Improving Health and Safety in Welding Through Remote Human–Robot Collaboration

Abstract

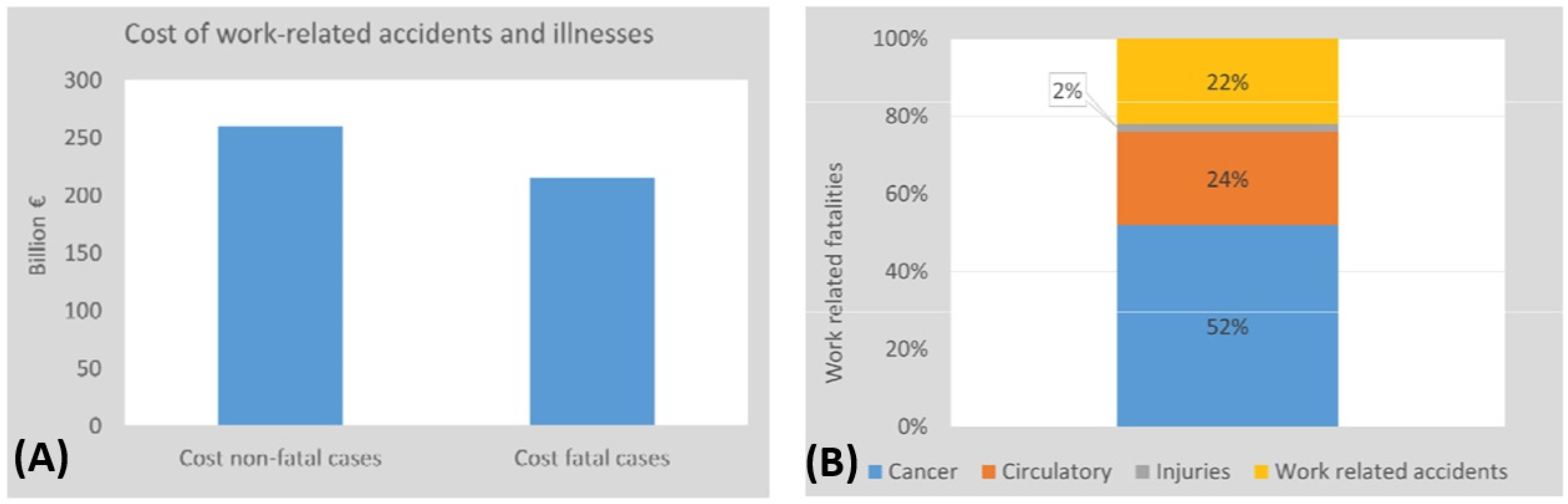

1. Introduction

- Disorders of the back, particularly involving the spine

- Disorders of the tendons, tendon calcifications, and joint capsules

- Shoulder lesions

- Chronic inflammation of the knee joint

- Chronic inflammation of the hip joint

2. Materials and Methods

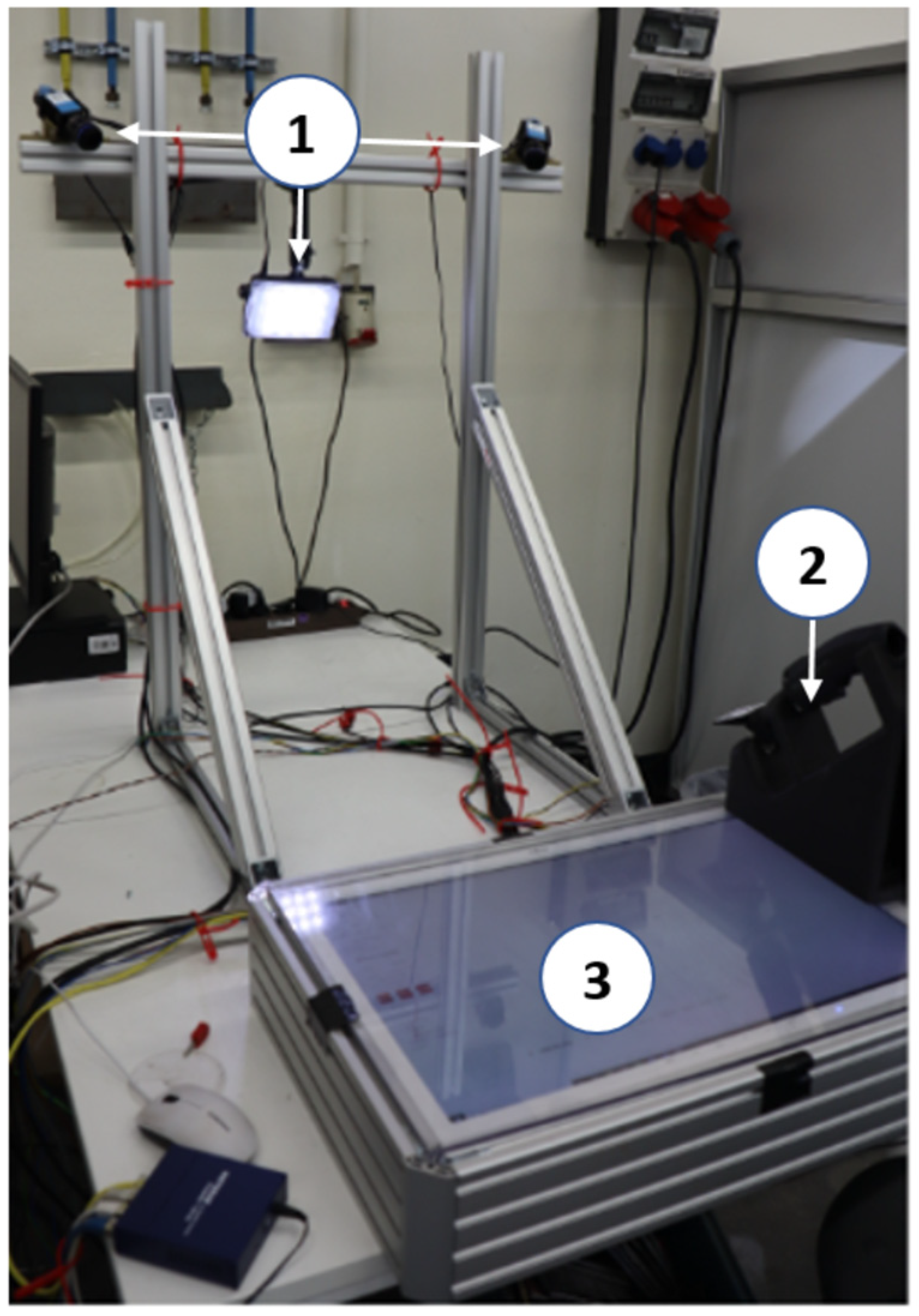

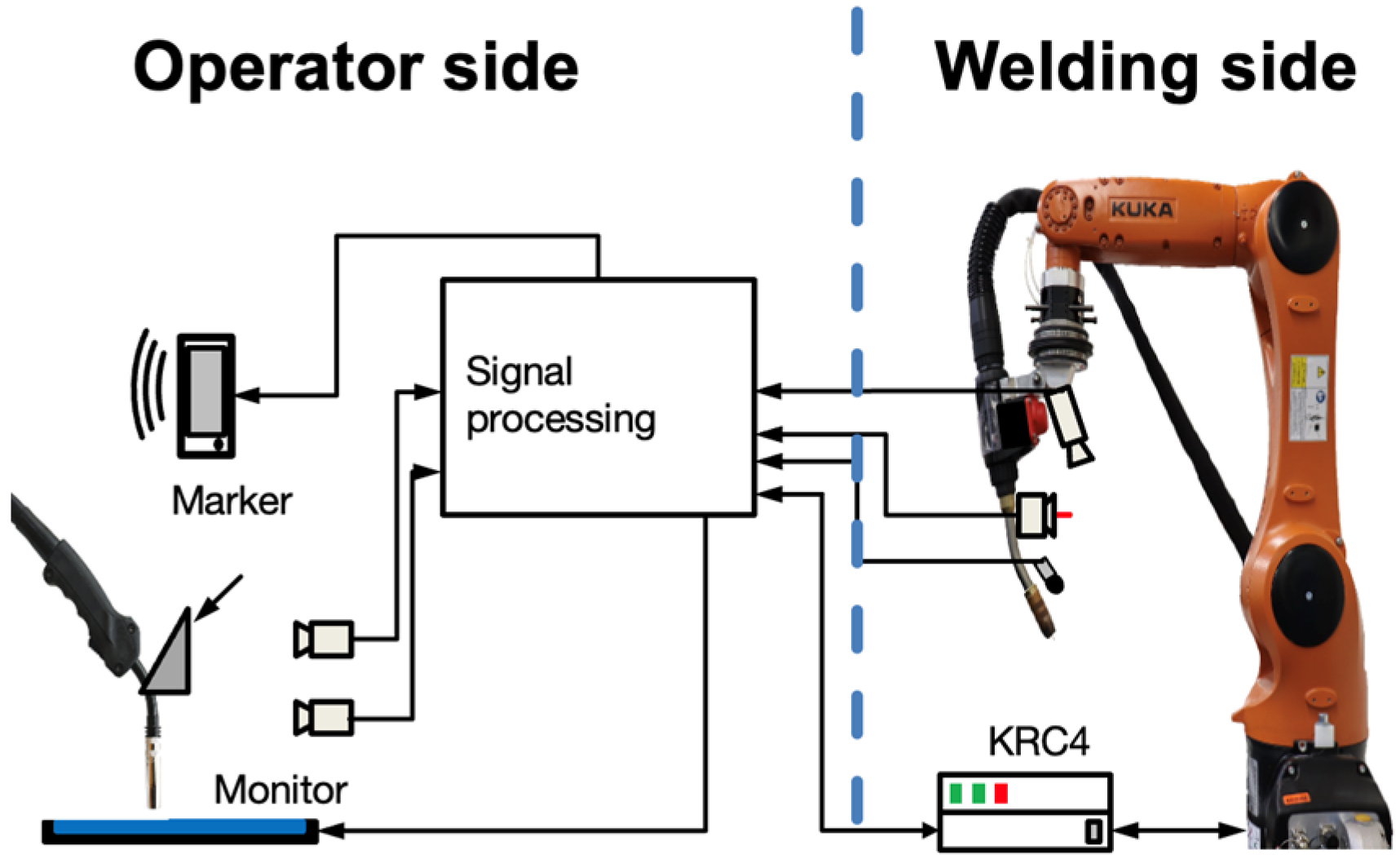

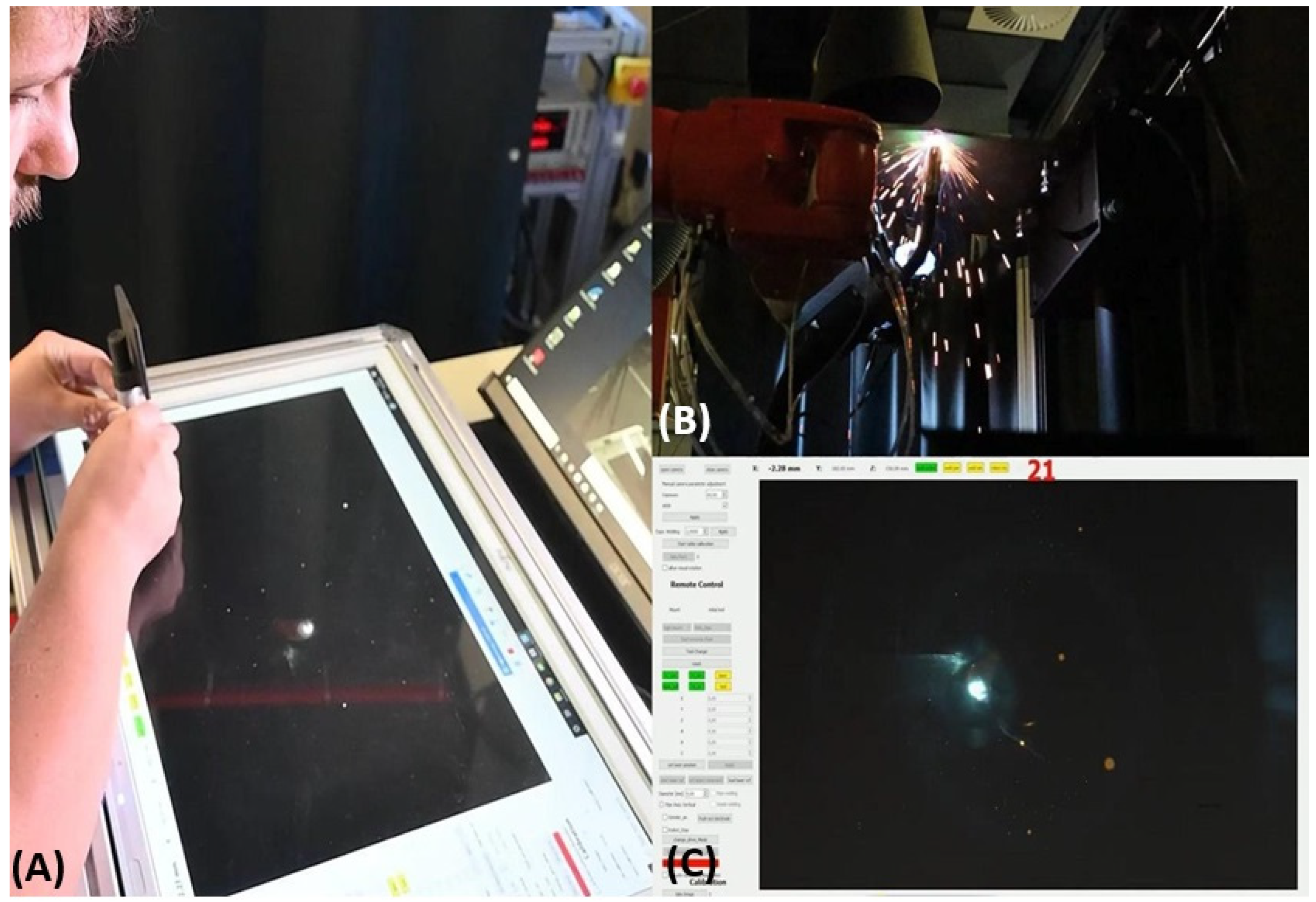

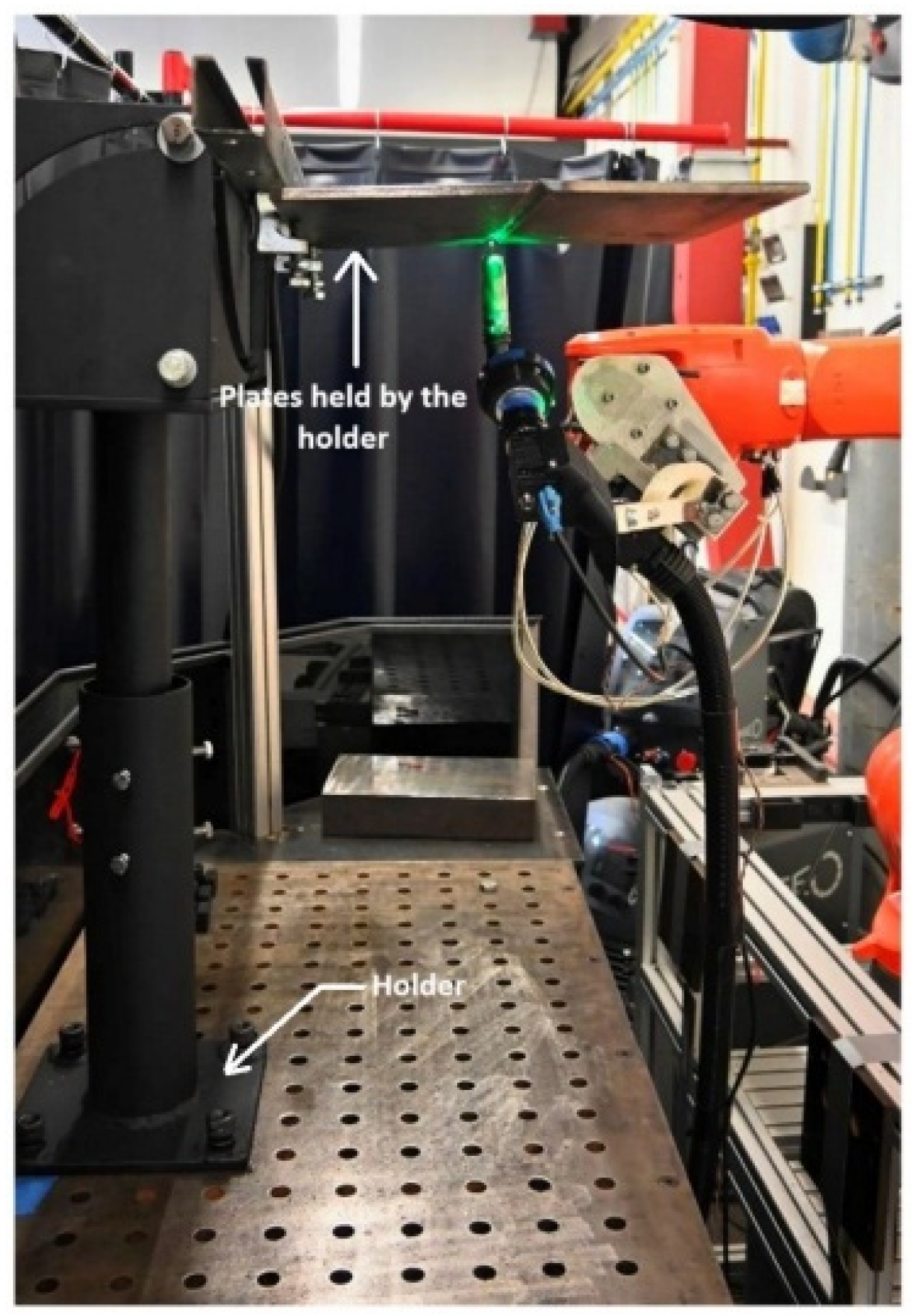

2.1. Experimental Setup

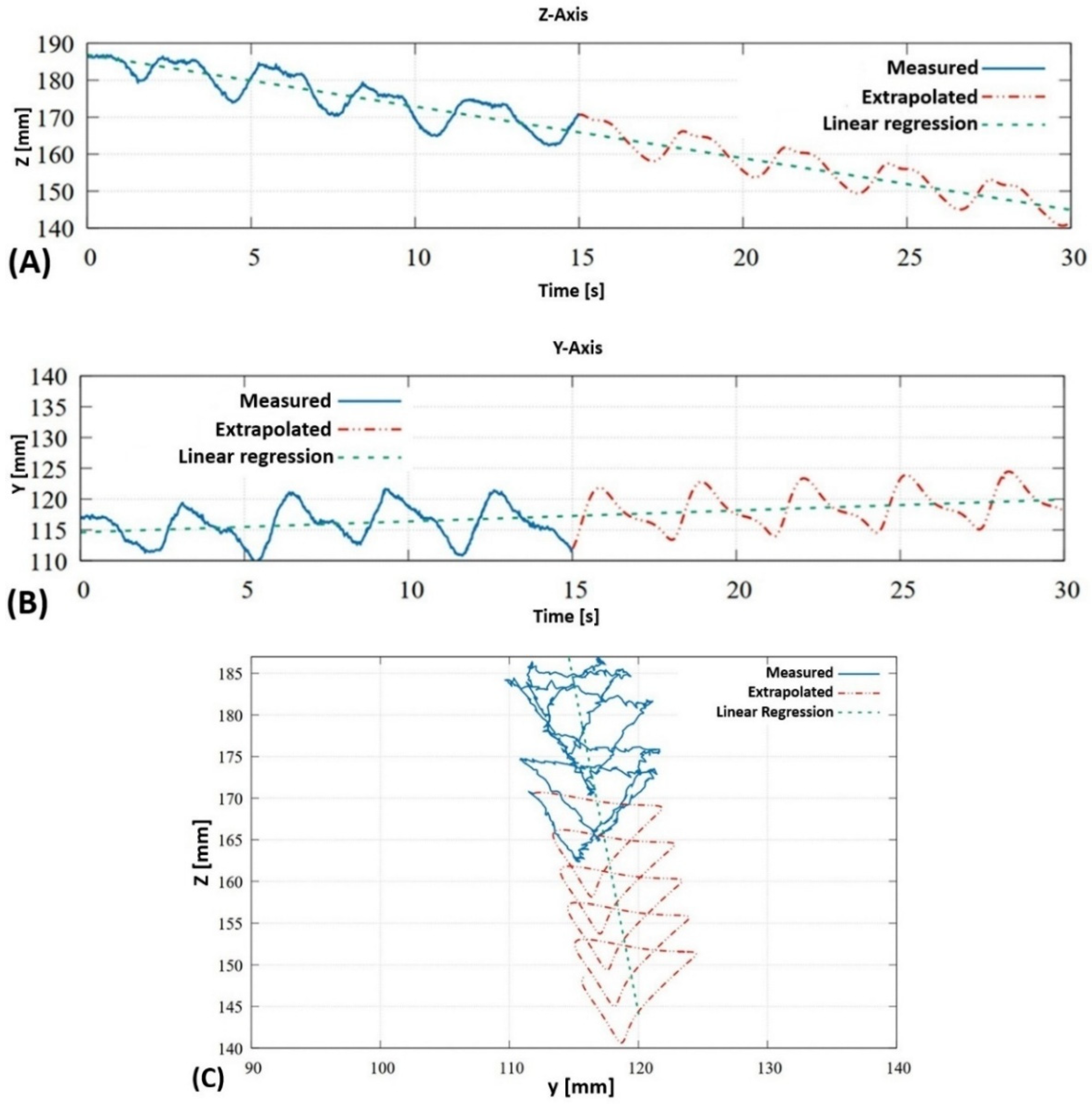

2.2. Motion Signal Analysis, Path Generation and Final System Development

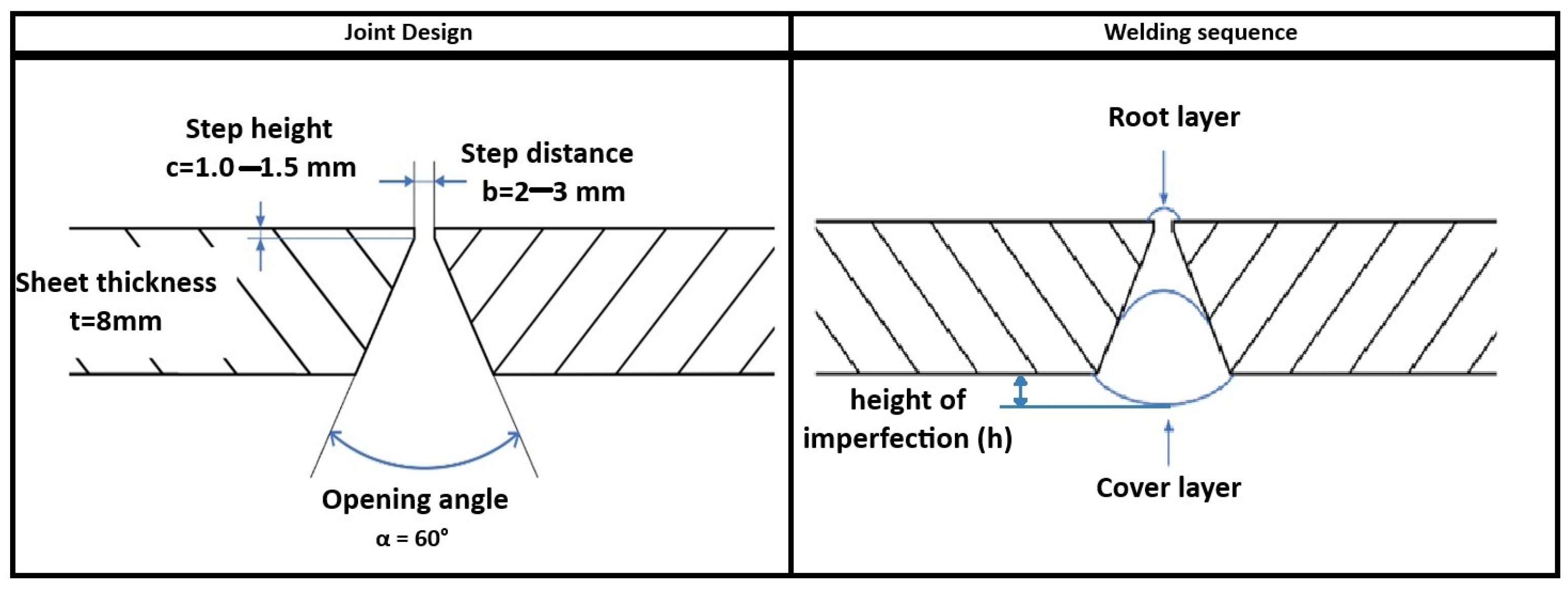

2.3. Materials and Experimental Methodology

3. Parameter Study for Overhead Welding with the Developed System

3.1. Parameter Study

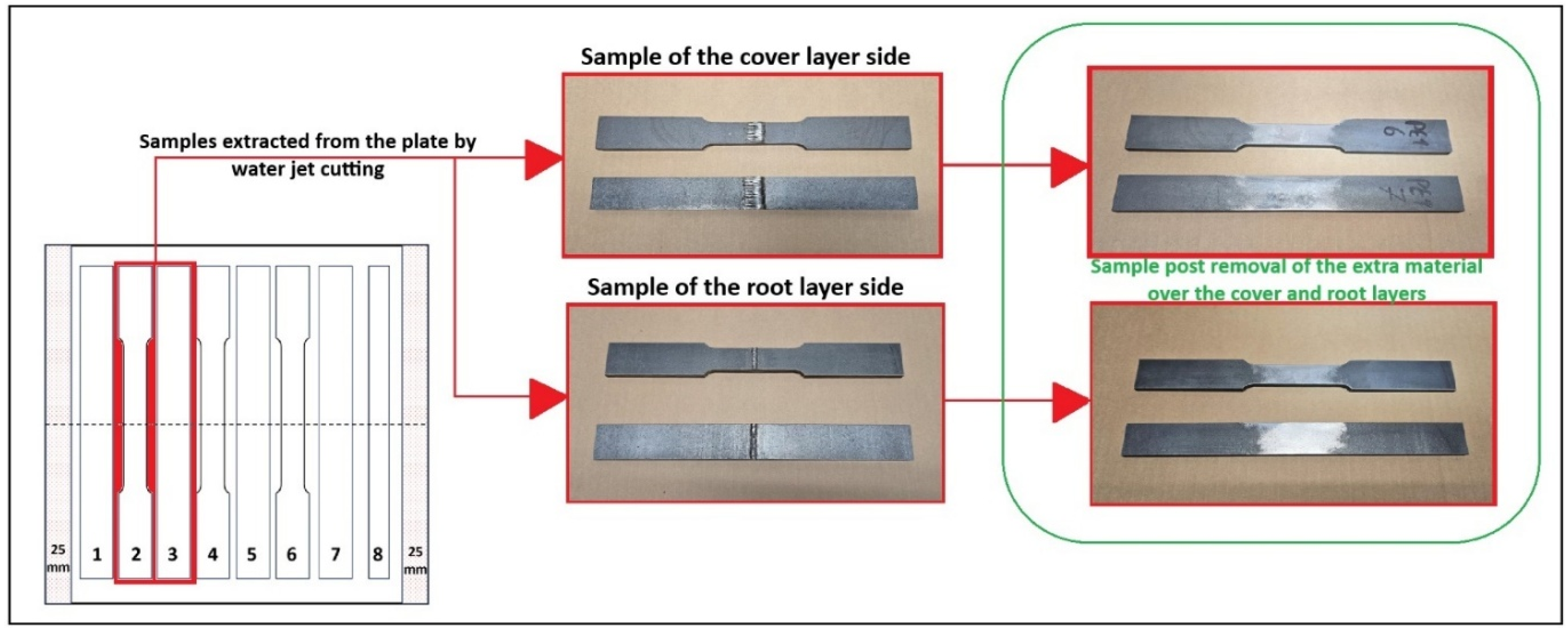

3.2. Sample Preparation

4. Results and Discussion

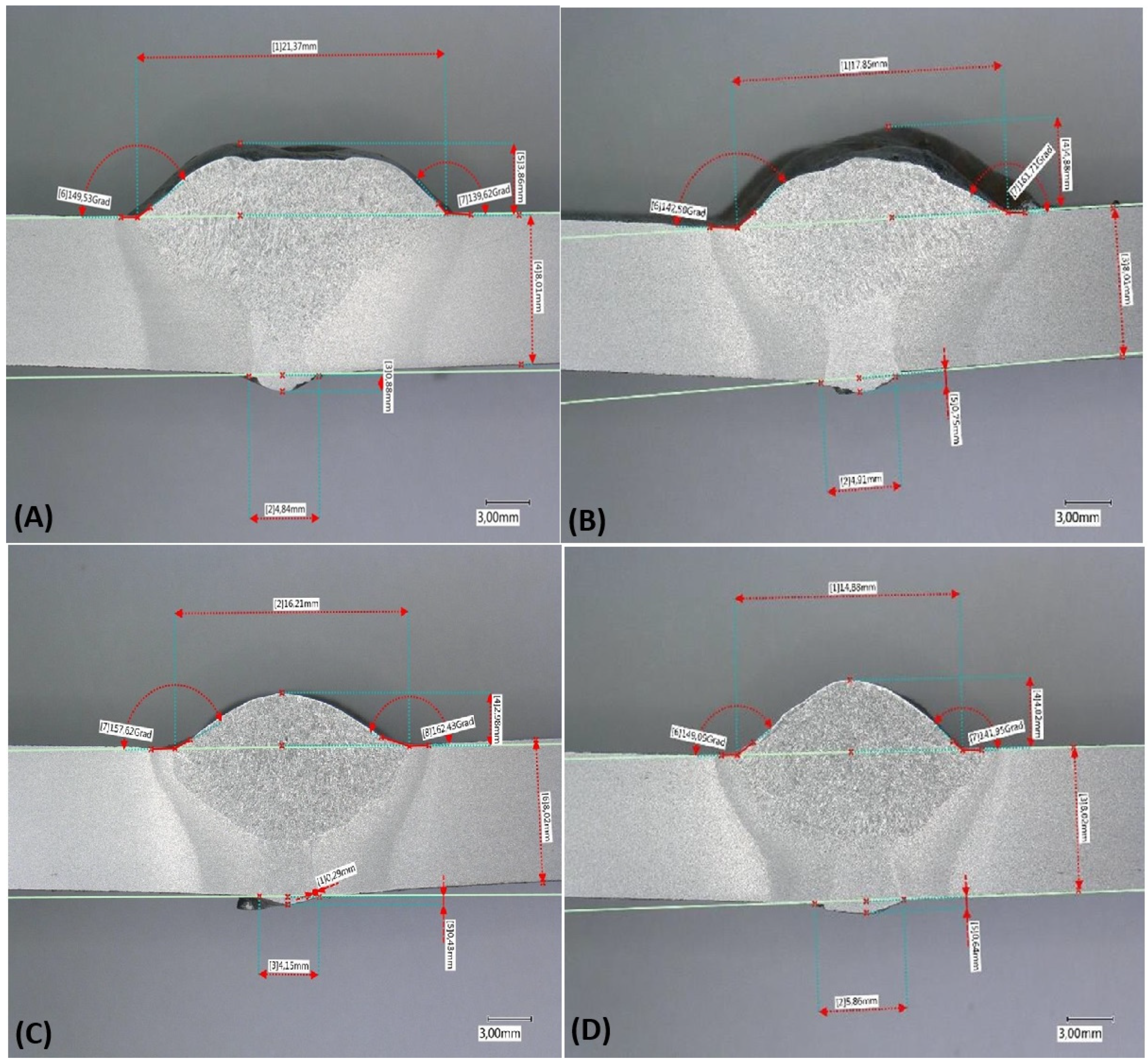

4.1. Weld Geometry Examination and Comparison with the Quality Norms

- Case 1. Excess penetration for plates with thickness greater than 3 mm.Highest category “B”: h ≤ 1 mm + 0.2b, but max. 3 mmMiddle category “C”: h ≤ 1 mm + 0.6b, but max. 4 mmLowest category “D”: h ≤ 1 mm + 1.0b, but max. 5 mm

- Case 2. Excess weld metal for plates with thickness greater than 3 mm.Highest category “B”: h ≤ 1 mm + 0.1b, but max. 5 mmMiddle category “C”: h ≤ 1 mm + 0.15b, but max. 7 mmLowest category “D”: h ≤ 1 mm + 0.25b, but max. 10 mm

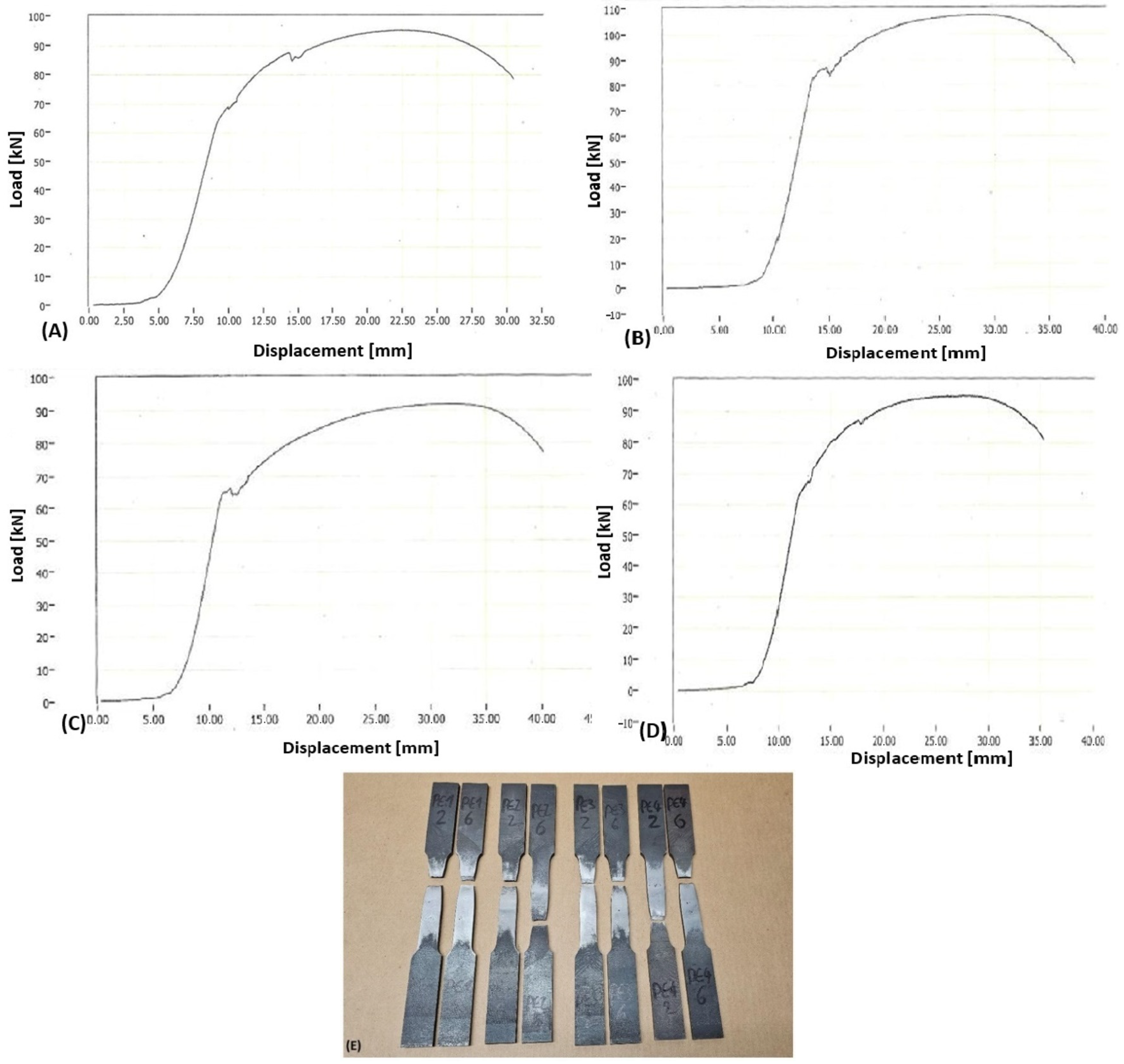

4.2. Mechanical Characterization

4.2.1. Tensile Test

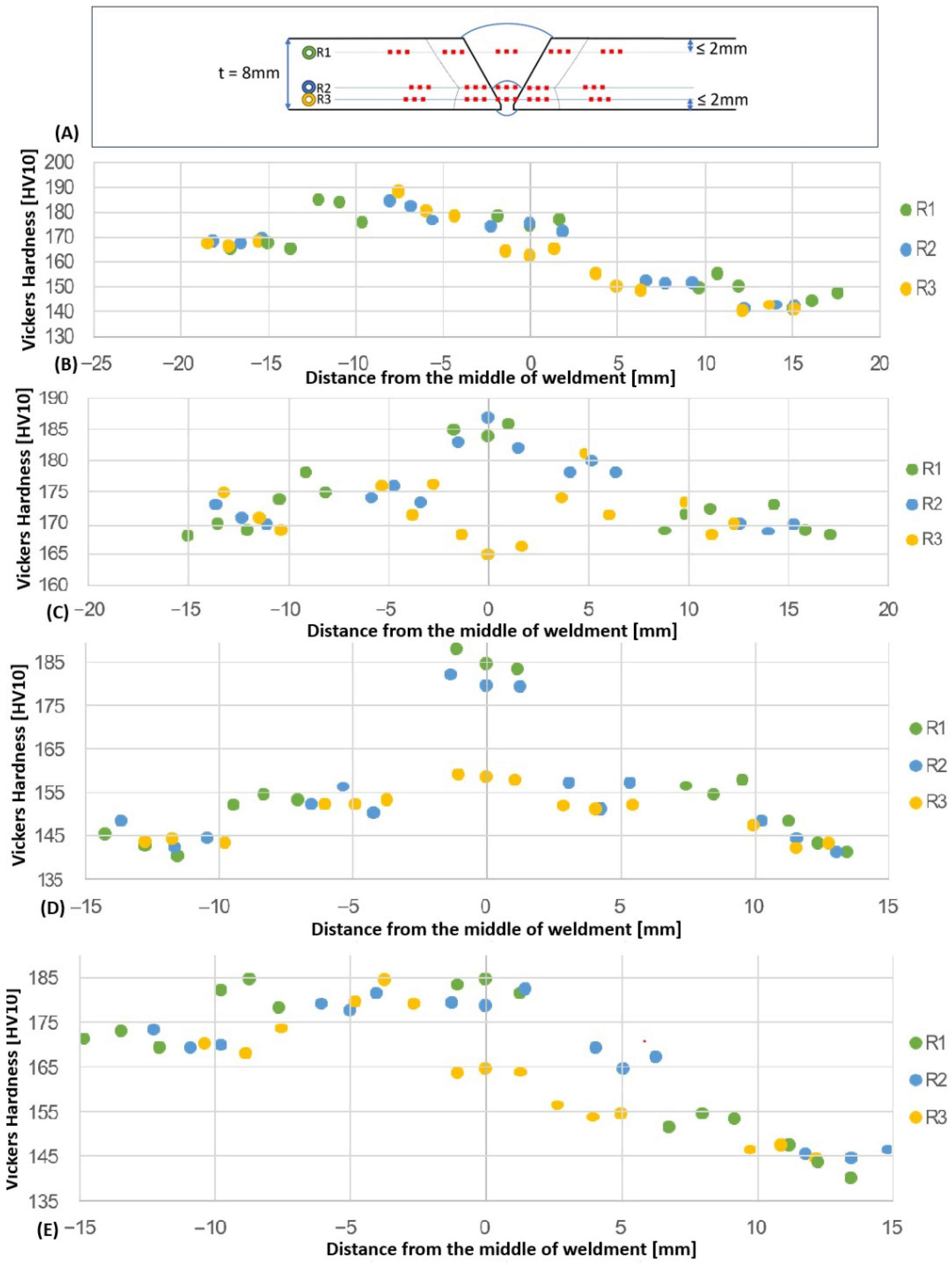

4.2.2. Bending and Hardness Tests

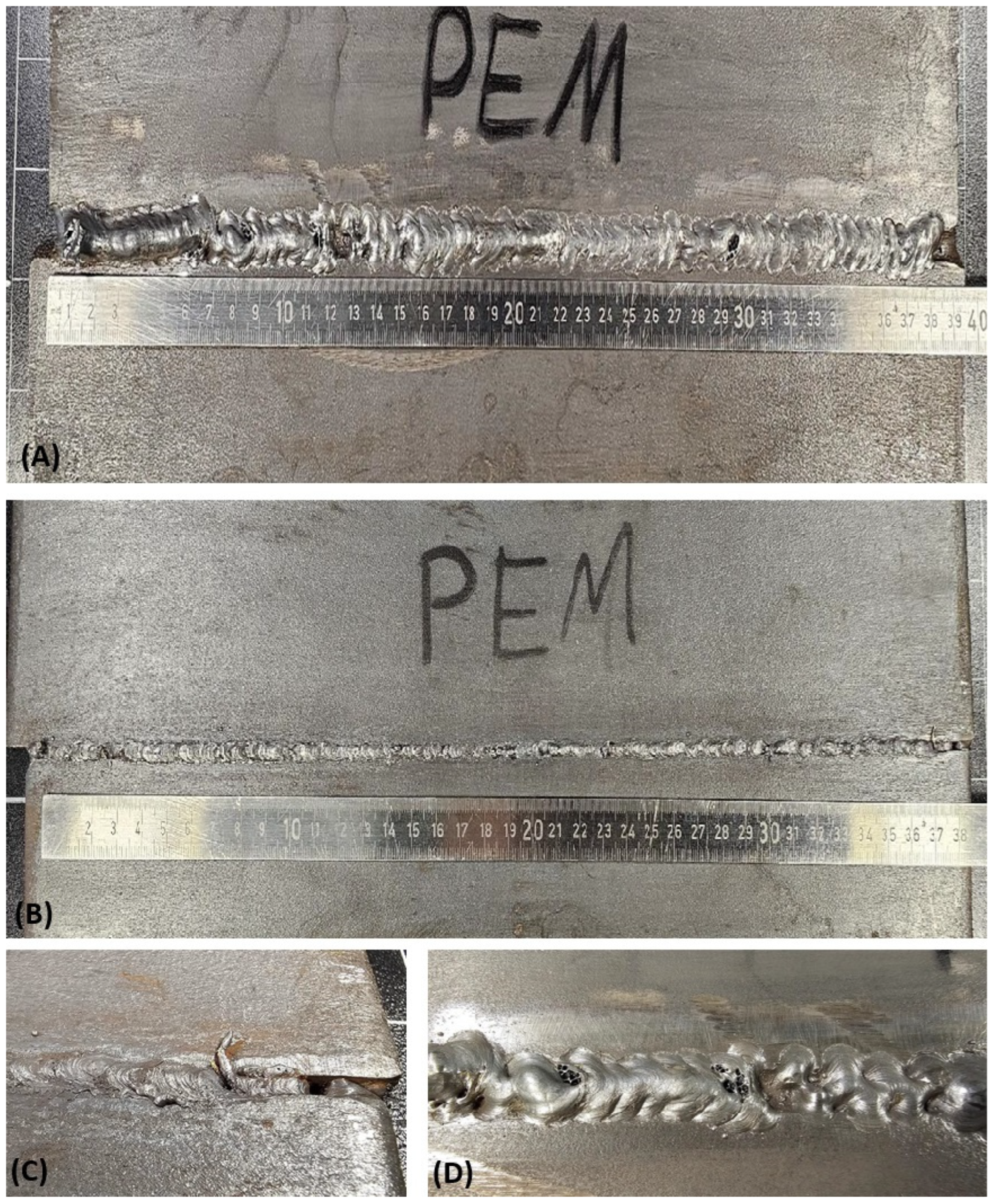

4.2.3. Comparison with Hand-Welded (Overhead) Samples

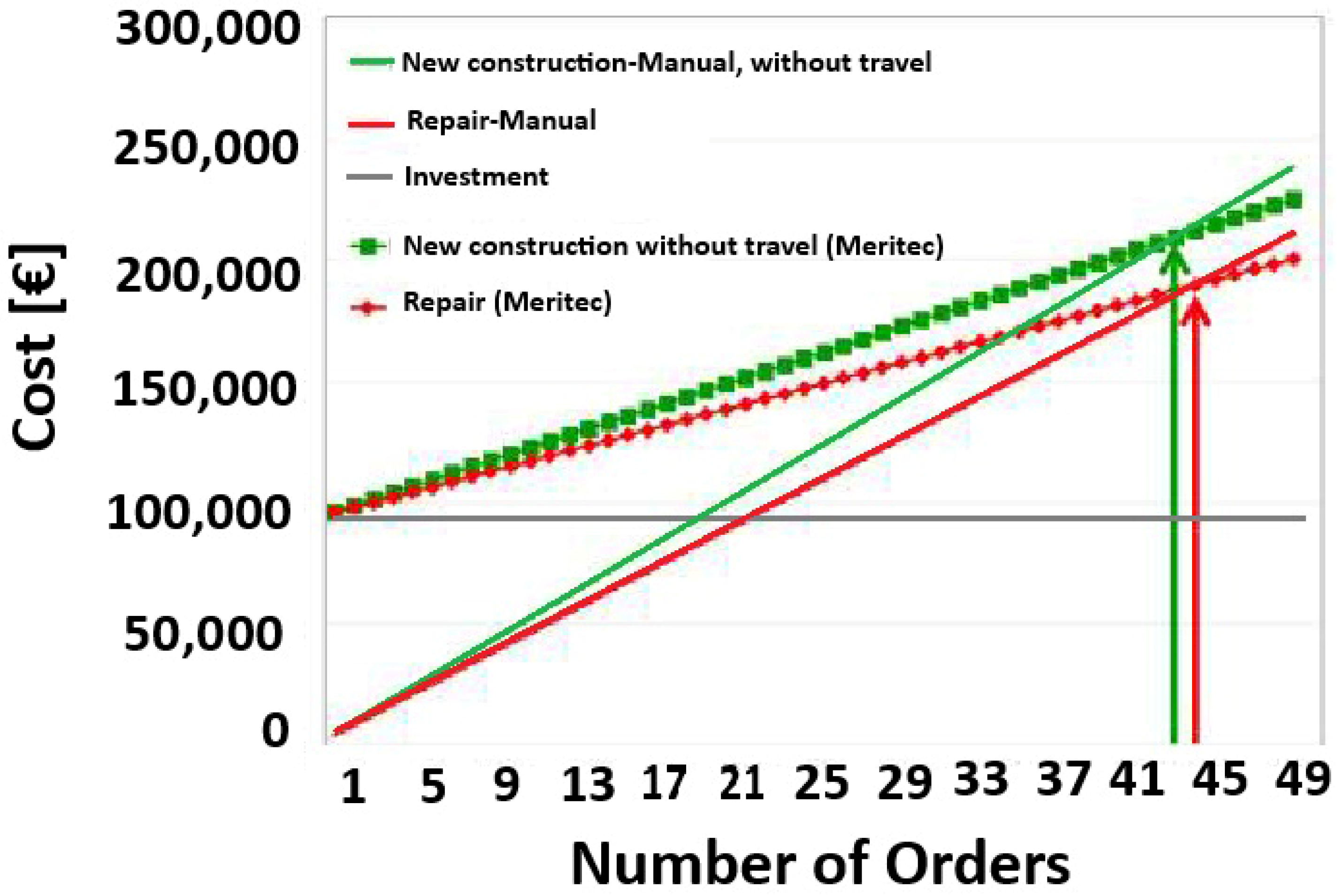

4.3. Economic Feasibility of the Developed Equipment

- Process step 1: Preparation of workstation, which includes the following:

- Set up the workstation and arrangements for cross transport of materials.

- Check the connection ends for roundness and angular accuracy and rework them if necessary.

- Prepare the weld edges (weld seam preparation).

- Process step 2: Welding

- Welding the root pass.

- Cleaning the seam and removing tacks (grinding).

- Check the interpass temperature.

- Visually inspect the seam for surface defects.

- Process step 3: Post-processing

- Sanding and cleaning the seam.

- Quality control.

- Acceptance (with documentation).

- Clean-up of the work area.

4.4. A Brief Proposal for Future Work

5. Conclusions

- The weld geometry was analysed for excessive penetration and weld metal. According to ISO 5817, excess penetration met the highest quality standard (Level B), while excess weld metal met the next level (Level C), indicating compliance with quality norms.

- Tensile strength tests yielded an average of 494 MPa, surpassing the base material’s minimum requirement of 360 MPa. All test samples fractured in the base material rather than the weld seam, further demonstrating the strength of the welds.

- Bending tests showed that the seams withstood a 180° bend without any damage.

- Hardness testing revealed variations in the base material due to differences in batches. However, the average hardness in the heat-affected zone (HAZ) of the weld seam was 189 HV, which meets the ISO 9015-1 standard.

- The developed system was compared to welds produced manually by the user. It was observed that, after some time, the user was affected by the ergonomic challenges, which in turn impacted the resulting weld quality. The MeRItec system therefore represents a significant improvement in workplace ergonomics for welders. It enables operators with no prior manual experience to produce weld seams that meet acceptance criteria. Nevertheless, operators must still become familiar with the system and receive appropriate training to use it effectively.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Staubli, S.; Zweimüller, J. Does raising the retirement age increase employment of older workers? J. Public Econ. 2013, 108, 17–32. [Google Scholar] [CrossRef] [PubMed]

- European Commission. The 2012 Ageing Report: Economic and Budgetary Projections for the 27 EU Member States (2010–2060); Directorate-General for Economic and Financial Affairs: Brussels, Belgium, 2012; ISBN 978-92-79-22850-6. [Google Scholar] [CrossRef]

- Bhumika, N.; Prabhu, G.V.; Ferreira, A.M.; Kulkarni, M.K.; Vaz, F.S.; Singh, Z. Respiratory Morbidity Among Welders in the Shipbuilding Industry, Goa. Indian J. Occup. Environ. Med. 2012, 16, 63–65. [Google Scholar] [CrossRef] [PubMed]

- Ozdemir, O.; Numanoglu, N.; Gonullu, U.; Savas, I.; Alper, D.; Gurses, H. Chronic Effects of Welding Exposure on Pulmonary Function Tests and Respiratory Symptoms. Occup. Environ Med. 1995, 52, 800–803. [Google Scholar] [CrossRef] [PubMed]

- European Agency for Safety and Health at Work. The Value of Occupational Safety and Health and the Societal Costs of Work-Related Injuries and Diseases; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar] [CrossRef]

- Ajoudani, A.; Albrecht, P.; Bianchi, M.; Cherubini, A.; Del Ferraro, S.; Fraisse, P.; Fritzsche, L.; Garabini, M.; Ranavolo, A.; Rosen, P.H.; et al. Smart Collaborative Systems for Enabling Flexible and Ergonomic Work Practices. IEEE Robot. Autom. Mag. 2020, 27, 169–176. [Google Scholar] [CrossRef]

- Lopes, D.R.; Schmitz, A.; Lenzi, A.R.; Catai, E.R.; Gadda, T.M.C. Simulation of Exposure to Metal Fumes in the SMAW Welding Process Using IH MOD 2.0: Occupational Health and Safety Assessment. Rev. Gest. Soc. Ambient. 2018, 18, e010362. [Google Scholar] [CrossRef]

- Islam, K.S.; Hossain, A.; Khan, M.R.; Islam, M.T. The Role of Age in Shaping Risk-Taking Behaviours and Safety Awareness in the Manufacturing Sector. Am. J. Adv. Technol. Eng. Solut. 2018, 1, 98–121. [Google Scholar] [CrossRef]

- Griffiths, A. Differential Health Effects of Work Organization by Age. In Occupational and Environmental Health: Recognizing and Preventing Disease and Injury, 6th ed.; Levy, B.S., Wegman, D.H., Baron, S.L., Sokas, R.K., Eds.; Oxford University Press: Oxford, UK, 2014; pp. 199–200. Available online: https://www.ncbi.nlm.nih.gov/books/NBK207715/ (accessed on 19 July 2025).

- Götz, S.; Hoven, H.; Müller, A.; Dragano, N.; Wahrendorf, M. Age Differences in the Association between Stressful Work and Sickness Absence among Full-Time Employed Workers: Evidence from the German Socio-Economic Panel. Int. Arch. Occup. Environ. Health 2018, 91, 479–496. [Google Scholar] [CrossRef] [PubMed]

- Frese, M.; Mohr, G. Prolonged Unemployment and Depression in Older Workers: A Longitudinal Study of Intervening Variables. Soc. Sci. Med. 1987, 25, 173–178. [Google Scholar] [CrossRef] [PubMed]

- Pfeil, S.; Holtz, K.; Kopf, K.A.; Hegerl, U.; Rummel-Kluge, C. Minor Depression in Older, Long-Term Unemployed People Seeking Vocational Support. BMC Psychiatry 2017, 17, 243. [Google Scholar] [CrossRef] [PubMed]

- Okunribido, O.; Wynn, T. Ageing and Work-Related Musculoskeletal Disorders: A Review of the Recent Literature; Research Report 779; Health and Safety Executive: Sudbury, UK, 2010. [Google Scholar]

- Plouvier, S.; Gourmelen, J.; Chastang, J.-F.; Lanoë, J.-L.; Leclerc, A. Low Back Pain Around Retirement Age and Physical Occupational Exposure during Working Life. BMC Public Health 2011, 11, 268. [Google Scholar] [CrossRef] [PubMed]

- Yeomans, L. An Update of the Literature on Age and Employment; Research Report RR832; Health and Safety Executive: Sudbury, UK, 2011. Available online: http://www.hse.gov.uk/research/rrpdf/rr832.pdf (accessed on 19 July 2025).

- Ilmarinen, J.E. Aging Workers. Occup. Environ. Med. 2001, 58, 546. [Google Scholar] [CrossRef] [PubMed]

- Ilmarinen, J. Ageing Workers in Finland and in the European Union: Their Situation and the Promotion of the Working Ability, Employability and Employment. Geneva Pap. Risk Insur. 2001, 26, 623–641. [Google Scholar] [CrossRef]

- Ilmarinen, J.; European Agency for Safety and Health at Work. Promoting Active Ageing in the Workplace. EU-OSHA. 2025. Available online: https://osha.europa.eu/en/publications/promoting-active-ageing-workplace (accessed on 19 July 2025).

- Sigma Ergonomics. Available online: https://www.sigmaoffice.gr/en/ergonomics/ (accessed on 11 July 2025).

- Liebers, F.; Caffier, G. Berufsspezifische Arbeitsunfähigkeit Durch Muskel-Skelett-Erkrankungen in Deutschland; Bundesanstalt für Arbeitsschutz und Arbeitsmedizin: Dortmund, Germany, 2009. [Google Scholar]

- Wang, Q.; Jiao, W.; Wang, P.; Zhang, Y. Digital Twin for Human-Robot Interactive Welding and Welder Behavior Analysis. IEEE/CAA J. Autom. Sinica 2021, 8, 334–343. [Google Scholar] [CrossRef]

- Lee, D.; Han, K. Vision-based construction robot for real-time automated welding with human-robot interaction. Autom. Constr. 2024, 168, 105782. [Google Scholar] [CrossRef]

- Zhao, M.; Liu, X.; Wang, K.; Liu, Z.; Dong, Q.; Wang, P.; Su, Y. Welding Seam Tracking and Inspection Robot Based on Improved YOLOv8s-Seg Model. Sensors 2024, 24, 4690. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Pal, R.; Singh, P.; Mohan, D. Occupational Hazard Exposure and General Health Profile of Welders in Rural Delhi. Indian J. Occup. Environ. Med. 2014, 18, 85–89. Available online: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4083517/ (accessed on 19 July 2025). [PubMed]

- Riccelli, M.G.; Goldoni, M.; Poli, D.; Mozzoni, P.; Cavallo, D.; Corradi, M. Welding Fumes, a Risk Factor for Lung Diseases, Chronic Obstructive Pulmonary Disease and Cancer. Int. J. Environ. Res. Public Health 2020, 17, 2552. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Zhang, W.J.; Zhang, Y.M. Mixed Reality Augmented Remote Welding System with Virtual Fixtures and Autonomous Agents. In Proceedings of the 2024 4th International Conference on Robot Control Engineering (ICRCE), Edinburgh, UK, 27–29 June 2024; pp. 131–137. [Google Scholar]

- Chan, W.P.; Hanks, G.; Sakr, M.; Zhang, H.; Zuo, T.; Van der Loos, H.M.; Croft, E. Design and Evaluation of an Augmented Reality Head-Mounted Display Interface for Human Robot Teams Collaborating in Physically Shared Manufacturing Tasks. ACM Trans. Hum.-Robot. Interact. (THRI) 2022, 11, 1–19. [Google Scholar]

- Ebel, L.C.; Zuther, P.; Maass, J.; Sheikhi, S. Motion Signal Processing for a Remote Gas Metal. Robotics 2020, 9, 30. [Google Scholar] [CrossRef]

- Ebel, L.C.; Maass, J.; Zuther, P.; Sheikhi, S. Trajectory Extrapolation for Manual Robot Remote Welding. Robotics 2021, 10, 77. [Google Scholar] [CrossRef]

- KUKA Aktiengesellschaft. Available online: https://www.kuka.com/en-gb/services/downloads?terms=Language:en:1 (accessed on 15 March 2020).

- Fronius USA LLC. Available online: https://www.fronius.com/en-us/usa (accessed on 15 March 2020).

- ISO 15614-1:2017; Specification and Qualification of Welding Procedures for Metallic Materials—Welding Procedure Test—Part 1: Arc and Gas Welding of Steels and Arc Welding of Nickel and Nickel Alloys. International Organization for Standardization: Geneva, Switzerland, 2017.

- DIN EN 10025-2:2019; Hot Rolled Products of Structural Steels—Part 2: Technical Delivery Conditions for Non-Alloy Structural Steels. Deutsches Institut für Normung: Berlin, Germany, 2019.

- DIN EN ISO 14175; Schweißzusätze: Gase und Mischgase für das Lichtbogenschweißen und Verwandte Prozesse. Beuth Verlag GmbH: Berlin, Germany, 2008.

- DIN EN ISO 14341; Schweißzusätze: Drahtelektroden und Schweißgut zum Metall-Schutzgasschweißen von Unlegierten Stählen und Feinkornstählen. Beuth Verlag GmbH: Berlin, Germany, 2020.

- weldingtool.eu. MAG-Schweißdraht G3Si1 HOT WELD M Ø 1.2 mm, Lagengespult Nach EN ISO 14341-A-G42 4-M21 2-C1 3Si1. Available online: https://www.weldingtool.eu/mag-schweissdraht-g3si1-hot-weld-m-o-1-2-mm-lagengespult-nach-en-iso-1434i-a-g42-4-m21-2-c1-3si1.html (accessed on 16 January 2024).

- DINSE GmbH. DINSE DIX PI 3006.M I—Operation Manual; DINSE GmbH: Hamburg, Germany, 2018. [Google Scholar]

- DINSE GmbH. DINSE DIX PI 3006.M I—Programmübersicht; DINSE GmbH: Hamburg, Germany, 2018. [Google Scholar]

- DVS. Internationaler Schweißfachingenieur Teil III—Skript; DVS: Düsseldorf, Germany, 2019. [Google Scholar]

- ISO 4136:2022; Destructive Tests on Welds in Metallic Materials: Transverse Tensile Test. International Organization for Standardization: Geneva, Switzerland, 2022.

- ISO 5173:2023; Destructive Tests on Welds in Metallic Materials: Bend Tests. International Organization for Standardization: Geneva, Switzerland, 2023.

- ISO 17639:2022; Destructive Tests on Welds in Metallic Materials: Macroscopic and Microscopic Examination of Welds. International Organization for Standardization: Geneva, Switzerland, 2022.

- ISO 5817:2014; Welding: Fusion-Welded Joints in Steel, Nickel, Titanium and Their Alloys (Beam Welding Excluded): Quality Levels for Imperfections. International Organization for Standardization: Geneva, Switzerland, 2014.

- DIN EN ISO 6892-1:2020; Metallische Werkstoffe: Zugversuch—Teil 1: Prüfverfahren bei Raumtemperatur. Beuth Verlag GmbH: Berlin, Germany, 2020.

- Arthur Weber. Stahlblech Band—S235JR+AR. Available online: https://www.arthurweber.ch/wp2021/wp-content/uploads/2022/08/Materialdatenblatt-Stahlblech-Band-%E2%80%93-S235JRAR.pdf (accessed on 17 January 2024).

- ISO 9015-1:2011; Destructive Tests on Welds in Metallic Materials: Hardness Testing—Part 1: Hardness Test on Arc Welded Joints. International Organization for Standardization: Geneva, Switzerland, 2011.

- ESAB Welding & Cutting GmbH. Die 4 Wichtigsten Arten von Schweißpositionen. Available online: https://esab.com/de/eur_de/esab-university/blogs/4-main-types-of-welding-positions/ (accessed on 1 February 2024).

- TECHNOLIT GmbH. Überblick der Wichtigsten Schweißpositionen Nach DIN EN ISO 6947. Available online: https://schweisstechnik.technolit.de/schweisstechnik-wissen/richtig-schweissen-basiswissen/schweisspositionen/ (accessed on 3 February 2024).

- Fronius International GmbH. Ergonomisches Schweißen—Ein Paradox? DVS Media GmbH. 29 September 2023. Available online: https://www.home-of-welding.com/news/ergonomisch-schweissen-ein-paradox-3603 (accessed on 13 February 2024).

- KEMPER GmbH. Ergonomie Beim Schweißen: Wie Exoskelette Für Entlastung Sorgen; Arbeitsschutz Schweißen—KEMPER GmbH. Available online: https://arbeitsschutz-schweissen.de/ergonomie-beim-schweissen-wie-exoskelette-fuer-entlastung-sorgen/ (accessed on 19 July 2025).

| Test No. | Wire Feed Rate [m/min] | Weld Current [A] | Remarks |

|---|---|---|---|

| 1 | 4.0 | 17 | -insufficient root volume -flank connection on the root side is sufficient |

| 2 | 4.0 | 17.1 | -root sag/excessive root volume -flank fusion defect |

| 3 | 4.0 | 16.9 | -insufficient root volume -flank connection on the root side is insufficient |

| 4 | 4.5 | 17.2 | -flank fusion defect |

| 5 | 4.5 | 17.4 | -insufficient root volume -flank fusion defect |

| 6 | 4.5 | 17.3 | / |

| 7 | 5.0 | 17.5 | / |

| 8 | 5.0 | 17.6 | -root penetration due to increased speed |

| 9 | 5.0 | 17.5 | / |

| 10 | 5.5 | 17.9 | -root sag/excessive root volume -root burn-out |

| 11 | 5.5 | 17.8 | -root burn-out |

| 12 | 5.5 | 17.8 | -root penetration due to increased speed |

| 13 | 6.0 | 18.3 | -root burn-out -arc deflection -flank fusion defect |

| Test No. | Wire Feed Rate [m/min] | Weld Current [A] | Remarks |

|---|---|---|---|

| 1 | 5.5 | 17.9 | / |

| 2 | 5.5 | 18.0 | / |

| 3 | 5.5 | 17.9 | / |

| 4 | 5.0 | 17.6 | -insufficient cover pass filling -flank fusion defects |

| 5 | 5.0 | 17.4 | / |

| 6 | 5.5 | 17.5 | -insufficient cover pass filling |

| 7 | 6.0 | 18.4 | -cover pass over-reinforcement -surface open pores |

| 8 | 6.0 | 18.3 | -gas nozzle sticking due to cover pass over-reinforcement |

| 9 | 5.0 | 18.3 | / |

| Weld Sequence | Process | Feed Wire Diameter [mm] | Current [A] | Voltage [V] | Current Type/Polarity | Wire Feed Rate [m/min] |

|---|---|---|---|---|---|---|

| Root | 135 | 1.0 | 125 | 17.5 | DC+ | 5.0 |

| Cover | 135 | 1.0 | 135 | 17.9 | DC+ | 5.5 |

| Sl. No. | Cover Layer | Root Layer | Case 1 | Case 2 | ||||

|---|---|---|---|---|---|---|---|---|

| b [mm] | h [mm] | b [mm] | h [mm] | Excess Penetration | Category | Excess Weld Metal | Category | |

| PE1 | 22 | 3 | 6 | 1 | 2.2 | B | 3.2 | B |

| PE2 | 18 | 3 | 6 | 1.5 | 2.2 | B | 3.7 | C |

| PE3 | 18.5 | 3.5 | 5 | 1.5 | 2 | B | 3.775 | C |

| PE4 | 15 | 2.5 | 5 | 2 | 2 | B | 3.25 | C |

| Sl. No. | Cross-Sectional Area [mm2] | Tensile Strength [MPa] | Minimal Required Tensile Strength [MPa] | Max. Load [kN] | Fracture Location |

|---|---|---|---|---|---|

| PE1_2 | 201.45 | 471 | 360 | 94.97 | BM |

| PE1_6 | 199.33 | 474 | 360 | 94.4 | BM |

| PE2_2 | 192.01 | 459 | 360 | 107.41 | BM |

| PE2_6 | 195.12 | 456 | 360 | 107.54 | BM |

| PE3_2 | 197.35 | 465 | 360 | 91.57 | BM |

| PE3_6 | 198.74 | 457 | 360 | 88.69 | BM |

| PE4_2 | 193.45 | 492 | 360 | 94.99 | BM |

| PE4_6 | 196.05 | 491 | 360 | 95.32 | BM |

| Sl. No. | Thickness “ts” [mm] | Width “b” [mm] | Sample Type | Bending Angle [°] | Remarks |

|---|---|---|---|---|---|

| PE1_1 | 8 | 32 | TRBB | 180 | Pass, no fracture |

| PE1_3 | 8 | 32 | TFBB | 180 | Pass, no fracture |

| PE1_5 | 8 | 32 | TRBB | 180 | Pass, no fracture |

| PE1_7 | 8 | 32 | TFBB | 180 | Pass, no fracture |

| PE2_1 | 8 | 32 | TRBB | 180 | Pass, no fracture |

| PE2_3 | 8 | 32 | TFBB | 180 | Pass, no fracture |

| PE2_5 | 8 | 32 | TRBB | 180 | Pass, no fracture |

| PE2_7 | 8 | 32 | TFBB | 180 | Pass, no fracture |

| PE3_1 | 8 | 32 | TRBB | 180 | Pass, no fracture |

| PE3_3 | 8 | 32 | TFBB | 180 | Pass, no fracture |

| PE3_5 | 8 | 32 | TRBB | 180 | Pass, no fracture |

| PE3_7 | 8 | 32 | TFBB | 180 | Pass, no fracture |

| PE4_1 | 8 | 32 | TRBB | 180 | Pass, no fracture |

| PE4_3 | 8 | 32 | TFBB | 180 | Pass, no fracture |

| PE4_5 | 8 | 32 | TRBB | 180 | Pass, no fracture |

| PE4_7 | 8 | 32 | TFBB | 180 | Pass, no fracture |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sheikhi, S.; Subadra, S.P.; Langer, R.; Ebel, L.C.; Mayer, E.; Zuther, P.; Maaß, J. Improving Health and Safety in Welding Through Remote Human–Robot Collaboration. Processes 2025, 13, 3017. https://doi.org/10.3390/pr13093017

Sheikhi S, Subadra SP, Langer R, Ebel LC, Mayer E, Zuther P, Maaß J. Improving Health and Safety in Welding Through Remote Human–Robot Collaboration. Processes. 2025; 13(9):3017. https://doi.org/10.3390/pr13093017

Chicago/Turabian StyleSheikhi, Shahram, Sharath P. Subadra, Robert Langer, Lucas Christoph Ebel, Eduard Mayer, Patrick Zuther, and Jochen Maaß. 2025. "Improving Health and Safety in Welding Through Remote Human–Robot Collaboration" Processes 13, no. 9: 3017. https://doi.org/10.3390/pr13093017

APA StyleSheikhi, S., Subadra, S. P., Langer, R., Ebel, L. C., Mayer, E., Zuther, P., & Maaß, J. (2025). Improving Health and Safety in Welding Through Remote Human–Robot Collaboration. Processes, 13(9), 3017. https://doi.org/10.3390/pr13093017