Progress Analysis and Prospect on the Influence of Early-Age Carbonation Curing on Properties of Cement-Based Materials

Abstract

1. Introduction

2. Principles of Early-Age Carbonation Curing

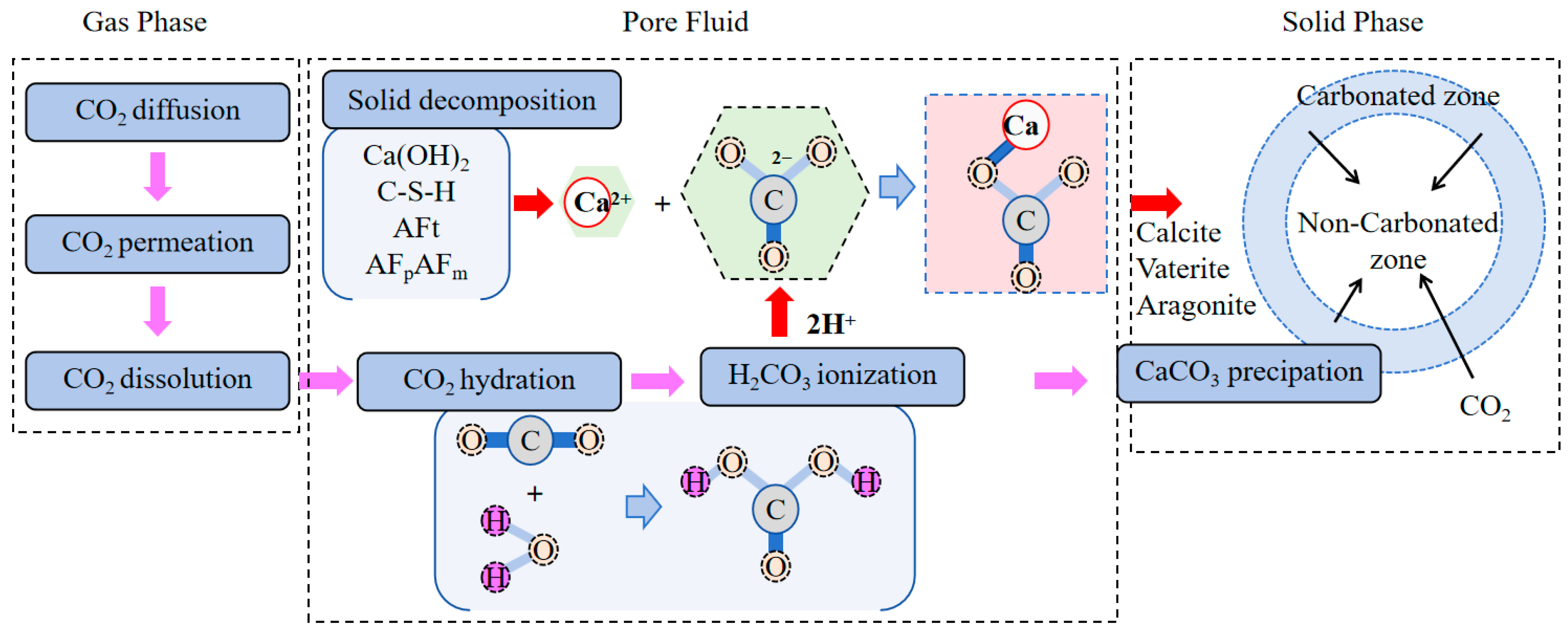

2.1. Reaction Mechanism of CO2 Carbonation

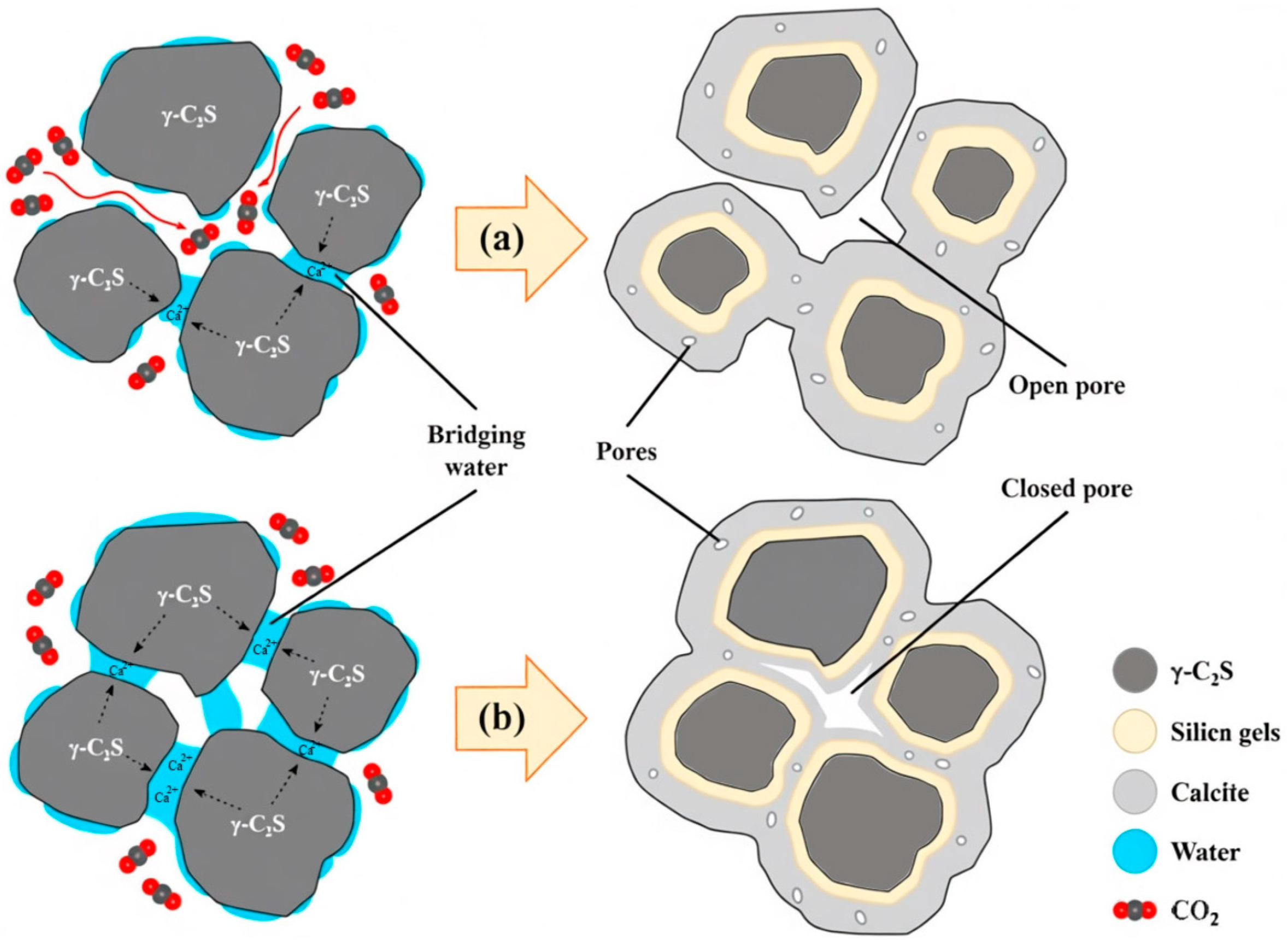

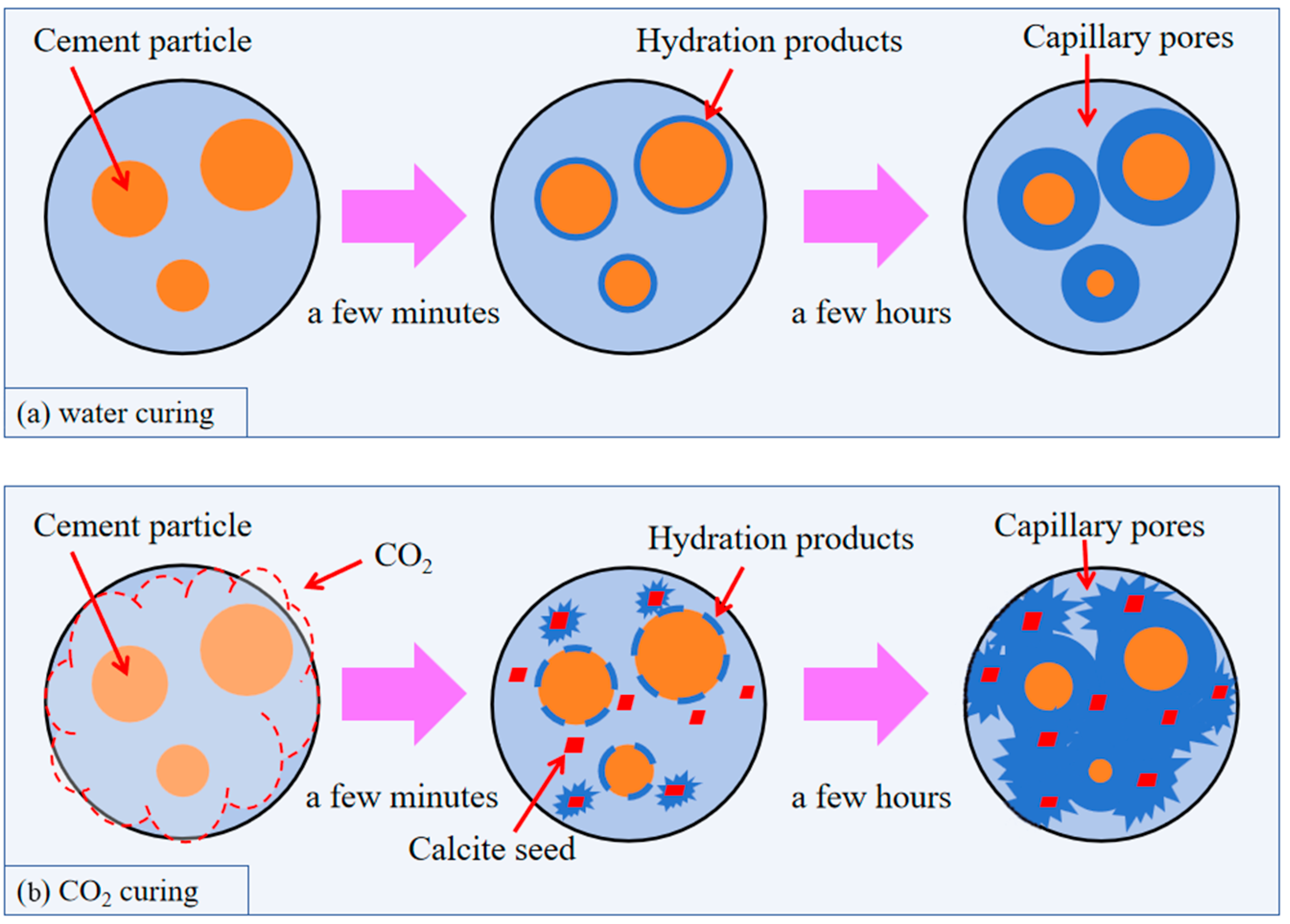

2.2. Carbonation Reaction Process

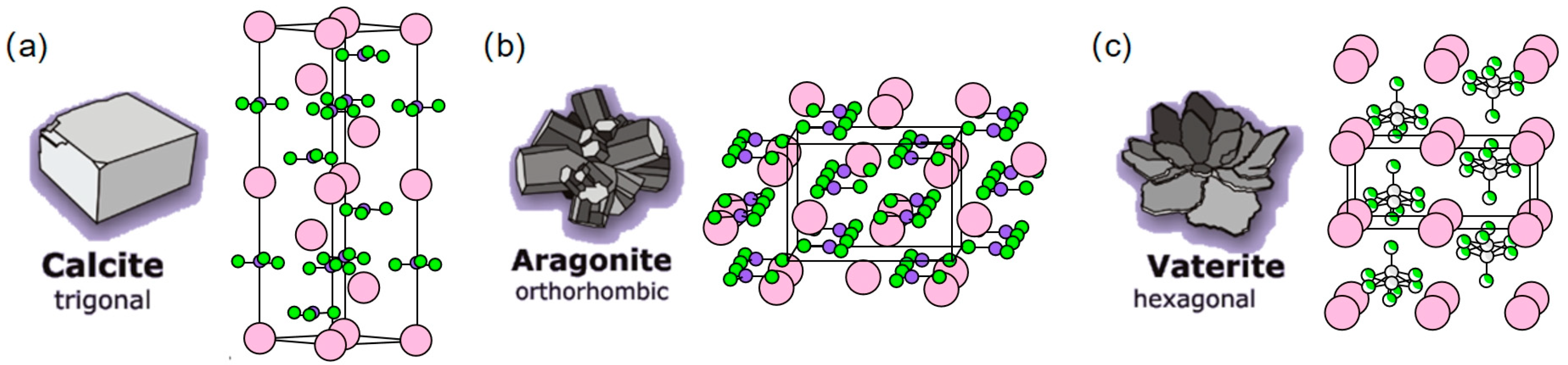

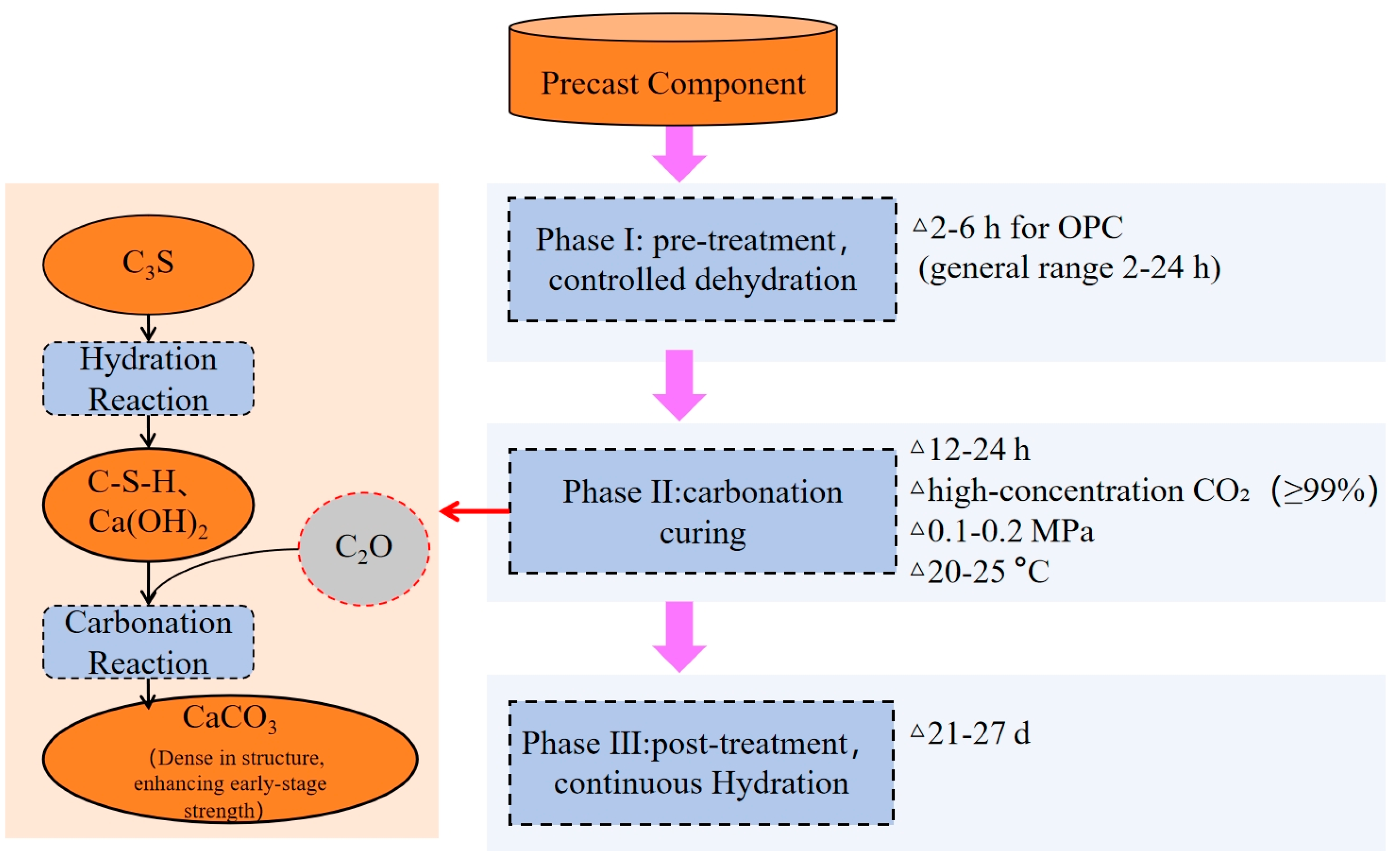

2.3. Carbonation Products

3. Early-Age Carbonation Curing Process and Influencing Factors

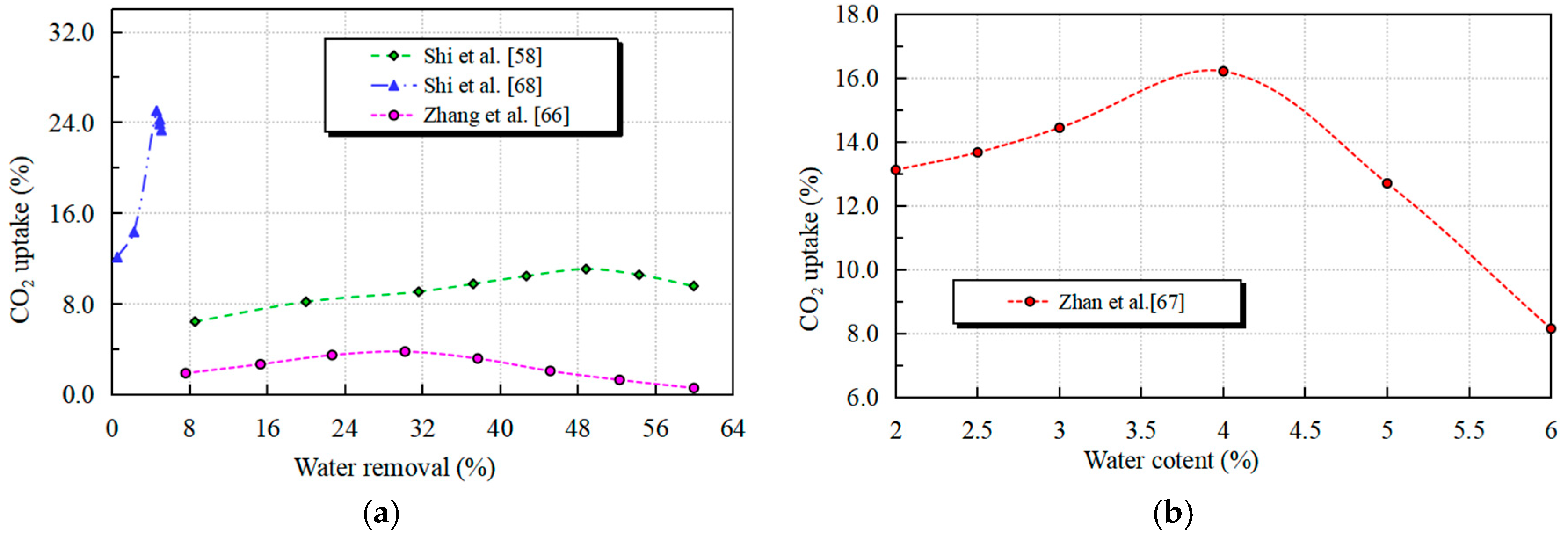

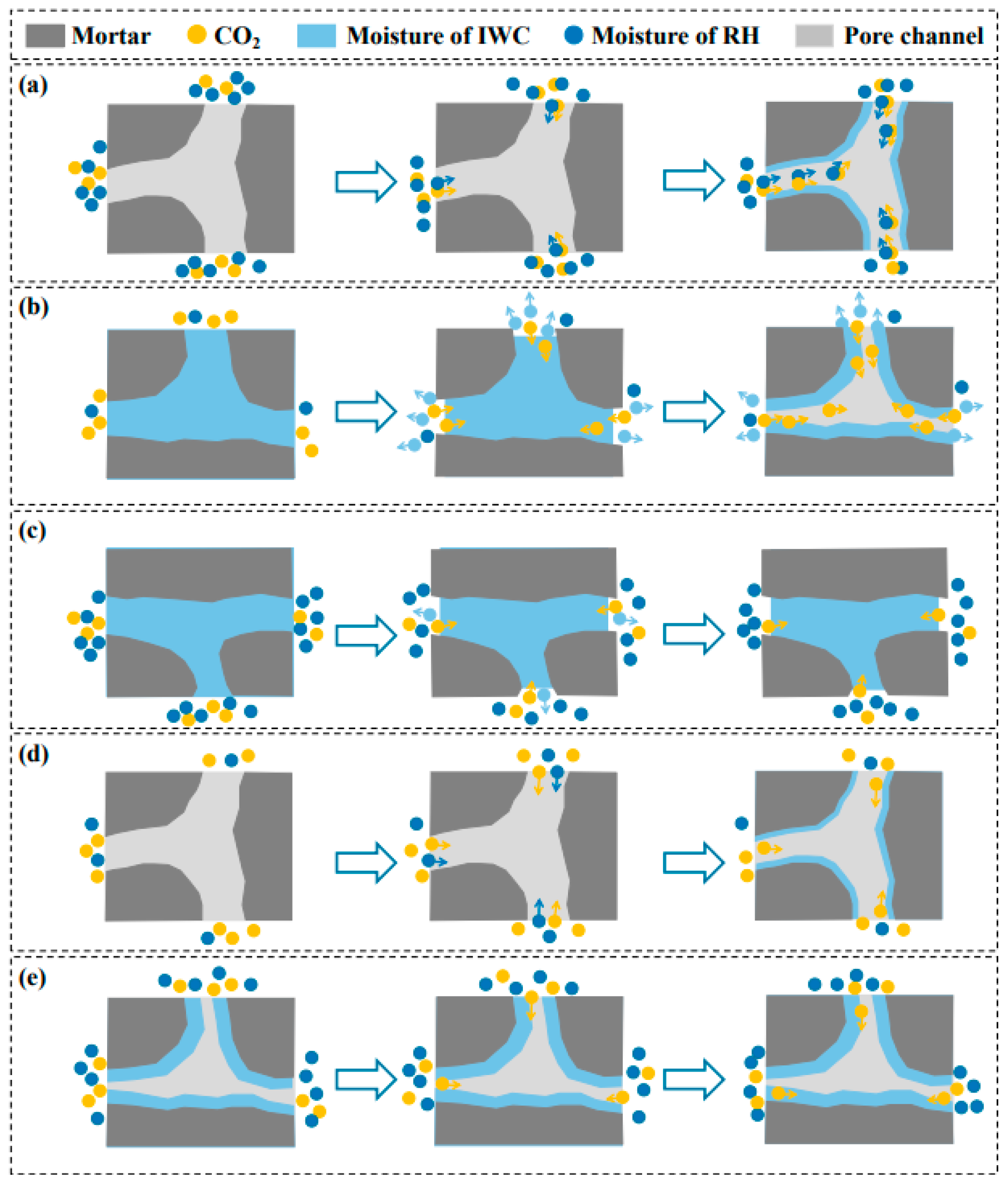

3.1. Moisture Content

3.2. Carbon Dioxide Concentration and Gas Pressure

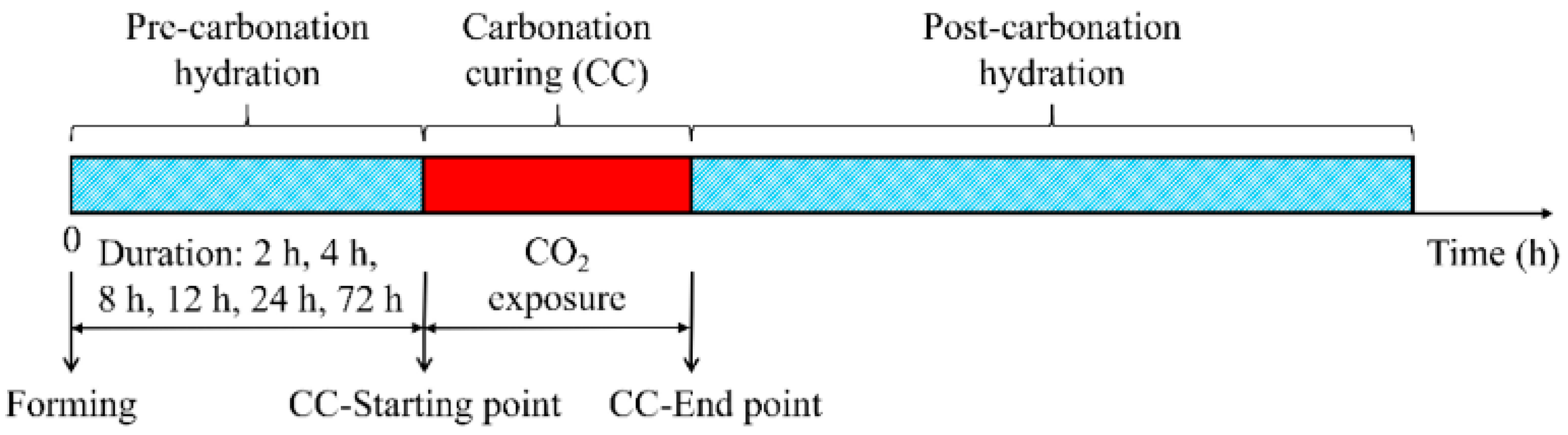

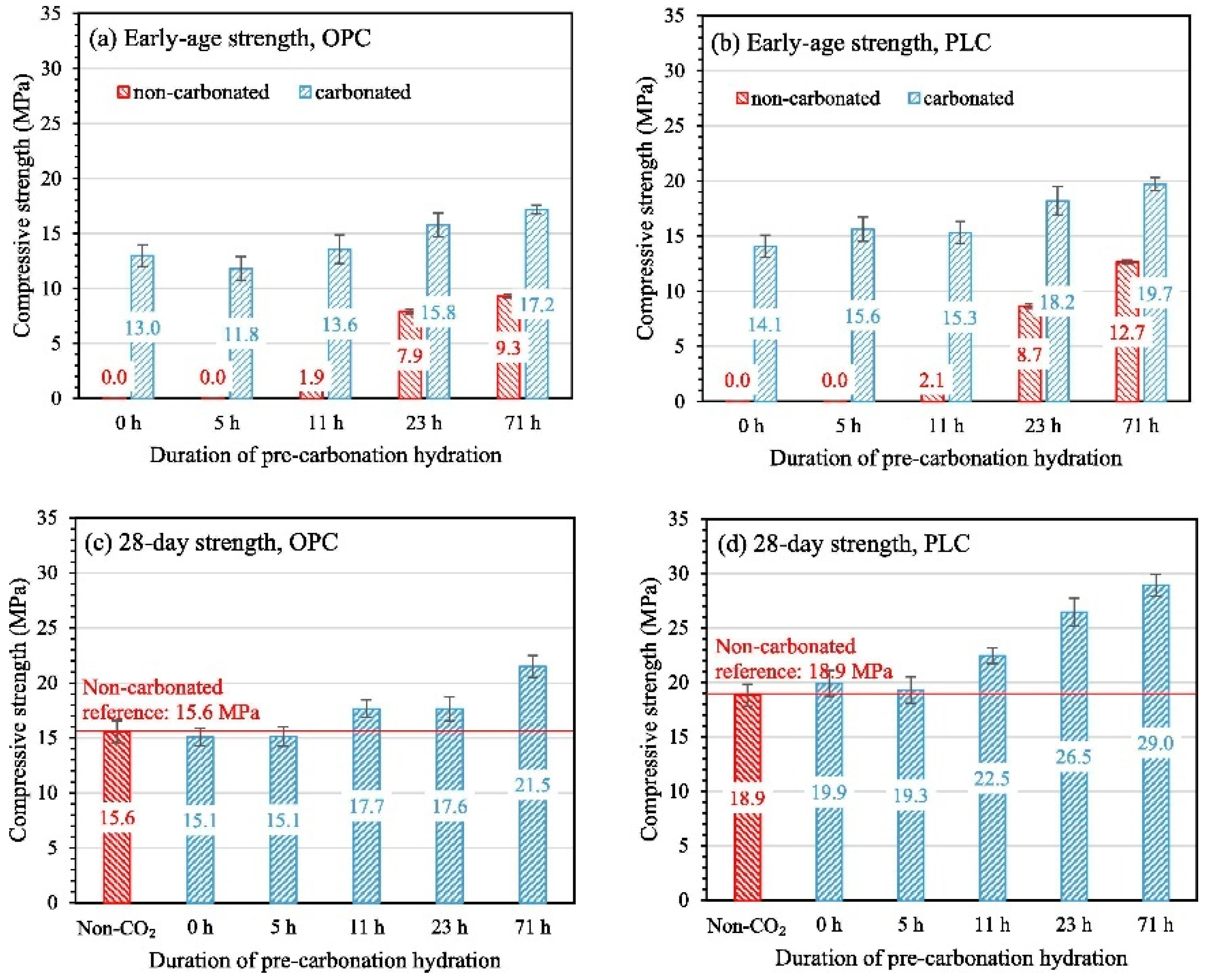

3.3. Pre-Hydration and Curing Duration

3.4. Other Key Influencing Factors

4. Impact of Early Carbonation Curing on Cementitious Materials

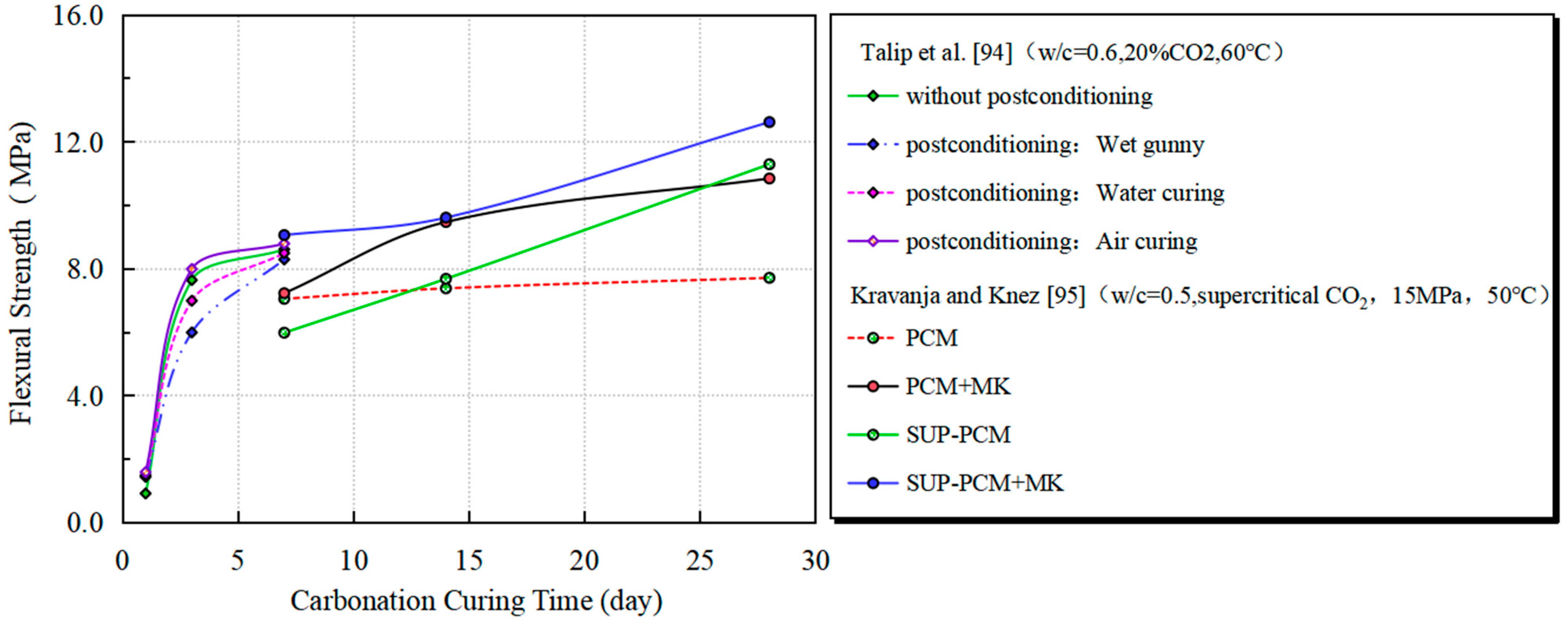

4.1. Mechanical Properties

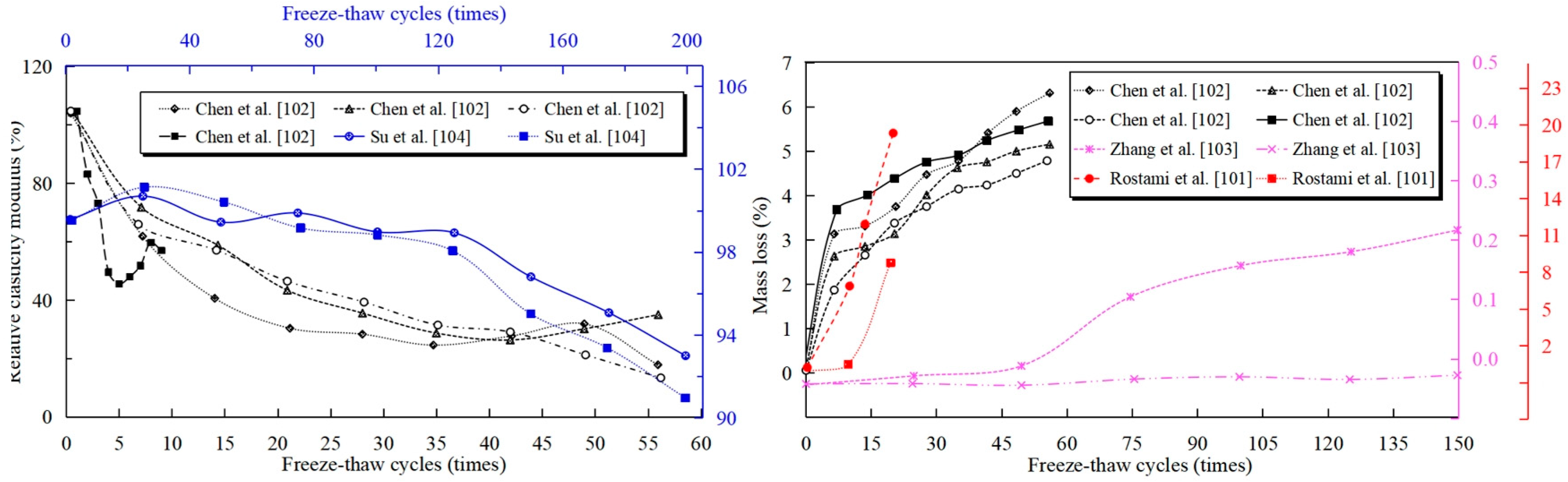

4.2. Influence on Durability

5. Microstructural Analysis

6. Practical Application: Large-Scale Carbonation Curing Scheme in Prefabricated Component Production

7. Conclusions and Prospects

- (1)

- Calcium carbonate exhibits superior thermal stability and erosion resistance compared to C-S-H gel in cementitious materials, with its composition and properties being more readily tunable. As a primary contributor to early-age strength, its performance warrants greater research focus on how mineral carbonation hydration activity influences resultant products—an area currently underexplored.

- (2)

- The formation and accumulation patterns of carbonation products substantially refine pore structures while enhancing cement paste impermeability and mechanical strength. Regulating temperature and CO2 concentration enables controlled transformation of calcium carbonate polymorphs to optimize target phase formation. Although industrial carbon sequestration primarily targets precast elements, precise carbonation process control effectively achieves carbon capture objectives in manufacturing settings.

- (3)

- Optimizing moisture content, curing duration, and pre-hydration time enhances carbon sequestration efficiency. Key parameters include ≈4.5% moisture content at 0.5 water–binder ratio and ≈40% dehydration rate at 0.3–0.4 ratios (varying by aggregate/concrete type). CO2 concentrations > 60% or pressure > 0.2 MPa inhibit carbonation kinetics, while excessive curing impairs mid-late hydration. Pre-hydration predominantly affects early-strength development, with clinker composition dictating requirements: slow-hydrating β-C2S necessitates 18 h pre-hydration (achieving 32.33% carbonation) versus shorter durations for C3S.

- (4)

- Early carbonation curing significantly improves chloride resistance, freeze–thaw durability, and sulfate attack resistance. By refining pores and densifying the matrix, it creates effective barriers against deleterious ion ingress, thereby extending structural service life. The process also elevates microhardness by ≈40%, with surface hardness exceeding internal values by >2× in modified cementitious systems.

- (5)

- Currently, the rules for the formation, distribution, and evolution of microstructures during concrete carbonation remain unclear. This is especially true for the interface interaction mechanism between carbonation products (e.g., calcite) and hydration products (e.g., C-S-H), the hydration–carbonation coupling process, the distribution of products in the interfacial transition zone (ITZ), and their long-term evolution behavior—these have not been systematically established, and research in admixture systems is even more limited. Going forward, priority should be given to advancing in situ monitoring technologies like Raman spectroscopy and XRD mapping to track the carbonation process in real time, while combining micromechanical tests to clarify interface behaviors. In testing, standardized accelerated carbonation experimental methods need to be developed, key parameter thresholds defined, and comparable data provided for industrial use. For long-term performance research, the limitations of short-term experiments must be addressed as follows: durability tracking should be conducted under the combined effects of natural carbonation and the environment to accurately assess concrete’s service life. In terms of materials and processes, efforts should be made to integrate carbonation technology with low-carbon materials such as recycled aggregates, geopolymers, and industrial waste residues, explore carbonation strengthening paths for non-traditional systems, and optimize the synergy between early carbonation and late hydration using kinetic models. Additionally, continuous, large-scale carbonation curing equipment should be developed, full-life-cycle assessments enhanced, and carbon emission reductions and economic benefits quantified to promote the application of this technology in practical engineering.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kweku, D.W.; Bismark, O.; Maxwell, A.; Desmond, K.A.; Danso, K.B.; Oti-Mensah, E.A.; Quachie, A.T.; Adormaa, B.B. Greenhouse Effect: Greenhouse Gases and Their Impact on Global Warming. J. Sci. Res. Rep. 2018, 17, 1–9. [Google Scholar] [CrossRef]

- Qin, Q.; Su, B.; Ma, Z.; Cui, K.; Chen, W.; Shen, P.; Zhao, Q.; Poon, C.S. Damage characterization of carbonated cement pastes with a gradient structure. Cem. Concr. Compos. 2024, 157, 105901. [Google Scholar] [CrossRef]

- Qin, Q.; Su, B.; Ma, Z.; Sun, R.; Zheng, Y.; Cui, K.; Shen, P.; Poon, C.S. Characterization of the inhomogeneity of mineralized steel slag compacts (MSSCs) and its effect on mechanical properties and damage. Cem. Concr. Compos. 2025, 162, 106152. [Google Scholar] [CrossRef]

- Mostafaei, H.; Kelishadi, M.; Bahmani, H.; Wu, C.; Ghiassi, B. Development of sustainable HPC using rubber powder and waste wire: Carbon footprint analysis, mechanical and microstructural properties. Eur. J. Environ. Civ. Eng. 2024, 29, 399–420. [Google Scholar] [CrossRef]

- Lin, Z.; Lyu, G.; Fang, K. Carbon emissions assessment of concrete and quantitative calculation of CO2 reduction benefits of SCMs: A case study of C30-C80 ready-mixed concrete in China. Case Stud. Constr. Mater. 2025, 22, e04287. [Google Scholar] [CrossRef]

- Chen, T.; Nelson, J.P.; Gupta, V.; Mobley, P.D. Life-cycle assessment of concrete production with carbon capture and carbon upcycling process. J. Environ. Manag. 2025, 391, 126303. [Google Scholar] [CrossRef]

- Machado, N.B.; Silvestre, J.D.; Bohne, R.A. Embodied GHG emissions of reinforced concrete and timber structures: Relevance, driving factors and target values. Build. Environ. 2025, 275, 112753. [Google Scholar] [CrossRef]

- Almasailam, F.; Purnell, P.; Black, L. Factors affecting the carbon footprint of reinforced concrete structures. Mater. Struct. 2025, 58, 116. [Google Scholar] [CrossRef]

- Qin, Q.; Su, B.; Ma, Z.; Sun, R.; Shen, P.; Li, J.; Poon, C.S. Investigation of mechanical properties and damage characterization of cement pastes prepared by coupled carbonation-hydration curing. Cem. Concr. Compos. 2025, 160, 106049. [Google Scholar] [CrossRef]

- Liang, X.; Ye, Z.; Chang, J. Early Hydration Activity of Composite with Carbonated Steel Slag. J. Chin. Ceram. Soc. 2012, 40, 226–233. [Google Scholar] [CrossRef]

- Alexander, M.; Beushausen, H. Durability, service life prediction, and modelling for reinforced concrete structures—Review and critique. Cem. Concr. Res. 2019, 122, 17–29. [Google Scholar] [CrossRef]

- Wang, X.; Tu, J. Carbonation performance of loaded portland cement, fly ash, and ground granulated blast furnace slag concretes. J. Harbin Eng. Univ. 2023, 44, 1426–1432. [Google Scholar]

- Zhang, D.; Li, V.C.; Ellis, B.R. Optimal Pre-hydration Age for CO2 Sequestration through Portland Cement Carbonation. ACS Sustain. Chem. Eng. 2018, 6, 15976–15981. [Google Scholar] [CrossRef]

- Beltrame, N.A.M.; de Medeiros-Junior, R.A.; Dias, R.L.; Witzke, F.B. Preliminary study of the effect of carbonation curing on geopolymers. Rev. IBRACON Estrut. Mater. 2024, 17, e17110. [Google Scholar] [CrossRef]

- Liu, Y.; Li, C.; Gao, Y.; Li, S. Hydration Properties of Circulating Fluidized Bed Fly Ash under Carbonation Condition. J. Build. Mater. 2024, 27, 837–845. [Google Scholar]

- Hu, X. Study on Mineral Carbonation Curing of SolidWaste Lightweight Concrete. Master’s Thesis, Zhejiang University, Hangzhou, China, 2019. [Google Scholar]

- Sharma, D.; Goyal, S. Accelerated carbonation curing of cement mortars containing cement kiln dust: An effective way of CO2 sequestration and carbon footprint reduction. J. Clean. Prod. 2018, 192, 844–854. [Google Scholar] [CrossRef]

- Shi, C.; Tu, Z.; Guo, M.-Z.; Wang, D. Accelerated carbonation as a fast curing technology for concrete blocks. In Sustainable and Nonconventional Construction Materials Using Inorganic Bonded Fiber Composites; Elsevier: Amsterdam, The Netherlands, 2017; pp. 313–341. [Google Scholar] [CrossRef]

- Hameed, R.; Seo, J.; Park, S.; Amr, I.T.; Lee, H.K. CO2 Uptake and Physicochemical Properties of Carbonation-Cured Ternary Blend Portland Cement–Metakaolin–Limestone Pastes. Materials 2020, 13, 4656. [Google Scholar] [CrossRef]

- Lyu, H.; Hao, L.; Li, L.; Zhang, S.; Poon, C.S. The development of sustainable cement pastes enhanced by the synergistic effects of glass powder and carbonation curing. J. Clean. Prod. 2023, 418, 4138237. [Google Scholar] [CrossRef]

- Li, X.; Li, X.; Fan, P.; Bao, W.; Chang, L.; Wang, J. Study on the impact of using decarbonized gasification slag for CO2 mineralization andstorage to prepare calcium carbonate. J. Fuel Chem. Technol. 2024, 52, 1193–1202. [Google Scholar] [CrossRef]

- Yuan, W.; Zhang, G.; Liu, L.; Wang, W.; Gong, K.; Luo, X.; Gu, T.; Zhang, L.; Zhao, F. Synergistic carbonation reaction mechanism of steel slag-magnesium slag. Constr. Build. Mater. 2025, 498, 144015. [Google Scholar] [CrossRef]

- Shi, C.; Liu, M.; He, P.; Ou, Z. Factors affecting kinetics of CO2curing of concrete. J. Sustain. Cem. Mater. 2012, 1, 24–33. [Google Scholar] [CrossRef]

- Berger, R.; Klemm, W. Accelerated curing of cementitious systems by carbon dioxide. Cem. Concr. Res. 1972, 2, 647–652. [Google Scholar] [CrossRef]

- Young, J.F.; Berger, R.L.; Breese, J. Accelerated Curing of Compacted Calcium Silicate Mortars on Exposure to CO2. J. Am. Ceram. Soc. 1974, 57, 394–397. [Google Scholar] [CrossRef]

- Zhao, S.; Liu, Z.; Wang, F.; Hu, S.; Liu, C. Effect of Extended Carbonation Curing on the Properties of γ-C2S Compacts and Its Implications on the Multi-Step Reaction Mechanism. ACS Sustain. Chem. Eng. 2021, 9, 6673–6684. [Google Scholar] [CrossRef]

- Wang, D.; Chang, J. Comparison on accelerated carbonation of β-C2S, Ca(OH)2, and C4AF: Reaction degree, multi-properties, and products. Constr. Build. Mater. 2019, 224, 336–347. [Google Scholar] [CrossRef]

- Zhang, W.; Cao, L.; Zhi, X.; Liu, L.; Ren, X.; Ye, J. Development on Hydration Activity, Properties of Low-Calcium Minerals and Its Clinkers. J. Chin. Ceram. Soc. 2023, 51, 2465–2477. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J.; Liu, L.; Ye, J.; Qian, J. Effect of Liquid Environment on Hydration Activity of Ternesite-Dicalcium Silicate Composite Minerals. J. Chin. Ceram. Soc. 2022, 50, 2070–2077. [Google Scholar] [CrossRef]

- Goodbrake, C.J.; Young, J.F.; Berger, R.L. Reaction of Hydraulic Calcium Silicates with Carbon Dioxide and Water. J. Am. Ceram. Soc. 1979, 62, 488–491. [Google Scholar] [CrossRef]

- Chang, J.; Fang, Y.; Shang, X. The role of β-C2S and γ-C2S in carbon capture and strength development. Mater. Struct. 2016, 49, 4417–4424. [Google Scholar] [CrossRef]

- Bersisa, A.; Moon, K.-Y.; Kim, G.; Cho, J.-S.; Park, S. Internal carbonation of calcium silicate cement incorporated with Na2CO3 and NaHCO3. Constr. Build. Mater. 2025, 462, 139732. [Google Scholar] [CrossRef]

- Shtepenko, O.; Hills, C.; Brough, A.; Thomas, M. The effect of carbon dioxide on β-dicalcium silicate and Portland cement. Chem. Eng. J. 2006, 118, 107–118. [Google Scholar] [CrossRef]

- Ashraf, W.; Olek, J. Carbonation behavior of hydraulic and non-hydraulic calcium silicates: Potential of utilizing low-lime calcium silicates in cement-based materials. J. Mater. Sci. 2016, 51, 6173–6191. [Google Scholar] [CrossRef]

- Monkman, S.; MacDonald, M.; Hooton, R.D.; Sandberg, P. Properties and durability of concrete produced using CO2 as an accelerating admixture. Cem. Concr. Compos. 2016, 74, 218–224. [Google Scholar] [CrossRef]

- Monkman, S.; MacDonald, M. Carbon dioxide upcycling into industrially produced concrete blocks. Constr. Build. Mater. 2016, 124, 127–132. [Google Scholar] [CrossRef]

- Beltrame, N.A.; Borçato, A.G.; Sakata, R.D.; Medeiros-Junior, R.A. Effect of carbonation curing and Na2O concentration of metakaolin-based geopolymer concrete on efflorescence formation. J. Build. Eng. 2025, 114, 114376. [Google Scholar] [CrossRef]

- Huntzinger, D.N.; Gierke, J.S.; Kawatra, S.K.; Eisele, T.C.; Sutter, L.L. Carbon Dioxide Sequestration in Cement Kiln Dust through Mineral Carbonation. Environ. Sci. Technol. 2009, 43, 1986–1992. [Google Scholar] [CrossRef]

- Rendek, E.; Ducom, G.; Germain, P. Carbon dioxide sequestration in municipal solid waste incinerator (MSWI) bottom ash. J. Hazard. Mater. 2006, 128, 73–79. [Google Scholar] [CrossRef]

- Venhuis, M.A.; Reardon, E.J. Carbonation of cementitious wasteforms under supercritical and high pressure subcritical conditions. Environ. Technol. 2003, 24, 877–887. [Google Scholar] [CrossRef]

- Dan, Y.; Liang, Y.; Xu, R.; Ning, F.; Chen, Z. Experimental study on early mechanical properties of recycled aggregate concrete after NaHCO3 carbonation. Acta Mater. Compos. Sin. 2025, 42, 3352–3365. [Google Scholar] [CrossRef]

- Haselbach, L.M.; Thomle, J.N. An alternative mechanism for accelerated carbon sequestration in concrete. Sustain. Cities Soc. 2014, 12, 25–30. [Google Scholar] [CrossRef]

- Deng, W.; Zhai, J.; Lai, H.; Lu, F.; Zong, Y.; Xiong, R.; Guan, B.; Chang, M. Research progress of microorgan-ism-carbonization modified steel slag and its effect on hydration characteristics of cement. Acta Mater. Compos. Sin. 2025, 42, 119–132. [Google Scholar] [CrossRef]

- Pan, X.; Shi, C.; Farzadnia, N.; Hu, X.; Zheng, J. Properties and microstructure of CO2 surface treated cement mortars with subsequent lime-saturated water curing. Cem. Concr. Compos. 2019, 99, 89–99. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B.; Qureshi, T.; Adak, D. Cement-based solidification of nuclear waste: Mechanisms, formulations and regulatory considerations. J. Environ. Manag. 2024, 356, 120712. [Google Scholar] [CrossRef]

- Teir, S.; Eloneva, S.; Zevenhoven, R. Production of precipitated calcium carbonate from calcium silicates and carbon dioxide. Energy Convers. Manag. 2005, 46, 2954–2979. [Google Scholar] [CrossRef]

- Morse, J.W.; Arvidson, R.S.; Lüttge, A. Calcium Carbonate Formation and Dissolution. Chem. Rev. 2007, 107, 342–381. [Google Scholar] [CrossRef]

- Chang, R.; Choi, D.; Kim, M.H.; Park, Y. Tuning Crystal Polymorphisms and Structural Investigation of Precipitated Calcium Carbonates for CO2 Mineralization. ACS Sustain. Chem. Eng. 2016, 5, 1659–1667. [Google Scholar] [CrossRef]

- Zhong, X. Parameters of Accelerated Carbonation of Steel Slag-Based Cementitious Materials and Its High Temperature Performance. Master’s Thesis, Hunan University, Changsha, China, 2021. [Google Scholar]

- Zhang, K.; Yio, M.; Wong, H.; Buenfeld, N. Real-time monitoring of carbonation of hardened cement pastes using Raman microscopy. J. Microsc. 2022, 286, 126–133. [Google Scholar] [CrossRef]

- Huang, H. Mechanism Research on CO2 Mineralcarbonation Curing of Building Materials Basedon Non-Hydraulic Cementitious Materials. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2019. [Google Scholar]

- Liu, M.; Hong, S.; Wang, Y.; Zhang, J.; Hou, D.; Dong, B. Compositions and microstructures of hardened cement paste with carbonation curing and further water curing. Constr. Build. Mater. 2021, 267, 121724. [Google Scholar] [CrossRef]

- Xue, K.; Wan, C.; Xu, Y.; Jiang, Y.; Cheng, Y. Effect of pre-hydration age on phase assemblage, microstructure and compressive strength of CO2 cured cement mortar. Constr. Build. Mater. 2022, 325, 126760. [Google Scholar] [CrossRef]

- Lu, J.; Ruan, S.; Liu, Y.; Wang, T.; Zeng, Q.; Yan, D. Morphological characteristics of calcium carbonate crystallization in CO2 pre-cured aerated concrete. RSC Adv. 2022, 12, 14610–14620. [Google Scholar] [CrossRef]

- Lai, C.; Liu, L.; Liu, J.; Chen, Z.; Zhang, S.; Li, M.; Wei, J.; Shi, C. Corrosion Resistance of Cement-based Materials by Carbonation Curing to Carbonic Acid Solution. J. Chin. Ceram. Soc. 2023, 51, 2890–2904. [Google Scholar] [CrossRef]

- Chen, X.; Li, S.; Hu, M.; Geng, Y.; Meng, S.; Jin, L.; Hu, Q.; Han, S. Early age accelerated carbonation of cementitious materials surface in low CO2 concentration condition. Constr. Build. Mater. 2024, 445, 137975. [Google Scholar] [CrossRef]

- Kottititum, B.; Phung, Q.T.; Maes, N.; Prakaypan, W.; Srinophakun, T. Early Age Carbonation of Fiber-Cement Composites under Real Processing Conditions: A Parametric Investigation. Appl. Sci. 2018, 8, 190. [Google Scholar] [CrossRef]

- Shi, C.; He, P.; Tu, Z. Effect of preconditioning on process and microstructure of carbon dioxide cured concrete. J. Chin. Ceram. Soc. 2014, 42, 996–1004. [Google Scholar]

- He, P.; Drissi, S.; Hu, X.; Liu, J.; Shi, C. Investigation on the influential mechanism of FA and GGBS on the properties of CO2-cured cement paste. Cem. Concr. Compos. 2023, 142, 105186. [Google Scholar] [CrossRef]

- Wang, W.; Wei, X.; Cai, X.; Deng, H.; Li, B. Mechanical and Microstructural Characteristics of Calcium Sulfoaluminate Cement Exposed to Early-Age Carbonation Curing. Materials 2021, 14, 3515. [Google Scholar] [CrossRef]

- Li, Z.; He, Z.; Chen, X. The Performance of Carbonation-Cured Concrete. Materials 2019, 12, 3729. [Google Scholar] [CrossRef] [PubMed]

- Alimi, W.O.; Adekunle, S.K.; Ahmad, S.; Amao, A.O. Carbon dioxide sequestration characteristics of concrete mixtures incorporating high-volume cement kiln dust. Case Stud. Constr. Mater. 2022, 17, e01414. [Google Scholar] [CrossRef]

- Lin, S.; Chen, P.; Xiang, W.; Hu, C.; Li, F.; Liu, J.; Ding, Y. Exploring the Effect of Moisture on CO2 Diffusion and Particle Cementation in Carbonated Steel Slag. Appl. Sci. 2024, 14, 3631. [Google Scholar] [CrossRef]

- Song, B.; Shi, C.; Hu, X.; Ouyang, K.; Ding, Y.; Ke, G. Effect of early CO2 curing on the chloride transport and binding behaviors of fly ash-blended Portland cement. Constr. Build. Mater. 2021, 288, 123113. [Google Scholar] [CrossRef]

- Morshed, A.Z.; Shao, Y. Influence of moisture content on CO2 uptake in lightweight concrete subject to early carbonation. J. Sustain. Cem. Mater. 2013, 2, 144–160. [Google Scholar] [CrossRef]

- Zhang, D.; Shao, Y. Early age carbonation curing for precast reinforced concretes. Constr. Build. Mater. 2016, 113, 134–143. [Google Scholar] [CrossRef]

- Zhan, B.J.; Poon, C.S.; Shi, C.J. Materials characteristics affecting CO2 curing of concrete blocks containing recycled aggregates. Cem. Concr. Compos. 2016, 67, 50–59. [Google Scholar] [CrossRef]

- Shi, C.; He, F.; Wu, Y. Effect of pre-conditioning on CO2 curing of lightweight concrete blocks mixtures. Constr. Build. Mater. 2012, 26, 257–267. [Google Scholar] [CrossRef]

- Šavija, B.; Luković, M. Carbonation of cement paste: Understanding, challenges, and opportunities. Constr. Build. Mater. 2016, 117, 285–301. [Google Scholar] [CrossRef]

- Suda, Y.; Tomiyama, J.; Saito, T.; Saeki, T. Effect of relative humidity on carbonation shrinkage and hydration product of cement paste. Cem. Sci. Concr. Technol. 2020, 73, 71–78. [Google Scholar] [CrossRef]

- Wu, L.; Zhang, W.; Jiang, H.; Ju, X.; Guan, L.; Liu, H.; Chen, S. Synergistic Effects of Environmental Relative Humidity and Initial Water Content of Recycled Concrete Aggregate on the Improvement in Properties via Carbonation Reactions. Materials 2023, 16, 5251. [Google Scholar] [CrossRef]

- Zuo, W.; Zhao, X.; Luo, J.; He, Z.; Zhao, J. Investigating the impact of carbonation curing concentrations on the mechanical properties and microstructure of recycled concrete. J. Build. Eng. 2024, 96, 110465. [Google Scholar] [CrossRef]

- Chang, J.; Fang, Y.; Shang, X.; Wang, J. Effect of Accelerated Carbonation on Microstructure of Calcium Silicate Hydrate. J. Chin. Ceram. Soc. 2015, 43, 1055–1060. [Google Scholar] [CrossRef]

- Bukowski, J.; Berger, R. Reactivity and strength development of CO2 activated non-hydraulic calcium silicates. Cem. Concr. Res. 1979, 9, 57–68. [Google Scholar] [CrossRef]

- Hu, L.; Jia, Y.; Chen, Z.; Yao, Y.; Sun, J.; Xie, Q.; Yang, H. An insight of carbonation-hydration kinetics and microstructure characterization of cement paste under accelerated carbonation at early age. Cem. Concr. Compos. 2022, 134, 104763. [Google Scholar] [CrossRef]

- Mejdoub, R.; Hammi, H.; Khitouni, M.; Suñol, J.J.; M’Nif, A. The effect of prolonged mechanical activation duration on the reactivity of Portland cement: Effect of particle size and crystallinity changes. Constr. Build. Mater. 2017, 152, 1041–1050. [Google Scholar] [CrossRef]

- Zhan, B.J.; Xuan, D.X.; Poon, C.S.; Shi, C.J. Mechanism for rapid hardening of cement pastes under coupled CO2-water curing regime. Cem. Concr. Compos. 2019, 97, 78–88. [Google Scholar] [CrossRef]

- Zhang, D.; Cai, X.; Jaworska, B. Effect of pre-carbonation hydration on long-term hydration of carbonation-cured cement-based materials. Constr. Build. Mater. 2020, 231, 117122. [Google Scholar] [CrossRef]

- Ndzila, J.S.; Yang, Z. Carbonation properties of ion-doped non-hydraulic calcium silicate binders: A review. J. Build. Eng. 2025, 105, 112427. [Google Scholar] [CrossRef]

- Chen, T.; Gao, X. Effect of carbonation curing regime on strength and microstructure of Portland cement paste. J. CO2 Util. 2019, 34, 74–86. [Google Scholar] [CrossRef]

- Papadakis, V.G.; Vayenas, C.G.; Fardis, M.N. A reaction engineering approach to the problem of concrete carbonation. AIChE J. 1989, 35, 1639–1650. [Google Scholar] [CrossRef]

- Wang, D.; Zhang, H.; Liu, M.; Fu, Y.; Si, Z.; Zhang, X.; Zhong, Q. The characterization and mechanism of carbonated steel slag and its products under low CO2 pressure. Mater. Today Commun. 2023, 35, 105827. [Google Scholar] [CrossRef]

- Wei, X.; Ni, W.; Wang, X.; Li, K. Current Research of the Carbonization Technology of Steel Slag. Conserv. Util. Miner. Resour. 2019, 39, 99–104. [Google Scholar] [CrossRef]

- Cheng, X.; Chen, H.; Liu, R.; Geng, C.; Song, Z.; Liu, B.; Tian, H.; Huang, H.; Hou, P.; Li, Q. Influence of C3S/C2S ratio of Portland cement on the performance of super sulfated cement. Mater. Rep. Solidwaste Ecomater. 2025, 1, 9520003. [Google Scholar] [CrossRef]

- Sakamoto, M.; Shimo, N.; Kurita, E. Sodium Ferrite Particle Powder and Production Method Thereof. U.S. Patent No. 12421132, 23 September 2025. [Google Scholar]

- Ukwattage, N.; Ranjith, P.; Li, X. Steel-making slag for mineral sequestration of carbon dioxide by accelerated carbonation. Measurement 2017, 97, 15–22. [Google Scholar] [CrossRef]

- Song, X.; Zhao, C.; Song, Y.; Guo, Y.; Kong, X. Mineralization maintenance of steel slag-fly ash solid waste composite alkali-inspired cementitious materials. Clean Coal Technol. 2024, 30, 89–99. [Google Scholar] [CrossRef]

- Forsdyke, J.C.; Lees, J.M. Model fitting to concrete carbonation data with non-zero initial carbonation depth. Mater. Struct. 2023, 56, 22. [Google Scholar] [CrossRef]

- Zhang, D.; Shao, Y. Effect of early carbonation curing on chloride penetration and weathering carbonation in concrete. Constr. Build. Mater. 2016, 123, 516–526. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, J.; Qin, L.; Chen, T.; Gao, X. Study on the early volume stability of cement-based materials during CO2 curing. J. Build. Eng. 2024, 95, 110354. [Google Scholar] [CrossRef]

- Zhang, Z.; Zheng, K.; Chen, L.; Yuan, Q. Enhancing carbonation-activated γ-C2S compacts through Na2CO3 post-curing: Alkalinity and mechanical properties improvement. J. Build. Eng. 2025, 103, 112136. [Google Scholar] [CrossRef]

- Duo, Z.D.; Brian, E.R.; Victor, L.C. Laboratory and Pilot Investigation on Properties of precast Engineered Cementitious Composites (ECC) Subjected to Carbonation Curing. In Proceedings of the 16th International Conference on Durability of Building Materials and Components, Beijing, China, 10–13 October 2023. [Google Scholar]

- Hu, W.-H.; Zhang, D.; Ellis, B.R.; Li, V.C. The Impact of Carbonation Curing on the Fatigue Behavior of Polyvinyl Alcohol Engineered Cementitious Composites (PVA-ECC). J. Adv. Concr. Technol. 2023, 21, 322–336. [Google Scholar] [CrossRef]

- Talip, A.R.A.; Khalid, N.H.A.; Sam, A.R.M. Performance of High-volume Carbide Lime Mortar Under Accelerated CO2 Curing Followed by Postconditioning Treatments. Pertanika J. Sci. Technol. 2025, 33, 677–691. [Google Scholar] [CrossRef]

- Kravanja, G.; Knez, Ž. Enhancing Strength and CO2 Uptake into Mortar Through Supercritical CO2 Treatment. In The 1st International Conference on Net-Zero Built Environment; Kioumarsi, M., Shafei, B., Eds.; Springer Nature: Cham, Switzerland, 2025; pp. 315–326. [Google Scholar] [CrossRef]

- Chen, T.; Bai, M.; Gao, X. Carbonation curing of cement mortars incorporating carbonated fly ash for performance improvement and CO2 sequestration. J. CO2 Util. 2021, 51, 101633. [Google Scholar] [CrossRef]

- Xian, X.; Zhang, D.; Lin, H.; Shao, Y. Ambient pressure carbonation curing of reinforced concrete for CO2 utilization and corrosion resistance. J. CO2 Util. 2022, 56, 101861. [Google Scholar] [CrossRef]

- Song, B.; Hu, X.; Pang, S.D.; Du, H.; Ke, G.; Shi, C. Effect of early CO2 curing on the chloride induced steel bars corrosion in cement mortars. J. Sustain. Cem. Mater. 2024, 13, 1063–1078. [Google Scholar] [CrossRef]

- Rostami, V.; Shao, Y.; Boyd, A.J.; He, Z. Microstructure of cement paste subject to early carbonation curing. Cem. Concr. Res. 2012, 42, 186–193. [Google Scholar] [CrossRef]

- Papadakis, V.G. Effect of supplementary cementing materials on concrete resistance against carbonation and chloride ingress. Cem. Concr. Res. 2000, 30, 291–299. [Google Scholar] [CrossRef]

- Rostami, V.; Shao, Y.; Boyd, A.J. Carbonation Curing versus Steam Curing for Precast Concrete Production. J. Mater. Civ. Eng. 2012, 24, 1221–1229. [Google Scholar] [CrossRef]

- Chen, T.; Gao, X. Use of Carbonation Curing to Improve Mechanical Strength and Durability of Pervious Concrete. ACS Sustain. Chem. Eng. 2020, 8, 3872–3884. [Google Scholar] [CrossRef]

- Zhang, D.; Shao, Y. Surface scaling of CO2-cured concrete exposed to freeze-thaw cycles. J. CO2 Util. 2018, 27, 137–144. [Google Scholar] [CrossRef]

- Su, A.; Chen, T.; Gao, X.; Li, Q.; Qin, L. Effect of carbonation curing on durability of cement mortar incorporating carbonated fly ash subjected to Freeze-Thaw and sulfate attack. Constr. Build. Mater. 2022, 341, 127920. [Google Scholar] [CrossRef]

- Alija, S.; Torrijo, F.; Quinta-Ferreira, M. Geological engineering problems associated with tunnel construction in karst rock masses: The case of Gavarres tunnel (Spain). Eng. Geol. 2013, 157, 103–111. [Google Scholar] [CrossRef]

- Li, C.; Wu, M.; Chen, Q.; Jiang, Z. Chemical and mineralogical alterations of concrete subjected to chemical attacks in complex underground tunnel environments during 20–36 years. Cem. Concr. Compos. 2018, 86, 139–159. [Google Scholar] [CrossRef]

- Zhou, G.; Huang, J.; Tao, X.; Luo, Q.; Zhang, R.; Liu, Z. Overview of 30 years of research on solubility trapping in Chinese karst. Earth-Sci. Rev. 2015, 146, 183–194. [Google Scholar] [CrossRef]

- Liu, L.; Xie, M.; He, Y.; Li, Y.; Wei, A.; Cui, X.; Shi, C. Expansion behavior and microstructure change of alkali-activated slag grouting material in carbonate environment. Constr. Build. Mater. 2020, 262, 120593. [Google Scholar] [CrossRef]

- Yang, F.; Lai, C.; Liu, L.; Chen, Z.; Jia, H.; Zhu, J.; Jiang, Z.; Shi, C.; Liu, J. A new method for improving the resistance of cement-based materials to carbonic acid water corrosion: Carbonation curing and further water curing. Constr. Build. Mater. 2024, 422, 135733. [Google Scholar] [CrossRef]

- Lin, L.; Wang, S.; Zhang, P.; Li, J.; Wang, S.; Zhong, J.; Zeng, L.; Qiu, X. Effect of curing regime on the strength development and microstructure evolution of high strength concrete. J. Build. Eng. 2023, 78, 107750. [Google Scholar] [CrossRef]

- Schwotzer, M.; Scherer, T.; Gerdes, A. Protective or damage promoting effect of calcium carbonate layers on the surface of cement based materials in aqueous environments. Cem. Concr. Res. 2010, 40, 1410–1418. [Google Scholar] [CrossRef]

- Chen, J.J.; Thomas, J.J.; Jennings, H.M. Decalcification shrinkage of cement paste. Cem. Concr. Res. 2006, 36, 801–809. [Google Scholar] [CrossRef]

- Watanabe, K.; Yokozeki, K.; Ashizawa, R.; Sakata, N.; Morioka, M.; Sakai, E.; Daimon, M. High durability cementitious material with mineral admixtures and carbonation curing. Waste Manag. 2006, 26, 752–757. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Li, L.; Gao, X.; Guo, M.; Qin, L. New insights into the role of early accelerated carbonation on the calcium leaching behavior of cement paste. Cem. Concr. Compos. 2023, 140, 105103. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, B.; Hu, X.; Liu, J.; Zhang, Z.; Pan, X.; Xie, Z.; Chang, J.; Zhang, T.; Nehdi, M.L.; et al. Effect of CO2 surface treatment on penetrability and microstructure of cement-fly ash–slag ternary concrete. Cem. Concr. Compos. 2021, 123, 104194. [Google Scholar] [CrossRef]

- Pan, X.; Shi, C.; Hu, X.; Ou, Z. Effects of CO2 surface treatment on strength and permeability of one-day-aged cement mortar. Constr. Build. Mater. 2017, 154, 1087–1095. [Google Scholar] [CrossRef]

- Lu, B.; He, P.; Liu, J.; Peng, Z.; Song, B.; Hu, X. Microstructure of Portland cement paste subjected to different CO2 concentrations and further water curing. J. CO2 Util. 2021, 53, 101714. [Google Scholar] [CrossRef]

- Xu, R.; Liang, Y.; Ning, F.; Chen, Z. The effect of NaHCO3 accelerated carbonation method on the early mechanical properties of recycled aggregate concrete. Structures 2024, 70, 101714. [Google Scholar] [CrossRef]

- Kim, S.; Seo, J.; Park, S.; Lee, H. Effect of accelerated carbonation curing on thermal evolution of hydrates in calcium sulfoaluminate cement. Constr. Build. Mater. 2024, 416, 135201. [Google Scholar] [CrossRef]

- Ning, J.; Zha, X.; Xiao, J.; Li, L.; Duan, Z. Integrated carbonation mixing and curing for cement paste: Enhancing CO2 uptake and early-age performance. J. Build. Eng. 2025, 113, 113979. [Google Scholar] [CrossRef]

- Liu, A.; Gong, Y.; Gao, S.; Ban, S.; Guo, J. Sulfate resistance of recycled concrete prepared with carbonation and nano SiO2 modified recycled coarse aggregates. J. Fuzhou Univ. Sci. Ed. 2023, 51, 256–263. [Google Scholar]

- Ghouleh, Z.; Guthrie, R.I.L.; Shao, Y.X. High-strength KOBM steel slag binder activated by carbonation. Constr. Build. Mater. 2015, 99, 175–183. [Google Scholar] [CrossRef]

- Chen, W.; Qi, Z.; Wang, Q.; Du, H. Strain-Hardening Cementitious Composites Enhanced by the Synergistic Effects of Carbonized Recycled Concrete Powder and Carbonation Curing. J. Mater. Civ. Eng. 2026, 38, 04025489. [Google Scholar] [CrossRef]

- Qin, L.; Mao, X.; Xie, Q.; Cui, W.; Bao, J.; Chen, T.; Gao, X.; Zhang, P. Effect of carbonation curing on the performance of cement paste added with carbide slag. Acta Mater. Compos. Sin. 2024, 41, 1001–1010. [Google Scholar] [CrossRef]

- Liu, Z.; Meng, W. Fundamental Understanding of Carbonation Curing and Durability of Carbonation-Cured Cement-Based Composites: A Review. J. CO2 Util. 2021, 44, 101428. [Google Scholar] [CrossRef]

- Bao, H.; Xu, G.; Yu, M.; Wang, Q.; Li, R.; Saafi, M.; Ye, J. Evolution of ITZ and its effect on the carbonation depth of concrete under supercritical CO2 condition. Cem. Concr. Compos. 2022, 126, 104336. [Google Scholar] [CrossRef]

- Memon, S.A.; Bekzhanova, Z.; Murzakarimova, A. A Review of Improvement of Interfacial Transition Zone and Adherent Mortar in Recycled Concrete Aggregate. Buildings 2022, 12, 1600. [Google Scholar] [CrossRef]

- Zhan, H.; Pan, G.; Huang, Y. Microstructure of interface transition zone in concrete under accelerated carbonation. J. Southeast Univ. Sci. Ed. 2015, 45, 569–574. [Google Scholar]

- Villagran-Zaccardi, Y.; Ellwood, L.; Perumal, P.; Torrenti, J.M.; Zhao, Z.; Bernard, E.; Hanein, T.; Ling, T.C.; Wang, W.; Zhang, Z.; et al. Carbonated recycled concrete aggregates in construction: Potential and bottlenecks identified by RILEM TC 309-MCP. Mater. Struct. 2024, 58, 20. [Google Scholar] [CrossRef]

- CarbonCure Precast: Frequently Asked Questions for Structural Engineers. CarbonCure Technologies Inc. 2023. Available online: https://www.carboncure.com/resources/carboncure-precast-frequently-asked-questions-for-structural-engineers/ (accessed on 24 November 2025).

- Zhan, B.; Poon, C.; Shi, C. CO2 curing for improving the properties of concrete blocks containing recycled aggregates. Cem. Concr. Compos. 2013, 42, 1–8. [Google Scholar] [CrossRef]

- Bawab, J.; El-Hassan, H.; Al Zagha, H.; El Gamal, M. Characterization and recycling of waste gabbro stone powder as a sustainable cement replacement. Clean. Waste Syst. 2025, 12, 100361. [Google Scholar] [CrossRef]

- Liu, Y.; Luo, P.; Jiang, S.; Liu, J.; Jing, D.; Liu, R. Influences of Preconditioning and Carbonization Time on Carbonization Effect of Foam Concrete and Analysis. Bull. Chin. Ceram. Soc. 2024, 43, 4027–4035. [Google Scholar]

- Sousa, V.; Silva, A.; Nogueira, R. Assessment of the Carbon Storage Potential of Portuguese Precast Concrete Industry. Buildings 2024, 14, 384. [Google Scholar] [CrossRef]

| Parameter | Recommended Range | Notes | References |

|---|---|---|---|

| CO2 Concentration | ≈60% | Higher concentrations increase uptake but with diminishing returns; surface densification may limit internal diffusion. | [72] |

| CO2 Pressure | 0.1–0.2 MPa | When the pressure exceeds 0.2 MPa, the effect of improving the carbonation degree is no longer significant. | [73,82] |

| Temperature | 20–25 °C | Most studies are conducted at room temperature. | [64,70] |

| Pre-curing Time | 2–6 h for OPC (general range 2–24 h) | The optimal time depends on the material system (e.g., approximately 2–6 h for ordinary Portland cement, and approximately 18 h may be required for systems containing β-C2S) and the set carbonation curing time. The goal is to control an appropriate initial moisture content. | [13,57,66,67,75] |

| Carbonation Curing Time | 2–24 h | The increase in compressive strength mainly occurs in the first few hours (e.g., within 2–24 h), after which the growth slows down. Excessively long times may lead to excessive densification of the surface, hindering the inward diffusion of CO2. The optimal time needs to be optimized in coordination with the pre-curing time. | [60,77] |

| Improvement Dimension | Microhardness | Porosity | ITZ Thickness | Elastic Modulus | ||

|---|---|---|---|---|---|---|

| Pre-carbonation Value | 0.15–0.25 GPa | 125–171 MPa | 24.97% (w/b 0.53) | 16.07% (w/b 0.35) | 47–79 µm | — |

| Post-carbonation Value | 0.45–0.50 GPa | 144–182 MPa | 20.29% | 12.27% | 35–51 µm | — |

| Improvement Magnitude (Absolute/Relative) | ≈0.30 GPa (≈200%) | ≈15–20 MPa (≈10–15%) | ≈4.7 percentage points | ≈3.8 percentage points | ≈12–28 µm (shrinkage ≈ 30%) | Up to 31% increase |

| Implication of Improvement | Increased hardness indicates enhanced resistance to local deformation, resulting from pore filling by calcium carbonate and interwoven C-S-H, making the interface denser. | (Recycled aggregate) higher microhardness signifies stronger bonding between old and new mortar, reducing microcrack development. | Reduced porosity directly decreases the permeability of CO2, moisture, and aggressive agents through the ITZ, enhancing durability. | A thinner ITZ indicates a reduced weak zone, leading to more uniform mechanical properties overall. | Increased elastic modulus reflects higher stiffness of the ITZ, aiding in load distribution and reducing stress concentration. | |

| References | [126] | [127] | [128] | [126] | [129] | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Chen, J.; Tang, L.; Yi, J.; Wu, K.; Zhang, J. Progress Analysis and Prospect on the Influence of Early-Age Carbonation Curing on Properties of Cement-Based Materials. Processes 2026, 14, 97. https://doi.org/10.3390/pr14010097

Chen J, Tang L, Yi J, Wu K, Zhang J. Progress Analysis and Prospect on the Influence of Early-Age Carbonation Curing on Properties of Cement-Based Materials. Processes. 2026; 14(1):97. https://doi.org/10.3390/pr14010097

Chicago/Turabian StyleChen, Junwen, Lei Tang, Jin Yi, Kexiong Wu, and Jiwang Zhang. 2026. "Progress Analysis and Prospect on the Influence of Early-Age Carbonation Curing on Properties of Cement-Based Materials" Processes 14, no. 1: 97. https://doi.org/10.3390/pr14010097

APA StyleChen, J., Tang, L., Yi, J., Wu, K., & Zhang, J. (2026). Progress Analysis and Prospect on the Influence of Early-Age Carbonation Curing on Properties of Cement-Based Materials. Processes, 14(1), 97. https://doi.org/10.3390/pr14010097