Experimental Investigation of the Mechanical Behaviors of Grouted Sand with UF-OA Grouts

Abstract

1. Introduction

2. Experimental Work

2.1. Specimen Preparation

2.2. Chemical Reaction of Grout Components

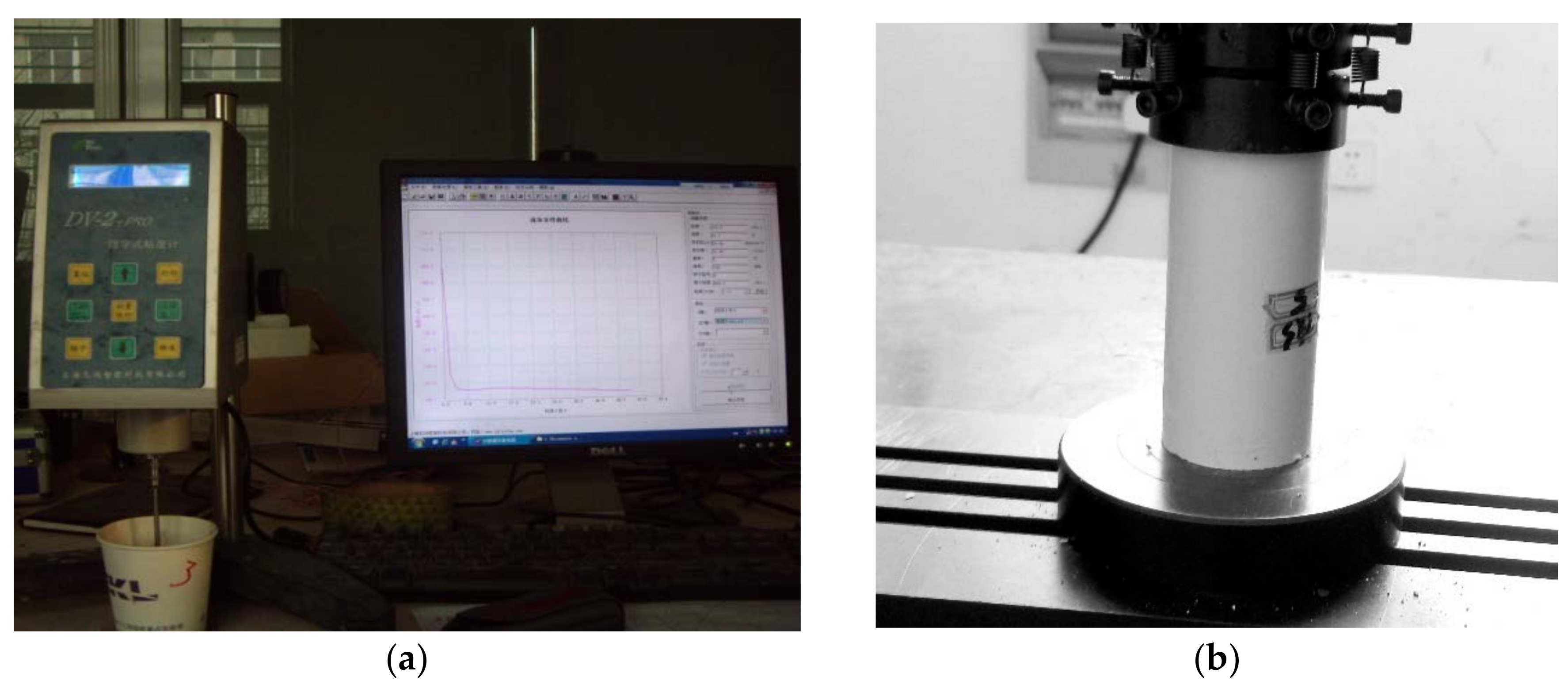

2.3. Properties of UF-OA Grouts

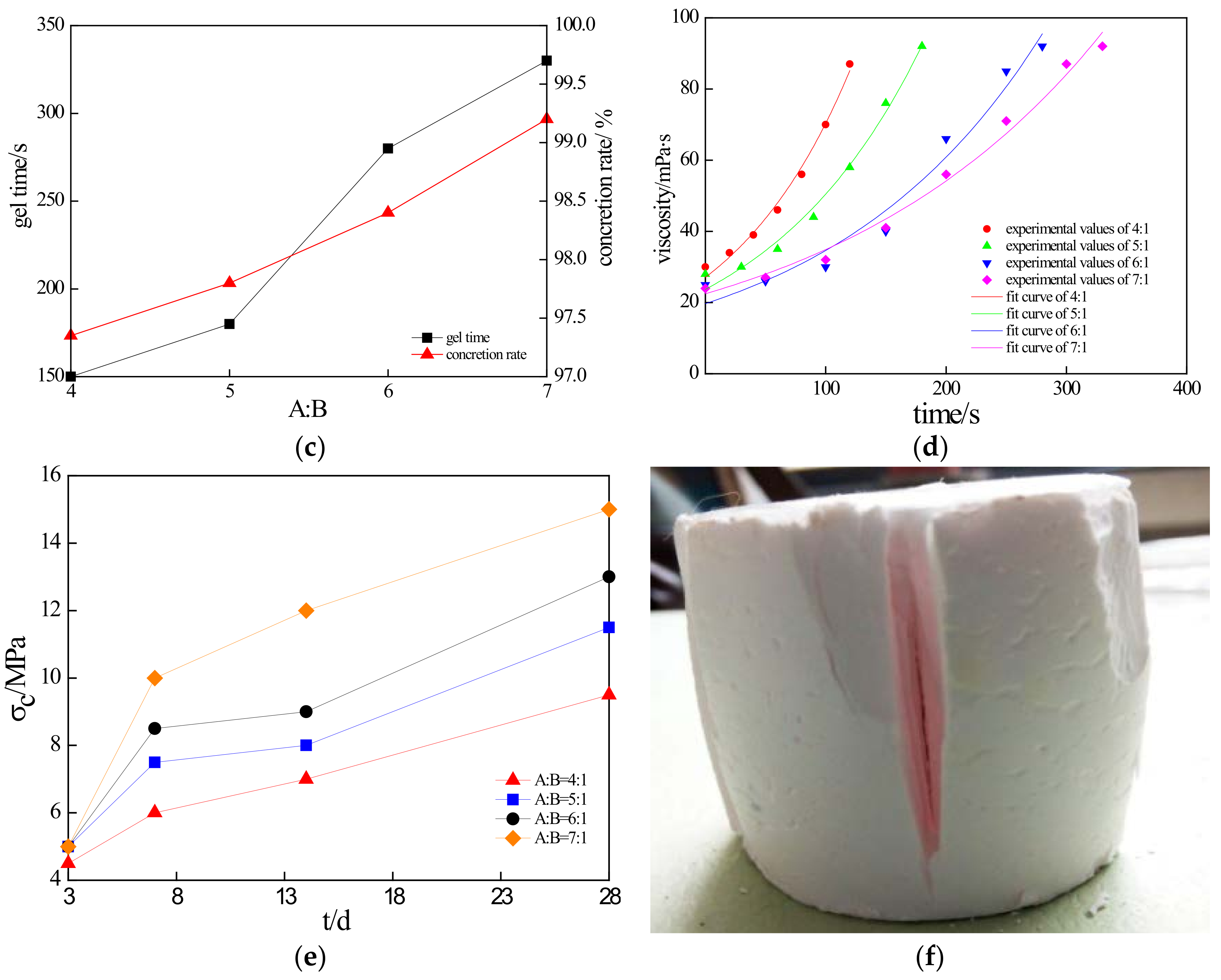

2.4. Laboratory Procedure

3. Results

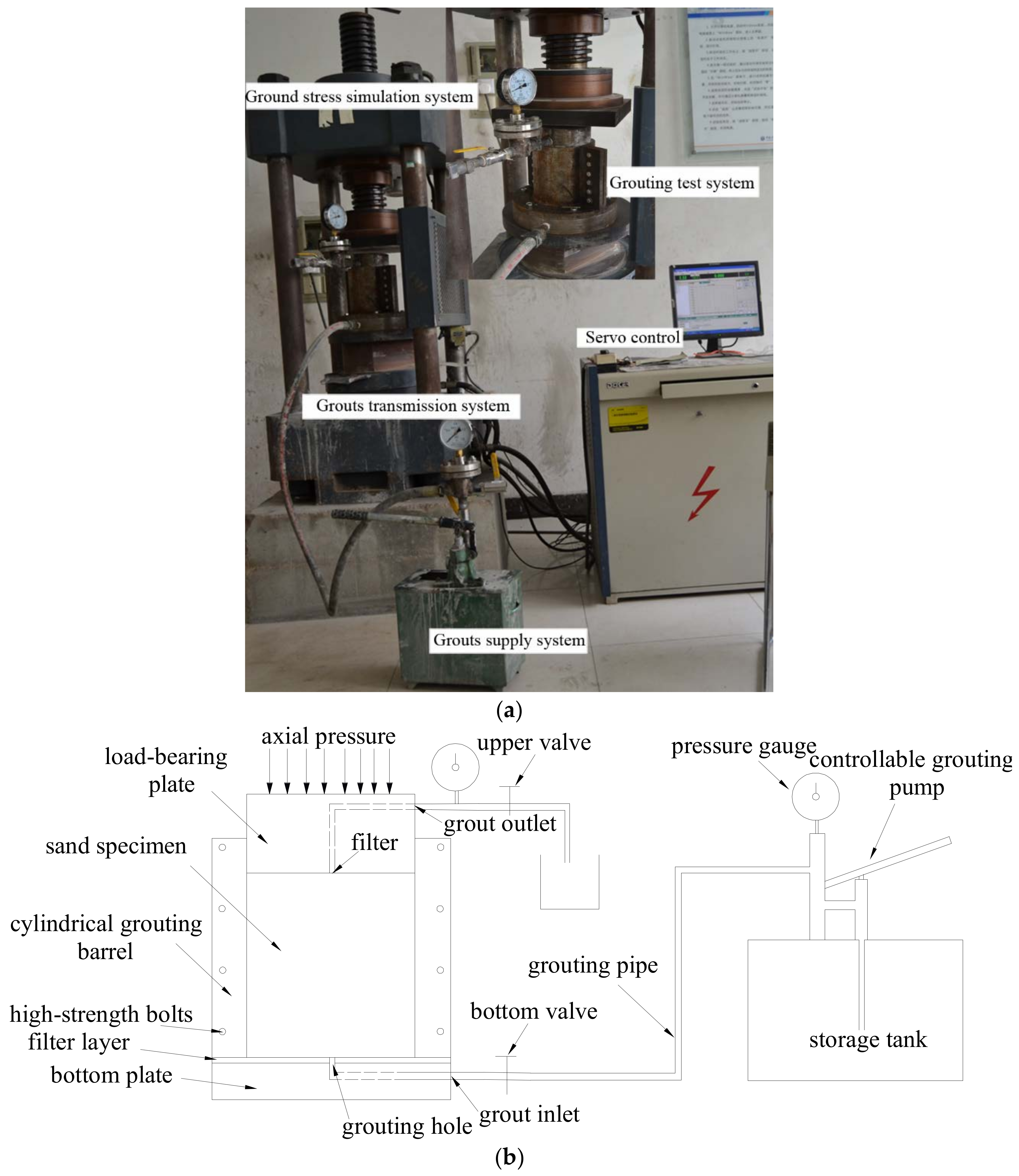

3.1. Macroscopic Mechanical Parameters

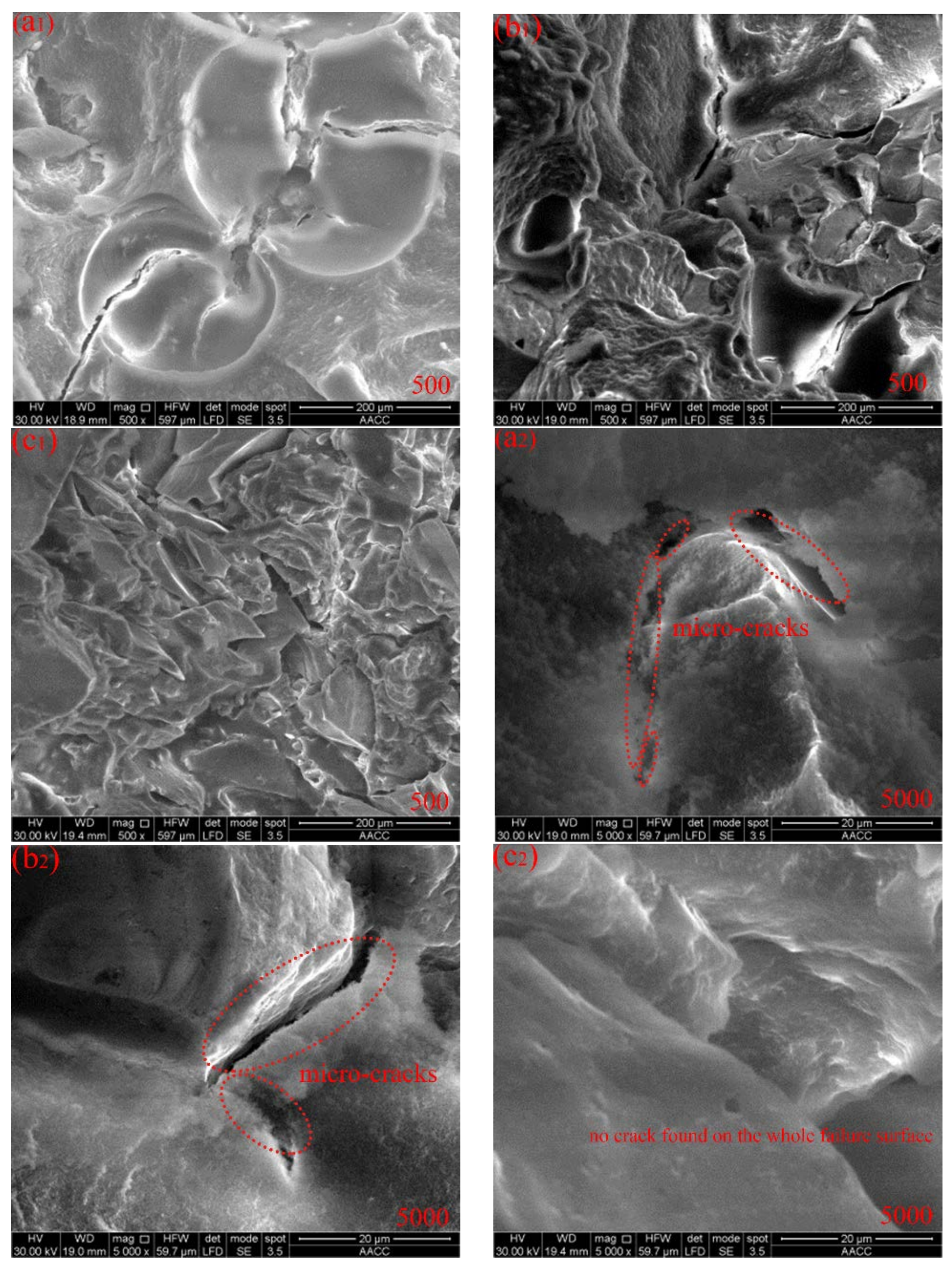

3.2. Microstructure Characteristics

4. Discussion

5. Conclusions

- (1)

- The gel time, concretion rate, and mechanical and rheological properties of the improved chemical grouts (UF-OA grouts) with various volume ratios of A and B were investigated to obtain a suitable ratio (A:B of 7) in the grouts used in this study.

- (2)

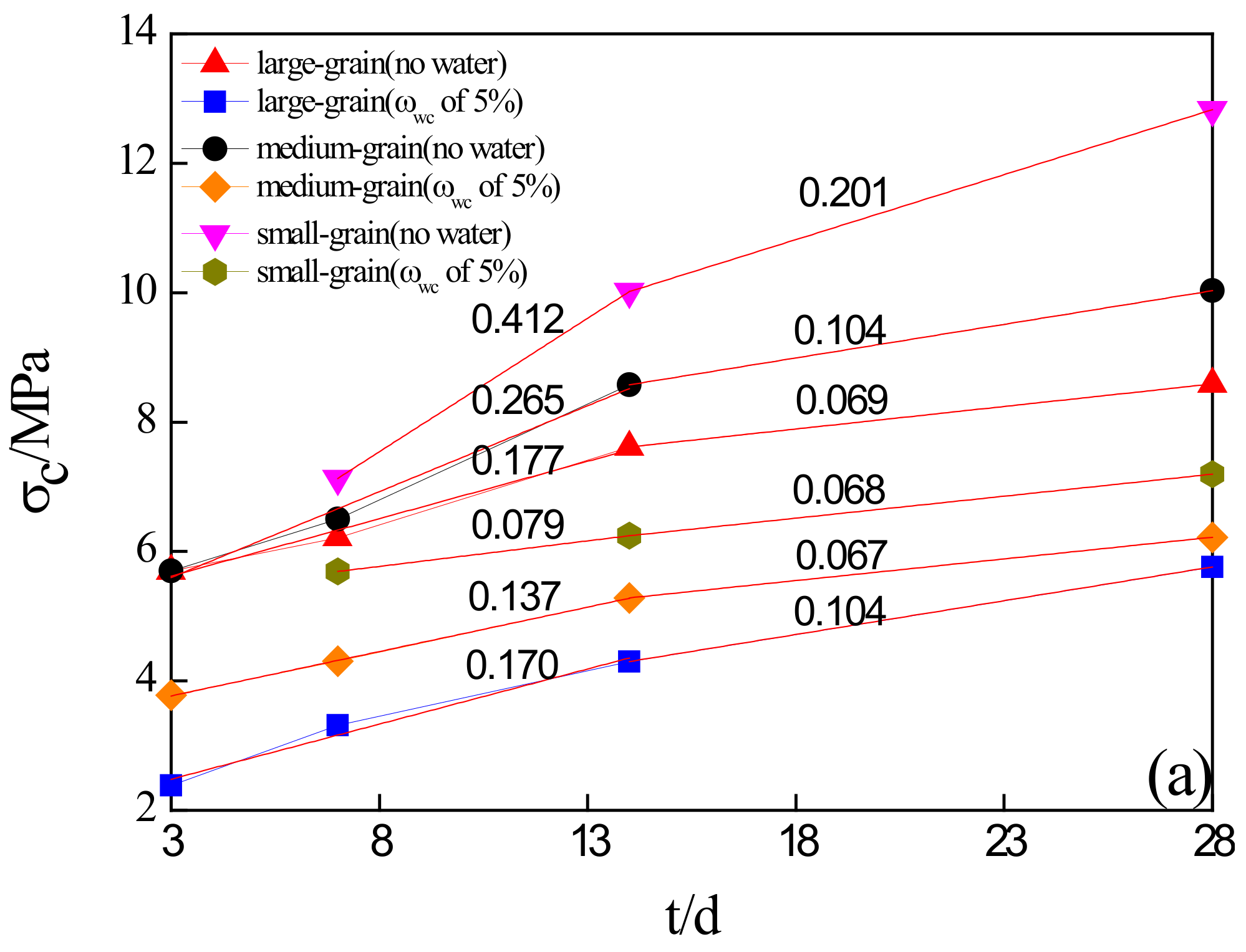

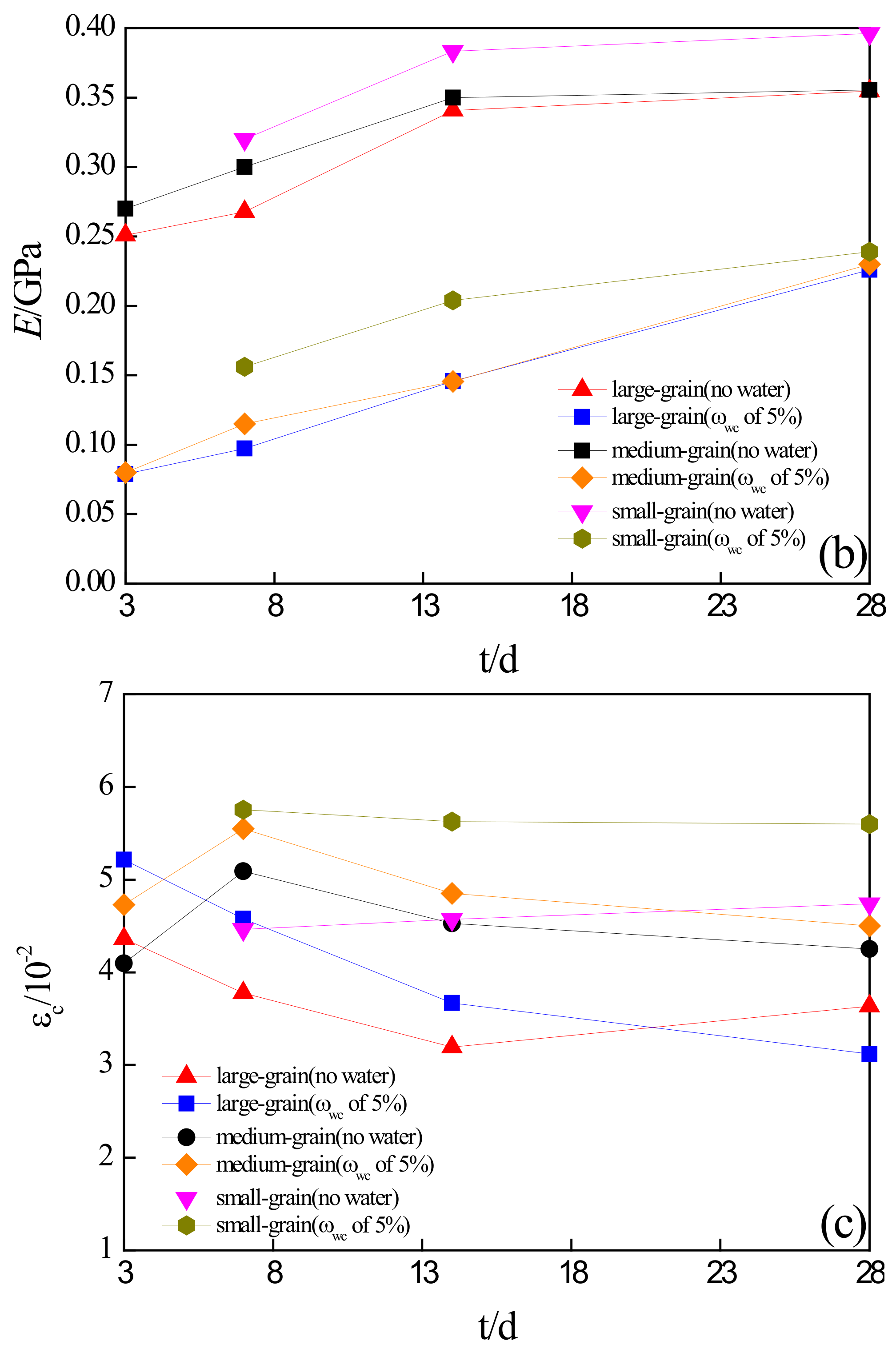

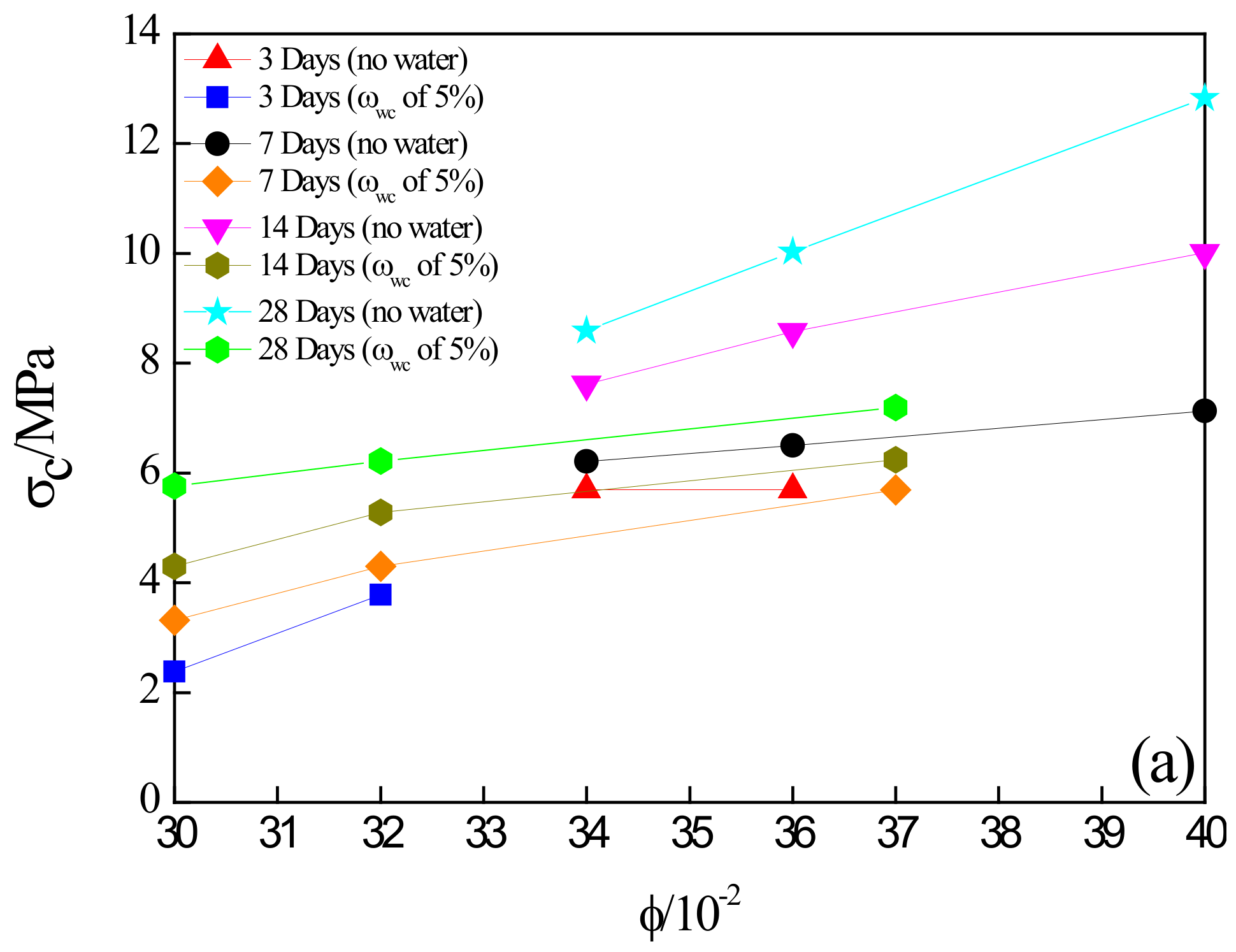

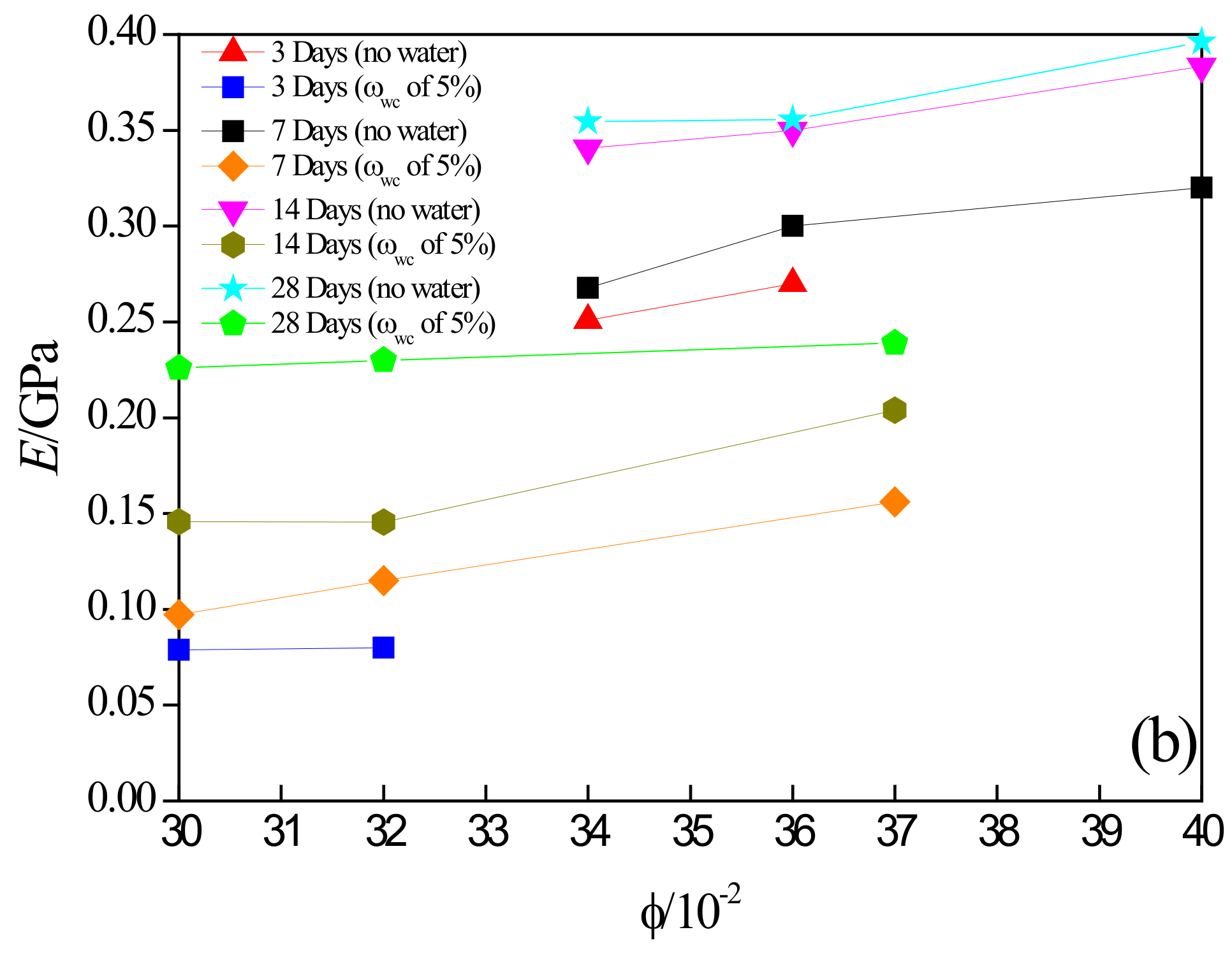

- With the increase in the grain size of the sand and the existence of initial water contained in sand, the values of the strength (UCS) and elastic moduli (E) for most of the grouted sand specimens decreased distinctly. Moreover, with the increase in the curing time, the UCS and E presented an increasing trend, and the mechanical behaviors of grouted sand after 14 days of curing were significantly improved. Moreover, the peak strains for the grouted specimens were found to remain constant with the increase of curing time after 14 days of curing.

- (3)

- The microstructural characteristics indicate that the finer grouted sand was found to achieve higher mechanical strength via the better filling performance.

- (4)

- Most of the grouted sand specimens under uniaxial compression at curing times of 3, 7, 14 and 28 days revealed desirable ductile failure characteristics.

Acknowledgements

Author Contributions

Conflicts of Interest

Notations

| ωwc | water content of initial sand (before grouting) |

| σ | standard deviation |

| φ | porosity |

| UF-OA | urea formaldehyde resin mixed with oxalate curing agent |

| σ1 | axial stress (MPa) |

| ε1 | axial strain (10−2) |

| UCS (σc) | uniaxial compressive strength (MPa) |

| E | elasticity modulus of grouted sand (GPa) |

| εc | peak axial strain (10−2) |

| t | curing time |

| SEM | scanning electron microscope |

References

- Liu, R.; Li, B.; Jiang, Y. A fractal model based on a new governing equation of fluid flow in fractures for characterizing hydraulic properties of rock fracture networks. Comput. Geotech. 2016, 75, 57–68. [Google Scholar] [CrossRef]

- Liu, R.; Jiang, Y.; Li, B.; Wang, X. A fractal model for characterizing fluid flow in fractured rock masses based on randomly distributed rock fracture networks. Comput. Geotech. 2015, 65, 45–55. [Google Scholar] [CrossRef]

- Huang, N.; Jiang, Y.; Li, B.; Liu, R. A numerical method for simulating fluid flow through 3-D fracture networks. J. Nat. Gas Sci. Eng. 2016, 33, 1271–1281. [Google Scholar] [CrossRef]

- Liu, R.; Li, B.; Jiang, Y. Critical hydraulic gradient for nonlinear flow through rock fracture networks: The roles of aperture, surface roughness, and number of intersections. Adv. Water Resour. 2016, 88, 53–65. [Google Scholar] [CrossRef]

- Avci, E. Performance of Novel Chemical Grout in Treating Sands. J. Mater. Civ. Eng. 2017, 29. [Google Scholar] [CrossRef]

- Avci, E.; Mollamahmutoğlu, M. UCS Properties of Superfine Cement–Grouted Sand. J. Mater. Civ. Eng. 2016, 28. [Google Scholar] [CrossRef]

- Mohammed, M.H.; Pusch, R.; Knutsson, S.; Hellström, G. Rheological Properties of Cement-Based Grouts Determined by Different Techniques. Engineering 2016, 6, 217–229. [Google Scholar] [CrossRef][Green Version]

- Tan, O.; Gungormus, G.; Zaimoglu, A.S. Effect of Bentonite, Fly Ash and Silica Fume cement injections on uniaxial compressive strength of granular bases. KSCE J. Civ. Eng. 2014, 18, 1650–1654. [Google Scholar] [CrossRef]

- Bras, A.; Gião, R.; Lúcio, V.; Chastre, C. Development of an injectable grout for concrete repair and strengthening. Cem. Concr. Comp. 2013, 37, 185–195. [Google Scholar] [CrossRef]

- Anagnostopoulos, C.A.; Papaliangas, T.; Manolopoulou, S.; Dimopoulos, T. Physical and mechanical properties of chemically grouted sand. Tunnell. Undergr. Space Technol. 2011, 26, 718–724. [Google Scholar] [CrossRef]

- Xing, H.G.; Dang, Y.H.; Yang, X.G.; Zhou, J.W. Experimental study of physical and mechanical properties of chemically grouted sand and gravel. Sens. Transducers 2014, 165, 164–169. [Google Scholar]

- Porcino, D.; Ghionna, V.N.; Granata, R.; Marcianò, V. Laboratory determination of mechanical and hydraulic properties of chemically grouted sands. Geomech. Geoeng. 2015, 11, 164–175. [Google Scholar] [CrossRef]

- Dayakar, P.; Raman, K.V.; Raju, K.V.B. Study on Permeation Grouting Using Cement Grout in Sandy Soil; Abzena: Cambridge, UK, 2012; Volume 4, pp. 5–10. [Google Scholar]

- Alaa, A.; Vipulanandan, C. Cohesive and Adhesive Properties of Silicate Grout on Grouted-Sand Behavior. J. Geotechn. Geoenviron. Eng. 1998, 124, 38–44. [Google Scholar]

- Delfosse-Ribay, E.; Djeran-Maigre, I.; Cabrillac, R.; Gouvenot, D. Factors Affecting the Creep Behavior of Grouted Sand. J. Geotech. Geoenviron. Eng. 2006, 132, 488–500. [Google Scholar] [CrossRef]

- Gonzalez, H.A.; Vipulanandan, C. Behavior of a Sodium Silicate Grouted Sand. In Proceedings of the Geo-Denver, Denver, CO, USA, 18–21 February 2007; pp. 1–10. [Google Scholar]

- Hassanlourad, M.; Salehzadeh, H.; Shahnazari, H. Undrained triaxial shear behavior of grouted carbonate sands. Int. J. Civ. Eng. 2011, 9, 307–314. [Google Scholar]

- Porcino, D.; Marcianò, V.; Granata, R. Static and dynamic properties of a lightly cemented silicate-grouted sand. Can. Geotech. J. 2011, 49, 1117–1133. [Google Scholar] [CrossRef]

- Park, B. Properties of Urea-Formaldehyde Resin Adhesives with Different Formaldehyde to Urea Mole Ratios. J. Adhes. 2015, 91, 677–700. [Google Scholar]

- Cao, X.X.; Zhang, Y.H.; Zhu, L.B.; Tan, H.Y.; Ji-You, G.U. Study on the Curing Characteristics and Synthesis Process of Modified Urea-formaldehyde Resin with Low Formaldehyde Release. In Proceedings of the 3rd International Conference and Exhibition on Biopolymers & Bioplastics, San Antonio, TX, USA, 12–14 September 2016. [Google Scholar]

- Yang, S.Q.; Liu, X.R.; Jing, H.W. Experimental investigation on fracture coalescence behavior of red sandstone containing two unparallel fissures under uniaxial compression. Int. J. Rock Mech. Min. Sci. 2013, 63, 82–92. [Google Scholar] [CrossRef]

- Schwarz, L.G.; Krizek, R.J. Hydrocarbon Residuals and Containment in Microfine Cement Grouted Sand. J. Mater. Civ. Eng. 2006, 18, 214–228. [Google Scholar] [CrossRef]

- Markou, I.N.; Droudakis, A.I. Factors Affecting Engineering Properties of Microfine Cement Grouted Sands. Geotech. Geol. Eng. 2013, 31, 1041–1058. [Google Scholar] [CrossRef]

- Zebovitz, S.; Krizek, R.J.; Atmatzidis, D.K. Injection of Fine Sands with Very Fine Cement Grout. J. Geotech. Eng. 1989, 115, 1717–1733. [Google Scholar] [CrossRef]

- Scerrato, D.; Giorgio, I.; Della Corte, A.; Madeo, A.; Limam, A. A micro-structural model for dissipation phenomena in the concrete. Int. J. Numer. Anal. Methods Geomech. 2015, 39, 2037–2052. [Google Scholar] [CrossRef]

- Giorgio, I.; Scerrato, D. Multi-scale concrete model with rate-dependent internal friction. Eur. J. Environ. Civ. Eng. 2016, 21, 821–839. [Google Scholar] [CrossRef]

- Contrafatto, L.; Cuomo, M.; Fazio, F. An enriched finite element for crack opening and rebar slip in reinforced concrete members. Int. J. Fract. 2012, 178, 33–50. [Google Scholar] [CrossRef]

- Christensen, R.M. Exploration of ductile, brittle failure characteristics through a two-parameter yield/failure criterion. Mater. Sci. Eng. A 2005, 394, 417–424. [Google Scholar] [CrossRef]

| Sand Category Used in the Tests | Grain Size (mm) | Water Content (%) | Average Initial Porosity | Average Mass Density (g/cm3) |

|---|---|---|---|---|

| Large-grain | 0.5 < d < 0.85 | 0 | 34 | 2.52 |

| 5 | 30 | 2.61 | ||

| Medium-grain | 0.25 < d < 0.42 | 0 | 36 | 2.67 |

| 5 | 32 | 2.74 | ||

| Small-grain | 0.11 < d < 0.21 | 0 | 40 | 2.72 |

| 5 | 37 | 2.80 |

| A:B | 4:1 | 5:1 | 6:1 | 7:1 |

| Elastic Modulus (MPa) | 120 | 140 | 180 | 220 |

| Poisson’s Ratio | 0.187 | 0.211 | 0.25 | 0.3 |

| Sand Types | ωwc (%) | UCS (MPa) | E (GPa) | εc (×10−2) | φ | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 d | 7 d | 14 d | 28 d | σ | 3 d | 7 d | 14 d | 28 d | σ | 3 d | 7 d | 14 d | 28 d | σ | |||

| Large | 0 | 5.70 | 6.21 | 7.62 | 8.59 | 1.34–3.12 | 0.25 | 0.27 | 0.34 | 0.35 | 0.14–0.29 | 4.36 | 3.78 | 3.19 | 3.63 | 0.04–0.09 | 34 |

| 5 | 2.38 | 3.31 | 4.30 | 5.76 | 1.21–2.45 | 0.08 | 0.10 | 0.15 | 0.23 | 0.21–0.35 | 5.22 | 4.58 | 3.67 | 3.12 | 0.05–0.10 | 30 | |

| Medium | 0 | 5.70 | 6.50 | 8.58 | 10.03 | 0.94–3.57 | 0.27 | 0.30 | 0.35 | 0.36 | 0.32–0.37 | 4.10 | 5.09 | 4.53 | 4.25 | 0.08–0.13 | 36 |

| 5 | 3.78 | 4.30 | 5.28 | 6.22 | 0.89–2.63 | 0.08 | 0.11 | 0.15 | 0.23 | 0.19–0.54 | 4.73 | 5.55 | 4.85 | 4.5 | 0.03–0.05 | 32 | |

| Small | 0 | - | 7.12 | 10.02 | 12.83 | 1.14–3.01 | - | 0.32 | 0.38 | 0.40 | 0.27–0.51 | - | 4.46 | 4.57 | 4.74 | 0.11–0.14 | 40 |

| 5 | - | 5.69 | 6.24 | 7.19 | 1.25–1.85 | - | 0.16 | 0.20 | 0.24 | 0.38–0.43 | - | 5.75 | 5.62 | 5.60 | 0.09–0.15 | 37 | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, Y.; Han, L.; Meng, Q.; Ma, D.; Han, G.; Gao, F.; Wang, S. Experimental Investigation of the Mechanical Behaviors of Grouted Sand with UF-OA Grouts. Processes 2018, 6, 37. https://doi.org/10.3390/pr6040037

Jin Y, Han L, Meng Q, Ma D, Han G, Gao F, Wang S. Experimental Investigation of the Mechanical Behaviors of Grouted Sand with UF-OA Grouts. Processes. 2018; 6(4):37. https://doi.org/10.3390/pr6040037

Chicago/Turabian StyleJin, Yuhao, Lijun Han, Qingbin Meng, Dan Ma, Guansheng Han, Furong Gao, and Shuai Wang. 2018. "Experimental Investigation of the Mechanical Behaviors of Grouted Sand with UF-OA Grouts" Processes 6, no. 4: 37. https://doi.org/10.3390/pr6040037

APA StyleJin, Y., Han, L., Meng, Q., Ma, D., Han, G., Gao, F., & Wang, S. (2018). Experimental Investigation of the Mechanical Behaviors of Grouted Sand with UF-OA Grouts. Processes, 6(4), 37. https://doi.org/10.3390/pr6040037