Effect of Moisture Content on the Grinding Process and Powder Properties in Food: A Review

Abstract

1. Introduction

2. Influence of Moisture Content on the Grinding Process

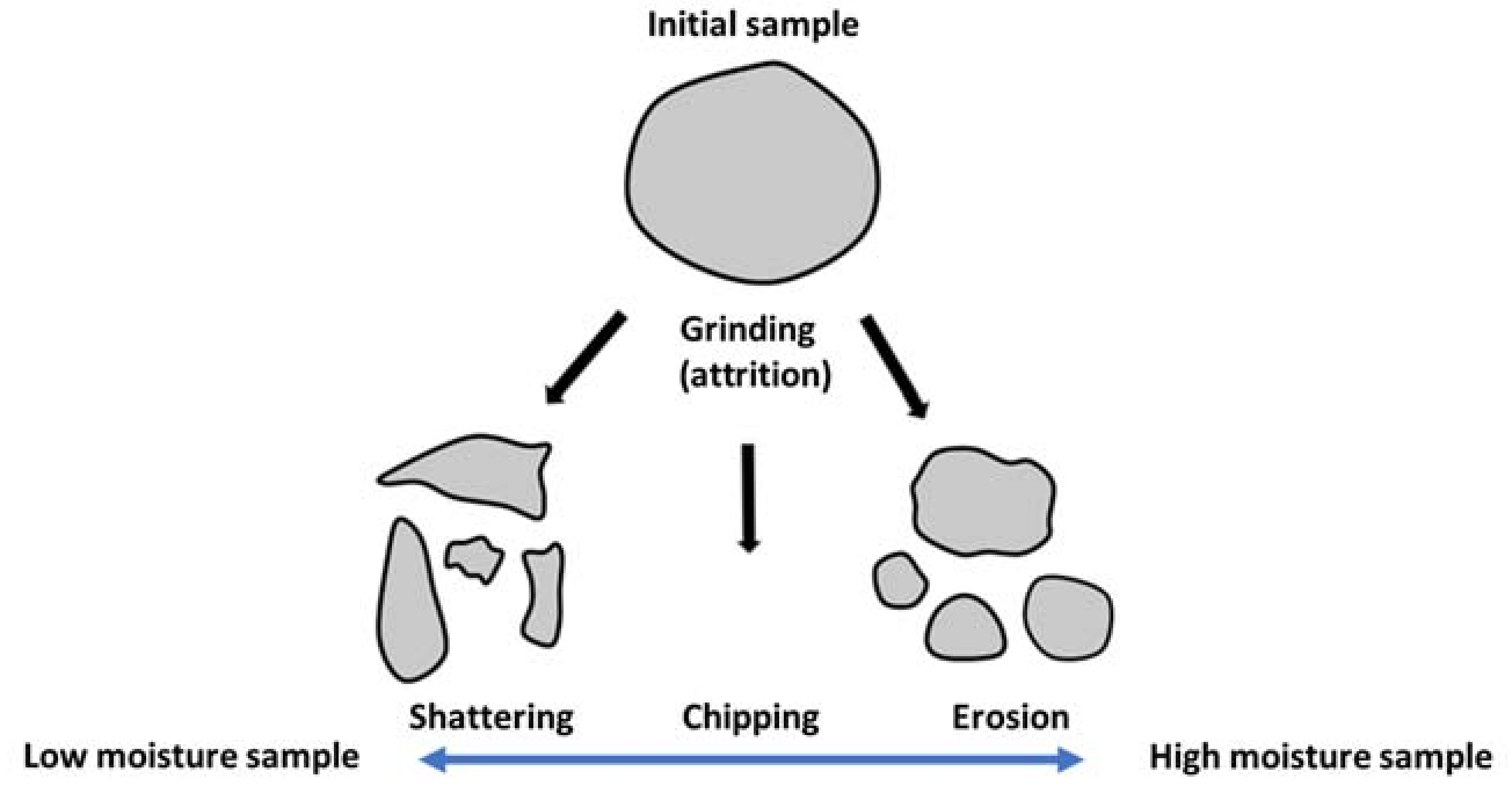

2.1. The Influence of Moisture Content on the Grinding Characteristics

2.2. Grinding Energy

2.3. Grinding Methods for Food Materials

2.3.1. Dry and Semi-Dry/Wet Grinding

2.3.2. Wet Grinding

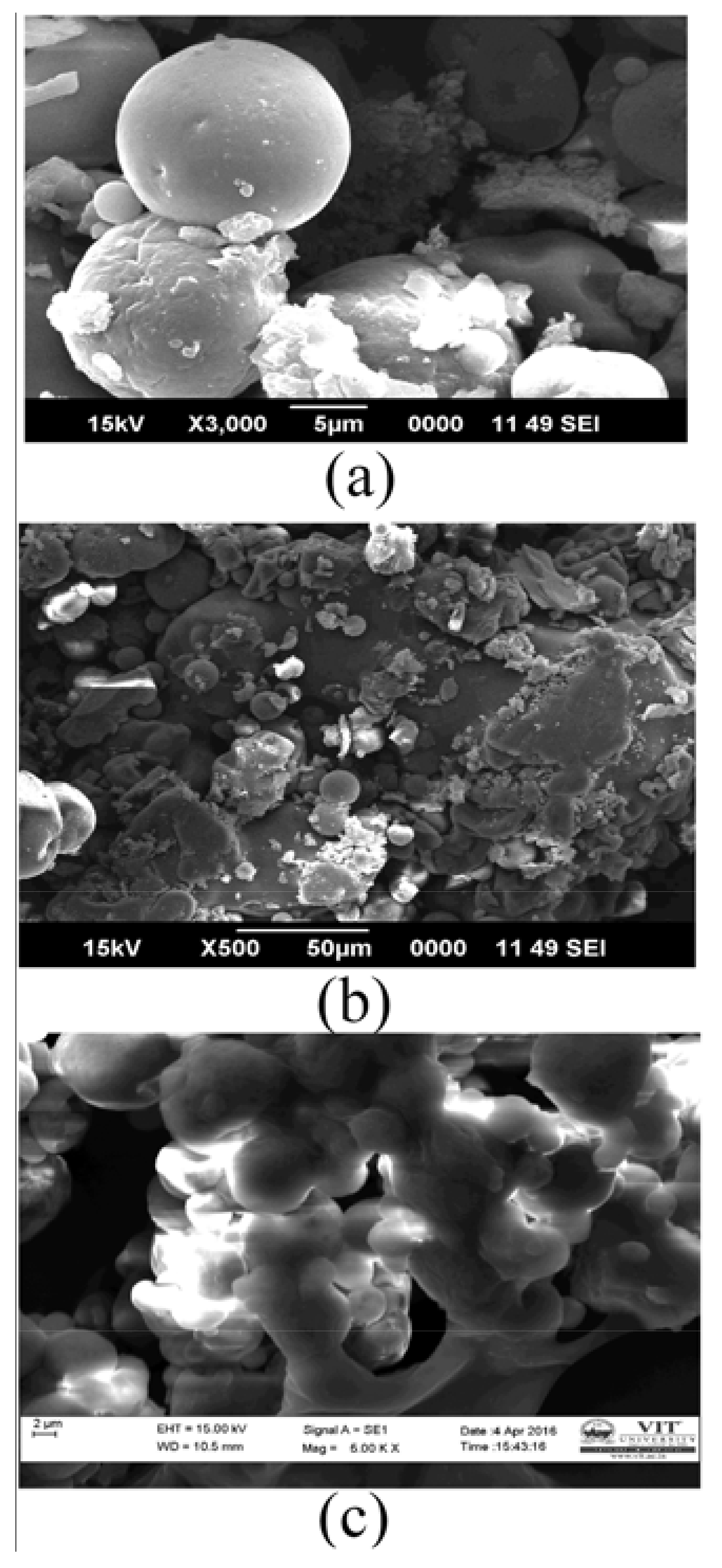

2.4. Particle Shape and Size Distribution

3. Effect of Moisture Content on the Flow Properties of Powder

4. Recent Grinding Methods and Powder Flowability Measurement Methods

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Murrieta-Pazos, I.; Gaiani, C.; Galet, L.; Calvet, R.; Cuq, B.; Scher, J. Food powders: Surface and form characterization revisited. J. Food Eng. 2012, 112, 1–21. [Google Scholar] [CrossRef]

- Kamdem, A.T.K.; Hardy, J. Influence of various conditions on meat grinding characteristics. J. Food Eng. 1995, 25, 179–196. [Google Scholar] [CrossRef]

- Djantou, E.B.; Mbofung, C.M.; Scher, J.; Desobry, S. A modelling approach to determine the effect of pre-treatment on the grinding ability of dried mangoes for powder production (Mangifera indica var Kent). J. Food Eng. 2007, 80, 668–677. [Google Scholar] [CrossRef]

- Barbosa-Cánovas, G.V.; Ortega-Rivas, E.; Juliano, P.; Yan, H. Food Powders: Physical Properties, Processing, and Functionality; Springer: New York, NY, USA, 2005; pp. 157–173. ISBN 978-0-306-47806-2. [Google Scholar]

- Ngamnikom, P.; Songsermpong, S. The effects of freeze, dry, and wet grinding processes on rice flour properties and their energy consumption. J. Food Eng. 2011, 104, 632–638. [Google Scholar] [CrossRef]

- Walde, S.G.; Balaswamy, K.; Velu, V.; Rao, D.G. Microwave drying and grinding characteristics of wheat (Triticum aestivum). J. Food Eng. 2002, 55, 271–276. [Google Scholar] [CrossRef]

- Muhamad, I.I.; Campbell, G.M. Effects of kernel hardness and moisture content on wheat breakage in the single kernel characterisation system. Innov. Food Sci. Emerg. Technol. 2004, 5, 119–125. [Google Scholar] [CrossRef]

- Dziki, D. Effect of preliminary grinding of the wheat grain on the pulverizing process. J. Food Eng. 2011, 104, 585–591. [Google Scholar] [CrossRef]

- Lee, Y.J.; Lee, M.G.; Yoon, W.B. Effect of seed moisture content on the grinding kinetics, yield and quality of soybean oil. J. Food Eng. 2013, 119, 758–764. [Google Scholar] [CrossRef]

- Moon, J.H.; Yoon, W.B. Effect of moisture content and particle size on grinding kinetics and flowability of balloon flower (Platycodon grandiflorum). Food Sci. Biotechnol. 2017, 1–10. [Google Scholar] [CrossRef]

- Lee, Y.J.; Yoon, W.B. Flow behavior and hopper design for black soybean powders by particle size. J. Food Eng. 2015, 144, 10–19. [Google Scholar] [CrossRef]

- Park, H.W.; Yoon, W.B. Measuring ring tensile stress and strain of surimi gels using a novel ring tensile test with image analysis. J. Food Eng. 2015, 163, 9–16. [Google Scholar] [CrossRef]

- Rozalli, N.H.M.; Chin, N.L.; Yusof, Y.A. Grinding characteristics of Asian originated peanuts (Arachishypogaea L.) and specific energy consumption during ultra-high speed grinding for natural peanut butter production. J. Food Eng. 2015, 152, 1–7. [Google Scholar] [CrossRef]

- Lee, Y.J.; Yoo, J.S.; Yoon, W.B. Grinding characteristics of black soybeans (Glycine max) at varied moisture contents: Particle size, energy consumption, and grinding kinetics. Int. J. Food Eng. 2014, 10, 347–356. [Google Scholar] [CrossRef]

- Henderson, S.M.; Perry, R.L. Agricultural Process Engineering; University of California: Oakland, CA, USA, 1970. [Google Scholar]

- Bond, F.C. Crushing and grinding calculations. Br. Chem. Eng. 1961, 6, 378–385. [Google Scholar]

- Teunou, E.; Fitzpatrick, J.J.; Synnott, E.C. Characterisation of food powder flowability. J. Food Eng. 1999, 39, 31–37. [Google Scholar] [CrossRef]

- Fitzpatrick, J.J.; Barringer, S.A.; Iqbal, T. Flow property measurement of food powders and sensitivity of Jenike’s hopper design methodology to the measured values. J. Food Eng. 2004, 61, 399–405. [Google Scholar] [CrossRef]

- Opaliński, I.; Chutkowski, M.; Stasiak, M. Characterizing moist food-powder flowability using a Jenike shear-tester. J. Food Eng. 2012, 108, 51–58. [Google Scholar] [CrossRef]

- Fadeyibi, A.; Osunde, Z.D.; Agidi, G.; Evans, E.C. Flow and strength properties of cassava and yam starch-glycerol composites essential in the design of handling equipment for granular solids. J. Food Eng. 2014, 129, 38–46. [Google Scholar] [CrossRef]

- Crowley, S.V.; Gazi, I.; Kelly, A.L.; Huppertz, T.; O’Mahony, J.A. Influence of protein concentration on the physical characteristics and flow properties of milk protein concentrate powders. J. Food Eng. 2014, 135, 31–38. [Google Scholar] [CrossRef]

- Falke, T.; de Payrebrune, K.M.; Kirchhof, S.; Kühnel, L.; Kühnel, R.; Mütze, T.; Kröger, M. An alternative DEM parameter identification procedure based on experimental investigation: A case study of a ring shear cell. Powder Technol. 2018, 328, 227–234. [Google Scholar] [CrossRef]

- Caparino, O.A.; Nindo, C.I.; Tang, J.; Sablani, S.S. Rheological measurements for characterizing sticky point temperature of selected fruit powders: An experimental investigation. J. Food Eng. 2017, 195, 61–72. [Google Scholar] [CrossRef]

- Saad, M.; Sadoudi, A.; Rondet, E.; Cuq, B. Morphological characterization of wheat powders, how to characterize the shape of particles? J. Food Eng. 2011, 102, 293–301. [Google Scholar] [CrossRef]

- Fu, X.; Huck, D.; Makein, L.; Armstrong, B.; Willen, U.; Freeman, T. Effect of particle shape and size on flow properties of lactose powders. Particuology 2012, 10, 203–208. [Google Scholar] [CrossRef]

- Pan, Z.; Tangratanavalee, W. Characteristics of soybeans as affected by soaking conditions. LWT-Food Sci. Technol. 2003, 36, 143–151. [Google Scholar] [CrossRef]

- Dziki, D. The crushing of wheat kernels and its consequence on the grinding process. Powder Technol. 2008, 185, 181–186. [Google Scholar] [CrossRef]

- Djantou, E.B.; Mbofung, C.M.F.; Scher, J.; Phambu, N.; Morael, J.D. Alternation drying and grinding (ADG) technique: A novel approach for producing ripe mango powder. LWT-Food Sci. Technol. 2011, 44, 1585–1590. [Google Scholar] [CrossRef]

- Jagtap, P.S.; Subramanian, R.; Singh, V. Influence of soaking on crushing strength of raw and parboiled rice. Int. J. Food Prop. 2008, 11, 127–136. [Google Scholar] [CrossRef]

- Laskowski, J.; Lysiak, G. Use of compression behaviour of legume seeds in view of impact grinding prediction. Powder Technol. 1999, 105, 83–88. [Google Scholar] [CrossRef]

- Kiryluk, J.; Kawka, A.; Gasiorowski, H.; Chalcarz, A.; Anioła, J. Milling of barley to obtain β-glucan enriched products. Nahr. Food 2000, 44, 238–241. [Google Scholar] [CrossRef]

- Balasubramanian, S.; Kumar, R.; Singh, K.K.; Zachariah, T.J.; Vikram, V. Size reduction characteristics of black pepper. J. Spices Aromat. Crop. 2013, 22, 138–147. [Google Scholar]

- Dabbour, M.I.; Bahnasawy, A.; Ali, S.; El-Haddad, Z. Grinding parameters and their effects on the quality of corn for feed processing. J. Food Process. Technol. 2015, 6, 1–8. [Google Scholar] [CrossRef]

- Probst, K.V.; Ambrose, R.P.K.; Pinto, R.L.; Bali, R.; Krishnakumar, P.; Ileleji, K.E. The effect of moisture content on the grinding performance of corn and corncobs by hammermilling. Trans. ASABE 2013, 56, 1025–1033. [Google Scholar] [CrossRef]

- Deng, L.; Manthey, F.A. Laboratory-scale milling of whole-durum flour quality: Effect of mill configuration and seed conditioning. J. Sci. Food Agric. 2017, 97, 3141–3150. [Google Scholar] [CrossRef] [PubMed]

- Balasubramanian, S.; Rajkumar, R.; Singh, K.K. Determination of grinding parameters of fenugreek seed. J. Spices Aromat. Crop. 2017, 26, 16–26. [Google Scholar] [CrossRef]

- Schorno, A.L.; Manthey, F.A.; Hall, C.A. Effect of seed moisture content on flaxseed (Linum usitatissimum L.) milling and milled product characteristics. J. Sci. Food Agric. 2009, 89, 2317–2322. [Google Scholar] [CrossRef]

- Oduro-Yeboah, C.; Mestres, C.; Amoa-Awua, W.; Fliedel, G.; Durand, N.; Matignon, B.; Michodjehoun, V.L.; Saalia, F.K.; Sakyi-Dawson, E.; Abbey, L. Steeping time and dough fermentation affect the milling behaviour and quality of white kenkey(nsiho), a sour stiff dumpling prepared from dehulled maize grains. J. Cereal Sci. 2016, 69, 377–382. [Google Scholar] [CrossRef]

- Velu, V.; Nagender, A.; Rao, P.G.P.; Rao, D.G. Dry milling characteristics of microwave dried maize grains (Zea mays L.). J. Food Eng. 2006, 74, 30–36. [Google Scholar] [CrossRef]

- Dijkink, B.H.; Langelaan, H.C. Milling properties of peas in relation to texture analysis. Part II. Effect of pea genotype. J. Food Eng. 2002, 51, 105–111. [Google Scholar] [CrossRef]

- Balasubramanian, S.; Sharma, R.; Kumar, S.R.V. Effect of Moisture Content and Feed Rate on Size Reduction of Pearl Millet. J. Food Sci. Eng. 2011, 1, 93–99. [Google Scholar]

- Jha, S.N.; Sharma, R. Physical, gravimetric and functional characterization of various milling fractions of popped gorgon nut (Euryale ferox). J. Food Sci. Technol. 2010, 47, 564–570. [Google Scholar] [CrossRef] [PubMed]

- Dziki, D.; Tomiło, J.; Różyło, R.; Laskowski, J.; Gawlik-dziki, U. Influence of moisture content on the mechanical properties and grinding energy requirements of dried quince (Cydonia Oblonga Miller). Teka. Comm. Mot. Energ. Agric. 2012, 12, 35–39. [Google Scholar]

- Hassoon, W.H.; Dziki, D. The effect of seed moisture and temperature on grinding characteristics of quinoa (Chenopodium quinoa Willd.). BIO Web Conf. 2018, 1006, 1–4. [Google Scholar] [CrossRef]

- Chiang, P.Y.; Yeh, A.I. Effect of soaking on wet-milling of rice. J. Cereal Sci. 2002, 35, 85–94. [Google Scholar] [CrossRef]

- Beta, T.; Rooney, L.W.; Taylor, J.R.N. Effect of chemical conditioning on the milling of high-tannin sorghum. J. Sci. Food Agric. 2000, 80, 2216–2222. [Google Scholar] [CrossRef]

- Dennett, A.L.; Trethowan, R.M. Milling efficiency of triticale grain for commercial flour production. J. Cereal Sci. 2013, 57, 527–530. [Google Scholar] [CrossRef]

- Doblado-Maldonado, A.F.; Flores, R.A.; Rose, D.J. Low moisture milling of wheat for quality testing of wholegrain flour. J. Cereal Sci. 2013, 58, 420–423. [Google Scholar] [CrossRef]

- Edwards, M.A.; Osborne, B.G.; Henry, R.J. Investigation of the effect of conditioning on the fracture of hard and soft wheat grain by the single-kernel characterization system: A comparison with roller milling. J. Cereal Sci. 2007, 46, 64–74. [Google Scholar] [CrossRef]

- Badmus, A.A.; Raji, A.O.; Akinoso, R. Effect of process parameters on work index, milling efficiency and some technological properties of yam flour using attrition mill. Food Bioprocess Technol. 2013, 6, 160–168. [Google Scholar] [CrossRef]

- McCabe, W.L.; Warren, L.; Smith, J.C.; Harriot, P. Unit Operations of Chemical Engineering, 5th ed.; McGraw-Hill: New York, NY, USA, 1993; ISBN 978-0072848236. [Google Scholar]

- Murthy, C.T.; Rani, M.; Rao, P.N.S. Optimal grinding characteristics of black pepper for essential oil yield. J. Food Process Eng. 2007, 22, 161–173. [Google Scholar] [CrossRef]

- Tong, L.T.; Gao, X.; Lin, L.; Liu, Y.; Zhong, K.; Liu, L.; Zhou, X.; Wang, L.; Zhou, S. Effects of semidry flour milling on the quality attributes of rice flour and rice noodles in China. J. Cereal Sci. 2015, 62, 45–49. [Google Scholar] [CrossRef]

- Tong, L.T.; Gao, X.; Zhou, X.; Zhong, K.; Liu, L.; Wang, L.; Zhou, S. Milling of glutinous rice by semidry method to produce sweet dumplings. J. Food Process Eng. 2016, 39, 330–334. [Google Scholar] [CrossRef]

- Asmeda, R.; Noorlaila, A.; Norziah, M.H. Effects of different grinding methods on chemical and functional properties of MR211 rice flour. Int. J. Food Eng. 2015, 1, 111–114. [Google Scholar] [CrossRef]

- Leewatchararongjaroen, J.; Anuntagool, J. Effects of dry-milling and wet-milling on chemical, physical and gelatinization properties of rice flour. Rice Sci. 2016, 23, 274–281. [Google Scholar] [CrossRef]

- Devaux, M.F.; Robert, P.; Melcion, J.P.; de Monredon, L.D. Particle size analysis of bulk powders using mathematical morphology. Powder Technol. 1997, 90, 141–147. [Google Scholar] [CrossRef]

- Singh, R.; Mangaraj, S.; Kulkarni, S.D. Particle-size analysis of tomato powder. J. Food Process. Preserv. 2006, 30, 87–98. [Google Scholar] [CrossRef]

- Bayram, M.; Öner, M.D. Bulgur milling using roller, double disc and vertical disc mills. J. Food Eng. 2007, 79, 181–187. [Google Scholar] [CrossRef]

- Gotoh, K.; Masuda, H.; Higashitani, K. Powder Technology Handbook, 2nd ed.; CRC Press: Boca Raton, FL, USA, 1997; ISBN 978-0824700157. [Google Scholar]

- Mitra, H.; Pushpadass, H.A.; Franklin, M.E.E.; Ambrose, R.P.K.; Ghoroi, C.; Battula, S.N. Influence of moisture content on the flow properties of basundi mix. Powder Technol. 2017, 312, 133–143. [Google Scholar] [CrossRef]

- Juarez-Enriquez, E.; Olivas, G.I.; Zamudio-Flores, P.B.; Ortega-Rivas, E.; Perez-Vega, S.; Sepulveda, D.R. Effect of water content on the flowability of hygroscopic powders. J. Food Eng. 2017, 205, 12–17. [Google Scholar] [CrossRef]

- Teunou, E.; Fitzpatrick, J.J. Effect of relative humidity and temperature on food powder flowability. J. Food Eng. 1999, 42, 109–116. [Google Scholar] [CrossRef]

- Landillon, V.; Cassan, D.; Morel, M.H.; Cuq, B. Flowability, cohesive, and granulation properties of wheat powders. J. Food Eng. 2008, 86, 178–193. [Google Scholar] [CrossRef]

- Opaliński, I.; Chutkowski, M.; Hassanpour, A. Rheology of moist food powders as affected by moisture content. Powder Technol. 2016, 294, 315–322. [Google Scholar] [CrossRef]

- Murthy, C.T.; Bhattacharya, S. Cryogenic grinding of black pepper. J. Food Eng. 2008, 85, 18–28. [Google Scholar] [CrossRef]

- Goswami, T.K.; Singh, M. Role of feed rate and temperature in attrition grinding of cumin. J. Food Eng. 2003, 59, 285–290. [Google Scholar] [CrossRef]

- Liu, H.; Zeng, F.; Wang, Q.; Ou, S.; Tan, L.; Gu, F. The effect of cryogenic grinding and hammer milling on the flavour quality of ground pepper (Piper nigrum L.). Food Chem. 2013, 141, 3402–3408. [Google Scholar] [CrossRef] [PubMed]

- Meghwal, M.; Goswami, T.K. Ambient and cryogenic grinding of fenugreek and flow characterization of its powder. J. Food Process Eng. 2013, 36, 548–557. [Google Scholar] [CrossRef]

- Meghwal, M.; Goswami, T.K. Comparative study on ambient and cryogenic grinding of fenugreek and black pepper seeds using rotor, ball, hammer and Pin mill. Powder Technol. 2014, 267, 245–255. [Google Scholar] [CrossRef]

- Sharma, L.K.; Agarwal, D.; Sharma, Y.; Rathore, S.S.; Saxena, S.N. Cryogenic grinding technology enhances volatile oil, oleoresin and antioxidant activity of cumin (Cuminum cyminum L.). Int. J. Seed Spices 2014, 4, 68–72. [Google Scholar]

- Barnwal, P.; Singh, K.K.; Mohite, A.; Sharma, A.; Saxena, S.N. Influence of cryogenic and ambient grinding on grinding characteristics of fenugreek powder: A comparative study. J. Food Process. Preserv. 2015, 39, 1243–1250. [Google Scholar] [CrossRef]

- Barnwal, P.; Kumar, P.; Singh, K.K.; Mohite, A.M. Selected engineering properties of cryogenic and ambient ground black pepper. J. Food Process. Preserv. 2017, 41. [Google Scholar] [CrossRef]

- Ghodki, B.M.; Goswami, T.K. Effect of grinding temperatures on particle and physicochemical characteristics of black pepper powder. Powder Technol. 2016, 299, 168–177. [Google Scholar] [CrossRef]

- Singh, K.K.; Goswami, T.K. Design of a cryogenic grinding system for spices. J. Food Eng. 1999, 39, 359–368. [Google Scholar] [CrossRef]

- Singh, K.K.; Goswami, T.K. Studies on cryogenic grinding of cumin seed. J. Food Process Eng. 1999, 22, 175–190. [Google Scholar] [CrossRef]

- Singh, K.K.; Goswami, T.K. Cryogenic grinding of cloves. J. Food Process. Preserv. 2000, 24, 57–71. [Google Scholar] [CrossRef]

- Meghwal, M.; Goswami, T.K. Flow characterization of ambiently and cryogenically ground black pepper (Piper nigrum) powder as a function of varying moisture content. J. Food Process Eng. 2017, 40. [Google Scholar] [CrossRef]

- Ghodki, B.M.; Goswami, T.K. DEM simulation of flow of black pepper seeds in cryogenic grinding system. J. Food Eng. 2017, 196, 36–51. [Google Scholar] [CrossRef]

- Ghodki, B.M.; Kumar, C.K.; Goswami, T.K. Modeling breakage and motion of black pepper seeds in cryogenic mill. Adv. Powder Technol. 2018, 29, 1055–1071. [Google Scholar] [CrossRef]

| Materials | Range of Moisture Content | Grinding Method | Grinder | Grinding Properties Influenced by Moisture Content | References |

|---|---|---|---|---|---|

| Balloon flower | 8–20% | Dry grinding | Domestic grinder |

| [10] |

| Barley | 10–14% | Dry grinding | Roller mill, impact mill |

| [31] |

| Black pepper | 5.5–17.6% (d.b.) | Dry grinding | Micro pulverizer-hammer mill |

| [32] |

| Black soybean | 4–20% | Dry grinding | Domestic grinder |

| [14] |

| Corn | 10–18% (w.b.) | Dry grinding | Hammer mill |

| [33] |

| Corn | 10.39–19.64% (w.b.) | Dry grinding | Hammer mill |

| [34] |

| Durum wheat | 9–15% | Dry grinding | Ultracentrifugal mill |

| [35] |

| Fenugreek seed | 5.1–17.3% (d.b.) | Dry grinding | Micro-pulverizer-hammer mill |

| [36] |

| Flaxseed | 5.5–10.5% | Dry grinding | Centrifugal cutting mill, hammer mill |

| [37] |

| Horse bean, pea, lupine, vetch | 10–18% | Dry grinding | Hammer mill |

| [30] |

| Maize (corn) | 30–42% (w.b.) | Dry grinding | Disc attrition mill |

| [38] |

| Maize (corn) | 9.6–32.5% (d.b.) | Dry grinding | Hammer mill |

| [39] |

| Mango | 12.83–17.75% | Dry grinding | Domestic grinder |

| [3] |

| Pea | 4.5–17% | Dry grinding | Classifier mill |

| [40] |

| Pearl millet | 6.2–12.3% (d.b.) | Dry grinding | Hammer mill |

| [41] |

| Popped gorgon nut | 6.2–12.3% (d.b.) | Dry grinding | Hammer mill |

| [42] |

| Quince | 10–14% (w.b.) | Dry grinding | Hammer mill |

| [43] |

| Quinoa | 10–14% (w.b.) | Dry grinding | Roller mill |

| [44] |

| Rice | 13–32% | Wet grinding | Hammer mill |

| [45] |

| Sorghum | 12–20% | Dry, Semi-wet grinding | Abrasive decortication, Roller mill |

| [46] |

| Soybean | 6–12% | Dry grinding | Domestic grinder |

| [9] |

| Soybean | 12–154% (d.b.) | Wet grinding | Domestic chopper |

| [26] |

| Triticale | 11–15% | Dry grinding | Disc mill, hammer mill |

| [47] |

| Wheat | 7.29–15.6% | Dry grinding | Automatic laboratory mill, disc mill |

| [48] |

| Wheat | 10–20% (d.b.) | Dry grinding | Hammer mill |

| [27] |

| Wheat | 10–20% (w.b.) | Dry grinding | Roller mill |

| [8] |

| Wheat | 8.9–16.3% | Dry grinding | Roller mill |

| [49] |

| Wheat | 6.7–11.1% (d.b.) | Dry grinding | Domestic grinder |

| [6] |

| Yam | 8–24% (w.b.) | Dry grinding | Disc mill |

| [50] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, H.; Lee, Y.J.; Yoon, W.B. Effect of Moisture Content on the Grinding Process and Powder Properties in Food: A Review. Processes 2018, 6, 69. https://doi.org/10.3390/pr6060069

Jung H, Lee YJ, Yoon WB. Effect of Moisture Content on the Grinding Process and Powder Properties in Food: A Review. Processes. 2018; 6(6):69. https://doi.org/10.3390/pr6060069

Chicago/Turabian StyleJung, Hwabin, Youn Ju Lee, and Won Byong Yoon. 2018. "Effect of Moisture Content on the Grinding Process and Powder Properties in Food: A Review" Processes 6, no. 6: 69. https://doi.org/10.3390/pr6060069

APA StyleJung, H., Lee, Y. J., & Yoon, W. B. (2018). Effect of Moisture Content on the Grinding Process and Powder Properties in Food: A Review. Processes, 6(6), 69. https://doi.org/10.3390/pr6060069