Experimental Study on the Creep Characteristics of Coal Measures Sandstone under Seepage Action

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Characterization

2.2. Testing System

- The axial pressure loading system uses the Electro-hydraulic servo rock mechanics test system of MTS816 to provide a stable and continuous axial load for the specimen during the test, as shown in Figure 2a.

- The confining pressure loading system applies a certain pressure to the specimen by using the pump to press the hydraulic oil into the cylinder.

- The seepage pressure loading system provides a continuous and stable seepage pressure for the specimen based on the injector concept, and this is an important part to achieve the seepage-creep coupling effect, as shown in Figure 2b.

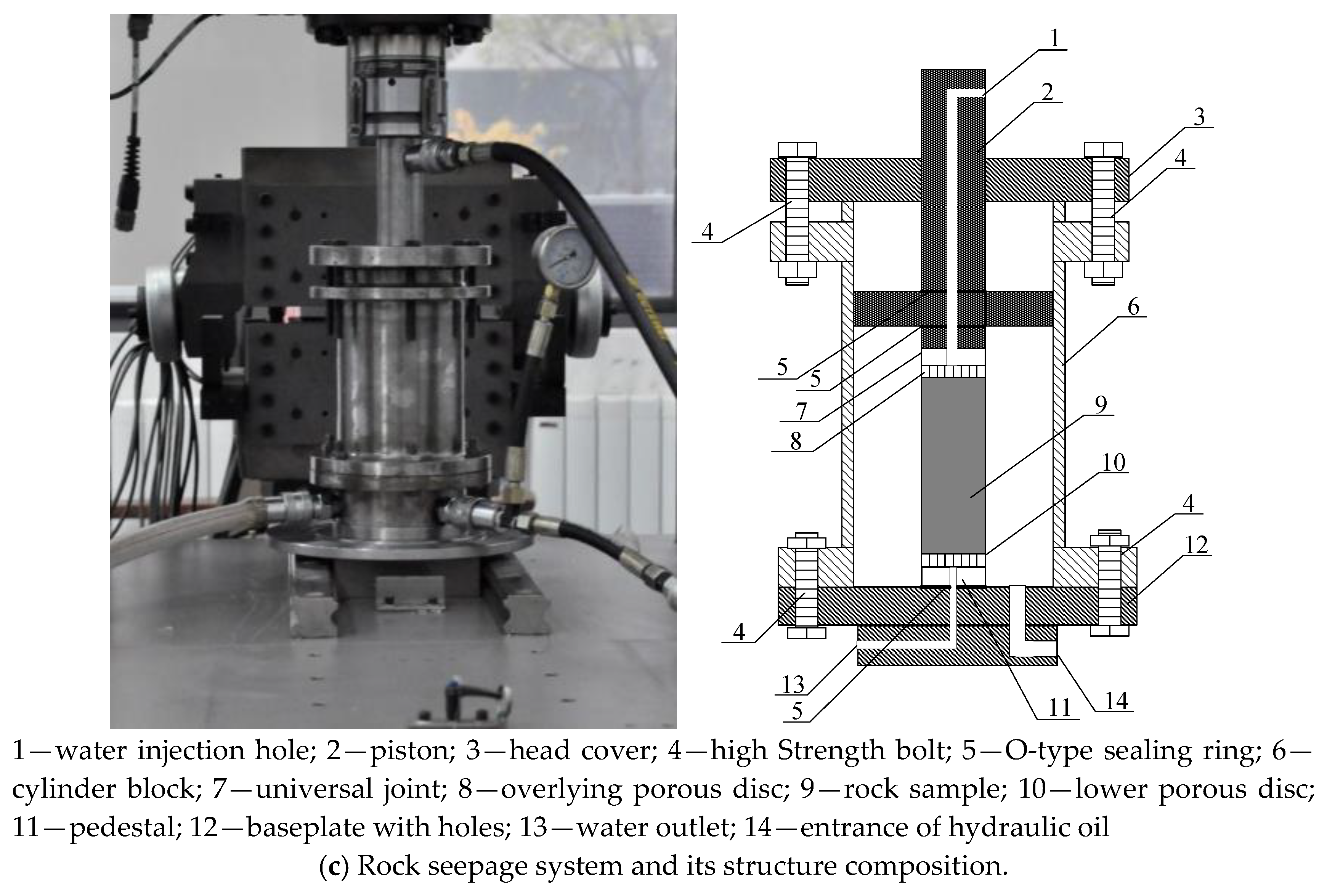

- The rock seepage system is the core part of the rock seepage-creep coupling test system. It is the central system of the axial loading system, confining pressure loading system and seepage pressure loading system. Figure 2c shows the structural compositions of the rock seepage system. As can be seen from the picture, the entire testing system is roughly composed of 14 parts.

- The data collecting and processing system includes a paperless recorder, a pressure transmitter, a flow sensor, and a computer terminal.

2.3. Test Scheme

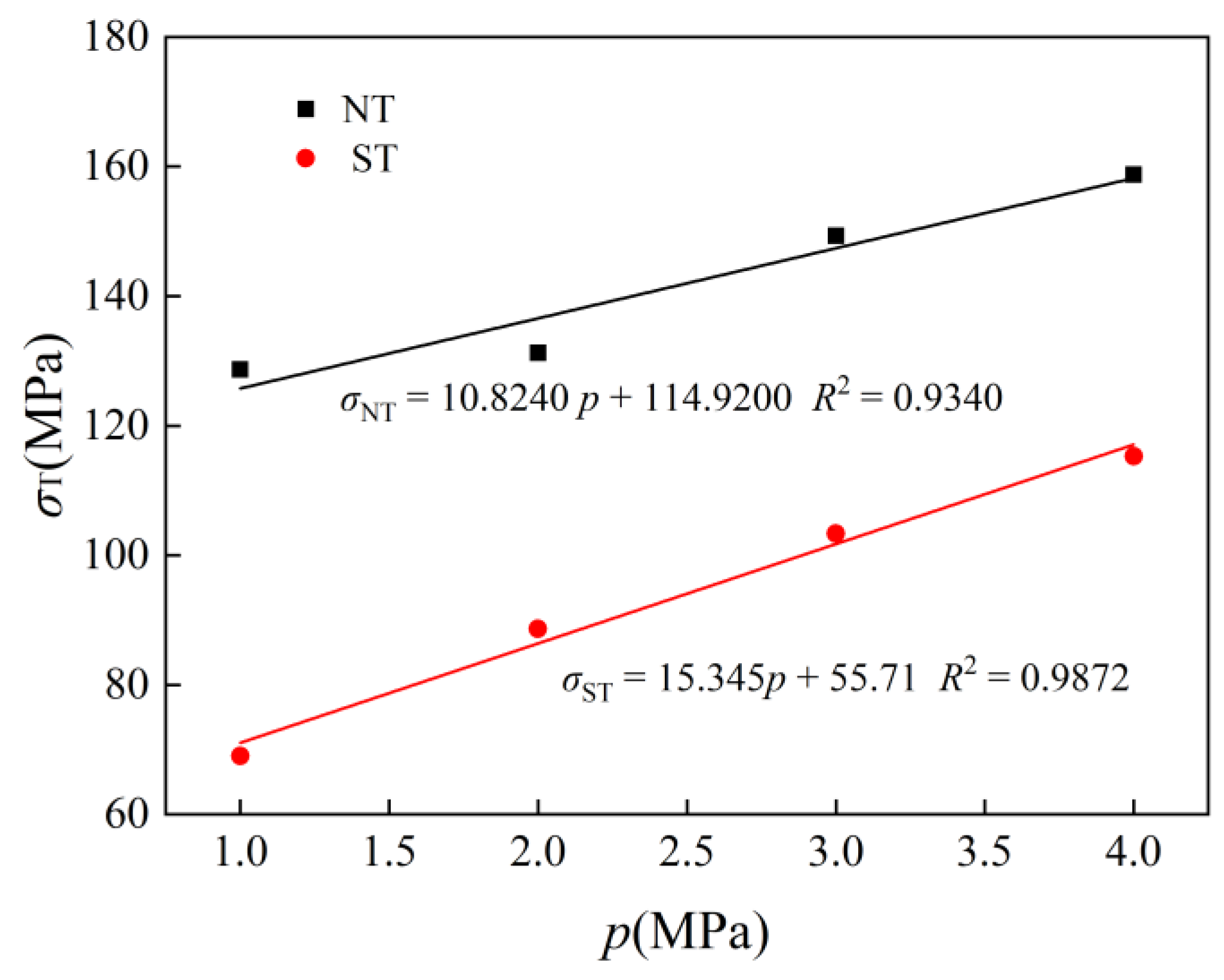

- Triaxial compression tests of sandstone. Triaxial tests of sandstone will be carried out under the natural state and the saturation state and the confining pressures are 1 MPa, 2 MPa, 3 MPa, and 4 MPa. Then the compressive strengths of sandstone under four confining pressures in two states are determined. According to the triaxial compressive strength, the load classification scheme of sandstone creep experiment can be obtained.

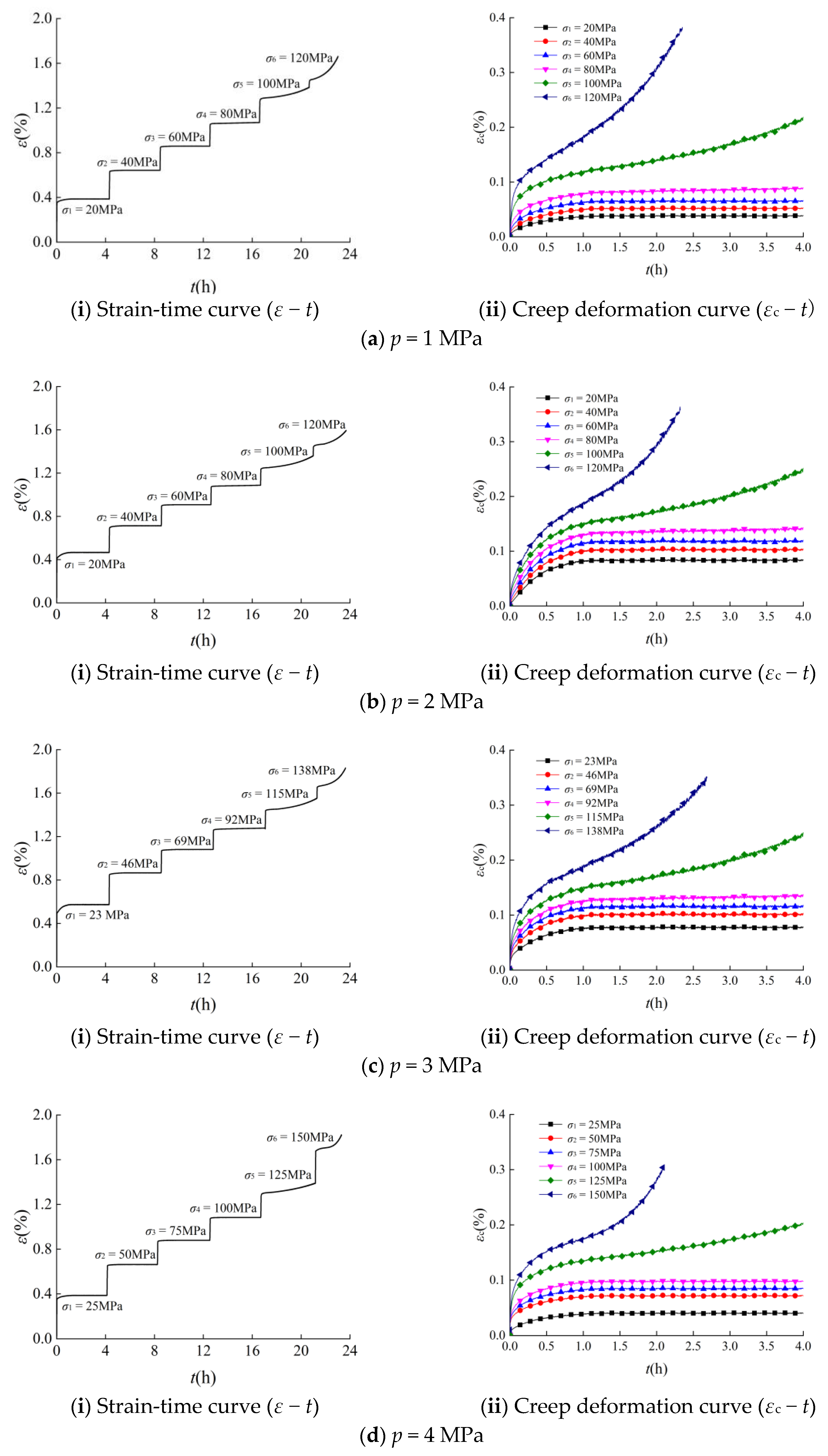

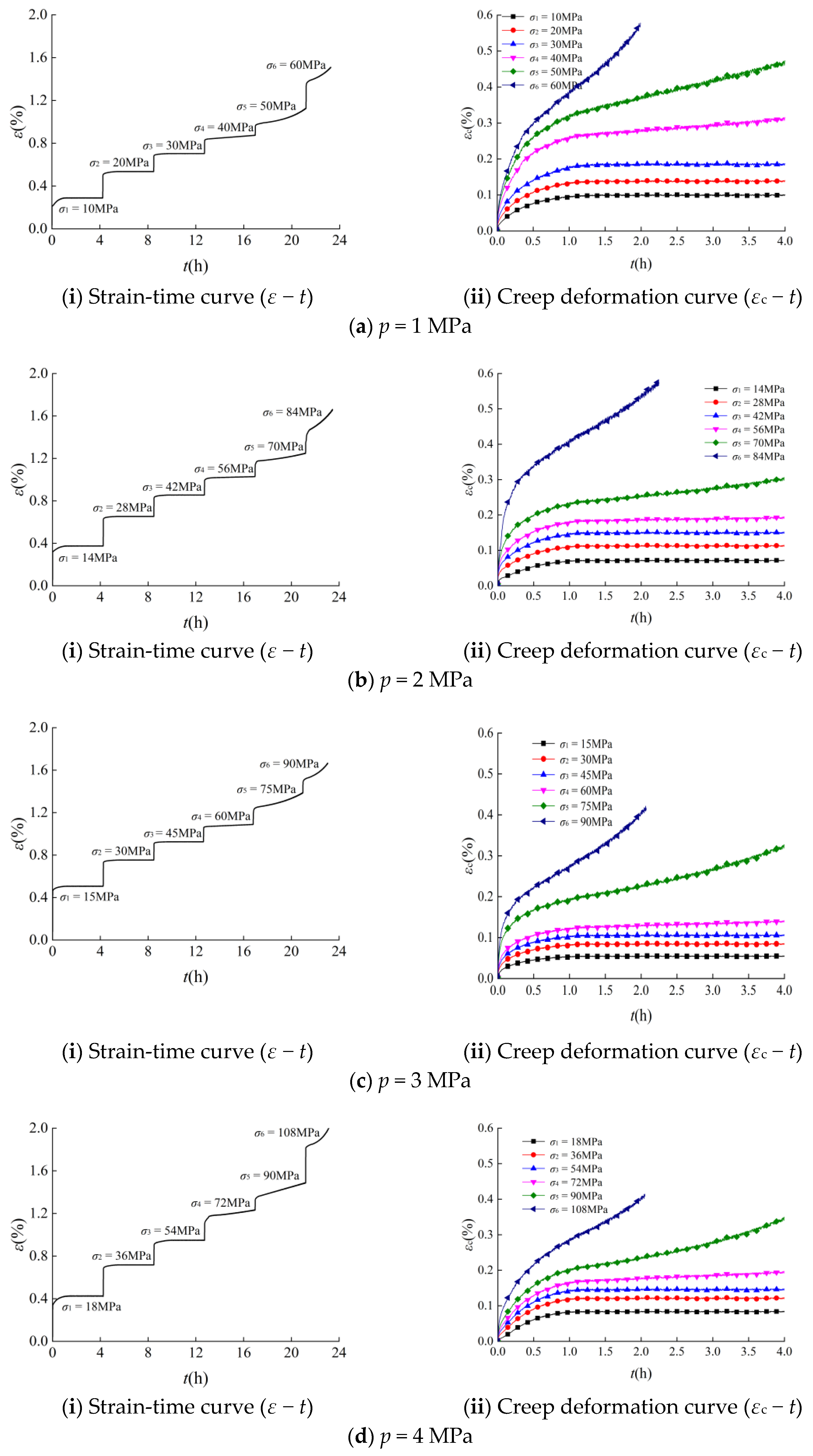

- Triaxial creep tests of sandstone. According to the different loading levels, the creep tests with confining pressures of 1 MPa, 2 MPa, 3 MPa, and 4 MPa are carried out under natural and saturation conditions respectively, and the creep characteristics of sandstone under two conditions are obtained finally.

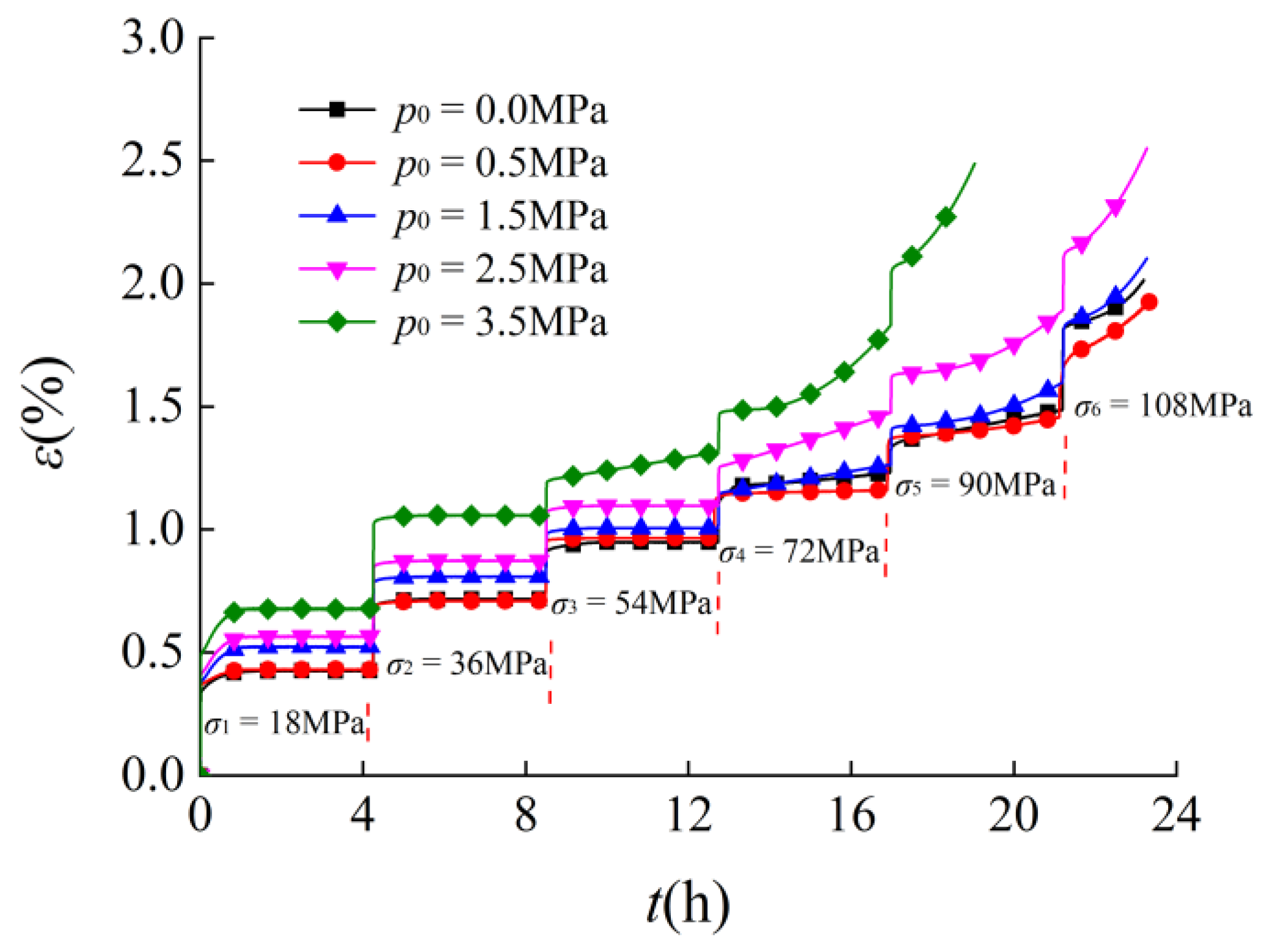

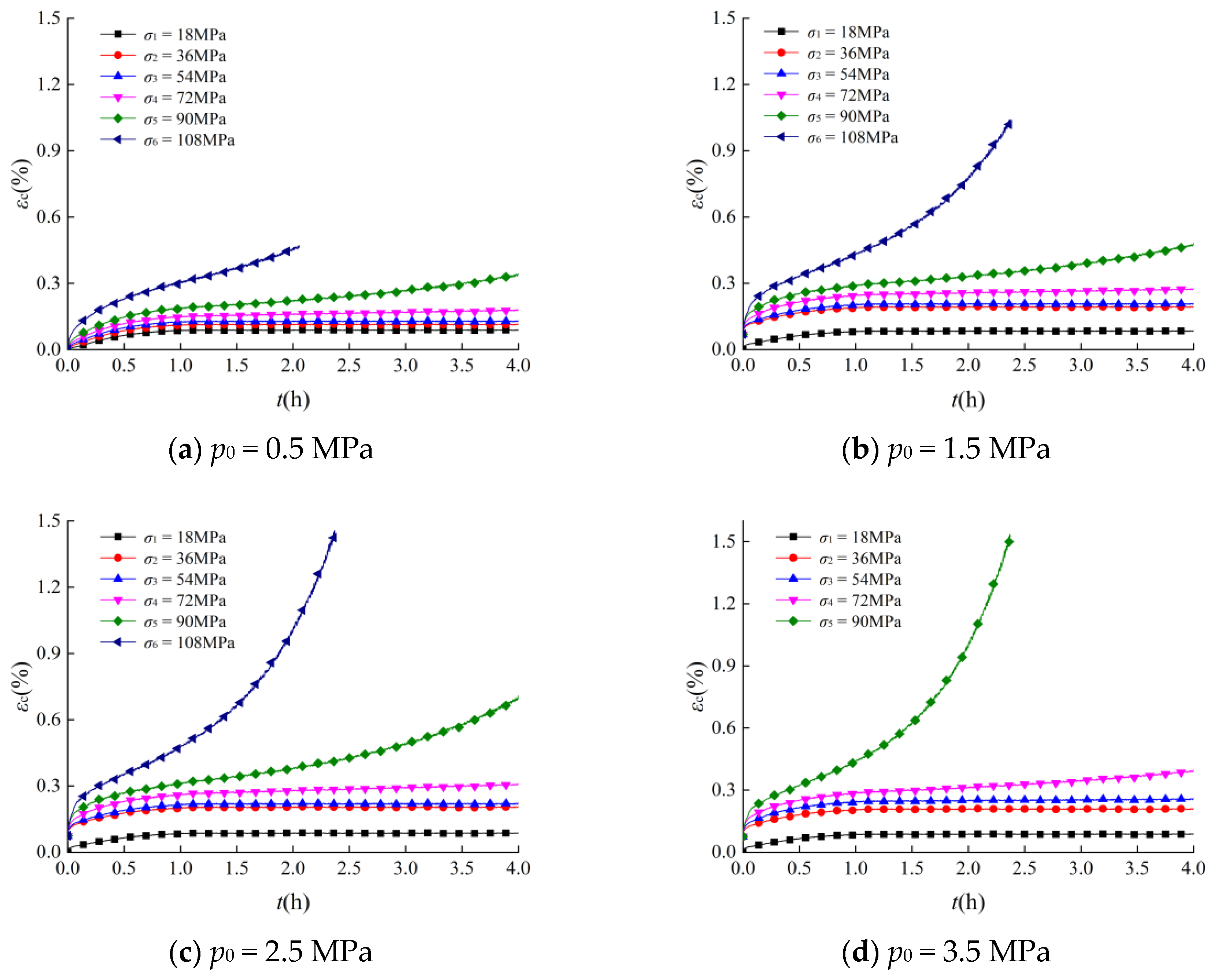

- Seepage-creep coupling tests of sandstone. Water saturated rock specimens are used as the targets to perform the rock creep tests under different seepage pressures. The confining pressure is 4 MPa, and the seepage pressure p0 is 0.5 MPa, 1.5 MPa, 2.5 MPa, and 3.5 MPa. The effect of seepage pressure on the creep deformation and permeability of sandstone can be obtained.

2.4. Load Grading

2.5. The Method of Microscopic Damage Test

3. Results and Discussion

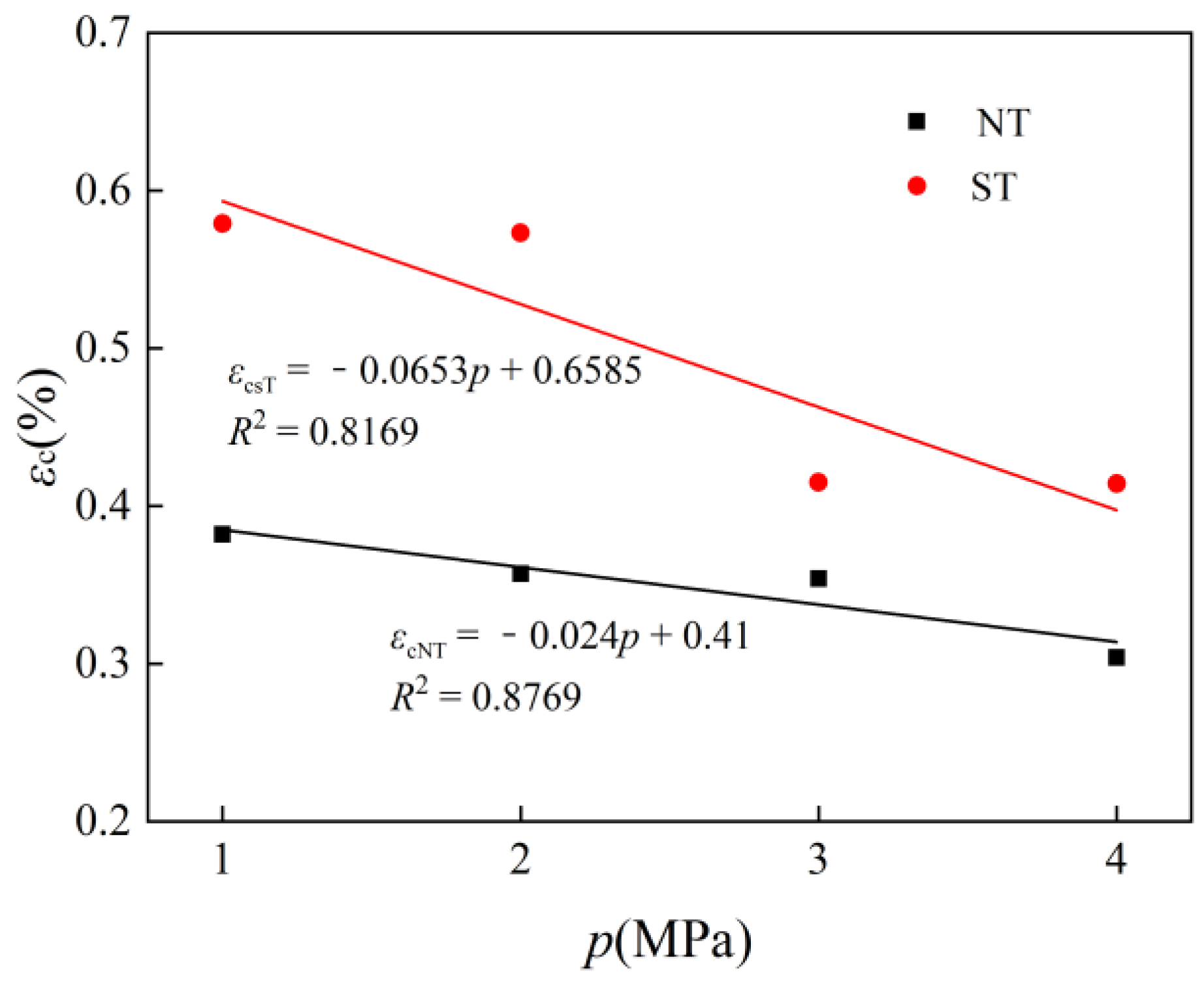

3.1. Creep Properties of Sandstone under Natural State and Saturation State

3.1.1. Creep Deformation Law of Sandstone under Two States

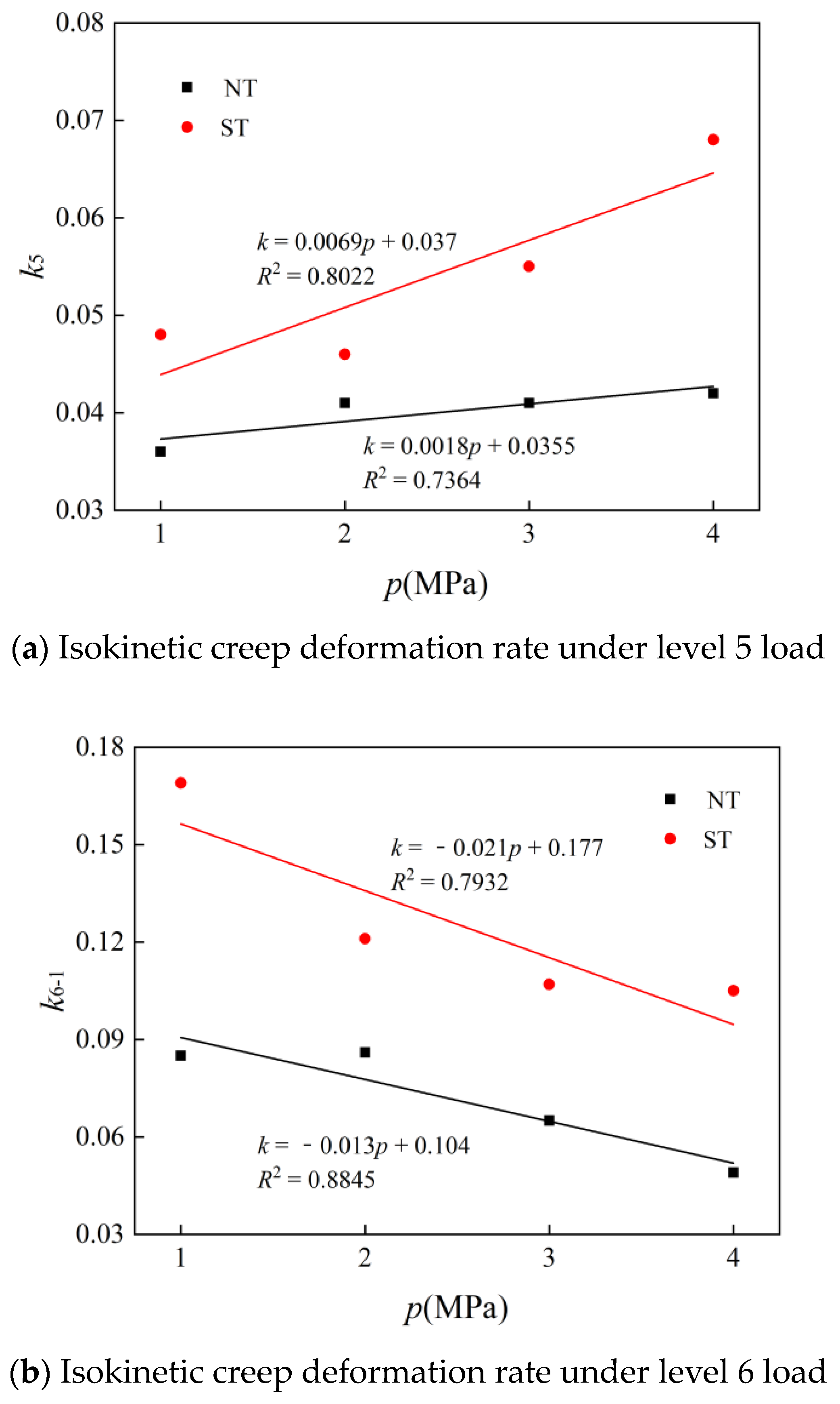

3.1.2. Creep Deformation Rate of Sandstone under Two States

3.2. Influence of Seepage Pressure on Seepage-Creep Properties of Sandstone

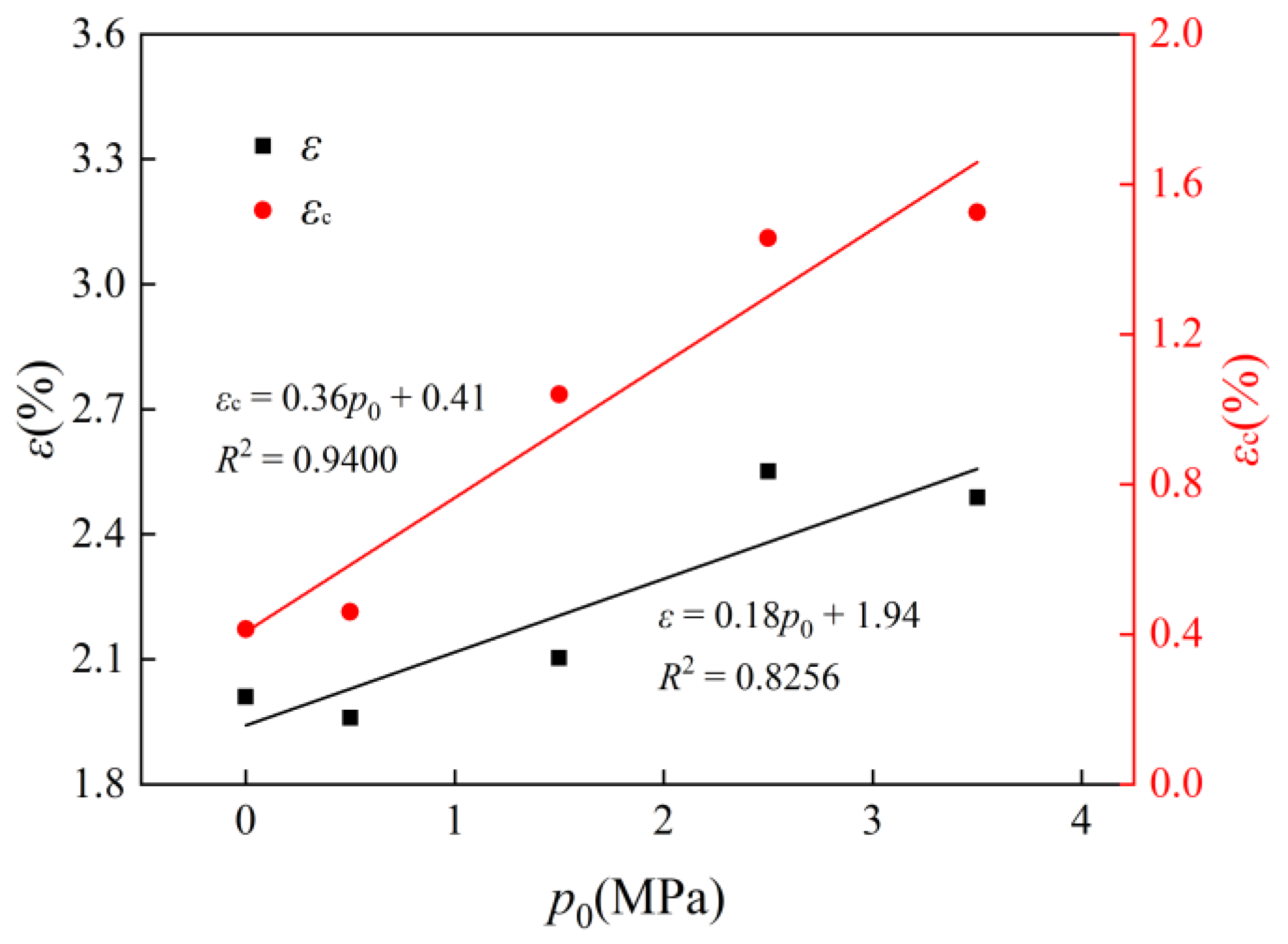

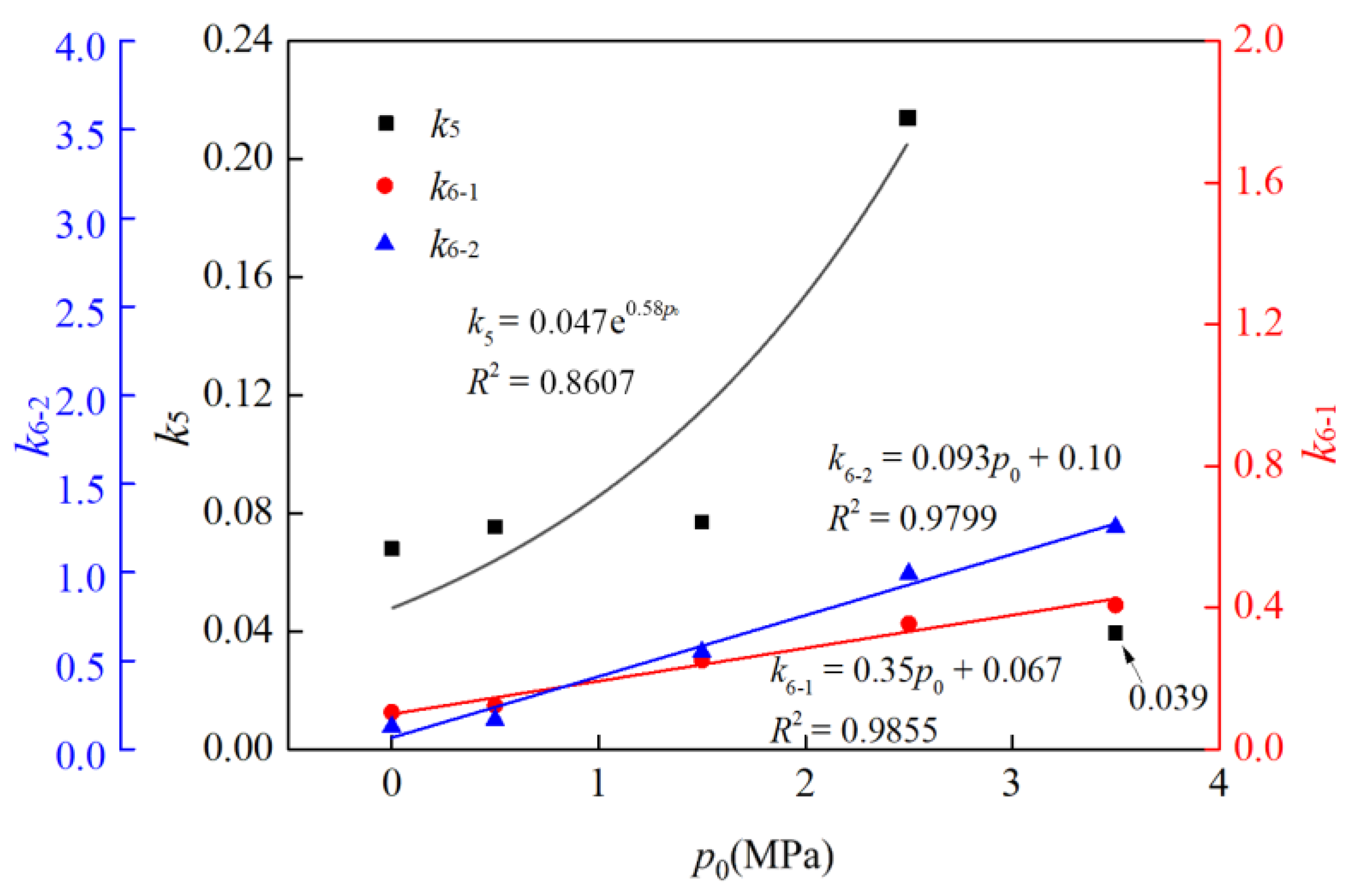

3.2.1. Variation of Creep Deformation of Sandstone with Seepage Pressure

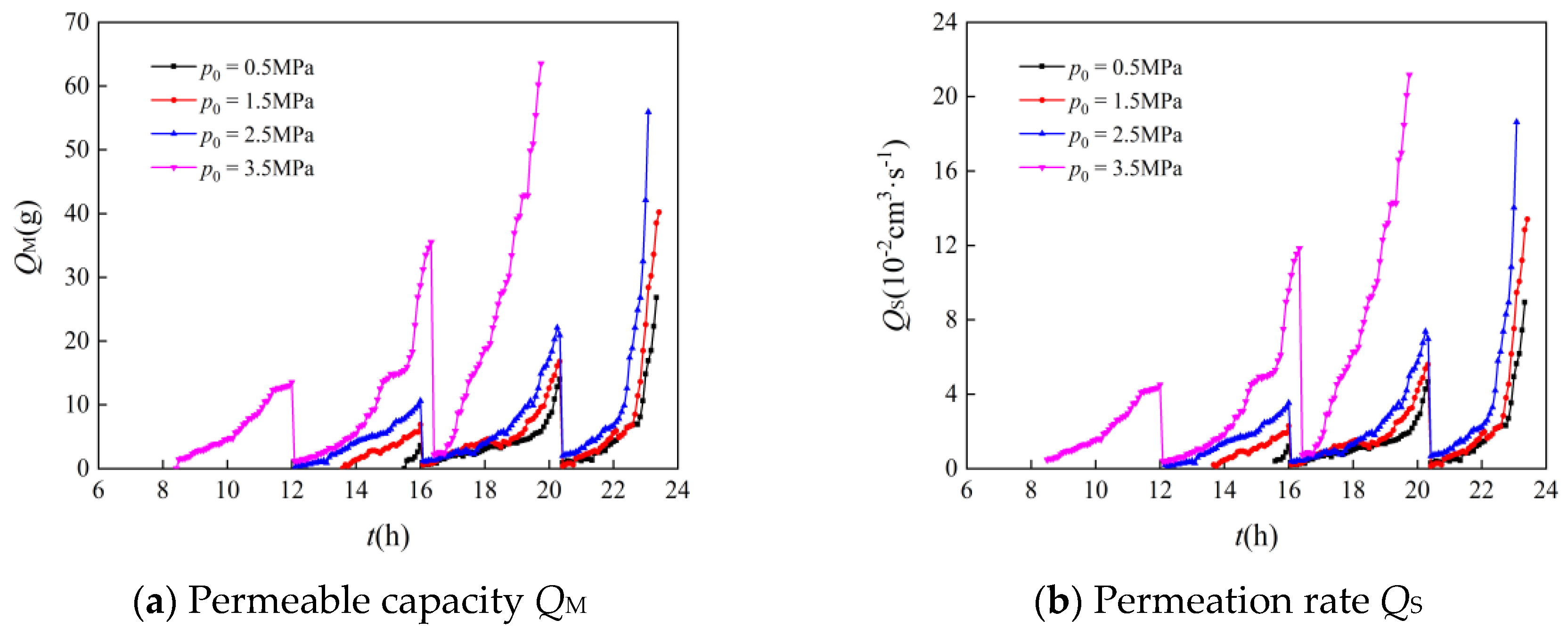

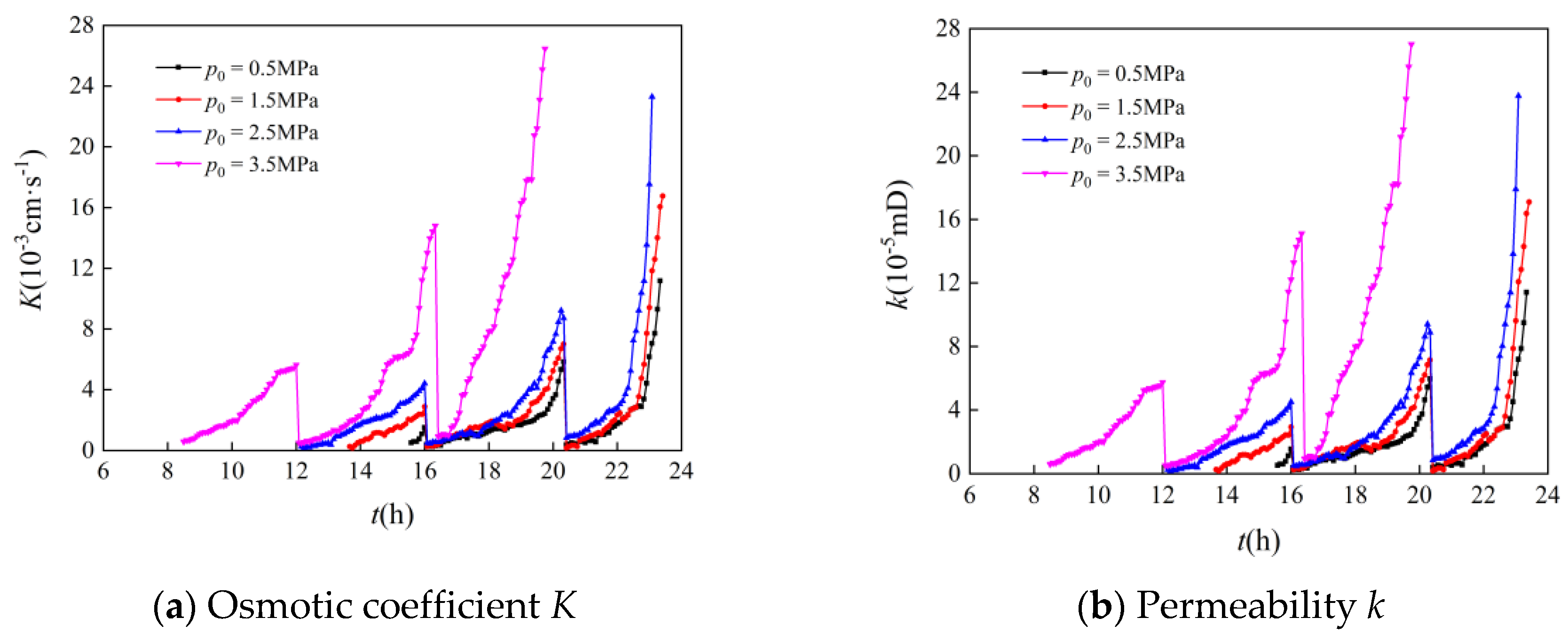

3.2.2. Variation of Seepage Properties of Sandstone with Seepage Pressure

3.3. Macroscopic and Microscopic Mechanism Study on Coal Measures Sandstone Rupture under Seepage-Creep Coupling

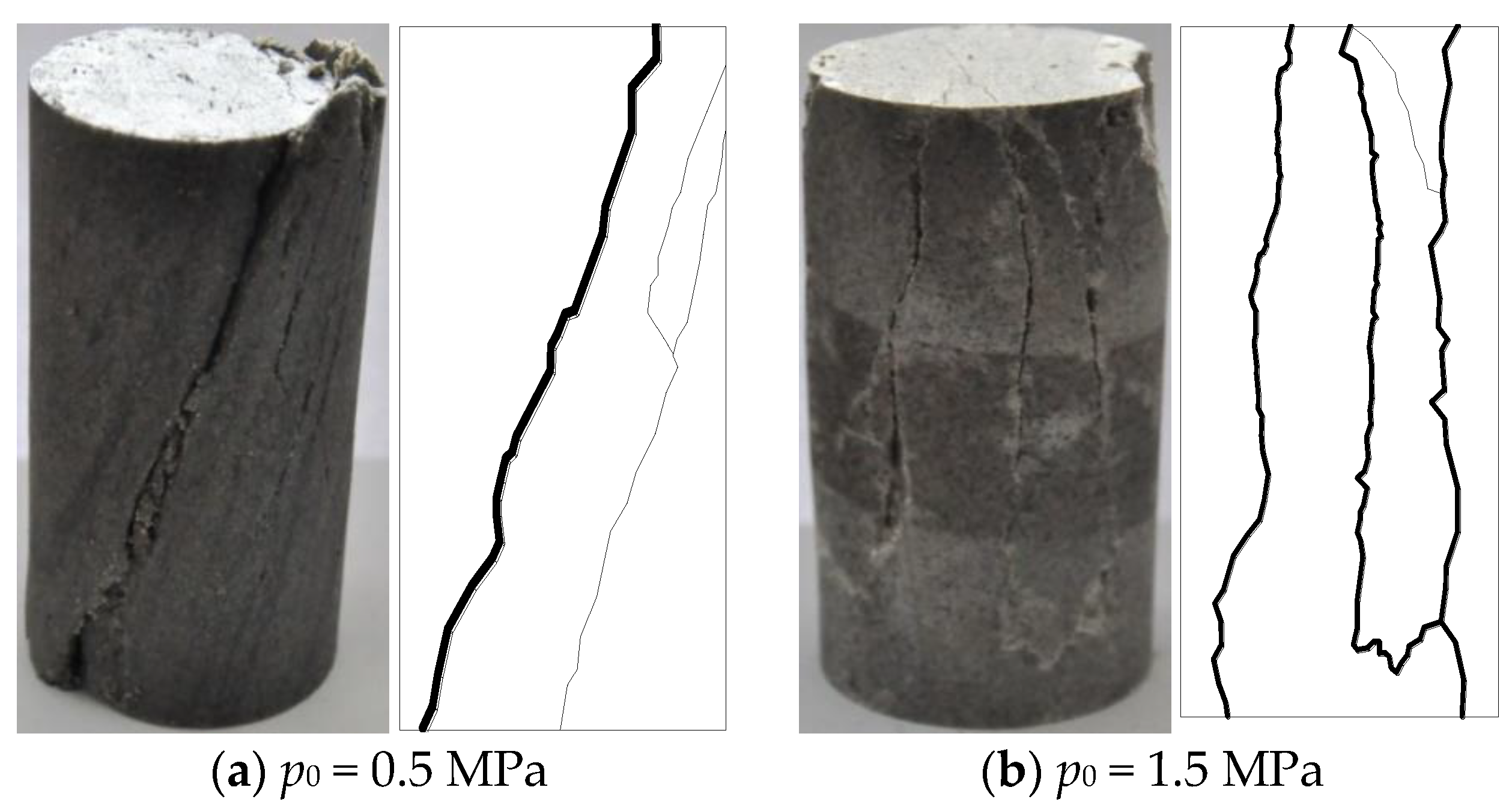

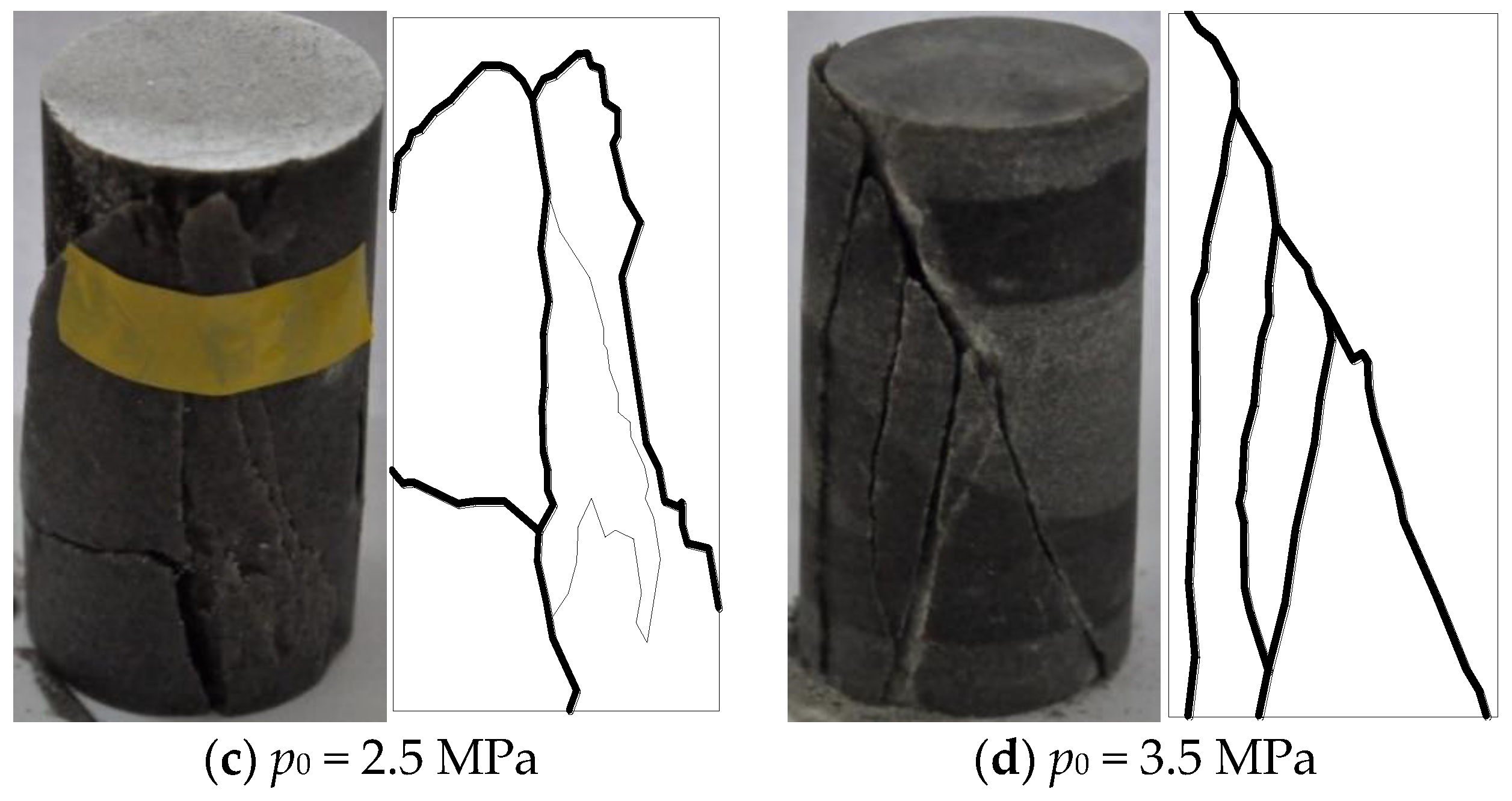

3.3.1. Macroscopic Characteristics of Sandstone Rupture

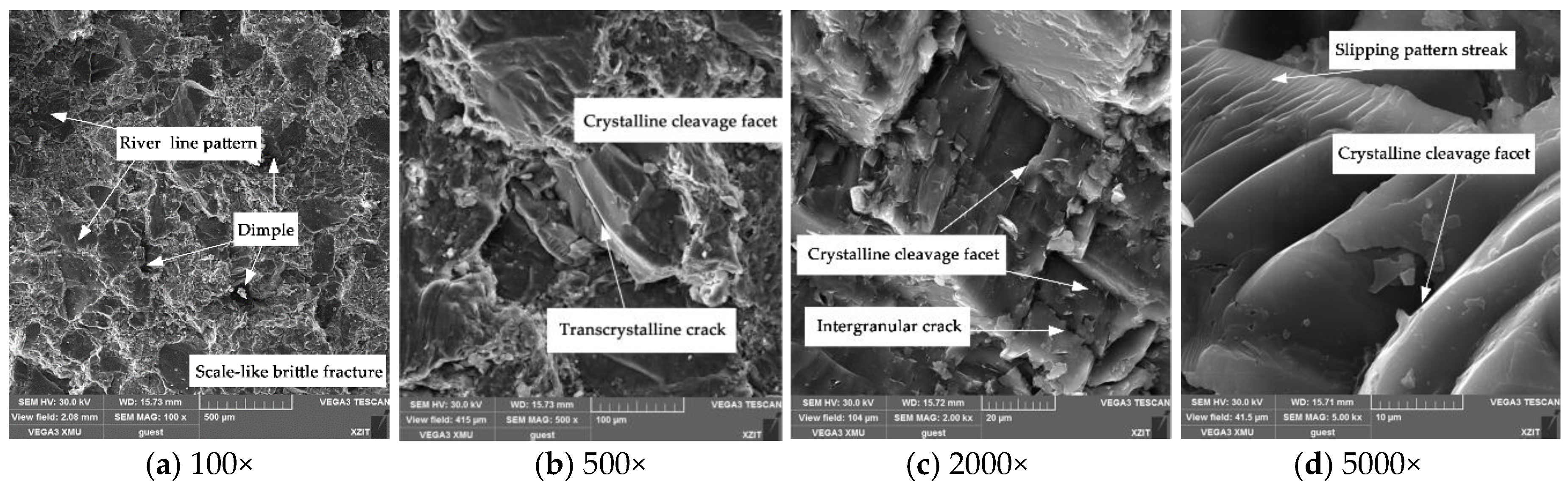

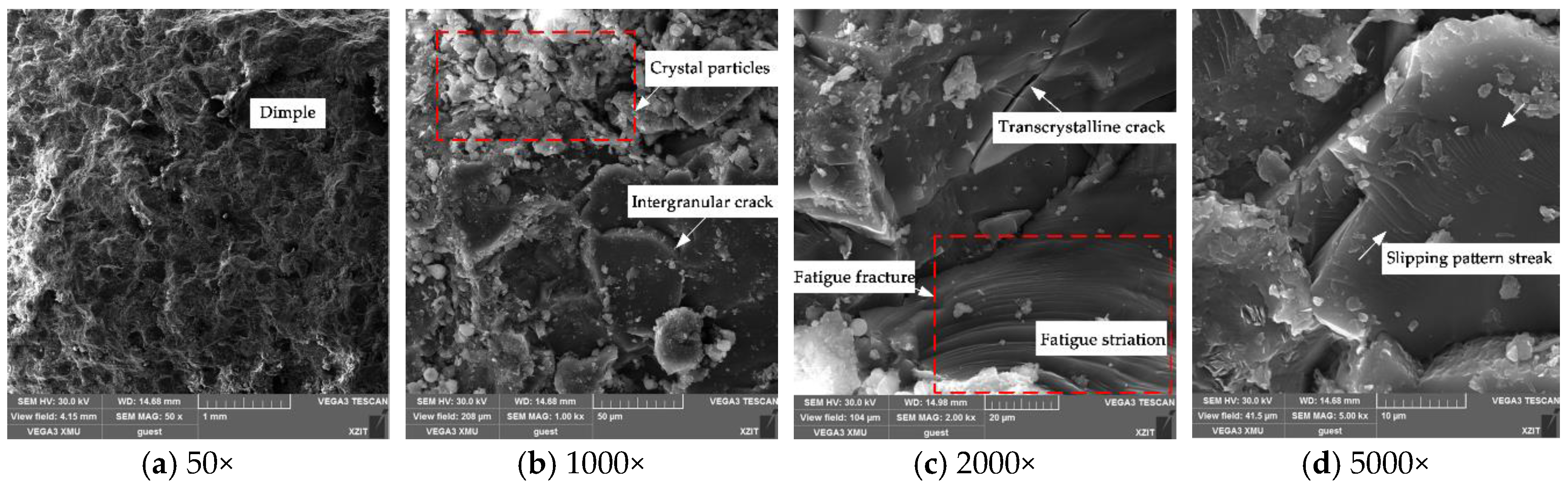

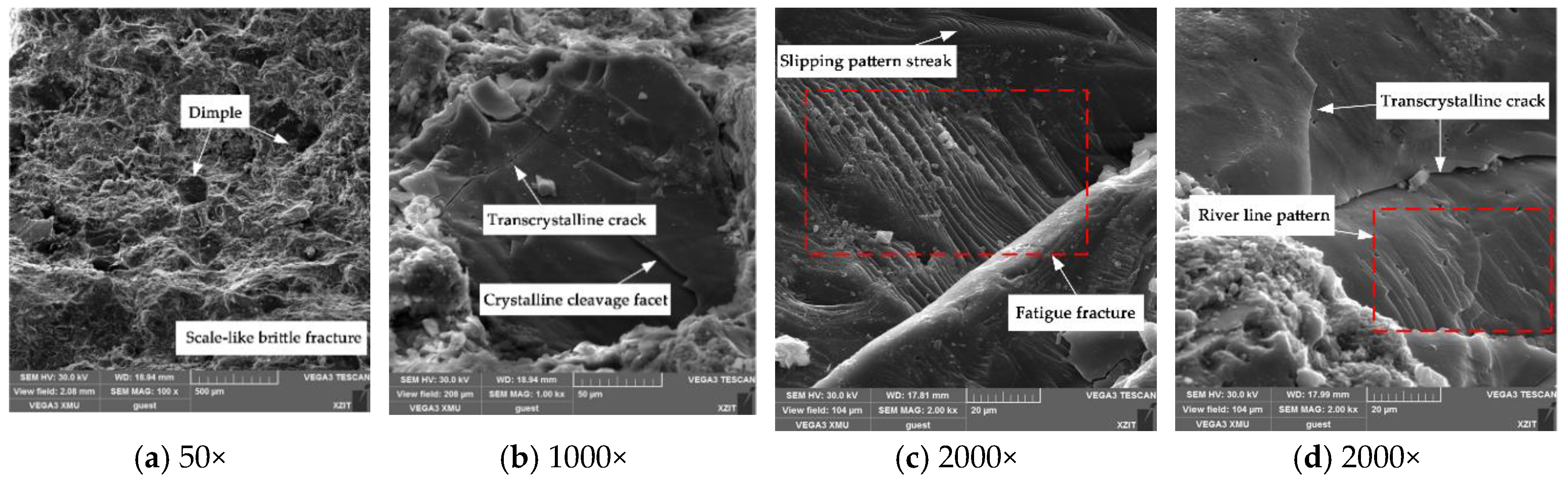

3.3.2. Microscopic Characteristics of Sandstone Rupture

3.3.3. Connection between Macroscopic and Microscopic Mechanism on Sandstone Rupture

4. Conclusions

- Based on the triaxial compression tests of coal measures sandstone, the creep tests of sandstone under natural and saturation state were carried out through the grading loading tests. The results showed that: The creep characteristic curves of sandstone in two conditions were the same, both including decelerating creep and steady creep at lower loading levels. When the loading level was higher, the creep curve included three complete processes: decelerating creep, isokinetic creep and accelerated creep.

- The seepage pressure had a significant effect on the creep deformation and permeability characteristics of coal measures sandstone. When the confining pressure was invariant, the constant creep deformation rate and accelerated creep deformation rate of sandstone increased rapidly with the increase of seepage pressure. With the change of time, the change of sandstone permeability parameters underwent three cycles, and the characteristics of change in each cycle were also divided into two stages: slow change stage and rapid change stage. The change rate gradually increased with the increase of seepage pressure. As the permeation pressure increased, the permeation parameters measured for the first time gradually decreased accordingly.

- When the confining pressure was invariant, with the increase of seepage pressure, the macroscopic damage of sandstone under natural and saturation conditions had a tendency of transition from tensile failure to shear failure. As the seepage pressure raised, the microscopic fracture mode of sandstone had changed from brittle fracture to ductile fracture and finally to brittle fracture. According to the macroscopic characteristics of sandstone rupture, microscopic morphology and fracture modes, the connection between macroscopic and microscopic mechanism on sandstone rupture was established.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- He, M.; Jing, H.; Sun, X. Research progress of soft rock engineering geomechanics in china coal mine. J. Eng. Geol. 2000, 8, 46–62. [Google Scholar]

- He, M. Engineering Mechanics of Soft Rock; Science Press: Beijing, China, 2002; pp. 52–109. ISBN 7-03-010340-8. [Google Scholar]

- He, M.; Xie, H.; Peng, S.; Jiang, Y. Study on rock mechanics in deep mining engineering. Chin. J. Rock. Mech. Eng. 2005, 24, 2803–2813. [Google Scholar]

- He, M. Conception system and evaluation indexes for deep engineering. Chin. J. Rock. Mech. Eng. 2005, 24, 2854–2858. [Google Scholar]

- Zhou, H.; Xie, H.; Zuo, J. Research progress of rock mechanics behavior under deep high ground stress. Adv. Mech. 2005, 35, 91–99. [Google Scholar]

- Xie, H.; Peng, S.; He, M. Basic Theory and Engineering Practice in Deep Mining; Science Press: Beijing, China, 2006; pp. 12–58. ISBN 7-03-016386-9. [Google Scholar]

- Sun, J. Rock rheological mechanics and its advance in engineering applications. Chin. J. Rock. Mech. Eng. 2007, 26, 1081–1106. [Google Scholar]

- He, F. The Research on Mechanism of Rock Creep-Seepage Coupling. Ph.D. Thesis, Liaoning Technical University, Fuxin, China, 2010. [Google Scholar]

- Yang, H.; Xu, J.; Nie, W.; Peng, S. Experimental study on creep of rocks under step loading of seepage pressure. Chin. J. Geotech. Eng. 2015, 37, 1613–1619. [Google Scholar]

- Griggs, D.T. Creep of Rocks. J. Geol. 1939, 37, 225–251. [Google Scholar] [CrossRef]

- Wang, G. Advanced Rock Mechanics Theory; Metallurgical Industry Press: Beijing, China, 1996. [Google Scholar]

- Zhou, W. Advanced Rock Mechanics; China Water & Power Press: Beijing, China, 1990. [Google Scholar]

- Maranini, E.; Brignoli, M. Creep behavior of a weak rock: Experimental characterization. Int. J. Rock. Mech. Min. 1999, 36, 127–138. [Google Scholar] [CrossRef]

- Fan, Q.; Li, S.; Gao, Y. Experimental study on creep properties of soft rock under triaxial compression. Chin. J. Rock. Mech. Eng. 2007, 7, 1381–1385. [Google Scholar]

- Chen, Y.; Sun, J. Rheological fracture characteristics of rock. Chin. J. Rock. Mech. Eng. 1996, 15, 20–24. [Google Scholar] [CrossRef]

- Li, J. Experimental study on the rheological shear properties of rock. Chin. J. Geotech. Eng. 2000, 3, 299–303. [Google Scholar]

- Zhang, Z.; Xu, W.; Zhao, H.; Jian, B. Investigation on shear creep experiments of sandstone with weak plane in xiangjiaba hydropower station. Chin. J. Rock. Mech. Eng. 2010, S2, 3693–3698. [Google Scholar]

- Yang, G.; Xie, D.; Zhang, C.; Pu, Y. CT identification of rock damage properties. Chin. J. Rock. Mech. Eng. 1996, 15, 48–54. [Google Scholar]

- Yang, G.; Lu, Z.; Pu, Y. The mechanic characteristics of damage propagation of rock under tri-axial stress condition. J. Xi’an Univ. Sci. Technol. 2000, 20, 101–104. [Google Scholar]

- Ge, X.; Ren, J.; Pu, Y.; Ma, W.; Zhu, Y. A real-in-time CT triaxial testing study of meso-damage evolution law of coal. Chin. J. Rock. Mech. Eng. 1999, 18, 497–502. [Google Scholar]

- Ge, X.; Ren, J. Study on the real intime CT test of the rock meso-damage. Sci. China 1999, 2, 104–111. [Google Scholar]

- Cao, S.; Liu, Y.; Zhang, L.; Jiang, Y. Experimental on acoustic emission of outburst-hazardous coal under uniaxial compression and creep. J. China Coal. Soc. 2007, 32, 1264–1268. [Google Scholar]

- Chen, W.; Zhao, F.; Gong, H. Study of triaxial creep mechanism of mica-quartz schist based on microscopic test. Chin. J. Rock. Mech. Eng. 2010, 29, 3578–3584. [Google Scholar]

- Zhang, Q.; Yang, W.; Chen, F.; Li, W.; Wang, J. Long-term strength and microscopic failure mechanism of hard brittle rocks. Chin. J. Geotech. Eng. 2011, 33, 1910–1918. [Google Scholar]

- Louis, C. Rock Hydraulics in Rock Mechanics; Springer Vienna: New York, NY, USA, 1974; pp. 36–108. [Google Scholar]

- Jones, F.O. A laboratory study of the effects of confining pressure on fracture flow andstorage capacity in carbonate rocks. J. Pet. Technol. 1975, 27, 21–27. [Google Scholar] [CrossRef]

- Nelson, R.A. Fracture Permeability in Porous Reservoirs: An Experimental and Field Approach. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 1975. [Google Scholar]

- Kranz, R.L.; Frankel, A.D.; Engelder, T. The permeability of whole and jointed Barre granite. Int. J. Rock. Mech. Min. 1979, 16, 225–234. [Google Scholar] [CrossRef]

- Gale, J.E. The effects of fracture type (induced versus natural) on the stress-fracture closure-fracture permeability relationships. In Proceedings of the 23rd U.S Symposium on Rock Mechanics (USRMS), Berkeley, CA, USA, 25–27 August 1982. [Google Scholar]

- Iwai, K. Fundamental Studies of Fluid Flow through a Single Fracture. Ph.D. Thesis, University of California, Oakland, CA, USA, 1976. [Google Scholar]

- Mordecai, M.; Morris, L.H. An investigation into the changes of permeability occurring in a sandstone when failed under triaxial stress conditions. In Proceedings of the 12th U.S. Symposium on Rock Mechanics (USRMS), Rolla, MI, USA, 16–18 November 1970. [Google Scholar]

- Li, S.; Chen, Z.; Miao, X.; Liu, Y. Experimental study on the properties of time-dependent deformation-seepage in water-saturated broken sandstone. J. Min. Saf. Eng. 2011, 28, 542–547. [Google Scholar]

- Miao, X.; Li, S.; Chen, Z.; Liu, W. Experimental study of seepage properties of broken sandstone under different porosities. Transp. Porous Med. 2011, 86, 805–814. [Google Scholar] [CrossRef]

- He, F.; Wang, L.; Wang, Z.; Yao, Z. Experimental study on creep seepage coupling law of coal (rock). J. China Coal. Soc. 2011, 36, 930–933. [Google Scholar]

- Zhu, Z.; Xu, W.; Zhang, A. Mechanism analysis and testing study on Damage and fracture of brittle rock. Chin. J. Rock. Mech. Eng. 2003, 22, 1411–1416. [Google Scholar]

- Zhang, S.; Cox, S.F.; Paterson, M.S. The influence of room temperature deformation on porosity and permeability in calcite aggregates. J. Geophys. Res. 1994, 99, 15761–15775. [Google Scholar] [CrossRef]

- Liu, R.; Li, B.; Jiang, Y. A fractal model based on a new governing equation of fluid flow in fractures for characterizing hydraulic properties of rock fracture networks. Comput. Geotech. 2016, 75, 57–68. [Google Scholar] [CrossRef]

- Li, B.; Liu, R.; Jiang, Y. Influences of hydraulic gradient, surface roughness, intersecting angle, and scale effect on nonlinear flow behavior at single fracture intersections. J. Hydrol. 2016, 538, 440–453. [Google Scholar] [CrossRef]

- Yang, T.; Tang, C.; Zhu, W.; Feng, Q. Coupling analysis of seepage and stresses in rock failure process. Chin. J. Geotech. Eng. 2001, 23, 489–493. [Google Scholar]

- Pu, H.; Cao, L.; Qiu, Y.; Qiu, P. Study of overlying strata creep affected by seepage in backfilling mining process. J. Min. Saf. Eng. 2015, 32, 846–852. [Google Scholar]

- Souley, M.; Homand, F.; Pepa, S.; Hoxha, D. Damage-induced permeability changes in granite: A case example at the URL in Canada. Int. J. Rock. Mech. Min. 2001, 38, 297–310. [Google Scholar] [CrossRef]

- Ma, D. Water-Rock-Sand Mixture Flow Theory of Crushed Rocks and Temporal-Spatial Evolution. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2017. [Google Scholar]

- Yao, B. Research on Variable Mass Fluid-Solid Coupling Dynamic Theory of Broken Rock Mass and Application. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2012. [Google Scholar]

- Wang, L. Accelerated Experimental Study on Permeability for Broken Mudstone with Mass Loss. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2014. [Google Scholar]

- Yan, Y. Research on Rock Creep Tests under Seepage Flow and Variable Parameters Creep Equation. Ph.D. Thesis, Tsinghua University, Beijing, China, 2009. [Google Scholar]

- Li, Y.; Ma, Z.; He, Y.; Wang, B.; Liang, X. Experimental Research on Permeability of Rocks of Coal-Bearing Strata. J. Exp. Mech. 2006, 21, 129–134. [Google Scholar] [CrossRef]

| Anorthite—Ca(Al2Si2O8) | Microcline Maximum—K(AlSi3) O8 | Kaolinite—Al2Si2O5(OH)4 | Quartz—SiO2 |

|---|---|---|---|

| 45.2% | 31.4% | 13.8% | 9.6% |

| ρ/(kg·m−3) | v/(m·s−1) | E/GPa | μ | σu/MPa | σT/MPa | σt/MPa | φ/° |

|---|---|---|---|---|---|---|---|

| 2540 | 2650 | 37.65 | 0.26 | 122.45 | 149.29 | 2.85 | 38 |

| Hierarchical Load | Natural Condition | Saturation Condition | ||||||

|---|---|---|---|---|---|---|---|---|

| p = 1 MPa | p = 2 MPa | p = 3 MPa | p = 4 MPa | p = 1 MPa | p = 2 MPa | p = 3 MPa | p = 4 MPa | |

| σ1 (MPa) | 20 | 20 | 23 | 25 | 10 | 14 | 15 | 18 |

| σ2 (MPa) | 40 | 40 | 46 | 50 | 20 | 28 | 30 | 36 |

| σ3 (MPa) | 60 | 60 | 69 | 75 | 30 | 42 | 45 | 54 |

| σ4 (MPa) | 80 | 80 | 92 | 100 | 40 | 56 | 60 | 72 |

| σ5 (MPa) | 100 | 100 | 115 | 125 | 50 | 70 | 75 | 90 |

| σ6 (MPa) | 120 | 120 | 138 | 150 | 60 | 84 | 90 | 108 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sha, Z.; Pu, H.; Li, M.; Cao, L.; Liu, D.; Ni, H.; Lu, J. Experimental Study on the Creep Characteristics of Coal Measures Sandstone under Seepage Action. Processes 2018, 6, 110. https://doi.org/10.3390/pr6080110

Sha Z, Pu H, Li M, Cao L, Liu D, Ni H, Lu J. Experimental Study on the Creep Characteristics of Coal Measures Sandstone under Seepage Action. Processes. 2018; 6(8):110. https://doi.org/10.3390/pr6080110

Chicago/Turabian StyleSha, Ziheng, Hai Pu, Ming Li, Lili Cao, Ding Liu, Hongyang Ni, and Jingfeng Lu. 2018. "Experimental Study on the Creep Characteristics of Coal Measures Sandstone under Seepage Action" Processes 6, no. 8: 110. https://doi.org/10.3390/pr6080110

APA StyleSha, Z., Pu, H., Li, M., Cao, L., Liu, D., Ni, H., & Lu, J. (2018). Experimental Study on the Creep Characteristics of Coal Measures Sandstone under Seepage Action. Processes, 6(8), 110. https://doi.org/10.3390/pr6080110