1. Introduction

Oil well production in the later stages often requires workover operations, such as tubing and casing corrosion inspection, which typically involve displacing the wellbore with water-based workover fluid (WBF) to provide a safe working environment. However, after water-based workover, the production recovery is frequently slow, the recovery degree is low, and the reservoir suffers severe damage. Studies have shown that when the formation pressure coefficient is below 1.0, filling the wellbore with water creates a pressure differential between the wellbore and the formation, causing water to leak into the formation pores under the resistance of fuzzy-ball forces [

1]. If the fuzzy-ball force is sufficient to balance the pressure differential, the system reaches mechanical equilibrium, and no further leakage occurs. During sand circulation or well cleaning operations, the circulation of workover fluid causes fluctuations in the pressure differential, breaking the equilibrium; the instantaneous leakage rate of water then increases sharply and continues to infiltrate until the fuzzy-ball force rises again to re-establish equilibrium, at which point fluid leakage ceases. This self-controlled leakage mechanism, governed by fuzzy-ball forces, explains why low-pressure wells can still complete workover despite a certain leakage rate.

After the operation, the water that has entered the formation is converted, under fuzzy-ball forces, into a backflow resistance. Rapidly reducing the hydrostatic pressure of the wellbore fluid column by means of gas lift, foam backflow, etc., can reverse the pressure differential between the wellbore and the formation, thereby enhancing the efficiency of water phase backflow. When the infiltrated water depth is excessive, and the formation pressure is insufficient to overcome the fuzzy-ball force required for backflow, production recovery is impeded [

2,

3,

4].

A large volume of water entering the reservoir dramatically increases the contact area with formation minerals and formation water, raising the risk of incompatibility and inducing physicochemical changes that cause various types of reservoir damage [

5,

6,

7].

Yu Dong et al. [

8] identified sensitive minerals, such as illite, kaolinite, montmorillonite, chlorite, and illite/montmorillonite interlayers, as well as siderite, pyrite, anhydrite, microcrystalline quartz, iron-bearing calcite, and dolomite in the sandstone units of the Dongfang 1-1 gas field; these minerals are prone to water sensitivity and rapid sensitivity damage during workover. Wang Lu-qi et al. [

9] systematically evaluated the sandstone reservoirs of the Daniu gas field and reported average damage rates ranging from 7.52% to 66.4% for six sensitivity categories (rapid sensitivity, water sensitivity, salt sensitivity, acid sensitivity, alkali sensitivity, stress sensitivity), with massive water influx significantly reducing reservoir permeability. Yang, H.T. [

10], studying an 8 m thick sandstone reservoir in an oilfield of the southwestern Ordos Basin, pointed out that the introduction of foreign workover fluids can cause incompatibility-induced chemical precipitation or hydraulic shear damage, thereby reducing pore connectivity or even causing blockage; mechanically, injected water may trigger pore collapse, fracture propagation, or rock deformation, destroying existing flow pathways.

To mitigate these damages, researchers have proposed various control strategies. Shao et al., focusing on medium- to high-porosity sandstones, developed a composite de-blocking system. (1) An organic workover cleaning fluid is applied to remove waxy, asphaltenic, and other organic deposits. (2) A high-efficiency breaker (PA-VERT) is used to reduce oil–water interfacial tension, fuzzy-ball resistance, and oil flow resistance during backflow, thereby facilitating the removal of infiltrated fluids. (3) A multi-acid system is employed to dissolve near-wellbore inorganic scales and stabilize expansive clay particles [

11]. Song Jifeng et al. [

12], targeting sandstones with porosity 12.4–17.1% and permeability 7.8–83.6 mD, introduced a composite organic phosphonate system that widens flow channels, enlarges oil-release areas, alters rock wettability, lowers interfacial tension, and reduces fuzzy-ball resistance, thereby improving the self-backflow capability of the injected fluid and controlling water lock damage.

Although these methods can address specific damage types, two major challenges remain. (1) A comprehensive reservoir damage assessment for a single well requires substantial time and effort, and for old wells, it is difficult to obtain representative core samples before workover; laboratory experiments based solely on drilling cores cannot fully reflect the long-term changes in pore throat characteristics and mineral structures after production, leading to insufficient evaluation accuracy. (2) The performance requirements of different damage control systems often conflict, so optimizing a single property can only avoid certain damages and cannot achieve holistic protection, leaving post-workover production still affected [

13,

14].

To fundamentally solve the reservoir damage caused by water-based workover fluids, it is necessary to control water ingress at the source, i.e., to implement temporary plugging. By introducing temporary plugging materials that balance the leakage pressure differential and seal the leakage pathways in the formation, water intrusion and associated damage can be markedly reduced. Currently, temporary plugging workover fluids for low-pressure oil and gas wells are classified into three major types: solid-phase, in situ solid-phase, and non-solid-phase systems.

Solid-phase temporary plugging adds rigid particles that match the formation pore throats, such as super-absorbent polymer (SAP) particles or oil-soluble plugging particles, to the workover fluid. Under the pressure differential, the resin particles enter the pores, deform to seal the flow channels, and form a dense mud cake on the wellbore wall to control leakage. To minimize particle-induced damage, a breaker is often pumped together with the particles or injected immediately after the operation to achieve de-blocking. Oil-soluble particles include brittle bridge plug particles and plastic filler particles; after reaching the near-well region, they deform under pressure and temperature to block pores and can later be dissolved by crude oil, condensate, diesel, or oil-wet surfactants. Solid-phase materials are simple, low-cost, and have high compressive strength, but the de-blocking steps are complex, residual particles may cause secondary damage, and slow degradation leads to delayed productivity recovery [

15]. The drawbacks are primarily concentrated in two aspects: plugging effectiveness and reservoir protection performance. On one hand, the transport of granular materials within fractures is influenced by factors such as fracture scale and morphology. Some particles tend to accumulate preferentially at the fracture entrance, forming a plugging barrier. However, this barrier is prone to failure under wellbore fluid dynamic disturbances, leading to repeated fluid losses [

16]. On the other hand, issues such as the complexity of the flowback treatment process, severe potential reservoir damage from residual particles, and slow productivity recovery due to the low degradation rate of the materials present further challenges [

17].

In situ solid-phase temporary plugging is represented by cured water and gel systems. Cured water is prepared as a liquid on the surface; after entering the formation, high-absorbent polymers undergo chemical reactions at elevated temperature and physically dehydrate to form a gel-like artificial wall in the pore throats or on the wellbore wall, blocking leakage. Chemical breakers, such as oxidizers or acids, can be used for de-blocking, or the gel can be left intact [

18]. Field applications in the Tarim Basin (nine wells) successfully blocked leakage in medium- to low-permeability reservoirs [

19]. Gel systems are tailored to pore throat size and fracture width by adding gel-type plugging agents; the strong absorbent resin binds free water, increases fluid viscosity, and forms soft particles that act as temporary plugs. De-blocking methods include perforation backflow, acid dissolution, or oil dissolution. Compared with solid-phase materials, in situ solid-phase systems are injected as liquids, have lower scale-matching requirements, and provide more reliable plugging; however, their de-blocking processes are also complex, and residual solids still pose a risk of damage.

Non-solid-phase systems are exemplified by foam workover fluids and fuzzy-ball workover fluids. Foam is generated by adding surfactants to the liquid phase and injecting gas, creating dense, irregularly sized bubbles that bridge pore throats under positive pressure differential; its plugging strength is weak, stability is poor, and the operational procedure is complicated, limiting its application. The fuzzy-ball fluid consists of a gas core, a surface tension-reducing membrane, a high-viscosity water layer, a fixing membrane, an improving membrane, polymer macromolecules, and a surfactant transition layer, forming a “one-core, two-layer, three-membrane [

20]” structure. When a large number of fuzzy balls are stably dispersed as individual units or linked chains within the liquid phase, they create a fuzzy-ball fluid. This fluid fills leakage pathways of various scales with randomly sized fuzzy balls, stacking to form a plugging structure. Through mechanisms such as differential pressure, pressure consumption, and support pressure, it balances the leakage pressure and achieves effective plugging of multi-scale pore throats, overcoming the limitations of traditional plugging materials that rely on precise channel-size evaluation [

21].

The experimental results show that the fuzzy-ball workover fluid exhibits density variation of less than 10% under 40 MPa and 30–130 °C; when the temperature rises to 200 °C, the reductions in plastic viscosity and apparent viscosity are below 17%, indicating excellent temperature and pressure resistance. It tolerates formation water salinity up to 8 × 10

4 mg/L [

22]. After exposure to 130 °C, 2.6 MPa, H

2S injection, and 48 h static holding, the apparent viscosity, plastic viscosity, and dynamic shear stress change by only 5.5%, demonstrating superior resistance to H

2S intrusion [

23]. The fuzzy-ball structure itself contains no solid phase and degrades readily; after degradation in the reservoir, it can be quickly backflowed, avoiding the residual damage associated with solid-phase or in situ solid-phase pluggers. In low-porosity, low-permeability coal column plug experiments, the permeability recovery of core samples after fuzzy-ball fluid backflow exceeds 96%; under multi-pressure natural gas multi-layer production conditions, the fluid’s impact on combined production flow is less than 10% damage [

24]. Owing to its plugging capability, temperature and pressure resistance, H

2S and gas intrusion resistance, and reservoir-protective advantages, the fuzzy-ball fluid has been developed into leak prevention drilling fluids [

25], completion fluids [

26], fracturing temporary plugging fluids, and workover fluids. It has been successfully applied in low-pressure oil–gas wells of the Ordos Basin [

27], the Puguang gas field, the Jidong oilfield [

28], and the Bohai oilfield [

29], solving the temporary plugging and reservoir damage control challenges of depleted gas reservoir storage injection wells [

30].

Overall, while numerous field studies have demonstrated the effectiveness of fuzzy-ball workover fluid for temporary plugging in low-pressure wells, a systematic elucidation of its reservoir protection mechanisms remains lacking. In particular, the differing plugging strength requirements of formations with various pressure coefficients and the stability of production recovery under fluctuating single-well fluid volumes have not been clearly understood. This paper combines laboratory experiments with field data analysis to reveal the reservoir protection mechanisms of fuzzy-ball workover fluid in low-pressure oil wells, providing theoretical foundations and technical references for reservoir-damage control using non-solid-phase temporary plugging systems represented by fuzzy-ball workover fluid.

Conventionally, the fuzzy-ball system is considered to provide reservoir protection advantages due to its absence of solid phases and self-generated solid-phase chemical reactions, allowing complete flowback after temporary plugging contact without leaving solid materials to block oil and water production channels in the formation. However, as the fuzzy-ball system remains a water-based fluid, the retention of large amounts of aqueous phase in the formation still poses risks of reservoir damage, such as incompatibility with formation water and hydraulic shear damage. In practical applications, such issues have not been observed, indicating that the reservoir protection mechanism of fuzzy-ball workover fluids differs from that of conventional solid-free plugging systems.

4. Field Application

In a low-pressure sandstone reservoir, the reservoir porosity is 12.5–23.6%, the permeability is 8.6–241.3 mD, and the formation pressure coefficient is 0.49–0.64. Five well times of the fuzzy-ball workover fluid application have been completed in the field.

4.1. Well X-1

Well X-1 has a well depth of 1256.65 m, a reservoir porosity of 0.22, a formation pressure coefficient of 0.64 before operation, and a leakage pressure difference of 0.49 MPa. The field preparation of the fuzzy-ball workover fluid was 1.10% coating agent + 0.50% fluffing agent + 0.30% core-forming agent + 0.30% film-forming agent + 0.10% sodium hydroxide. The formulation performance was a density of 0.97 g/cm3, a pH value of 10, an apparent viscosity of 17.5 mPa·s, a plastic viscosity of 10.0 mPa·s, a dynamic shear force of 7.5 Pa, and a dynamic plastic ratio of 0.75 Pa/mPa·s. For the first well cleaning operation, the oil pump injected 15.0 m3 of cavity-containing workover fluid from tubing at a displacement of 250 L/min, and the maximum pump pressure was 6.0 MPa. There is no leakage in circulation; workover fluid of 2.0 m3, pure oil of 10.5 m3 (containing gas), and mixed slurry of 2.9 m3 are returned. For the second well cleaning operation, the oil pump injected 18.0 m3 of cavity-containing workover fluid from tubing at a displacement of 400 L/min, the maximum pump pressure was 2.0 MPa, and the circulation leakage rate was 0.27 m3/h. A total of 10.4 m3 of workover fluid and 7.3 m3 of oil–water mixture was returned. This lasted for 4 days, and the well washing operation was successfully completed. Production resumed on the 26th day after the workover operation, and the formation fluid production index was 13.70 m3/(d·MPa), which was 17.09% higher than that before the operation at 11.70 m3/(d·MPa).

4.2. Well X-2

Well X-2 has a well depth of 1136.56 m, a reservoir porosity of 0.23, a formation pressure coefficient of 0.49 before operation, and a leakage pressure difference of 0.45 MPa. The field preparation of fuzzy-ball workover fluid was 1.00% coating agent + 0.50% fluffing agent + 0.30% core-forming agent + 0.30% film-forming agent + 0.10% sodium hydroxide. The formulation properties were a density of 0.98 g/cm3, pH 10, an apparent viscosity of 16.5 mPa·s, a plastic viscosity of 10.0 mPa·s, a dynamic shear force of 6.5 Pa, and a dynamic plastic ratio of 0.65 Pa/mPa·s. During the first well washing operation, the fuzzy-ball workover fluid was pumped from tubing at 12.8 m3, and there was no leakage in circulation; the workover fluid returned was 5.4 m3. For the second well cleaning operation, the oil pump injected 21.8 m3 of cavity-containing workover fluid from tubing at a discharge rate of 200~450 L/min, a pump pressure of 2.0~2.5 MPa, and a circulation leakage rate of 0.45 m3/h. A total of 20.27 m3 of workover fluid was returned. This lasted for 4 days, and the well washing operation was successfully completed. After the workover operation, the liquid production index of Well X-2 is 23.33 m3/(d·MPa), which is 5.90% higher than that of 22.03 m3/(d·MPa) before the operation.

4.3. Well X-3

Well X-3 has a well depth of 1256.56 m, a reservoir porosity of 0.21, a formation pressure coefficient of 0.56, and a leakage pressure difference of 4.48 MPa. The field preparation of fuzzy-ball workover fluid was 1.22% coating agent + 0.50% fluffing agent + 0.28% core-forming agent + 0.50% film-forming agent + 0.10% sodium hydroxide. The formulation properties were a density of 0.96 g/cm3, pH 9.5, an apparent viscosity of 20.5 mPa·s, a plastic viscosity of 10.0 mPa·s, a dynamic shear force of 9.5 Pa, and a dynamic plastic ratio of 0.95 Pa/mPa·s. For the first well washing operation, the oil recovery rate is 6.0 m3, and the slurry mixing rate is 2.9 m3. For the second well washing operation, 45.0 m3 of fuzzy-ball workover fluid was pumped at 500 L/min; the pump pressure was 1~3 MPa, and the circulation leakage rate was 0.01 m3/h. The workover fluid returned is 51.6 m3 (gas-containing), the oil slurry is 0.5 m3, and the clean water is 2.0 m3. This lasted for 3 days, and the well washing operation was successfully completed. After the workover operation, the fluid production index of Well X-3 is 33.62 m3/(d·MPa), which is 9.16% higher than that of 30.80 m3/(d·MPa) before the operation.

4.4. Well X-4

Well X-4 has a well depth of 1505.67 m, a reservoir porosity of 0.25, a formation pressure coefficient before operation of 0.62, and a leakage pressure difference of 3.27 MPa. The field preparation of fuzzy-ball workover fluid was 1.00% coating agent + 0.50% fluffing agent + 0.30% core-forming agent + 0.50% film-forming agent + 0.10% sodium hydroxide. The formulation properties were a density of 0.91 g/cm3, pH 9, an apparent viscosity of 30.0 mPa·s, a plastic viscosity of 13.0 mPa·s, a dynamic shear force of 17.0 Pa, and a dynamic plastic ratio of 1.31 Pa/mPa·s. For the first well cleaning operation, 42.0 m3 of cavity-servicing fluid was pumped from tubing at a displacement of 560 L/min at a pump pressure of 3.1~3.5 MPa. There is no circulation loss; workover fluid 5.7 m3, oil 6.0 m3, and slurry 2.0 m3 are returned. For the second well cleaning operation, the oil pump injected 44.8 m3 of cavity-containing workover fluid from tubing at a discharge rate of 560 L/min, a pump pressure of 0.6~3.1 MPa, and a circulation leakage rate of 0.80 m3/h. It returned workover fluid 3.8 m3 and slurry 0.5 m3. This lasted 6 days, and the well-washing operation was successfully completed. After the workover operation, the fluid production index of Well X-4 is 70.62 m3/(d·MPa), which is 22.90% higher than that of Well X-4 before the workover operation at 57.47 m3/(d·MPa).

4.5. Well X-5

Well X-5 has a well depth of 1875.06 m, a reservoir porosity of 0.21, a formation pressure coefficient of 0.59 before operation, and a leakage pressure difference of 5.58 MPa. The field preparation of fuzzy-ball workover fluid was 1.10% coating agent + 0.50% fluffing agent + 0.30% core-forming agent + 0.30% film-forming agent + 0.10% sodium hydroxide. The formulation properties were a density of 0.97 g/cm3, pH 9, an apparent viscosity of 25.0 mPa·s, a plastic viscosity of 13.0 mPa·s, a dynamic shear force of 12.0 Pa, and a dynamic plastic ratio of 0.92 Pa/mPa·s. For the first well washing operation, 40.0 m3 of cast-in workover fluid is pumped from tubing at a displacement of 300 L/min; the maximum pump pressure is 8.0 MPa, circulation is free of leakage, and pure oil (gas) 3.1 m3, mixed slurry 1.2 m3, and mud 2.0 m3 are returned. For the second well cleaning operation, the oil pump injected 35.0 m3 of cavity-containing workover fluid from tubing at a discharge rate of 500 L/min; the maximum pump pressure was 3.0 MPa, and the circulation leakage rate was 0.01 m3/h. It returned workover fluid 31.5 m3, slurry 0.5 m3, and water 3.5 m3. This lasted for 4 days, and the well washing operation was successfully completed. After the workover operation, the liquid production index of Well X-5 is 61.60 m3/(d·MPa), which is 53.30% higher than that of 40.18 m3/(d·MPa) before the operation.

5. Analysis and Discussion of the Results

5.1. The Plugging Strength of Fuzzy-Ball Workover Fluid Is Positively Correlated with the Plugging Radius

In this case, the length of the sand pack pipe represents the plugging radius of the fuzzy-ball workover fluid, and the plugging strength of the system is characterized by the difference between the injection pressure of the fuzzy-ball workover fluid and the injection pressure of clean water. Compare the variation rule of fuzzy-ball sac plugging strength with the plugging radius of the system. See

Table 1 for experimental data.

It can be seen from

Table 1 that the initial injection clean water inlet pressure of five sand-filled pipes with different lengths is 0.31~1.58 MPa, the inlet pressure value when injecting fuzzy-ball workover fluid is 3.56~20.17 MPa, and the calculated relative clean water injection pressure increases by 3.25~18.59 MPa. The plugging strength of the system is characterized by the increase in the fuzzy-ball workover fluid relative to the water injection pressure displacement and is taken as the dependent variable. The plugging radius of the system is characterized by the length of the sand-filled pipe and is taken as the independent variable. The mathematical relationship between the plugging strength and the plugging radius of the fuzzy-ball workover fluid is established by the multiple regression method. See Equation (1).

According to Equation (1), the larger the plugging radius of the fuzzy-ball workover fluid, the higher the plugging strength of the system. The plugging strength increases by 1.029 MPa when the plugging radius increases by 0.1 m. Collect the field operation data of five low-pressure oil wells and use the temporary plugging strength of the characterization system to improve the formation pressure amplitude after the injection of the fuzzy-ball workover fluid. See Equation (2) for the calculation method.

In Equation (2), we have the following:

P0—formation pore pressure, MPa;

ΔP—temporary plugging strength, MPa;

Pf—wellbore fluid column pressure, MPa;

Pb—wellhead pump pressure, MPa.

The calculation method of wellbore fluid column pressure is shown in Equation (2).

In Equation (3), we have the following:

P—workover fluid density in the wellbore, g/cm3;

g—gravitational acceleration, 9.8 m/s2;

H—wellbore fluid column height, m.

In Equation (3), the wellbore fluid column height is taken as the formation depth value.

According to Equations (2) and (3), the calculation equation of temporary plugging strength after field fuzzy-ball workover fluid injection is obtained as follows:

The temporary plugging strength of fuzzy-ball workover fluid in five wells on site is calculated; see

Table 1,

Table 2,

Table 3 and

Table 4.

According to the field operation data of five low-pressure oil wells, assuming that the fuzzy-ball workover fluid is relatively evenly distributed after injection into the formation, the calculation equation of system injection volume and plugging radius is obtained. See Equation (5).

The sealing radius calculation method is obtained by deformation of Equation (5); see Equation (6) as follows:

n—Equations (5) and (6);

D—the outer diameter of casing, m;

V—the volume of the squeezed formation, m3;

φ—formation porosity, dimensionless (fraction);

According to Equation (6), the plugging radius distribution of five wells on site is calculated; see

Table 2.

Table 2.

Data table of temporary plugging strength and plugging radius distribution calculation for five field low-pressure oil wells using fuzzy-ball workover fluid.

Table 2.

Data table of temporary plugging strength and plugging radius distribution calculation for five field low-pressure oil wells using fuzzy-ball workover fluid.

| Well Number | Temporary Plugging Strength (MPa) | Sealing Radius (m) |

|---|

| X-1 | 10.06 | 0.24 |

| X-2 | 7.96 | 0.17 |

| X-3 | 12.93 | 0.26 |

| X-4 | 7.78 | 0.26 |

| X-5 | 14.98 | 0.22 |

Furthermore, the geological factors of the formation affected by the leakage of five low-pressure oil wells are considered (reservoir top depth, reservoir bottom depth, reservoir thickness, formation pressure coefficient, formation porosity), as well as workover engineering factors (fuzzy-ball workover fluid density, apparent viscosity, plastic viscosity, pump injection rate, plugging radius, etc.). Therefore, a total of 14 geological engineering factors for single-well field construction are collected, and the characteristic coefficient and contribution coefficient distribution of all factors on temporary plugging strength are calculated by the multiple regression method, as shown in

Table 3.

Table 3.

Data on influence characteristic coefficients and contribution coefficients for the temporary plugging strength of five field low-pressure oil wells.

Table 3.

Data on influence characteristic coefficients and contribution coefficients for the temporary plugging strength of five field low-pressure oil wells.

| Influencing Factors | Contribution Coefficient | Characteristic Coefficient |

|---|

| Reservoir Top Depth | 0.0004 | −0.0029 |

| Reservoir Bottom Depth | 0.0052 | 0.0423 |

| Reservoir Thickness | 0.0062 | −0.0499 |

| Formation Pressure Coefficient | 0.0000 | / |

| Formation Porosity | 0.0000 | / |

| Density | 0.0000 | / |

| Apparent Viscosity | 0.0928 | 0.7475 |

| Plastic Viscosity | 0.0000 | / |

| Yield Stress | 0.4648 | −3.7435 |

| Yield Stress–Plastic Viscosity Ratio | 0.0000 | / |

| pH Value | 0.3264 | −2.6286 |

| Displacement Rate | 0.0041 | 0.0331 |

| Pump Pressure | 0.1001 | −0.8063 |

| Plugging Radius | 0.8102 | 0.9674 |

| To Calculate the Variance | 0.09 | 0.11 |

| To Calculate the Standard Deviation | 0.30 | 0.33 |

According to the data in

Table 3, the contribution coefficient calculation yielded a variance of 0.09 and a standard deviation of 0.30; the influence characteristic coefficient calculation resulted in a variance of 0.11 and a standard deviation of 0.33. These computational results demonstrate a certain level of reliability. Further comparative analysis of the computed data is required. The contribution coefficient of the fuzzy-ball workover fluid’s plugging radius reaches 0.81, indicating that it plays a dominant controlling role in the temporary plugging strength of the system. Specifically, the plugging radius within the formation primarily governs the system’s temporary plugging strength, where a larger plugging radius results in higher temporary plugging strength of the system.

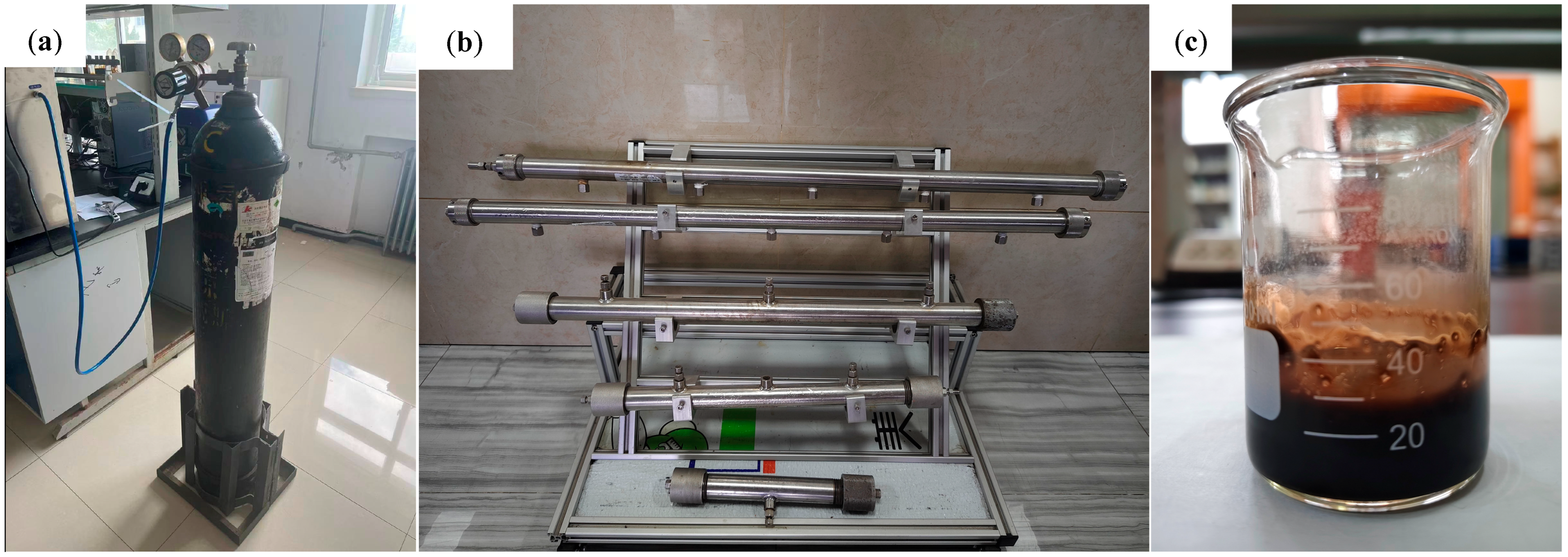

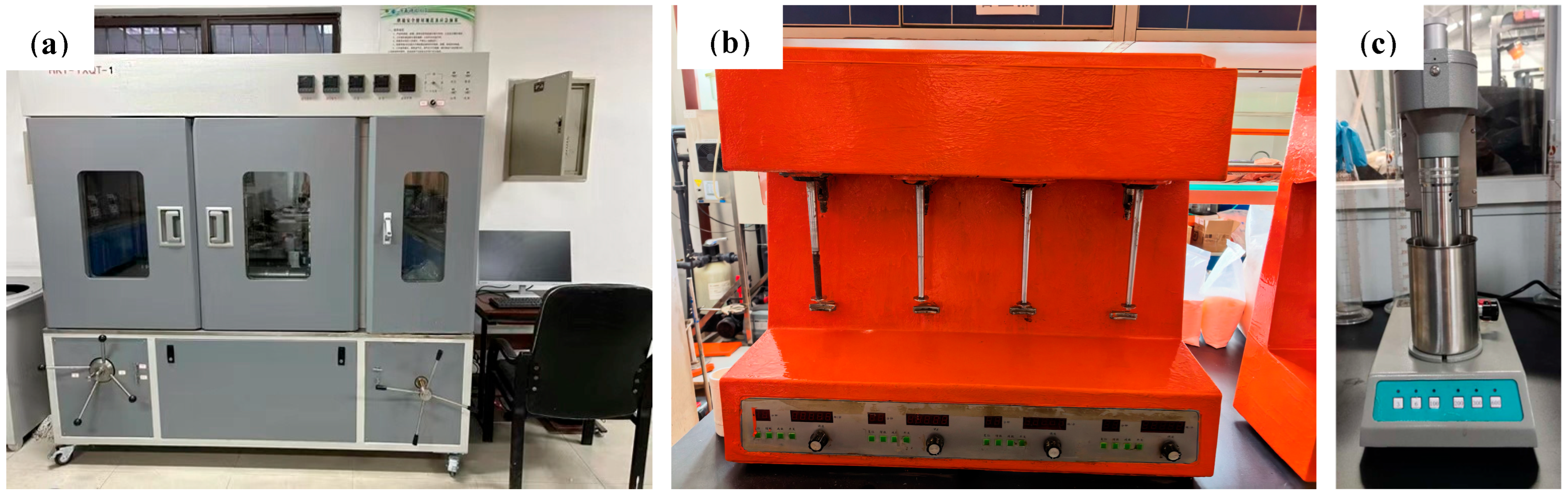

5.2. The Fuzzy-Ball Workover Fluid Mixed with Crude Oil Reduces Crude Oil Viscosity

Indoor workover fluid is mixed with crude oil according to the volume ratio of 1:1, simulating the mixing effect after the system directly contacts with formation crude oil and representing the state that the system is injected into the formation and directly contacts with crude oil. Considering the general water production of a large number of low-pressure oil wells after long-term production, the fuzzy-ball workover fluid is mixed with crude oil and formation water according to the volume ratio of 1:1:1, simulating the mixing effect after the system contacts with formation crude oil and formation water and representing the state that the system is injected into the formation and contacts with both crude oil and clean water.

The two kinds of mixed liquids were kept standing at a constant temperature of 60 °C, and the apparent viscosity and plastic viscosity of the mixed liquids were measured with a six-speed rotary viscometer at intervals of 16 h. See

Table 4 for the experimental data.

Table 4.

Viscosity change data of two kinds of mixed solutions after standing.

Table 4.

Viscosity change data of two kinds of mixed solutions after standing.

| | Standing Time/h | Apparent Viscosity/mPa·s | Plastic Viscosity/mPa·s |

|---|

| Volume ratio of Fuzzy-Ball Workover Fluids and crude oil: 1:1 | 0 | 22.5 | 12.5 |

| 16 | 22.0 | 12.0 |

| 32 | 21.0 | 11.5 |

| 48 | 19.5 | 10.5 |

| 64 | 19.5 | 10.0 |

| 80 | 18.5 | 10.0 |

| Volume ratio of fuzzy-ball workover fluid, crude oil, and formation water: 1:1:1 | 0 | 13.5 | 7.0 |

| 16 | 13.0 | 6.5 |

| 32 | 13.0 | 6.0 |

| 48 | 12.5 | 6.0 |

| 64 | 12.0 | 5.5 |

| 80 | 11.5 | 5.0 |

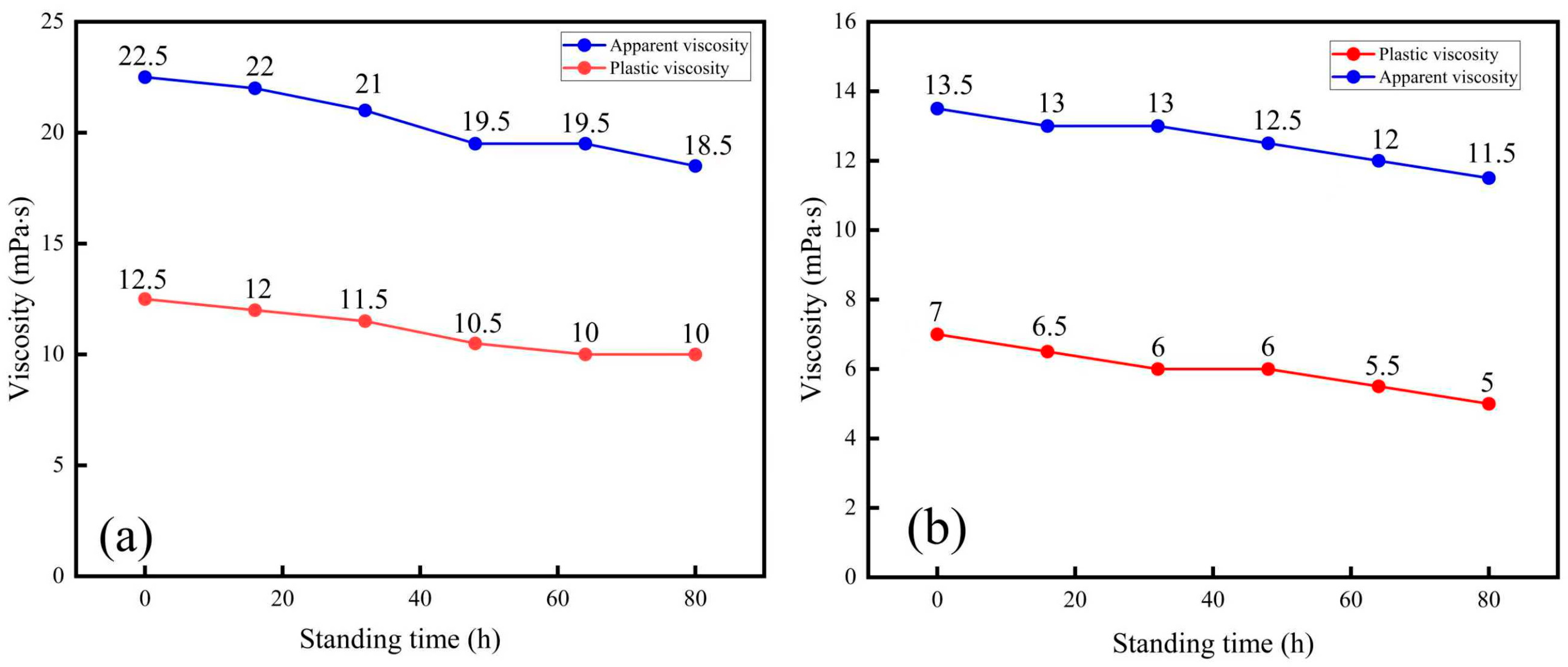

According to

Table 4, with the standing time as the abscissa and the apparent viscosity and plastic viscosity of the 1:1 mixture of wool sac and crude oil as the ordinate, draw the viscosity change curve of the mixture, as shown in

Figure 3a. Taking the standing time as the abscissa and the apparent viscosity and plastic viscosity of the 1:1:1 mixture of wool sac, crude oil, and formation water as the ordinate, draw the viscosity change curve of the mixture, as shown in

Figure 3b.

In

Figure 3, after the fuzzy-ball workover fluid is mixed with crude oil and left standing for 80 h, the apparent viscosity of the mixed fluid gradually decreases from 22.5 mPa·s to 18.5 mPa·s, with a decrease of 4.0 mPa·s, and the plastic viscosity decreases from 12.5 mPa·s to 10.0 mPa·s, with a decrease of 2.5 mPa·s. After the wool ball workover fluid was mixed with crude oil and clean water and stood for 80 h, the apparent viscosity of the mixed fluid decreased from 13.5 mPa·s to 11.5 mPa·s, with a decrease of 2.0 mPa·s. The plastic viscosity decreased from 7.0 mPa·s to 5.0 mPa·s, a decrease of 2.0 mPa·s. It can be seen that the viscosity of the two mixed solutions showed a downward trend after standing. The experiment shows that the wool ball workover fluid can reduce the viscosity of crude oil in both water-bearing and water-free environments and achieve the effect of reducing the flow resistance of crude oil.

Further, with the standing time as the independent variable and the apparent viscosity and plastic viscosity of the 1:1 mixture of wool sac and crude oil as the dependent variables, the equations of the apparent viscosity and plastic viscosity of the two-phase mixture changing with the standing time are established, as shown in Equations (7) and (8).

The following are found in the equations:

AV—the apparent viscosity, mPa·s;

PV—the plastic viscosity, mPa·s;

t—the standing time, h.

Equations (7) and (8) are used to calculate the attenuation coefficients a1 and b1 of the apparent viscosity and plastic viscosity of the two-phase mixed liquid with time.

Taking the standing time as the independent variable, and the apparent viscosity and plastic viscosity of the 1:1:1 mixture of fuzzy-ball fluids, crude oil, and formation water as the dependent variables, the equations of the apparent viscosity and plastic viscosity of the three-phase mixture with the standing time are established, as shown in Equations (9) and (10).

Equations (9) and (10) are used to calculate the attenuation coefficients a2 and b2 of apparent viscosity and plastic viscosity of the three-phase mixed liquid with time.

Comparing the attenuation coefficients of apparent viscosity and plastic viscosity of two-phase and three-phase mixed solutions with time, it can be found that the attenuation rates of apparent viscosity and plastic viscosity of the mixed system only decreased by 0.028 and 0.012 after mixing the water phase, and the attenuation rates were basically stable.

The analysis shows that when surfactants, such as betaine and sodium dodecylbenzenesulfonate, are in contact with high viscosity crude oil after the wool sac is mixed with crude oil, their lipophilic and hydrophilic molecular structures can be adsorbed on natural emulsifiers, such as colloid and asphaltene or paraffin microcrystals in crude oil, effectively destroying the network structure formed by these macromolecules and thus significantly reducing the structural viscosity of crude oil [

31,

32]. At the same time, polyols [

33] in the system can form a flexible film at the oil–water interface and cooperate with the nucleating agent to produce a slight emulsion dispersion effect on crude oil, dispersing some crude oil into tiny droplets. The apparent viscosity of this “water-in-oil” emulsion is usually much lower than that of the original heavy oil. Together, they realize the chemical modification and viscosity reduction in crude oil and greatly reduce its flow resistance in pores. On the whole, after the fuzzy-ball workover fluid is injected into the formation, it can reduce the viscosity of crude oil, improve the outflow capacity of crude oil near the well, realize the effect of cleaning the near-well channel, and improve the recovery effect of fluid production capacity after the workover operation.

5.3. After Cleaning the Near-Well Fluid Production Channel with Fuzzy-Ball Workover Fluid, the Recovery Effect of Oil Well Fluid Production Will Be Improved

Laboratory experiments are conducted to test the influence of the oil phase permeability recovery characterization system on reservoir fluid production channels before and after gel breaking of fuzzy-ball workover fluid, and the calculation equation is shown in (11).

The following are found in the equation:

Sk—permeability recovery rate, %;

K1—initial permeability, 10−3 μm2;

K2—permeability after flowback, 10−3 μm2;

Q1—volume of fluid passing through the rock sample per unit time, cm3/s;

Q2—volume of fluid passing through the rock sample after flowback per unit time, cm3/s;

μ—fluid viscosity, mPa·s;

L—rock sample length, cm;

A—rock sample cross-sectional area, cm2;

ΔP1—initial pressure differential across the rock sample, MPa;

ΔP2—pressure differential across the rock sample after flowback, MPa.

According to Equations (12) and (13), the permeability recovery distribution data of sand-filled pipes with five lengths are obtained by calculation, as shown in

Table 5.

As can be seen from

Table 5, the initial oil phase permeability is 48.5–52.1 mD, the oil phase permeability is 54.3–66.2 mD, and the permeability recovery rate is 112–127%, which is 112–127% higher than the initial value.

The experiment shows that the longer the length of the sand-filled pipe, the larger the plugging radius of the fuzzy-ball workover fluid. After the system is plugged, the gel-broken backflow is implemented, and the recovery rate of formation oil phase permeability is higher, exceeding 100%. Analysis indicates that certain surfactant components in the fuzzy-ball workover fluid are squeezed into the formation. After mixing with crude oil, they reduce the oil viscosity, enabling the previously immobile oil to initiate flow and achieve channel-cleaning effects. This enhances the channel’s liquid production capacity compared to pre-blockage conditions, ultimately resulting in a measured post-breaking oil phase permeability that exceeds the initial value in experiments.

For five well times of field operation, the recovery rate n of the single-well fluid production index is calculated according to the fluid production index before and after operation, as shown in Equation (13).

The following are found in the equation:

n is the recovery rate of the liquid production index, 1%;

S1—the liquid production index after operation;

S2—the fluid production index before operation.

It is considered that for oil wells, the recovery effect of reservoir production is affected by five geological parameters, such as reservoir depth, reservoir thickness, formation pressure coefficient, formation porosity, and formation permeability, three performance parameters, such as density, apparent viscosity, and plastic viscosity of fuzzy-ball workover fluid, three workover process parameters, such as field system pumping displacement, plugging radius, and system temporary plugging strength, and twelve factors, such as the fluid production index before oil well operation. Therefore, taking the recovery rate of the liquid production index as the dependent variable and the recovery rate of the liquid production index n after workover operation as the target parameter, the multiple regression method is used to calculate the influence characteristic coefficient and contribution coefficient of all 12 parameters on the recovery rate of the liquid production index. Based on the contribution coefficient greater than 0, the main control factors affecting the recovery rate of the liquid production index are optimized, and the control equations of all main control factors on the recovery rate of the liquid production index are obtained, as shown in Equation (14).

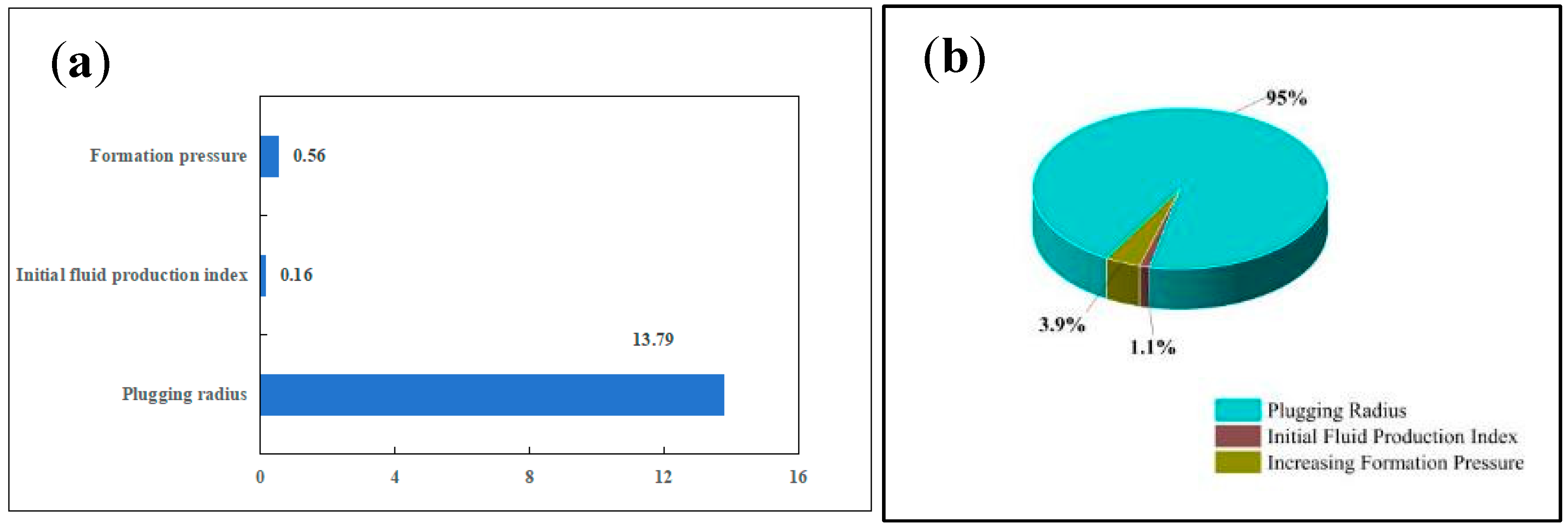

Compare the contribution coefficient distributions of the three main control factors in Equation (14), as shown in

Figure 4.

Analyze the data in

Figure 4. It can be found that

(1) the recovery rate of the fluid production index after workover fluid for oil wells is mainly related to the plugging radius, initial fluid production index, and increasing formation pressure. From the contribution coefficient, the contribution coefficient of equivalent plugging radius is 0.95, the initial fluid production index and the increase in formation pressure are only 0.01 and 0.04, and the equivalent plugging radius has a decisive influence on the fluid recovery ability of the fuzzy-ball workover fluid.

(2) The larger the plugging radius of the fuzzy-ball workover fluid, the higher the recovery rate of the fluid production index, and the recovery rate of the fluid production index increases by 13.79% for every 1 m increase in the calculated plugging radius. The larger the plugging radius, the deeper the fuzzy-ball workover fluid can contact the formation fluid production channel, effectively plugging the high water cut section near the well. At the same time, depending on the viscosity reduction effect of surfactants and other components in the system on the formation of crude oil, the fluidity of crude oil is improved, thus improving the recovery rate of the fluid production index.

(3) The higher the initial liquid production index, the lower the recovery rate of the liquid production index. For every 1% increase in the initial liquid production index, the recovery rate of the liquid production index decreases by 0.16%. Oil wells with a high initial fluid production index usually have good formation conditions and relatively low water cut. During workover, there is limited room for the fuzzy-ball workover fluid to transform its original seepage channel, and even the seepage capacity near the well may be slightly reduced due to liquid phase retention or interfacial tension change, so the recovery rate is not obviously improved or even slightly reduced.

(4) With the application of fuzzy-ball workover fluid, the pressure-bearing capacity of the formation is enhanced. Observation data indicate a negative correlation between the fluid production index recovery rate and the formation pressure-bearing capacity, with the recovery rate decreasing by approximately 0.56% for every 1 MPa increase in pressure-bearing capacity. Improving formation pressure-bearing capacity usually means that workover fluid forms a strong sealing layer near the well, which is helpful to control water production, but it may also hinder oil phase seepage, especially in heterogeneous reservoirs. Too high pressure-bearing capacity may inhibit the flow of crude oil, thus affecting the recovery effect of the liquid production index.

Due to the use of sodium dodecyl benzene sulfonate surfactants in the wool ball workover fluid, gas bubbles are formed to reduce the interfacial tension between oil and water and promote the bound crude oil in the channel to enter the flowing state [

34]. From the physical and chemical point of view, the fluid recovery ability of the sandstone reservoir is improved, which shows a positive improvement effect. Therefore, maintaining the leakage rate moderately is beneficial to rapidly improve the recovery ability of formation fluid production after operation.

The research shows that the recovery rate of oil well fluid production after the fuzzy-ball workover fluid operation is affected by the equivalent plugging radius of the formation, and it is positively correlated. Considering the plugging mechanism of the wool ball, the improvement of formation bearing capacity by wool ball workover fluid is also related to the plugging radius. The research shows that, for the oil wells with malignant leakage, by increasing the plugging radius of workover fluid in the formation, the formation pressure can be increased to meet the plugging requirements, and at the same time, the recovery effect of formation fluid production capacity can be improved, which is beneficial for improving reservoir protection.