Investigation on Reinforcement and Lapping Effect of Fracture Grouting in Yellow River Embankment

Abstract

:1. Introduction

2. Experimental Scheme and Testing Procedure

2.1. Grouting Material Laboratory Experiment

2.1.1. Raw Material

2.1.2. Experimental Scheme

2.1.3. Testing Procedure

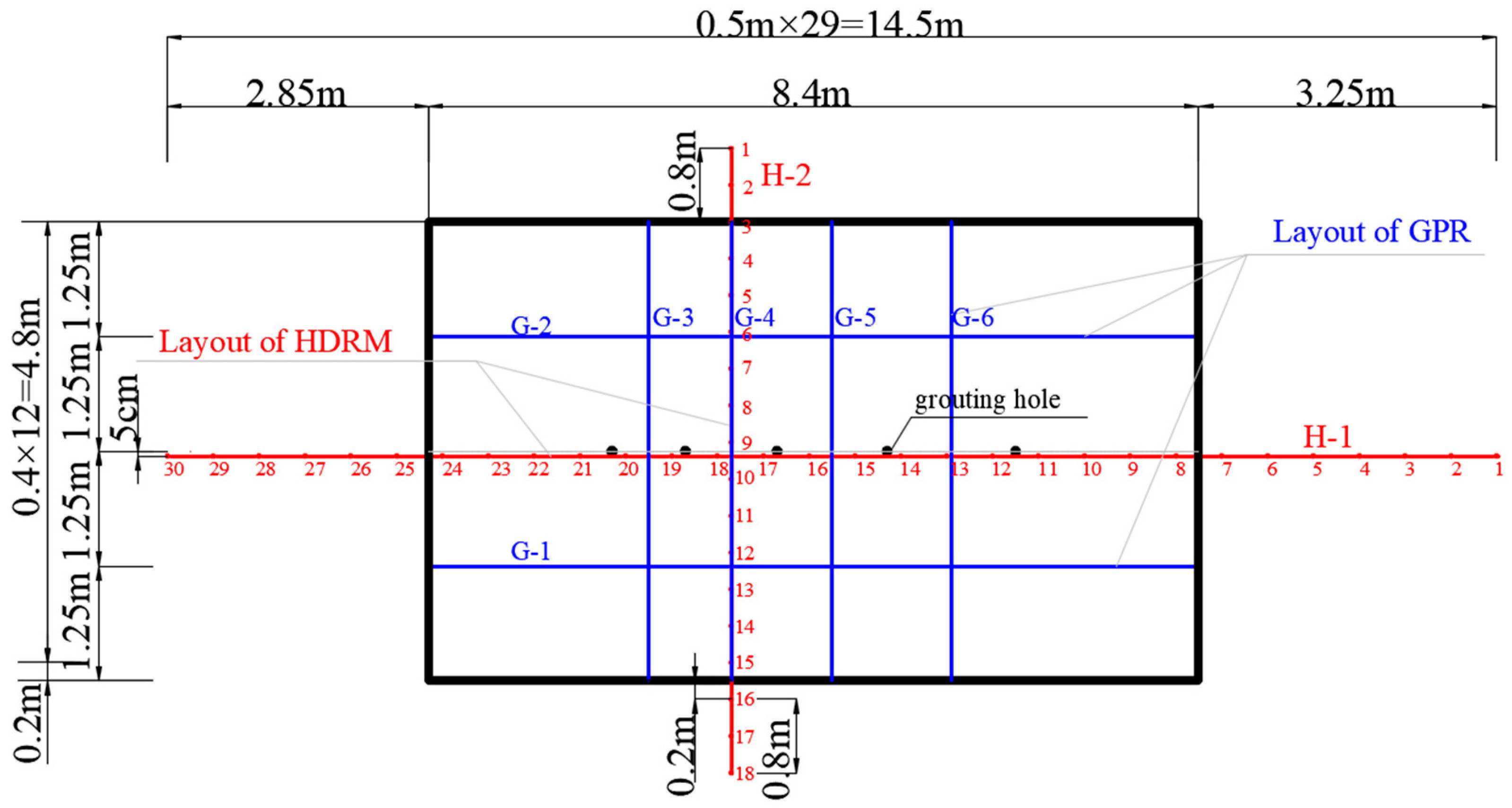

2.2. In Situ Grouting Test

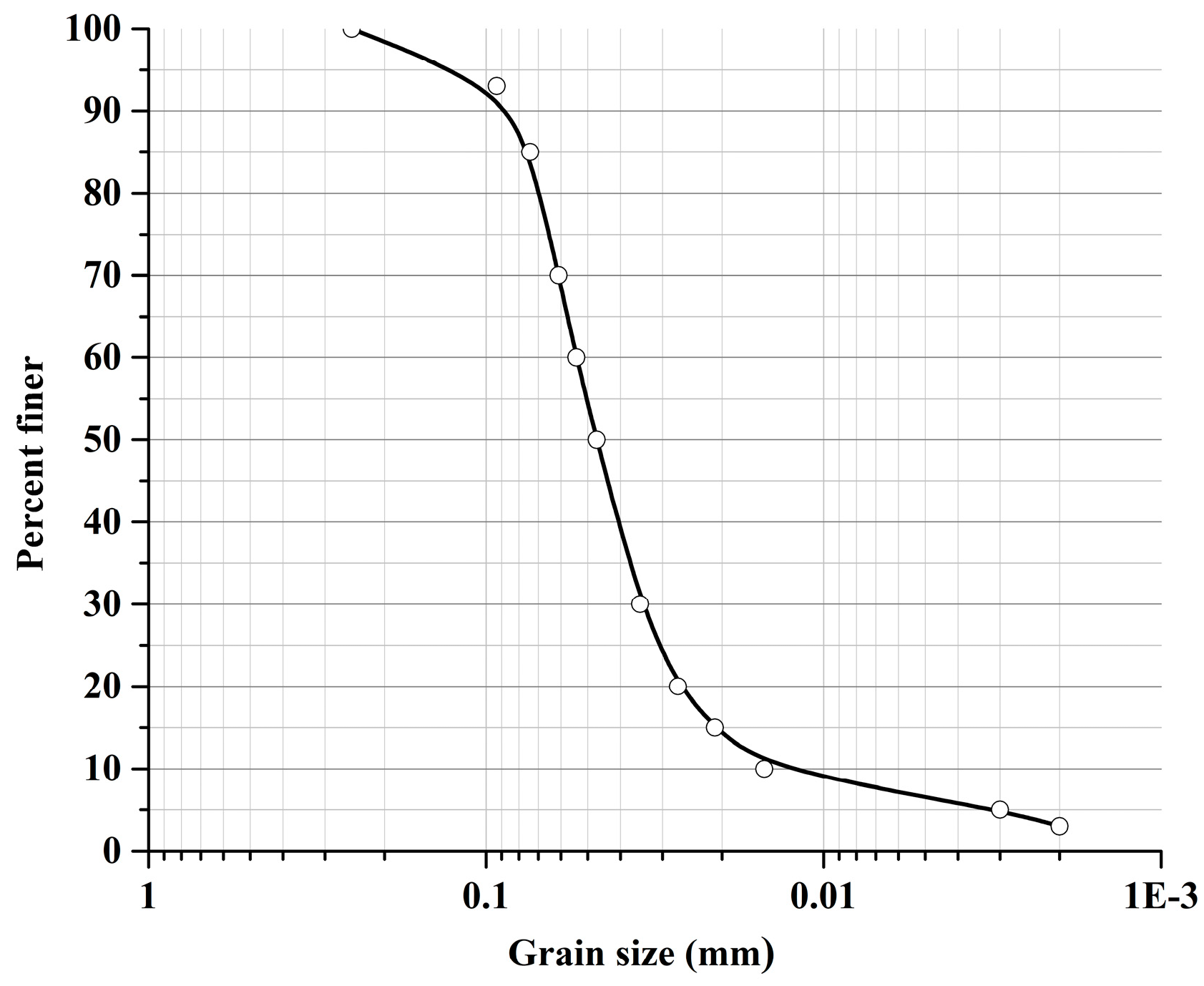

2.2.1. Yellow River Silt

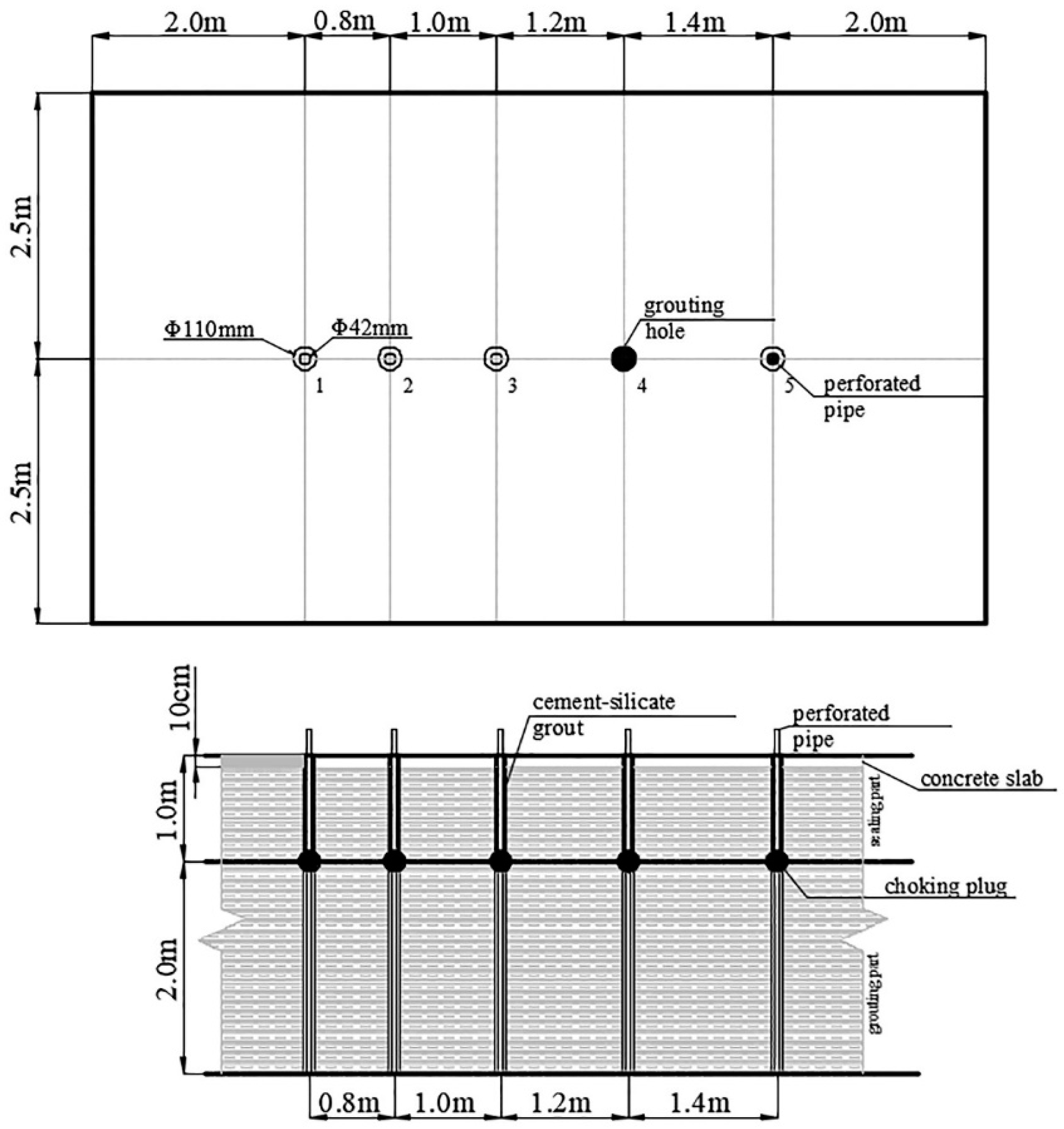

2.2.2. Design of In Situ Grouting Tests

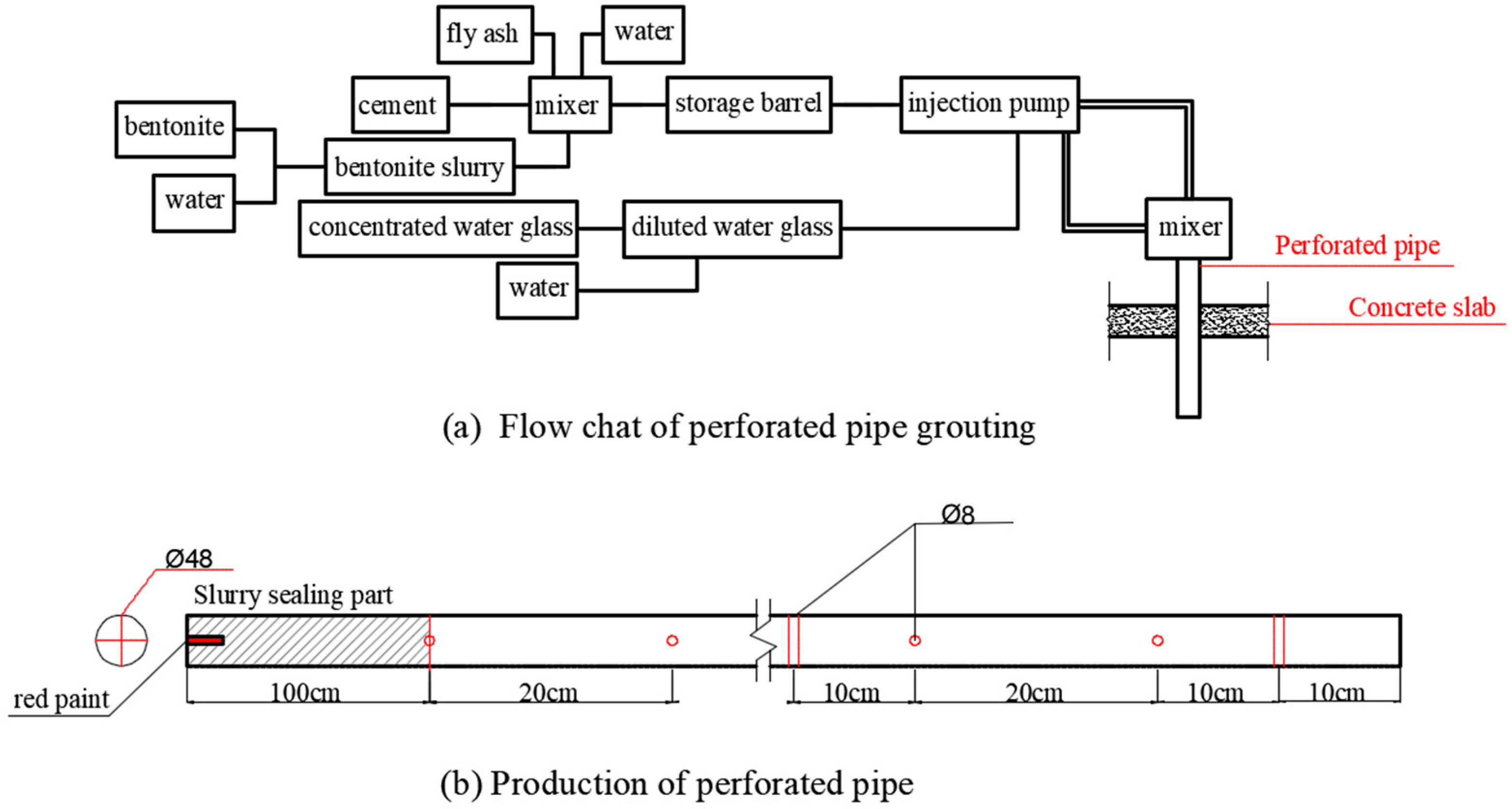

2.2.3. Grouting Procedure

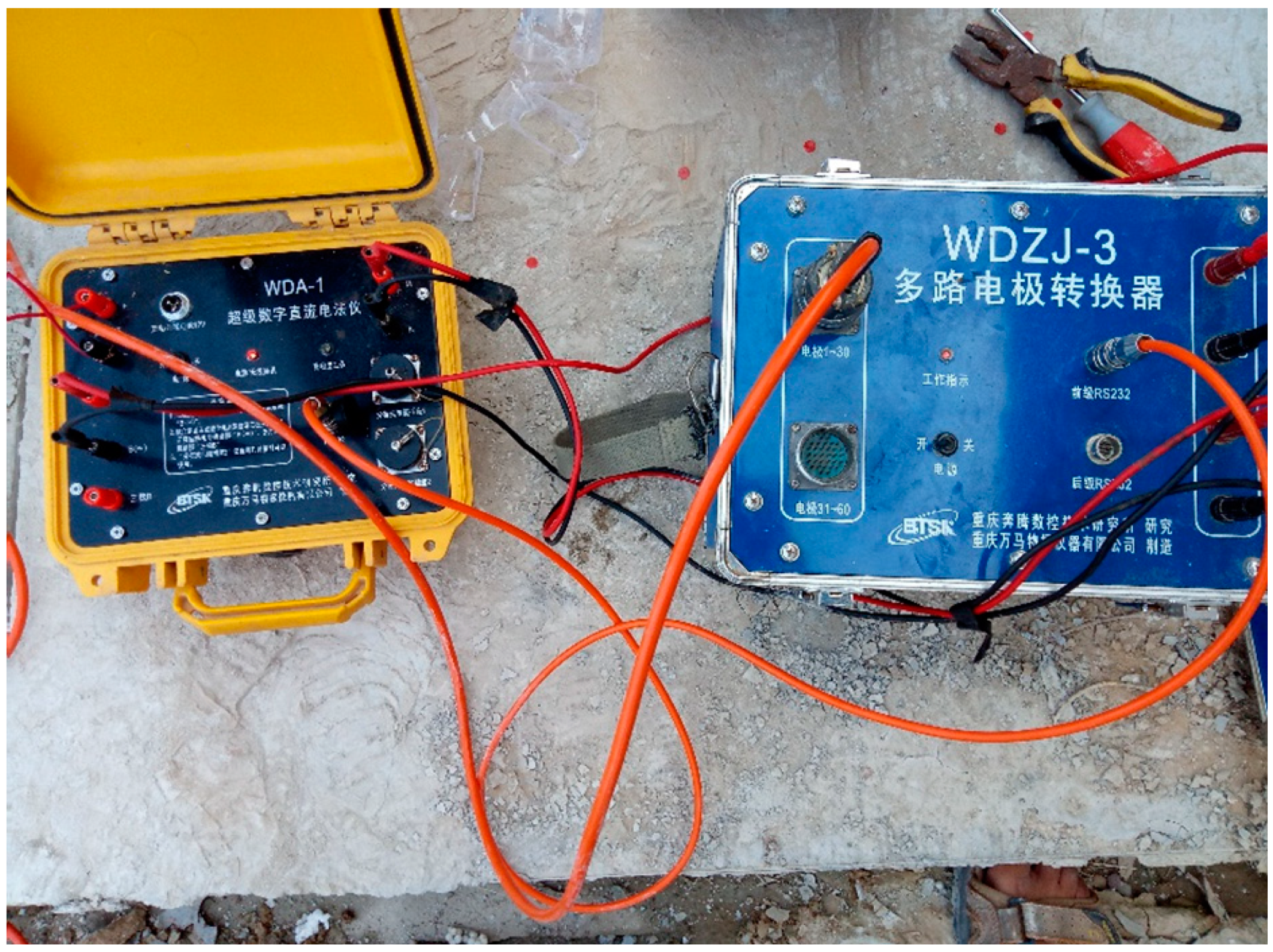

2.2.4. Geophysical Prospecting Method

3. Discussion of Laboratory Results

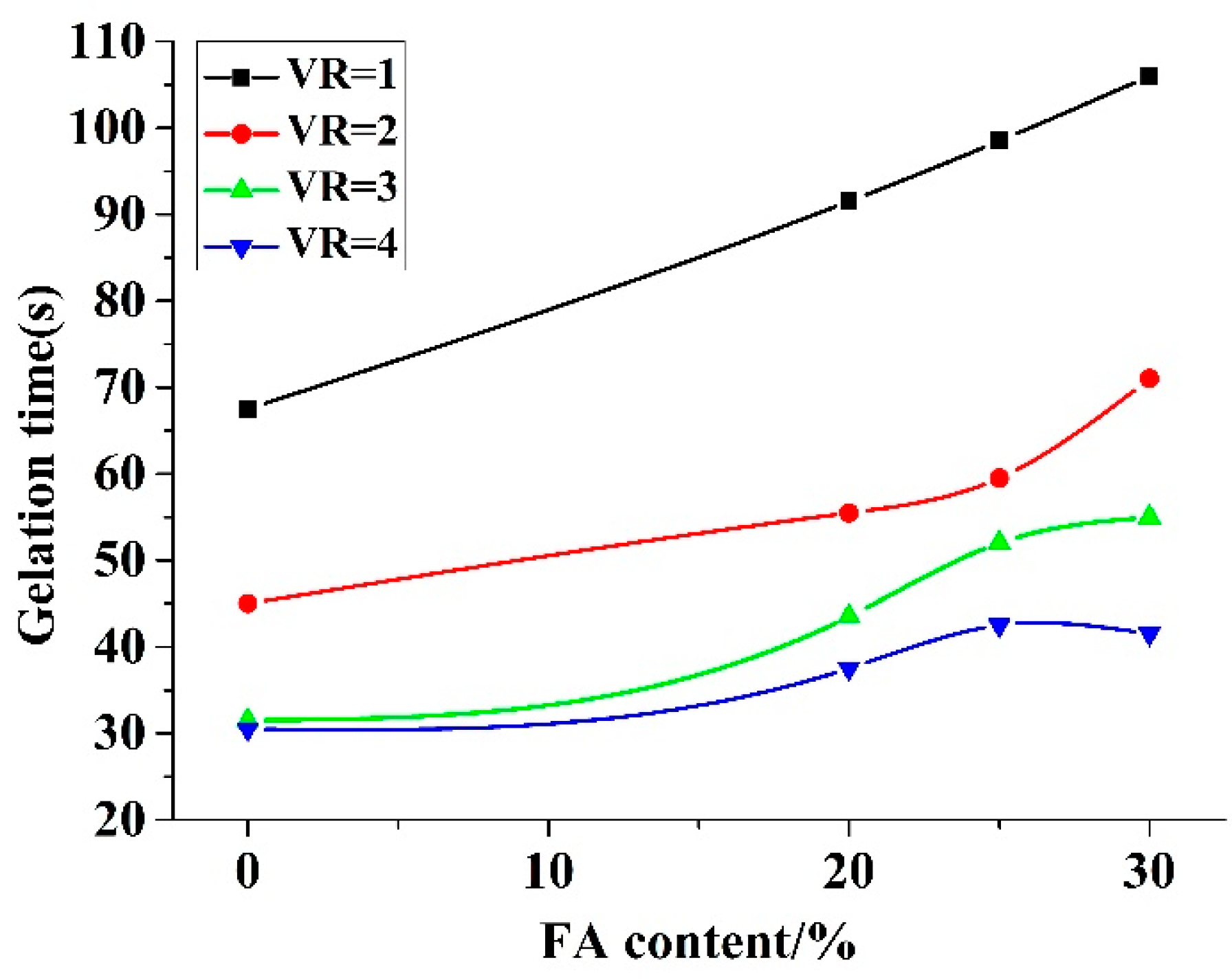

3.1. Gelation Time of the Slurry

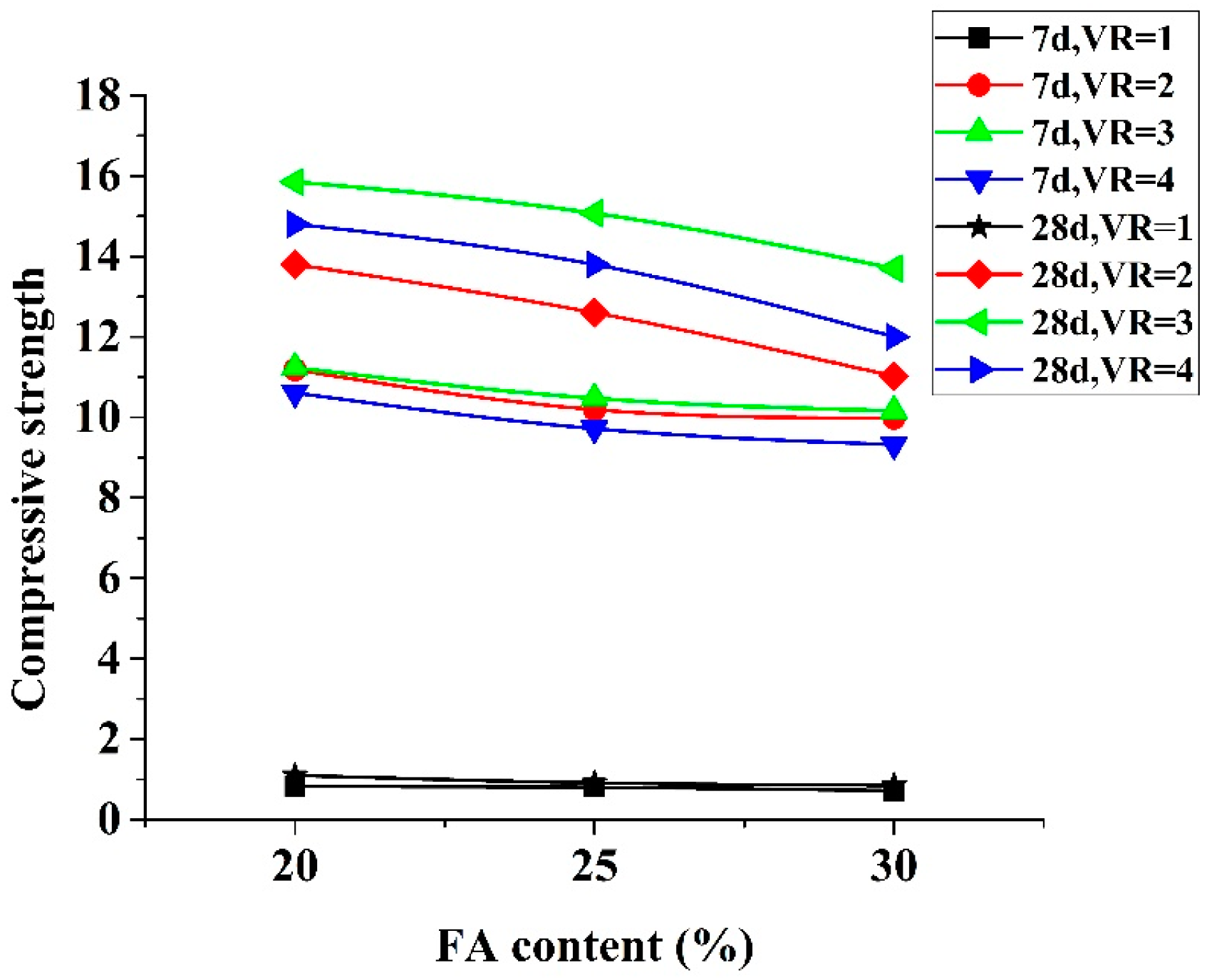

3.2. Strength of the Specimen

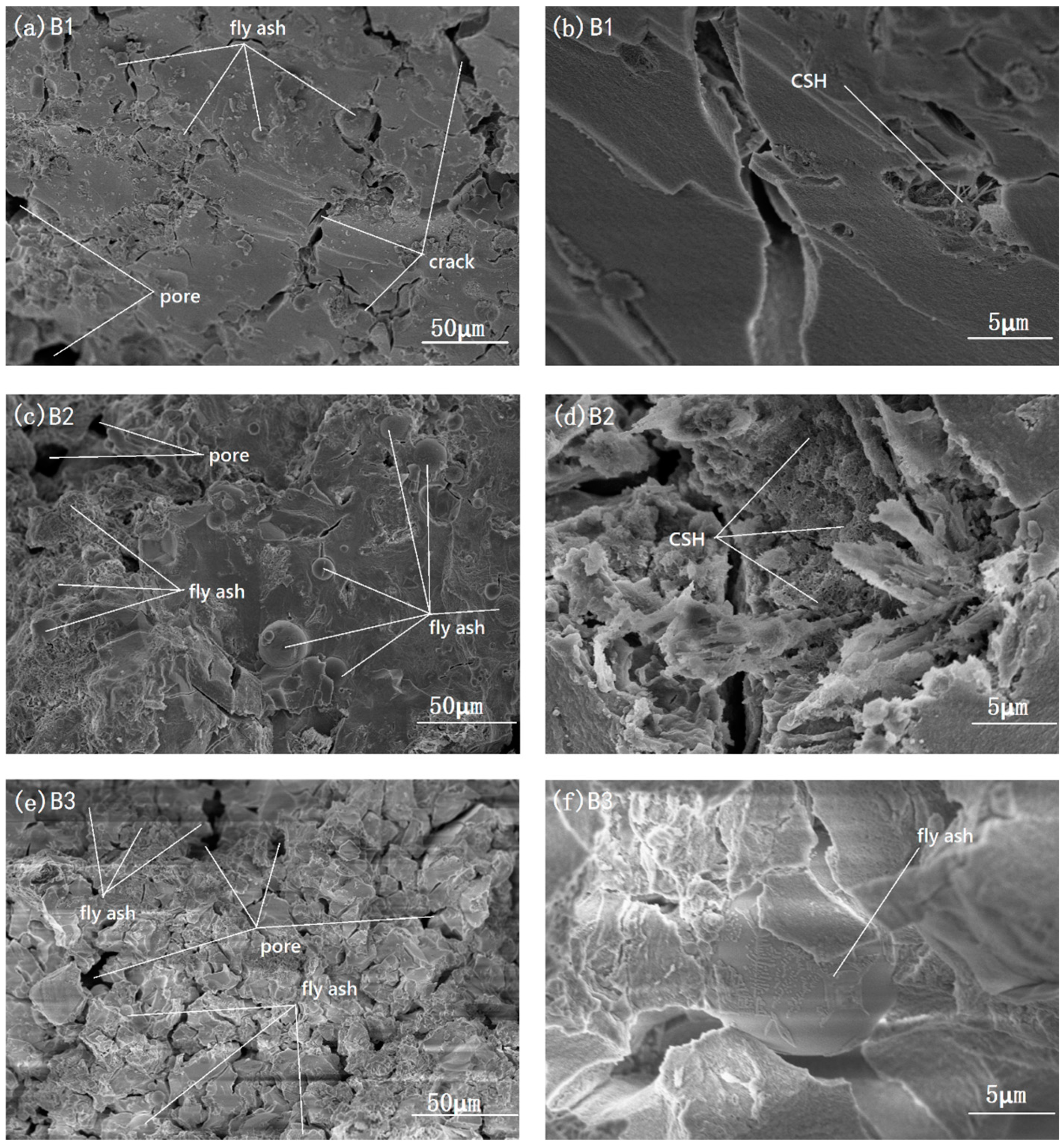

3.3. SEM Analysis of Specimen

4. Discussion of In Situ Test Results

4.1. Geophysical Prospecting for Grouting Effectiveness

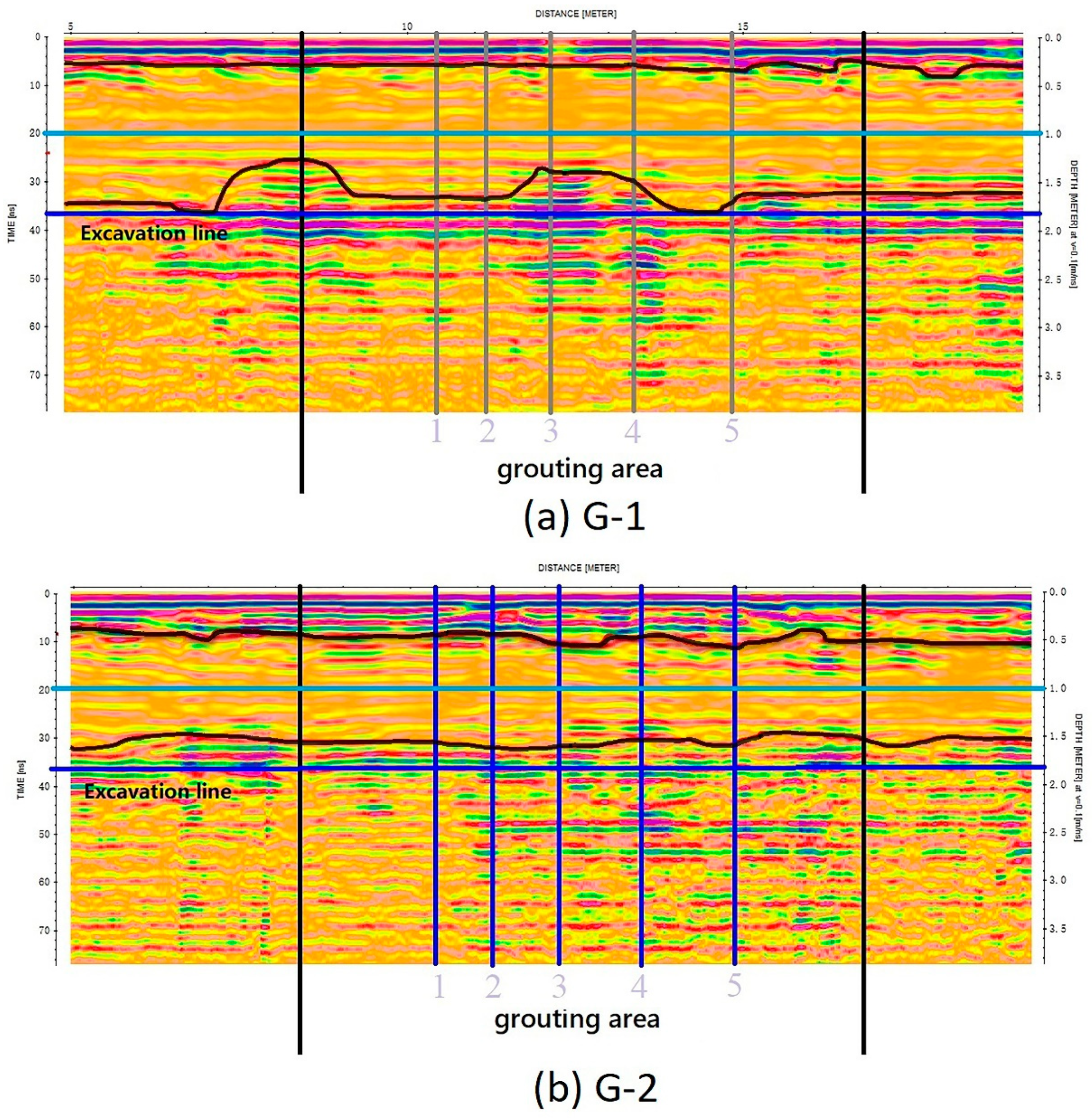

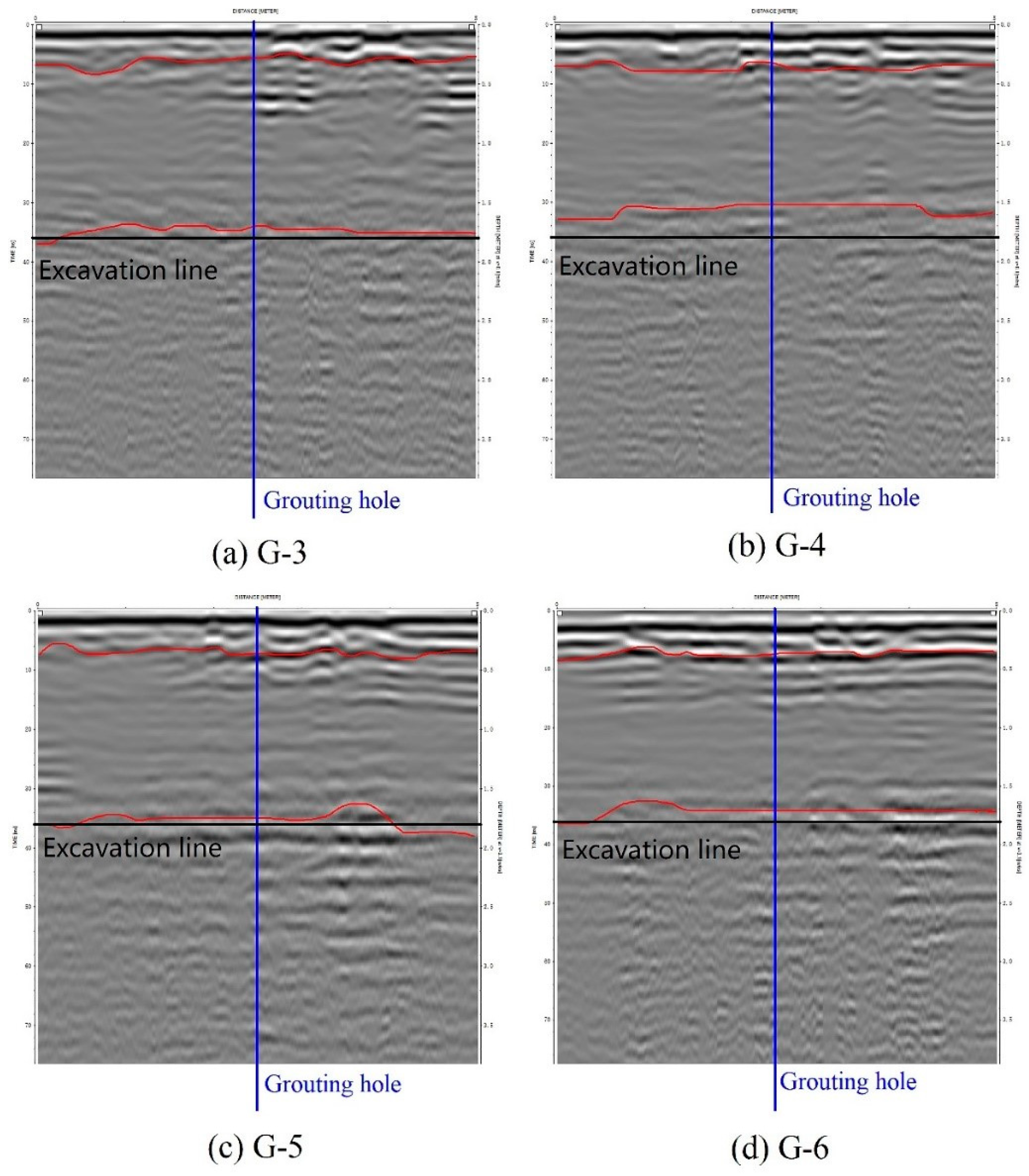

4.1.1. Results in Axial Direction

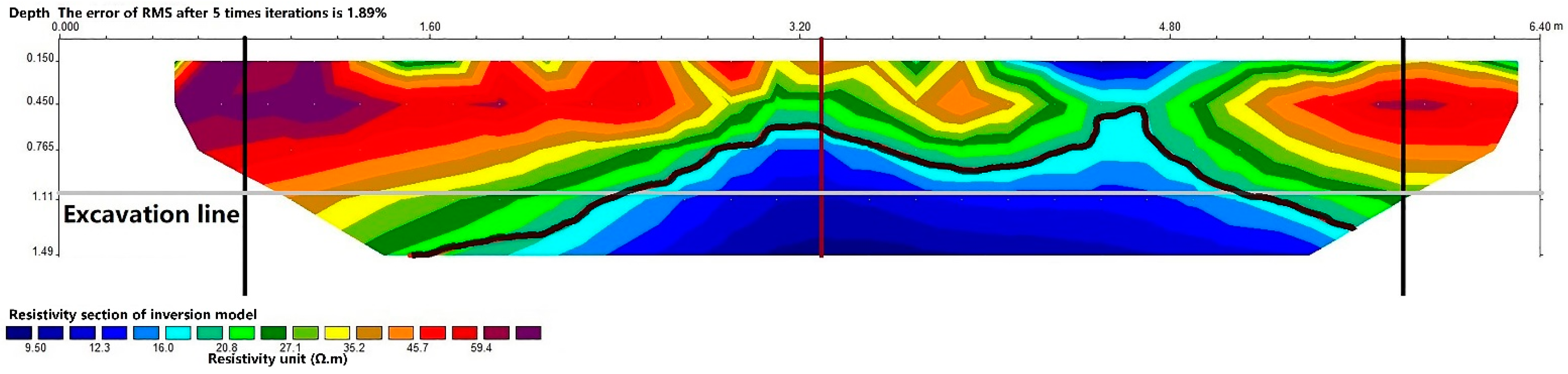

4.1.2. Vertical Direction

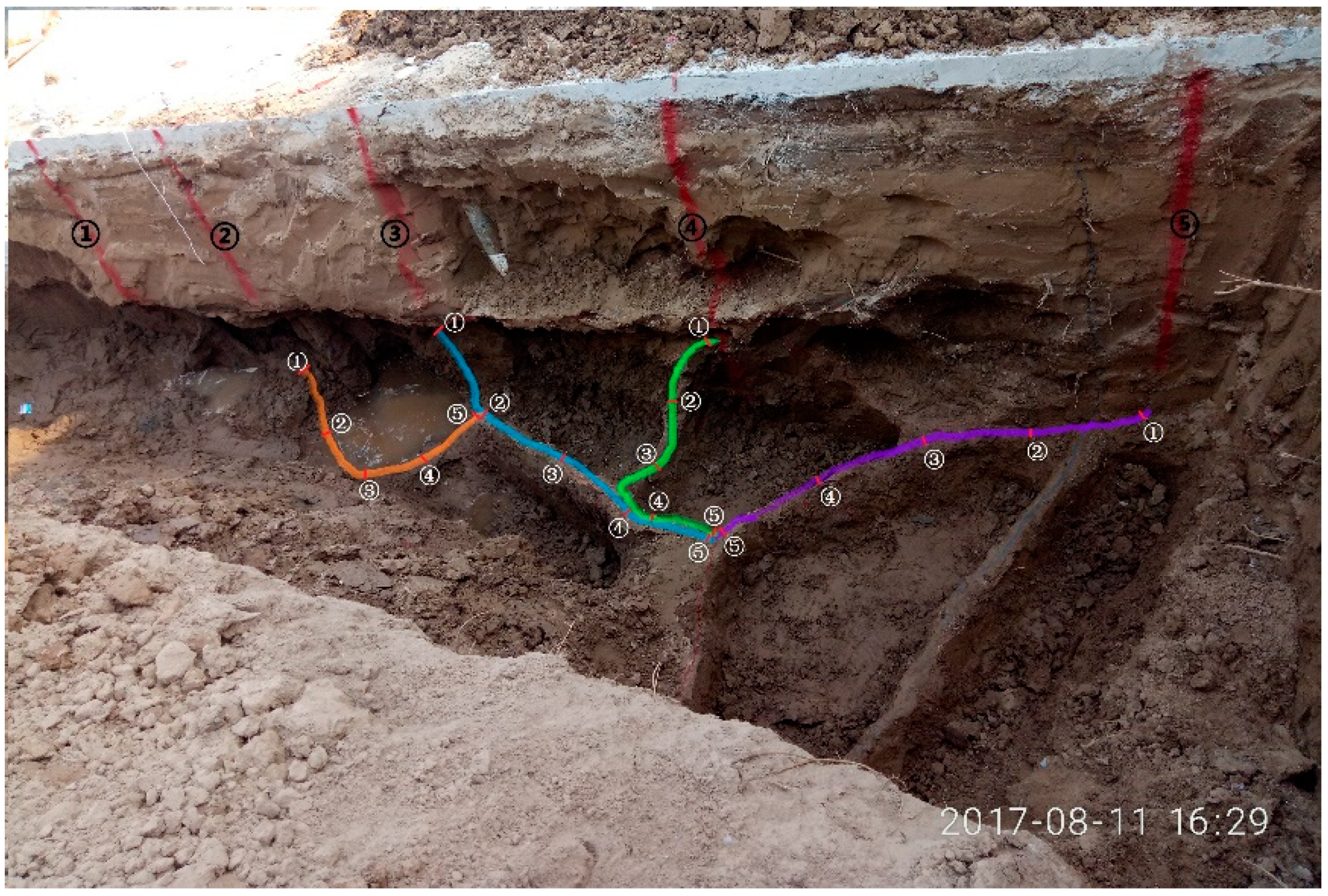

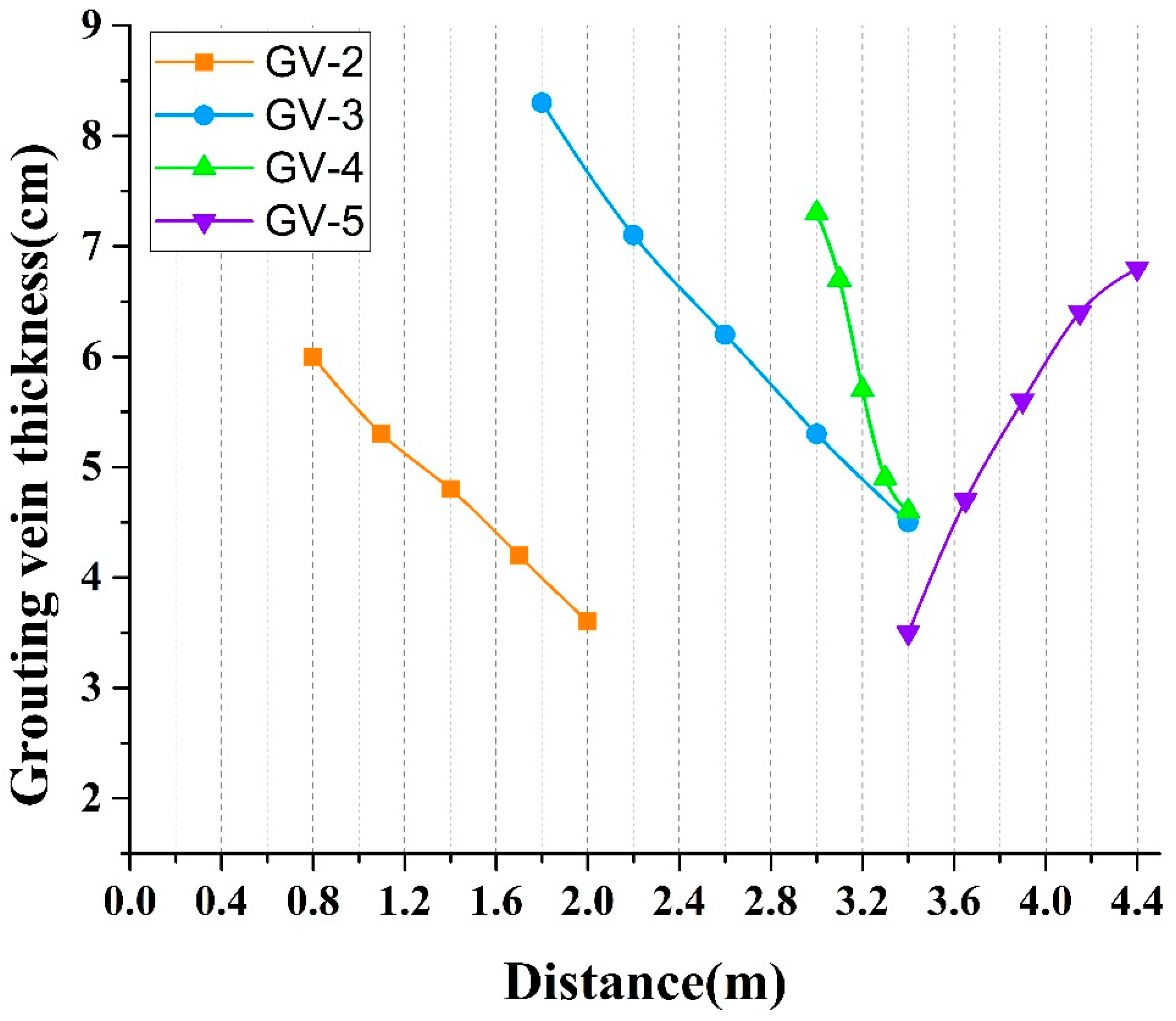

4.2. Pit Prospecting for Grouting Effectiveness

5. Conclusions

- (1)

- Compared with pure cement–silicate grouts, the gelation time of the improved slurry is longer and gelation time increases as fly ash content increases. The optimum mixing proportion of the compound cement–silicate grout is 70% cement, 25% fly ash, and 5% bentonite, and the best volume ratio is 2 for the investigated cases.

- (2)

- Good agreement is found between the ground-penetrating radar and high-density resistivity methods and the two geophysical prospecting methods can both reflect the anti-seepage effectiveness of fracture grouting on site.

- (3)

- The pit prospecting result shows that grouting material mainly flows along the axial direction of the embankment, which means that the treatment used to generate directional fracture is proven to be effective. The injection hole interval distance is suggested to be 1.2 m, where the lapping effect of the grouting veins is relatively significant.

- (4)

- For the investigated cases, the average thickness of the grouting veins is approximately 6.0 cm and the corresponding permeability coefficient is averagely 1.6 × 10−6 cm/s, which meets the anti-seepage criterion in practice.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liu, H.N.; Wang, J.M.; Wang, S.J.; Liu, H.D.; Hu, B. Seepage analysis of unsaturated soil levee slopes in lower reaches of Yellow River. Rock Soil Mech. 2006, 27, 1835–1840. [Google Scholar] [CrossRef]

- Zhao, Y.K.; Liu, H.D.; Li, Q.A. Slope stability analysis of lower reaches’ dikes of Yellow River under flood immersion and water level rapid drawdown. Rock Soil Mech. 2011, 32, 1495–1499. [Google Scholar] [CrossRef]

- Zhang, H.M.; Li, Z.B.; Yao, W.Y. Design method of drain system for dike in lower reaches of Yellow River. J. Hydraul. Eng. 2006, 37, 865–869. [Google Scholar] [CrossRef]

- Zhang, X.Y. Study on Failure Mechanism and Methodology of Safety Assessment of the Lower Yellow River Dike. Ph.D. Thesis, Hohai University, Nanjing, China, 2005. [Google Scholar]

- Bai, Y.N.; Liu, X.K. Grouting of the Earth Dam Body and Embankment; China Water Conservancy Press: Beijing, China, 1982; pp. 1–94. [Google Scholar]

- Luo, C.Q. Discussion on the construction technique of spit grouting in body of earth dam. Chin. J. Rock Mech. Eng. 2005, 24, 1605–1611. [Google Scholar] [CrossRef]

- Jorne, F.; Henriques, F.M.A. Evaluation of the grout injectability and types of resistance to grout flow. Constr. Build. Mater. 2016, 122, 171–183. [Google Scholar] [CrossRef]

- Azadi, M.R.; Taghichian, A.; Taheri, A. Optimization of cement-based grouts using chemical additives. J. Rock Mech. Geotech. Eng. 2017, 9, 623–637. [Google Scholar] [CrossRef]

- Pasian, L.; Secco, M.; Piqué, F.; Artioli, G.; Rickerby, S.; Cather, S. Lime-based injection grouts with reduced water content: An assessment of the effects of the water-reducing agents ovalbumin and ethanol on the mineralogical evolution and properties of grouts. J. Cult. Herit. 2018, 30, 70–80. [Google Scholar] [CrossRef]

- Liu, R.C.; Li, B.; Jiang, Y.J. Critical hydraulic gradient for nonlinear through rock fracture networks: The roles of aperture, surface roughness, and number of intersections. Adv. Water Resour. 2016, 88, 53–65. [Google Scholar] [CrossRef]

- Liu, R.C.; Jiang, Y.J.; Li, B.; Wang, X. A fracture model for characterizing fluid flow in fractured rock masses based on randomly distributed rock fracture networks. Comput. Geotech. 2015, 65, 45–55. [Google Scholar] [CrossRef]

- Warner, J.; Jefferies, M.; Garner, S. Compaction Grouting for Sinkhole Repair at WAC Bennett Dam. In Proceedings of the International Conference on Grouting and Ground Treatment, New Orleans, LA, USA, 10–12 February 2003; pp. 869–880. [Google Scholar]

- Grotenhuis, R. Fracture Grouting in Theory. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2004. [Google Scholar]

- Tunçdemir, F.; Ergun, M.U. A Laboratory Study into Fracture Grouting of Fissured Ankara Clay. In Proceedings of the Geo-Frontiers Congress, Austin, TX, USA, 24–26 January 2005; pp. 1–12. [Google Scholar]

- Bezuijen, A.; Grotenhuis, R.T.; Tol, A.F.V.; Bosch, J.W.; Haasnoot, J.K. Analytical model for fracture grouting in sand. J. Geotech. Geoenviron. Eng. 2011, 137, 611–620. [Google Scholar] [CrossRef]

- Yoneyama, K.; Okuno, T.; Nakaya, A.; Tosaka, H. Experimental and numerical study on fracture grouting by fine particle cement. Chem. Lett. 2012, 1994, 9–12. [Google Scholar]

- Yun, J.W.; Park, J.J.; Kwon, Y.S.; Kim, B.K.; Lee, I.M. Cement-based fracture grouting phenomenon of weathered granite soil. KSCE J. Civil Eng. 2016, 21, 232–242. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, S.; Sloan, S.W.; Sheng, D.; Pakzad, R. Experimental investigation of pressure grouting in sand. Soils Found. 2016, 56, 161–173. [Google Scholar] [CrossRef]

- Sun, F.; Zhang, D.L.; Chen, T.L.; Zhang, X.P. Meso-mechanical simulation of fracture grouting in soil. Chin. J. Geotech. Eng. 2010, 32, 474–480. [Google Scholar]

- Liu, Q.; Zheng, X.L.; Liu, H.J.; Wang, J.G.; Dong, S.Y. Experimental studies on liquefaction behavior of silt in the huanghe river delta. World Earthq. Eng. 2007, 23, 161–166. [Google Scholar] [CrossRef]

- Xiao, J.; Liu, J.; Peng, L.; Chen, L. Effects of compactness and water yellow-river alluvial silt content on its mechanical behaviors. Rock Soil Mech. 2008, 29, 409–414. [Google Scholar] [CrossRef]

- Song, X.G.; Zhang, H.B.; Wang, S.G.; Jia, Z.X.; Guan, Y.H. Hydrophilic characteristics and strength decay of silt roadbed in yellow river alluvial plain. Chin. J. Geotech. Eng. 2010, 32, 1594–1602. [Google Scholar]

- Zhu, D.Y.; Guan, Y.H.; Liu, H.Z.; Wang, Q.; Zhang, Q.T. Model tests on fracture grouting reinforcement of silt embankment by using soletanche method. Chin. J. Geotech. Eng. 2012, 34, 1425–1431. [Google Scholar]

- Chen, C.L.; Ma, S.X.; Li, L.L.; Cai, Z.P. Study on post-cyclic undrained deformation and strength characteristics of saturated silt in the floodplain of the Yellow river. J. Hydraul. Eng. 2014, 45, 801–808. [Google Scholar] [CrossRef]

- Shi, M.S.; Xia, W.Y.; W, F.M.; L, H.; Pan, Y.H. Experimental study on bond performance between polymer anchorage body and silt. Chin. J. Geotech. Eng. 2014, 36, 724–730. [Google Scholar]

- ASTM C618-05. Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM: West Conshohocken, PA, USA, 2005. [Google Scholar]

- Sha, F.; Li, S.; Liu, R.; Li, Z.; Zhang, Q. Experimental study on performance of cement-based grouts admixed with fly ash, bentonite, superplasticizer and water glass. Constr. Build. Mater. 2018, 161, 282–291. [Google Scholar] [CrossRef]

- Hwang, H.; Yoon, J.; Rugg, D.; Mohtar, C.S.E. Hydraulic Conductivity of Bentonite Grouted Sand. In Proceedings of the Geo-Frontiers Congress, Dallas, TX, USA, 13–16 March 2011; pp. 1372–1381. [Google Scholar]

- Liu, J.; Hu, L.Q.; Xu, B.J.; Yue, X.L.; Qi, B.L.; Zhong, Q. Study on cement-based seepage grouting materials for earth-rock dam. J. Shandong Univ. Eng. Sci. 2016, 47, 9–15. [Google Scholar]

- Chinese National Quality and Technical Supervision & Chinese Ministry of Construction. Method of Testing Cements-Determination of Strength; Standards Press of China: Beijing, China, 1999; pp. 1–12. [Google Scholar]

- Cui, X. Traffic-induced settlement of subgrade of low liquid limit silt in yellow river delta. China Civ. Eng. J. 2012, 45, 154–162. [Google Scholar]

- Collaboration of Rock and Soil Grouting Theory and Engineering Examples. Rock and Soil Grouting Theory and Engineering Examples; Science Press: Beijing, China, 2001; pp. 71–94. [Google Scholar]

- National Development and Reform Commission of the People’s Republic of China. Technical Specification of Grouting for Earth Dam; China Water & Power Press: Beijing, China, 2010; pp. 1–18. [Google Scholar]

- Shi, M.S.; Yu, D.M.; Wang, F.M. Bending Properties of a polymer grout. J. Mater. Sci. Eng. 2010, 28, 514–517. [Google Scholar]

| Material | CaO (%) | SiO2 (%) | Al2O3 (%) | Fe2O3 (%) |

|---|---|---|---|---|

| PC | 62.60 | 22.61 | 4.35 | 2.46 |

| FA | 3.75 | 54.64 | 28.09 | 6.20 |

| Water Absorption | Swell Volume | Colloid Valence | Particle Size (75 μm) | Water Content |

|---|---|---|---|---|

| 420% (2 h) | 49 mL/g | 630 mL/15 g | 95% | 9% |

| Number | VR | FA/% | PC/% | B/% |

|---|---|---|---|---|

| A1 | 1:1 | 20 | 75 | 5 |

| A2 | 1:1 | 25 | 70 | 5 |

| A3 | 1:1 | 30 | 65 | 5 |

| B1 | 2:1 | 20 | 75 | 5 |

| B2 | 2:1 | 25 | 70 | 5 |

| B3 | 2:1 | 30 | 65 | 5 |

| C1 | 3:1 | 20 | 75 | 5 |

| C2 | 3:1 | 25 | 70 | 5 |

| C3 | 3:1 | 30 | 65 | 5 |

| D1 | 4:1 | 20 | 75 | 5 |

| D2 | 4:1 | 25 | 70 | 5 |

| D3 | 4:1 | 30 | 65 | 5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Wan, Z.; Xie, Q.; Li, C.; Liu, R.; Cheng, M.; Han, B. Investigation on Reinforcement and Lapping Effect of Fracture Grouting in Yellow River Embankment. Processes 2018, 6, 75. https://doi.org/10.3390/pr6070075

Liu J, Wan Z, Xie Q, Li C, Liu R, Cheng M, Han B. Investigation on Reinforcement and Lapping Effect of Fracture Grouting in Yellow River Embankment. Processes. 2018; 6(7):75. https://doi.org/10.3390/pr6070075

Chicago/Turabian StyleLiu, Jian, Zhi Wan, Quanyi Xie, Cong Li, Rui Liu, Mengying Cheng, and Bo Han. 2018. "Investigation on Reinforcement and Lapping Effect of Fracture Grouting in Yellow River Embankment" Processes 6, no. 7: 75. https://doi.org/10.3390/pr6070075

APA StyleLiu, J., Wan, Z., Xie, Q., Li, C., Liu, R., Cheng, M., & Han, B. (2018). Investigation on Reinforcement and Lapping Effect of Fracture Grouting in Yellow River Embankment. Processes, 6(7), 75. https://doi.org/10.3390/pr6070075