Research on Carbon Dioxide Pipeline Leakage Localization Based on Gaussian Plume Model

Abstract

1. Introduction

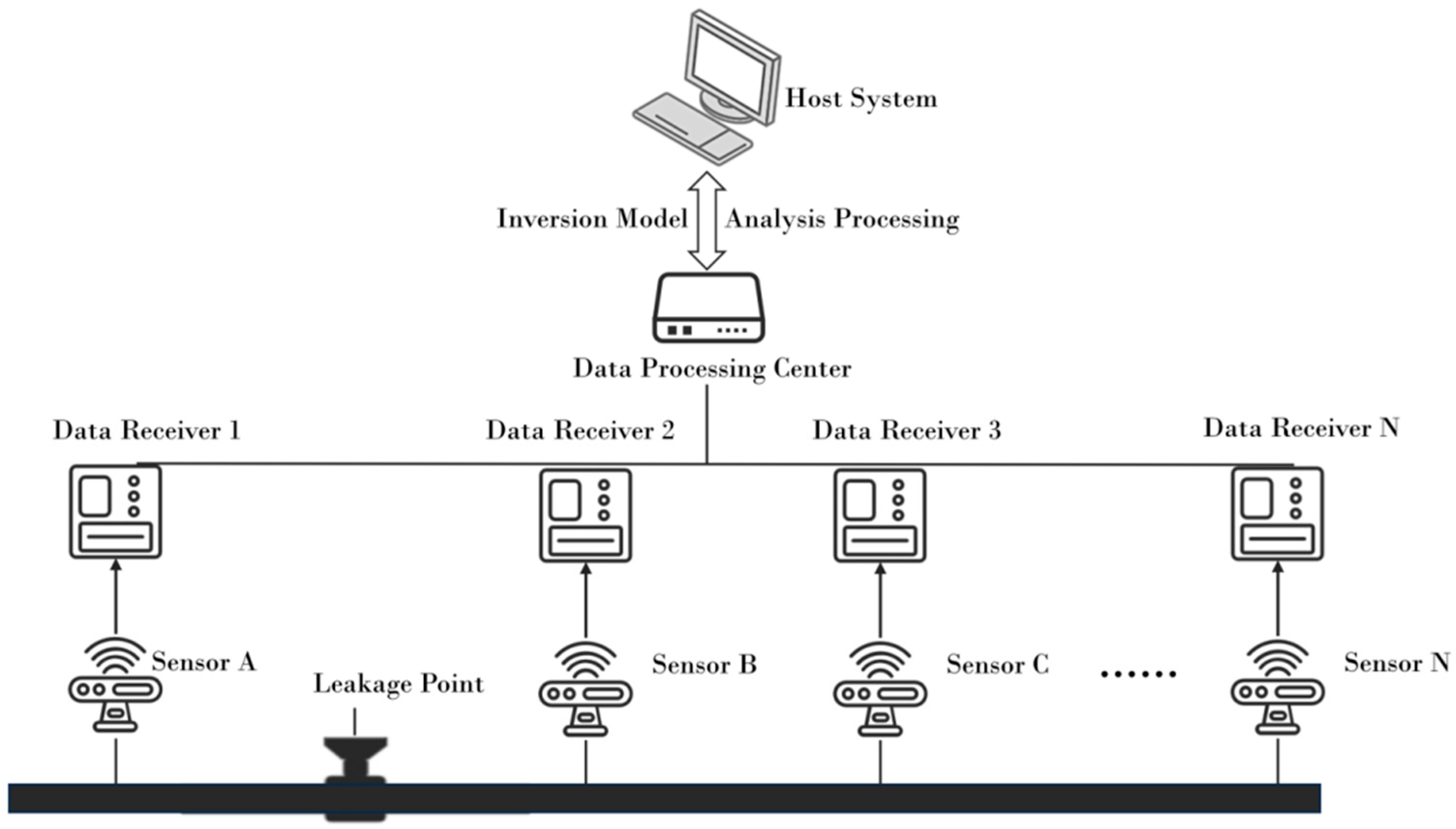

2. Leakage Localization Model Establishment

2.1. Gaussian Plume Model

- (1)

- The model assumes a point source in a free space without underlying surfaces or obstacles.

- (2)

- The leaked CO2 follows a two-dimensional normal distribution in both horizontal and vertical directions.

- (3)

- The CO2 pipeline rupture is treated as a single point source with uniform and continuous emission strength.

- (4)

- The wind speed is constant, and its direction remains straight.

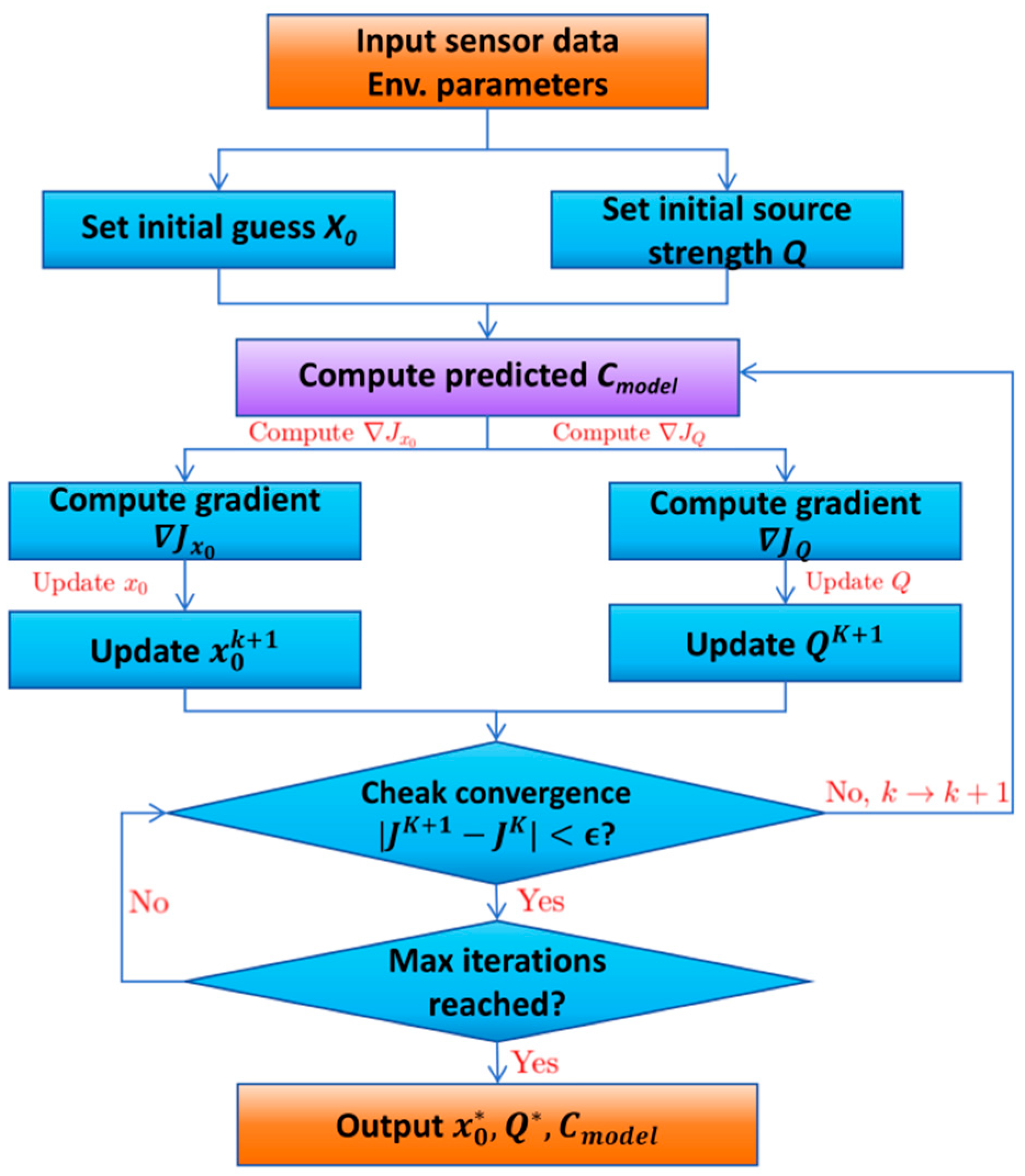

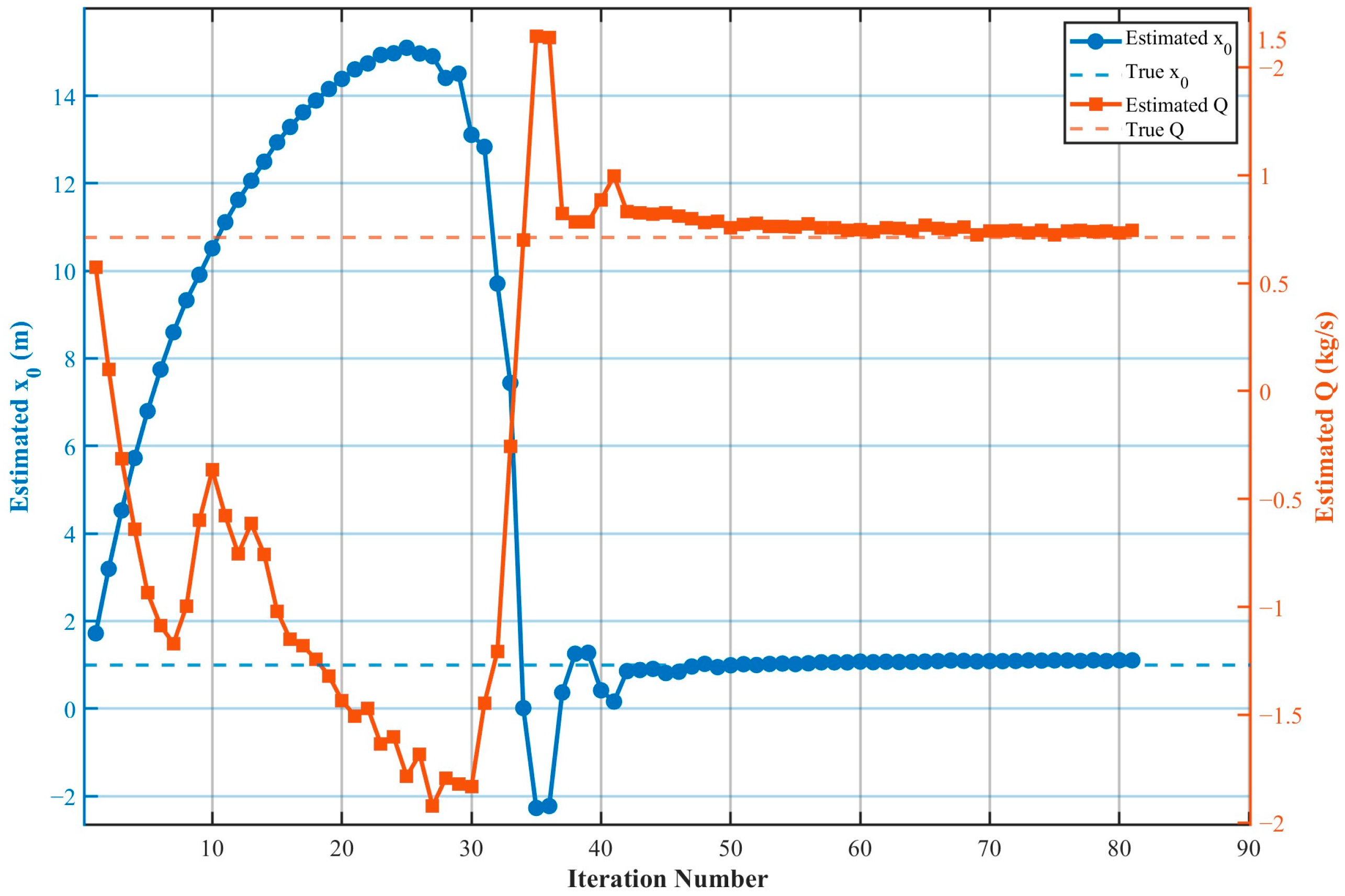

2.2. Model Solution

2.2.1. Construction of Objective Error Function

2.2.2. Iterative Optimization

3. Leakage Localization Model Validation

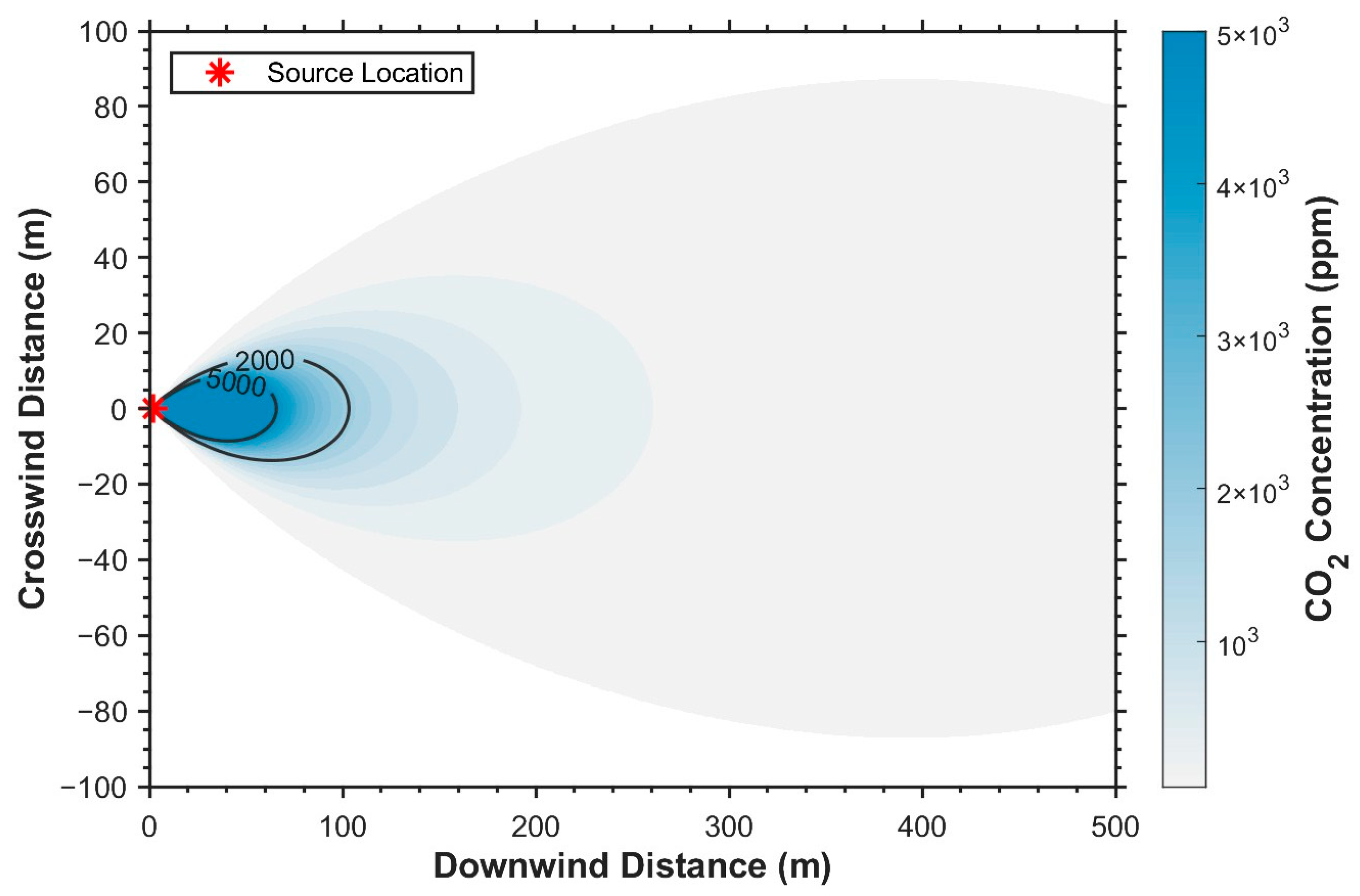

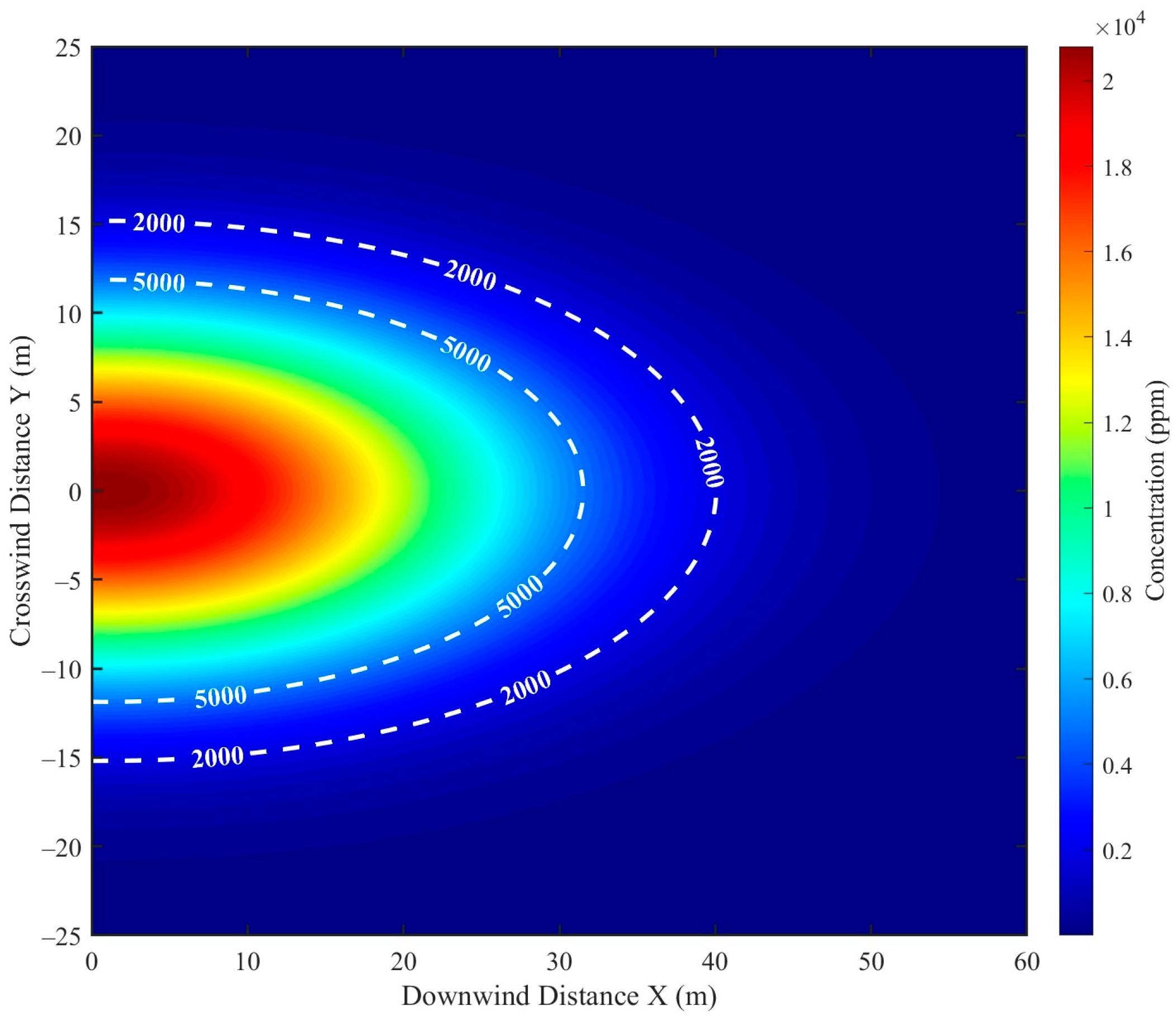

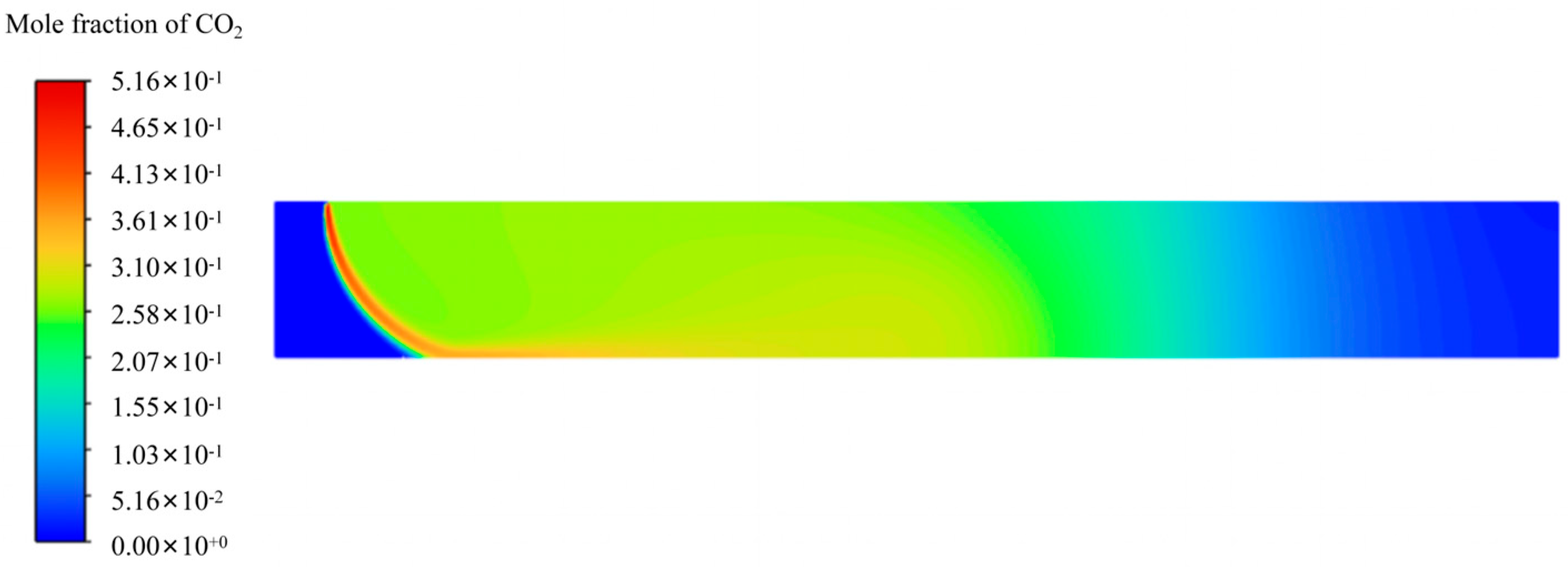

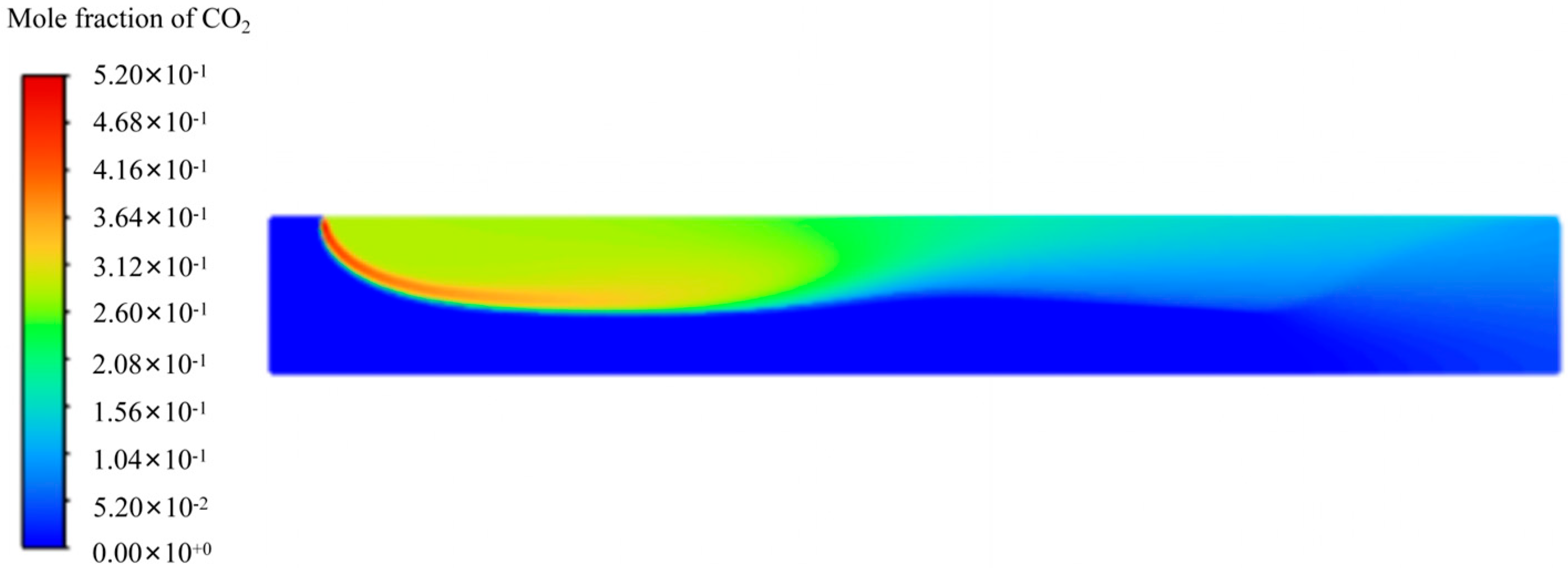

3.1. Numerical Simulation Verification

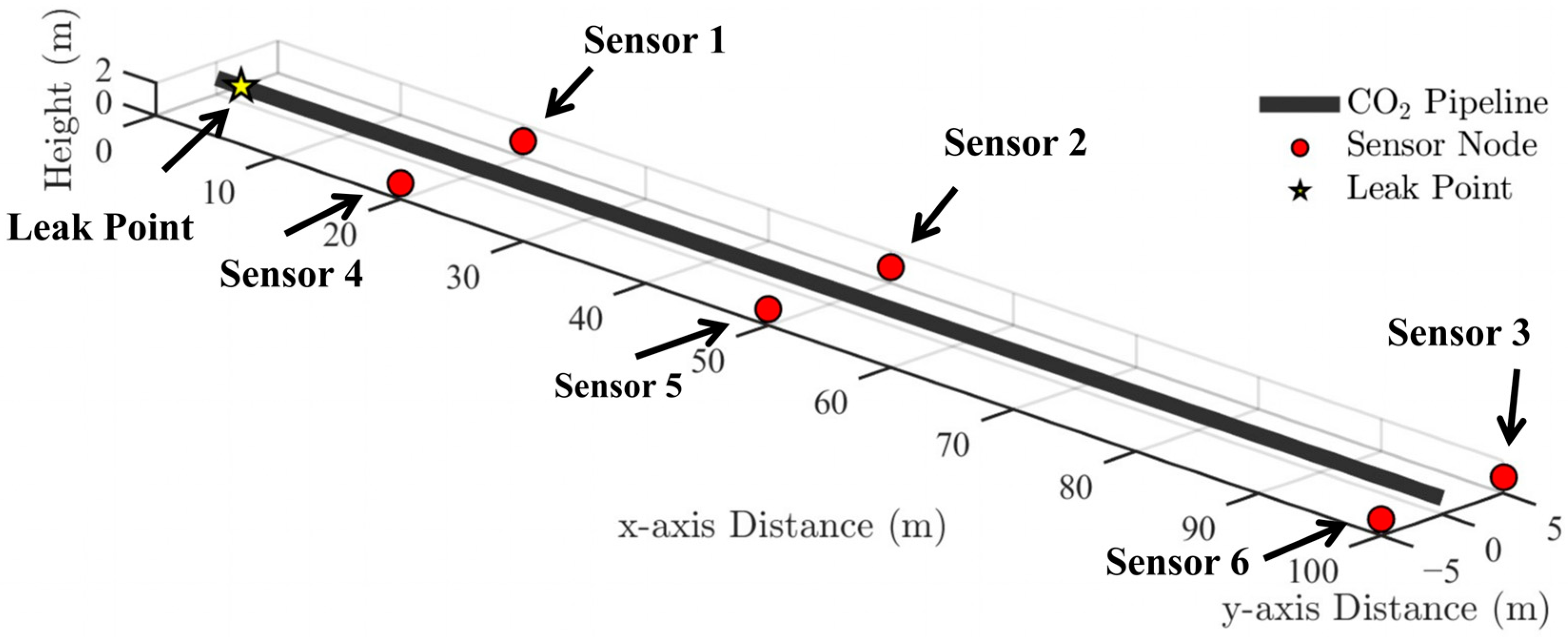

3.1.1. Simulation Setup

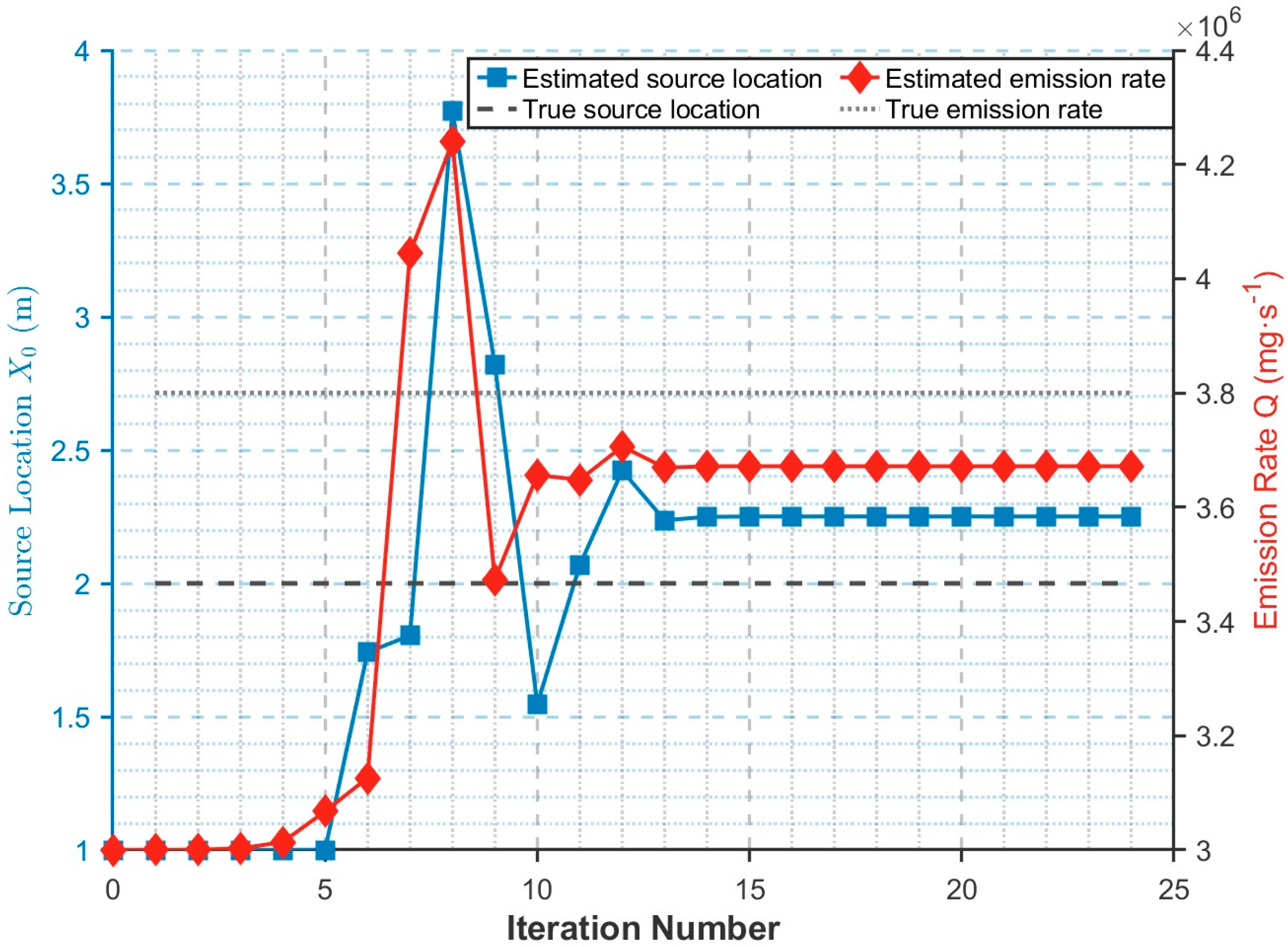

3.1.2. Model Prediction

Fundamental Parameters

Simulation Results

Error Analysis

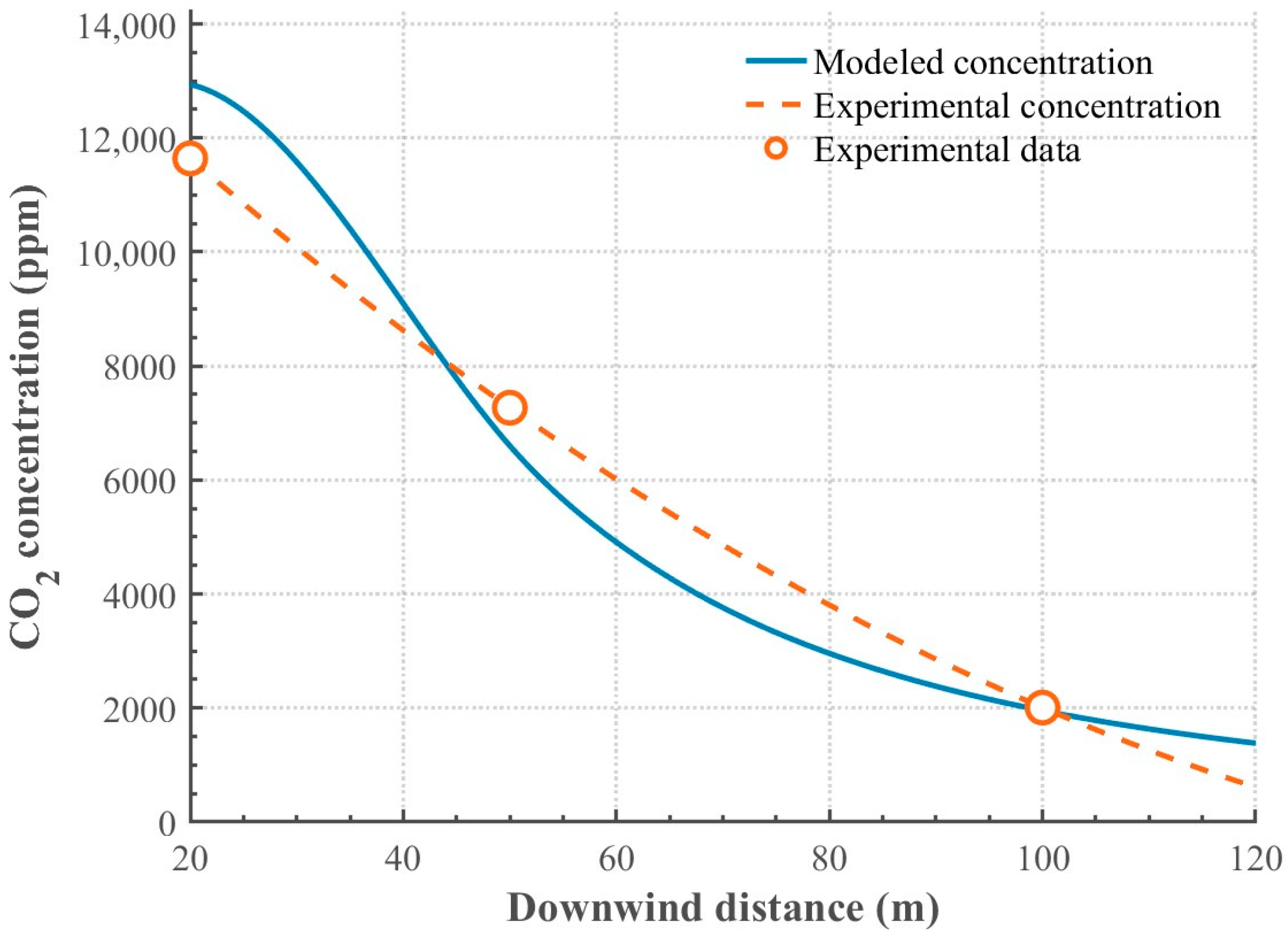

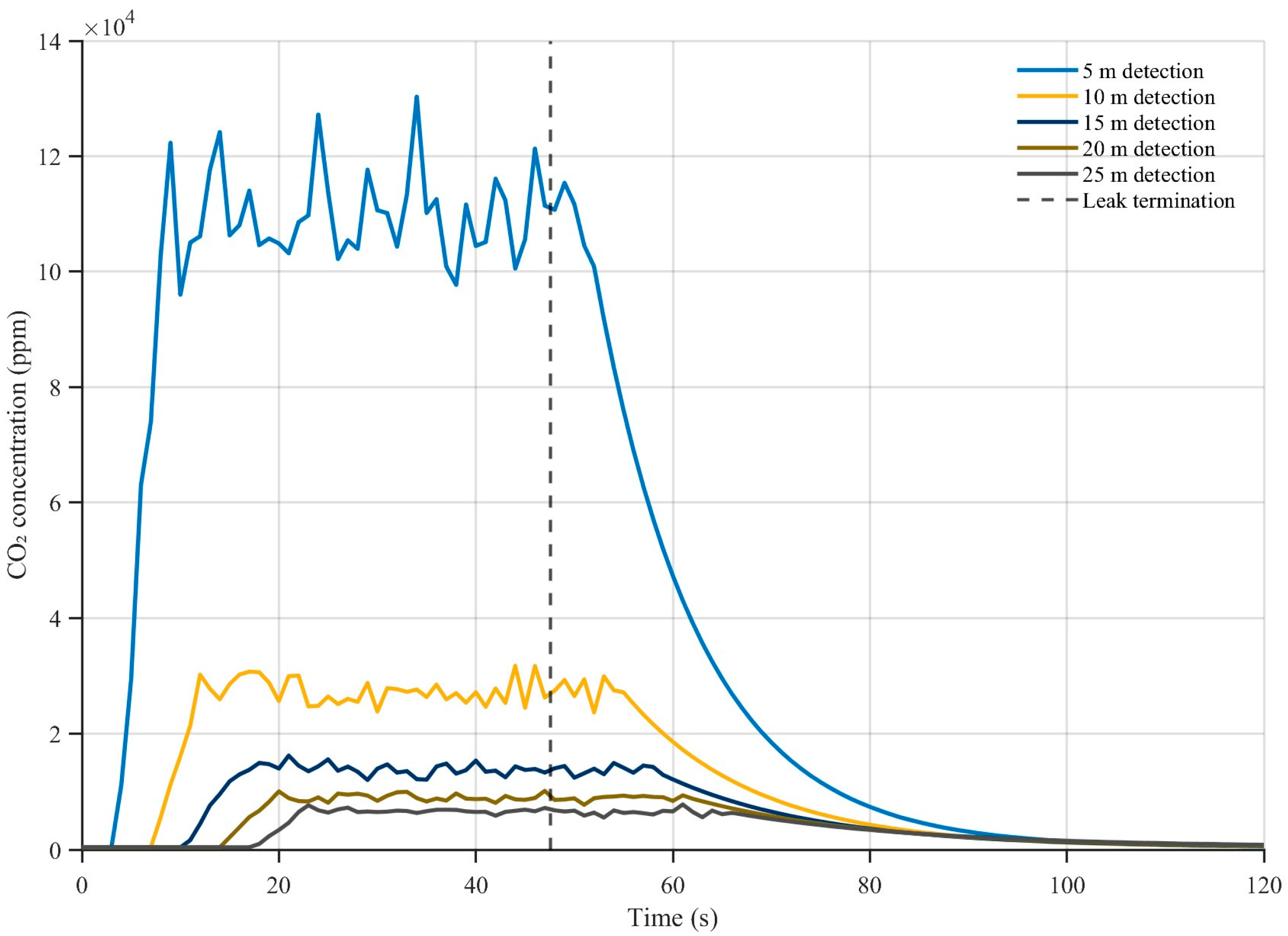

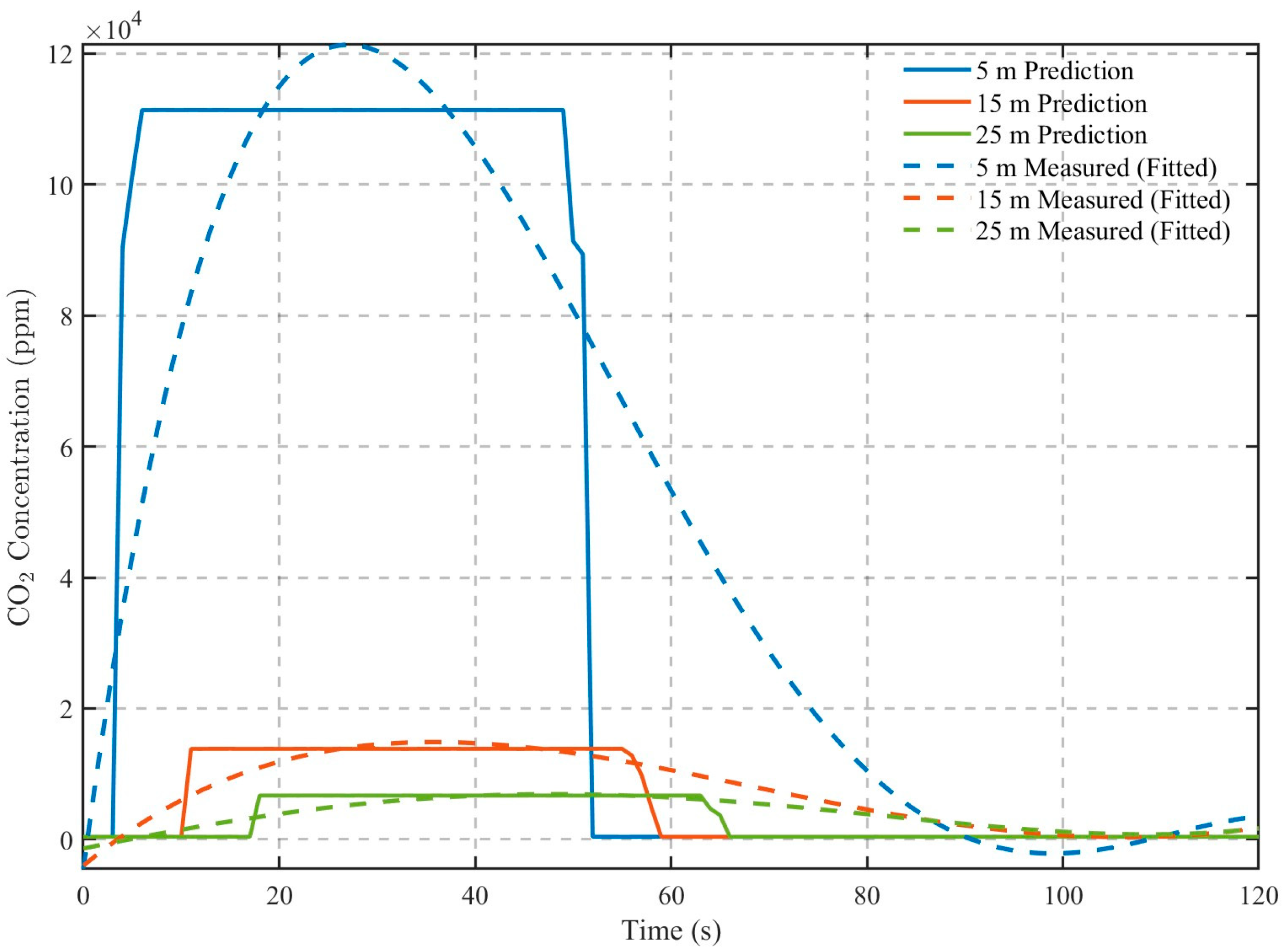

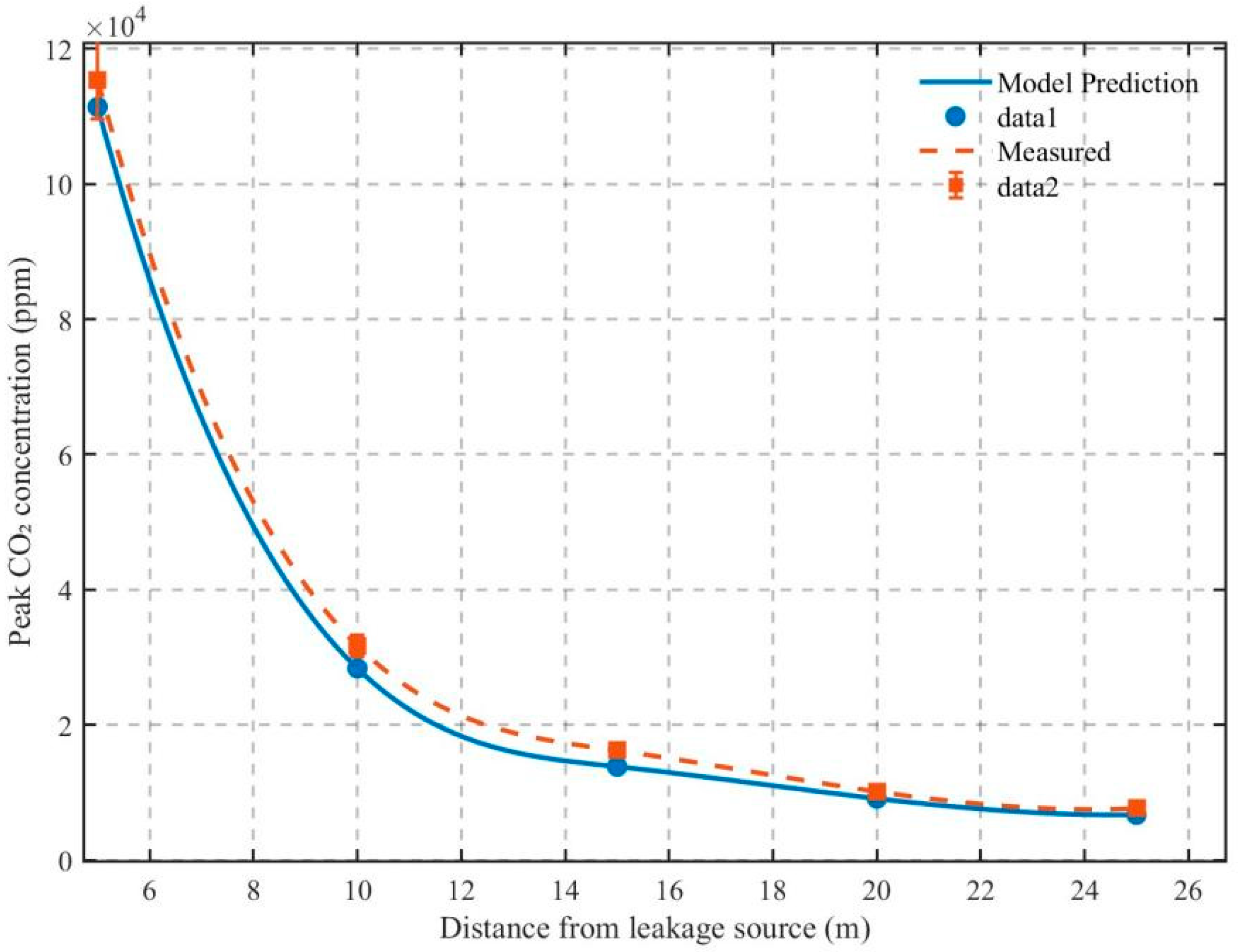

3.2. Field Experiment Validation

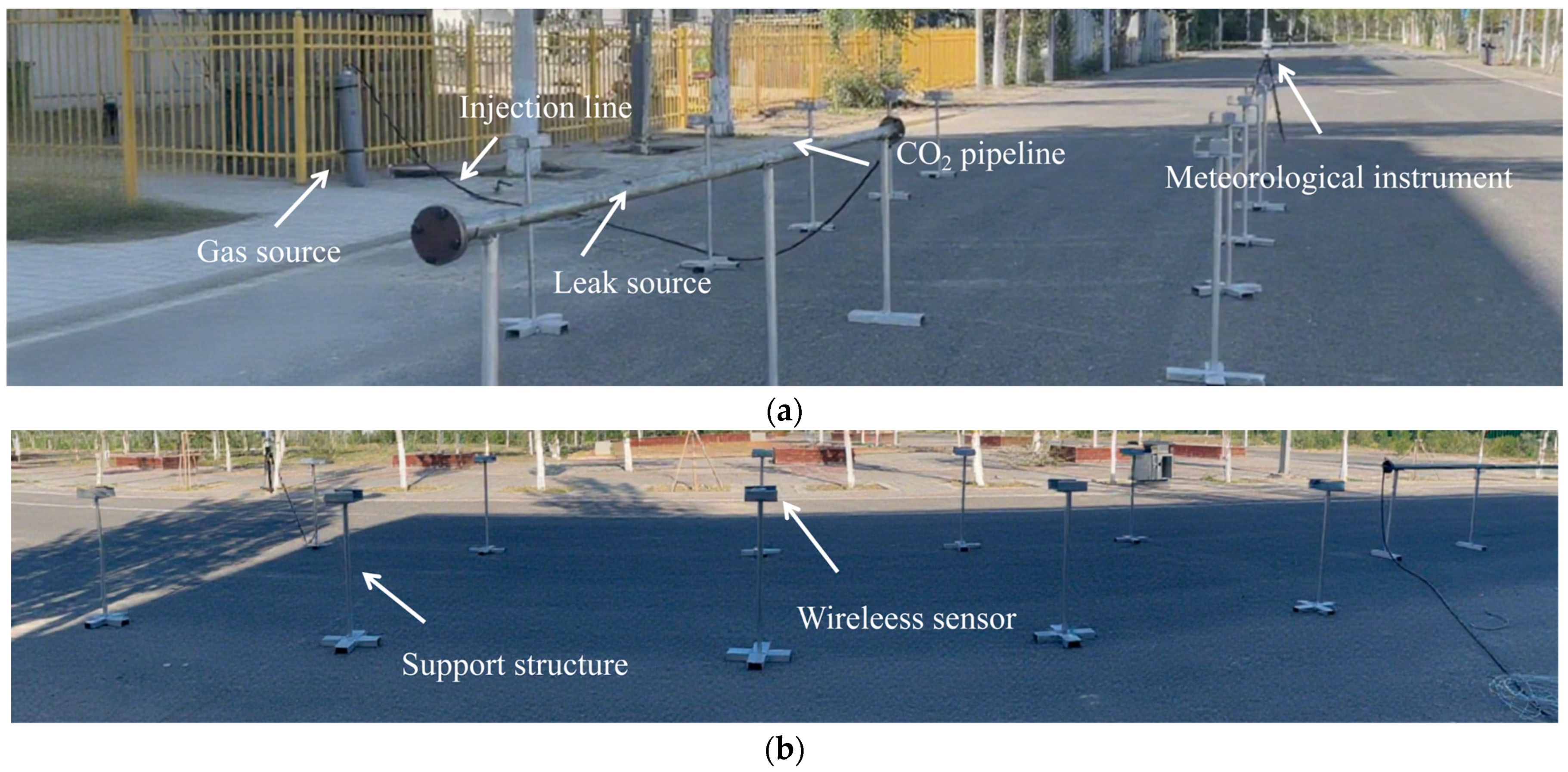

3.2.1. Experimental Platform Setup

3.2.2. Experimental Results

3.2.3. Model Validation

4. Model Adaptability Analysis

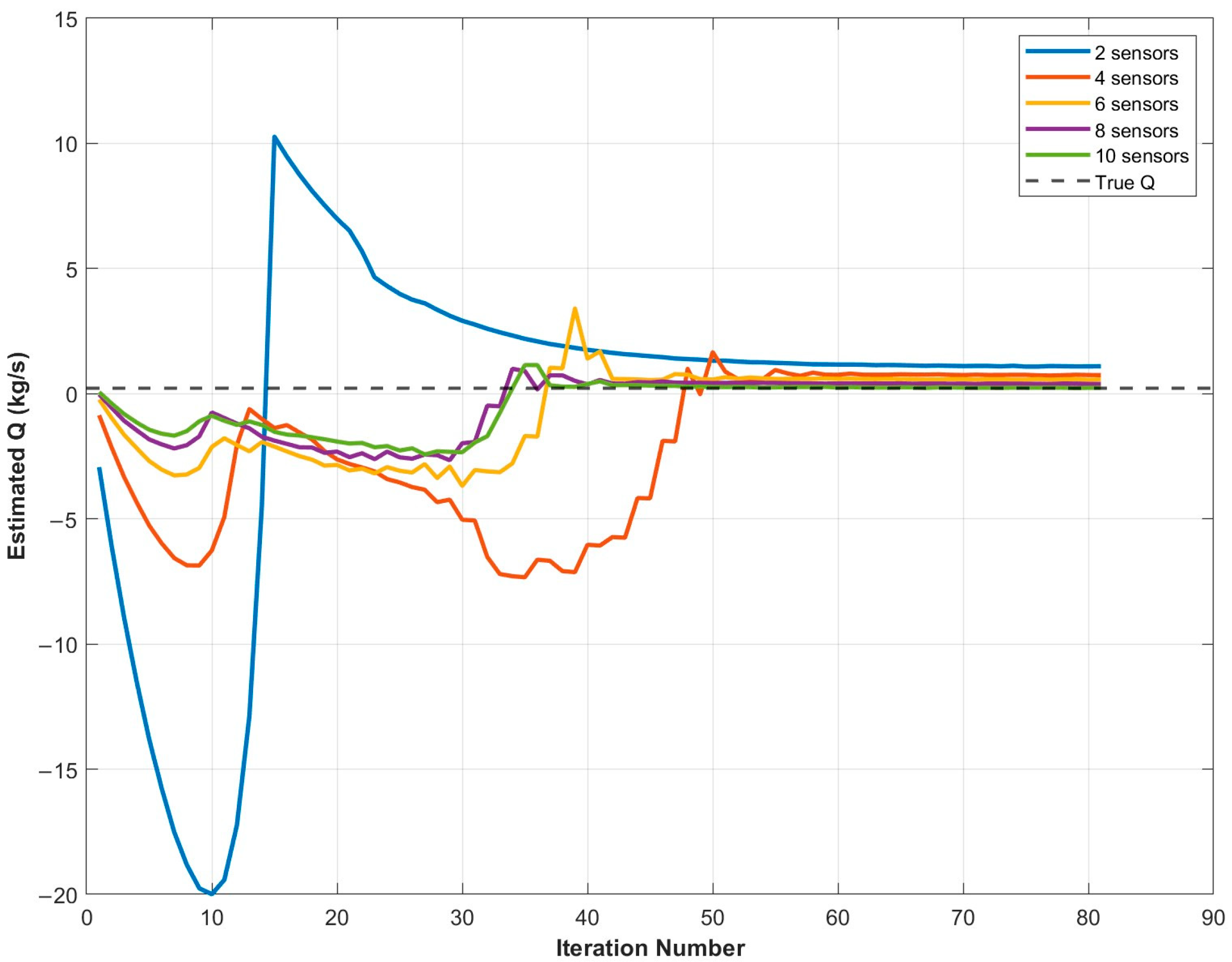

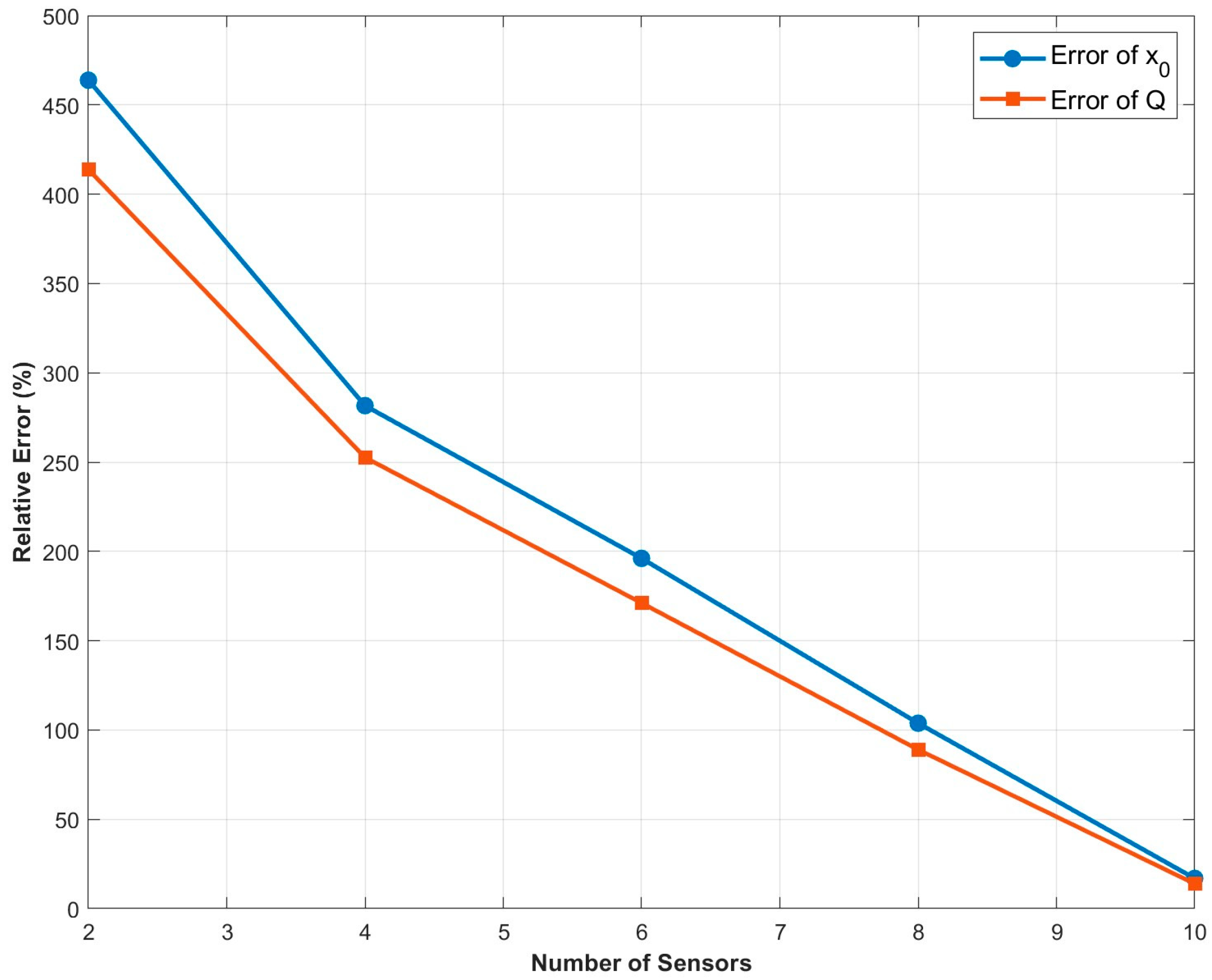

4.1. Effect of Sensor Number on Model Localization Accuracy

4.2. Influence of Leak Source Characteristics on Model Applicability

4.3. Influence of Wind Speed on Model Prediction Performance

5. Engineering Application

6. Conclusions

- (1)

- This study addresses the problem of CO2 pipeline leak detection and localization by integrating a wireless sensor network with the Gaussian plume model, thereby establishing a comprehensive CO2 leak detection and localization framework. Comparisons between model predictions and simulated experimental measurements indicate a leak location error of approximately 12.5% and a leak rate error of approximately 3.5%, meeting engineering accuracy requirements. The model enables rapid localization of the leak point and prediction of the CO2 concentration distribution along the pipeline, providing technical support for safe pipeline operation.

- (2)

- Field experiments further validated the applicability of the model. The predicted concentration profiles closely match the measured data, with errors controlled within 3.5–14.7%, accurately capturing the dispersion patterns and concentration variations at different distances. Moreover, the number and spatial arrangement of sensors significantly affect the inversion accuracy; optimized sensor deployment can enhance leak localization precision and source strength estimation reliability. The combination of WSN and the Gaussian plume model demonstrates clear advantages over standalone WSNs in rapid leak localization, source strength estimation, and risk prediction.

- (3)

- The model’s performance under complex meteorological conditions, multi-source leaks, and optimal WSN node placement requires further investigation. Future work will focus on optimizing sensor layout and incorporating multi-source data along with environmental parameter corrections to enhance the model’s robustness and accuracy in real-world complex scenarios, providing more comprehensive and reliable technical support for CO2 pipeline leak detection.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Lu, H.; Guo, L.; Azimi, M.; Huang, K. Oil and Gas 4.0 era: A systematic review and outlook. Comput. Ind. 2019, 111, 68–90. [Google Scholar] [CrossRef]

- Ebi, K.L.; Boyer, C.; Ogden, N.; Paz, S.; Berry, P.; Campbell-Lendrum, D.; Hess, J.J.; Woodward, A. Burning embers: Synthesis of the health risks of climate change. Environ. Res. Lett. 2021, 16, 044042. [Google Scholar] [CrossRef]

- Rockström, J.; Gaffney, O.; Rogelj, J.; Meinshausen, M.; Nakicenovic, N. A roadmap for rapid decarbonization. Science 2017, 376, 870–872. [Google Scholar] [CrossRef]

- Khan, M.D.; Khushnood, M.; Ali, M.; Imran, H. A techno-economic assessment of CO2 pipeline transportation in Asia: Challenges and future prospects. Energy Rep. 2022, 8, 4680–4692. [Google Scholar] [CrossRef]

- Cao, Z.; Hu, Y.; Chen, L.; Yan, X.; Yu, S.; Yu, J. Experimental study of leakage characteristics and risk prediction of N2-containing dense-phase CO2 pipelines in real transportation conditions. Process Saf. Environ. Prot. 2024, 187, 1112–1125. [Google Scholar] [CrossRef]

- Hu, Q.; Zhang, H.; Zhao, X.; Meng, L.; Li, Y.; Zhang, L.; Zhu, J.; Wang, W. Carbon dioxide pipeline leakage risk assessment based on pipeline failure probability correction and CO2 concentration dispersion distance prediction. J. Pipeline Sci. Eng. 2025, 5, 100293. [Google Scholar] [CrossRef]

- Jacobson, T.A.; Kler, J.S.; Hernke, M.T.; Braun, R.K.; Meyer, K.C.; Funk, W.E. Direct human health risks of increased atmospheric carbon dioxide. Nat. Sustain. 2019, 2, 691–701. [Google Scholar] [CrossRef]

- Chen, L.; Hu, Y.; Liu, Z.; Yan, X.; Yu, S.; Ding, J.; Liu, P. Experimental research on the fracture and arrest process of supercritical CO2 pipelines. Int. J. Press. Vessels Pip. 2024, 208, 104000. [Google Scholar] [CrossRef]

- Clarion Ledger. Hundreds Evacuated, Dozens Hospitalized After Gas Pipe Rupture in Mississippi. Clarion Ledger, 23 February 2020. Available online: https://time.com/5789425/pipe-rupture-mississipi/ (accessed on 15 September 2025).

- Lakhani, N. ‘Wake-up call’: Pipeline Leak Exposes Carbon Capture Safety Gaps, Advocates Say. The Guardian, 19 April 2024. Available online: https://www.theguardian.com/us-news/2024/apr/19/exxon-pipeline-leak-carbon-capture-safety-gaps (accessed on 8 May 2025).

- Bonne, J.-L.; Donnat, L.; Albora, G.; Burgalat, J.; Chauvin, N.; Combaz, D.; Cousin, J.; Decarpenterie, T.; Duclaux, O.; Dumelié, N. A measurement system for CO2 and CH4 emissions and an evaluation of Gaussian-plume atmospheric inversion approaches. Atmos. Meas. Tech. 2024, 17, 4471–4490. [Google Scholar] [CrossRef]

- Zhao, J.; Li, J.; Bai, Y. Research on leakage detection technology of natural gas pipeline based on modified Gaussian plume model and Markov chain Monte Carlo method. Process Saf. Environ. Prot. 2023, 174, 138–150. [Google Scholar] [CrossRef]

- Newman, T.; Nemeth, C.; Jones, M.; Jonathan, P. Probabilistic inversion modeling of gas emissions: A gradient-based MCMC estimation of Gaussian plume parameters. Atmos. Environ. 2024, 318, 120217. [Google Scholar] [CrossRef]

- Sun, C.; Yan, Y.; Zhang, W.; Shao, D. Measurement of CO2 leakage from pipelines under CCS conditions: Methodology for continuous quantification. Int. J. Greenh. Gas Control 2024, 237, 115164. [Google Scholar] [CrossRef]

- Aminaho, N.S.; Aminaho, E.N. Artificial Intelligence Based Solutions for CO2 Pipeline Monitoring: A Review. SSRN Working Paper 2025. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=5265609 (accessed on 15 September 2025).

- Marchi, A.; Cavalagli, N.; Ubertini, F. Experimental investigations of distributed fiber optic sensors for pipeline monitoring. Sensors 2023, 23, 6205. [Google Scholar] [CrossRef]

- Gong, Y.; Liu, Z.; Li, W.; Bao, C.; He, Z.; Jian, Y.; Wang, X.; Huang, H.; Song, X. A review on gas pipeline leak detection: Acoustic-based methods and applications. Information 2025, 16, 731. [Google Scholar] [CrossRef]

- Wang, X.; Xu, M.; Yang, Y.; Jiang, Z. Heterogeneous data fusion model for gas leakage detection. J. Loss Prev. Process Ind. 2025, 98, 105767. [Google Scholar] [CrossRef]

- Kolosov, A.; Large, S.; Inbar, E. Distributed fiber-optic sensing (DAS/DTS) for oil and gas pipeline monitoring: A review. J. Pet. Sci. Eng. 2022, 210, 110072. [Google Scholar] [CrossRef]

- Kang, Z.; Qian, X.; Li, Y.; Hou, L.; Huang, Z.; Duanmu, W.; Yuan, M. Feature extraction of natural gas leakage for an intelligent warning model: A data-driven analysis and modeling. Process Saf. Environ. Prot. Trans. Inst. Chem. Eng. Part B 2023, 109, 104823. [Google Scholar] [CrossRef]

- Nguyen, H.A.D.; Le, T.H.; Azzi, M.; Ha, Q.P. Monitoring and estimation of urban emissions with low-cost sensor networks and deep learning. Ecol. Inform. 2024, 82, 102750. [Google Scholar] [CrossRef]

- Zhou, Z.; Yang, Y.; Shi, Y.; Wang, Y.; Wu, W.; Qu, G. Observing CO2 emissions from global key coal-fired power plants based on Orbiting carbon Observatory-3 satellite and improved Gaussian plume model. J. Clean. Prod. 2025, 518, 145245. [Google Scholar] [CrossRef]

- Zhu, Z.; Chen, B.; Zhao, Y.; Ji, Y. Multi-sensing paradigm based urban air quality monitoring and hazardous gas source analyzing: A review. J. Saf. Sci. Resil. 2021, 2, 131–145. [Google Scholar] [CrossRef]

- Cheng, W.; Liu, X. An adaptive Gaussian dispersion model for air pollution simulation with complex terrain constraints. Atmos. Environ. 2021, 254, 118358. [Google Scholar] [CrossRef]

- Ražnjević, A.; van Heerwaarden, C.; Krol, M. Evaluation of two common source estimation measurement techniques: Methane plume dispersion using real-time sensors. Atmos. Meas. Tech. 2022, 15, 3611–3623. [Google Scholar] [CrossRef]

- Wang, R.; Chen, B.; Qiu, S.; Zhu, Z.; Qiu, X. Data assimilation in air contaminant dispersion using a Pasquill–Gifford stability-based parameterization. Atmosphere 2017, 8, 170. [Google Scholar] [CrossRef]

- Langford, N.J. Carbon dioxide poisoning. Toxicol. Rev. 2005, 24, 229–235. [Google Scholar] [CrossRef]

- Azuma, K.; Kagi, N.; Yanagi, U.; Osawa, H. Effects of low-level inhalation exposure to carbon dioxide in indoor environments: A short review on human health and psychomotor performance. Environ. Int. 2018, 121, 51–56. [Google Scholar] [CrossRef]

- Rhoads, W.J.; Corsi, R.L.; Waring, M.S. Increased indoor CO2 from mask-wearing during the COVID-19 pandemic and its potential neurodevelopmental implications for children. Environ. Res. 2021, 202, 111715. [Google Scholar] [CrossRef]

- Li, Y.; Jiang, F.; Jia, M.; Feng, S.; Lai, Y.; Ding, J.; He, W.; Wang, H.; Wu, M.; Wang, J.; et al. Improved estimation of CO2 emissions from thermal power plants using the Gaussian plume model. Sci. Total Environ. 2024, 930, 167145. [Google Scholar] [CrossRef]

- Micallef, A.; Micallef, C. The Gaussian plume model equation for atmospheric dispersion corrected for multiple reflections at parallel boundaries. Science 2024, 6, 48. [Google Scholar] [CrossRef]

- Jia, M.; Fish, R.; Daniels, W.S.; Sprinkle, B.; Hammerling, D. A fast and lightweight implementation of the Gaussian puff model for near-field atmospheric transport of trace gases. Sci. Rep. 2025, 15, 11234. [Google Scholar] [CrossRef]

- Xu, Z.; Chen, G.; Li, F.; Chen, L.; Cheng, Y. A survey on surface reconstruction based on 3D Gaussian splatting. PeerJ Comput. Sci. 2025, 11, e3034. [Google Scholar] [CrossRef]

- Liang, X. Perforation failure analysis of pipeline elbow at a receiving station. Eng. Fail. Anal. 2024, 158, 107042. [Google Scholar] [CrossRef]

- Alhomyani, H.; Alajlan, D.; Kabli, M. Multi-Hop Routing Protocols for Oil Pipeline Leak Detection Applications. Electronics 2022, 11, 2078. [Google Scholar] [CrossRef]

- Lin, X.; Li, G.; Wang, Y.; Zeng, K.; Yang, W.; Wang, F. Advances in intelligent identification of fiber-optic vibration signals in oil and gas pipelines. J. Pipeline Sci. Eng. 2024, 4 Pt A, 10184. [Google Scholar] [CrossRef]

| Simulated Sensor ID | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Coordinates (m) | (20, 5, 1) | (50, 5, 1) | (100, 5, 1) | (20, −5, 1) | (50, −5, 1) | (100, −5, 1) |

| Concentration (ppm) | 11,323 | 7136 | 1951 | 11,961 | 7399 | 2065 |

| Atmospheric Stability Classes | δy/m | δz/m |

|---|---|---|

| A | 0.22α (1 + 0.0001x)−0.5 | 0.20α |

| B | 0.16α (1 + 0.0001x)−0.5 | 0.12α |

| C | 0.11α (1 + 0.0001x)−0.5 | 0.08α (1 + 0.0002x)−0.5 |

| D | 0.08α (1 + 0.0001x)−0.5 | 0.06α (1 + 0.0015x)−0.5 |

| E | 0.06α (1 + 0.0001x)−0.5 | 0.03α (1 + 0.0003x)−1 |

| F | 0.04α (1 + 0.0001x)−0.5 | 0.016α (1 + 0.0003x)−1 |

| Wind Speed (m/s) | Daytime Solar Radiation Intensity | Overcast Daytime or Clear Night | Cloudy Night (Cloud Cover) | |||

|---|---|---|---|---|---|---|

| Strong | Moderate | Weak | ≥5/10 | ≤4/10 | ||

| <2 | A | A~B | B | D | — | — |

| 2~3 | A~B | B | C | D | E | F |

| 3~5 | B | B~C | C | D | D | E |

| 5~6 | C | C~D | D | D | D | D |

| >6 | C | D | D | D | D | D |

| Item | Source Strength (kg/s) | Leakage Location (m) | Concentration at 20 m (ppm) | Concentration at 50 m (ppm) | Concentration at 100 m (ppm) |

|---|---|---|---|---|---|

| Simulated Data | 3.80 | 2.00 | 11,642 | 7268 | 2008 |

| Model Prediction | 3.67 | 2.25 | 12,939 | 6601 | 1956 |

| Relative Error | 3.5% | 12.5% | 10.0% | 10.1% | 2.7% |

| Parameter | Pipeline Diameter | CO2 Gas Cylinder Capacity | Initial Pressure | Leakage Orifice Diameter | Leakage Rate | Wind Speed |

|---|---|---|---|---|---|---|

| Value | 80 mm | 25 kg | 5.85 MPa | 10 mm | 0.21 kg/s | 1.4 m/s |

| Model Type | Applicable Leak Source | Characteristics | Engineering Application |

|---|---|---|---|

| Gaussian Plume Model | Continuous source | Forms a stable plume along the wind direction with lateral Gaussian distribution | Suitable for long-term continuous leak monitoring and source strength estimation |

| Gaussian Puff Model | Point source/Instantaneous release | Initially high local concentration that disperses over time | Applicable for short-term leak events, emergency response, or theoretical investigations |

| Gaussian Sphere Model | Theoretical uniform dispersion | Three-dimensional spherical symmetry(idealized theoretical model) | Suitable for theoretical analysis or model validation; limited practical engineering applications |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Li, F.; Chen, J.; Wang, Z.; Wang, D.; Ran, Y. Research on Carbon Dioxide Pipeline Leakage Localization Based on Gaussian Plume Model. Processes 2025, 13, 2994. https://doi.org/10.3390/pr13092994

Li X, Li F, Chen J, Wang Z, Wang D, Ran Y. Research on Carbon Dioxide Pipeline Leakage Localization Based on Gaussian Plume Model. Processes. 2025; 13(9):2994. https://doi.org/10.3390/pr13092994

Chicago/Turabian StyleLi, Xinze, Fengming Li, Jiajia Chen, Zixu Wang, Dezhong Wang, and Yanqi Ran. 2025. "Research on Carbon Dioxide Pipeline Leakage Localization Based on Gaussian Plume Model" Processes 13, no. 9: 2994. https://doi.org/10.3390/pr13092994

APA StyleLi, X., Li, F., Chen, J., Wang, Z., Wang, D., & Ran, Y. (2025). Research on Carbon Dioxide Pipeline Leakage Localization Based on Gaussian Plume Model. Processes, 13(9), 2994. https://doi.org/10.3390/pr13092994