Characterization of Pores and Fractures in Soft Coal from the No. 5 Soft Coalbed in the Chenghe Mining Area

Abstract

1. Introduction

2. Materials and methods

2.1. Selection of Coal Samples

2.2. Experimental Equipment and Test Methods

2.2.1. Mercury Intrusion Porosimetry

2.2.2. Low-Temperature Nitrogen Adsorption Method

2.2.3. SEM Observation

3. Results and Discussion

3.1. Characteristics of Pore Structure

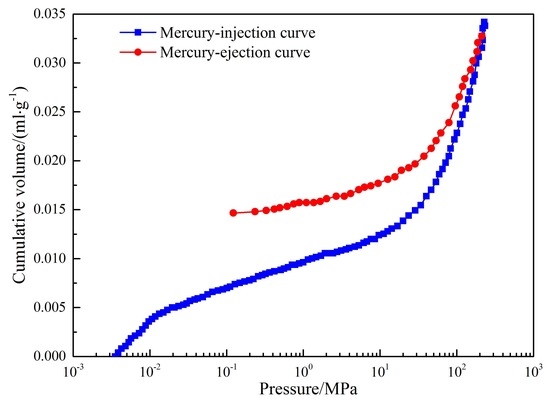

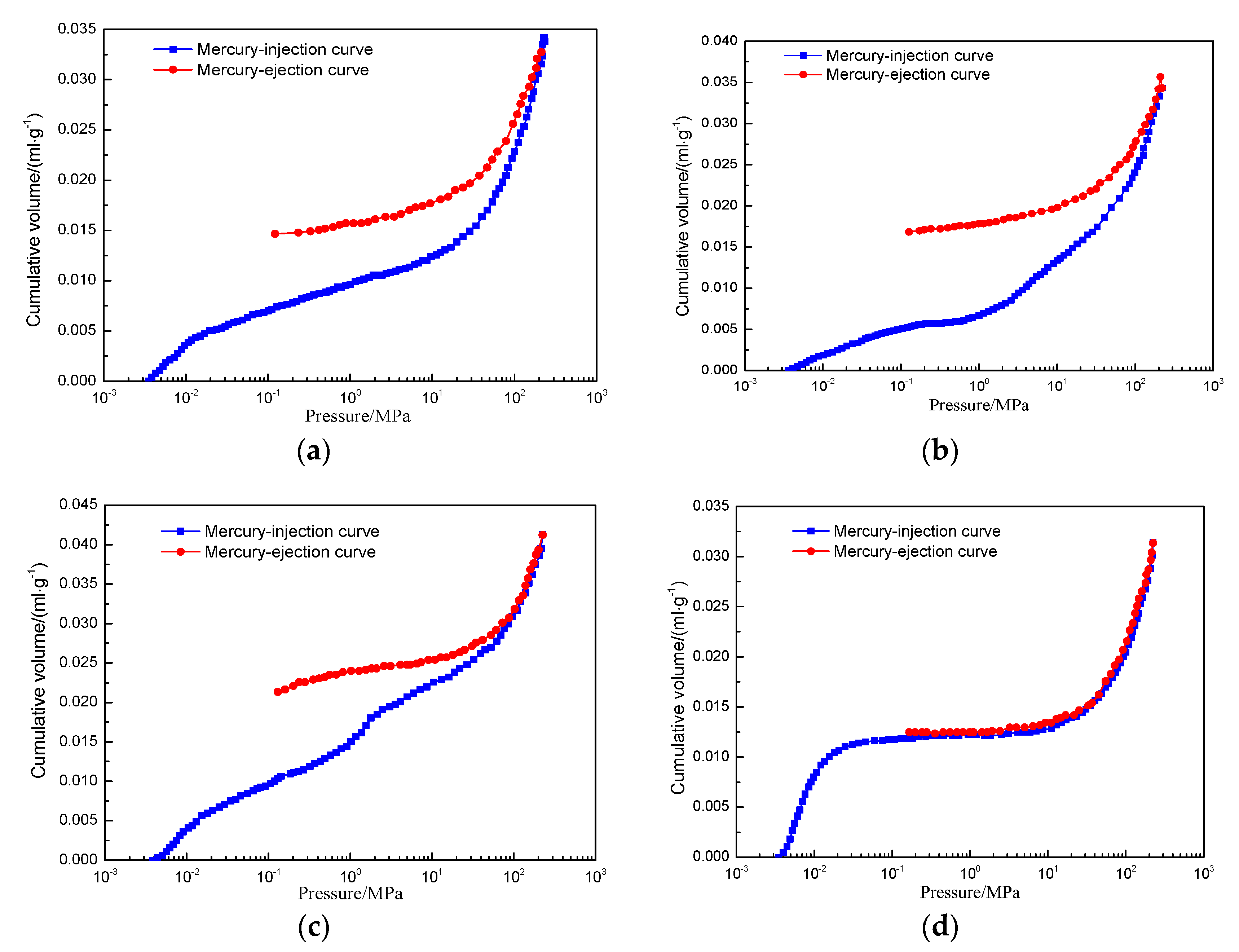

3.1.1. Measuring Pore Structure by Mercury Intrusion Porosimetry

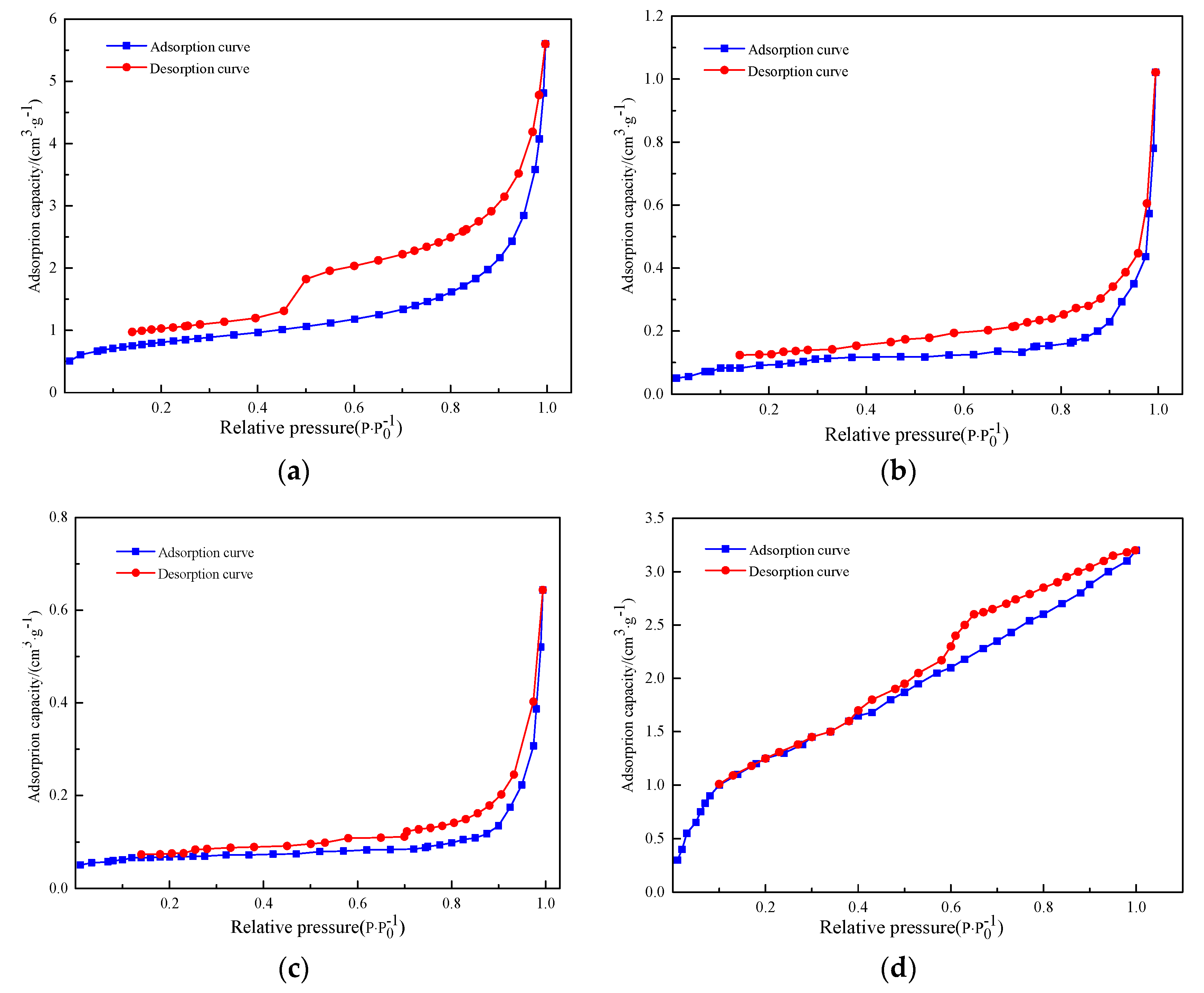

3.1.2. Measuring Pore Structure by Low-Temperature Nitrogen Adsorption

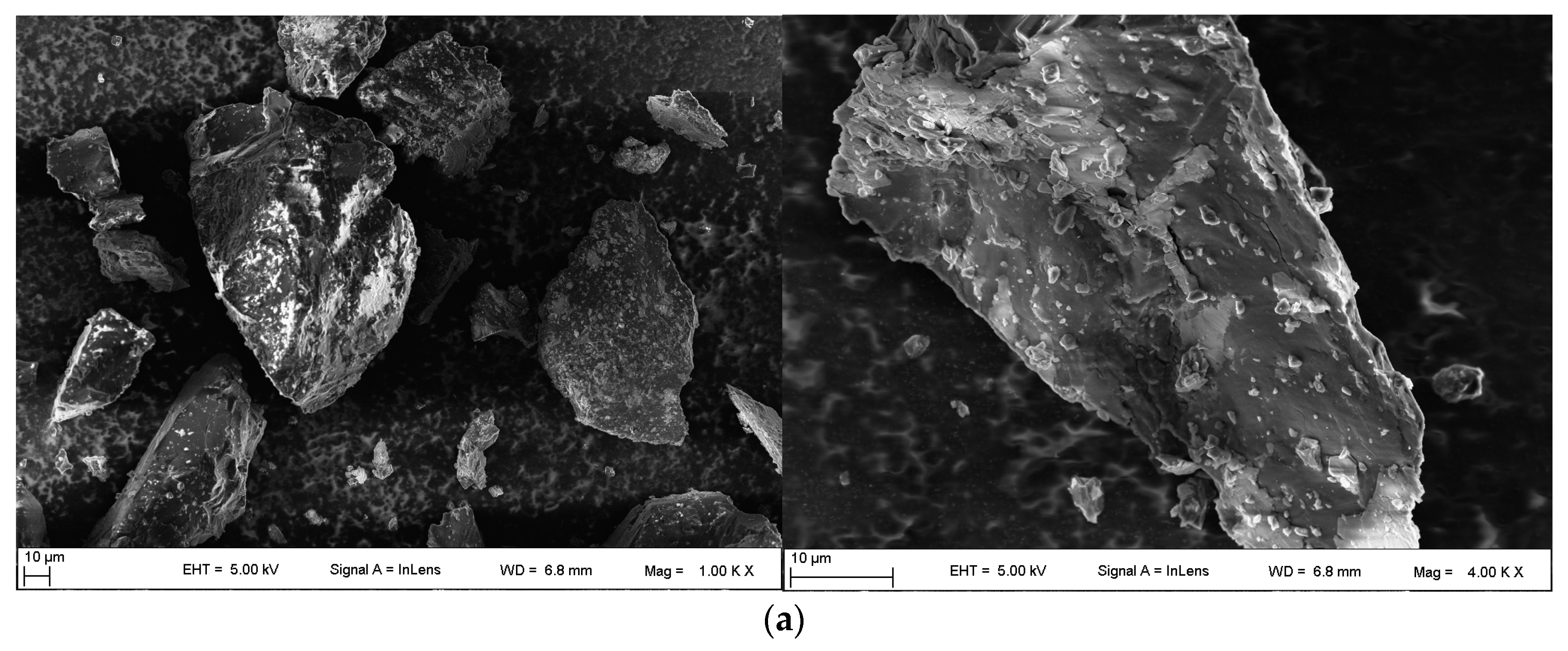

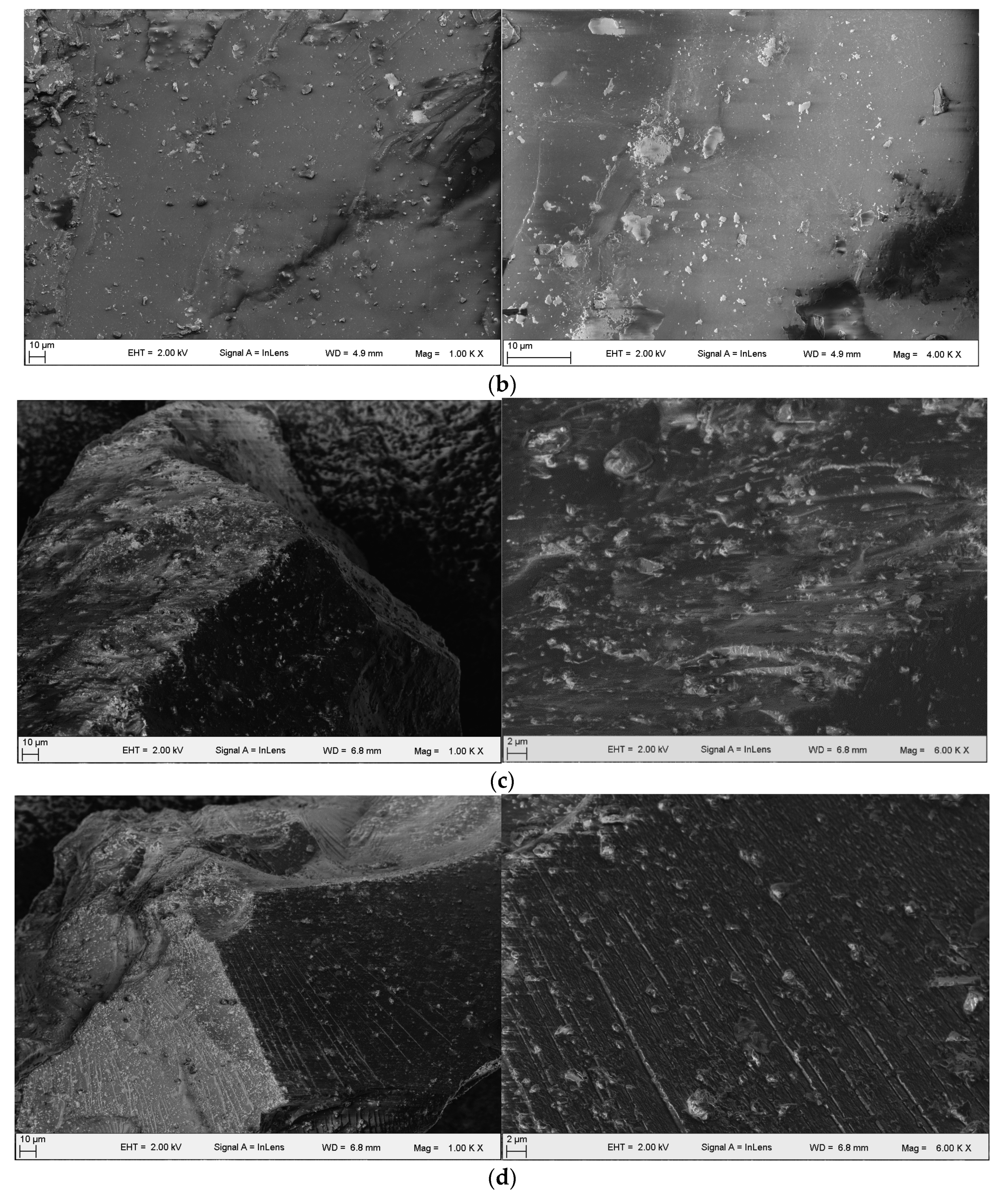

3.1.3. Observing Pore Structure by Using SEM

3.2. Fractal Characteristics of Pore Structures

3.2.1. Mercury Intrusion Method

3.2.2. Low-Temperature Nitrogen Adsorption

3.2.3. Images Taken by SEM

3.3. Prospect of Future Work

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Asif, M.; Muneer, T. Energy supply, its demand and security issues for developed and emerging economies. Renew. Sustain. Energy Rev. 2007, 11, 1388–1413. [Google Scholar] [CrossRef]

- Zhang, Y.; Shao, W.; Zhang, M.; Li, H.J.; Yin, S.J.; Xu, Y.J. Analysis 320 coal mine accidents using structural equation modeling with unsafe conditions of the rules and regulations as exogenous variables. Accid. Anal. Prev. 2016, 92, 189–201. [Google Scholar] [CrossRef] [PubMed]

- Geng, F.; Saleh, J.H. Challenging the emerging narrative: Critical examination of coalmining safety in China, and recommendations for tackling mining hazards. Saf. Sci. 2015, 75, 36–48. [Google Scholar] [CrossRef]

- Chen, H.; Qi, H.; Long, R.; Zhang, M. Research on 10-year tendency of China coal mine accidents and the characteristics of human factors. Saf. Sci. 2012, 50, 745–750. [Google Scholar] [CrossRef]

- Li, X.L.; Li, Z.H.; Wang, E.Y.; Liang, Y.P.; Li, B.L.; Chen, P.; Liu, Y.J. Pattern recognition of mine microseismic (MS) and blasting events based on wave fractal features. Fractals 2018, 26, 1850029. [Google Scholar] [CrossRef]

- Wang, L.; Cheng, Y.P.; Liu, H.Y. An analysis of fatal gas accidents in Chinese coal mines. Saf. Sci. 2014, 62, 107–113. [Google Scholar] [CrossRef]

- Yin, W.; Fu, G.; Yang, C.; Jiang, Z.G.; Zhu, K.; Gao, Y. Fatal gas explosion accidents on Chinese coal mines and the characteristics of unsafe behaviors: 2000–2014. Saf. Sci. 2017, 92, 173–179. [Google Scholar] [CrossRef]

- Nanda, S.; Reddy, S.N.; Mitra, S.K.; Kozinski, J.A. The progressive routes for carbon capture and sequestration. Energy Sci. Eng. 2016, 4, 99–122. [Google Scholar] [CrossRef]

- Yu, C.H.; Huang, C.H.; Tan, C.S. A review of CO2 capture by absorption and adsorption. Aerosol Air Qual. Res. 2012, 12, 745–769. [Google Scholar] [CrossRef]

- Jokar, S.M.; Rahimpour, M.R.; Shariati, A.; Iulianelli, A.; Bagnato, G.; Vita, A. Pure hydrogen production in membrane reactor with mixed reforming reaction by utilizing waste gas: A case study. Processes 2016, 4, 33. [Google Scholar] [CrossRef]

- Cheng, Y.P.; Wang, L.; Zhang, X.L. Environmental impact of coal mine methane emissions and responding strategies in China. Int. J. Greenh. Gas Control 2011, 5, 157–166. [Google Scholar] [CrossRef]

- Hu, Q.T.; Liang, Y.P.; Wang, H.; Zou, Q.L.; Sun, H.T. Intelligent and integrated techniques for coalbed methane (CBM) recovery and reduction of greenhouse gas emission. Environ. Sci. Pollut. Res. 2017, 24, 17651–17668. [Google Scholar]

- Karacan, C.Ö.; Ruiz, F.A.; Cotè, M.; Phippsc, S. Coal mine methane: A review of capture and utilization practices with benefits to mining safety and to greenhouse gas reduction. Int. J. Coal Geol. 2011, 86, 121–156. [Google Scholar] [CrossRef]

- Ju, Y.; Sun, Y.; Sa, Z.; Pan, J.N.; Wang, J.L.; Hou, Q.L.; Li, Q.G.; Yan, Z.F.; Liu, J. A new approach to estimate fugitive methane emissions from coal mining in China. Sci. Total. Environ. 2016, 543, 514–523. [Google Scholar] [CrossRef] [PubMed]

- Zhou, F.; Xia, T.; Wang, X.; Zhang, Y.F.; Sun, Y.N.; Liu, J.S. Recent developments in coal mine methane extraction and utilization in China: A review. J. Nat. Gas Sci. Eng. 2016, 31, 437–458. [Google Scholar] [CrossRef]

- Zhao, J.L.; Xu, H.; Tang, D.; Mathews, J.P.; Li, S.; Tao, S. A comparative evaluation of coal specific surface area by CO2 and N2 adsorption and its influence on CH4 adsorption capacity at different pore sizes. Fuel 2016, 183, 420–431. [Google Scholar] [CrossRef]

- Zhao, J.L.; Xu, H.; Tang, D.Z.; Mathews, J.P.; Li, S.; Tao, S. Coalbed porosity and fracture heterogeneity of macrolithotypes in the Hancheng Block, eastern margin, Ordos Basin, China. Int. J. Coal Geol. 2016, 159, 18–29. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.; Zou, Q.; Zhu, C.j. Microscopic mechanism for enhanced coal bed methane recovery and outburst elimination by hydraulic slotting: A case study in Yangliu mine, China. Greenh. Gases Sci. Technol. 2016, 6, 597–614. [Google Scholar] [CrossRef]

- Liu, T.; Lin, B.; Yang, W. Impact of matrix–fracture interactions on coal permeability: Model development and analysis. Fuel 2017, 207, 522–532. [Google Scholar] [CrossRef]

- Li, Q.G.; Lin, B.Q.; Zhai, C. The effect of pulse frequency on the fracture extension during hydraulic fracturing. J. Nat. Gas Sci. Eng. 2014, 21, 296–303. [Google Scholar] [CrossRef]

- Li, Q.G.; Lin, B.Q.; Zhai, C. A new technique for preventing and controlling coal and gas outburst hazard with pulse hydraulic fracturing: A case study in Yuwu coal mine, China. Nat. Hazards 2015, 75, 2931–2946. [Google Scholar] [CrossRef]

- Zou, Q.L.; Lin, B.Q.; Liu, T.; Zhou, Y.; Zhang, Z.; Yan, F.Z. Variation of methane adsorption property of coal after the treatment of hydraulic slotting and methane pre-drainage: A case study. J. Nat. Gas Sci. Eng. 2014, 20, 396–406. [Google Scholar] [CrossRef]

- Zou, Q.; Lin, B.; Zheng, C.; Zheng, C.S.; Hao, Z.Y.; Zhai, C.; Liu, T.; Liang, J.Y.; Yan, F.Z.; Yang, W.; et al. Novel integrated techniques of drilling–slotting–separation-sealing for enhanced coal bed methane recovery in underground coal mines. J. Nat. Gas Sci. Eng. 2015, 26, 960–973. [Google Scholar] [CrossRef]

- Radlinski, A.P.; Mastalerz, M.; Hinde, A.L.; Hainbuchner, M.; Rauch, H.; Baron, M.; Lin, J.S.; Fan, l.; Thiyagarajan, P. Application of SAXS and SANS in evaluation of porosity, pore size distribution and surface area of coal. Int. J. Coal Geol. 2004, 59, 245–271. [Google Scholar] [CrossRef]

- Gryglewicz, G.; Machnikowski, J.; Lorenc-Grabowska, E.; Lota, G.; Frackowiak, E. Effect of pore size distribution of coal-based activated carbons on double layer capacitance. Electrochim. Acta 2005, 50, 1197–1206. [Google Scholar] [CrossRef]

- Ross, D.J.K.; Bustin, R.M. The importance of shale composition and pore structure upon gas storage potential of shale gas reservoirs. Mar. Pet. Geol. 2009, 26, 916–927. [Google Scholar] [CrossRef]

- Gan, H.; Nandi, S.P.; Walker, P.L. Nature of the porosity in American coals. Fuel 1972, 51, 272–277. [Google Scholar] [CrossRef]

- Cai, Y.D.; Liu, D.M.; Pan, Z.J.; Pan, Z.J.; Yao, Y.B.; Li, J.Q.; Qiu, Y.K. Pore structure and its impact on CH4 adsorption capacity and flow capability of bituminous and subbituminous coals from Northeast China. Fuel 2013, 103, 258–268. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Solano, N.; Bustin, R.M.; Bustin, A.M.M.; Chalmers, G.R.L.; He, L.; Melnichenko, B.; Radliński, A.P.; Blach, T.P. Pore structure characterization of North American shale gas reservoirs using USANS/SANS, gas adsorption, and mercury intrusion. Fuel 2013, 103, 606–616. [Google Scholar] [CrossRef]

- Yao, Y.B.; Liu, D.M.; Tang, D.Z.; Tang, S.H.; Huang, W.H. Fractal characterization of adsorption-pores of coals from North China: An investigation on CH4 adsorption capacity of coals. Int. J. Coal Geol. 2008, 73, 27–42. [Google Scholar] [CrossRef]

- Fu, H.J.; Tang, D.Z.; Xu, H.; Xu, T.; Chen, B.L.; Hu, P.; Yin, Z.Y.; Wu, P.; He, G.J. Geological characteristics and CBM Exploration potential evaluation: A case study in the middle of the southern Junggar Basin, NW China. J. Nat. Gas Sci. Eng. 2016, 30, 557–570. [Google Scholar] [CrossRef]

- Hou, S.H.; Wang, X.M.; Wang, X.J.; Yuan, Y.D.; Pan, S.D.; Wang, X.M. Pore structure characterization of low volatile bituminous coals with different particle size and tectonic deformation using low pressure gas adsorption. Int. J. Coal Geol. 2017, 183, 1–13. [Google Scholar] [CrossRef]

- Kenvin, J.; Jagiello, J.; Mitchell, S.; Pérez-Ramírez, J. Unified method for the total pore volume and pore size distribution of hierarchical zeolites from argon adsorption and mercury intrusion. Langmuir 2015, 31, 1242–1247. [Google Scholar] [CrossRef]

- Melnichenko, Y.B.; Radlinski, A.P.; Mastalerz, M.; Cheng, G.; Rupp, J. Characterization of the CO2 fluid adsorption in coal as a function of pressure using neutron scattering techniques (SANS and USANS). Int. J. Coal Geol. 2009, 77, 69–79. [Google Scholar] [CrossRef]

- Okolo, G.N.; Everson, R.C.; Neomagus, H.W.J.P.; Roberts, M.J.; Sakurovs, R. Comparing the porosity and surface areas of coal as measured by gas adsorption, mercury intrusion and SAXS techniques. Fuel 2015, 141, 293–304. [Google Scholar] [CrossRef]

- Zhao, Y.X.; Sun, Y.F.; Liu, S.M.; Wang, K.; Jiang, Y.D. Pore structure characterization of coal by NMR cryoporometry. Fuel 2017, 190, 359–369. [Google Scholar] [CrossRef]

- Karpyn, Z.T.; Alajmi, A.; Radaelli, F.; Halleck, P.M.; Grader, A.S. X-ray CT and hydraulic evidence for a relationship between fracture conductivity and adjacent matrix porosity. Eng. Geol. 2009, 103, 139–145. [Google Scholar] [CrossRef]

- Watanabe, N.; Ishibashi, T.; Hirano, N.; Ohsaki, Y.; Tsuchiya, Y.; Tamagawa, T.; Okabe, H.; Tsuchiya, N. Precise 3D numerical modeling of fracture flow coupled with X-ray computed tomography for reservoir core samples. SPE J. 2011, 16, 683–691. [Google Scholar] [CrossRef]

- Golab, A.; Ward, C.R.; Permana, A.; Lennox, P.; Botha, P. High-resolution three-dimensional imaging of coal using microfocus X-ray computed tomography, with special reference to modes of mineral occurrence. Int. J. Coal Geol. 2013, 113, 97–108. [Google Scholar] [CrossRef]

- Jing, Y.J.; Armstrong, R.T.; Ramandi, H.L.; Mostaghimi, P. Coal cleat reconstruction using micro-computed tomography imaging. Fuel 2016, 181, 286–299. [Google Scholar] [CrossRef]

- Jing, Y.; Armstrong, R.T.; Mostaghimi, P. Digital coal: Generation of fractured cores with microscale features. Fuel 2017, 207, 93–101. [Google Scholar] [CrossRef]

- Liu, S.; Sang, S.; Wang, G.; Ma, J.S.; Wang, X.; Wang, W.F.; Du, Y.; Wang, T. FIB-SEM and X-ray CT characterization of interconnected pores in high-rank coal formed from regional metamorphism. J. Pet. Sci. Eng. 2017, 148, 21–31. [Google Scholar] [CrossRef]

- Zhou, S.D.; Liu, D.M.; Cai, Y.D.; Yao, Y.B.; Li, B. 3D characterization and quantitative evaluation of pore-fracture networks of two Chinese coals using FIB-SEM tomography. Int. J. Coal Geol. 2017, 174, 41–54. [Google Scholar] [CrossRef]

- Li, Z.T.; Liu, D.M.; Cai, Y.D.; Shi, Y.L. Investigation of methane diffusion in low-rank coals by a multiporous diffusion model. J. Nat. Gas Sci. Eng. 2016, 33, 97–107. [Google Scholar] [CrossRef]

- Li, Z.T.; Liu, D.M.; Cai, Y.D.; Ranjith, P.G.; Yao, Y.B. Multi-scale quantitative characterization of 3-D pore-fracture networks in bituminous and anthracite coals using FIB-SEM tomography and X-ray μ-CT. Fuel 2017, 209, 43–53. [Google Scholar] [CrossRef]

- Louw, E.B.; Mitchell, G.D.; Wang, J.; Winans, R.E.; Mathews, J.P. Constitution of drop-tube-generated coal chars from vitrinite-and inertinite-rich South African coals. Energy Fuels 2015, 30, 112–120. [Google Scholar] [CrossRef]

- Zhou, H.; Wilkes, G.L. Comparison of lamellar thickness and its distribution determined from d.s.c. SAXS, TEM and AFM for high-density polyethylene films having a stacked lamellar morphology. Polymer 1997, 38, 5735–5747. [Google Scholar] [CrossRef]

- Agbabiaka, A.; Wiltfong, M.; Park, C. Small angle X-ray scattering technique for the particle size distribution of nonporous nanoparticles. J. Nanoparticles 2013, 2013, 11. [Google Scholar] [CrossRef]

- Lee, S.; Fischer, T.B.; Stokes, M.R.; Klingler, R.J.; Ilavsky, J.; McCarty, D.K.; Wigand, M.; Derkowski, A.; Winans, R.E. Dehydration effect on the pore size, porosity, and fractal parameters of shale rocks: Ultrasmall-angle X-ray scattering study. Energy Fuels 2014, 28, 6772–6779. [Google Scholar] [CrossRef]

- Thomson, W. 4. On the equilibrium of vapour at a curved surface of liquid. Proc. R. Soc. Edinb. 1872, 7, 63–68. [Google Scholar] [CrossRef]

- Chen, P.; Tang, X.Y. The research on the adsorption of nitrogen in low temperature and micro-pore properties in coal. J. China Coal Soc. 2001, 26, 552–556. [Google Scholar]

- Yan, J.M.; Zhang, P.Y.; Gao, J.C. Adsorption and Cohesion; Science Press: Beijing, China, 1986; pp. 113–137. [Google Scholar]

- De Boer, J.H. The Structure and Properties of Porous Materials; Butterworths: London, UK, 1958; Volume 389, pp. 68–94. [Google Scholar]

- Li, Y.H.; Gao, Q.L.; Rudolph, V. Compressibility and fractal dimension of fine coal particles in relation to pore structure characterisation using mercury porosimetry. Part. Part. Syst. Charact. 1999, 16, 25–31. [Google Scholar] [CrossRef]

- Zhu, J.F.; Liu, J.Z.; Yang, Y.M.; Cheng, J.; Zhou, J.H.; Cen, K.F. Fractal characteristics of pore structures in 13 coal specimens: Relationship among fractal dimension, pore structure parameter, and slurry ability of coal. Fuel Process. Technol. 2016, 149, 256–267. [Google Scholar] [CrossRef]

- Ai, T.; Zhang, R.; Zhou, H.W.; Pei, J.L. Box-counting methods to directly estimate the fractal dimension of a rock surface. Appl. Surf. Sci. 2014, 314, 610–621. [Google Scholar] [CrossRef]

- Li, J.; Du, Q.; Sun, C. An improved box-counting method for image fractal dimension estimation. Pattern Recognit. 2009, 42, 2460–2469. [Google Scholar] [CrossRef]

- Sarkar, N.; Chaudhuri, B.B. An efficient differential box-counting approach to compute fractal dimension of image. IEEE Trans. Syst. Man Cybern. 1994, 24, 115–120. [Google Scholar] [CrossRef]

| Sample | Protodyakonov Coefficient | Initial Speed of Methane Diffusion (mL/s) | Porosity (%) | Adsorption Constant | Industrial Analysis | |||

|---|---|---|---|---|---|---|---|---|

| a (cm3/g) | b (Mpa−1) | Aad (%) | Mad (%) | Vdaf (%) | ||||

| HY | 0.93 | 22.27 | 11.19 | 22.66 | 1.34 | 33.28 | 0.54 | 18.35 |

| SY | 0.87 | 20.15 | 11.63 | 17.37 | 1.51 | 34.58 | 0.66 | 23.17 |

| XZ | 0.73 | 26.87 | 10.86 | 18.76 | 1.27 | 30.98 | 1.71 | 21.10 |

| DJH | 2.21 | 5.05 | 8.91 | 14.12 | 1.31 | 11.25 | 0.57 | 15.85 |

| Sample | Vitrinite Reflectance (%) | Macerals | Mineral Content (%) | ||

|---|---|---|---|---|---|

| Vitrinite Content (%) | Inertinite Content (%) | Chitinous Content (%) | |||

| HY | 1.57 | 69.2 | 30.0 | 0 | 0.8 |

| SY | 1.76 | 73.8 | 18.7 | 0 | 7.5 |

| XZ | 1.86 | 65.1 | 33.6 | 0.1 | 1.2 |

| DJH | 1.78 | 40.4 | 46.6 | 0 | 12.8 |

| Sample | Displacement Pressures (MPa) | Mean Radius of Throat (nm) | Mercury Saturation (%) | Mercury Ejection Ratio (%) | Proportions of Pore Volume (%) | |||

|---|---|---|---|---|---|---|---|---|

| Macropore | Mesopore | Small Pore | Micropore | |||||

| HY | 0.04 | 215.51 | 84.52 | 65.37 | 4.53 | 10.77 | 44.98 | 39.72 |

| SY | 0.06 | 176.73 | 70.48 | 48.76 | 6.16 | 26.48 | 45.44 | 21.92 |

| XZ | 0.05 | 213.30 | 79.99 | 59.22 | 7.89 | 13.03 | 43.59 | 35.49 |

| DJH | 0.03 | 341.29 | 92.97 | 97.73 | 1.85 | 41.74 | 22.55 | 33.86 |

| Sample | BET SSA (m2/g) | Langmuir SSA (m2/g) | BJH Pore Volume (m2/g) | Mean Pore Size (nm) |

|---|---|---|---|---|

| HY | 10.4317 | 13.2485 | 0.006214 | 8.2244 |

| SY | 10.4228 | 12.1175 | 0.006117 | 8.9146 |

| XZ | 14.3245 | 16.2412 | 0.007415 | 6.2112 |

| DJH | 8.2412 | 10.3258 | 0.004157 | 13.5496 |

| Sample | Pore Diameter Range (nm) | K | Db |

|---|---|---|---|

| HY | 74.16~100,000 | 1.0679 | 2.9321 |

| SY | 89.21~100,000 | 1.1083 | 2.8917 |

| XZ | 77.69~100,000 | 1.0826 | 2.9174 |

| DJH | 93.45~100,000 | 1.1298 | 2.7303 |

| Sample | p/p0 Range | Fractal Dimensions of Pore Surfaces Calculated by Equation (5) | Fractal Dimensions of Pore Surfaces Calculated by Equation (6) |

|---|---|---|---|

| HY | 0.15~0.96 | 2.34 | 2.23 |

| SY | 0.44~0.99 | 2.26 | 2.18 |

| XZ | 0.41~0.99 | 2.31 | 2.12 |

| DJH | 0.44~0.99 | 1.84 | 1.81 |

| Sample | Amplification | Fractal Dimension of Pore Distribution | Correlation Coefficient | Fractal Dimension of Pore SSA | Correlation Coefficient |

|---|---|---|---|---|---|

| HY | 4.00KX | 1.0743 | 0.9558 | 2.6783 | 0.9673 |

| SY | 4.00KX | 1.1696 | 0.9545 | 2.6421 | 0.9649 |

| XZ | 6.00KX | 1.1248 | 0.9512 | 2.2646 | 0.9704 |

| DJH | 6.00KX | 1.0054 | 0.9578 | 2.1642 | 0.9621 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, P.; Liang, Y.; Zhao, S.; Peng, S.; Li, X.; Meng, R. Characterization of Pores and Fractures in Soft Coal from the No. 5 Soft Coalbed in the Chenghe Mining Area. Processes 2019, 7, 13. https://doi.org/10.3390/pr7010013

Wei P, Liang Y, Zhao S, Peng S, Li X, Meng R. Characterization of Pores and Fractures in Soft Coal from the No. 5 Soft Coalbed in the Chenghe Mining Area. Processes. 2019; 7(1):13. https://doi.org/10.3390/pr7010013

Chicago/Turabian StyleWei, Pan, Yunpei Liang, Song Zhao, Shoujian Peng, Xuelong Li, and Ran Meng. 2019. "Characterization of Pores and Fractures in Soft Coal from the No. 5 Soft Coalbed in the Chenghe Mining Area" Processes 7, no. 1: 13. https://doi.org/10.3390/pr7010013

APA StyleWei, P., Liang, Y., Zhao, S., Peng, S., Li, X., & Meng, R. (2019). Characterization of Pores and Fractures in Soft Coal from the No. 5 Soft Coalbed in the Chenghe Mining Area. Processes, 7(1), 13. https://doi.org/10.3390/pr7010013