Facile Fabrication of Recyclable, Superhydrophobic, and Oleophilic Sorbent from Waste Cigarette Filters for the Sequestration of Oil Pollutants from an Aqueous Environment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of Adsorbent

2.3. Characterisations of Adsorbents

2.4. Batch Adsorption Tests

3. Results and Discussion

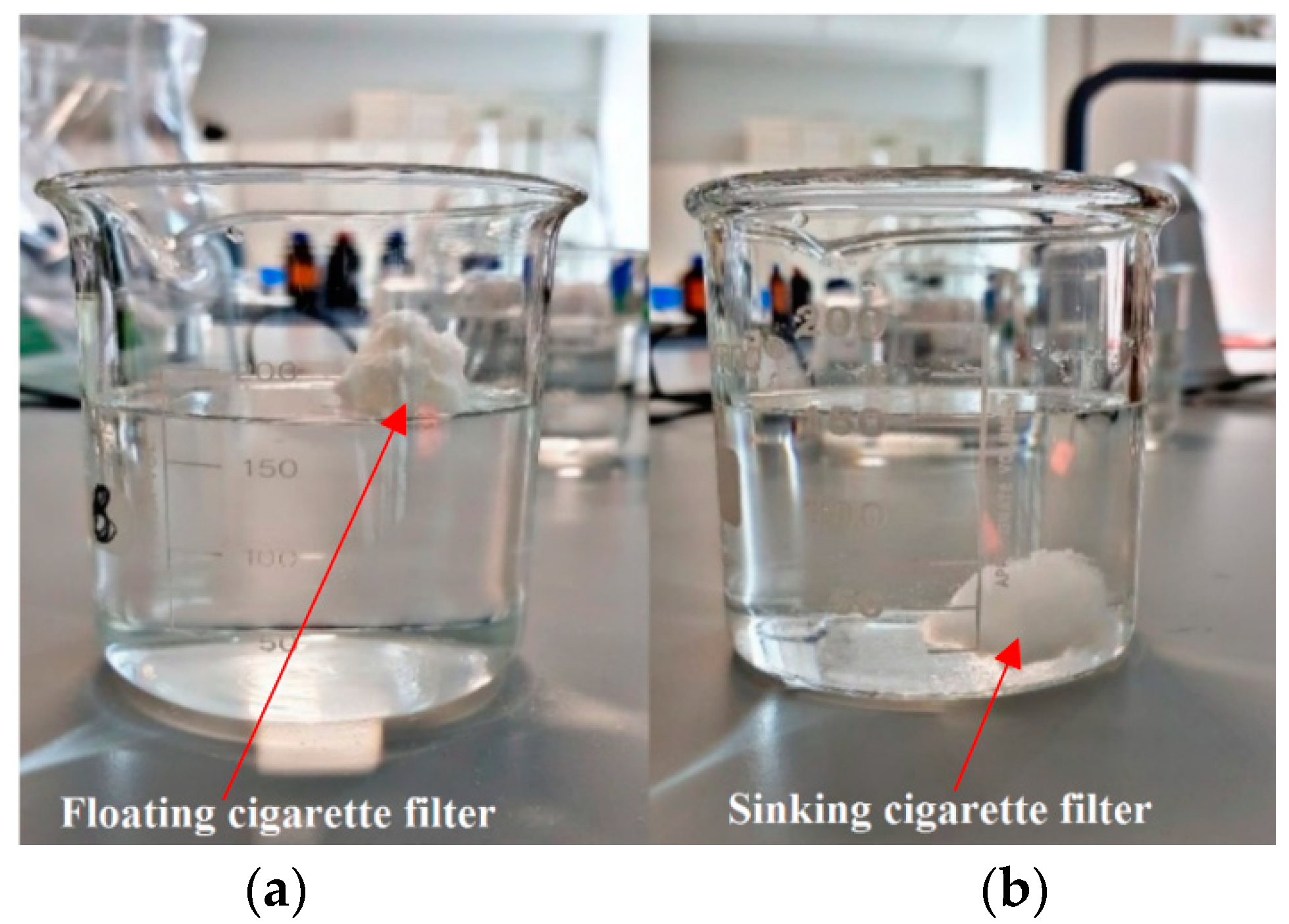

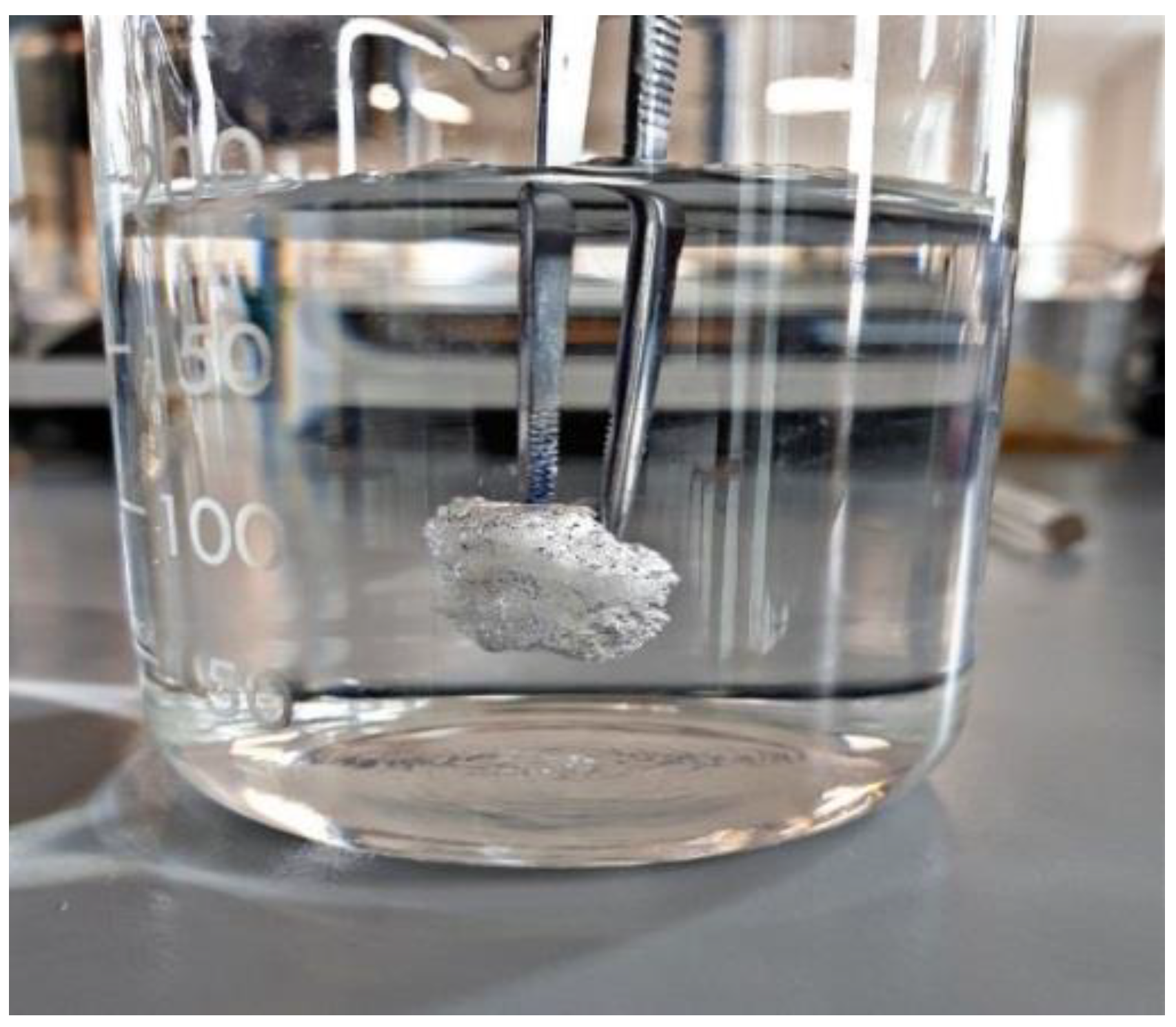

3.1. Surface Modification of the Adsorbents

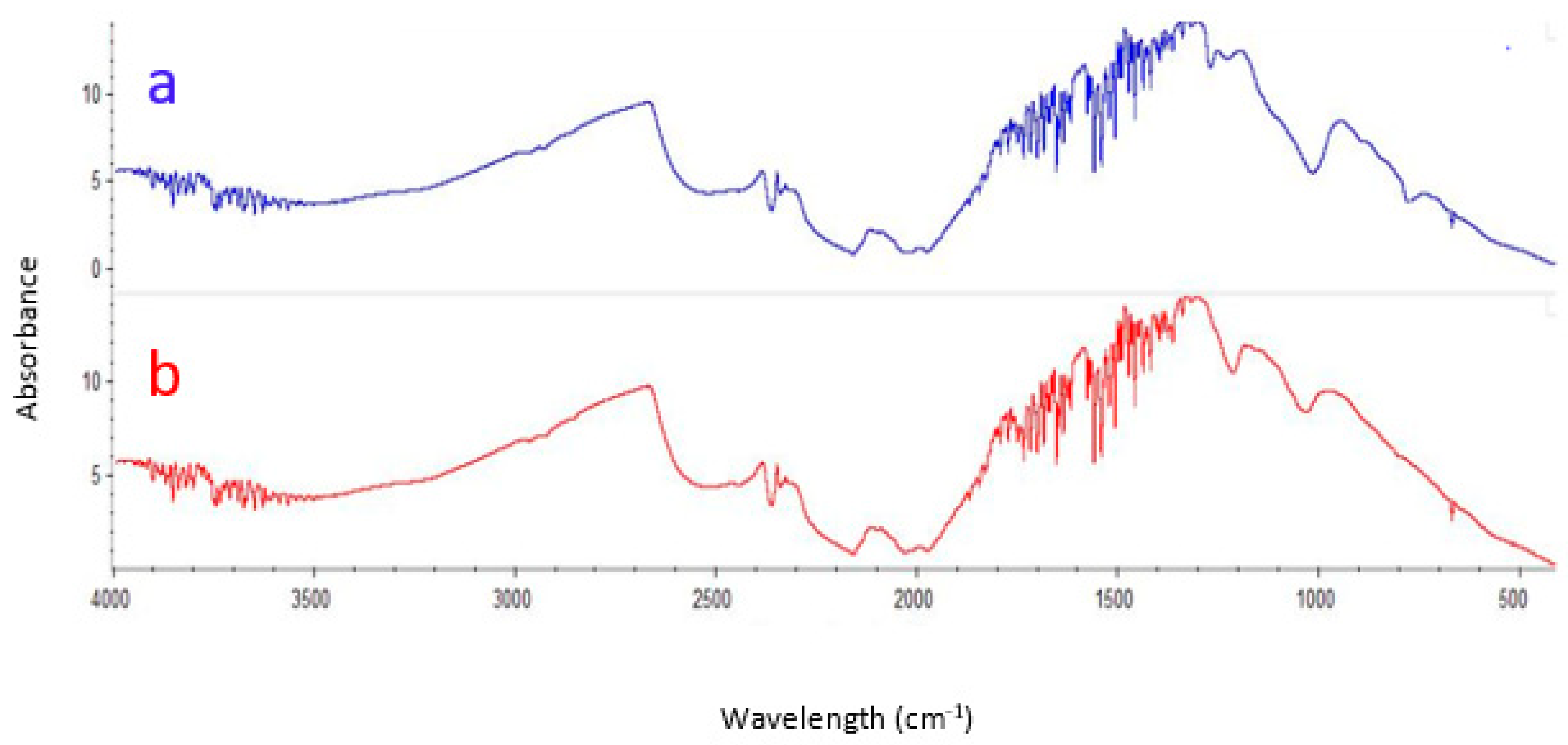

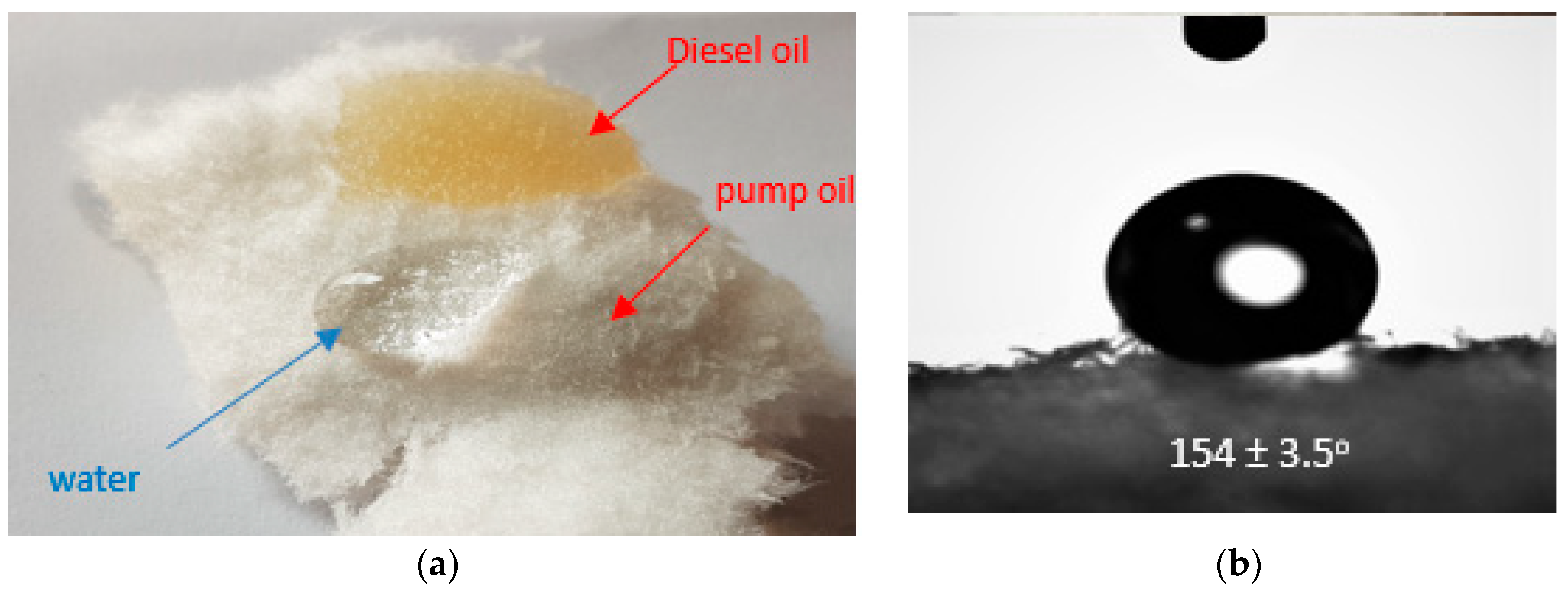

3.2. Surface Characterisation of Adsorbent Filters

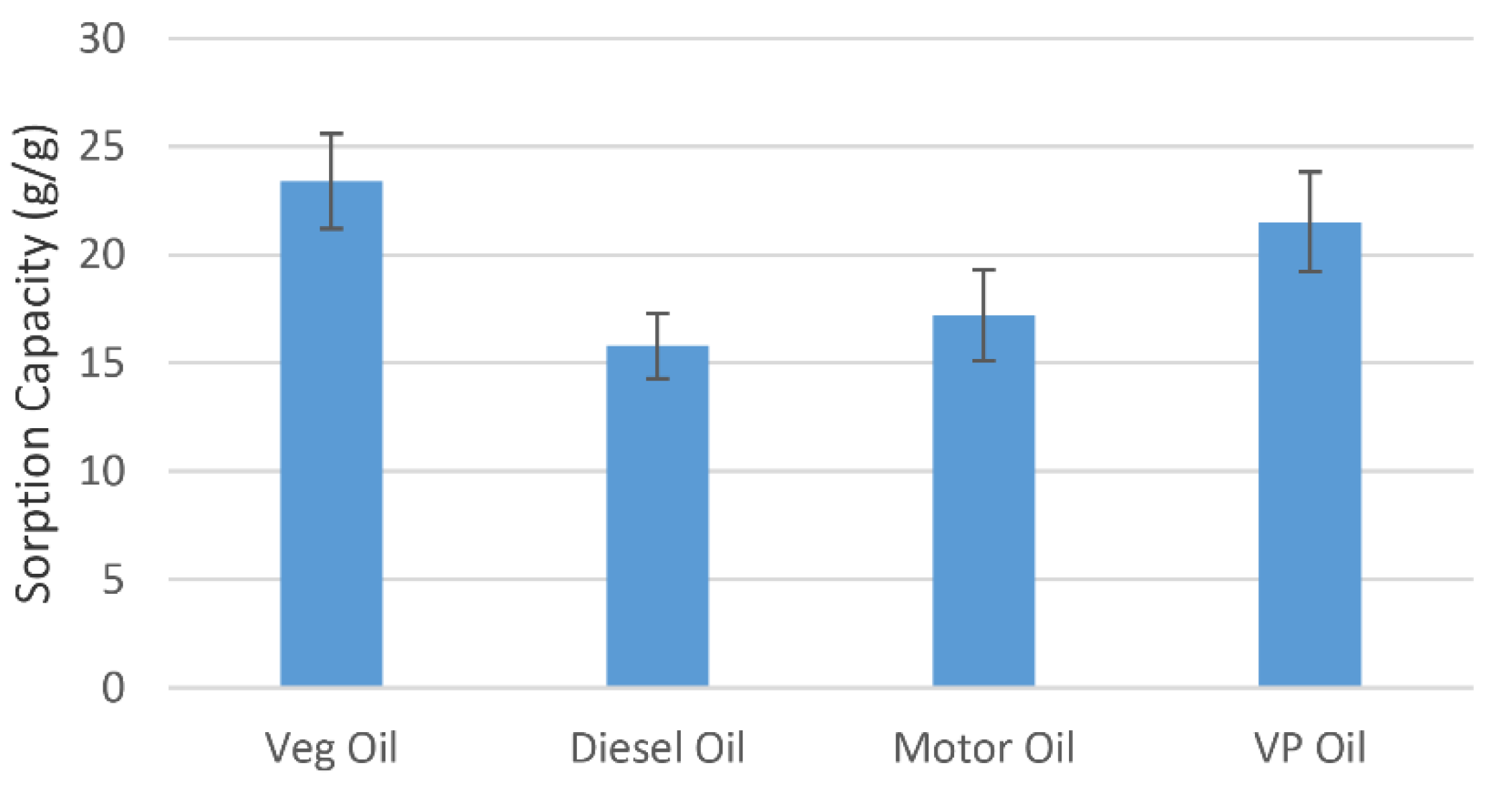

3.3. Oil Adsorption Capacities of Cigarette Filters

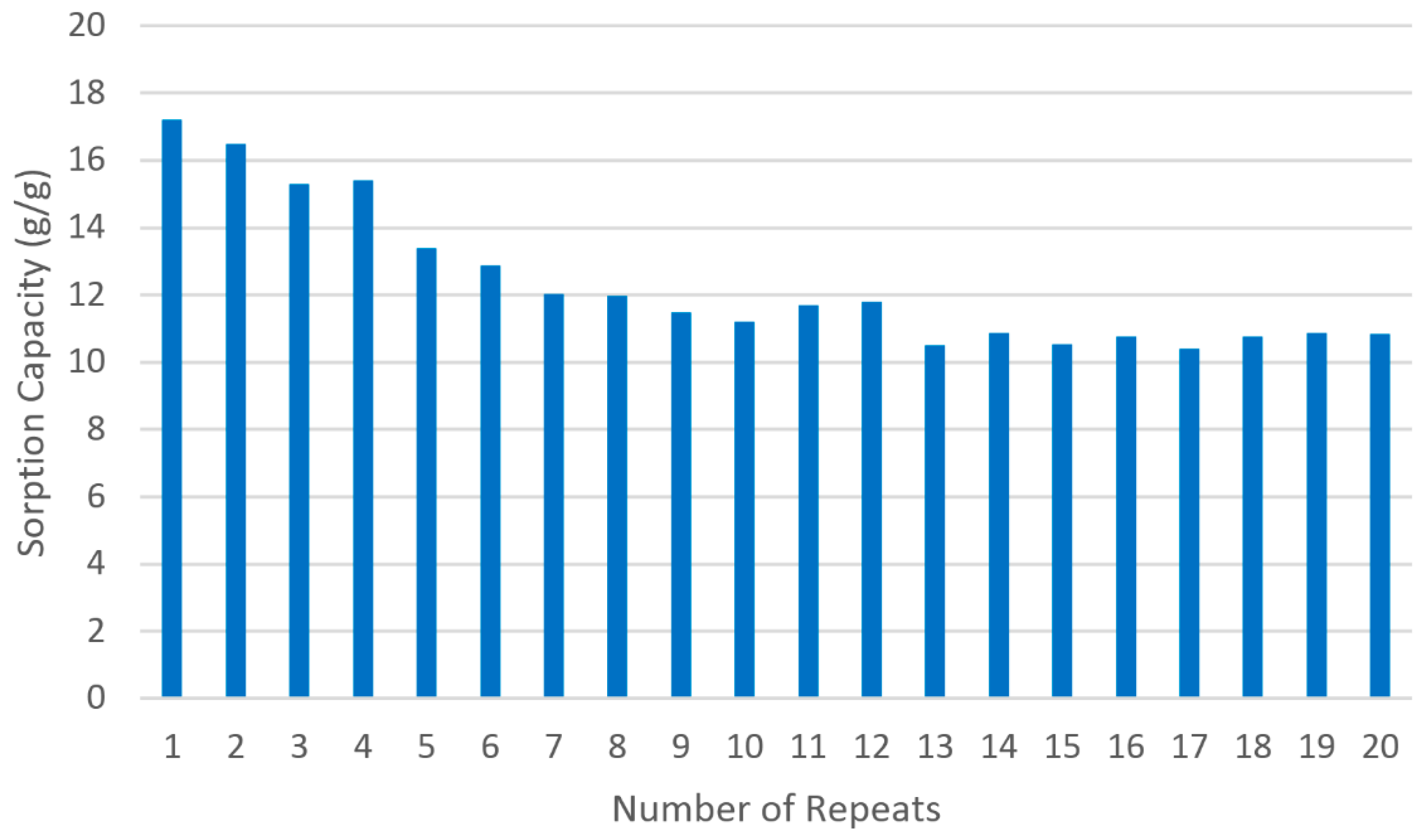

3.4. Recyclability of Cigarette Filters and Shredded Cigarette Filters

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ifelebuegu, A.O.; Ukpebor, J.E.; Ahukannah, A.U.; Nnadi, E.O.; Theophilus, S.C. Environmental effects of crude oil spill on the physicochemical and hydrobiological characteristics of the Nun River, Niger Delta. Environ. Monit. Assess. 2017, 189, 173. [Google Scholar] [CrossRef] [PubMed]

- Somasundaran, P.; Patra, P.; Farinato, R.S.; Papadopoulos, K. Oil Spill Remediation: Colloid Chemistry-Based Principles and Solutions; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Ifelebuegu, A.O.; Johnson, A. Non-conventional low-cost cellulose and keratin based biopolymeric sorbents for oil/water separation and spill clean-up: A Review. Crit. Rev. Environ. Sci. Technol. 2017, 47, 964–1001. [Google Scholar] [CrossRef]

- Feng, J.; Nguyen, S.T.; Fan, Z.; Duong, H.M. Advanced Fabrication and Oil Absorption Properties of Super-Hydrophobic Recycled Celluose Aerogels. Biochem. Eng. J. 2015, 270, 168–175. [Google Scholar]

- Speight, J.G.; Arjoon, K.K. Bioremediation of Petroleum and Petroleum Products; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Zhao, J.; Xiao, C.; Feng, Y.; Xu, N. A Review: Polymethacrylate Fibres as Oil Absorbents. Polym. Rev. 2013, 53, 527–545. [Google Scholar] [CrossRef]

- Wan, C.; Lu, Y.; Jiao, Y.; Jin, C.; Sun, Q.; Li, J. Fabrication of Hydrophobic Electrically Conductive and Flame-Resistant Carbon Aerogels by Pyrolysis of Regenerated Cellulose Aerogels. Carbohydr. Polym. 2015, 118, 115–118. [Google Scholar] [CrossRef] [PubMed]

- Ifelebuegu, A.O.; Tuan Vu Anh Nguyen, P.U.I.; Zenebu, M. Liquid-phase sorption characteristics of human hair as a natural oil spill sorbent. J. Environ. Chem. Eng. 2015, 3, 938–943. [Google Scholar] [CrossRef]

- Sabir, S. Approach of Cost Effective Absorbents for Oil Removal from Oily Water. Crit. Rev. Environ. Sci. Technol. 2015, 45, 1916–1945. [Google Scholar] [CrossRef]

- Sarbatly, R.; Krishnaiah, D.; Kamin, Z. A Review of polymer nano-fibres by electrospinning and their application in oil-water separation for cleaning up marine oil spills. Mar. Pollut. Bull. 2016, 106, 8–16. [Google Scholar] [CrossRef] [PubMed]

- Kushwaha, S.; Soni, H.; Ageetha, V.; Padmaja, P. An insight into the production, characterization, and mechanisms of action of low-cost adsorbents for removal of organics from aqueous solution. Crit. Rev. Environ. Sci. Technol. 2013, 43, 443–549. [Google Scholar] [CrossRef]

- Novotny, T.E.; Lum, K.; Smith, E.; Wang, V.; Barnes, R. Cigarette Butts and the Case for an Environmental Policy on Hazardous Cigarette Waste. Int. J. Environ. Res. Public Health 2009, 6, 1691–1705. [Google Scholar] [CrossRef] [PubMed]

- Gould, H. Why Cigarette Butts Threaten to Stub Out Marine Life. Available online: https://www.theguardian.com/sustainable-business/2015/jun/09/why-cigarette-butts-threaten-to-stub-out-marine-life (accessed on 16 June 2017).

- Lee, J. Get Your Butt Off the Ground: Consequences of Cigarette Waste and Litter—Reducing Methods. Available online: http://scholarship.claremont.edu/cgi/viewcontent.cgi?article=1043&context=pomona_theses (accessed on 16 June 2018).

- Slaughter, E.; Gersberg, R.M.; Watanabe, K.; Rudolph, J.; Stransky, C.; Novotny, T.E. Toxicity of Cigarette Butts and their Chemical Components to Marine and Freshwater Fish. Tob. Control 2011, 20, 25–29. [Google Scholar] [CrossRef] [PubMed]

- Kabasci, S. Bio-Based Plastics—Materials and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2014. [Google Scholar]

- Zhao, J.; Zhang, N.S.; Qu, C.T.; Wu, X.M.; Zhang, J.T.; Zhang, X. Cigarette butts and their application in corrosion inhibition for N80 steel at 90 °C in a hydrochloric acid solution. Ind. Eng. Chem. Res. 2010, 49, 3986–3991. [Google Scholar] [CrossRef]

- Liu, C.; Chen, B.; Yang, J.; Li, C. One-step fabrication of superhydrophobic and superoleophilic cigarette filters for oil-water separation. J. Adhes. Sci. Technol. 2015, 29, 2399–2407. [Google Scholar] [CrossRef]

- He, F.; Sui, C.; He, X.; Li, M. Facile Synthesis of Strong Alumina-Cellulose Aerogels by Freeze-Drying Method. Mater. Lett. 2015, 152, 9–12. [Google Scholar] [CrossRef]

- Lim, M.B.; Hu, M.; Manandhar, S.; Sakshaug, A.; Strong, A.; Riley, L.; Pauzauskie, P.J. Ultrafast Sol-Gel Synthesis of Graphene Aerogel Materials. Carbon 2015, 95, 616–624. [Google Scholar] [CrossRef]

- Cao, N.; Lyu, Q.; Li, J.; Wang, Y.; Yang, B.; Szunerits, S.; Boukherroub, R. Facile Synthesis of Flourinated Polydopamine/Chitosan/Reduced Graphene-Oxide Composite Aerogel for Efficient Oil/Water Separation. Chem. Eng. J. 2017, 326, 17–28. [Google Scholar] [CrossRef]

- Ren, R.P.; Li, W.; Lv, Y.K. A Robust, Super Hydrophobic Graphene Aerogel as a Recyclable Sorbent for Oils and Organic Solvents at Various Temperatures. J. Colloid Interface Sci. 2017, 500, 63–68. [Google Scholar] [CrossRef] [PubMed]

- Han, S.; Sun, Q.; Zheng, H.; Li, J.; Jin, C. Green and Facile Fabrication of Carbon Aerogels from Cellulose-Based Waste Newspaper for Solving Organic Pollution. Carbohydr. Polym. 2016, 136, 95–100. [Google Scholar] [CrossRef] [PubMed]

- Jin, C.; Han, S.; Li, J.; Sun, Q. Fabrication of Cellulose-Based Aerogels from Waste Newspaper without any Pre-treatment and their use for Absorbents. Carbohydr. Polym. 2015, 123, 150–156. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, S.T.; Feng, J.; Ng, S.K.; Wong, J.P.W.; Tan, V.B.C.; Duong, H.M. Advanced Thermal Insulation and Absorption Properties of Recycled Cellulose Aerogels. Colloids Surf. A 2014, 445, 128–134. [Google Scholar] [CrossRef]

- Schmitt, M. Analysis of silanes and of siloxanes formation by Raman spectroscopy. RSC Adv. 2014, 4, 1907–1917. [Google Scholar] [CrossRef]

- Munief, W.M.; Heib, F.; Hempel, F.; Lu, X.; Schwartz, M.; Pachauri, V.; Hempelmann, R.; Schmitt, M.; Ingebrandt, S. Silane deposition via gas-phase evaporation and high-resolution surface characterization of the ultra-thin siloxane coatings. Langmuir 2018. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Liu, H.; Chen, S.; Ding, S. Hierarchical Porous MWCNTs-Silica Aerogel Synthesis for High-Efficiency Oily Water Treatment. J. Environ. Chem. Eng. 2016, 4, 3274–3282. [Google Scholar] [CrossRef]

- Wei, Q.F.; Mather, R.R.; Fotheringham, A.F.; Yang, R.D. Evaluation of nonwoven polypropylene oil sorbents in marine oil-spill recovery. Mar. Pollut. Bull. 2003, 46, 780–783. [Google Scholar] [CrossRef]

- Wang, J.; Geng, G.; Wang, A.; Liu, X.; Du, J.; Zou, Z.; Zhang, S.; Han, F. Double biomimetic fabrication of robustly superhydrophobic cotton fiber and its application in oil spill cleanup. Ind. Crops Prod. 2015, 77, 36–43. [Google Scholar] [CrossRef]

- Ifelebuegu, A.O.; Momoh, Z. An Evaluation of the Adsorptive Properties of Coconut Husk for Oil Spill Cleanup International. J. Chem. Eng. 2015, 2, 115–119. [Google Scholar]

- Liao, Q.; Su, X.; Zhu, W.; Hua, W.; Qian, Z.; Liu, L.; Yao, J. Flexible and durable cellulose aerogels for highly effective oil/water separation. RSC Adv. 2016, 6, 63773–63781. [Google Scholar] [CrossRef]

- Angelova, D.; Uzunov, I.; Uzunova, S.; Gigova, A.; Minchev, L. Kinetics of oil and oil products adsorption by carbonized rice husks. Chem. Eng. J. 2011, 172, 306–311. [Google Scholar] [CrossRef]

- Xiao, N.; Zhou, Y.; Ling, Z.; Qiu, J. Synthesis of a carbon nanofiber/carbon foam composite from coal liquefaction residue for the separation of oil and water. Carbon 2013, 59, 530–536. [Google Scholar] [CrossRef]

- Ou, J.; Wan, B.; Wang, F.; Xue, M.; Wu, H.; Li, W. Superhydrophobic fibers from cigarette filters for oil spill cleanup. RSC Adv. 2016, 50, 44469–44474. [Google Scholar] [CrossRef]

- Zhu, L.; Wang, Y.; Wang, Y.; You, L.; Shen, X.; Li, S. An Environmentally Friendly Carbon Aerogel Derived from Waste Pomelo Peel for the Removal of Organic Pollutants/Oils. Microporous Mesoporous Mater. 2017, 241, 285–292. [Google Scholar] [CrossRef]

| Adsorbent Material | Oil Type | Adsorption Capacity (g/g) | References |

|---|---|---|---|

| Polypropylene | Crude oil | 9.1–10 | [29] |

| Superhydrophobic cotton | Crude oil | 52.6 | [30] |

| Graphene aerogels | Motor oil | 26 | [22] |

| Recycled cellulose aerogels | Motor oil | 18–20 | [25] |

| Coconut coir fibre | Diesel oil | 6.53 | [31] |

| Recycled cellulose aerogels | Motor oil | 40–95 | [4] |

| Cellulose Aerogel | Pump oil | 59.32 | [32] |

| Carbonised rice husk | Diesel oil | 5.5 | [33] |

| Carbon foam | Motor oil | 25 | [34] |

| Cigarette filters | Veg oil | 25.6 | This study |

| Diesel oil | 15.8 | ||

| Motor oil | 17.2 | ||

| VP oil | 21.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ifelebuegu, A.O.; Lale, E.E.; Mbanaso, F.U.; Theophilus, S.C. Facile Fabrication of Recyclable, Superhydrophobic, and Oleophilic Sorbent from Waste Cigarette Filters for the Sequestration of Oil Pollutants from an Aqueous Environment. Processes 2018, 6, 140. https://doi.org/10.3390/pr6090140

Ifelebuegu AO, Lale EE, Mbanaso FU, Theophilus SC. Facile Fabrication of Recyclable, Superhydrophobic, and Oleophilic Sorbent from Waste Cigarette Filters for the Sequestration of Oil Pollutants from an Aqueous Environment. Processes. 2018; 6(9):140. https://doi.org/10.3390/pr6090140

Chicago/Turabian StyleIfelebuegu, Augustine O., Egetadobobari E. Lale, Fredrick U. Mbanaso, and Stephen C. Theophilus. 2018. "Facile Fabrication of Recyclable, Superhydrophobic, and Oleophilic Sorbent from Waste Cigarette Filters for the Sequestration of Oil Pollutants from an Aqueous Environment" Processes 6, no. 9: 140. https://doi.org/10.3390/pr6090140

APA StyleIfelebuegu, A. O., Lale, E. E., Mbanaso, F. U., & Theophilus, S. C. (2018). Facile Fabrication of Recyclable, Superhydrophobic, and Oleophilic Sorbent from Waste Cigarette Filters for the Sequestration of Oil Pollutants from an Aqueous Environment. Processes, 6(9), 140. https://doi.org/10.3390/pr6090140