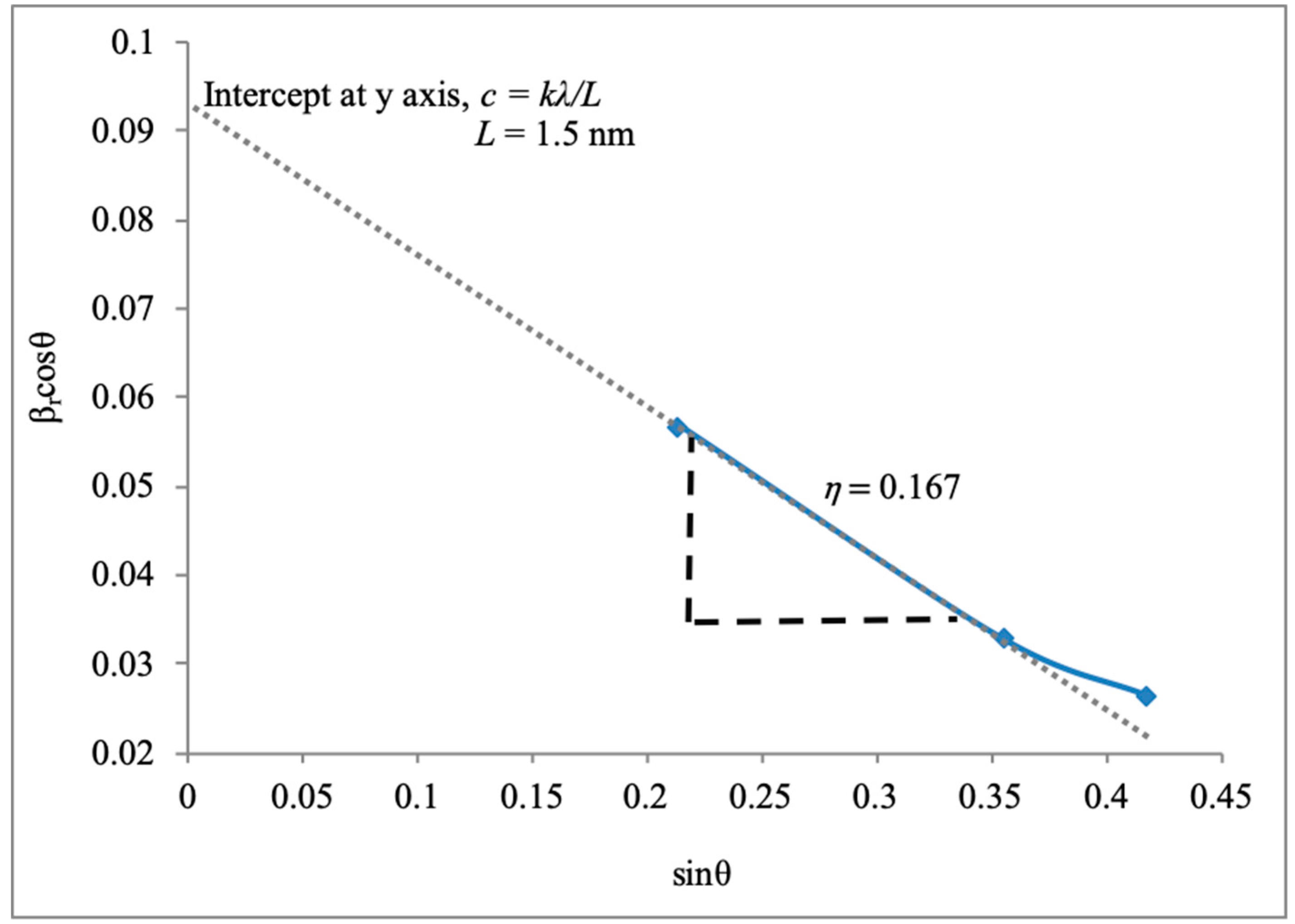

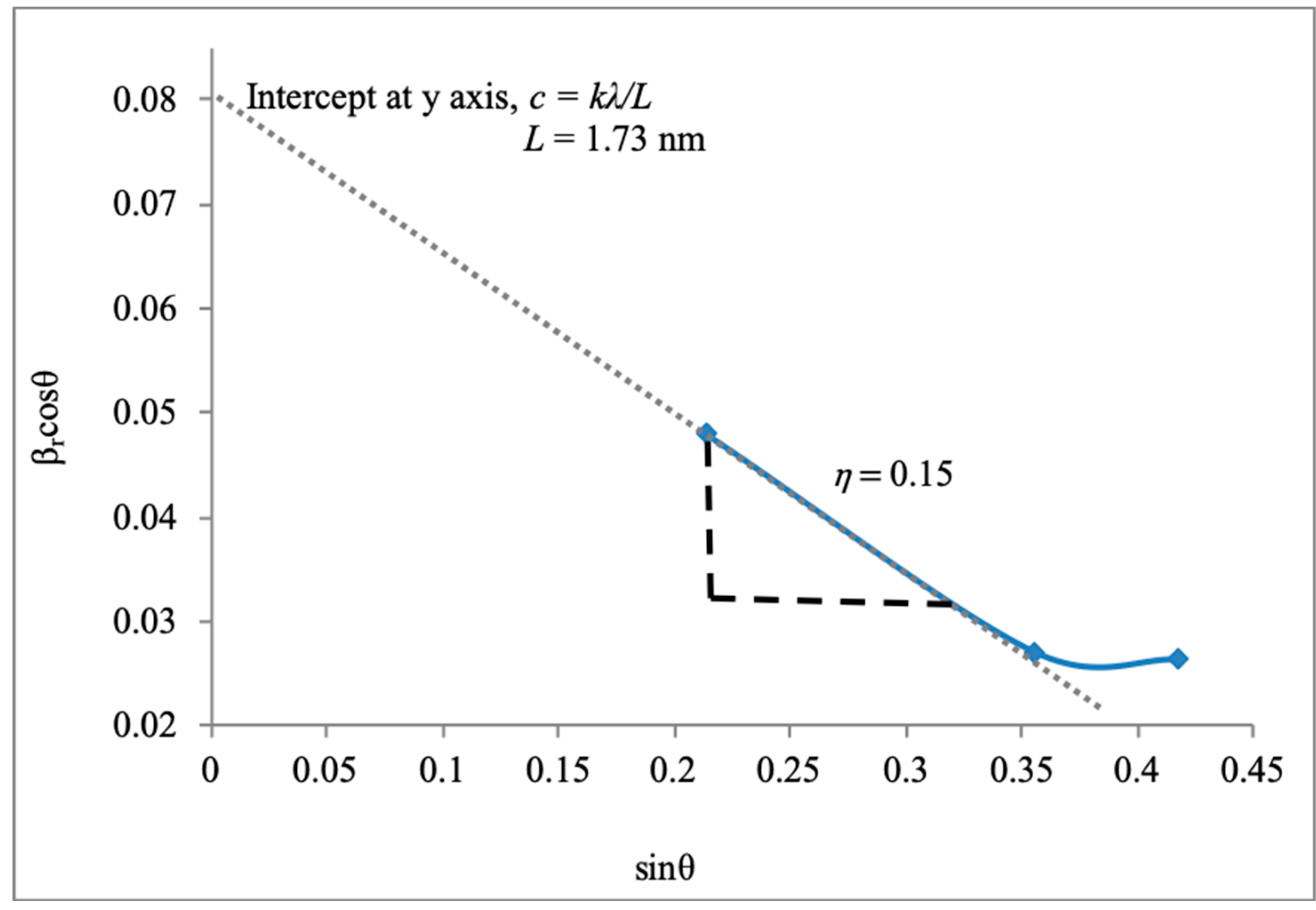

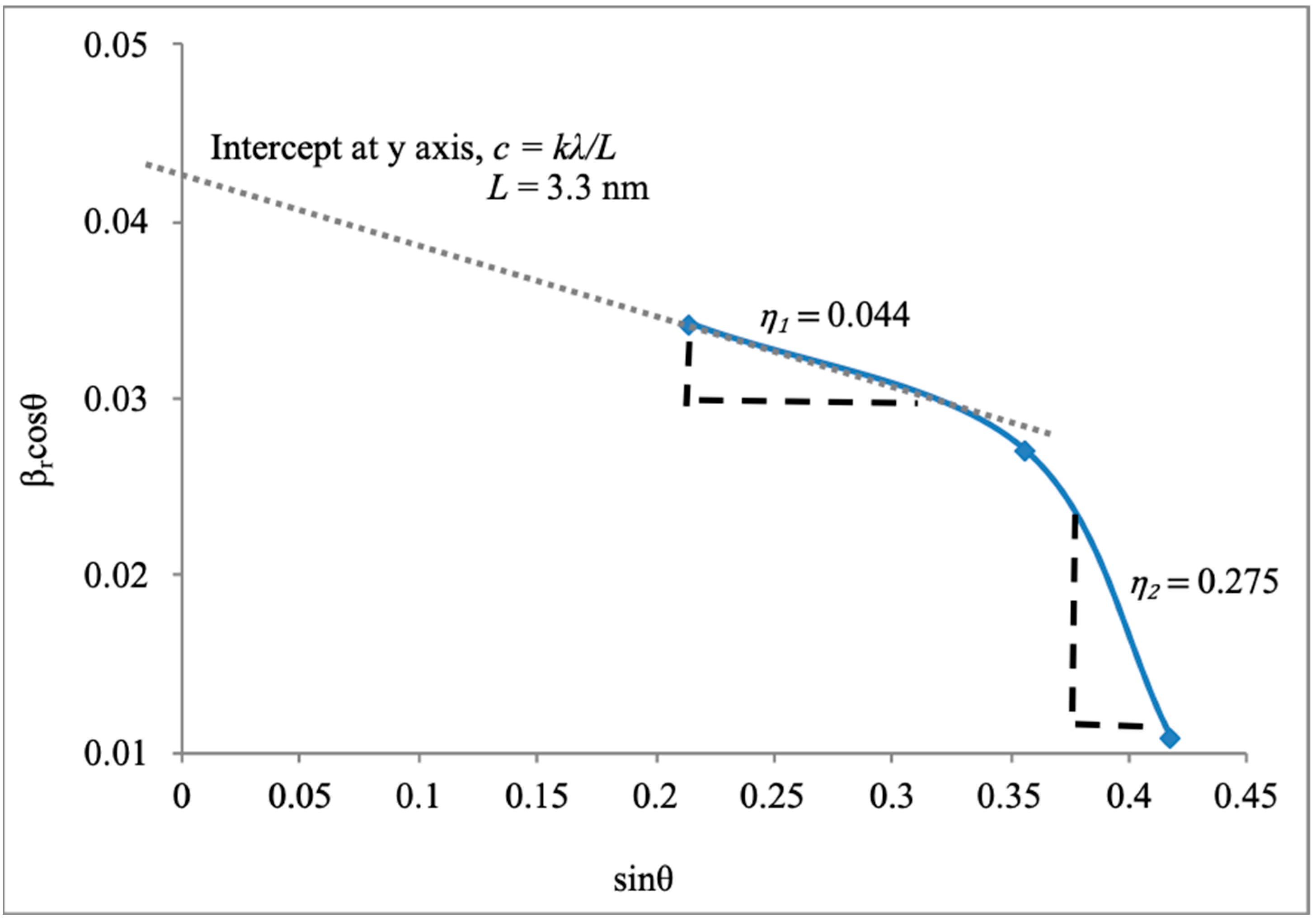

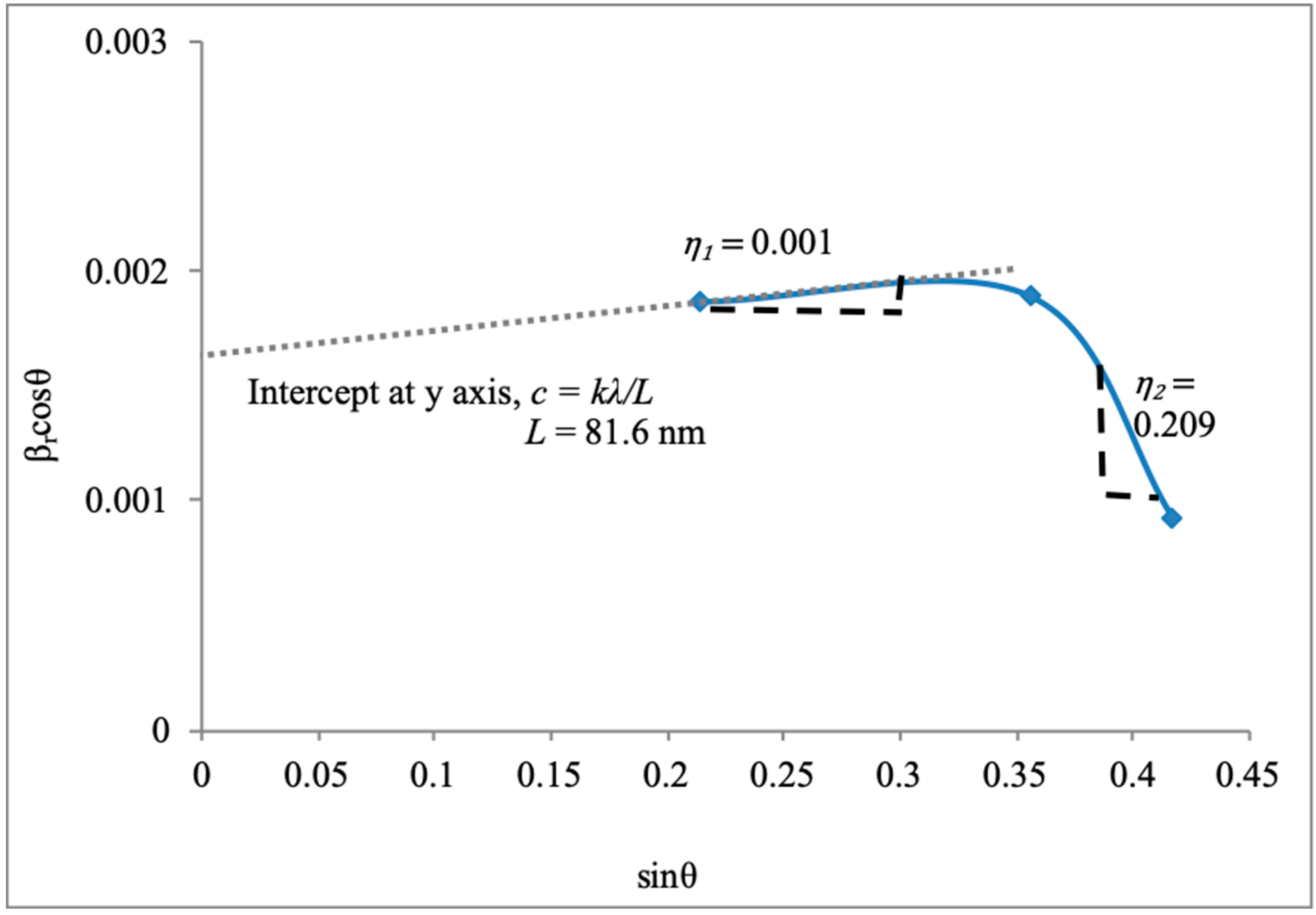

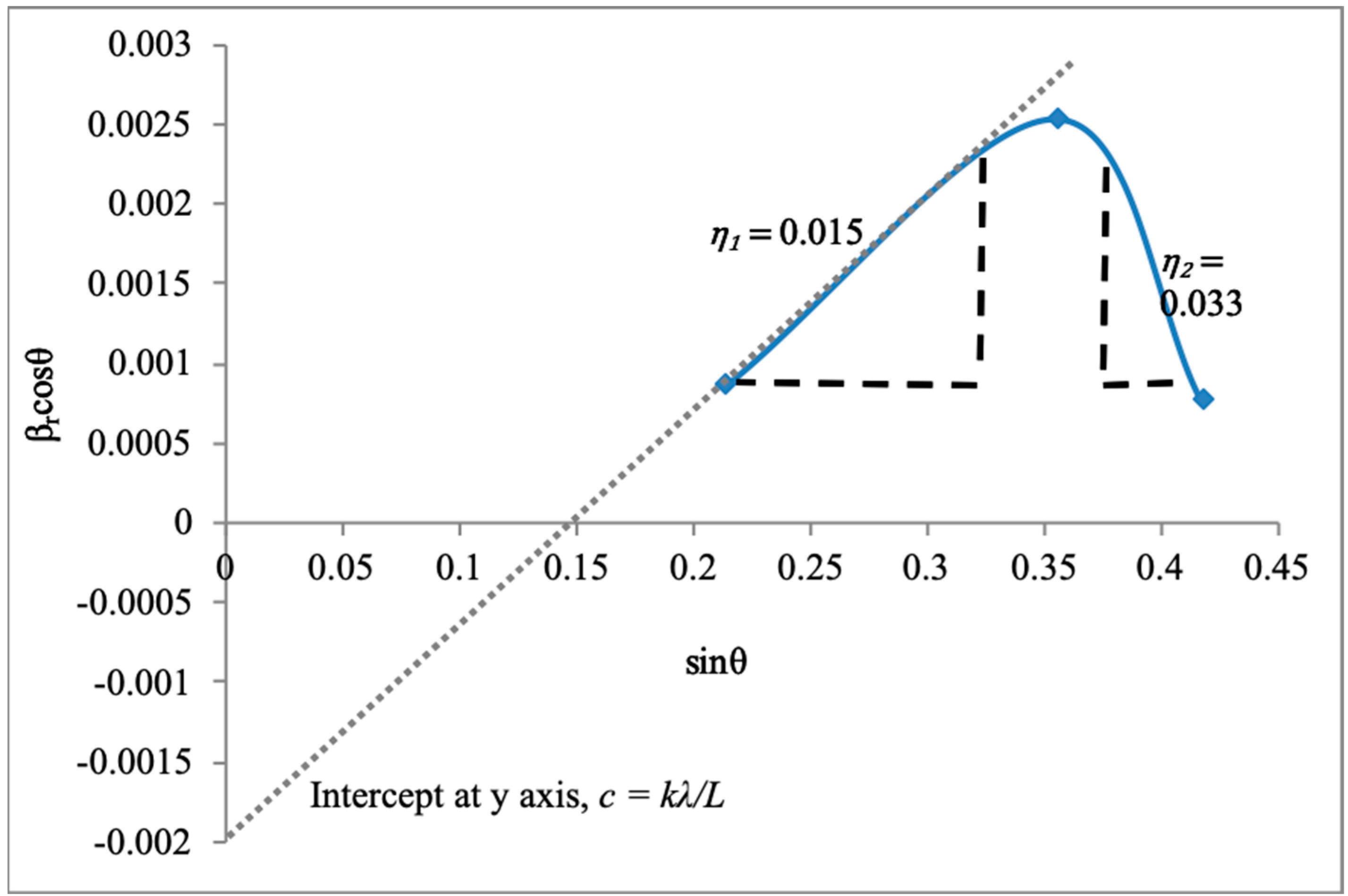

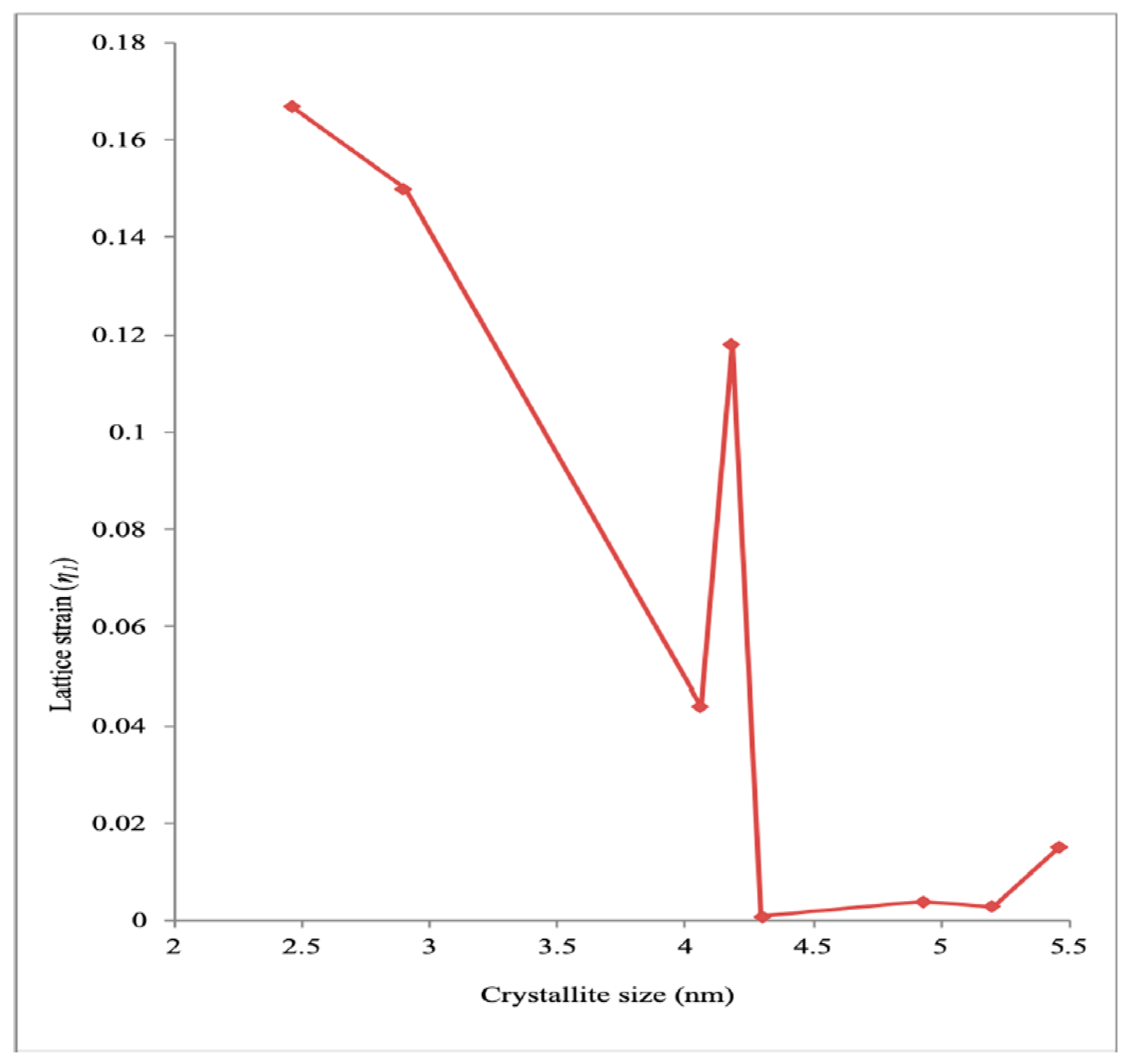

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Sung, Y.-M.; Kwak, W.-C.; Kim, T.G. Coarsening kinetics of Mn-doped CdSe nanocrystals. Cryst. Growth Des. 2008, 8, 1186–1190. [Google Scholar] [CrossRef]

- Jiang, F.; Muscat, A.J. Ligand-controlled growth of ZnSe quantum dots in water during Ostwald ripening. Langmuir 2012, 28, 12931–12940. [Google Scholar] [CrossRef] [PubMed]

- Smith, A.M.; Nie, S. Semiconductor nanocrystals: structure, properties, and band gap engineering. Acc. Chem. Res. 2010, 43, 190–200. [Google Scholar] [CrossRef] [PubMed]

- Erwin, S.C.; Zu, L.J.; Haftel, M.I.; Efros, A.L.; Kennedy, T.A.; Norris, D.J. Doping semiconductor nanocrystals. Nature 2005, 436, 91–94. [Google Scholar] [CrossRef] [PubMed]

- Alivisatos, P. Semiconductor clusters, nanocrystals, and quantum dots. Science 1996, 271, 933–937. [Google Scholar] [CrossRef]

- Kwak, W.C.; Sung, Y.M.; Kim, T.G.; Chae, W.S. Synthesis of Mn-doped zinc blende CdSe nanocrystals. Appl. Phys. Lett. 2007, 90. [Google Scholar] [CrossRef]

- Yousaf, M.; Wang, Y.; Chen, Y.; Wang, Z.; Firdous, A.; Ali, Z.; Mahmood, N.; Zou, R.; Guo, S.; Han, R.P. A 3D Trilayered CNT/MoSe2/C Heterostructure with an Expanded MoSe2 Interlayer Spacing for an Efficient Sodium Storage. Adv. Energy Mater. 2019, 9, 1900567. [Google Scholar] [CrossRef]

- Farooq, M.U.; Butt, S.; Gao, K.; Zhu, Y.; Sun, X.; Pang, X.; Khan, S.U.; Mohmed, F.; Mahmood, A.; Mahmood, N.; et al. Cd-doping a facile approach for better thermoelectric transport properties of BiCuSeO oxyselenides. RSC Adv. 2016, 6, 33789–33797. [Google Scholar] [CrossRef]

- Farooq, M.U.; Butt, S.; Gao, K.; Sun, X.; Pang, X.; Khan, S.U.; Xu, W.; Mohmed, F.; Mahmood, A.; Mahmood, N. Enhanced thermoelectric efficiency of Cu2− xSe–Cu2S composite by incorporating Cu2S nanoparticles. Ceram. Int. 2016, 42, 8395–8401. [Google Scholar] [CrossRef]

- Jian, X.; Tian, W.; Li, J.; Deng, L.; Zhou, Z.; Zhang, L.; Lu, H.; Yin, L.; Mahmood, N. Ferroferric oxide/multiwalled carbon nanotube vs polyaniline/ferroferric oxide/multiwalled carbon nanotube multiheterostructures for highly effective microwave absorption. ACS Appl. Mater. Interfaces 2019, 11, 15869–15880. [Google Scholar] [CrossRef]

- Williamson, G.; Hall, W. X-ray line broadening from filed aluminium and wolfram. Acta Metall. 1953, 1, 22–31. [Google Scholar] [CrossRef]

- Hamizi, N.A.; Johan, M.R.; Chowdhury, Z.Z.; Wahab, Y.A.; Al-Douri, Y.; Saat, A.M.; Pivehzhani, O.A. Optical structure modification induced by lattice strain in Mn-doped CdSe QDs. Opt. Mater. 2018, 86, 441–448. [Google Scholar] [CrossRef]

- Hamizi, N.A.; Johan, M.R. Synthesis and size dependent optical studies in CdSe quantum dots via inverse micelle technique. Mater. Chem. Phys. 2010, 124, 395–398. [Google Scholar] [CrossRef]

- Bryan, J.D.; Gamelin, D.R. Activation of high-TC ferromagnetism in Co2+: TiO2 and Cr3+: TiO2 nanorods and nanocrystals by grain boundary defects. Prog. Inorg. Chem. 2012, 54, 47–126. [Google Scholar]

- Scherrer, P. Bestimmung der inneren Struktur und der Größe von Kolloidteilchen mittels Röntgenstrahlen. Göttinger Nachr. 1918, 2, 98–100. [Google Scholar]

- Langford, J.I.; Wilson, A. Scherrer after sixty years: A survey and some new results in the determination of crystallite size. J. Appl. Crystallogr. 1978, 11, 102–113. [Google Scholar] [CrossRef]

- Stokes, A.R.; Wilson, A.J.C. The diffraction of X rays by distorted crystal aggregates-I. Proc. Phys. Soc. 1944, 56, 174. [Google Scholar] [CrossRef]

- Smith, J.G.; Fieser, L.F.; Fieser, M. Fieser and Fieser’s Reagents for Organic Synthesis; John Wiley and Sons: New York, NY, USA, 1990; Volume 1–12. [Google Scholar]

- Thanikaikarasan, S.; Shajan, X.S.; Dhanasekaran, V.; Mahalingam, T.J. X-ray line broadening and photoelectrochemical studies on CdSe thin films. Mater. Sci. 2011, 46, 4034–4045. [Google Scholar] [CrossRef]

- Smith, A.M.; Mohs, A.M.; Nie, S. Tuning the optical and electronic properties of colloidal nanocrystals by lattice strain. Nat. Nanotechnol. 2009, 4, 56–63. [Google Scholar] [CrossRef]

- Devi, L.S.; Devi, K.N.; Sharma, B.I.; Sarma, H.N. Influence of Mn doping on structural and optical properties of CdS nanoparticles. Indian J. Phys. 2014, 88, 477–482. [Google Scholar] [CrossRef]

- Jian, Z.; Hejing, W. The physical meanings of 5 basic parameters for an X-ray diffraction peak and their application. Chin. J. Geochem. 2003, 22, 38–44. [Google Scholar] [CrossRef]

- Chen, H.Y.; Maiti, S.; Nelson, C.A.; Zhu, X.; Son, D.H. Tuning Temperature dependence of dopant luminescence via local lattice strain in core/shell nanocrystal structure. J. Phys. Chem. C 2012, 116, 23838–23843. [Google Scholar] [CrossRef]

- Gong, K.; Kelley, D.F. Lattice strain limit for uniform shell deposition in zincblende CdSe/CdS quantum dots. J. Phys. Chem. Lett. 2015, 6, 1559–1562. [Google Scholar] [CrossRef]

- Meulenberg, R.W.; Jennings, T.; Strouse, G.F. Compressive and tensile stress in colloidal CdSe semiconductor quantum dots. Phys. Rev. B 2004, 70, 235311. [Google Scholar] [CrossRef]

- Chen, X.; Lou, Y.; Samia, A.C.; Burda, C. Coherency strain effects on the optical response of core/shell heteronanostructures. Nano Lett. 2003, 3, 799–803. [Google Scholar] [CrossRef]

- Thanh, N.T.; Maclean, N.; Mahiddine, S. Mechanisms of nucleation and growth of nanoparticles in solution. Chem. Rev. 2014, 114, 7610–7630. [Google Scholar] [CrossRef]

- Agostinelli, E.; Battistoni, C.; Fiorani, D.; Mattogno, G.; Nogues, M. An XPS study of the electronic structure of the ZnxCd1− xCr2 (X= S, Se) spinel system. J. Phys. Chem. Solids 1989, 50, 269–272. [Google Scholar] [CrossRef]

- Ivanov-Ehmin, B.; Nevskaya, N.; Zajtsev, B.; Ivanova, T. Synthesis and properties of calcium and strontium hydroxomanganates (3). Zhurnal Neorg. Khimii 1982, 27, 3101–3104. [Google Scholar]

- Dai, Q.; Sabio, E.M.; Wang, W.; Tang, J. Pulsed laser deposition of Mn doped CdSe quantum dots for improved solar cell performance. Appl. Phys. Lett. 2014, 104, 183901. [Google Scholar] [CrossRef]

| Reaction Time | Crystallite Size | Lattice Parameter, a |

|---|---|---|

| (min) | (nm) | (Å) |

| 0 | 2.46 | 2.09 |

| 0.2 | 2.90 | 2.13 |

| 0.5 | 4.06 | 2.14 |

| 1 | 4.18 | 2.16 |

| 5 | 4.30 | 2.24 |

| 16 | 4.93 | 2.29 |

| 46 | 5.20 | 2.37 |

| 90 | 5.46 | 2.56 |

| Reaction Time | FWHM (radians) | ||

|---|---|---|---|

| (min) | (111) | (220) | (311) |

| 0 | 0.058 | 0.035 | 0.029 |

| 0.2 | 0.049 | 0.029 | 0.029 |

| 0.5 | 0.035 | 0.029 | 0.012 |

| 1 | 0.034 | 0.052 | 0.029 |

| 5 | 0.033 | 0.058 | 0.035 |

| 16 | 0.029 | 0.029 | 0.029 |

| 46 | 0.027 | 0.046 | 0.029 |

| 90 | 0.026 | 0.052 | 0.029 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hamizi, N.A.; Johan, M.R.; Ghazali, N.; Abdul Wahab, Y.; Chowdhury, Z.Z.; Akbarzadeh, O.; Sagadevan, S.; Badruddin, I.A.; Yunus Khan, T.M.; Kamangar, S. Lattice Strain Analysis of a Mn-Doped CdSe QD System Using Crystallography Techniques. Processes 2019, 7, 639. https://doi.org/10.3390/pr7100639

Hamizi NA, Johan MR, Ghazali N, Abdul Wahab Y, Chowdhury ZZ, Akbarzadeh O, Sagadevan S, Badruddin IA, Yunus Khan TM, Kamangar S. Lattice Strain Analysis of a Mn-Doped CdSe QD System Using Crystallography Techniques. Processes. 2019; 7(10):639. https://doi.org/10.3390/pr7100639

Chicago/Turabian StyleHamizi, Nor Aliya, Mohd Rafie Johan, Nadiah Ghazali, Yasmin Abdul Wahab, Zaira Zaman Chowdhury, Omid Akbarzadeh, Suresh Sagadevan, Irfan Anjum Badruddin, T. M. Yunus Khan, and Sarfaraz Kamangar. 2019. "Lattice Strain Analysis of a Mn-Doped CdSe QD System Using Crystallography Techniques" Processes 7, no. 10: 639. https://doi.org/10.3390/pr7100639

APA StyleHamizi, N. A., Johan, M. R., Ghazali, N., Abdul Wahab, Y., Chowdhury, Z. Z., Akbarzadeh, O., Sagadevan, S., Badruddin, I. A., Yunus Khan, T. M., & Kamangar, S. (2019). Lattice Strain Analysis of a Mn-Doped CdSe QD System Using Crystallography Techniques. Processes, 7(10), 639. https://doi.org/10.3390/pr7100639