A Cost-Effective Redundant Digital Excitation Control System and Test Bed Experiment for Safe Power Supply for Process Industry 4.0

Abstract

1. Introduction

2. Related Work

- -

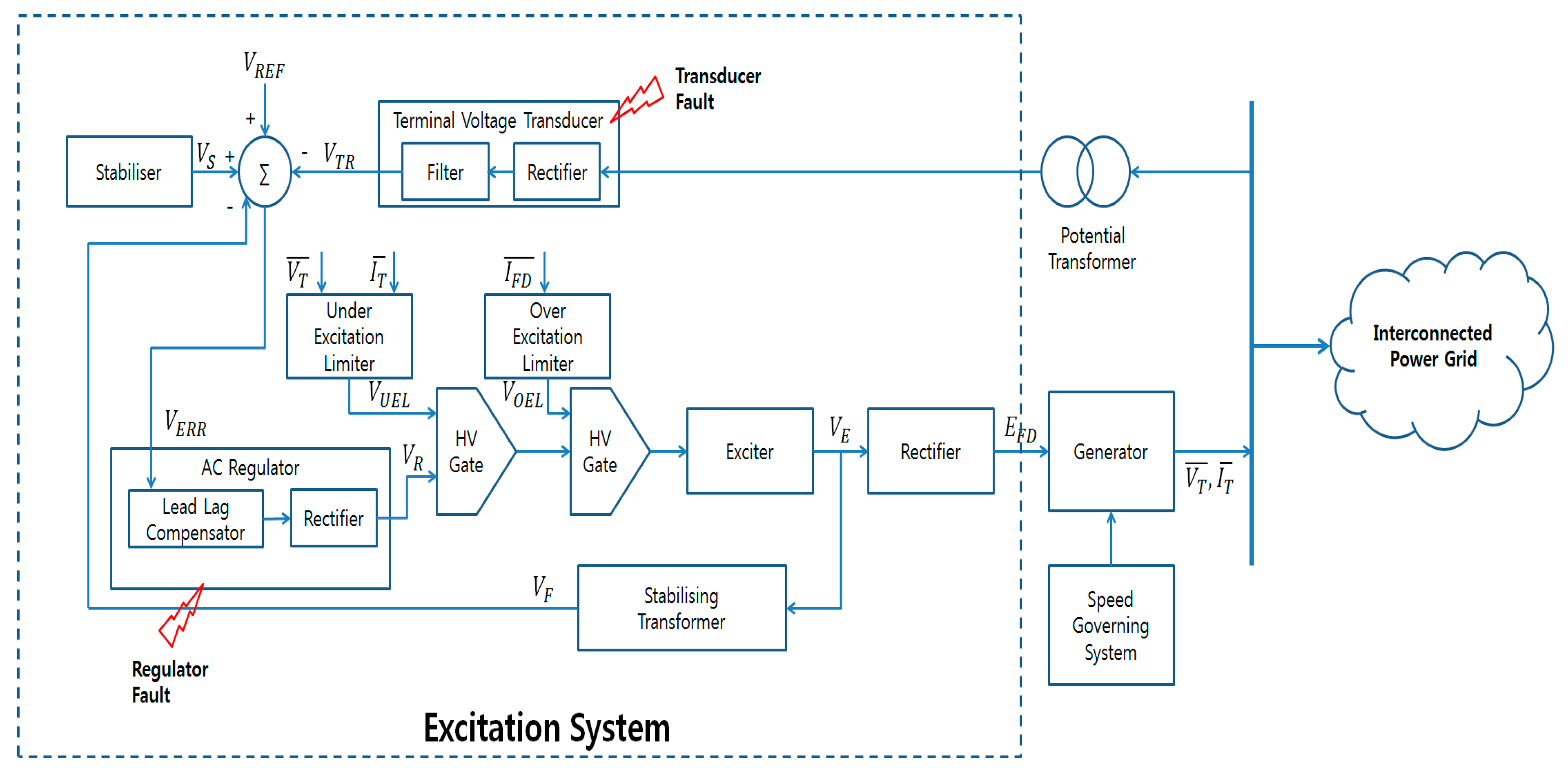

- Summation point: the point where a control error occurs due to the voltage reference value VREF and the terminal voltage transducer output VC. The additional signal from power system stabilizer (PSS) output VS could be transmitted.

- -

- Automatic voltage regulator (AVR): This has either a proportional character with lead-lag compensation (transient gain reduction) or employs a proportional integral and derivative (PID) control. The latter is digital and often used in European countries [42].

- -

- The output VA of AVR: This feeds a field voltage or a field current in the manner described as an inner loop (Figure 1) that forms a dependency between AVR output VAandexciter output voltage EFD and current IFD linear, also compensating the changes in the supply voltage. Murdoch et al. suggested that FVR is rarely used for most of the potential source exciters [43]. Here, the regulator output VREG is equivalent to VA [44].

2.1. Generator Excitation Control System

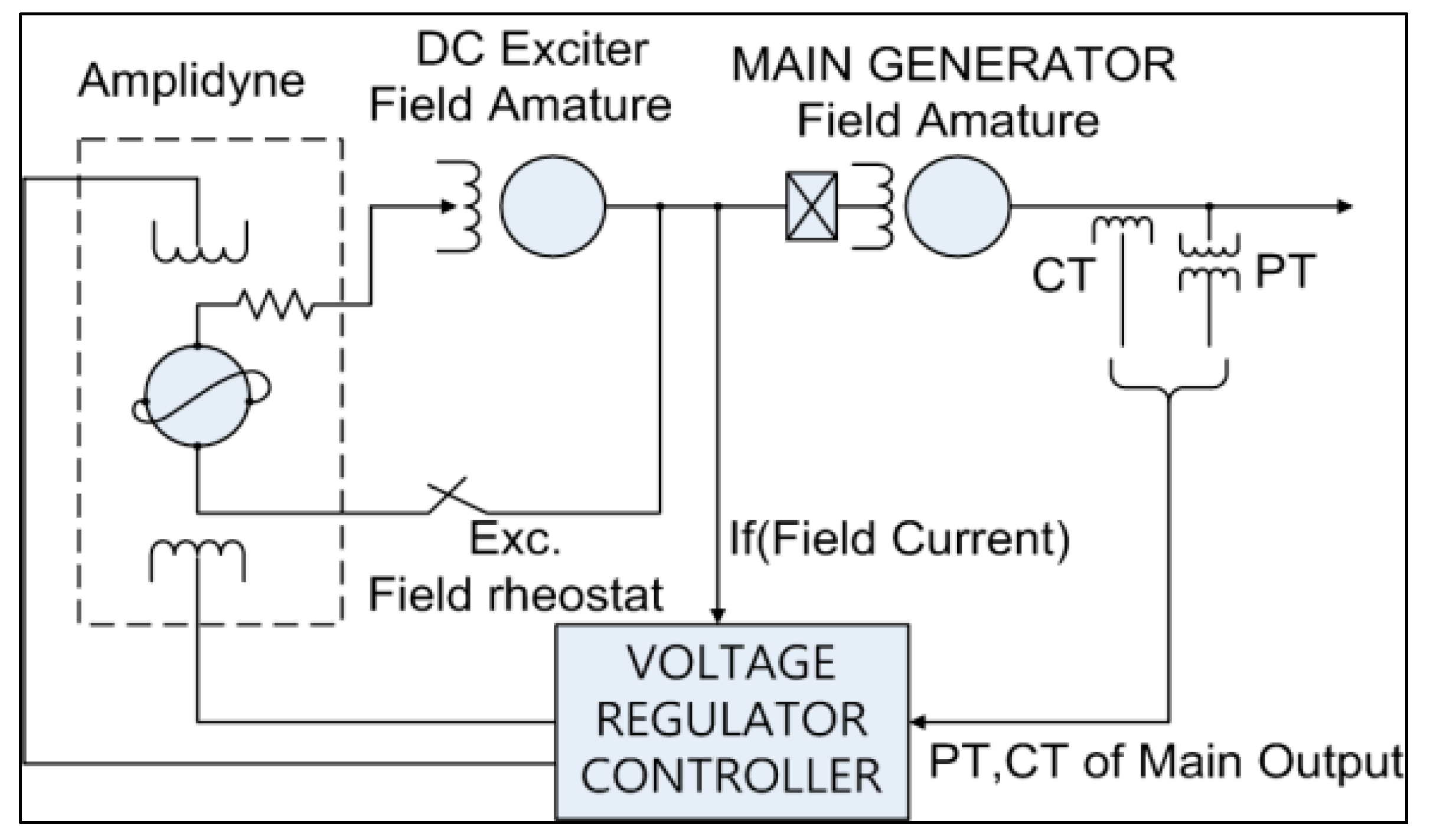

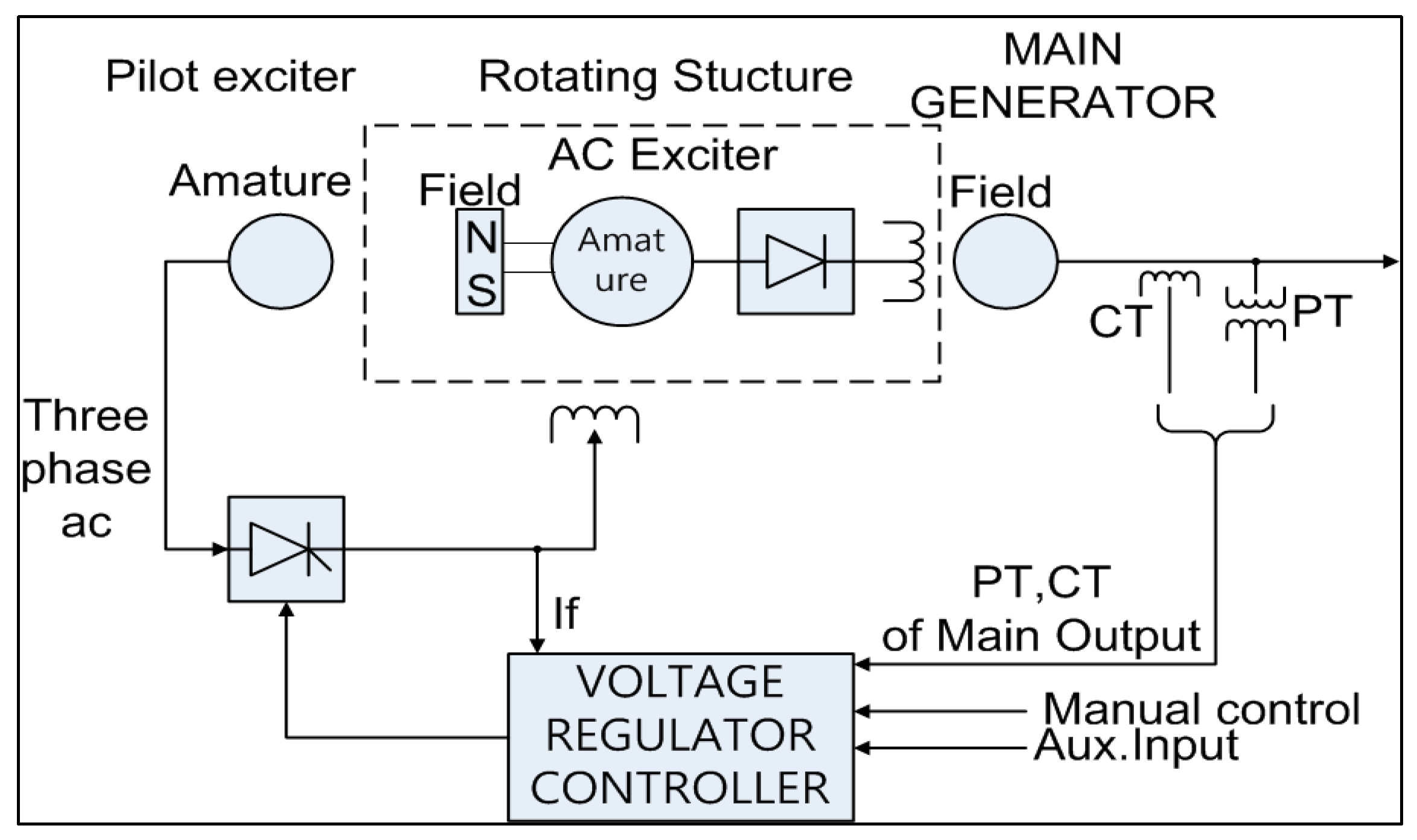

2.2. Direct Current Excitation System

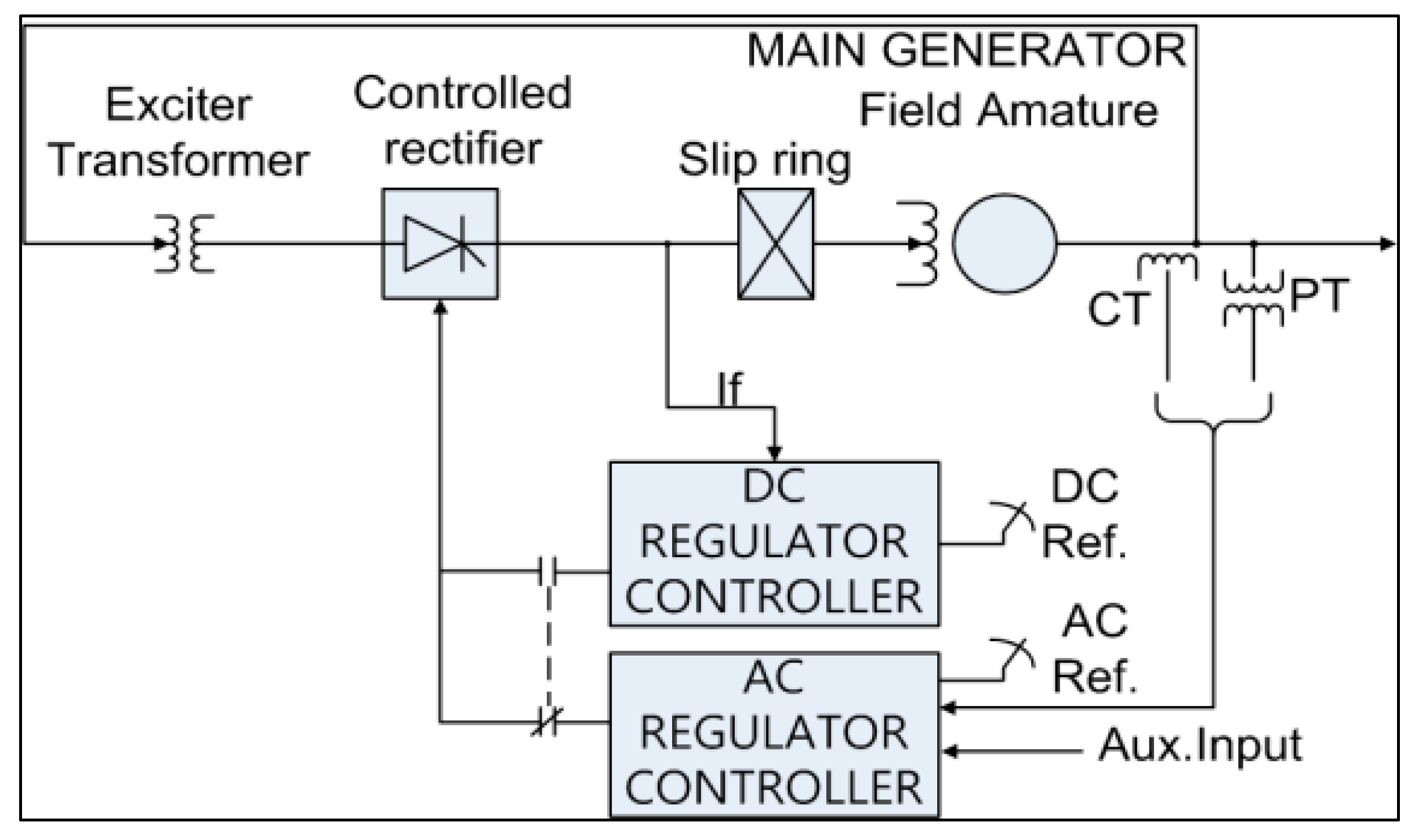

2.3. Static Excitation System

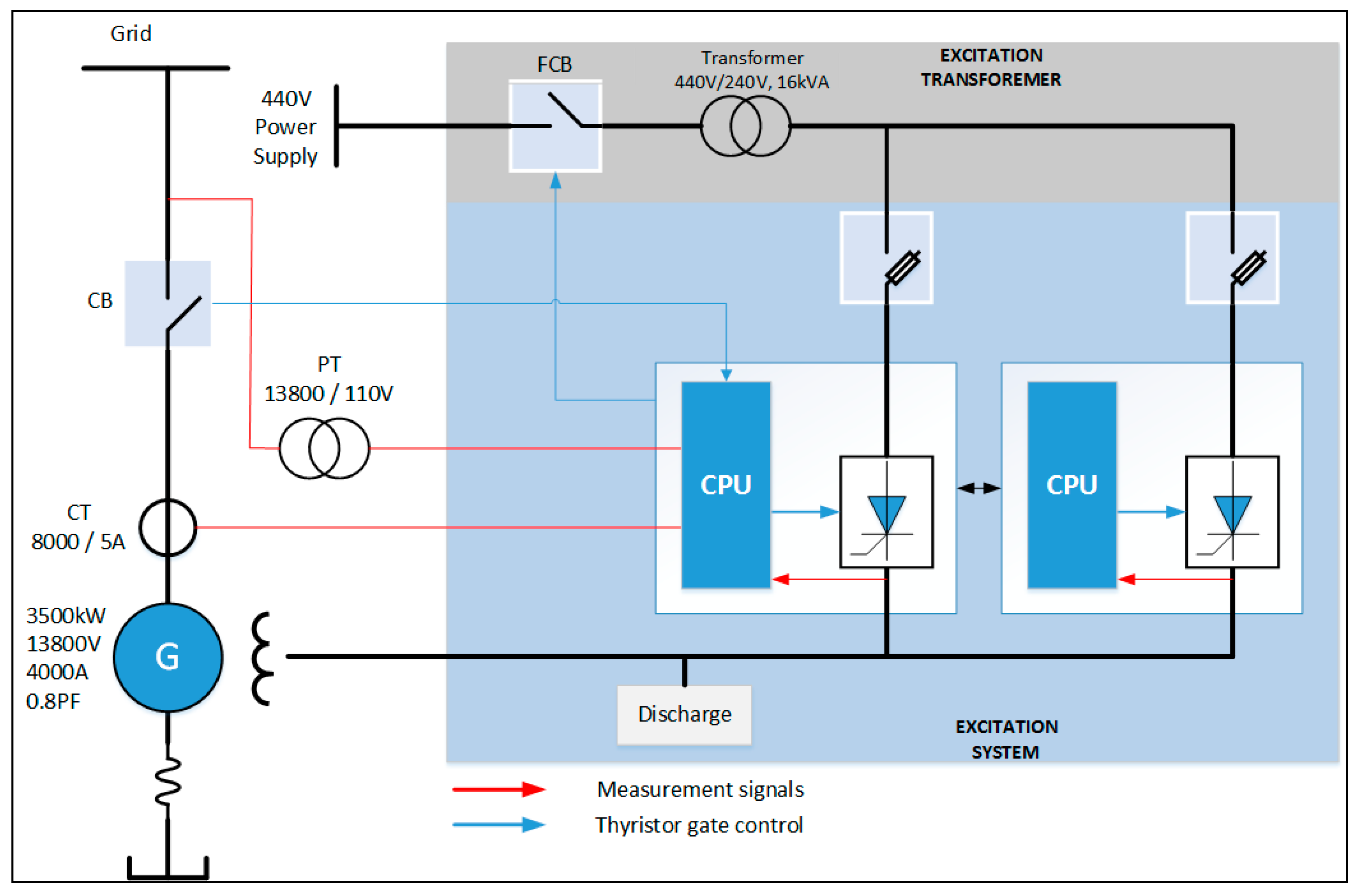

3. Cost-Effective Redundant Digital Excitation Control System

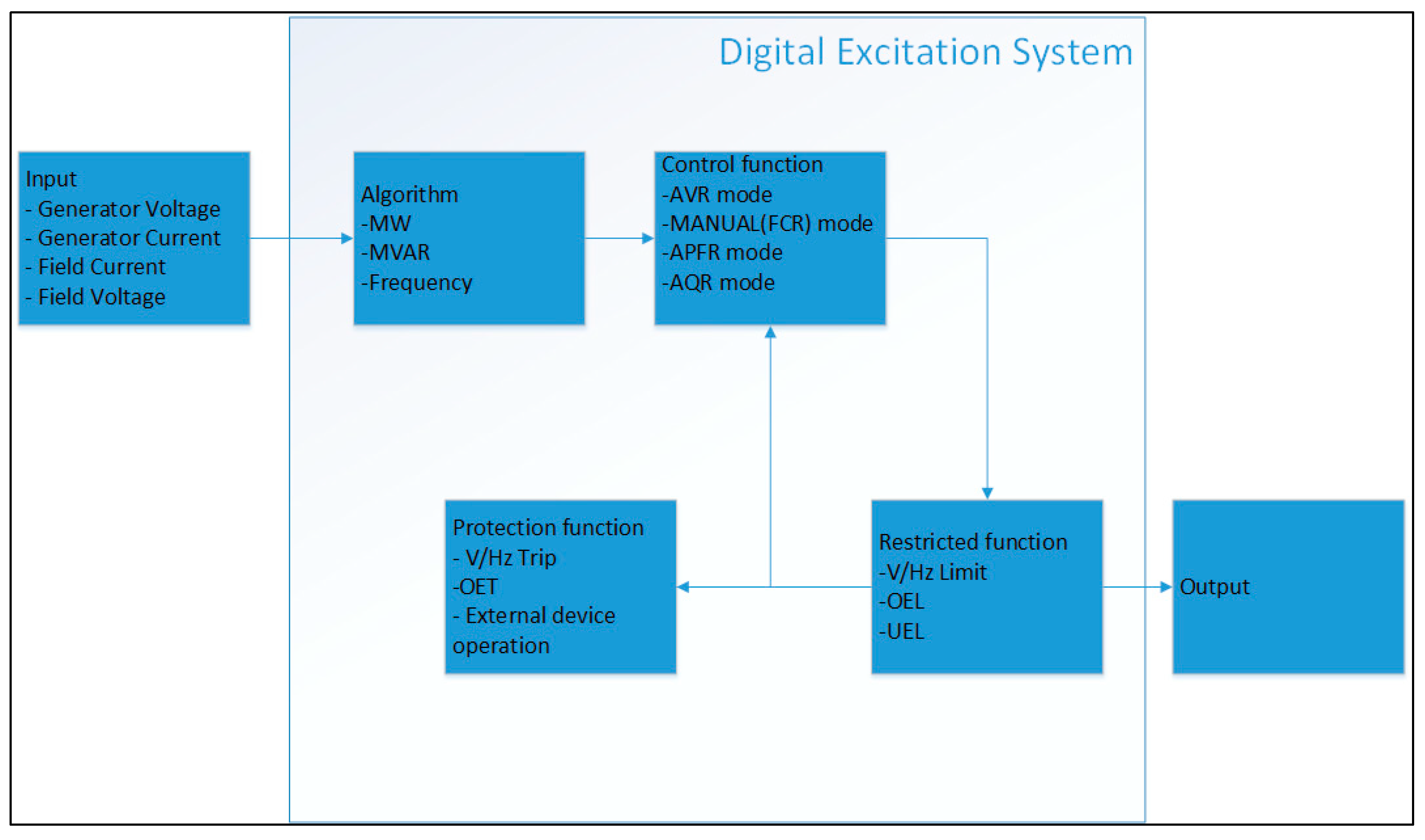

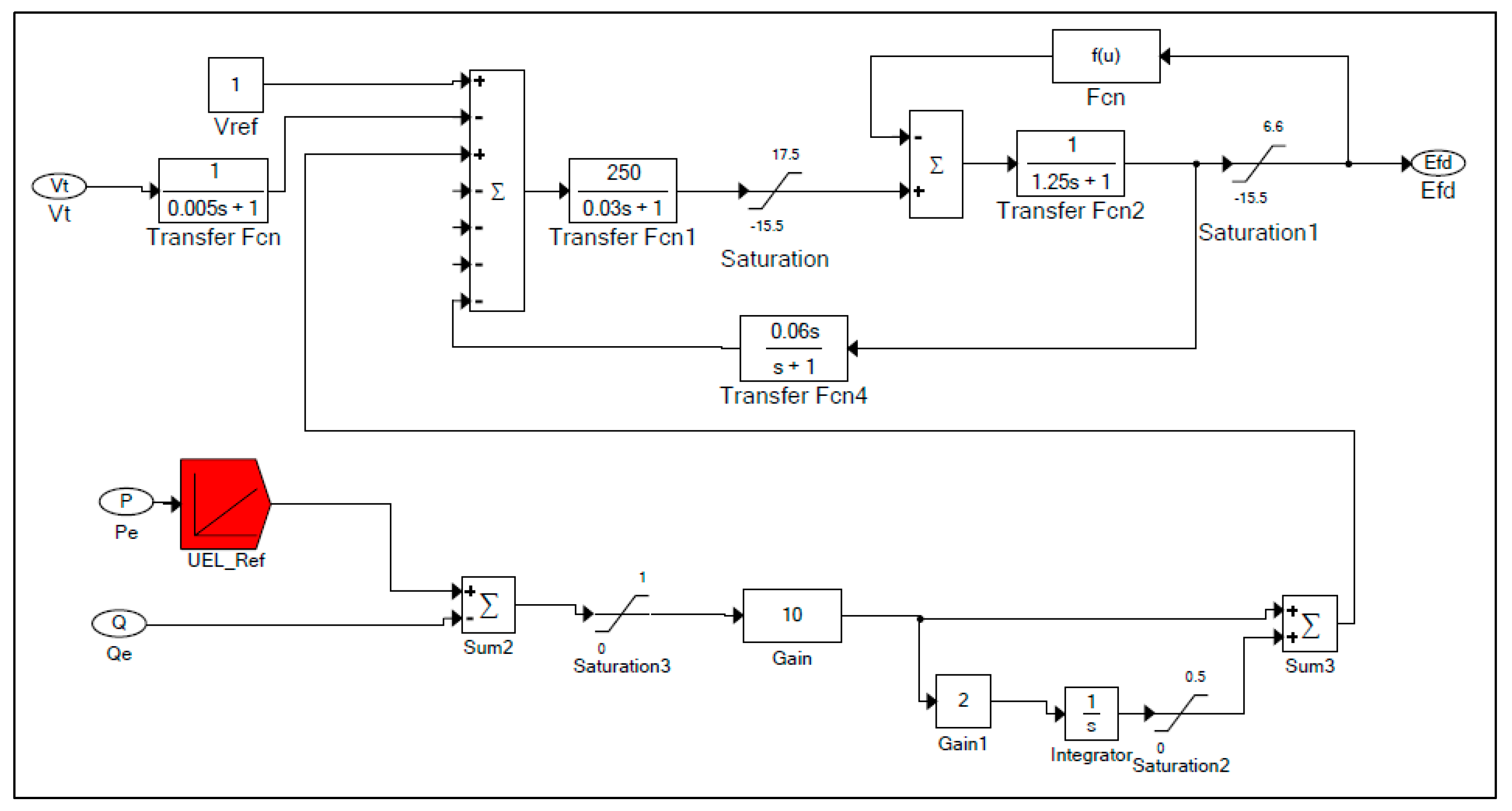

3.1. Digital Excitation Control System Algorithm

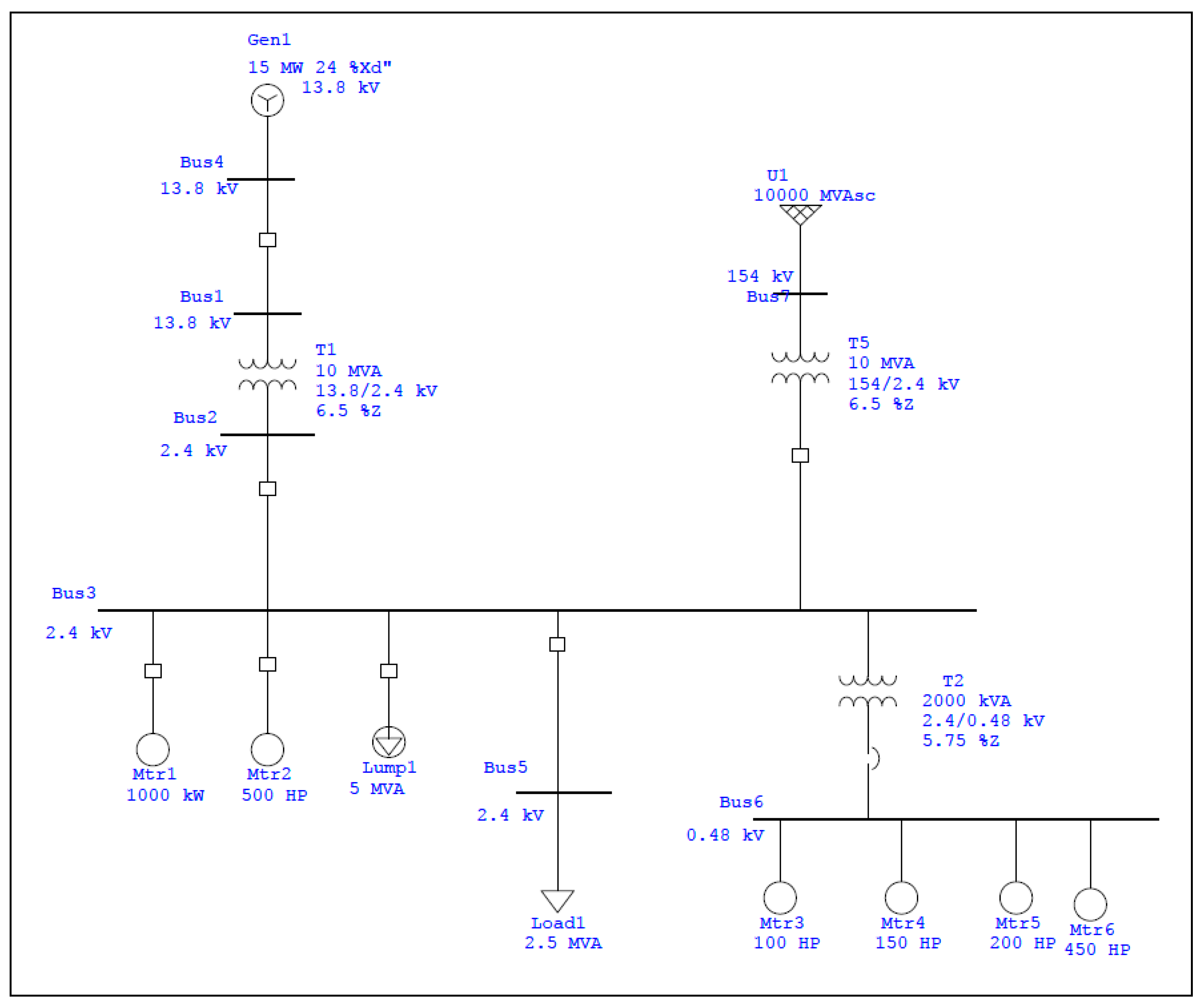

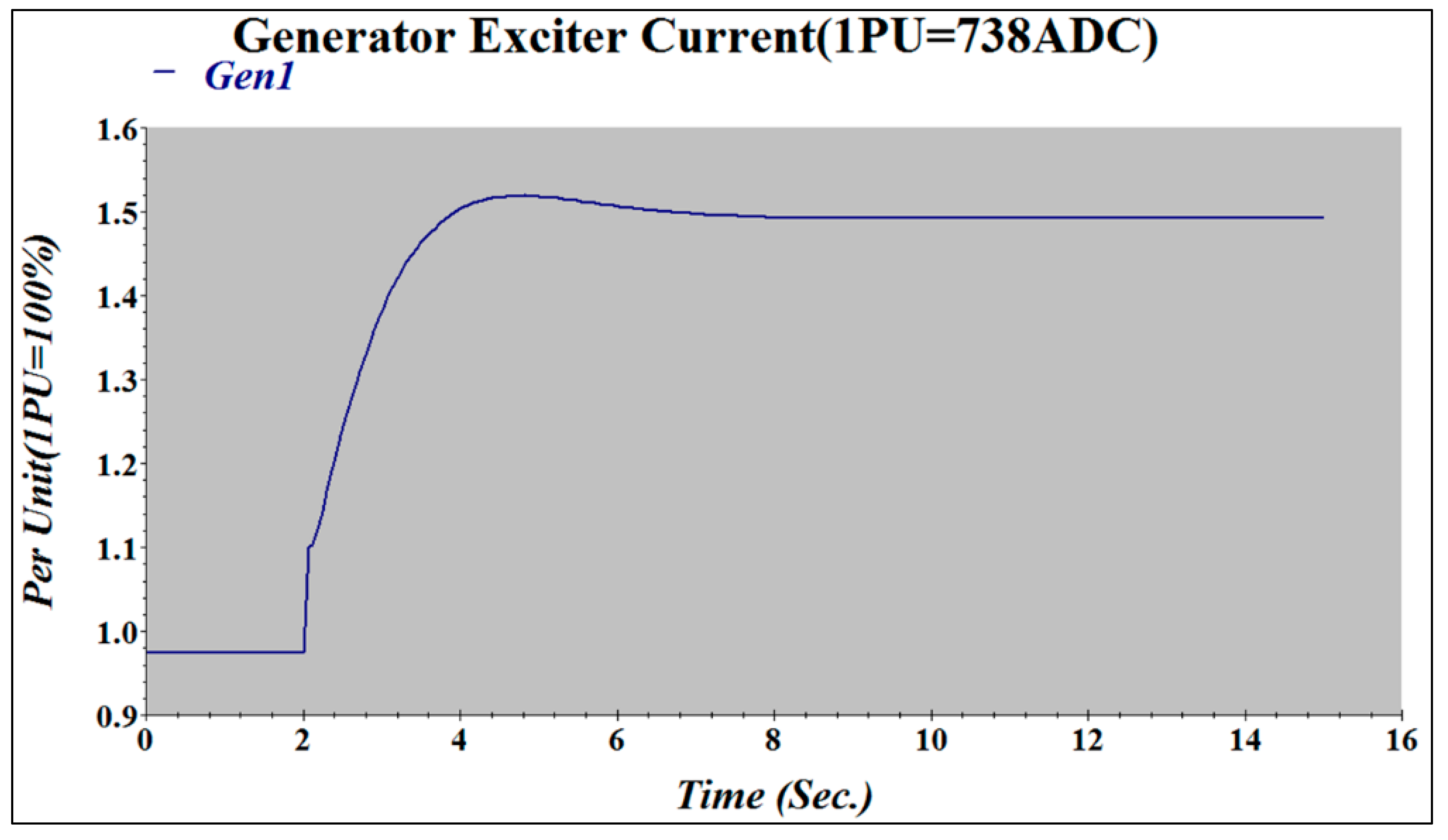

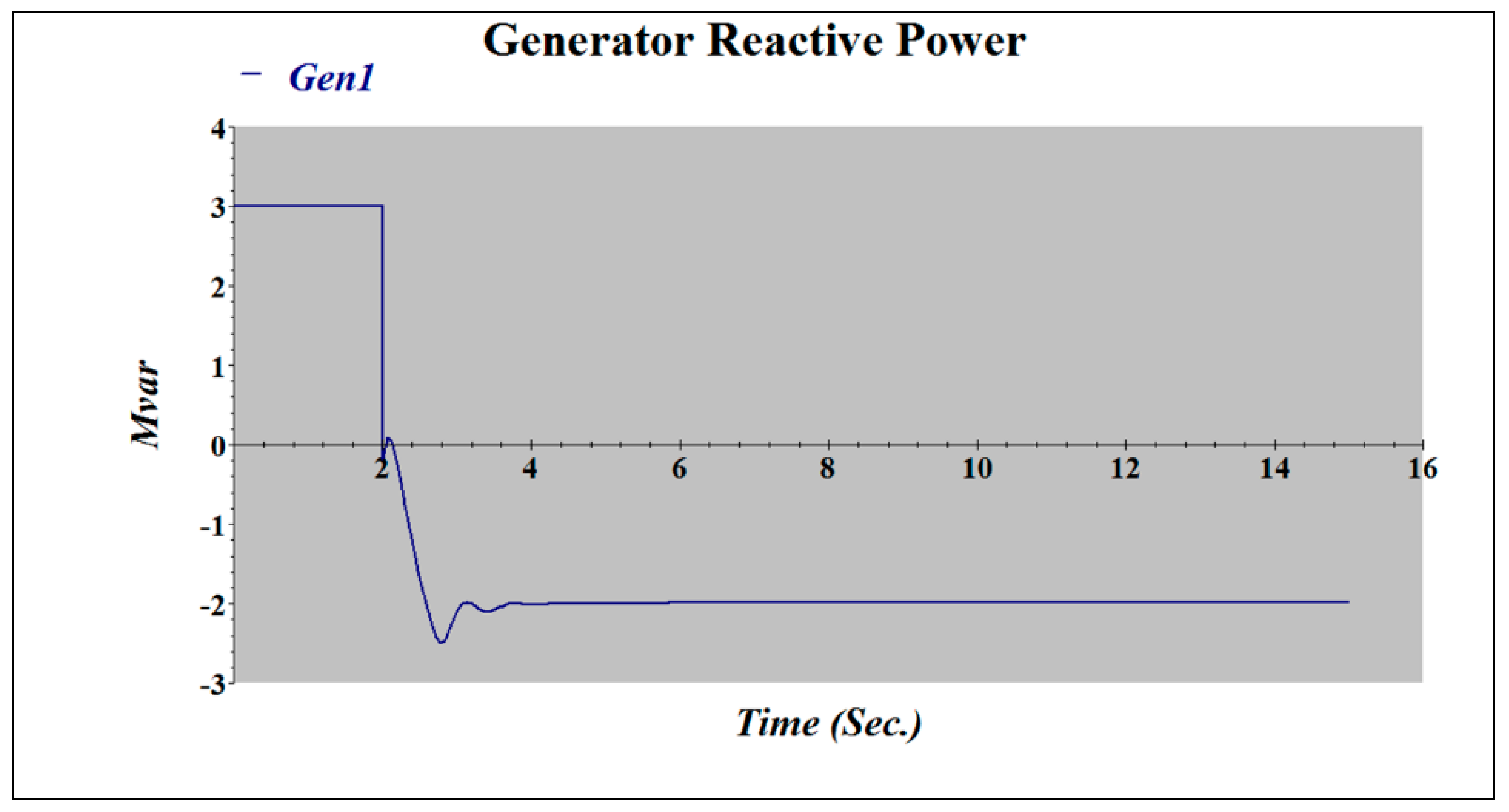

3.2. Simulation of Digital Excitation Control System

4. Field Test of Cost-Effective Redundant Digital Excitation Control System

- (1)

- Test for establishment of initial voltage

- (2)

- Test for establishment of initial current

- (3)

- Step response test

- (4)

- Under-excitation limit test

- (5)

- Over-flux (V/Hz)

- (6)

- Over-excitation protection

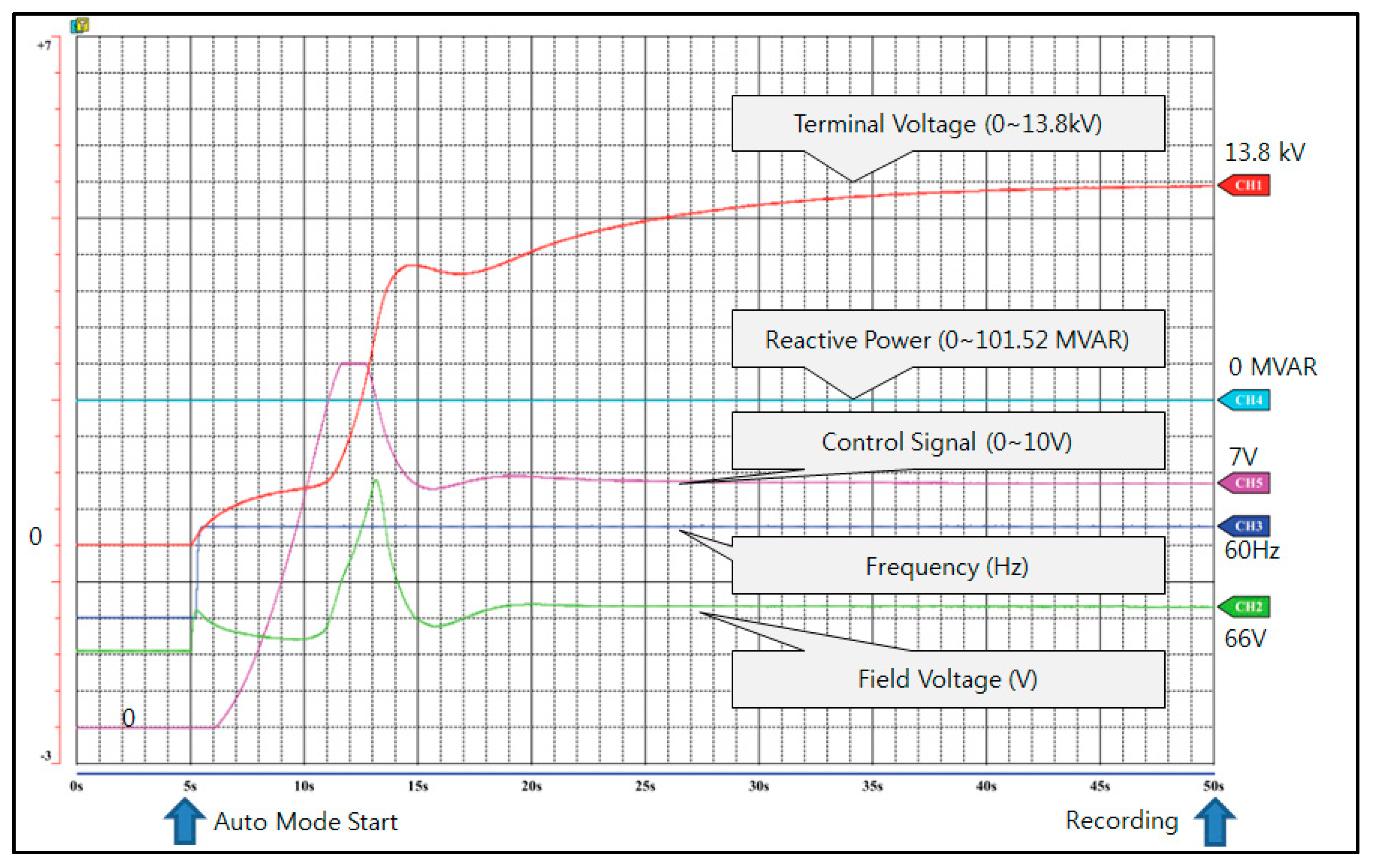

4.1. Establishment of Initial Voltage

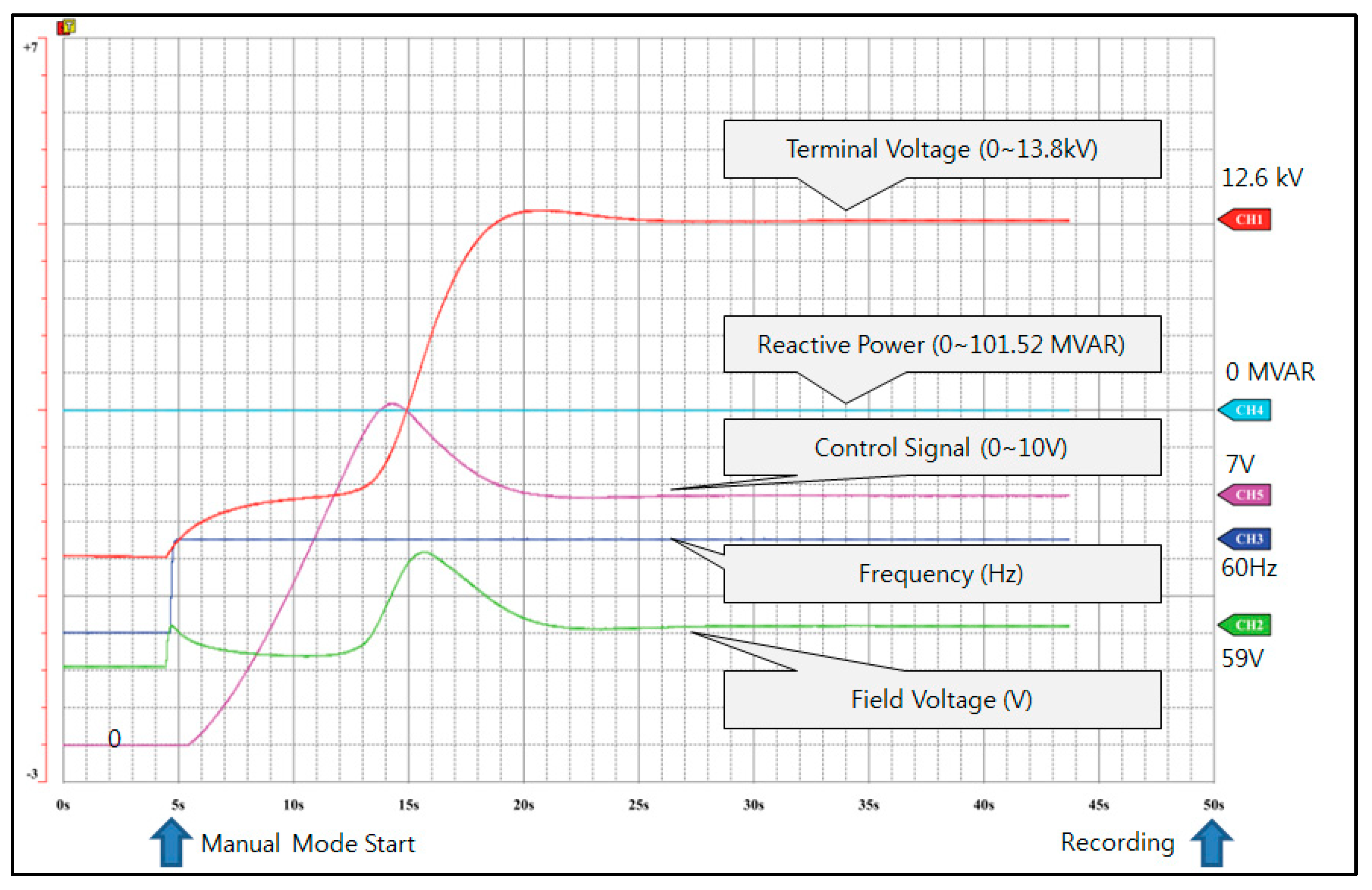

4.2. Test for Initial Current Establishment

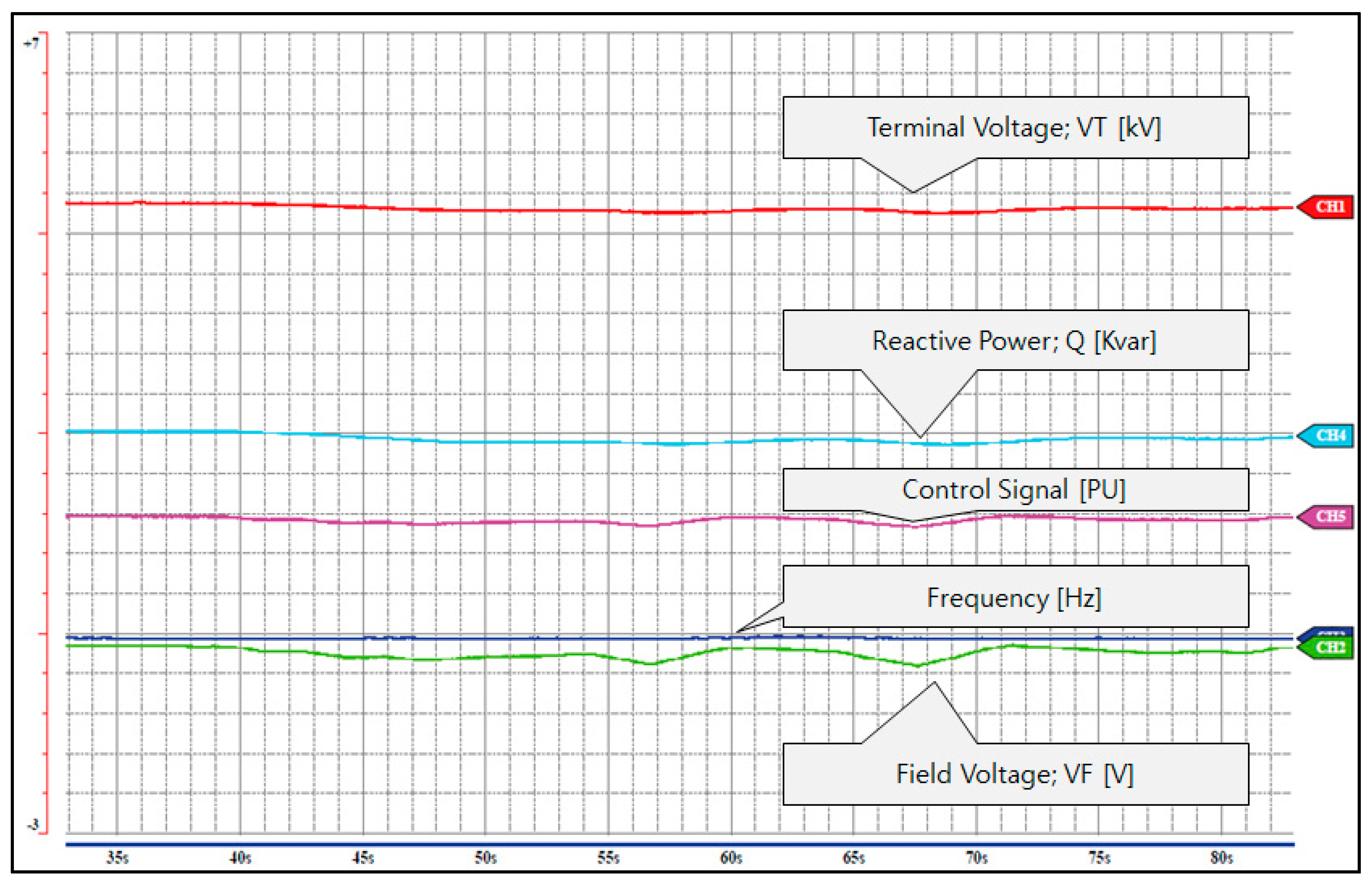

4.3. Step-Response Test

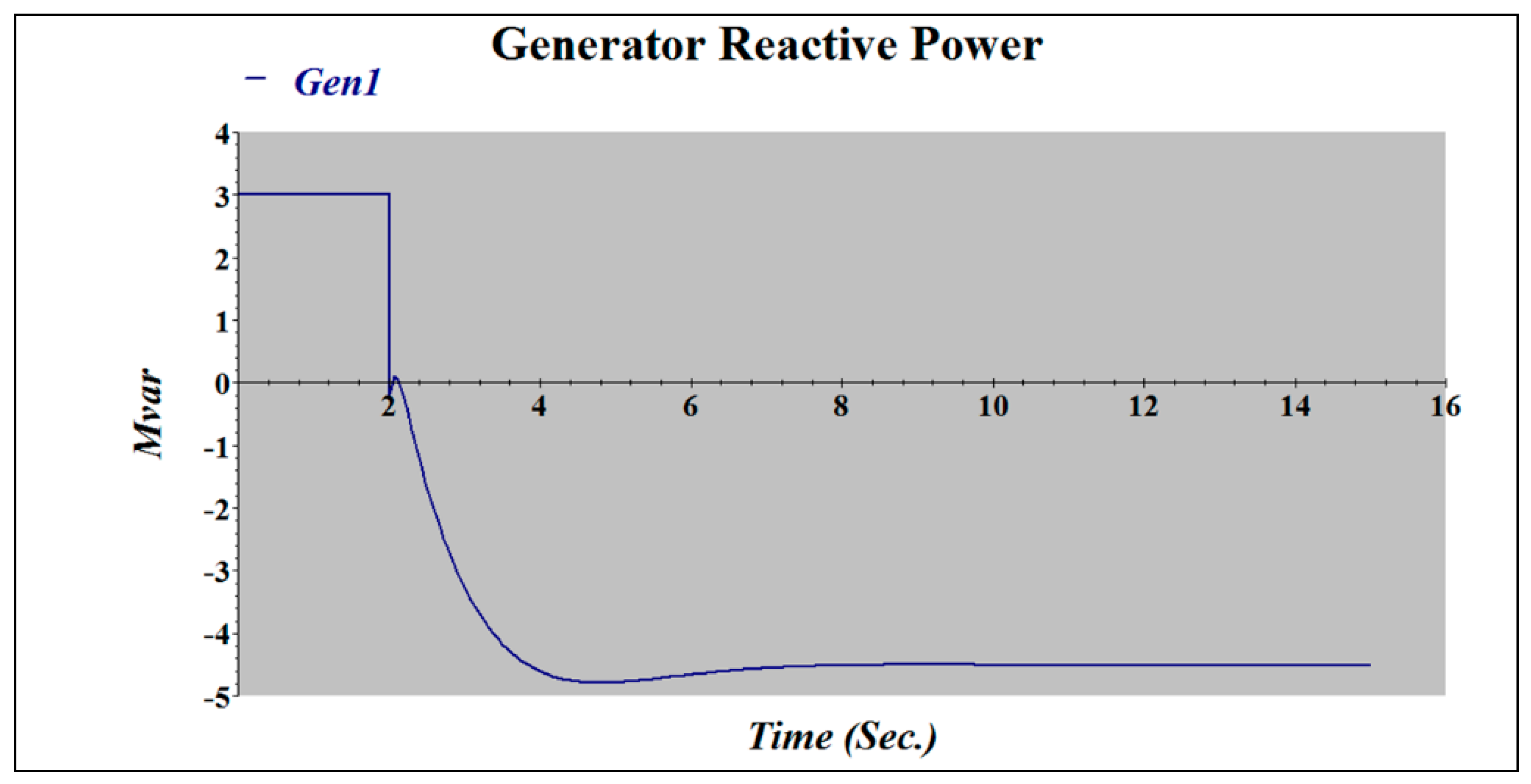

4.4. Under-Excitation Limit Test

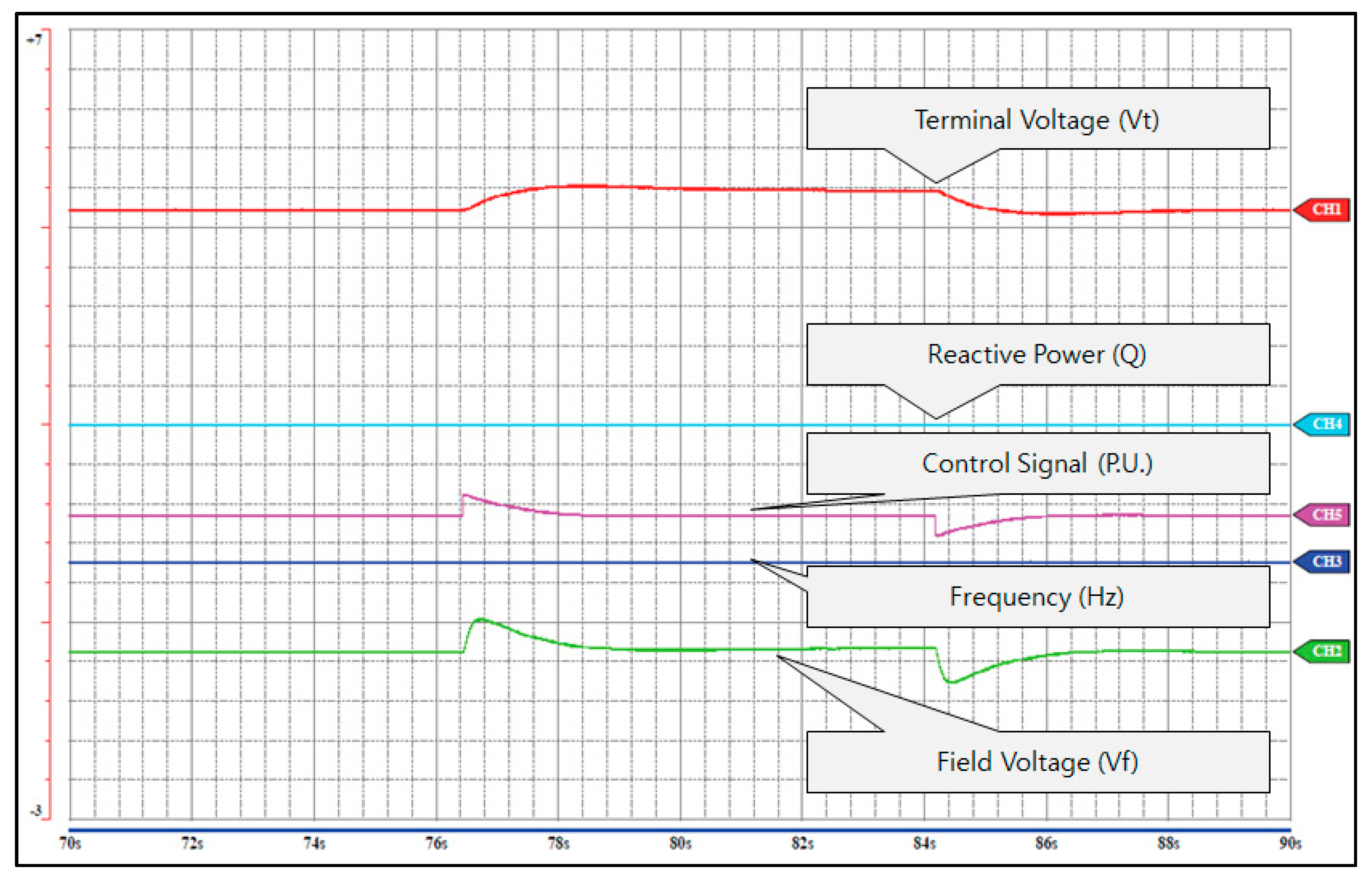

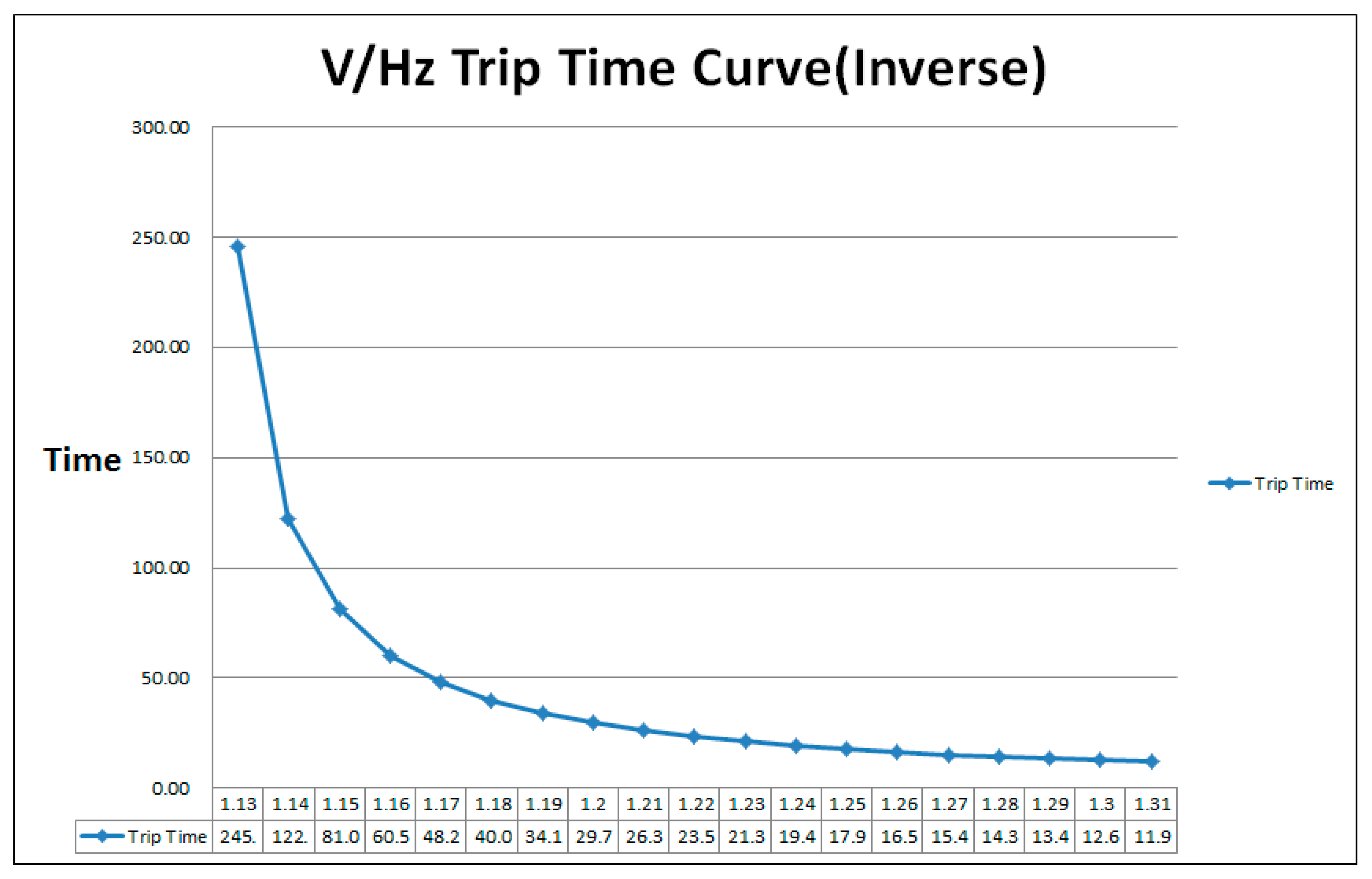

4.5. Over-Flux (V/Hz) Test

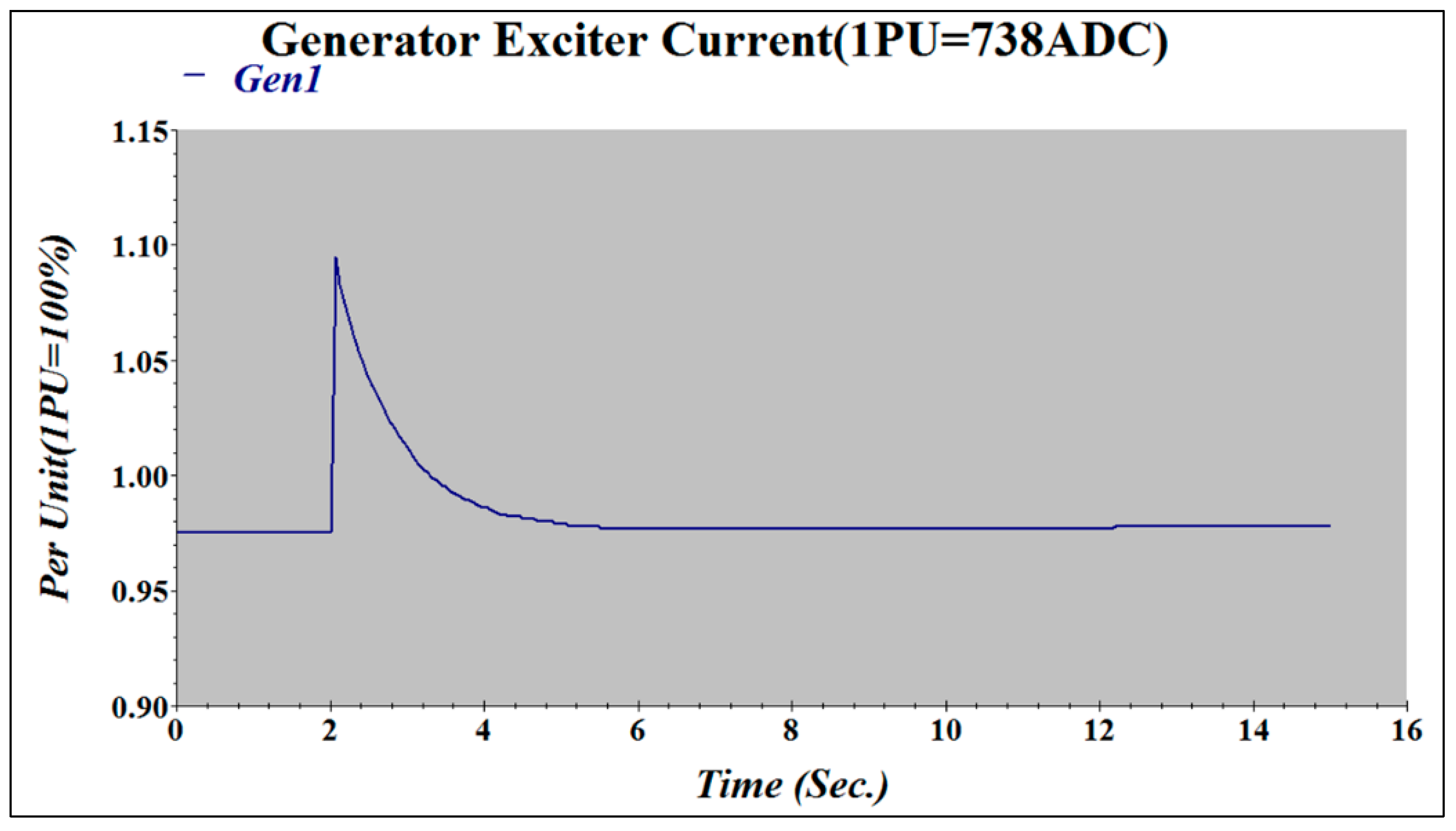

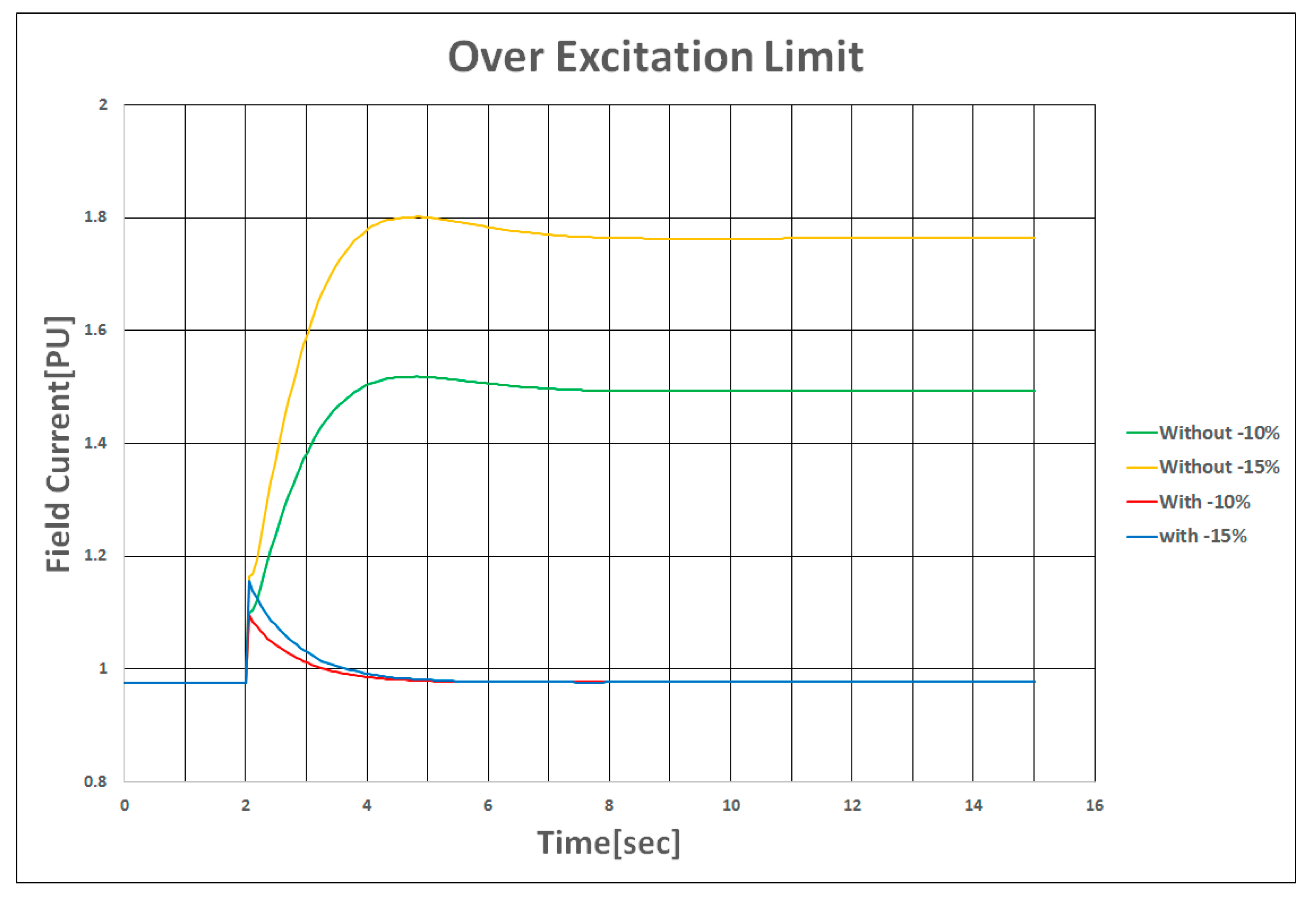

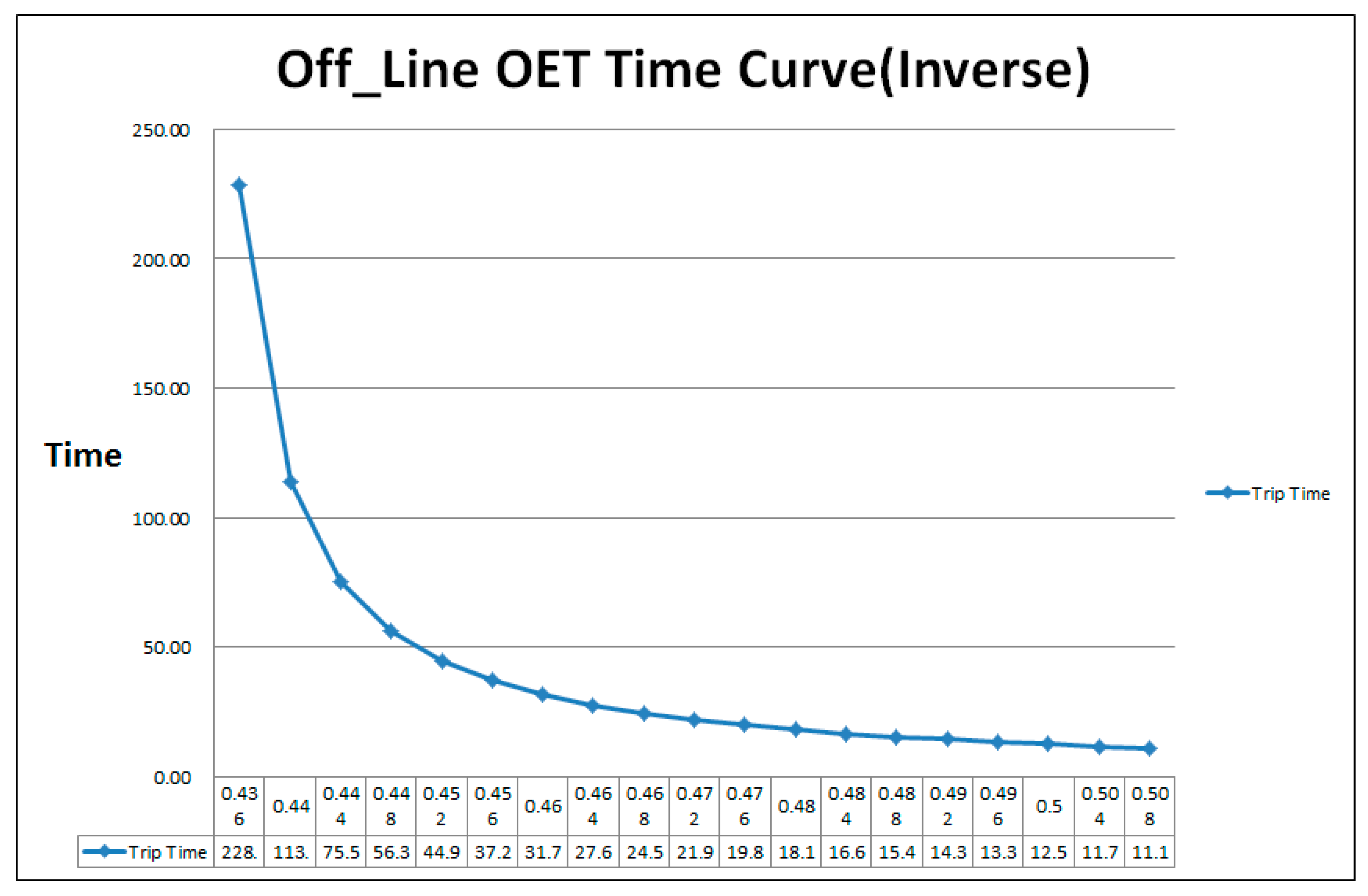

4.6. Over-Excitation Protection Test

5. Cost-Effective Redundant Digital Excitation Control System and Test Bed Experiment at Kanudi Power Plant in Papua New Guinea

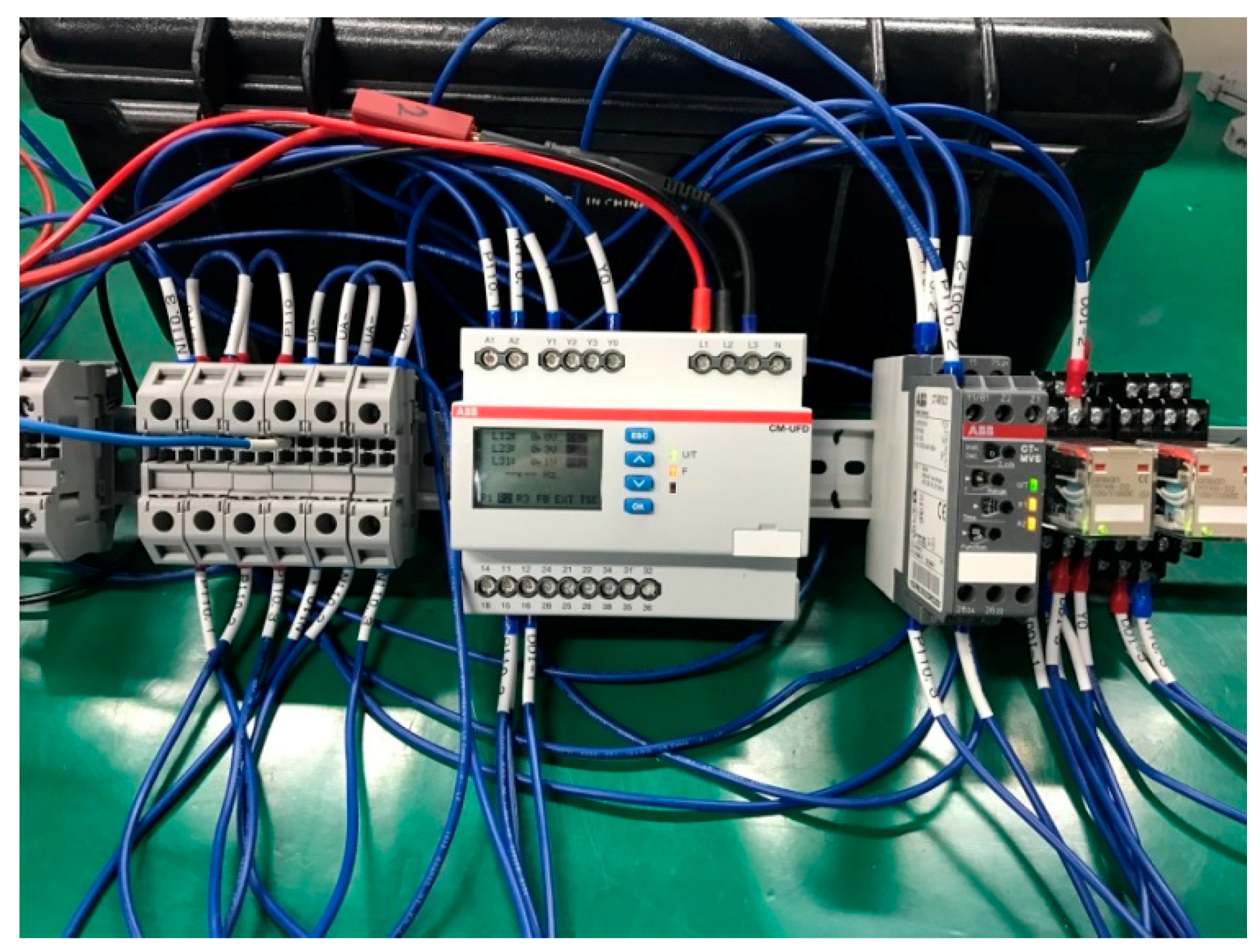

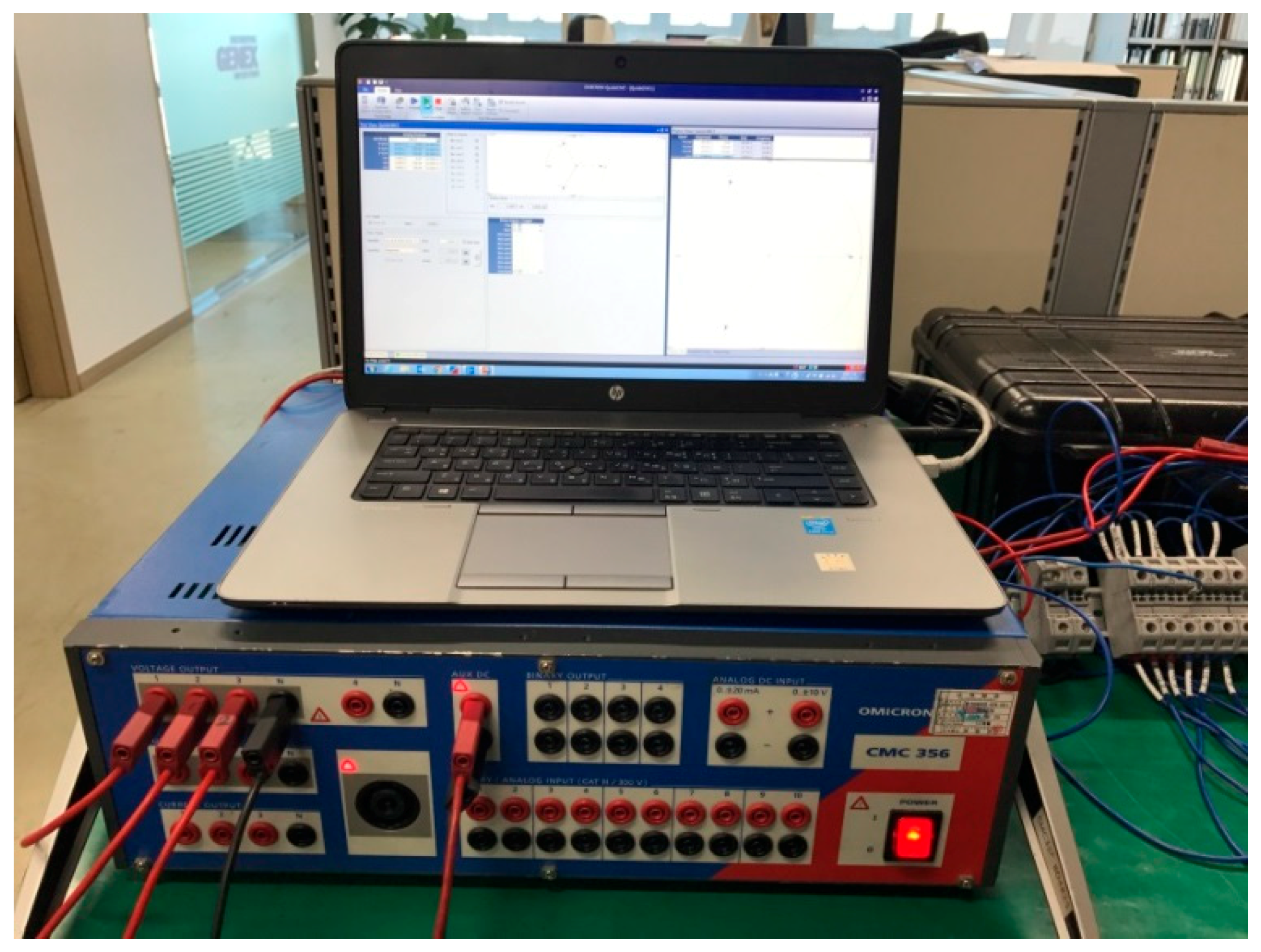

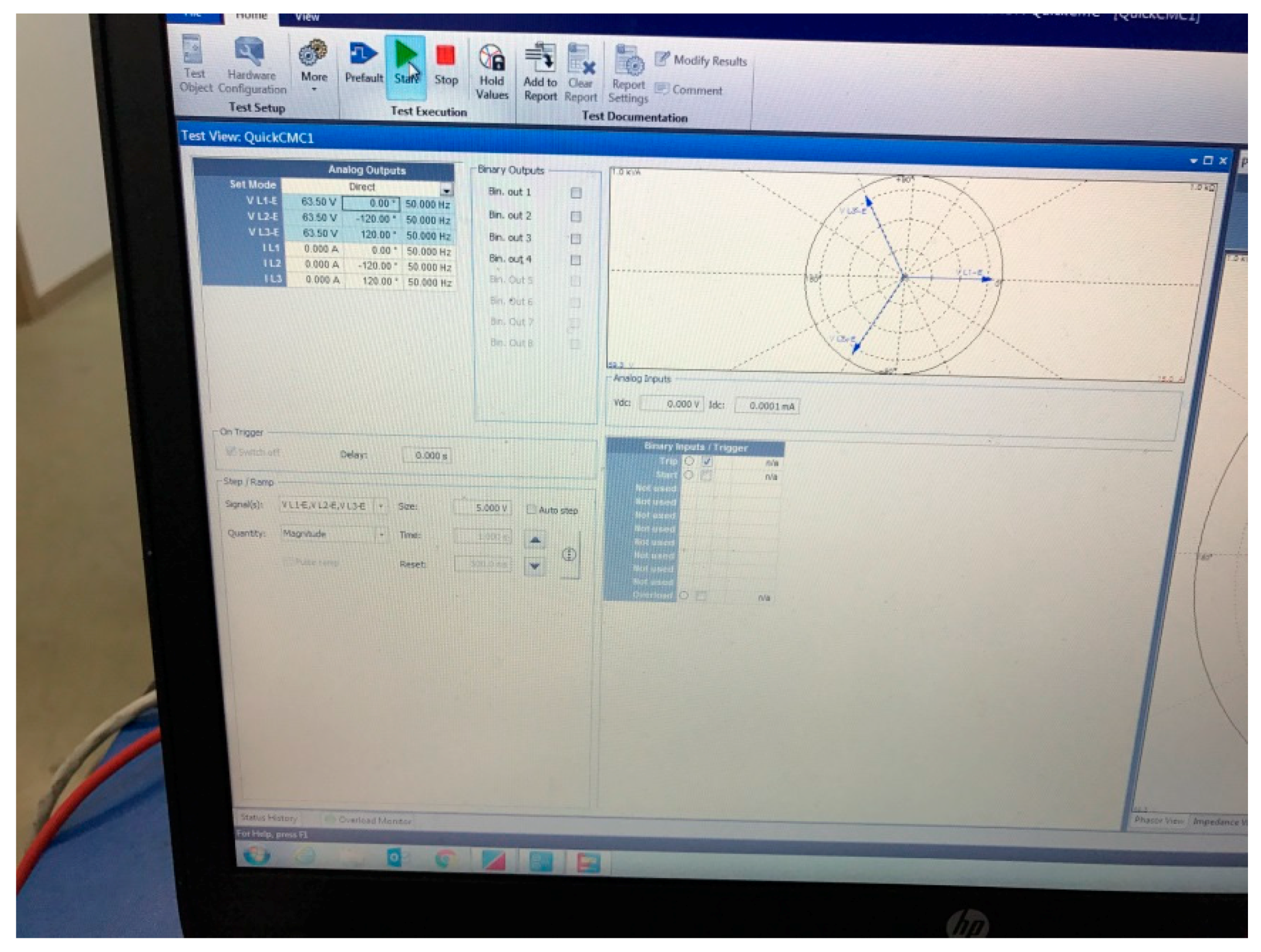

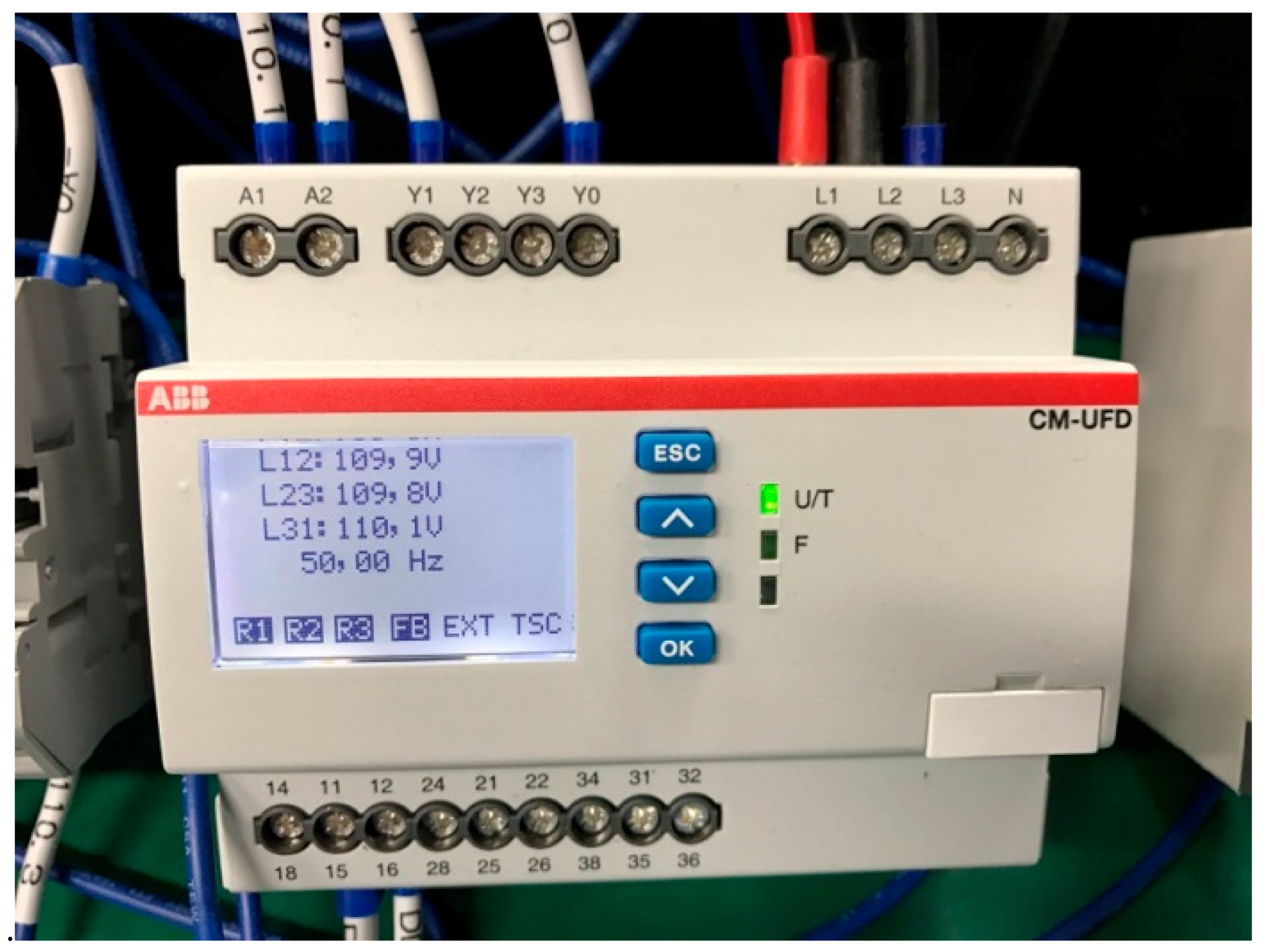

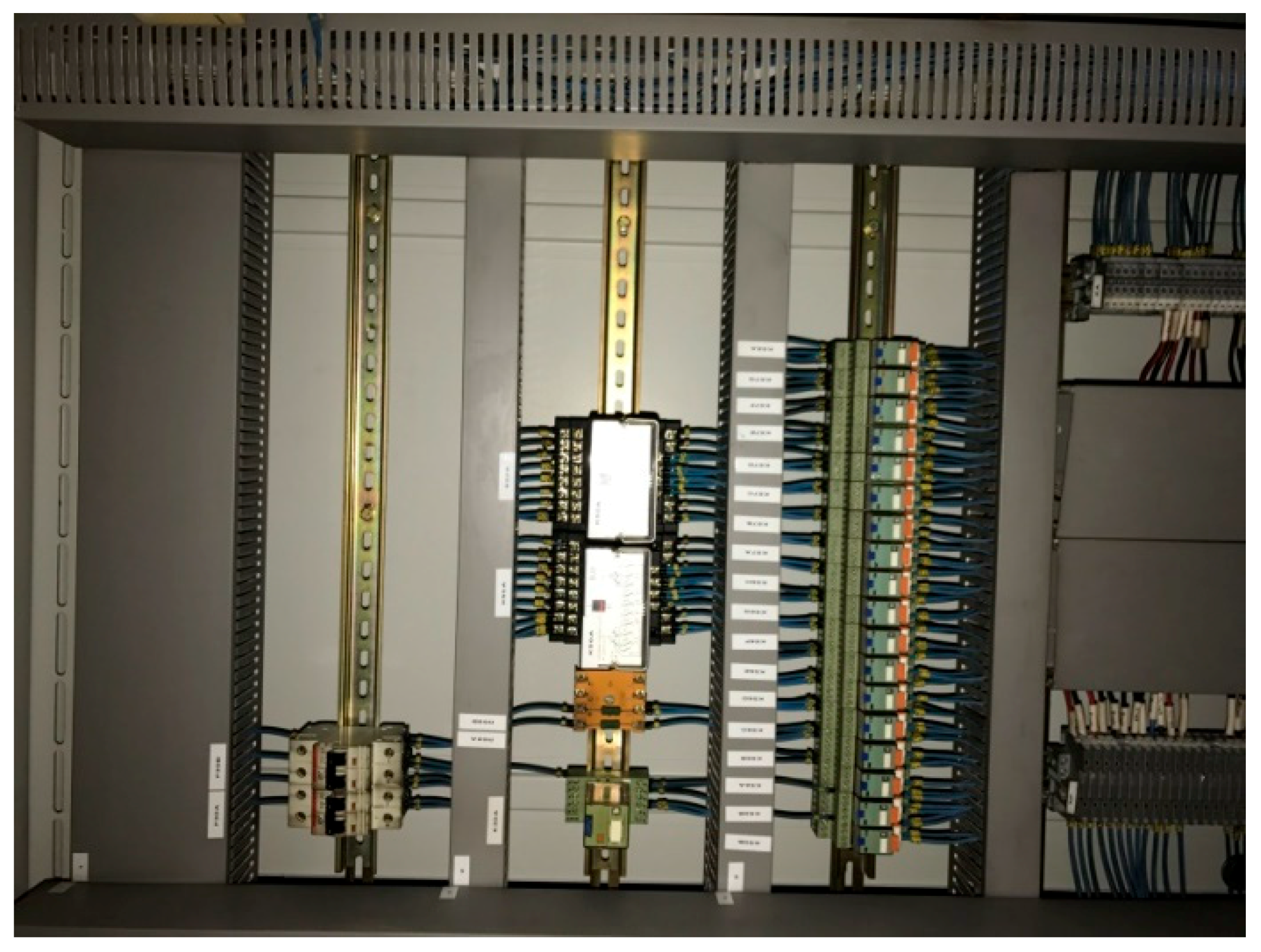

5.1. Test Bed Replacing Protective Relay at Kanudi Power Plant and Validation

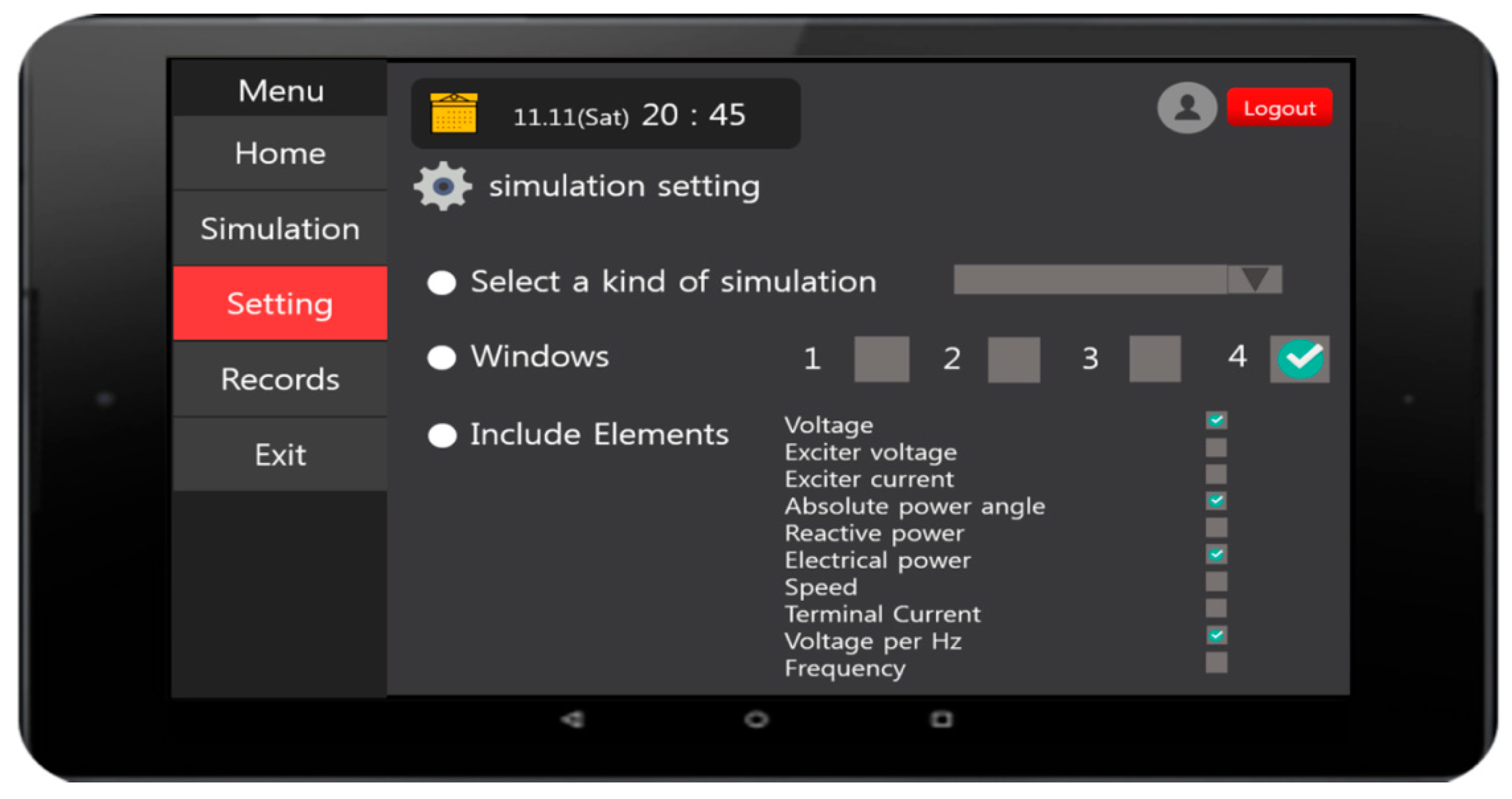

5.2. An Environment Monitoring Application for Smart Devices of Java Android-Based Excitation System

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| The ANSI | American National Standard Institute |

| AVR | Auto Voltage Regulator |

| Device number 27 | Under Voltage (IEEE Std C37.2-1996) |

| Device number 81 | Under Frequency (IEEE Std C37.2-1996) |

| ETAP | Electrical Transient Analyzer Program |

| FCR | Field Current Regulator |

| HMI | Human-Machine Interface |

| IoT | Internet of Things |

| ICT | Information and Communications Technologies |

| KEPCO | Korea Electric Power Corporation’s |

| OEL | Over Excitation Limit |

| OET | Over Excitation Trip |

| UEL | Under Excitation Limit |

References

- Lee, H.-G. Algorithm Development and Test Bed of Redundant Digital Excitation Control System. Ph.D. Thesis, University of Seoul, Seoul, Korea, 2018; pp. 1–31. (In Korean). [Google Scholar]

- Basler, M.J. Excitation System: The Current State of the Art. In Proceedings of the 2006 IEEE Power Engineering Society General Meeting, Montreal, QC, Canada, 18–22 June 2006. [Google Scholar]

- IEEE Digital Excitation System Task Force. Computer Models for Representation of Digital-Based Excitation Systems. IEEE Trans. Energy Convers. 1996, 11, 607–615. [Google Scholar]

- Park, J.; Harley, R.; Venayagamoorthy, G. Indirect Adaption control for Synchronous Generator: Comparison of MLP/RBF Neural Networks Approach with Lyapunov Stability Analysis. IEEE Trans. Neural Netw. 2004, 15, 460–464. [Google Scholar] [CrossRef] [PubMed]

- Venayagamoorthy, G.; Harley, R. Two Separate Continually Online-Tranied Neurocont rollers for Excitation and Turbine Control of a Turbogenerator. IEEE Trans. Ind. Appl. 2002, 38, 887–893. [Google Scholar] [CrossRef]

- Hariri, A.; Malik, O.P. Self-learning Adaptive-Network-Based Fuzzy Logic Power System Stabilizer in Multi-Machine Power System. Eng. Intell. Syst. 2001, 9, 129–136. [Google Scholar]

- Shamsollahi, P.; Malik, O.P. Real-Time Implementation and Experimental Studies of a Neural Adaptive Power System Stabilizer. IEEE Trans. Energy Convers. 1999, 14, 737–742. [Google Scholar] [CrossRef]

- Shamsollahi, P.; Malik, O.P. Generalized Neuron-Based Adaptive PSS for Multi machine Environment. IEEE Trans. Power Syst. 2005, 20, 358–366. [Google Scholar]

- IEEE Task Force on Excitat Ion Limiters. Under excitation Limiter Models for Power System Stability studies. IEEE Trans. Energy Convers. 1995, 10, 524–531. [Google Scholar]

- Ramakrishnan, K. Delay-Dependent Stability of Networked Generator-Excitation Control Systems: An LMI Based Approach. IFAC-PapersOnLine 2016, 49, 431–436. [Google Scholar] [CrossRef]

- Kundur, P.; Balu, N.J.; Lauby, M.G. Power System Stability and Control; McGraw-Hill: New York, NY, USA, 1994; Volume 23. [Google Scholar]

- Shah, D.; Nandi, S.; Neti, P. Stator-interturn-fault detection of doubly fed induction generators using rotor-current and search-coil-voltage signature analysis. IEEE Trans. Ind. Appl. 2009, 45, 1831–1842. [Google Scholar] [CrossRef]

- Hemmati, S.; Kojoori, S.S.; Saied, S.; Lipo, T.A. Modelling and experimental validation of internal short-circuit fault in salient-pole synchronous machines using numerical gap function including stator and rotor core saturation. IET Electr. Power Appl. 2013, 7, 391–399. [Google Scholar] [CrossRef]

- Hao, L.; Sun, Y.; Qiu, A.; Wang, X. Steady-state calculation and online monitoring of interturn short circuit of field windings in synchronous machines. IEEE Trans. Energy Convers. 2012, 27, 128–138. [Google Scholar] [CrossRef]

- Saha, S.; Aldeen, M.; Tan, C.P. Unsymmetrical fault diagnosis in transmission/distribution networks. Int. J. Electr. Power Energy Syst. 2013, 45, 252–263. [Google Scholar] [CrossRef]

- He, Z.; Fu, L.; Lin, S.; Bo, Z. Fault detection and classification in EHV transmission line based on wavelet singular entropy. IEEE Trans. Power Deliv. 2010, 25, 2156–2163. [Google Scholar] [CrossRef]

- Saha, S.; Aldeen, M.; Tan, C.P. Fault detection in transmission networks of power systems. Int. J. Electr. Power Energy Syst. 2011, 33, 887–900. [Google Scholar] [CrossRef]

- Saha, S.; Aldeen, M. Generic scalable fault diagnosis system for multimachine power grids. Int. J. Electr. Power Energy Syst. 2014, 59, 36–57. [Google Scholar] [CrossRef]

- Saha, S.; Aldeen, M. Modelling of Transmission Line Faults in Power System. In Proceedings of the 31st IASTED International Conference on Modelling, Identification and Control, Innsbruck, Austria, 14–16 February 2011. [Google Scholar]

- Mahat, P.; Zhe, C.; Bak-Jensen, B.; Bak, C.L. A simple adaptive overcurrent protection of distribution systems with distributed generation. IEEE Trans. Smart Grid 2011, 2, 428–437. [Google Scholar] [CrossRef]

- Chen, W.-H.; Liu, C.-W.; Tsai, M.-S. On-line fault diagnosis of distribution substations using hybrid cause-effect network and fuzzy rule-based method. IEEE Trans. Power Deliv. 2000, 15, 710–717. [Google Scholar] [CrossRef]

- Thukaram, D.; Khincha, H.; Vijaynarasimha, H. Artificial neural network and support vector machine approach for locating faults in radial distribution systems. IEEE Trans. Power Deliv. 2005, 20, 710–721. [Google Scholar] [CrossRef]

- Baxevanos, I.S.; Labridis, D.P. Implementing multiagent systems technology for power distribution network control and protection management. IEEE Trans. Power Deliv. 2007, 22, 433–443. [Google Scholar] [CrossRef]

- Salim, R.H.; de Oliveira, K.; Filomena, A.D.; Resener, M.; Bretas, A.S. Hybrid fault diagnosis scheme implementation for power distribution systems automation. IEEE Trans. Power Deliv. 2008, 23, 1846–1856. [Google Scholar] [CrossRef]

- Xiang, C.; Huang, E.X.; Yang, Z.; Wei, D. Fault Diagnosis for Excitation System Based on Wavelet Analyses. In Proceedings of the Second International Conference on Innovative Computing, Information and Control (ICICIC’07), Kumamoto, Japan, 5–7 September 2007; p. 611. [Google Scholar]

- Saha, S.; Aldeen, M. Excitation System Fault Diagnosis in Multi-Machine Power Grids. In Proceedings of the 2013 Australasian Universities Power Engineering Conference (AUPEC 2013), Hobart, Australia, 29 September–3 October 2013; University of Tasmania: Hobart, Australia, 2013. [Google Scholar]

- Aldeen, M.; Saha, S.; Evans, R.J. Faults Detection and Mitigation in Excitation Control of Synchronous Machines in Large-Scale Power Grids. In Proceedings of the 2015 IEEE 8th GCC Conference and Exhibition, Muscat, Oman, 1–4 February 2015. [Google Scholar]

- Khaitan, S. On-Line Cascading Event Tracking and Avoidance Decision Support Tool. Ph.D. Thesis, Iowa State University, Ames, IA, USA, 2008. [Google Scholar]

- Farnham, S.B.; Schenectady, N.Y.; Swarthout, R.W. Field excitation in relation to machine and system operation. Trans. Am. Inst. Electr. Eng. 1953, 72, 1215–1223. [Google Scholar]

- IEEE Std. 421.5-2005. IEEE Recommended Practice for Excitation System Models for Power System Stability Studies; IEEE: Piscataway, NJ, USA, 2006. [Google Scholar]

- Guttromson, R.T. Modeling distributed energy resource dynamics on the transmission system. IEEE Trans. Power Syst. 2002, 17, 1148–1153. [Google Scholar] [CrossRef]

- Teleke, S.; Abdulahovic, T.; Thiringer, T.; Svensson, J. Dynamic performance comparison of synchronous condenser and SVC. IEEE Trans. Power Deliv. 2008, 23, 1606–1612. [Google Scholar] [CrossRef]

- Vieira, J.C.; Freitas, W.; Xu, W.; Morelato, A. An investigation on the nondetection zones of synchronous distributed generation anti-islanding protection. IEEE Trans. Power Deliv. 2008, 23, 593–600. [Google Scholar] [CrossRef]

- Taborda, J. Comparison between Detailed and Simplified AC Exciter Models. In Proceedings of the 2010 IEEE PES General Meeting, Providence, RI, USA, 25–29 July 2010. [Google Scholar]

- Koo, K.L. Modeling and Cosimulation of AC Generator Excitation and Governor Systems Using Simulink Interfaced to PSS/E. In Proceedings of the 2004 IEEE PES Power Systems Conference and Exposition, New York, NY, USA, 10–13 October 2004; Volume 2, pp. 1095–1100. [Google Scholar]

- Lindenmeyer, D.; Moshref, A.; Schaeffer, M.C.; Benge, A. Simulation of the start-up of a Hydro Power plant for the emergency power supply of a nuclear powerstation. IEEE Trans. Power Syst. 2001, 16, 163–169. [Google Scholar] [CrossRef]

- Bhaskar, R.; Crow, M.L.; Ludwig, E.; Erickson, K.T.; Shah, K.S. Nonlinear parameterestimation of excitation systems. IEEE Trans. Power Syst. 2000, 15, 1225–1231. [Google Scholar] [CrossRef]

- Byoung-Kon, C.; Hsiao-Dong, C.; Hongbin, W.; Hua, L.; Yu, D.C. Exciter Model Reduction and Validation for Large-Scale Power System Dynamic Security Assessment. In Proceedings of the 2008 IEEE PES General Meeting—Conversion and Delivery of Electrical Energy in the 21st Century, Pittsburgh, PA, USA, 20–24 July 2008. [Google Scholar]

- Rasouli, M.; Karrari, M. Nonlinear identification of a brushless excitationsystem via field tests. IEEE Trans. Energy Convers. 2004, 19, 733–740. [Google Scholar] [CrossRef]

- IEEE Committee. Computer representation of excitation systems. IEEE Trans. Power Appar. Syst. 1968, 87, 1460–1464. [Google Scholar]

- Glaninger-Katschnig, A.; Nowak, F.; Bachle, M.; Taborda, J. New Digital Excitation System Models in Addition to IEEE.421.5 2005. In Proceedings of the 2010 IEEE PES General Meeting, Providence, RI, USA, 25–29 July 2010. [Google Scholar]

- Hajagos, L.M.; Basler, M.J. Changes to IEEE 421.5 Recommended Practice for Excitation System Models for Power System Stability Studies. In Proceedings of the 2005 IEEE Power Engineering Society General Meeting, San Francisco, CA, USA, 16 June 2005; pp. 334–336. [Google Scholar]

- Murdoch, A.; Boukarim, G.E.; D’Antonio, M.J.; Zeleznik, J. Use of the Latest 421.5 Standards for Modeling Today’s Excitation Systems. In Proceedings of the 2005 IEEE PES General Meeting, San Francisco, CA, USA, 16 June 2005; Volume 1, pp. 989–994. [Google Scholar]

- Máslo, K.; Kasembe, A.; Kolcun, M. Simplification and unification of IEEE standard models for excitation systems. Electr. Power Syst. Res. 2016, 140, 132–138. [Google Scholar] [CrossRef]

- Liu, J.; Miura, Y.; Bevrani, H.; Ise, T. Enhanced Virtual Synchronous Generator Control for Parallel Inverters in Microgrids. IEEE Trans. Smart Grid 2017, 8, 2268–2277. [Google Scholar] [CrossRef]

- Kim, K.; Schaefer, R.C. Tuning a PID Controller for a Digital Excitation Control System. IEEE Trans. Ind. Appl. 2005, 41, 485–492. [Google Scholar] [CrossRef]

- Lee, H.-G. Development of Cost-Effective Redundant Digital Excitation Control System in Small Power Plants. Master’s Thesis, University of Seoul, Seoul, Korea, 2014; pp. 1–26. (In Korean). [Google Scholar]

- Godhwani, A.; Basler, M.J. A Digital Excitation Control System for Use on Brushless Excited Synchronous Generators. IEEE Trans. Energy Convers. 1996, 11, 616–620. [Google Scholar] [CrossRef]

- Kim, K.; Rao, P.; Burnworth, J.A. Self-Tuning of the PID Controller for a Digital Excitation Control System. IEEE Trans. Ind. Appl. 2010, 46, 1518–1524. [Google Scholar]

- Godhwani, A.; Basler, M.J.; Kim, K.; Eberly, T.W. Commissioning Experience with a Modern Digital Excitation System. IEEE Trans. Energy Convers. 1998, 13, 183–187. [Google Scholar] [CrossRef]

- Hingston, R.S.; Ham, P.A.; Green, N.J. Development of a Digital Excitation Control System. In Proceedings of the Fourth International Conference on Electrical Machines and Drives, London, UK, 13–15 September 1989. [Google Scholar]

- Machowski, J.; Bialek, J.W.; Robak, S.; Bumby, J.R. Excitation control system for use with synchronous generators. IEE Proc. Gener. Transm. Distrib. 1998, 145, 537–546. [Google Scholar] [CrossRef]

- Kim, K.; Basler, M.J.; Godhwani, A. Supplemental Control in a Modern Digital Excitation System. In Proceedings of the 2000 IEEE Power Engineering Society Winter Meeting, Singapore, 23–27 January 2000; Volume 1, pp. 1–4. [Google Scholar]

- Kanniah, J.; Malik, O.P.; Hope, G.S. Excitation Control of Synchronous Generators Using Adaptive Eegulators Part I—Theory and Simulation Results. IEEE Trans. Power Appar. Syst. 1984, 5, 897–903. [Google Scholar] [CrossRef]

- Yang, L.; Wang, J.; Ma, Y.; Wang, J.; Zhang, X.; Tolbert, L.M.; Wang, F.F.; Tomsovic, K. Three-Phase Power Converter-based Real-Time Synchronous Generator Emulation. IEEE Trans. Power Electron. 2017, 32, 1651–1665. [Google Scholar] [CrossRef]

- Zhao, H.; Yang, Q.; Zeng, H. Multi-Loop Virtual Synchronous Generator Control of Inverter-based DGs under Microgrid Dynamics. IET Gener. Transm. Distrib. 2017, 11, 795–803. [Google Scholar] [CrossRef]

- Serban, I.; Ion, C.P. Microgrid control based on a grid-forming inverter operating as virtual synchronous generator with enhanced dynamic response capability. Int. J. Electr. Power Energy Syst. 2017, 89, 94–105. [Google Scholar] [CrossRef]

- Nasiri, M.; Milimonfared, J.; Fathi, S.H. Modeling, analysis and comparison of TSR and OTC methods for MPPT and power smoothing in permanent magnet synchronous generator-based wind turbines. Energy Convers. Manag. 2014, 86, 892–900. [Google Scholar] [CrossRef]

- Lee, H.G.; Kim, H.S. A Method for Replacing Protective Relay at Kanudi Power Plant and Validation. In Advances in Computer Science and Ubiquitous Computing. Lecture Notes in Electrical Engineering; Springer: Singapore, 2017; Volume 474, pp. 143–148. [Google Scholar]

- Lee, H.G.; Kim, H.S. Implementation of Redundant Digital Excitation Control System Algorithm. In Advances in Computer Science and Ubiquitous Computing. Lecture Notes in Electrical Engineering; Springer: Singapore, 2017; Volume 474, pp. 131–136. [Google Scholar]

- Lee, H.G.; Kim, H.S. Cost-Effective Redundant Digital Excitation Control System. In Proceedings of the MUE 2017, Seoul, Korea, 22–24 May 2017; p. 1. [Google Scholar]

| Parameter | Value |

|---|---|

| Rated Capacity | 112,800 [KVA] |

| Rated Voltage and Frequency | 13,800 [V], 60 [Hz] |

| Field Voltage and Current | 300 [V], 900 [A] |

| Power Factor | 0.9 |

| Contents | Terminal Voltage | Frequency | Control Signal |

|---|---|---|---|

| Measurements | 13,785 V | 60 Hz | 1.337 [PU] |

| Contents | Field Current | Field Voltage | - |

| Measurements | 288 A | 66 V | - |

| Contents | Terminal Voltage | Frequency | Control Signal |

|---|---|---|---|

| Measurements | 12,637 V | 60 Hz | 1.335 [PU] |

| Contents | Field Current | Field Voltage | - |

| Measurements | 254 A | 59 V | - |

| Description | P.U | Actual Value |

|---|---|---|

| Inverse Pickup 1 | 1.12 | Generator voltage: 15.45 kV |

| Inverse Pickup 2 | 1.18 | Generator voltage: 16.28 kV |

| Inverse Trip Time | 40 | - |

| Description | P.U | Actual Value |

|---|---|---|

| Inverse Pickup 1 | 0.432 | Field Current: 635.4A |

| Inverse Pickup 2 | 0.45 | Field Current: 380.7A |

| Inverse Trip Time | 50 | - |

| Parameter | Value |

|---|---|

| Rated Capacity | 16,087 [KVA] |

| Rated Voltage and Frequency | 11,000 [V], 50 [Hz] |

| Field Voltage and Current | 243 [V], 377 [A] |

| Power Factor | 0.8 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.-G.; Huh, J.-H. A Cost-Effective Redundant Digital Excitation Control System and Test Bed Experiment for Safe Power Supply for Process Industry 4.0. Processes 2018, 6, 85. https://doi.org/10.3390/pr6070085

Lee H-G, Huh J-H. A Cost-Effective Redundant Digital Excitation Control System and Test Bed Experiment for Safe Power Supply for Process Industry 4.0. Processes. 2018; 6(7):85. https://doi.org/10.3390/pr6070085

Chicago/Turabian StyleLee, Hoon-Gi, and Jun-Ho Huh. 2018. "A Cost-Effective Redundant Digital Excitation Control System and Test Bed Experiment for Safe Power Supply for Process Industry 4.0" Processes 6, no. 7: 85. https://doi.org/10.3390/pr6070085

APA StyleLee, H.-G., & Huh, J.-H. (2018). A Cost-Effective Redundant Digital Excitation Control System and Test Bed Experiment for Safe Power Supply for Process Industry 4.0. Processes, 6(7), 85. https://doi.org/10.3390/pr6070085