1. Introduction

Benxi is an important old industrial base in China, known as the “Green Steel Capital”. This region has extremely rich iron ore reserves, exceeding 20 billion tons [

1]. The main iron mines include the Nanfen Open-pit Mine and the Waitoushan Iron Mine, both of which produce high-grade iron ore concentrate with few impurities. In addition, this region is also abundant in limestone, clay, coal, and water resources.

The iron ore deposits in the Benxi region are pre-Cambrian sedimentary metamorphic [

2]. The Nanfen Open-pit Mine is characterized by low levels of harmful elements, such as phosphorus and sulfur, making it an excellent site for making high-quality “ginseng iron”. The Waitoushan Iron Mine contains fewer mineral types, with low contents of quartz, iron oxide, amphibole, carbonate minerals, and sulfides [

2,

3]. The high-grade iron ore concentrate produced from these two mines, with few impurities, forms the basis for the development of the iron and steel industry in Benxi. Moreover, other resources ensure the supply of refractory materials and auxiliary fuel [

2,

4]. For example, the Tianshifu clay mine, with its suitable composition and refractory temperature ranging from 1580 °C to 1750 °C, provides raw materials for refractory production. The Niuxintai, Caitun, and Xihu Coal Mines supply sufficient metallurgical fuel for Benxi Steel. Additionally, the Taizi River continuously provides water resources for Benxi Steel.

With its abundant mineral resources and complete energy and water resource guarantees, Benxi had favorable preconditions for the development of its iron and steel industry, establishing a long-standing history of metallurgy and a well-developed modern steel industry chain.

2. Overview of Ironmaking History in the Benxi Region, Liaoning, China

The history of metallurgy in the Benxi region can be traced back to the Liao Dynasty.

The History of Liao mentions that by the reign of Yelü Deguang, ironmaking had already appeared in the Taizi River basin, described as “having the benefits of wood, iron, salt, and fish” [

5]. By the Ming Dynasty, Benxi had become an important iron-producing area in Liaodong. At this time, there were five ironworks in Benxi, with an annual output of nearly 50,000 catties (approximately 25,000 kg), accounting for one-seventh of the total output in the Liaodong region [

6]. During the Qing Dynasty, according to the

Shengjing tongzhi [

7], with the development of the commodity economy, Benxi became the center for coal mining and ironmaking. Coal mining and ironmaking sites were widely distributed, producing military, agricultural, and household products. These agricultural and household products were sold throughout the northeastern region and even exported to Korea. This marked the peak of ironmaking in the Benxi region during the feudal period. For a long time, metallurgy in Benxi has played an important historical role and served as a driving force for industrial development.

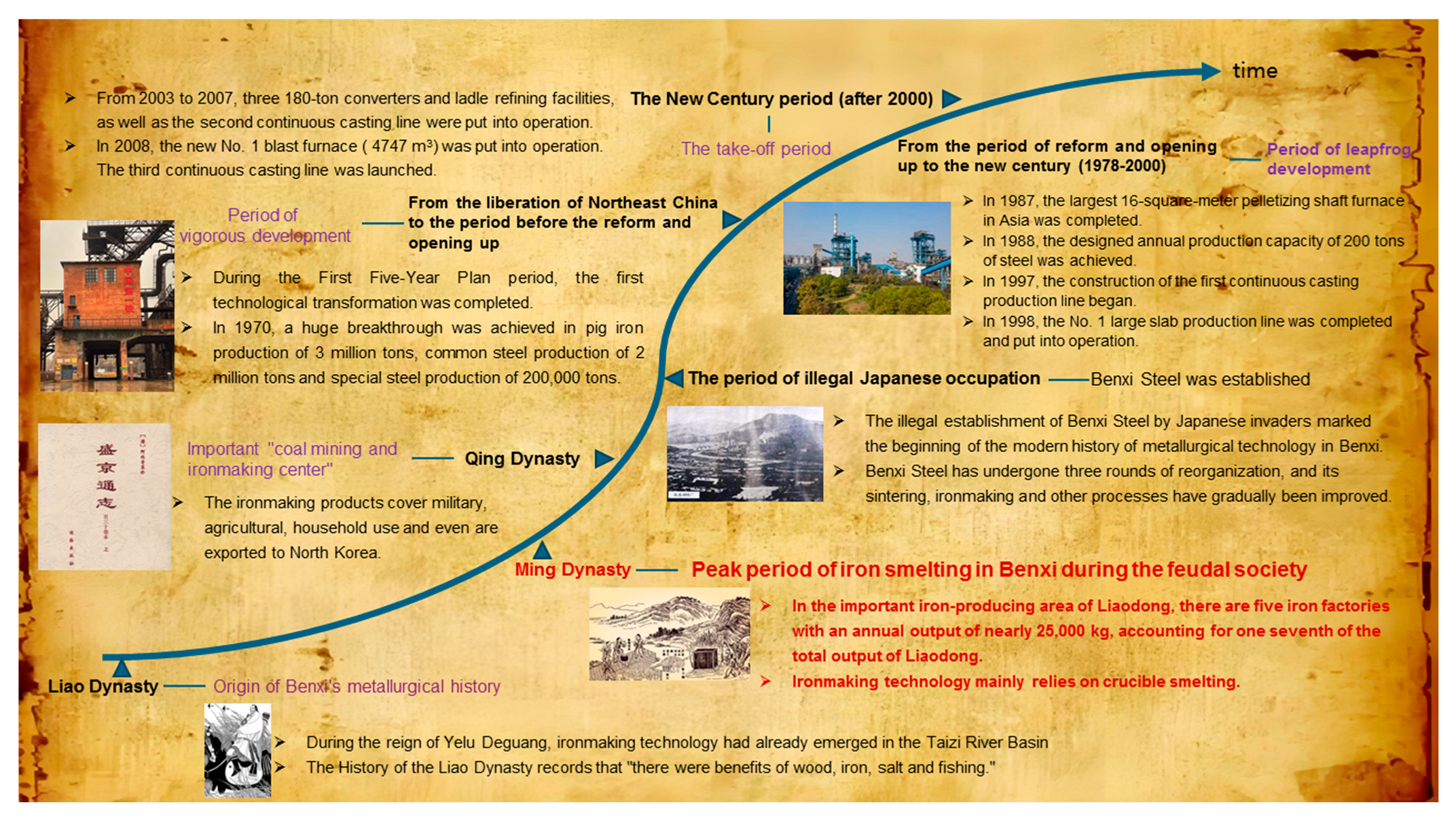

The history of metallurgical technology development in the Benxi region is extensive, spanning nearly 2900 years and can be divided into several stages: feudal development; illegal Japanese occupation; and the periods from the liberation of Northeast China to its reform and opening up, from the reform and opening up to the new century, and the new century itself [

8].

During the feudal development period, the main ironmaking technology in the Benxi region was based on the crucible.

The History of Benxihu [

9] provides a detailed description of the methods, equipment, and processes involved. According to the authors’ description, “iron plates were laid on the fire bed, with branches and coal placed on top, and crucibles were arranged above them. Two or three fire points were ignited, and bellows were used to blow air into the equipment. After one day and night, the iron could be melted. After solidification, the crucibles were broken to extract the pig iron. The pig iron was then melted in a granite furnace bed, and the molten iron was poured out through an outlet. It was first collected in an iron basket and then poured into molds to produce the final product.” This method had relatively low smelting efficiency but was adopted until the end of the feudal period. With the outbreak of the Russo-Japanese and Sino-Japanese Wars in Northeast China, the nearly 1200-year history of feudal metallurgy in Benxi came to an end.

During the period of illegal Japanese occupation, the Japanese invaders created Benxi Steel illegally, marking the beginning of modern metallurgical technology in this region. Since then, metallurgical technology in Benxi has centered around Benxi Steel. During this period, the Benxi metallurgical industry underwent three reorganizations, and the processes and equipment used for sintering, ironmaking, coking, and pelletizing gradually improved.

After the war, the Benxi metallurgical industry started to develop, before the reform and opening-up of Northeast China. Various units and mines gradually resumed production. Although production efficiency improved, there was no fundamental technological progress. During the “First Five-Year Plan,” Benxi Steel underwent its first technological transformation. In 1970, Benxi Steel welcomed its second transformation, achieving a production capacity of 3 million tons of pig iron, 2 million tons of common steel, and 200,000 tons of special steel. From the reform and opening up of Northeast China to the new century, Benxi Steel production gradually stabilized, infrastructure construction accelerated, and technology continued to improve. In 1987, the largest pelletizing shaft furnace in Asia at that time (16 square meters) was built; in 1988, a design capacity of 200,000 tons of steel per year was achieved [

2,

10]. In March 1997, the first continuous casting production line was constructed, and in 1998, the No. 1 large slab production line was completed and put into operation.

Entering the new century, Benxi Steel’s ironmaking and steelmaking equipment continued to upgrade. In 2008, a new No. 1 blast furnace with a volume of 4747 cubic meters was put into operation. From 2003 to 2007, three 180-ton converters and corresponding equipment for hot metal pretreatment, ladle refining, and continuous casting (the second continuous casting line) were successively put into production. The third continuous casting line began construction in 2008, and after its commissioning, this technology reached the most advanced level in China [

8,

10]. Today, Benxi Steel continues to fill product gaps and enhance its core competitiveness.

Figure 1 shows a map of the historical development of metallurgy in the Benxi area. In summary, during the feudal period, the Benxi region became an important iron-producing area. Due to the corrupt government system of the Qing Dynasty and the lack of technological innovation during this time, the subsequent Ming Dynasty marked the peak of ironmaking in the Benxi region during the feudal period. In the context of the development of ancient Chinese ironmaking technologies, the processes during the Ming Dynasty were primarily divided into crucible ironmaking and blast furnace ironmaking. However, other scholars have predominantly analyzed and discussed the latter process. Using historical records, detailed analyses have been conducted on various technical aspects of blast furnace ironmaking, including reactor construction, the structure, the bellows, and fuel utilization. In contrast, there is a significant scarcity of records and research on the crucible ironmaking process of the Ming Dynasty. To date, no ancient blast furnace ironmaking relics or technical evidence have been found in the Benxi region, which continued to rely mainly on crucible ironmaking up to the Ming Dynasty. Therefore, analyzing the ironmaking of this period not only helps clarify the characteristics and evolution of the ironmaking process in the Benxi region but also supplements the understanding of ancient crucible ironmaking technology.

3. Analysis of Ming Dynasty Metallurgical Technology in Benxi Region

3.1. Crucible Ironmaking Method and the Wangguan Ironmaking Site in Benxi

The crucible ironmaking method is a great invention of ancient Chinese laborers and shares the same origin with blast furnace ironmaking, both evolving from the mature crucible copper smelting technology in ancient China [

11,

12]. Ironmaking crucibles have been unearthed at sites such as Wafangzhuang in Nanyang, Henan, and Qinghe Town in Hebei, indicating that this method became relatively mature by at least the Western Han Dynasty. Due to its simplicity, low cost, and ease of operation, crucible ironmaking was suitable for small-scale production in localized areas and remained popular in regions such as Shanxi, Shandong, Liaoning, and Henan in China until modern times. However, in terms of its contribution to the national iron output, the blast furnace method has always been the mainstay of ironmaking.

The process flow of crucible ironmaking is as follows [

13]: Firstly, the ore is crushed and sieved to remove large impurities. Then, it is mixed with anthracite (as a reducing agent) and black soil (as a flux) and loaded into the crucible. After installation, the crucible opening is tightly covered with tiles or cinder, and then the crucible is placed into the furnace. Next, a layer of broken bricks or tiles is laid at the bottom of the furnace to ensure ventilation. It is ignited and air is blown to reduce and melt the ore into pig iron at a high temperature. The entire process usually takes a relatively long time, and the specific duration depends on the size of the furnace and the temperature. The crucible ironmaking method is a time-honored technique that is widely used due to its simple structure, low cost, and easy operation. A structural diagram of a crucible furnace is shown in

Figure 2 [

13].

The Wangguan ironmaking site, which is the focus of this study, is located on the north slope of Wangguan Gully in Shangniu Village, the Niuxintai Sub-district Office, on the east side of the Taizi River in Benxi City, with geographical coordinates of 123°05′ E and 41°10′ N. The area’s irregular topography, characterized by uneven and rugged surfaces, is the result of ore mining activities. Field surveys at the Wangguan site have revealed numerous fragments of clay pots (i.e., ironmaking crucibles) and slag blocks, indicating that crucible ironmaking was practiced. According to The Complete Records of Liaodong from the Ming Dynasty, Liaodong was divided into twenty-five “Wei” (military and administrative units), each equivalent to a modern-day “division,” and each “Wei” had an ironmaking site. Three such sites were located in the Benxi region. Historical research indicates that the Weining Camp in Benxi had a Hundred-Household Iron Yard, and Wangguan Gully was under its jurisdiction. Therefore, the Wangguan ironmaking site is identified as the location of the Weining Camp Hundred-Household Iron Yard recorded in historical documents.

A review of the available ancient literature shows that the Boshan County Annals, compiled in the 18th year of Qianlong’s reign during the Qing Dynasty (1753), is the most comprehensive and accurate document recording the crucible ironmaking method. Yanshan Miscellany, published in the fourth year of Kangxi’s reign (1665), is the earliest document of this technology. The author of Yanshan Miscellany, Sun Tingquan, from Yanshen Town, Boshan County (now Zibo, Shandong Province), introduced the crucible method from Shanxi to Shandong in the second year of Kangxi’s reign. Regarding the northeastern region where Benxi is located, Richthofen speculated that this ironmaking technology originated from Shandong. This speculation is based on the fact that most residents in Liaodong were immigrants or descendants from the Shandong Peninsula, and there are many folk tales in the northeast region about Shandong craftsmen engaging in mining and smelting activities locally. Consequently, some scholars believe that the crucible ironmaking technology in the northeastern region of China was introduced in Shandong during the Qing Dynasty. However, this view contradicts the reported dating of the Wangguan site. According to Veritable Records of the Ming Dynasty, Weining Camp, where the Wangguan site is located, had become the largest ironmaking site in Liaodong during the reign of Emperor Chengzu of Ming (1402–1424), with an annual iron output of over ten thousand catties. This predates the introduction of crucible ironmaking from Shanxi to Shandong, recorded in Yanshan Miscellany, by at least 239 years. Considering that the establishment of local administrative institutions in Liaoning can be traced back to the Warring States period in ancient China, and this region had long been integrated with the Central Plains cultural area, it is more reasonable to speculate that the crucible ironmaking method was introduced to Northeast China during or even before the Ming Dynasty.

3.2. Physicochemical Analysis of Samples and Discussion of the Ironmaking Site and Technology

The crucible, slag, and pig iron fragments studied in this paper were all collected on-site at Wangguan. Some of the iron samples were derived from iron-based agricultural tools (such as shovels, hoes, sickles, and choppers) unearthed at the site and are now housed in the Benxi Museum. The exhibits mainly feature agricultural tools. Despite the number of samples tested being small, they are still representative.

For the crucible fragments and the slag samples, a Bruker XRF (D8 ADVANCE) was used for composition analysis (Bruker Co., Billerica, MA, USA). Meanwhile, an Oxford X-Max20 scanning electron microscope and an energy spectrometer (Oxford Instruments, Abingdon, UK), as well as a Shimadzu X-ray diffraction analyzer, were employed to analyze the crucibles (Shimadzu, Kyoto, Japan). To prevent the Ming Dynasty iron agricultural tools from being damaged or destroyed, non-destructive composition detection was carried out on these cultural relics using the American SciAps handheld XRF mineral element analyzer, model X-200 (SciAps, Inc., Boston, MA, USA). The detection range was from 0.01% to 99.9%, and the detection accuracy was 0.001%. The carbon content in the pig iron fragments collected from the site was determined using the ICP chemical analysis method, with a detection accuracy of 10−6.

3.2.1. Crucible Fragments

The design of crucibles affects the efficiency and success of metallurgical activities. Investigating the materials, raw materials, processes, and properties of crucibles can help assess ancient people’s mastery of metallurgical technology and explore how metallurgical production was organized. Two groups of crucible fragments (C1 and C2) collected were analyzed in this study, with the main compositions shown in

Table 1.

According to

Table 1, the main components of the crucibles from Wangguan are SiO

2, Al

2O

3, and Fe

2O

3. The presence of Fe

2O

3 is likely due to the adhesion of slag during the smelting process, rather than being part of the original refractory material. Excluding Fe

2O

3, the average mass fractions of SiO

2 and Al

2O

3 in the two crucible fragments are 64.1% and 33.8%, respectively, resulting in a molar ratio of SiO

2 to Al

2O

3 of approximately 3.2:1. This suggests that the raw material used for these crucibles was high-alumina clay, which has been widely distributed in Benxi, Liaoning, China, since ancient times. Additionally, high-quality high-alumina clay deposits were found in Niuxintai Town, which is only 2.8 km from Wangguan. Therefore, it is conceivable that local materials were used and calcined at around 1000 °C to convert high-alumina clay into refractory materials with mullite (3Al

2O

3·2SiO

2) for the main crystalline phase, which were then used by ancient craftsmen in the Benxi region for ironmaking.

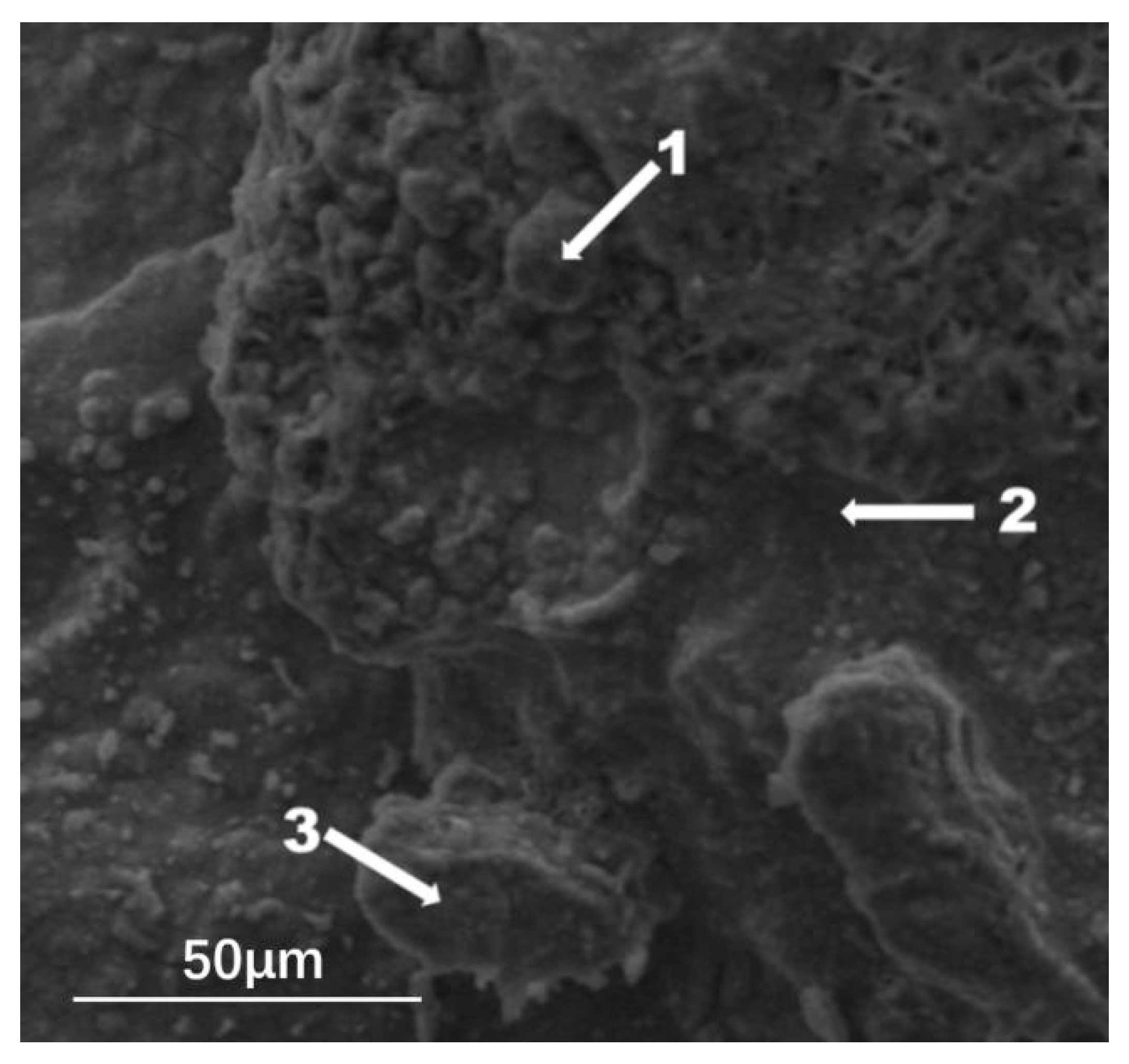

The scanning electron microscopy and energy spectrum analysis results of the crucible fragments from the site (

Figure 3 and

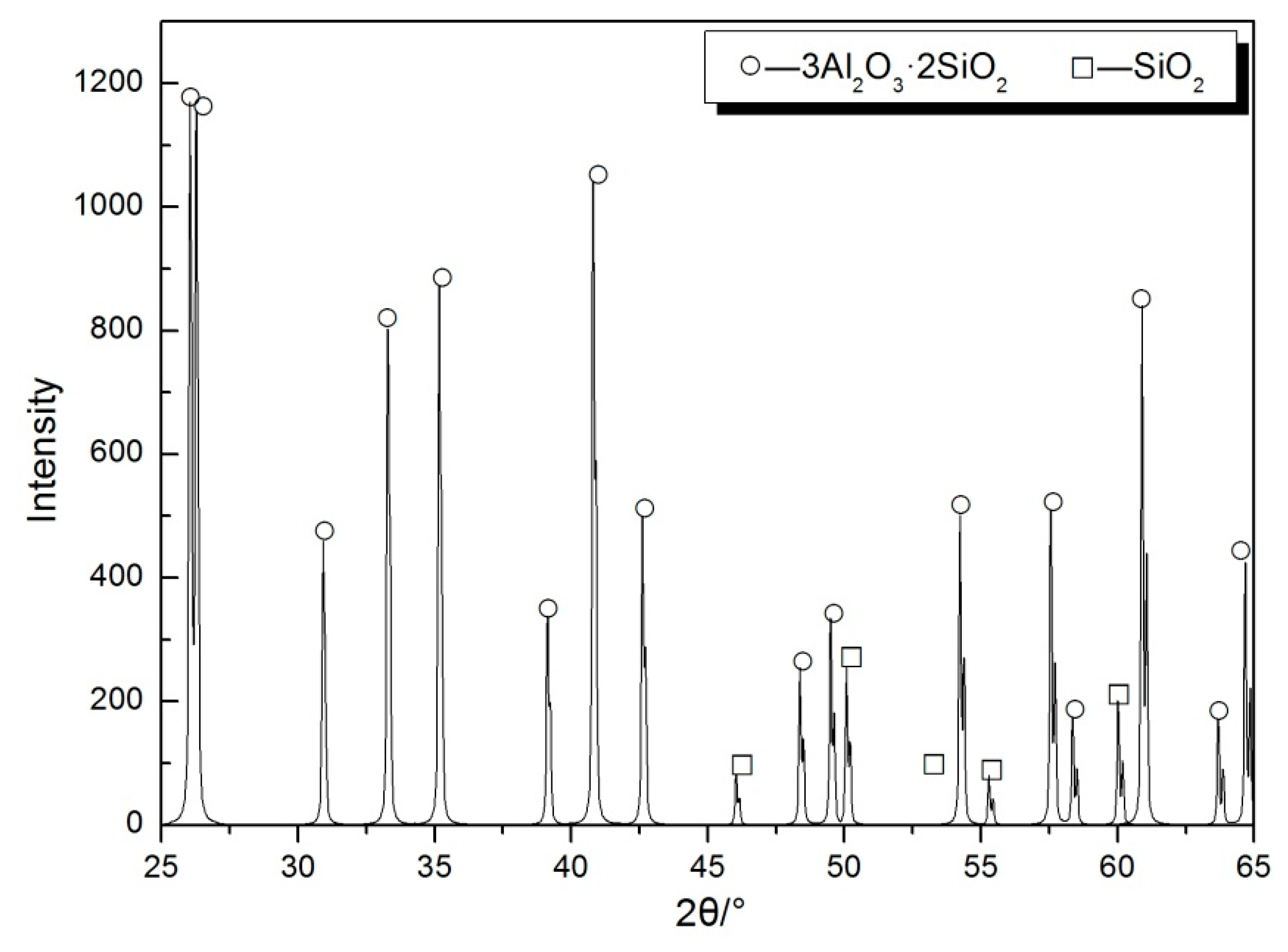

Table 2) show that the crucible body is mainly composed of a mullite phase. As shown in the XRD curve in

Figure 4, in addition to mullite, the phase in the crucible also contains a small amount of SiO

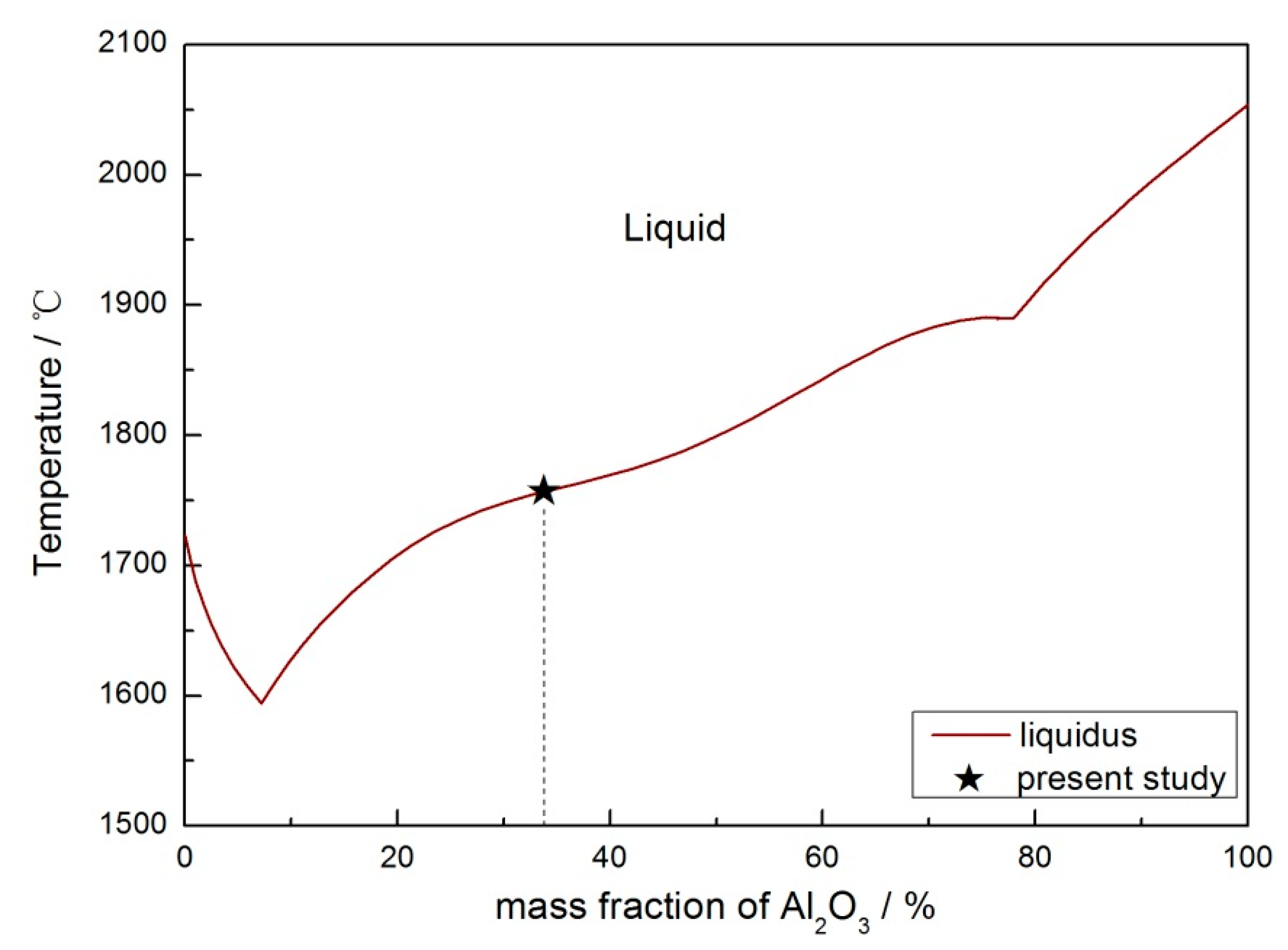

2. According to the liquidus of the Al

2O

3-SiO

2 system shown in

Figure 5, the refractoriness of the crucibles from the Wangguan site reaches above 1700 °C.

3.2.2. Slag Samples

The three groups of slag samples (S1–S3) collected from the site were analyzed, with the main components shown in

Table 3.

As indicated by the data in

Table 3, the main components of the slag samples are SiO

2, Al

2O

3, and Fe

2O

3, with the Fe

2O

3 content ranging from 11.1% to 34.0%. This is consistent with the detection of Fe

2O

3 in the crucible fragments shown in

Table 1. It also suggests that the crucible ironmaking process at that time was unstable, with significant fluctuations in the reduction degree of iron ore. Additionally, the highest content of CuO in the slag samples was 0.0196%, which is far below the criterion of the CuO content and greater than 0.5% in ancient non-ferrous metallurgical slag [

14,

15,

16]. This further confirms that the slag samples collected from the site are indeed from ancient ironmaking activities. It is noteworthy that, unlike the slag from ancient ironmaking sites in other regions, which is almost sulfur-free [

17,

18,

19], the slag samples studied in this study contain SO

3 at levels ranging from 0.229% to 0.379%. The sulfur content in the iron agricultural tools ranges from 0.014% to 1.05% (cf.

Table 4). The SiO

2 content in the slag samples ranges from 39.3% to 56.9%, and the Al

2O

3 content ranges from 19.2% to 25.9%, while the CaO and MgO contents range only from 0.904% to 2.08% and from 0.871% to 1.16%, respectively. These characteristics indicate that the samples belong to a typical high-silica, high-alumina aluminosilicate slag system, and no fluxes, such as limestone and dolomite, were added during the smelting process. According to modern ironmaking principles, the aluminosilicate slag system is not conducive to slag–iron separation and sulfur removal from molten iron. From a different perspective, this also explains why the crucible ironmaking process was unstable and why pig iron had a high sulfur content at that time.

3.2.3. Pig Iron Samples

Non-contact equipment was used to analyze the composition of Ming Dynasty iron-based agricultural tools (T1–T5) unearthed from the Wangguan ironmaking site, which are currently housed in Benxi Museum. The main results are shown in

Table 3.

It should be noted that the contactless equipment used could not measure the carbon content in the agricultural tools. Therefore, a chemical analysis of the carbon content of the remaining pig iron sheets at the site was conducted. The carbon content ranged from 2.0% to 2.4%, indicating a relatively low carbon content. This composition is similar to the crucible ironmaking products in the Shanxi region (carbon content: 1.30–2.46%) [

13,

20]. The reason for this is that the crucible itself does not have sufficient height to form a long liquid dripping zone. During the downward dripping of molten iron, it has less contact with solid carbon, resulting in insufficient carburization and a low overall carbon content.

As documented in

Tiāngōng Kāiwù [

21], “Coal is found throughout the world and is used for smelting metals and stones...”. Since the Han Dynasty, there have been records of coal use for smelting in the

Benxihu area, and coal mining activities were also documented during the Sui, Tang, Liao, and Jin Dynasties, indicating that coal production in this region has never been interrupted. In modern times, during the coal production process by the Benxihu Coal and Iron Company, remnants of mining from the Ming and Qing Dynasties have been discovered multiple times. The iron ore resources in the Benxi region have historically been characterized by a low sulfur content. Additionally, based on the analysis of slag composition, no fluxes such as limestone were added during the process of crucible ironmaking. Therefore, the sole source of sulfur in slag–metal can be attributed to the reducing agent or fuel used. Given that the Benxi region has long possessed the dual advantages of iron ore and coal resources, and considering that the total sulfur content in local coal ranges from 0.92% to 2.90%, which is significantly higher than the content in other coal-producing regions in China, it can be inferred that coal resources have likely been widely used in ironmaking activities in the Benxi region at least since the Ming Dynasty. According to the records, during the Ming Dynasty, coal was used to produce “hái tàn” (i.e., coke) for the “

Hundred-Household Iron Yard” in Weining Camp near Benxi [

22]. As is well known, the coking process of coal can remove most of the sulfur. This indicates that the craftsmen in the Benxi region during the Ming Dynasty had already mastered the technology of using coke as a fuel and a reducing agent to control the sulfur content in pig iron. However, research [

23,

24,

25] suggests that although coke was already in use during the Ming Dynasty, its application was not widespread. During the Ming Dynasty, iron smelters still used coal as the main fuel, so the sulfur content in slag and pig iron was relatively high.