Design and Study of a New Rotary Jet Wellbore Washing Device

Abstract

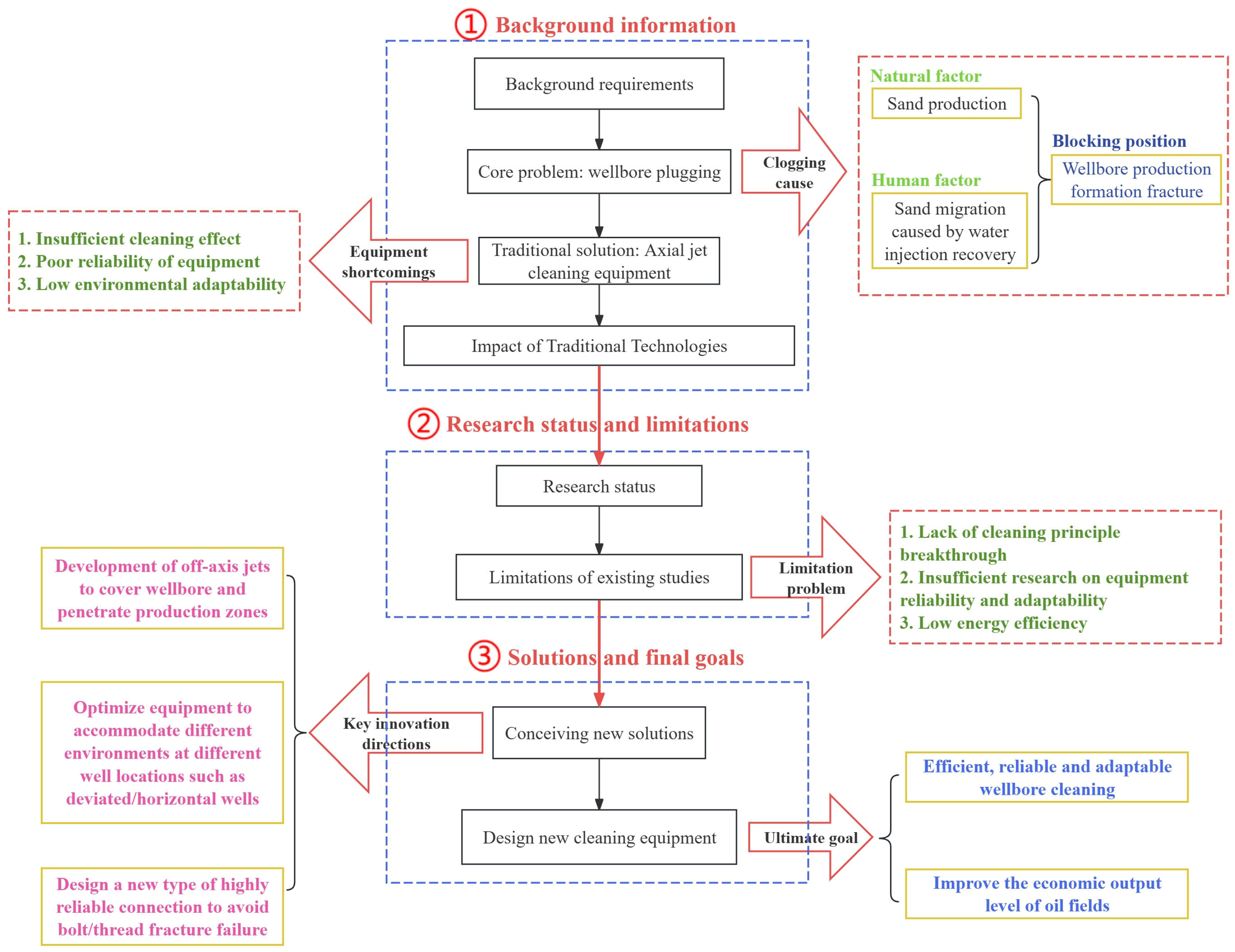

1. Introduction

2. Requirement Analysis and Method Design of Rotary Jet Wellbore Cleaning

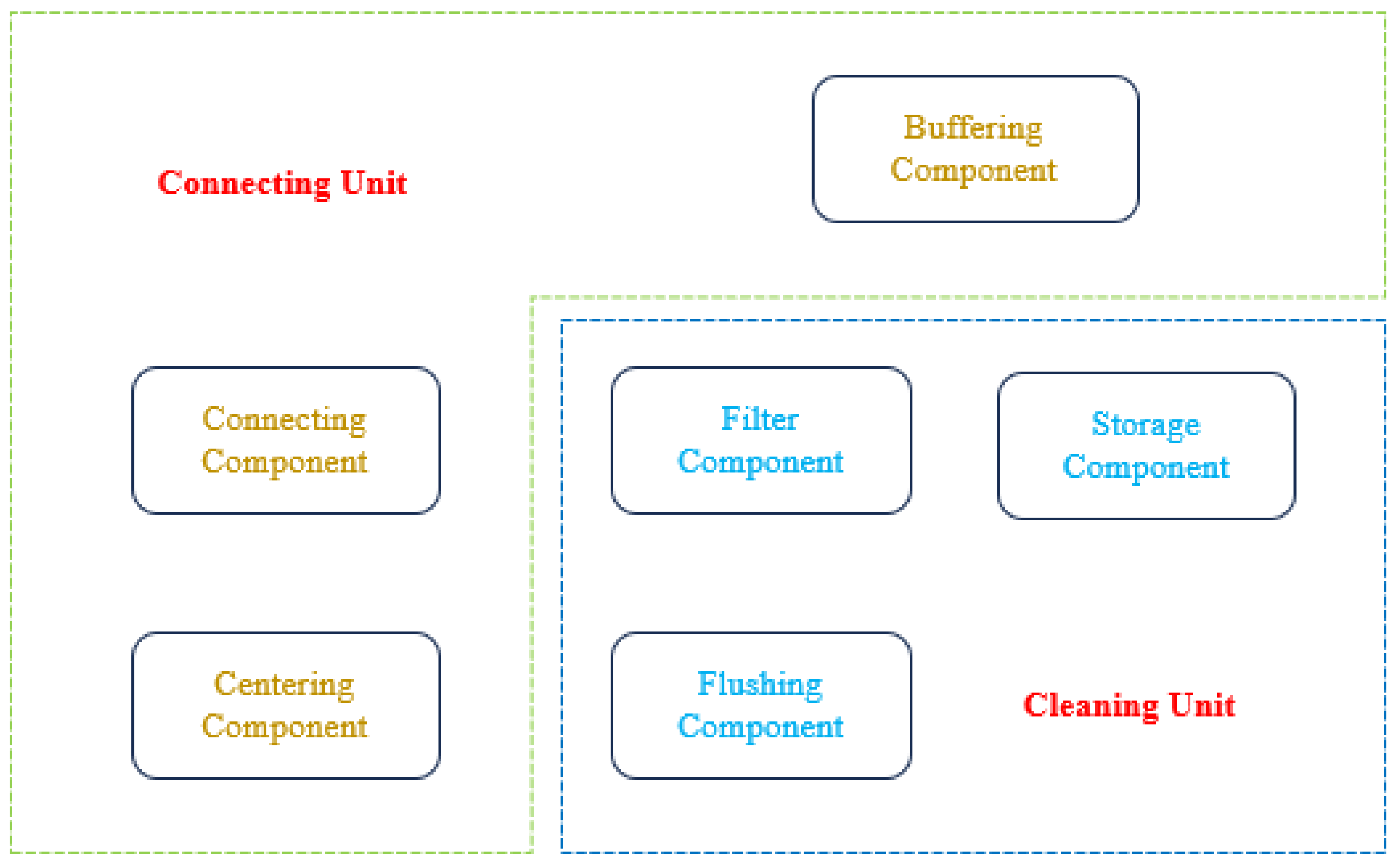

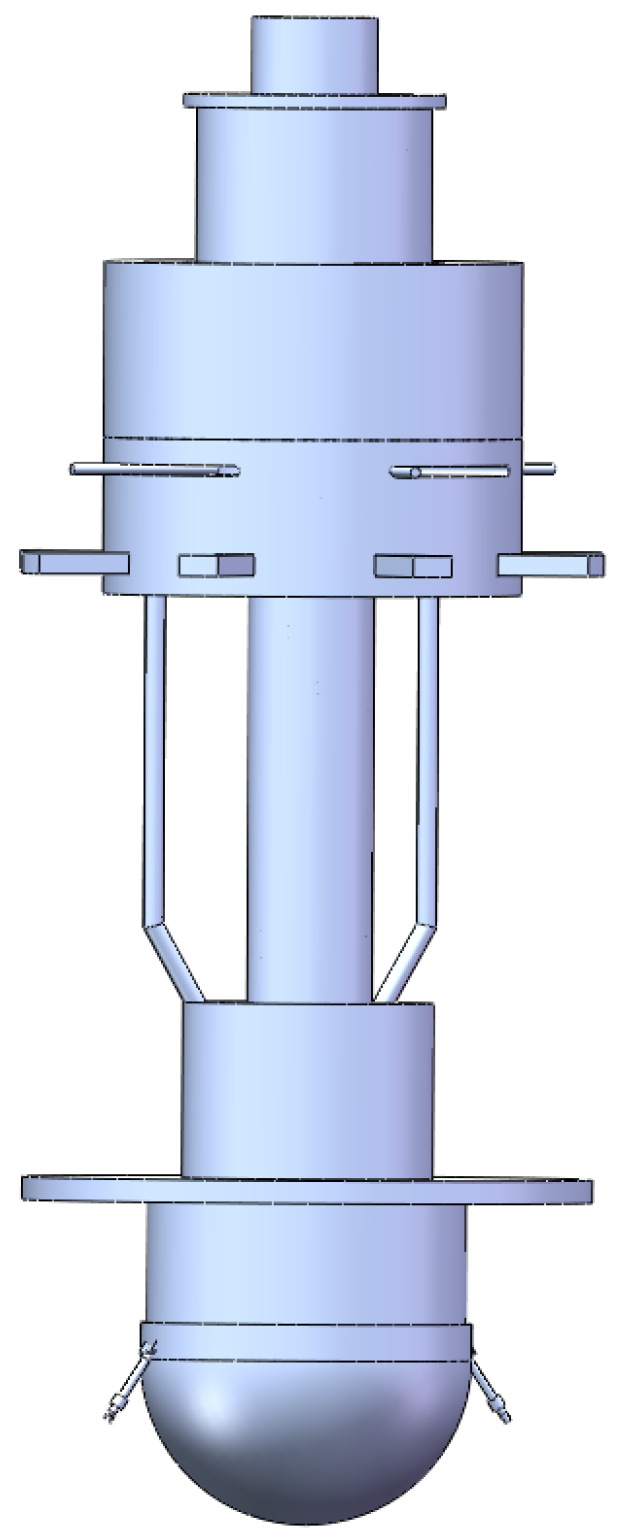

3. Design of Rotary Jet Wellbore Cleaning Equipment Module

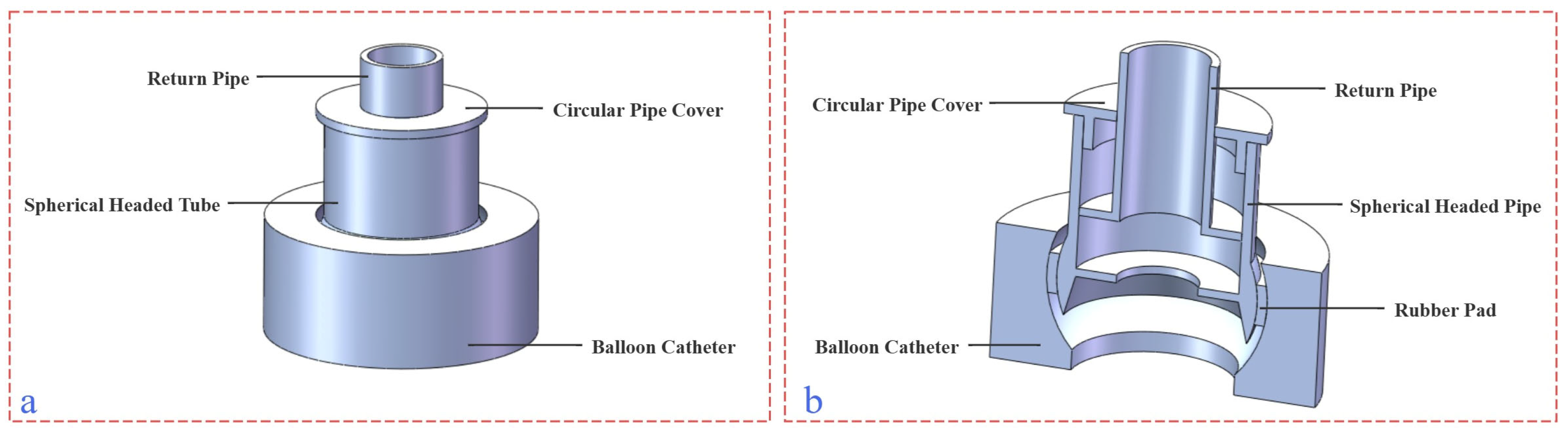

3.1. Elastic Connection Module

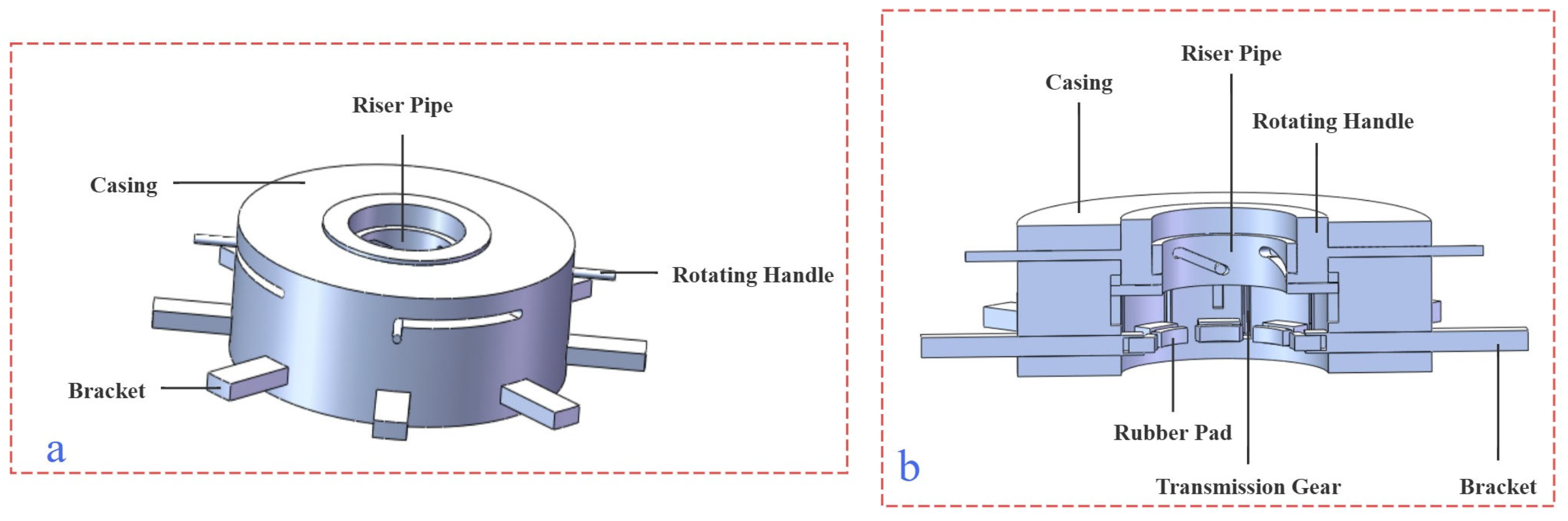

3.2. Downstroke Quick-Assembly Module

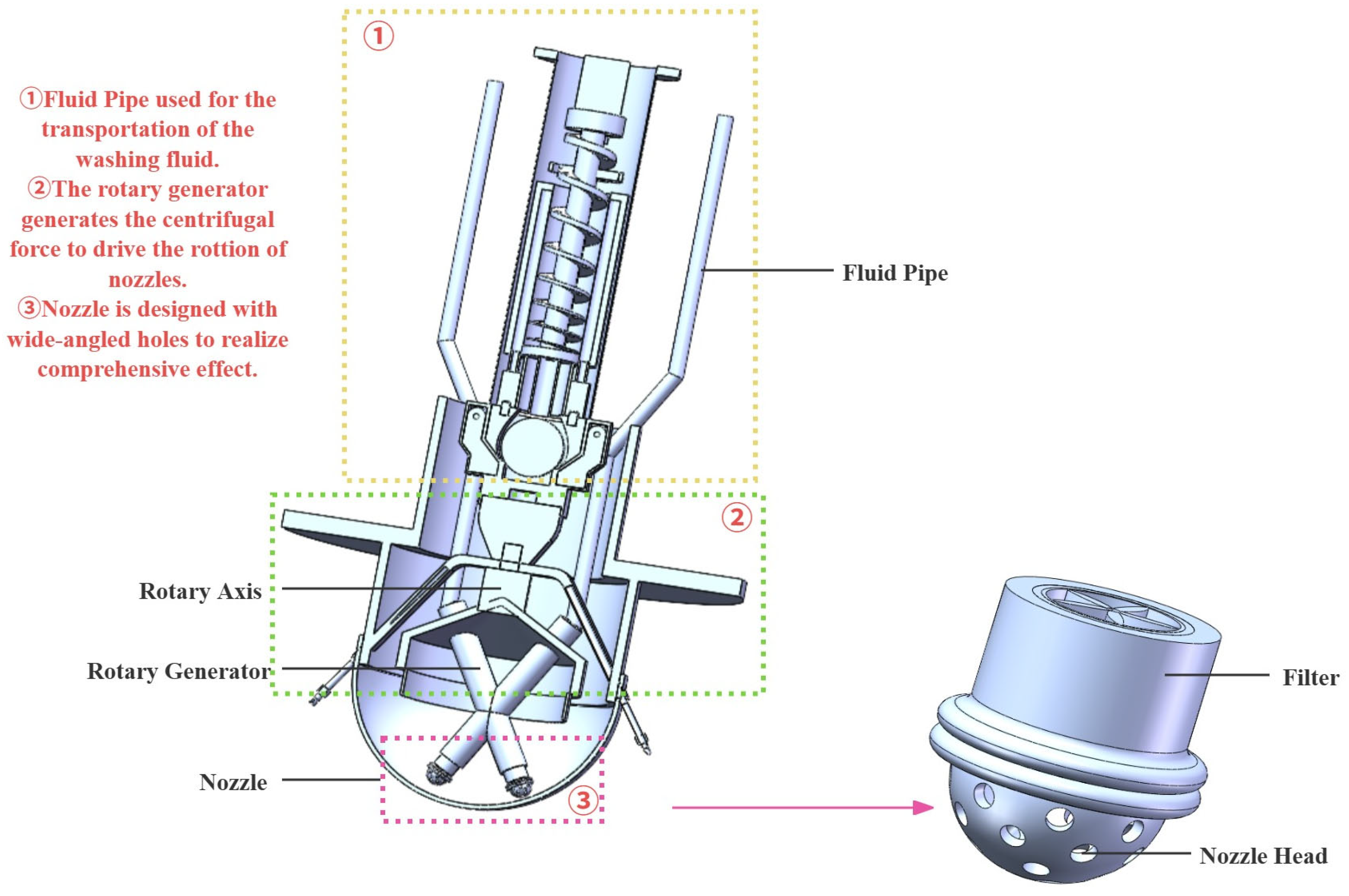

3.3. Hydraulic Rotary Washing Module

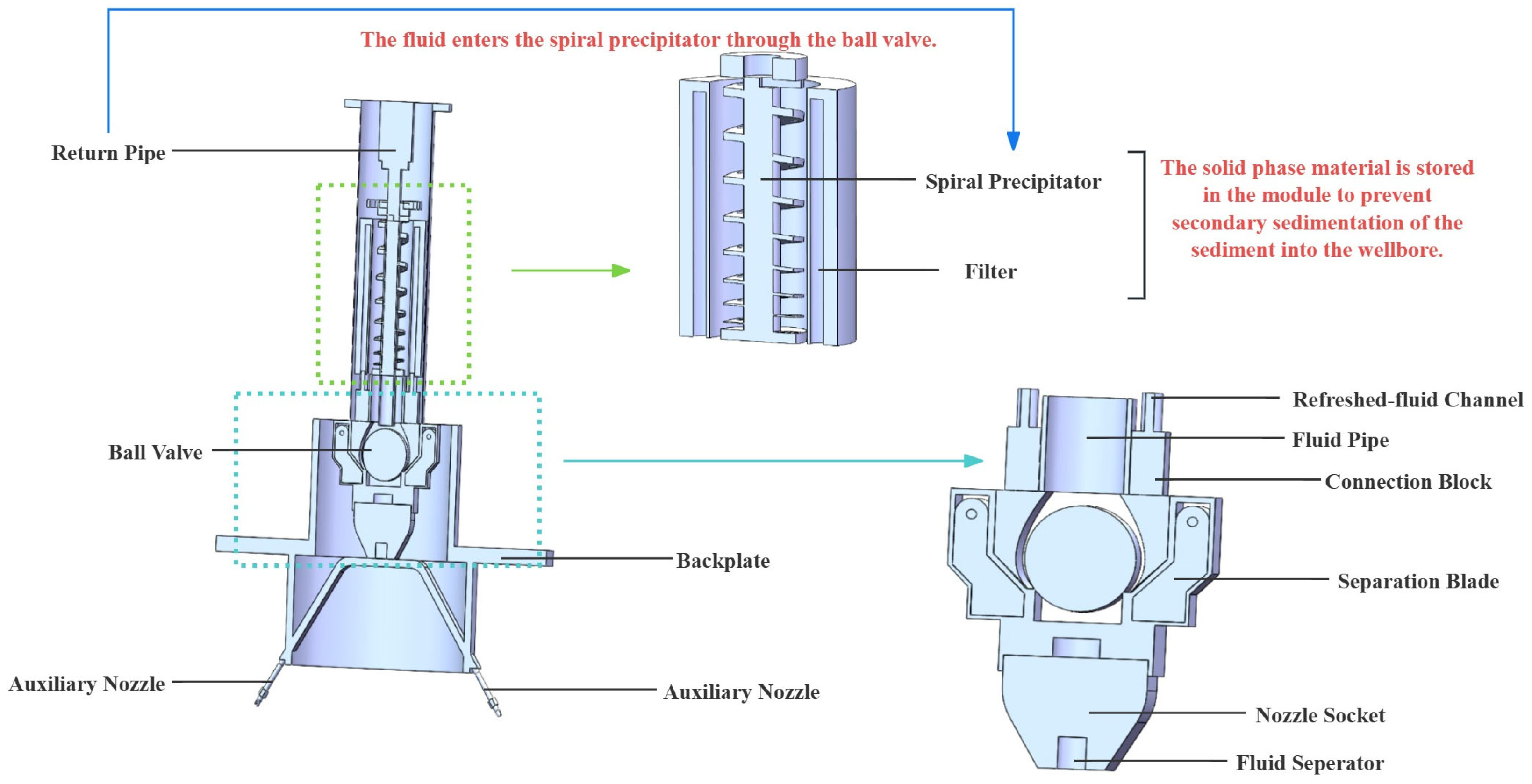

3.4. Rotary Filtration Storage Module

4. Feasibility Prospects of Rotary Jet Wellbore Cleaning Device

4.1. Applicability of Rotary Jet Wellbore Cleaning Device

4.2. Optimization Prospect of Rotary Jet Wellbore Cleaning Device

5. Conclusions and Prospects

- (1)

- The elastic connection module solves the problems of wellbore damage and equipment working difficulties caused by the rigid connection of traditional equipment and improves the adaptability of cleaning equipment to different types of wellbores. The downstroke quick assembly module realizes the rapid connection and straightening of the equipment through a single-step operation, reduces the labor consumption of the traditional equipment in the assembly and disassembly process, shortens the non-working time, and improves the overall work efficiency. Since the team is currently working on a conceptual design, quantitative analysis of the structural size requires further study to meet the installation requirements for typical usage scenarios.

- (2)

- Compared with the traditional axial jet cleaning equipment, the hydraulic rotary washing module greatly improves the jet coverage area, improves the cleaning effect, effectively restores the permeability of the wellbore and reservoir, and prolongs the working life of the wellbore. The rotary filtration storage module filters and stores impurities, reduces the probability of equipment being washed and worn by impurities, and realizes the recovery and reuse of the well washing fluid, realizes multi-angle and multi-level rotary cleaning, and significantly improves the cleaning coverage and operation intensity. Field tests and simulations lack performance parameters and influencing factors, and the research team has planned to further screen influencing factors and conduct quantitative calculations and analysis in a study next year to examine the improvements in the cleaning effect, energy efficiency, and removal efficiency.

- (3)

- The whole equipment design considers the shortages of traditional washing equipment. The flexible structure design effectively avoids sticking accidents caused by insufficient rigidity under complex working conditions and significantly improves operational safety. The introduction of a compression modular design in the connection part not only simplifies the disassembly process but also more reliably prevents failure caused by loosening or fatigue of the connection parts. Cleaning efficiency and uniformity of coverage are greatly improved by the rotating jet, and residue removal is achieved. The spiral sedimentation storage module can effectively separate and temporarily store the waste generated by cleaning and prevent the occurrence of backflow and secondary deposition, thus ensuring continuous and efficient cleaning performance and reducing the efficiency loss caused by interrupted cleaning.

- (4)

- The rotary jet wellbore cleaning equipment effectively improves the coverage area of cleaning and scouring by using fluid kinetic energy efficiently and improves the cleaning efficiency and effect. The integrated cleaning fluid filtration and secondary utilization module conceptually improves the utilization rate of the cleaning fluid by the equipment, reduces the overall energy consumption and raw material loss of the equipment, and realizes the joint optimization of the cleaning degree, efficiency, energy, and material consumption of the well washing operation. Quantitative data should be analyzed in further works.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Terms and Abbreviations

| LWD | Logging While Drilling |

| CFD | Computational Fluid Dynamics |

| Wellbore cleaning | An engineering operation that injects well washing fluid into wellbore through pumping equipment to remove impurities to improve wellbore working conditions |

| Water injection | A technical means of injecting qualified water into an oil reservoir through an injection well, with the aim of supplementing formation energy and maintaining reservoir pressure |

| Downhole falling objects | All kinds of objects accidentally dropped into the well during oil and gas drilling or downhole operation, including but not limited to drilling tools, tools, instruments, parts, etc. |

| Jet cleaning | Wellbore cleaning with a high-pressure fluid jet, mainly achieved by two mechanisms, namely shock pressure wave and bottom hole crossflow |

| Tools jamming | Common accidents in drilling operations, usually caused by tools stuck in keyways, debris accumulation, or downhole falling objects, etc. |

References

- Wang, H.; Liu, C.; Yao, F.; Song, X.; Xu, X.; Liu, Y.; Zhao, L.; Wang, P.; Ma, B. Research and application of cleaning and automation technology for downhole operations in Daqing Oilfield. Pet. Sci. Technol. Forum 2022, 41, 86–93. [Google Scholar] [CrossRef]

- Yu, J. Technical research and application of oilfield cleaning operation. Energy Conserv. Pet. Petrochem. Ind. 2023, 13, 56–60. [Google Scholar] [CrossRef]

- Sun, J.; Yang, J.; Bai, Y.; Lyu, K.; Liu, F. Research progress and development of deep and ultra-deep drilling fluid technology. Pet. Explor. Dev. Online 2024, 51, 1022–1034. [Google Scholar] [CrossRef]

- Da, W.; Wei, Z.; Jun, J. The key problems of ultra-deep drilling engineering. Chin. Sci. Bull. 2018, 63, 2698–2706. [Google Scholar] [CrossRef]

- Hahn, S.; Polat, B.; Jamali, S.; Wittig, V.; Bracke, R. Water jet drilling technology for application in geothermal environments. Geomech. Tunn. 2022, 15, 74–81. [Google Scholar] [CrossRef]

- Wang, H.; Huang, H.; Bi, W.; Ji, G.; Zhou, B.; Zhuo, L. Deep and ultra-deep oil and gas well drilling technologies: Progress and prospect. Nat. Gas Ind. B 2022, 9, 141–157. [Google Scholar] [CrossRef]

- Zhao, J.; Ren, L.; Lin, C.; Lin, R.; Hu, D.; Wu, J.; Song, Y.; Shen, C.; Tang, D.; Jiang, H. A review of deep and ultra-deep shale gas fracturing in China: Status and directions. Renew. Sustain. Energy Rev. 2025, 209, 115111. [Google Scholar] [CrossRef]

- Amer, M.; Salem, S.; Farahat, M.; Salem, A. Reducing drilling cost of geothermal wells by optimizing drilling operations: Cost effective study. Untradtional Resour. 2025, 7, 100196. [Google Scholar] [CrossRef]

- Brice, L.; Jean, D. Simultaneous initiation and growth of multiple radial hydraulic fractures from a horizontal wellbore. J. Mech. Phys. Solids 2015, 82, 235–258. [Google Scholar] [CrossRef]

- Wu, X.; Lai, X.; Hu, J.; Lu, C.; Yang, X.; Zhou, Y.; Wu, M. Efficiency-safety coordination optimization in drilling process under complex formations. Neurocomputing 2025, 630, 129732. [Google Scholar] [CrossRef]

- Zhang, H.; Yang, S.; Liu, D.; Li, Y.; Luo, W.; Li, J. Wellbore cleaning technologies for shale-gas horizontal wells: Difficulties and countermeasures. Nat. Gas Ind. B 2020, 7, 190–195. [Google Scholar] [CrossRef]

- Li, Y.; He, M.; Cai, M.; Xu, S. Hole Cleaning and Critical Transport Rate in Ultra-Deep, Oversized Wellbores. Fluid Dyn. Mater. Process. 2025, 21, 799–817. [Google Scholar] [CrossRef]

- Hu, W.; Zhang, J.; Guan, N.; Zhu, H. Cuttings transport characteristics and multi-objective optimization design of a novel hole cleaning tool. Geoenergy Sci. Eng. 2025, 254, 2949–8910. [Google Scholar] [CrossRef]

- Gao, W. Casing Drilling Technology to Drilling Site. Appl. Mech. Mater. 2012, 2016, 63–66. [Google Scholar] [CrossRef]

- Chen, M.; Si, L.; Dai, J.; Liu, Y.; Wang, Z.; Wei, D.; Li, X. A variable structure robust control strategy for automatic drilling tools loading and unloading system. Control Eng. Pract. 2025, 161, 106340. [Google Scholar] [CrossRef]

- Huang, H.; Li, J.; Sun, X.; Yu, B.; Zhang, W.; Ma, L. Influence analysis on the storage capacity of hydrogen-blended natural gas pipeline. Comput. Energy Sci. 2024, 1, 3–16. [Google Scholar] [CrossRef]

- Shao, X.; Cui, B.; Liu, Y.; Xie, X.; Song, G.; Reng, L.; Xu, J. Application of circular well washing technology in South Yanchuan coalbed gas field. Reserv. Eval. Dev. 2022, 12, 651–656. [Google Scholar] [CrossRef]

- Ji, Y. Discussion on low density well washing technology and its application in oil wells. Chem. Eng. Equip. 2020, 7, 147–148. [Google Scholar] [CrossRef]

- Ai, X.; Chen, M. Wellbore Cleaning Degree and Hydraulic Extension in Shale Oil Horizontal Wells. Fluid Dyn. Mater. Process. 2024, 20, 661–670. [Google Scholar] [CrossRef]

- Al-Shargabi, M.; Davoodi, S.; Wood, D.; Al-Rubaii, M.; Minaev, M.; Rukavishnikov, V.S. Hole-cleaning performance in non-vertical wellbores: A review of influences, models, drilling fluid types, and real-time applications. Geoenergy Sci. Eng. 2024, 233, 212551. [Google Scholar] [CrossRef]

- Xian, B.; Liu, G.; Bi, Y.; Gao, D.; Wang, L.; Cao, Y.; Shi, B.; Zhang, Z.; Zhang, Z.; Tian, L.; et al. Coalbed methane recovery enhanced by screen pipe completion and jet flow washing of horizontal well double tubular strings. J. Nat. Gas Sci. Eng. 2022, 99, 104430. [Google Scholar] [CrossRef]

- Gao, D. Some research advances in well engineering technology for untradtional hydrocarbon. Nat. Gas Ind. B 2022, 9, 41–50. [Google Scholar] [CrossRef]

- Sun, X.; Tao, L.; Qu, J.; Yao, D.; Hu, Q. Evaluating the effectiveness of cleaning tools for enhanced efficiency in reamed wellbore operations. Geoenergy Sci. Eng. 2025, 246, 213620. [Google Scholar] [CrossRef]

- Sun, X.; Hu, Q.; Yan, L.; Chen, Y.; Zhang, K.; Qu, J. A magnetic torque optimization method for a hydraulic-magnetic coupling-drive cuttings cleaning tool. Nat. Gas Ind. B 2019, 6, 374–383. [Google Scholar] [CrossRef]

- Youssef, A.S.; Mahmoud, A.A.; Elkatatny, S.; Al Shafloot, T. A review of the critical conditions required for effective hole cleaning while horizontal drilling. Petroleum 2025, 11, 143–157. [Google Scholar] [CrossRef]

- Yang, L.; Li, Y.; Wang, D.; Guo, Y.; Li, D. Research on deposition particles carrying with washing tools during well cleaning. J. Pet. Sci. Eng. 2022, 219, 111097. [Google Scholar] [CrossRef]

- Wu, D.; Zhang, H.; Zhang, S.; Tan, J.; Sun, P.; Luo, Y.; Gao, S.; Xue, Y. Determining whether the swirling jet is applicable in bottom-hole cleaning: A CFD study. J. Pet. Sci. Eng. 2022, 208, 109317. [Google Scholar] [CrossRef]

- Song, X.; Li, G.; Huang, Z.; Wang, H.; Tian, S.; Shi, H. Experimental study on horizontal wellbore cleanout by rotating jets. J. Pet. Sci. Eng. 2010, 75, 71–76. [Google Scholar] [CrossRef]

- Pandya, S.; Ahmed, R.; Shah, S. Experimental study on wellbore cleanout in horizontal wells. J. Pet. Sci. Eng. 2019, 177, 466–478. [Google Scholar] [CrossRef]

- Song, H.; Guo, J.; Li, J.; Zhang, S.; de Oliveira, A.J.S.; He, A. Application of multifunctional wellbore cleaning fluid in the removal of residual drilling fluids in ultra-deep wells: Research progress and prospects. Geoenergy Sci. Eng. 2024, 243, 213329. [Google Scholar] [CrossRef]

| Patents | Key Innovations | Year | Country |

|---|---|---|---|

| Downhole tool for wellbore cleaning or for moving fluids in a wellbore | Driving unit powered by a conductive device | 2012 | CN |

| Jet hole cleaning tool | Pressure-regulated rotating jet | 2019 | CN |

| Method for cleaning horizontal wellbore during drilling | Mechanical scraper promotes the removal of mud and sand and prevents accumulation | 2024 | RU |

| Method and apparatus for automatic drill removal | Self-cleaning integrated cuttings capture and throttling system | 2024 | US |

| Use of high-power ultrasound for improved hole cleaning in drilling operations | High-frequency power ultrasonic generators and sensors | 2025 | SA |

| Type | Phenomena | Impact |

|---|---|---|

| Tool and string damage [22,23] | Improper connection or jamming of mechanical scraping tools causes damage to the inner wall of the tubing and casing | Risk of casing damage and corrosion |

| Low efficiency [24,25,26] | Complicated installation and disassembly process, highly dependent on manual operation and calibration, and high auxiliary time | Additional labor costs and downtime of equipment |

| Limited cleaning effect [27,28,29] | Mainly relies on directional jet, limited cleaning coverage, and a blind area | Inadequate removal effect and remaining deposits |

| Improper treatment of flowback fluid [30] | Low utilization rate of well cleaning fluid, insufficient performance of fluid, and extensive treatment of waste liquid | Reduced cleaning efficiency, increased waste liquid treatment cost, and additional environmental protection pressure |

| Module | Risk Level | Risk | Analysis | Improvements |

|---|---|---|---|---|

| Connection Module | High | Equipment jamming | Traditional equipment areas lack the ability to adjust the curvature | Balloon catheter design adaptable for different angles of wellbore trajectory |

| Assembly Module | Low | Low efficiency | Complicated manual operation and complex connection process | Fast connection and sealing of equipment with a single rotation |

| High | Downhole objects caused by connection failure | Failure to connect parts such as screws or threads | Riser pipe and bracket arrays avoid joint failures caused by rotational and vibration conditions | |

| Washing Module | Low–Medium | Repeated flushing and low energy efficiency | Fixed direction of flow cannot cover the wellbore and bottom hole direction | Multi-angle, large-area coverage through rotating nozzles |

| Storage Module | Low–Medium | Sediment reverse flow deposition reduces the cleaning effect | Ineffective collection and storage of washed sediment | Using a spiral precipitator to collect sediment to prevent backflow |

| Low | Excessive dosage of washing fluid | Most well cleaning fluids are used for recycling | Returned fluid is purified and reused |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Ji, Z.; Feng, Q.; Yang, S.; Sun, X. Design and Study of a New Rotary Jet Wellbore Washing Device. Processes 2025, 13, 3015. https://doi.org/10.3390/pr13093015

Li S, Ji Z, Feng Q, Yang S, Sun X. Design and Study of a New Rotary Jet Wellbore Washing Device. Processes. 2025; 13(9):3015. https://doi.org/10.3390/pr13093015

Chicago/Turabian StyleLi, Shupei, Zhongrui Ji, Qi Feng, Shuangchun Yang, and Xiuli Sun. 2025. "Design and Study of a New Rotary Jet Wellbore Washing Device" Processes 13, no. 9: 3015. https://doi.org/10.3390/pr13093015

APA StyleLi, S., Ji, Z., Feng, Q., Yang, S., & Sun, X. (2025). Design and Study of a New Rotary Jet Wellbore Washing Device. Processes, 13(9), 3015. https://doi.org/10.3390/pr13093015