Furfural Residue to Rheology Accessible Suspension Fertilizer upon Artificial Humification

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Artificial Humification of Furfural Residue

2.3. Preparation of Humic Acid-Containing Suspension Fertilizer

2.4. Characterizations

3. Results and Discussion

3.1. Parameter Optimization of Hydrothermal Humification

3.2. Characterization of Resulting Humic Acid

3.2.1. Elemental Analysis

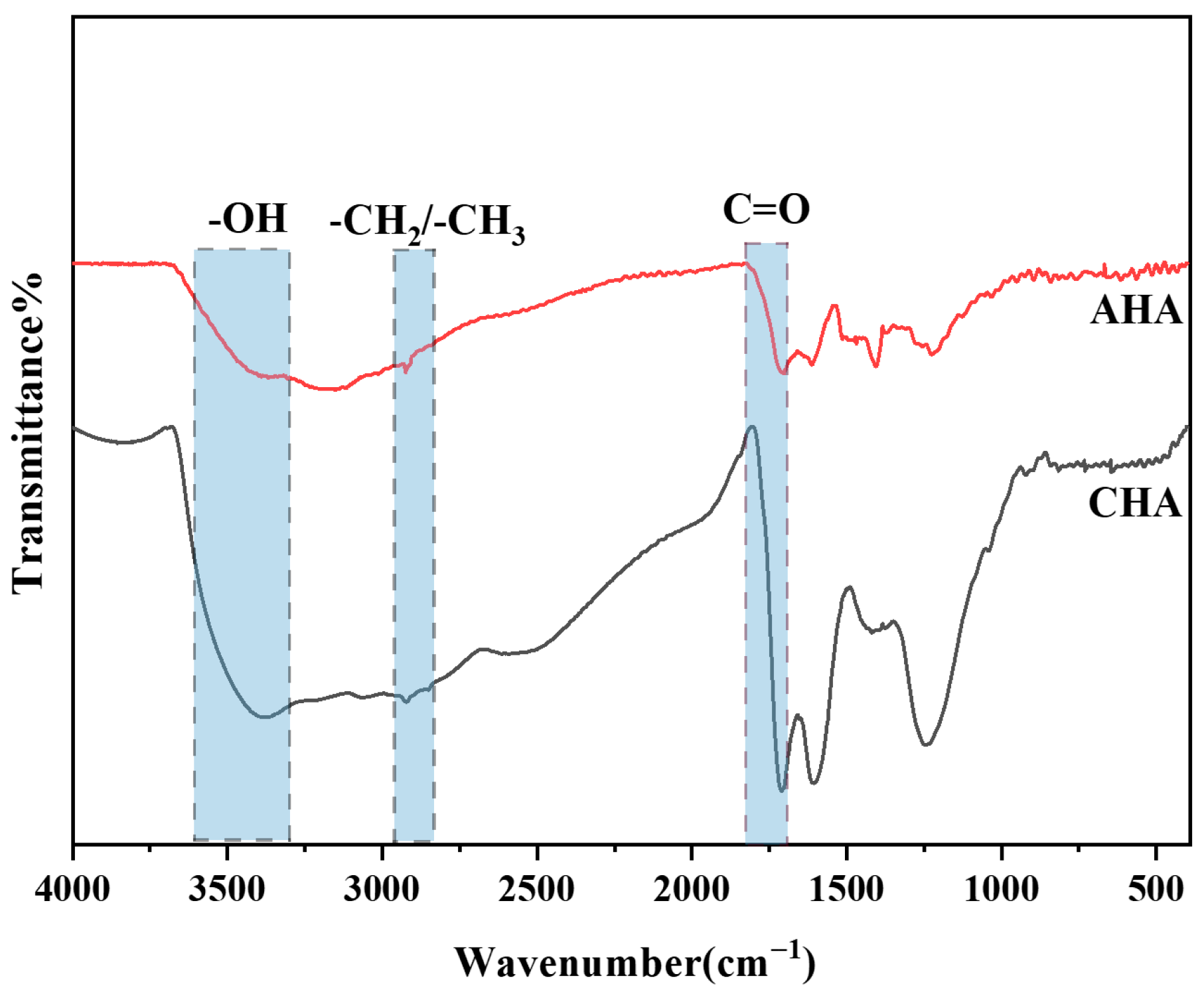

3.2.2. Fourier Transform Infrared Spectroscopy

3.2.3. X-Ray Photoelectron Spectroscopy

3.2.4. Aromaticity Analysis

3.3. Humic Acid-Containing Suspension Fertilizer

3.3.1. Influence of Dispersants

3.3.2. Influence of Thickeners

3.3.3. Influence of Antimicrobial Agents

3.4. Variable-Temperature Rheological Test

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Inkoua, S.; Li, C.; Fan, H.; Bkangmo Kontchouo, F.M.; Sun, Y.; Zhang, S.; Hu, X. Pyrolysis of furfural residues: Property and applications of the biochar. J. Environ. Manag. 2022, 316, 115324. [Google Scholar] [CrossRef]

- Wang, B.; Ran, M.; Fang, G.; Wu, T.; Ni, Y. Biochars from lignin-rich residue of furfural manufacturing process for heavy metal ions remediation. Materials 2020, 13, 1037. [Google Scholar] [CrossRef]

- Mao, X.; Kang, Q.; Liu, Y.; Siyal, A.A.; Ao, W.; Ran, C.; Fu, J.; Deng, Z.; Song, Y.; Dai, J. Microwave-assisted pyrolysis of furfural residue in a continuously operated auger reactor: Biochar characterization and analysis. Energy 2019, 168, 573–584. [Google Scholar] [CrossRef]

- Sun, Y.; Wang, Z.; Liu, Y.; Meng, X.; Qu, J.; Liu, C.; Qu, B. A Review on the Transformation of Furfural Residue for Value-Added Products. Energies 2020, 13, 21. [Google Scholar] [CrossRef]

- Bai, J.; He, Z.; Yang, L.; Wei, X.; Hu, J.; Li, P.; Yan, Z.; Chen, Z.; Chang, C. Preparation and characterization of furfural residue derived char-based catalysts for biomass tar cracking. Waste Manag. 2024, 179, 182–191. [Google Scholar] [CrossRef]

- Wang, M.; Li, Y.; Zhang, Y.; Hu, X.; Li, Q.; Su, Y.; Zhao, W. Exploration of the H2O2 oxidation process and characteristic evaluation of humic acids from two typical lignites. ACS Omega 2021, 6, 24051–24061. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.; Antonietti, M. Artificial humic acids: Sustainable materials against climate change. Adv. Sci. 2020, 7, 1902992. [Google Scholar] [CrossRef] [PubMed]

- Olaetxea, M.; De Hita, D.; Garcia, C.A.; Fuentes, M.; Baigorri, R.; Mora, V.; Garnica, M.; Urrutia, O.; Erro, J.; Zamarreño, A.M.; et al. Hypothetical framework integrating the main mechanisms involved in the promoting action of rhizospheric humic substances on plant root- and shoot- growth. Appl. Soil Ecol. 2018, 123, 521–537. [Google Scholar] [CrossRef]

- Yang, F.; Du, Q.; Sui, L.; Cheng, K. One-step fabrication of artificial humic acid-functionalized colloid-like magnetic biochar for rapid heavy metal removal. Bioresour. Technol. 2021, 328, 124825. [Google Scholar] [CrossRef]

- Chen, P.; Yang, R.; Pei, Y.; Yang, Y.; Cheng, J.; He, D.; Huang, Q.; Zhong, H.; Jin, F. Hydrothermal synthesis of similar mineral-sourced humic acid from food waste and the role of protein. Sci. Total Environ. 2022, 828, 154440. [Google Scholar] [CrossRef] [PubMed]

- Fu, Z.; Sun, K.; Fan, H.; Li, C.; Liu, H.; Zhang, S.; Ding, K.; Gao, G.; Hu, X. Understanding evolution of the products and emissions during chemical activation of furfural residue with varied potassium salts. J. Clean. Prod. 2022, 357, 131936. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, S.; Cheng, K.; Antonietti, M. A hydrothermal process to turn waste biomass into artificial fulvic and humic acids for soil remediation. Sci. Total Environ. 2019, 686, 1140–1151. [Google Scholar] [CrossRef] [PubMed]

- Sobreira, H.d.A.; Ferreira, M.V.; Faria, A.M.d.; Assunção, R.M.N.d. Commercial organomineral fertilizer produced through granulation of a blend of monoammonium phosphate and pulp and paper industry waste post-composting. Ind. Crops Prod. 2024, 222, 119816. [Google Scholar] [CrossRef]

- Wang, R.; Li, D.; Deng, F.; Cao, Z.; Zheng, G. Production of artificial humic acid from rice straw for fertilizer production and soil improvement. Sci. Total Environ. 2024, 906, 167548. [Google Scholar] [CrossRef]

- Shao, Y.; Bao, M.; Huo, W.; Ye, R.; Liu, Y.; Lu, W. Production of artificial humic acid from biomass residues by a non-catalytic hydrothermal process. J. Clean. Prod. 2022, 335, 130302. [Google Scholar] [CrossRef]

- Cao, P.; Li, H.; Li, Y.; Yin, J. Comparison of two kinds of methods on humic acids in weathered coal and soils. Chin. Agric. Sci. Bull. 2007, 23, 277–279. [Google Scholar]

- He, F.; Zhou, X.; Luo, T.; Wang, X. Study on the preparation of high-concentration ammonium phosphate suspension fertilizer from wet-process phosphoric acid and its rheological properties. J. Taiwan Inst. Chem. Eng. 2024, 161, 105497. [Google Scholar] [CrossRef]

- Wang, S.; Wang, Y.; He, X.; Lu, Q. Degradation or humification: Rethinking strategies to attenuate organic pollutants. Trends Biotechnol. 2022, 40, 1061–1072. [Google Scholar] [CrossRef]

- Wang, X.; Muhmood, A.; Dong, R.; Wu, S. Synthesis of humic-like acid from biomass pretreatment liquor: Quantitative appraisal of electron transferring capacity and metal-binding potential. J. Clean. Prod. 2020, 255, 120243. [Google Scholar] [CrossRef]

- Gong, G.; Li, Z.; Zhang, Y.; Ma, L.; Wang, Z.; Li, R.; Liang, S.; Lu, S.; Ma, L. Preparation and structural characterisation of coal-based fulvic acid based on lignite. J. Mol. Struct. 2022, 1260, 132766. [Google Scholar] [CrossRef]

- Lee, J.G.; Yoon, H.Y.; Cha, J.-Y.; Kim, W.-Y.; Kim, P.J.; Jeon, J.-R. Artificial humification of lignin architecture: Top-down and bottom-up approaches. Biotechnol. Adv. 2019, 37, 107416. [Google Scholar] [CrossRef]

- Yang, B.; Zheng, J.; Sun, Y.; Chen, X.; Yan, X.; Davronbek, B.; Wu, J.; Boguta, P.; Zhang, L.; Ren, J.; et al. Air heating-alkaline hydrothermal production of artificial humic acid: Rapid and efficient humification of waste biomass. J. Environ. Chem. Eng. 2025, 13, 116770. [Google Scholar] [CrossRef]

- Pihlaja, J.P.K. Molecular size distribution and spectroscopic properties of aquatic humic substances. Anal. Chim. Acta 1997, 337, 133–149. [Google Scholar] [CrossRef]

- Huang, F.; Liu, H.; Wen, J.; Zhao, C.; Dong, L.; Liu, H. Underestimated humic acids release and influence on anaerobic digestion during sludge thermal hydrolysis. Water Res. 2021, 201, 117310. [Google Scholar] [CrossRef]

- Kolb, C.G.; Lehmann, M.; Kulmer, D.; Zaeh, M.F. Modeling of the stability of water-based graphite dispersions using polyvinylpyrrolidone on the basis of the DLVO theory. Heliyon 2022, 8, e11988. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Li, Y.; Xiang, D.; Zhang, W.; Bai, X. Stability of lutein in O/W emulsion prepared using xanthan and propylene glycol alginate. Int. J. Biol. Macromol. 2020, 152, 371–379. [Google Scholar] [CrossRef] [PubMed]

- Pang, Y.; Li, X.; Zhou, M.; Li, Y.; Gao, W.; Qiu, X. Relationship between the hydrophilicity of lignin dispersants and their performance towards pesticide particles. Holzforschung 2016, 70, 653–660. [Google Scholar] [CrossRef]

- Dullens, R.P.A.; Bechinger, C. Shear thinning and local melting of colloidal crystals. Phys. Rev. Lett. 2011, 107, 138301. [Google Scholar] [CrossRef]

- Li, Y.; Bi, H.; Shen, S. Thixotropy of aqueous suspensions containing Mg-Al hydrotalcite-like compound and low-substituted cationic starch: Comparison between oscillatory shear and thixotropic loop measurements. Chin. J. Chem. 2011, 29, 1101–1106. [Google Scholar] [CrossRef]

- Abu Elella, M.H.; Goda, E.S.; Gab-Allah, M.A.; Hong, S.E.; Pandit, B.; Lee, S.; Gamal, H.; Rehman, A.u.; Yoon, K.R. Xanthan gum-derived materials for applications in environment and eco-friendly materials: A review. J. Environ. Chem. Eng. 2021, 9, 104702. [Google Scholar] [CrossRef]

- Sinlapapanya, P.; Palamae, S.; Buatong, J.; Saetang, J.; Zhang, B.; Fu, Y.; Benjakul, S. Synergistic effect of hyperoside and amentoflavone found in cashew leaf crude extract and potassium sorbate on inhibition of food spoilage bacteria. J. Agric. Food Res. 2025, 21, 101886. [Google Scholar] [CrossRef]

- Hao, L.; Zhou, J. Experimental study on the rheological properties of MF lubricant based on the Herschel-Bulkley model. J. Supercond. Nov. Magn. 2022, 35, 3333–3346. [Google Scholar] [CrossRef]

- Bogusz, P.; Rusek, P.; Brodowska, M.S. Suspension Fertilizers: How to Reconcile Sustainable Fertilization and Environmental Protection. Agriculture 2021, 11, 1008. [Google Scholar] [CrossRef]

| Run | Liquid–Solid Ratio | Temperature/°C | Time/h |

|---|---|---|---|

| 1 | 5 | 160 | 5 |

| 2 | 6 | 160 | 15 |

| 3 | 7 | 160 | 10 |

| 4 | 5 | 170 | 15 |

| 5 | 6 | 170 | 10 |

| 6 | 7 | 170 | 5 |

| 7 | 5 | 180 | 10 |

| 8 | 6 | 180 | 5 |

| 9 | 7 | 180 | 15 |

| Run | Liquid–Solid Ratio/(w/w) (A) | Time/h (B) | Temperature/°C (C) | FA/(g/5 g) | HA/(g/5 g) |

|---|---|---|---|---|---|

| 1 | 5 | 5 | 160 | 0.63 | 0.04 |

| 2 | 15 | 6 | 160 | 1.16 | 1.12 |

| 3 | 10 | 7 | 160 | 1.08 | 0.31 |

| 4 | 15 | 5 | 170 | 1.10 | 1.03 |

| 5 | 10 | 6 | 170 | 0.90 | 0.61 |

| 6 | 5 | 7 | 170 | 0.62 | 0.15 |

| 7 | 10 | 5 | 180 | 0.93 | 0.22 |

| 8 | 5 | 6 | 180 | 0.57 | 0.04 |

| 9 | 15 | 7 | 180 | 0.89 | 1.26 |

| Experimental Indicators | Factor | S | f | S/f | F | Significance |

|---|---|---|---|---|---|---|

| FA | A | 0.335 | 2 | 0.167 | 15.491 | 0.061 |

| B | 0.001 | 2 | 0 | 0.038 | 0.963 | |

| C | 0.038 | 2 | 0.019 | 1.777 | 0.360 | |

| Error | 0.022 | 2 | 0.011 | |||

| Total sum | 7.295 | 9 | ||||

| HA | A | 1.7880 | 2 | 0.894 | 34.285 | 0.028 |

| B | 0.0460 | 2 | 0.023 | 0.890 | 0.529 | |

| C | 0.0200 | 2 | 0.010 | 0.379 | 0.725 | |

| Error | 0.0520 | 2 | 0.026 | |||

| Total sum | 4.4450 | 9 |

| Sample | Element Content | Element Content Ratio | ||||||

|---|---|---|---|---|---|---|---|---|

| C | N | O | H | S | H/C | O/C | (N + O)/C | |

| AHA | 43.38 | 2.85 | 22.82 | 6.79 | 0.43 | 0.16 | 0.53 | 0.59 |

| CHA | 50.80 | 1.43 | 30.80 | 6.45 | 0.46 | 0.13 | 0.61 | 0.63 |

| Sample | E2/E3 | E4/E6 | ΔlgK | Aroma Degree |

|---|---|---|---|---|

| AHA | 2.46 | 2.92 | 0.59 | 35.81 |

| CHA | 2.31 | 2.90 | 0.49 | 36.85 |

| T/°C | Thixotropic Ring Area/mPa | τ * | K | n | R2 |

|---|---|---|---|---|---|

| 15 | 29,699 | 3.6617 | 11.0216 | 0.2853 | 0.9978 |

| 25 | 36,241 | 11.1291 | 16.7009 | 0.2145 | 0.9972 |

| 35 | 12,990 | 6.6362 | 12.2830 | 0.2364 | 0.9958 |

| 45 | 12,623 | 5.0820 | 5.7544 | 0.3263 | 0.9974 |

| 55 | 5623 | 3.3072 | 4.6158 | 0.3366 | 0.9990 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Bate, N.; Yang, X.; Li, S.; Yang, J.; Li, X.; He, F.; Xu, D.; Yan, Z.; Zhong, B.; Wang, X. Furfural Residue to Rheology Accessible Suspension Fertilizer upon Artificial Humification. Processes 2026, 14, 50. https://doi.org/10.3390/pr14010050

Bate N, Yang X, Li S, Yang J, Li X, He F, Xu D, Yan Z, Zhong B, Wang X. Furfural Residue to Rheology Accessible Suspension Fertilizer upon Artificial Humification. Processes. 2026; 14(1):50. https://doi.org/10.3390/pr14010050

Chicago/Turabian StyleBate, Nasen, Xiuying Yang, Shuangqin Li, Jingxu Yang, Xue Li, Fuduo He, Dehua Xu, Zhengjuan Yan, Benhe Zhong, and Xinlong Wang. 2026. "Furfural Residue to Rheology Accessible Suspension Fertilizer upon Artificial Humification" Processes 14, no. 1: 50. https://doi.org/10.3390/pr14010050

APA StyleBate, N., Yang, X., Li, S., Yang, J., Li, X., He, F., Xu, D., Yan, Z., Zhong, B., & Wang, X. (2026). Furfural Residue to Rheology Accessible Suspension Fertilizer upon Artificial Humification. Processes, 14(1), 50. https://doi.org/10.3390/pr14010050