Model-Based Stochastic Fault Detection and Diagnosis of Lithium-Ion Batteries

Abstract

1. Introduction

2. Theoretical Backgrounds

2.1. Thermal Model of Lithium-ion Battery

- Observational uncertainty: This includes measurement errors in experimental data, such as the measurements of voltage, current, and surface temperatures.

- Parametric uncertainty: This refers to uncertainty in parameters, which may originate from the observational uncertainty or result from lack of information. It may be advantageous to represent a model parameter, e.g., Re in Equation (1), as a random variable with a distribution other than a fixed value.

- Structural uncertainty: This describes the differences between a model and the actual Li-ion battery system. For example, models in Equations (1) and (2) may not be an exact representation of the thermal dynamics of a Li-ion battery cell.

2.2. Generalized Polynomial Choas Expansion

2.3. Formulation of FDD Problem

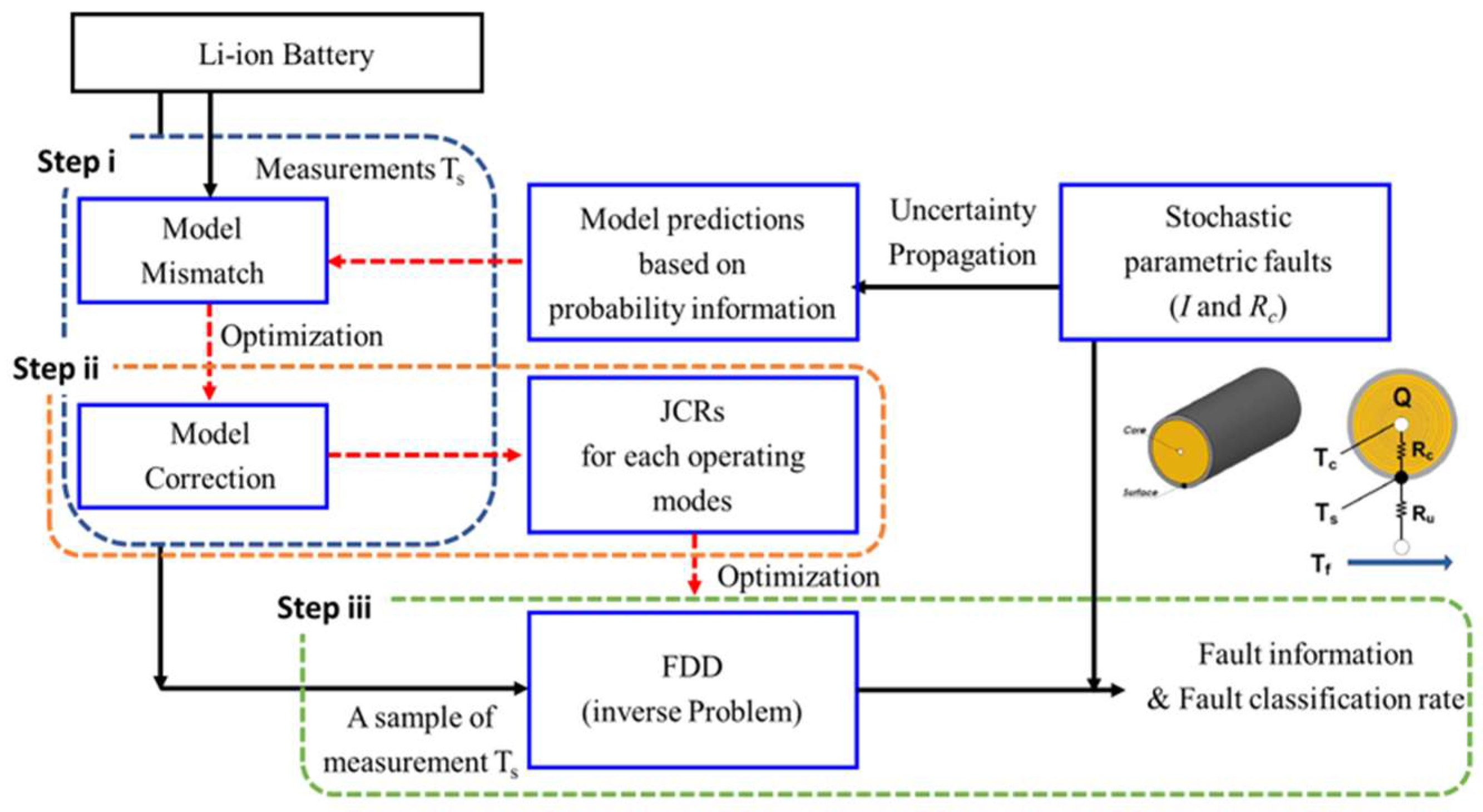

3. Methodology of Fault Detection and Diagnosis

3.1. Fault Detection Algorithm Using JCR Profiles

3.2. Optimization-Based Model Correction

3.3. Summary of FDD Algorithm

4. Results and Discussion

4.1. Uncertainty Propagation and Model Predictions

4.2. FDD Using JCR Profiles and Computational Efficiency

4.3. FDD Results Using JCRs in Combination with Model Correction

5. Conclusions

Author Contributions

Conflicts of Interest

Appendix A. Results of the gPC Expansion for the Lumped Thermal Model of Li-Ion Battery

Appendix B. Definition and Description of Faults and Their Mean Values

| JCRs (Mode) | Mean Values | Type |

|---|---|---|

| JCR 1 (Faulty 1) | I = 16.2, Rc = 1.68 | Individual fault |

| JCR 2 (Faulty 3) | I = 16.2, Rc = 2.28 | Simultaneous faults |

| JCR 3 (Normal) | I = 13.8, Rc = 1.68 | No fault |

| JCR 4 (Faulty 2) | I = 13.8, Rc = 2.28 | Individual fault |

Appendix C. Summary of Comparison between gPC and MC

| Method | Classification Rate | Computational Time |

|---|---|---|

| gPC | 0.94 | 5 s |

| MC (100 samples) | 0.75 | 324 s * |

References

- Tarascon, J.-M.; Armand, M. Issues and challenges facing rechargeable lithium batteries. Nature 2001, 414, 359–367. [Google Scholar] [CrossRef] [PubMed]

- Yan, W.; Zhang, B.; Zhao, G.; Weddington, J.; Niu, G. Uncertainty Management in Lebesgue-Sampling-Based Diagnosis and Prognosis for Lithium-Ion Battery. IEEE Trans. Ind. Electron. 2017, 64, 8158–8166. [Google Scholar] [CrossRef]

- Dey, S.; Biron, Z.A.; Tatipamula, S.; Das, N.; Mohon, S.; Ayalew, B.; Pisu, P. Model-based real-time thermal fault diagnosis of Lithium-ion batteries. Control Eng. Pract. 2016, 56, 37–48. [Google Scholar] [CrossRef]

- Wang, Q.; Ping, P.; Zhao, X.; Chu, G.; Sun, J.; Chen, C. Thermal runaway caused fire and explosion of lithium ion battery. J. Power Sources 2012, 208, 210–224. [Google Scholar] [CrossRef]

- Charkhgard, M.; Farrokhi, M. State-of-Charge Estimation for Lithium-Ion Batteries Using Neural Networks and EKF. IEEE Trans. Ind. Electron. 2010, 57, 4178–4187. [Google Scholar] [CrossRef]

- Zhang, J.; Lee, J. A review on prognostics and health monitoring of Li-ion battery. J. Power Sources 2011, 196, 6007–6014. [Google Scholar] [CrossRef]

- Ding, S.X. Model-Based Fault Diagnosis Techniques: Design Schemes, Algorithms and Tools, 2nd ed.; Springer: Berlin, Germany, 2013. [Google Scholar] [CrossRef]

- Du, Y.; Budman, H.; Duever, T.A. Comparison of stochastic fault detection and classification algorithms for nonlinear chemical processes. Comput. Chem. Eng. 2017, 106, 57–70. [Google Scholar] [CrossRef]

- Venkatasubramanian, V.; Rengaswamy, R.; Yin, K.; Kavuri, S.N. A review of process fault detection and diagnosis: Part I: Quantitative model-based methods. Comput. Chem. Eng. 2003, 27, 293–311. [Google Scholar] [CrossRef]

- Guo, G.; Long, B.; Cheng, B.; Zhou, S.; Xu, P.; Cao, B. Three-dimensional thermal finite element modeling of lithium-ion battery in thermal abuse application. J. Power Sources 2010, 195, 2393–2398. [Google Scholar] [CrossRef]

- Chen, S.C.; Wan, C.C.; Wang, Y.Y. Thermal analysis of lithium-ion batteries. J. Power Sources 2005, 140, 111–124. [Google Scholar] [CrossRef]

- Smith, K.; Wang, C.-Y. Power and thermal characterization of a lithium-ion battery pack for hybrid-electric vehicles. J. Power Sources 2006, 160, 662–673. [Google Scholar] [CrossRef]

- Doughty, D.H.; Butler, P.C.; Jungst, R.G.; Roth, E.P. Lithium battery thermal models. J. Power Sources 2002, 110, 357–363. [Google Scholar] [CrossRef]

- Lin, X.; Perez, H.E.; Siegel, J.B.; Stefanopoulou, A.G.; Li, Y.; Anderson, R.D.; Ding, Y.; Castanier, M.P. Online Parameterization of Lumped Thermal Dynamics in Cylindrical Lithium Ion Batteries for Core Temperature Estimation and Health Monitoring. IEEE Trans. Control Syst. Technol. 2013, 21, 1745–1755. [Google Scholar] [CrossRef]

- Klein, R.; Chaturvedi, N.A.; Christensen, J.; Ahmed, J.; Findeisen, R.; Kojic, A. Electrochemical Model Based Observer Design for a Lithium-Ion Battery. IEEE Trans. Control Syst. Technol. 2013, 21, 289–301. [Google Scholar] [CrossRef]

- Dey, S.; Ayalew, B. A Diagnostic Scheme for Detection, Isolation and Estimation of Electrochemical Faults in Lithium-Ion Cells. In Proceedings of the ASME 2015 Dynamic Systems and Control Conference, Columbus, OH, USA, 28–30 October 2015. [Google Scholar] [CrossRef]

- Muddappa, V.S.; Anwar, S. Electrochemical Model Based Fault Diagnosis of Li-Ion Battery Using Fuzzy Logic. In Proceedings of the ASME 2014 International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014. [Google Scholar] [CrossRef]

- Dey, S.; Mohon, S.; Pisu, P.; Ayalew, B. Sensor Fault Detection, Isolation, and Estimation in Lithium-Ion Batteries. IEEE Trans. Control Syst. Technol. 2016, 24, 2141–2149. [Google Scholar] [CrossRef]

- Lombardi, W.; Zarudniev, M.; Lesecq, S.; Bacquet, S. Sensors fault diagnosis for a BMS. In Proceedings of the 2014 European Control Conference (ECC), Strasbourg, France, 24–27 June 2014. [Google Scholar] [CrossRef]

- He, H.; Liu, Z.; Hua, Y. Adaptive Extended Kalman Filter Based Fault Detection and Isolation for a Lithium-Ion Battery Pack. Energy Procedia 2015, 75, 1950–1955. [Google Scholar] [CrossRef]

- Gao, Z.; Ding, S.X.; Cecati, C. Real-time fault diagnosis and fault-tolerant control. IEEE Trans. Ind. Electron. 2015, 62, 3752–3756. [Google Scholar] [CrossRef]

- Izadian, A.; Khayyer, P.; Famouri, P. Fault Diagnosis of Time-Varying Parameter Systems with Application in MEMS LCRs. IEEE Trans. Ind. Electron. 2009, 56, 973–978. [Google Scholar] [CrossRef]

- Du, Y.; Duever, T.A.; Budman, H. Generalized Polynomial Chaos-Based Fault Detection and Classification for Nonlinear Dynamic Processes. Ind. Eng. Chem. Res. 2016, 55, 2069–2082. [Google Scholar] [CrossRef]

- Du, Y.; Duever, T.A.; Budman, H. Fault detection and diagnosis with parametric uncertainty using generalized polynomial chaos. Comput. Chem. Eng. 2015, 76, 63–75. [Google Scholar] [CrossRef]

- Guo, H.; Wang, X.; Wang, L.; Chen, D. Delphi Method for Estimating Membership Function of Uncertain Set. J. Uncertain. Anal. Appl. 2016, 4, 3. [Google Scholar] [CrossRef]

- Liu, B. Uncertainty Theory: A Branch of Mathematics for Modeling Human Uncertainty; Springer: Berlin, Germany, 2010. [Google Scholar] [CrossRef]

- Patton, R.J.; Putra, D.; Klinkhieo, S. Friction compensation as a fault tolerant control problem. Int. J. Syst. Sci. 2010, 41, 987–1001. [Google Scholar] [CrossRef]

- Sidhu, A.; Izadian, A.; Anwar, S. Adaptive Nonlinear Model-Based Fault Diagnosis of Li-Ion Batteries. IEEE Trans. Ind. Electron. 2015, 62, 1002–1011. [Google Scholar] [CrossRef]

- Yan, X.-G.; Edwards, C. Nonlinear robust fault reconstruction and estimation using a sliding mode observer. Automatica 2007, 43, 1605–1614. [Google Scholar] [CrossRef]

- Spanos, P.D.; Zeldin, B.A. Monte Carlo Treatment of Random Fields: A Broad Perspective. Appl. Mech. Rev. 1998, 51, 219–237. [Google Scholar] [CrossRef]

- Xiu, D. Numerical Methods for Stochastic Computation: A Spectral Method Approach; Princeton University Press: Princeton, NJ, USA, 2010. [Google Scholar]

- Mandur, J.; Budman, H. Robust optimization of chemical processes using Bayesian description of parametric uncertainty. J. Process Control 2014, 24, 422–430. [Google Scholar] [CrossRef]

- Lin, X.; Fu, H.; Perez, H.E.; Siege, J.B.; Stefanopoulou, A.G.; Ding, Y.; Castanier, M.P. Parameterization and Observability Analysis of Scalable Battery Clusters for Onboard Thermal Management. Oil Gas Sci. Technol. 2013, 68, 165–178. [Google Scholar] [CrossRef]

- Savoye, F.; Venet, P.; Millet, M.; Groot, J. Impact of Periodic Current Pulses on Li-Ion Battery Performance. IEEE Trans. Ind. Electron. 2012, 59, 3481–3488. [Google Scholar] [CrossRef]

- Lin, X.; Stefanopoulou, A.G.; Perez, H.E.; Siegel, J.B.; Li, Y.; Anderson, R.D. Quadruple Adaptive Observer of the Core Temperature in Cylindrical Li-ion Batteries and their Health Monitoring. In Proceedings of the 2012 American Control Conference (ACC), Montreal, QC, Canada, 27–29 June 2012. [Google Scholar] [CrossRef]

- Mahamud, R.; Park, C. Reciprocating air flow for Li-ion battery thermal management to improve temperature uniformity. J. Power Sources 2011, 196, 5685–5696. [Google Scholar] [CrossRef]

- Smith, K.; Kim, G.; Darcy, E.; Pesaran, A. Thermal/electrical modeling for abuse-tolerant design of lithium ion modules. Int. J. Energy Res. 2010, 34, 204–215. [Google Scholar] [CrossRef]

- Mathew, M.; Janhunen, S.; Rashid, M.; Long, F.; Fowler, M. Comparative Analysis of Lithium-Ion Battery Resistance Estimation Techniques for Battery Management Systems. Energies 2018, 11, 1490. [Google Scholar] [CrossRef]

- Pukelsheim, F. The Three Sigma Rule. Am. Stat. 1994, 48, 88–91. [Google Scholar] [CrossRef]

- Du, Y.; Budman, H.; Duever, T. Parameter estimation for an inverse nonlinear stochstic problem: Reactivity ratio studies in copolymerization. Macromol. Simul. 2017, 26, 1600095. [Google Scholar] [CrossRef]

| Model Parameters | Cc | Cs | Re | Rc | Ru |

|---|---|---|---|---|---|

| Units | JK−1 | JK−1 | m | KW−1 | KW−1 |

| Value | 268 | 18.8 | 10 | 2 | 1.5 |

| Modes | Description | Type |

|---|---|---|

| Normal | , | No fault |

| Faulty 1 | , | Individual fault |

| Faulty 2 | , | Individual fault |

| Faulty 3 | , | Simultaneous faults |

| rFCR (%) | JCR 1 | JCR 2 | JCR 3 | JCR 4 |

|---|---|---|---|---|

| without correction | 59.1 | 62.3 | 59.9 | 69.7 |

| with correction | 89.6 | 89.7 | 82.7 | 88.4 |

| 1% | 2% | 3% | 4% | 5% | |

|---|---|---|---|---|---|

| rFCR (%) | 95 | 89.6 | 84.5 | 78.2 | 72.7 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Son, J.; Du, Y. Model-Based Stochastic Fault Detection and Diagnosis of Lithium-Ion Batteries. Processes 2019, 7, 38. https://doi.org/10.3390/pr7010038

Son J, Du Y. Model-Based Stochastic Fault Detection and Diagnosis of Lithium-Ion Batteries. Processes. 2019; 7(1):38. https://doi.org/10.3390/pr7010038

Chicago/Turabian StyleSon, Jeongeun, and Yuncheng Du. 2019. "Model-Based Stochastic Fault Detection and Diagnosis of Lithium-Ion Batteries" Processes 7, no. 1: 38. https://doi.org/10.3390/pr7010038

APA StyleSon, J., & Du, Y. (2019). Model-Based Stochastic Fault Detection and Diagnosis of Lithium-Ion Batteries. Processes, 7(1), 38. https://doi.org/10.3390/pr7010038