Research on the Calculation Method of Dynamic Effective Stress Coefficient Based on P-Wave Velocity

Abstract

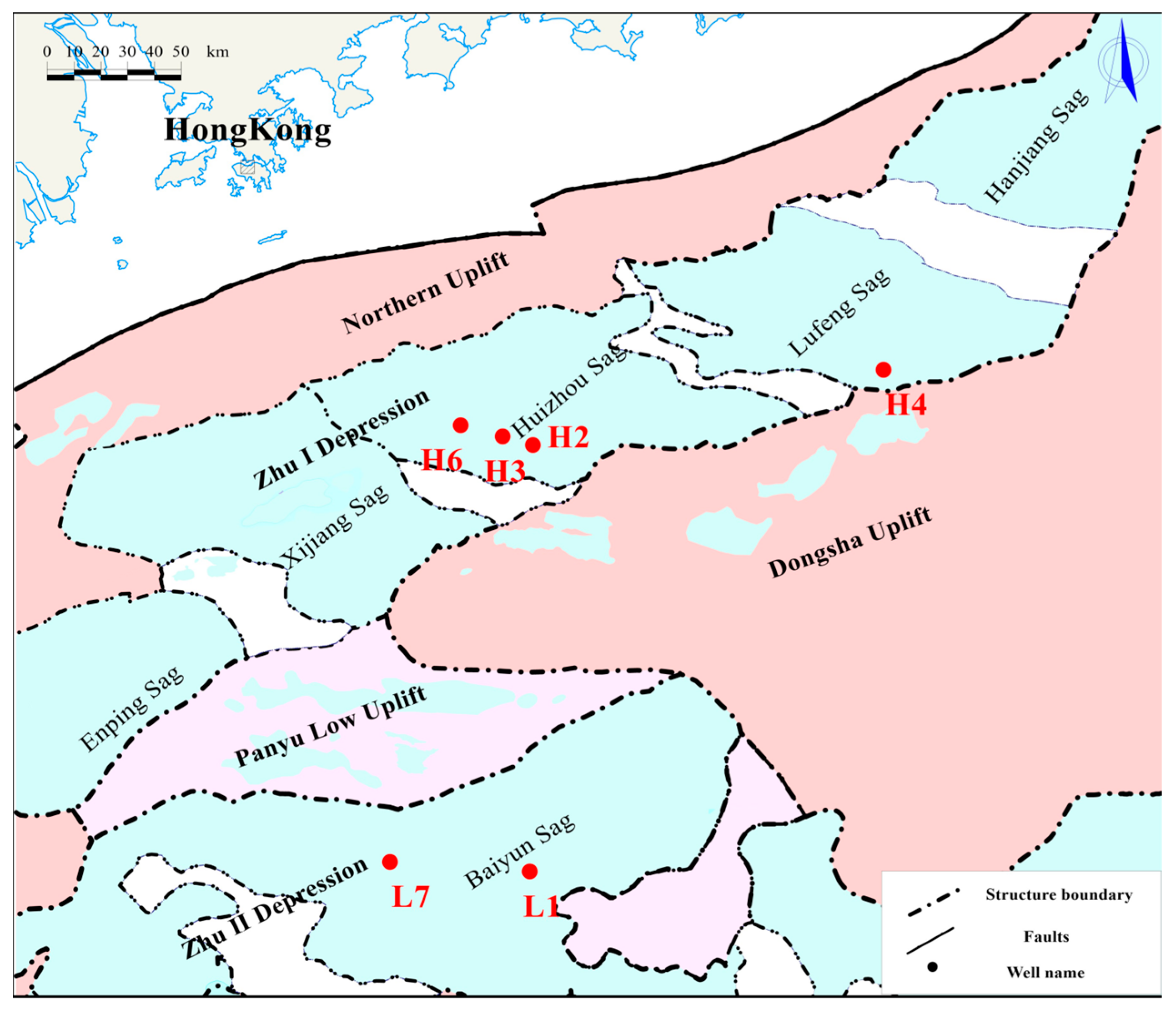

1. Introduction

2. Estimation of Dynamic Effective Stress Coefficient

2.1. Formula for Estimating Dynamic Effective Stress Coefficient

2.2. Fluid Saturation Estimation and Method Robustness Verification

2.2.1. Fluid Saturation Estimation Method

2.2.2. Method Robustness Verification

2.3. Matrix Parameters Estimation

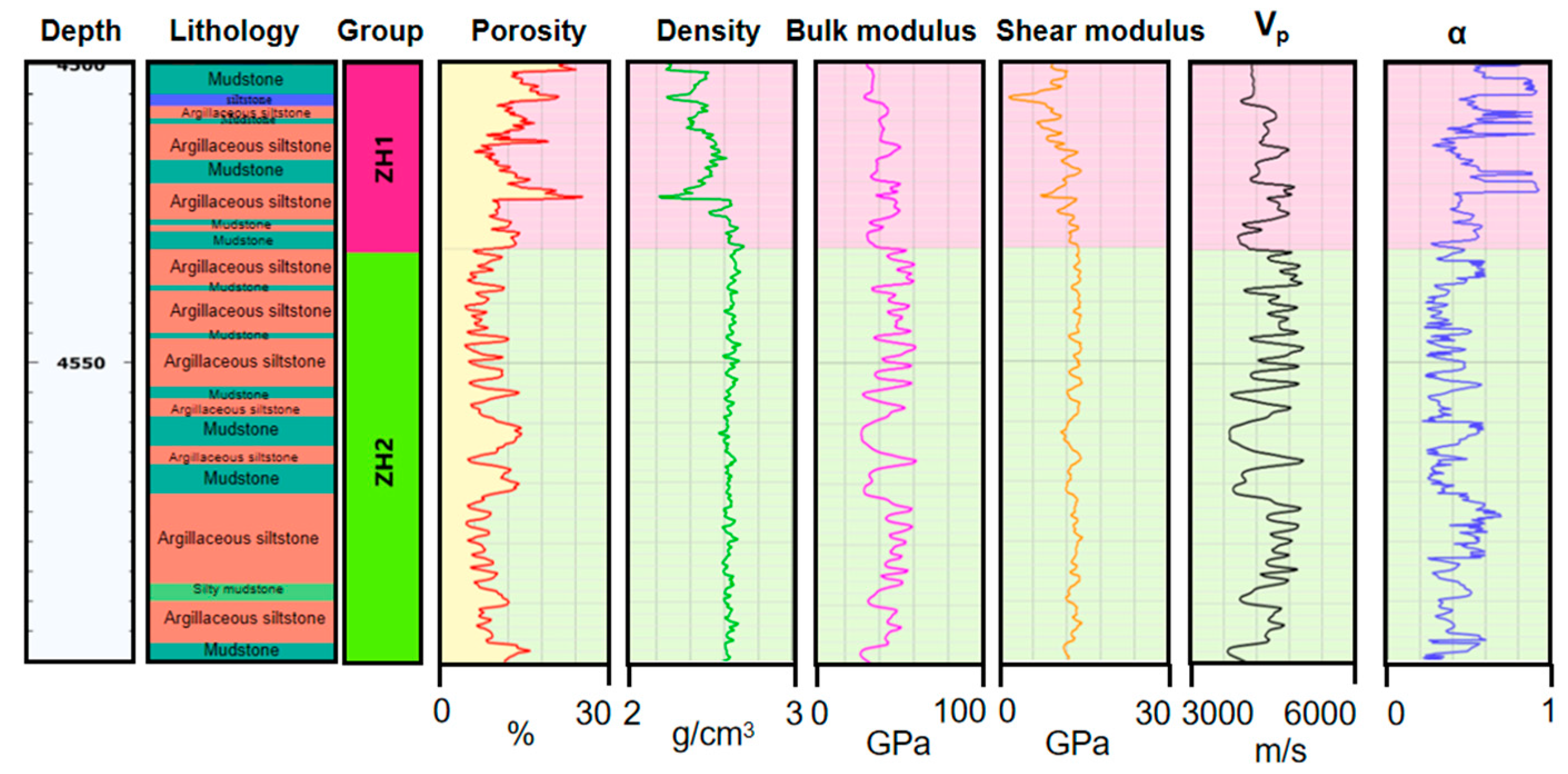

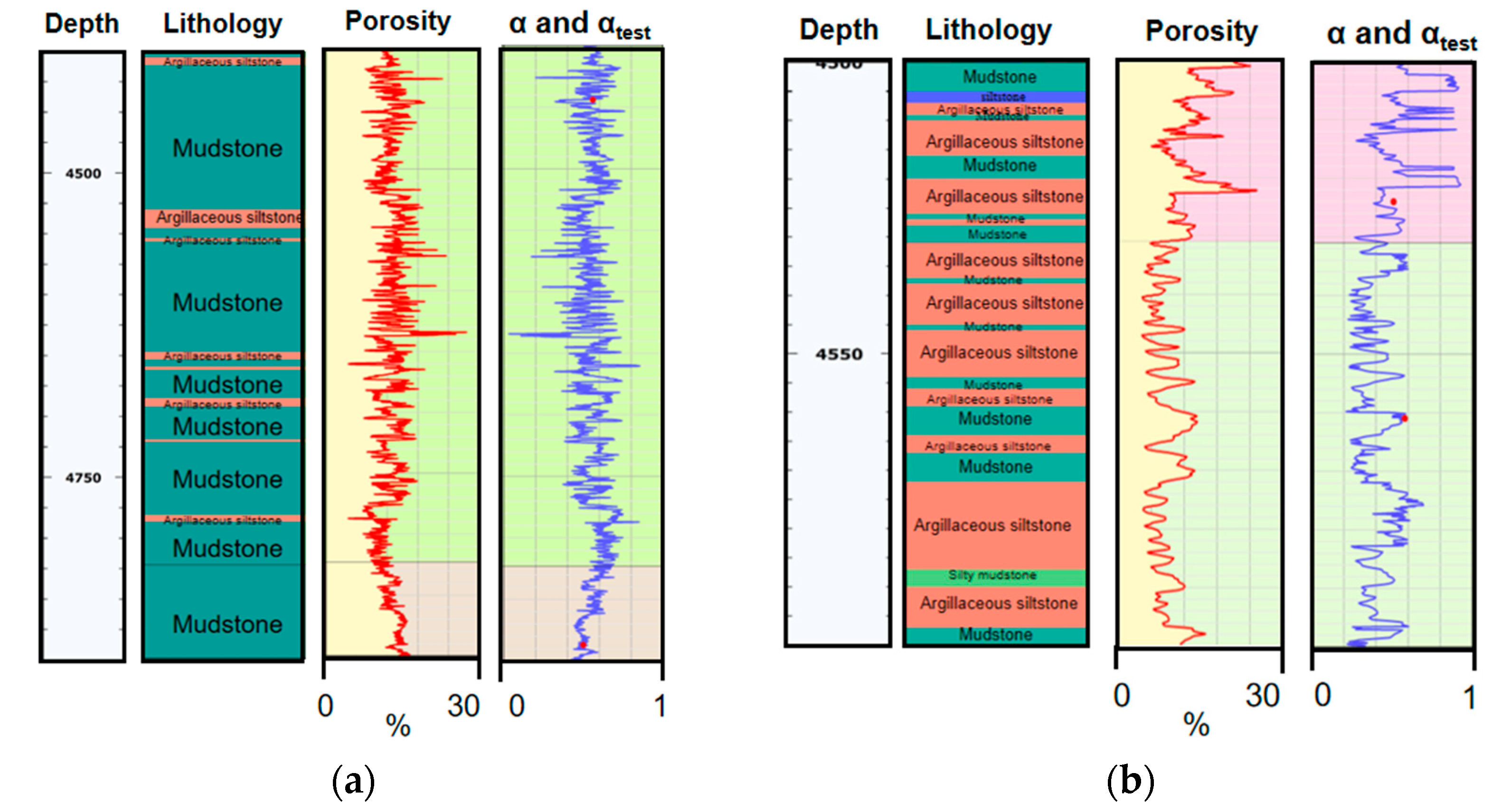

2.4. Dynamic Effective Stress Coefficient Estimation Results (Logging)

2.5. Logging Data Processing Process

- Porosity logging method: The neutron porosity logging and density logging combination method is adopted [32]. Neutron porosity logging measures the porosity by the content of hydrogen nuclei in the formation, and density logging calculates the porosity based on the difference between the formation density and the matrix density. The final porosity value is obtained by weighted averaging the two logging results.

- Density logging data correction: First, the borehole enlargement correction is performed. According to the caliper logging data, the correction coefficient is determined; then, the shale content correction is carried out. The correction formula:

- where is the corrected density, is the logging density, is the shale content, and is the shale density.

- Acoustic data filtering method: The wavelet transform filtering method is used to filter the acoustic logging data [33]. The main frequency range of the effective signal is determined to be 10–20 kHz, and the noise signals outside this frequency range are filtered out to improve the signal-to-noise ratio of the data.

- 1.

- Collect logging data (P-wave velocity, density, caliper, resistivity, etc.) and core experimental data of the study area.

- 2.

- Correct the density logging data and filter the acoustic data according to the above logging data processing process.

- 3.

- Estimate the fluid saturation of the logging interval using the Archie formula.

- 4.

- Calculate the P-wave modulus of saturated rock (), rock matrix (), and pore fluid () based on Formulas (4) and (5), and the definition of P-wave modulus.

- 5.

- Calculate the intermediate variables A and B according to Formula (8).

- 6.

- Calculate the ESC using Formula (9) (for gas-bearing intervals, use Formula (10)).

- 7.

- Verify the calculation results with core experimental data and correct the model if necessary.

3. Experimental Study of Dynamic Effective Stress Coefficient

3.1. Experimental Principle

3.2. Experimental Samples and Experimental Methods

3.3. Experimental Results

4. Discussion

4.1. Analysis of -Porosity Cross Plots

- For dense mudstone (porosity less than 0.1), the value is less than 0.4, which is completely consistent with the logging results of the lower reservoir section of well H6, where the porosity is less than 10% and the value is relatively low;

- For argillaceous siltstone (porosity 0.1~0.2), the value is concentrated in the range of 0.4~0.7, matching the evolutionary characteristics of observed for intercalated argillaceous siltstone in the reservoir section of well L1;

- For fine sandstone (porosity greater than 0.2), the value is greater than 0.7, which further verifies the rule proposed in Section 2.2 that “sandstone layers with higher porosity have larger ESCs”.

4.2. Comparison with Logging Results

4.3. Analysis of Influencing Factors of Effective Stress Coefficient

5. Conclusions

- (1)

- Based on the Gassmann equation and P-wave modulus approximation, this study realizes a multi-lithology ESC estimation method using P-wave velocity, density, and porosity, and applies it to the logging of the study block. Experimental verification confirms the method’s reliability, enabling ESC estimation and formation pressure prediction in the absence of shear wave velocity.

- (2)

- The study block’s dense mudstone/argillaceous siltstone (low porosity) exhibits ESC < 1: logging-derived ESC ranges 0.3–0.8, and laboratory-averaged ESC is 0.5–0.6 (lower than conventional sandstone’s α ≈ 1). Poor pore connectivity in dense rocks weakens fluid pressure’s contribution to effective stress, so setting ESC = 1 for formation pressure prediction is inappropriate.

- (3)

- The ESC decreases with increasing differential stress (confining pressure—pore pressure).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Terzaghi, K. Theoretical Soil Mechanics; John Wiley & Sons, Inc.: New York, NY, USA, 1923. [Google Scholar]

- Biot, M.A. General theory of three-dimensional consolidation. J. Appl. Phys. 1941, 12, 155–164. [Google Scholar] [CrossRef]

- Biot, M.A. Theory of propagation of elastic waves in a fluid saturated porous solid. I. Low frequency range and II. Higher—Frequency range. Acoust. Soc. Am. 1956, 28, 168–191. [Google Scholar] [CrossRef]

- Berryman, J.G. Effective stress for transport properties of inhomogeneous porous rock. J. Geophys. Res. Solid Earth 1992, 97, 17409–17424. [Google Scholar] [CrossRef]

- Berryman, J.G. Effective-stress rules for pore-fluid transport in rocks containing two minerals. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1993, 30, 1165–1168. [Google Scholar] [CrossRef]

- Nur, A.; Byerlee, J.D. An exact effective stress law for elastic deformation of rock with fluids. J. Geophys. Res. 1971, 76, 6414–6419. [Google Scholar] [CrossRef]

- Gurevich, B. A simple derivation of the effective stress coefficient for seismic velocities in porous rocks. Geophysics 2004, 69, 393–397. [Google Scholar] [CrossRef]

- Banthia, B.S.; King, M.S.; Fatt, I. Ultrasonic shear-wave velocities in rocks subjected to simulated overburden pressure and internal pore pressure. Geophysics 1965, 30, 117–121. [Google Scholar] [CrossRef]

- Todd, T.; Simmons, G. Effect of pore pressure on the velocity of compressional waves in low-porosity rocks. J. Geophys. Res. 1972, 77, 3731–3743. [Google Scholar] [CrossRef]

- Hornby, B.E. An experimental investigation of effective stress principals for sedimentary rocks. In Proceedings of the 66th Annual International Meeting of the Society of Exploration Geophysicists, Denver, CO, USA, 10–15 November 1996; pp. 1707–1710. [Google Scholar] [CrossRef]

- Sarker, R.; Batzle, M. Effective stress coefficient in shales and its applicability to Eaton’s equation. Lead. Edge 2008, 27, 798–804. [Google Scholar] [CrossRef]

- Hilterman, F. Seismic Amplitude Interpretation; Society of Exploration Geophysicists: Huston, TX, USA; European Association of Geoscientists & Engineers: Odijk, The Netherlands; Geophysical Development Corporation: Houston, TX, USA, 2001. [Google Scholar]

- Geertsma, J. Velocity-log interpretation. The effect of rockbulk compressibility. Soc. Petr. Eng. J. 1961, 1, 235–248. [Google Scholar] [CrossRef]

- Krief, M.; Garat, J.; Stellingwerff, J.; Ventre, J. A petrophysical interpretation using the velocities of P and S waves (full-waveform sonic). Log Anal. 1990, 31, 355–369. [Google Scholar]

- Nur, A.M.; Mavko, D.; Dvorkin, J.; Gal, D. Critical porosity: The key to relating physical properties to porosity in rocks. In Proceedings of the 1995 SEG Annual Meeting, Houston, TX, USA, 8–13 October 1995; pp. 878–881. [Google Scholar]

- Ma, Z.G. Experimental investigation into Biot’s coefficient and rock elastic moduli. Oil Gas Geol. 2008, 29, 135–140. [Google Scholar]

- Yu, H. Dynamic effective pressure coefficient calibration. Geophysics 2015, 80, D65–D73. [Google Scholar] [CrossRef]

- Zhang, S.C.; Li, J.X.; Wang, Y. Research on dynamic effective stress coefficient of tight sandstone reservoirs. J. Pet. Sci. Eng. 2020, 190, 107125. [Google Scholar] [CrossRef]

- Jia, L.C. Experimental study on dynamic and static effective stress coefficients of transversely isotropic shale. Chin. J. Rock Mech. Eng. 2023, 42, 4130–4139. [Google Scholar] [CrossRef]

- Wang, H.S.; Hu, T.Y. Estimation of the effective stress coefficient for multi-lithology. In Proceedings of the 78th SEG Annual International Meeting, Dallas, TX, USA, 16–21 October 2016; pp. 3200–3204. [Google Scholar]

- Shi, M.X.; Liu, Z.D.; Yang, X.F.; Yang, J.R.; Chen, X.J.; Liu, H.Z.; Cao, J. Review and prospect of formation pore pressure prediction technology by geophysical well logging. Prog. Geophys. 2020, 35, 1845–1853. [Google Scholar] [CrossRef]

- Wyllie, M.R.J.A.; Gregory, R.; Gardner, L.W. Elastic wave velocities in heterogeneous and porous media. Geophysics 1956, 21, 41–70. [Google Scholar] [CrossRef]

- Gassmann, F. Über die Elastizität poroser Medien. Veirteljahrsschrift Der Naturforschenden Ges. Zürich 1951, 96, 1–23. [Google Scholar]

- Pickett, G.R. Acoustic Charater Logs and Their Applications in Formation Evaluation. J. Pet. Technol. 1963, 15, 659–667. [Google Scholar] [CrossRef]

- Mavko, G.; Mukerji, T.; Dvorkin, J. The Rock Physics Handbook—Tools for Seismic Analysis in Porous Media; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Mavko, G.; Chan, C.; Mukerji, T. Fluid substitution: Esti-mating changes in Vp without knowing Vs. Geophysics 1995, 60, 1750–1755. [Google Scholar] [CrossRef]

- Batzle, M.; Wang, Z. Seismic properties of pore fluids. Geophysics 1992, 57, 1396–1408. [Google Scholar] [CrossRef]

- Ramos da Silva, M.; Schroeder, C.; Verbrugge, J.C. Poroelastic behaviour of a water-saturated limestone. Int. J. Rock Mech. Min. Sci. 2010, 47, 797–807. [Google Scholar] [CrossRef]

- Guo, J.Y.; Li, M.; Zhuang, M.W.; Sun, Y. Rock physics model for velocity–pressure relations and its application to shale pore pressure estimation. Pet. Explor. Dev. 2023, 50, 360–372. [Google Scholar] [CrossRef]

- Bowers, G.L. Pore pressure estimation from velocity data: Accounting for overpressure mechanisms besides under compaction. Geophysics 1995, 60, 1051–1060. [Google Scholar] [CrossRef]

- He, J.; Rui, Z.H.; Ling, K.G. A new method to determine Biot‘s coefficients of Bakken samples. J. Nat. Gas Sci. Eng. 2016, 35, 259–264. [Google Scholar] [CrossRef]

- Smith, G.C.; Gidlow, P.M. Weighted equation for fluid substitution in sandstones. Geophysics 1987, 52, 1396–1408. [Google Scholar] [CrossRef]

- Dejtrakulwong, P.; Mavko, G. Fluid substitution for thinly interbedded sand-shale sequences using the mesh method. Geophysics 2016, 81, D599–D609. [Google Scholar] [CrossRef]

- Hu, D.W.; Ma, T.; Zu, K.; Wang, Q.; Yang, F.; Zhou, H. Research progress of testing method and characterization model of effective stress coefficient of rock. Chin. J. Rock Mech. Eng. 2025, 44, 1959–1987. [Google Scholar] [CrossRef]

- Gao, T.Y. Prediction study of tight sandstone reservoirs: A case study of tight sandstone reservoirs in Lishu area. Basic Sci. Eng. Technol. Ser. I 2024, 2024. [Google Scholar]

- Eaton, B.A. The equation for geopressure prediction from well logs. J. Pet. Technol. 1975, 27, 1353–1360. [Google Scholar] [CrossRef]

- Zhou, Y.Q.; He, X.L.; Lin, K.; Qin, S.; Zhang, C.; Liu, Z. Formation pressure estimation method based on dynamic effective stress coefficient. Xinjiang Pet. Geol. 2023, 44, 245–251. [Google Scholar]

| Sample | Matrix Velocity Change | ESC Change Amplitude | Matrix Density Change | ESC Change Amplitude |

|---|---|---|---|---|

| H18 | +10% | −4.2% | +2% | −1.5% |

| H18 | −10% | +5.1% | −2% | +2.3% |

| H48 | +10% | −3.8% | +2% | −1.2% |

| H48 | −10% | +4.5% | −2% | +1.8% |

| L11 | +10% | −3.5% | +2% | −1.0% |

| L11 | −10% | +4.0% | −2% | +1.5% |

| L15 | +10% | +4.0% | +2% | −1.3% |

| L15 | −10% | +4.8% | −2% | +2.0% |

| Sample | Depth (m) | Quartz (%) | Feldspar (%) | Calcite (%) | Siderite (%) | Others (%) | Clay (%) | Porosity (%) |

|---|---|---|---|---|---|---|---|---|

| H18 | 4444.02 | 45.0 | 0.7 | 0 | 25.6 | 0 | 28.7 | 17.6 |

| H48 | 4887.05 | 63.6 | 2.6 | 0 | 6.2 | 0 | 27.6 | 14.8 |

| L11 | 4524.1 | 53.6 | 12.7 | 10.5 | 4.6 | 2.2 | 16.4 | 10.6 |

| L15 | 4561.7 | 49.8 | 2.7 | 12.2 | 0 | 4.8 | 30.4 | 13.3 |

| Num | Sample | Depth (m) | 1 | 2 | 3 | 4 | average |

|---|---|---|---|---|---|---|---|

| 1 | H18 | 4444.02 | 0.66 | 0.65 | 0.62 | 0.61 | 0.64 |

| 2 | H48 | 4887.05 | 0.54 | 0.50 | 0.50 | 0.47 | 0.50 |

| 3 | L11 | 4524.1 | 0.53 | 0.50 | 0.45 | 0.44 | 0.48 |

| 4 | L15 | 4561.7 | 0.54 | 0.53 | 0.46 | / | 0.51 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Wang, Z.; Huang, K.; Liu, D.; Ren, Q.; Jiang, M.; Chen, Z.; Rutatina, K.; Wang, X. Research on the Calculation Method of Dynamic Effective Stress Coefficient Based on P-Wave Velocity. Processes 2026, 14, 127. https://doi.org/10.3390/pr14010127

Wang Z, Huang K, Liu D, Ren Q, Jiang M, Chen Z, Rutatina K, Wang X. Research on the Calculation Method of Dynamic Effective Stress Coefficient Based on P-Wave Velocity. Processes. 2026; 14(1):127. https://doi.org/10.3390/pr14010127

Chicago/Turabian StyleWang, Zhuochao, Keke Huang, Daoli Liu, Qinpei Ren, Man Jiang, Zhaoming Chen, Kato Rutatina, and Xiaoqiong Wang. 2026. "Research on the Calculation Method of Dynamic Effective Stress Coefficient Based on P-Wave Velocity" Processes 14, no. 1: 127. https://doi.org/10.3390/pr14010127

APA StyleWang, Z., Huang, K., Liu, D., Ren, Q., Jiang, M., Chen, Z., Rutatina, K., & Wang, X. (2026). Research on the Calculation Method of Dynamic Effective Stress Coefficient Based on P-Wave Velocity. Processes, 14(1), 127. https://doi.org/10.3390/pr14010127