Abstract

This review presents a comprehensive summary of the recent advancements in treatment technologies and resource utilization strategies for mine tailings, and highlights the funding support provided by Hunan Province, China for scientific and technological innovation in the field. The work begins by examining the environmental risks associated with mine tailings, emphasizing their potential to cause ecological damage and result in significant resource waste. Building on this context, the review delves into the physical, chemical, and mineralogical characteristics of tailings, elucidating how these intrinsic properties underpin their potential for recycling and valorization. Subsequently, it explores a range of resource utilization approaches, including the recovery of valuable metals, land reclamation, backfilling of abandoned mining voids, and the production of construction materials. The current state of application and the key technical and regulatory challenges faced during implementation are critically analyzed. In conclusion, the review highlights the progress made in tailings management and valorization in Hunan Province, China, and proposes a forward-looking strategy that integrates technological innovation with policy and regulatory support to promote sustainable development in the region.

1. Introduction

The efficient treatment and resource utilization of mining tailings represent a core challenge for the global mining industry’s sustainable development, particularly in regions abundant in mineral resources but with fragile ecological environments [1]. As an important “hometown of nonferrous metals” and “hometown of non-metallic minerals” in southern China, Hunan Province has long relied on its rich mineral resources (157 mineral types have been discovered, and 124 mineral types have proven reserves) to drive rapid regional economic development. However, large-scale mining activities have also given rise to severe environmental and safety issues. As of 2023, the cumulative stockpiling of tailings in the province has reached 3 billion tons, with an annual new discharge of approximately 399 million tons, while the comprehensive utilization rate is only 30%, far lower than the level in developed countries [2]. A large number of tailings not only occupy a great deal of land and damage vegetation but also threaten the water security of 40 million people in the Xiangjiang River Basin due to heavy metal leakage and even trigger typical ecological crises such as “cadmium-contaminated rice”.

In recent years, with the advancement of the “dual-carbon” goals and the deepening of the concept of green development, the reduction, harmless treatment, and resource utilization of tailings have become a key breakthrough in the transformation of Hunan’s mining industry. Currently, the governance of tailings in the province faces multiple bottlenecks. First, at the technical level, the separation of low-grade associated minerals is difficult, and technologies such as the recovery of fine-grained valuable components and the stabilization of heavy metals are still immature; Second, at the management level, the traditional model of “emphasizing mining while neglecting governance” has led to a large number of historical debts, and the policy incentives and regulatory system need to be improved; Third, at the economic level, the high cost of activation treatment and the insufficient extension of the industrial chain have restricted the large-scale application of high-value utilization of tailings.

This review adopts a research method combining systematic review and case analysis, systematically combing the research progress in tailings treatment technology and resource utilization in Hunan Province. It first analyzes the environmental hazards and physicochemical characteristics of tailings, then summarizes the application status and challenges of key technologies such as valuable component recovery, mine reclamation, goaf backfilling, and building material preparation, analyzes the governance effectiveness by combining typical cases in the province, and discusses the technological innovation trends based on the funding directions of scientific funds.

Compared with existing global or national-level reviews on mine tailings treatment, this study possesses significant innovation and unique value. First, it focuses on Hunan Province, the core region known as the “hometown of nonferrous metals”, and closely links the province’s prominent tailings-related contradictions (including large stockpiling volume, low utilization rate, and pollution in the Xiangjiang River Basin) with local mineral characteristics (low-grade associated ores and fine-grained minerals) as well as the goals of the 14th Five-Year Plan, thereby avoiding overly generalized macro-discussions. Second, it innovatively constructs an integrated “technology-policy-fund” framework, connecting tailings utilization technologies with Hunan’s scientific research fund support and regulatory policies. The scientific research fund support includes the Natural Science Foundation of Hunan Province and the Scientific Research Foundation of Hunan Provincial Department of Education, which fills the gap in existing studies where technological progress is disconnected from policy guidance and fund input. Third, it verifies the effectiveness of technologies through typical local projects in Hunan, China, such as the fluorite recovery project from nonferrous metal tailings in Shizhuyuan, Chenzhou, Hunan, China and the full-tailings paste backfilling project in Baoshan Mine, Chenzhou, Hunan, China. This enables the review to not only have theoretical summary value but also provide practical guidance for regional tailings governance.

The study aims to provide a theoretical reference for constructing a tailings governance system and help Hunan Province achieve a dynamic balance between mineral resource development and ecological protection [3].

2. Hazards of Mine Tailings

Tailings are one of the products of mineral processing operations, referring to the part with the lowest content of useful target components. In the past, tailings were often regarded as waste. However, with the continuous development of production technology, the waste exhibits their economic value for further recycling and utilization. With the continuous advancement of mineral resource development, the accumulation of mine tailings is increasing. It was pointed out that an important task of China’s circular economy in the mining industry at present is to develop and utilize a large number of tailings that have been put aside for a long time [3]. Achieving zero-waste discharge is not only an inevitable requirement for the full utilization of mineral resources but also an important measure for the protection of the ecological environment. A clear understanding of the hazards of mine tailings is an essential foundation for formulating reasonable response strategies to ensure the sustainable development of the ecological environment and human society.

2.1. Formation of Environmental Pollution

Tailings often contain various heavy metal elements such as lead, cadmium, mercury, and arsenic [4]. These elements can easily enter the ecosystem through water and soil under natural conditions, leading to ecological environment pollution [5]. For example, lead-containing tailings may cause excessive lead content in the soil, affecting crops and threatening human health through the food chain. Additionally, residual flotation reagents and inhibitors in tailings may negatively impact aquatic organisms and soil microorganisms [6]. Some tailings also contain radioactive substances such as uranium and thorium, which, although present in low concentrations, may pose long-term threats to the ecological environment and human health [7,8].

2.2. Inducement of Natural Disasters

Large accumulations of tailings can form massive slopes with poor stability. Under the influence of natural factors such as heavy rain and earthquakes or human factors such as improper stacking methods, landslides and mudslides are prone to occur. These disasters may bury surrounding land, buildings, and people, causing significant loss of life and property. Additionally, underground mining activities can create goafs, which may lead to ground subsidence under the pressure of tailings accumulation if not properly treated. This not only damages surface facilities but may also disrupt groundwater systems, affecting the living water and agricultural irrigation of surrounding residents. Currently, tailings are mainly stored in tailings ponds. If the design, construction, or management of tailings ponds is improper, dam failure accidents may occur. After a dam failure, a large amount of tailings slurry can rapidly flood downstream areas, causing devastating impacts on farmland, villages, and towns, leading to immeasurable losses [9].

2.3. Destruction of Land Vegetation

Mining tailings disposal occupies a large amount of land resources. This land may originally have been fertile farmland, forests, or grasslands. After occupation, its ecological functions are lost, affecting the sustainable use of land and biodiversity. Mining activities such as blasting and excavation directly destroy surface vegetation, while tailings disposal further hinders the recovery and growth of vegetation. Without vegetation cover, the land is prone to soil erosion and desertification, leading to ecological degradation.

2.4. Waste of Mineral Resources

Tailings often contain a certain amount of valuable mineral components such as copper, gold, and silver. Due to technical and economic reasons, these components are not fully utilized during the beneficiation process, resulting in resource waste [3]. With the advancement of technology and the improvement of beneficiation techniques, the recovery and utilization of valuable components in tailings have become possible. Currently, the comprehensive utilization of mine tailings mainly focuses on the preparation of building materials and soil improvement, with other areas of utilization still underdeveloped [10]. For example, there is significant potential for further research and development in extracting valuable elements from tailings and preparing new materials.

3. Properties of Tailings

Although tailings are a type of solid waste, they contain a large amount of precious metals and rare earth elements. It is estimated that tailings retain 5% to 15% of various valuable minerals and metals from the original ore [11]. A comprehensive understanding of the physical, chemical, and mineralogical properties of tailings is a key prerequisite for evaluating tailings resource utilization and recycling schemes. Determining the particle size distribution, mineral phases, and elemental composition of tailings helps assess the feasibility of tailings recycling.

3.1. Physical Properties

The particle size of tailings is influenced by the grinding process, beneficiation process, and the hardness of minerals in the ore. The particle size range of tailings generally ranges from 2 μm to 2 mm. Tailings typically contain about 70–80 wt% sand particles and 20–30 wt% clay particles [12]. Tailings particles usually have angular and irregular shapes, resulting from the mechanical crushing and grinding processes during ore processing. Harder minerals form angular, smooth-edged particles, while softer minerals often form jagged fragments [13]. Over time, the sharp edges of particles in tailings ponds become rounded and smooth due to weathering [14]. The specific surface area of tailings is related to particle size and shape, ranging from 0.5 to 7.2 m2/g, with porosity between 30 and 40%.

The bulk density of tailings typically ranges from 1.8 to 1.9 g/cm3. In tailings ponds, the density of tailings increases with depth due to the weight of the overburden [15], ranging from 2.6 to 2.9 g/cm3. The density of tailings is determined by the type of minerals present in the parent deposit. For example, tailings from denser rocks such as diorite, gabbro, and diabase have higher densities compared to tailings from lighter minerals such as quartzite [16].

3.2. Chemical Properties

The pH of tailings depends on the type of source ore. The key factor controlling the pH of tailings is the balance between the acid produced by sulfide mineral oxidation and the acid neutralization by carbonate mineral dissolution [17]. When sulfide oxidation exceeds neutralization, the pH of tailings is usually acidic. For example, tailings containing a large amount of active sulfide minerals (such as pyrite) typically have an acidic pH. In contrast, tailings with high carbonate content tend to maintain a more neutral or alkaline state due to the consumption of proton acidity by carbonate dissolution [18].

The chemical composition of tailings is influenced by the nature of the ore, the reagents used in the mineral recovery process, the recovery rate of the target minerals, and the physicochemical changes during tailings storage. The main chemical components of most tailings are SiO2, Al2O3, Fe2O3, MgO, CaO, Na2O and K2O, as shown in Table 1. Tailings may also contain a high residual percentage of valuable minerals, indicating the potential for further resource recovery from tailings. However, due to the heterogeneity of the ore, the elemental composition often varies even within the same tailings. This natural variation, along with the evolution process during storage, makes the chemical properties of tailings complex and diverse. Characterizing the changes in chemical composition is key to assessing the feasibility of tailings resource utilization [18].

Table 1.

The main chemical composition of five types of tailings.

3.3. Mineralogical Characteristics

The main mineral composition of tailings (Table 2) reflects the original gangue mineralogy of the processed deposit. The main mineral phases include quartz (SiO2), carbonate minerals such as calcite (CaCO3) and dolomite (CaMg(CO3)2), sulfide minerals such as pyrite (FeS2), sphalerite (ZnS), and galena (PbS), feldspar group silicates, and clay minerals such as kaolinite (Al4[Si4O10](OH)8) and illite (K,H3O)(Al,Mg,Fe)2(Si,Al)4O10 [(OH)2,(H2O)]. Quartz is commonly found in many types of tailings, accounting for about 3–50% of the tailings mass, especially in gold and sulfide tailings [35]. Pyrite is mainly found in copper, copper-zinc, and other non-ferrous metal tailings [36]. Phosphate tailings have a high content of carbonate minerals such as dolomite and calcite. Mica tailings have a high content of mica [37].

Table 2.

Main mineral composition of different kinds of tailings.

4. Comprehensive Utilization of Tailings

Tailings recycling can be defined as the process of directly using tailings in their original form for specific purposes without any reprocessing [45]. Tailing reuse refers to the process of recycling tailings as raw materials through certain reprocessing procedures to convert them into new valuable products or applications. As early as the 1920s, mining-developed countries began researching the resource utilization of tailings and achieved significant ecological and economic benefits. China started relatively late in the comprehensive recycling of tailings, with a utilization rate of tailings (30%) far lower than that of mining-developed countries (60%) [2]. In recent years, China has conducted extensive research on the comprehensive utilization of tailings, mainly focusing on four aspects: recovery of valuable components, reclamation, backfilling of abandoned mining areas, and preparation of building materials.

4.1. Recovery of Valuable Components

Recovering valuable components from tailings not only generates economic benefits and reduces the consumption of natural resources but also minimizes waste production [46,47]. Valuable minerals and metals in tailings often exist in fine and ultra-fine particles within gangue minerals [47]. Advances in mineral separation and extraction technologies have made it possible to economically recover these valuable components [48]. However, recovering valuable components from tailings still faces significant challenges, primarily in technical and economic aspects.

In terms of technical bottlenecks, tailings contain a large amount of fine particles smaller than 150 μm, and effective enrichment methods are currently lacking [48]. To address this issue, current research is focused on developing efficient selective collectors and specialized equipment to improve the flotation recovery and efficiency of fine-grained minerals. For example, new technologies such as fluidized roasting, selective flocculation flotation, or carrier flotation can effectively separate valuable metals from ultra-fine particles, thereby increasing concentrate grade and recovery rates [49,50,51].

In terms of economic factors, the costs of energy, water, and chemical reagents during the recovery process, as well as fluctuations in metal prices and commodity cycles, must be taken into account. Although research and pilot tests have demonstrated the technical feasibility of recovering valuable components from tailings, scaling up to industrial levels remains challenging. To enhance economic viability, research trends are shifting toward: (1) developing low-energy pretreatment methods (e.g., mechanical activation) and biohydrometallurgical technologies to reduce processing costs; and (2) exploring multi-metal synergistic recovery and cascade utilization models to distribute costs and enhance overall profitability by extracting multiple valuable elements [52,53]. Additionally, integrating tailings recycling into a circular economy framework and internalizing environmental costs through policy incentives are considered important pathways to improve project economics.

Despite these challenges, factors such as the growing demand for metals in production and daily life, declining ore grades, environmental crises, and risk management will continue to drive further application of valuable component recovery from tailings [54]. Future development relies on the integration of technological innovation and economic model innovation to achieve a win-win situation for both environmental and economic benefits.

4.2. Reclamation

Tailings reclamation refers to the process of closing a tailings pond after it reaches the end of its service life, covering its surface with a certain thickness of soil suitable for vegetation growth, and planting vegetation. This process is a key component of the mining life cycle, with the main purpose of restoring vegetation on mining land, rebuilding ecosystems, and restoring their original ecological functions [55]. Reclamation technology can be implemented on-site through vegetation to repair mine tailings and has been proven to be a promising strategy. In 1988, the State Council issued the “Land Reclamation Regulations,” which clearly stated the principle of “whoever damages, reclaims,” effectively promoting the development of reclamation work in China [36].

In recent years, many studies have focused on exploring methods for tailings reclamation, including direct vegetation restoration, indirect vegetation restoration, and bioremediation [55]. Direct vegetation restoration focuses on directly planting vegetation on tailings, using amendments to promote successful vegetation growth [56]. Studies have shown that amendments such as compost products and waste mushroom compost significantly improve soil and vegetation quality in tailings ponds [57]. Indirect vegetation restoration involves layering functional cover materials, including coarse stones and topsoil, on the surface of tailings, then establishing a vegetation layer as the final surface layer. Tailings surface reclamation usually requires at least 30 cm of soil cover, facing challenges such as scarce topsoil and inappropriate cover materials. Bioremediation uses microorganisms to address environmental problems caused by tailings and is a more sustainable solution [58]. Microorganisms in tailings develop new mechanisms such as bioleaching and biomineralization, genetic adaptation and horizontal gene transfer, community synergy, metal tolerance, and detoxification, enabling these organisms to play a role in restoring damaged ecosystems [59]. Currently, research on using microorganisms for tailings bioremediation is limited, but bioremediation has shown potential in treating acid mine drainage in mining areas as a green and sustainable method [60].

4.3. Backfilling of Abandoned Mining Areas

Backfilling abandoned mining areas with tailings is a green solution for tailings disposal and one of the most effective ways to recycle tailings [61]. Cemented paste backfill technology is commonly used to mix tailings with cement into a paste, which is then used as backfill material in underground mining areas, improving the stability of surrounding rock and soil and reducing or even eliminating the risk of geological disasters in abandoned mining areas [62]. Backfilling abandoned mining areas with tailings achieves resource utilization of tailings and solves environmental issues related to tailings ponds and abandoned mining areas [63]. Using tailings as backfill material not only reduces enterprise operating costs but also greatly improves the resource utilization rate of tailings.

The application of cemented paste backfill technology in abandoned mining areas includes three main processes: tailings thickening, mixing, and pipeline transportation. Among these, mixing is a very important step, aiming to disperse, wet, and mix cementitious materials, tailings, and additives to form a stable paste suitable for transportation. Cemented paste backfill technology achieves the transformation of the mixture from slurry to paste [64], but the impact of the mixing process on paste performance is often overlooked [65]. Many studies have shown that the mixing process can change the rheological, hydration, and hardening mechanical properties of cemented paste backfill (CPB) [62]. Therefore, research on slurry mixing is of great significance for improving the theory of paste backfill and its promotion and application.

4.4. Preparation of Building Materials

The use of tailings as building materials is mainly aimed at meeting the growing global demand for concrete products, reducing the consumption of Portland cement and the exploitation of natural resources [66]. Numerous studies have used tailings as aggregates in cement-based composites [67]. Although this approach can enhance the mechanical properties of concrete materials, it has limited effect in reducing carbon dioxide emissions during the production of concrete materials. Therefore, more studies tend to use tailings as supplementary cementitious materials and geopolymer precursors [68]. Supplementary cementitious materials refer to materials other than the main cementitious materials (such as cement) used to enhance or improve the performance of concrete in civil engineering and building materials. Currently, using tailings as geopolymer precursors is also a popular research direction in the field of tailings resource utilization. For instance, Yang Youzhi’s study treated molybdenum tailings via alkaline hydrothermal activation and compounded them with slag, successfully preparing a ‘one-part geopolymer’. This geopolymer only requires the addition of water for use, which simplifies the preparation process [69]. The team led by Yi Yuanrong adopted a saponification/hydrogen peroxide synergistic foaming process, using 60% fly ash and 40% spodumene tailings as raw materials to prepare porous geopolymers. The porous geopolymers have a porosity of 45–55% and a compressive strength of 8–12 MPa, which can be used for the preparation of lightweight partition boards and sound-absorbing materials, with a cost 30% lower than that of traditional ceramsite products [70].

Geopolymerization is a highly promising technology for tailings recycling. It activates aluminosilicate precursors such as tailings through an alkaline activation solution to form a geopolymer gel [71]. Taking the reaction of common tailings (mainly containing aluminosilicate minerals) with a NaOH alkaline activator as an example, its simplified chemical equation can be expressed as:

x(Al2O3·2SiO2·2H2O) + 2nNaOH ⟶ nNa2O·xAl2O3·2xSiO2·yH2O + zH2O

During the reaction process, aluminosilicate minerals are depolymerized under the action of the alkaline activator to form active aluminosilicate ions, and these ions further polymerize to form a geopolymer gel with a three-dimensional network structure [72].

From the perspective of microstructural changes, when the tailings are in an inactivated state, the bonding between the internal mineral particles is relatively loose, the pore structure is unevenly distributed, and the pore size is relatively large. After the geopolymerization reaction is carried out using an alkaline activator, the aluminosilicate minerals in the tailings gradually dissolve, and the released silicon and aluminum monomers undergo a polymerization reaction in an alkaline environment to form a highly cross-linked three-dimensional network structure [73]. This structure enables the geopolymer gel to tightly wrap the tailings particles and fill the original pores, thus significantly improving the microstructure of the material. Under a scanning electron microscope, it can be observed that the surface of the tailings particles before the reaction is relatively rough, with obvious edges and corners and large pores; while the geopolymer gel exhibits a continuous and dense structure, and the tailings particles are evenly embedded in it, greatly enhancing the integrity and stability of the material [74]. Additionally, the research shows that tailings geopolymers have a significant effect in solidifying heavy metals and can effectively reduce the potential harm of tailings to the environment [75].

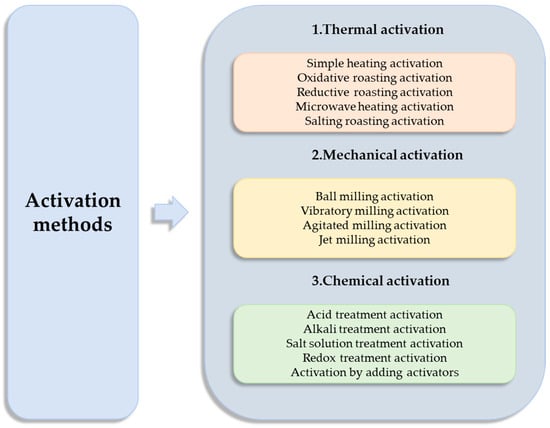

However, whether using tailings as supplementary cementitious materials or geopolymer precursors, the key technology lies in the activation of tailings to enable the tailings to exhibit high pozzolanic activity. Currently, the main methods for tailings activation include thermal activation, mechanical activation, and chemical activation (as shown in Figure 1). Meanwhile, as shown in Table 3, the three activation methods have their own advantages and disadvantages.

Figure 1.

Activation methods of tailings.

Table 3.

Comparison of different activation methods for tailings utilization.

4.4.1. Thermal Activation

Thermal activation aims to convert crystal phase in tailings into amorphous phase and thereby improving pozzolanic reactivity [76]. For tailings with high quartz content, thermal activation has little effect on improving their pozzolanic activity. Generally, thermal activation of tailings can be carried out in the temperature range of 400–800 °C [77]. When thermal activation is performed at temperatures above 750 °C, decarbonization of carbonate minerals (such as calcite and dolomite) and dehydroxylation of mica also occur [78], resulting in high energy consumption and high carbon dioxide emissions. Additionally, excessively high temperatures during thermal activation can cause sintering, increasing the particle size of tailings and affecting their pozzolanic activity [79].

4.4.2. Mechanical Activation

Mechanical activation generally increases the reactivity of tailings by grinding to produce new surfaces, crystal structure defects, and phase changes, but there is no significant change in chemical composition [80]. Although reducing the particle size of tailings is beneficial for improving their pozzolanic activity, the effect of mechanical activation is determined by the chemical composition of the tailings. Additionally, after mechanical activation, when the particle size of tailings is too small, particle aggregation usually occurs. The average particle size of mechanically activated tailings is generally controlled between 20 and 50 mm [81]. Currently, there is limited in-depth research on mechanical activation of tailings, and there is insufficient comparative research on the energy consumption of different grinding methods.

4.4.3. Chemical Activation

Chemical activation promotes the dissolution of silica and alumina by adding chemical alkali activators, thereby producing new cementitious materials with hardening properties comparable to cement-based composite materials. Currently, commonly used chemical activators include Na2SiO3, NaOH, Ca(OH)2, KOH, Na2SO4, and CaSO4 [82]. One of the main applications of chemical activation is the production of geopolymer concrete from mine tailings. For geopolymers, in addition to the total content of Al2O3 + Fe2O3 + SiO2, the ratio of SiO2 to Al2O3 in tailings is also crucial. Depending on the alkali activator used, the optimal SiO2/Al2O3 and SiO2/Na2O ratios required for tailings may vary significantly [79].

Thermal and mechanical activation can directly improve the reactivity of tailings, but chemical activation is more dependent on alkali activators, and its effect is indirect. Therefore, chemical activation is usually combined with thermal and mechanical activation. For example, chemical-mechanical activation can be achieved by adding chemical activators (such as lime, blast furnace slag, silica fume, and gypsum) to tailings and then grinding them together in a mill. Binary or ternary ultrafine particle materials prepared from tailings have attracted great interest in the concrete industry. However, a lot of research is still needed to understand the mechanism of the chemical activation process.

4.5. Tailings Comprehensive Utilization Technology Stage

Table 4 lists some examples of tailings utilization technologies. It can be seen that the current technologies for tailings resource utilization show an obvious maturity gradient, forming a diversified development pattern ranging from large-scale application to laboratory exploration.

Table 4.

Cases of comprehensive utilization of tailings technology.

At the level of industrial application, the heating flotation-gravity separation combined process developed by Luoyang Molybdenum Group for Luanchuan molybdenum-tungsten tailings is the most typical. Through reagent research and development as well as process innovation, it has achieved a tungsten recovery rate reaching up to 95.11% and molybdenum 75.45%, with the purity of associated garnet concentrate reaching 83%. The annual sales revenue can reach 1.5 billion yuan, pioneering the efficient recovery of low-grade associated ores. Other similar mature technologies include the gravity-magnetic separation combined process for Heilongjiang copper tailings, with gold and iron recovery rates reaching 35.44% and 89.34%, respectively; and the simple flotation-gravity separation process adopted for Henan lead-zinc tailings, with a maximum lead recovery rate of 49.21%. All these technologies demonstrate the industrialization advantages of short process and low cost. In the field of bulk utilization, the technology for preparing glass-ceramics from iron tailings and steel slag has realized large-scale production in Baotou, with an annual tailings processing capacity of 500,000 tons and the product hardness reaching Mohs 9 grade; the full solid waste cementitious material developed by Tongling Nonferrous Metals has been applied to filling 11 mines and national highway subgrades, reducing costs by 15% and consuming 300,000 tons of tailings per 100 km, which significantly improves the level of tailings reduction.

Technologies in the industrialization preparation stage are represented by the lithium-selecting tailings from Sichuan Ke’eryin. The “grinding-desliming-lithium flotation” process obtains lithium concentrate with 5.07% Li2O from tailings with 0.51% Li2O, with a recovery rate of 59.21%. Laboratory verification has been completed, and it has the conditions for large-scale production. Although Chongqing coal-measure high-sulfur tailings have achieved index breakthroughs through sulfuric acid leaching for aluminum extraction (Al2O3 leaching rate of 87.25%) and alkali leaching for silicon extraction (SiO2 content of 85 g/L), the industrialization process still needs optimization. The technologies of preparing high-performance glass-ceramics through melt crystallization and preparing ceramic composites through sintering in the pilot test stage, although showing potential for high added value, have not yet formed stable production capacity. At the laboratory exploration level, the bioleaching and oxalic acid pretreatment technology developed by Tarbiat Modares University has increased the recovery rates of praseodymium (Pr), cerium (Ce), and europium (Eu) from gold tailings by 24.4%, 14.4%, and 9.1%, respectively, but it has not been scaled up due to bottlenecks such as microbial environment control. This technological gradient distribution not only creates significant economic benefits through mature technologies but also reserves future development potential through pilot test and laboratory technologies, forming a coordinated development pattern of “economic benefits-environmental governance-technological reserves” for tailings resource utilization.

5. Current Status and Resources Utilization of Mine Tailings in Hunan Province

5.1. Current Status of Mine Tailings in Hunan Province

Hunan Province, often referred to as the “Hometown of Non-ferrous Metals” and the “Hometown of Non-metallic Minerals,” boasts abundant mineral resources. By 2023, 157 types of minerals had been discovered in the province, with proven reserves of 124 types [92]. While these resources have significantly contributed to the region’s economic development, they have also led to serious social and environmental issues, including catastrophic tailings dam failures and widespread tailings pollution.

Mineral deposits in Hunan are typically characterized by low-grade ores and a high degree of mineral association. Due to decades of inefficient and extensive mining practices, a substantial portion of the valuable resources has remained underutilized, leading to excessive accumulation of tailings. According to the report of the Hunan Provincial People’s Government, as of November 2023, there are 226 tailings reservoirs in the province, mainly associated with lead, zinc, gold, and manganese mining operations [93]. As dam heights continue to increase, the risk to nearby communities also grows, raising significant safety concerns.

According to the National Bureau of Statistics, in 2020, Hunan accounted for 4.71% of China’s total population but only 2.21% of the national land area [94]. The vast quantity of tailings exacerbated the province’s already limited land availability. Moreover, tailings accumulation has severely damaged local ecosystems, destroying vegetation and placing a heavy burden on the environment, thereby threatening both residents’ quality of life and the long-term ecological sustainability of the region.

Table 5 summarizes the tailings stockpile, utilization, and governance progress. It is estimated that the ore mining output in Hunan Province is approximately 570 million metric tons, and the total tailings storage capacity had reached 352.69 million cubic meters by the end of 2023. Despite these staggering figures, comprehensive tailings management in the province remains at an early stage, with a utilization rate of only about 30%, and the annual increment of unused tailings reached 399 million tons. As a result, environmental issues associated with tailings are becoming increasingly severe [95]. To address this, During the 14th Five-Year Plan period, Hunan Province has successfully applied for national demonstration projects for three consecutive years, having secured a total of 900 million RMB in central government funding for mine restoration initiatives. This funding has supported the rehabilitation of 4908 hectares of historical legacy abandoned mining sites. A target has been set to increase the utilization rate to 35% by 2025, demonstrating the government’s emphasis and determination to promote tailings resource utilization.

Table 5.

Tailings stockpile, utilization, and governance progress.

Table 6 summarizes the land and ecological impacts by tailings. At present, mining activities in Hunan Province have destroyed 174,809 hectares of land and vegetation, accounting for 0.83% of the province’s total area, with 9000 hectares of vegetation severely degraded, mainly in Western Hunan and Yiyang City. As early as 2012, EHS Environment, Health and Safety Network reported that heavy metal-contaminated land in the province had reached 28,000 hectares—roughly 0.74% of the provincial cultivated land—with the Xiangjiang River Basin identified as the most affected region. Pollution of the river has compromised the drinking and agricultural water supply for more than 40 million people. In 2013, the well-known “cadmium-contaminated rice” incident was traced to Yiyang City in the Xiangjiang Basin, revealing the infiltration of cadmium-contaminated water into the food chain [101].

Table 6.

Land and ecological impacts by tailings.

Table 7 gives the typical pollutant concentrations in tailings from different region in Hunan Province, China. In 2018, CCTV Finance’s Economic Half Hour exposed illegal mining activities by private enterprises in Huayuan County, Xiangxi Tujia and Miao Autonomous Prefecture. Dozens of unregulated tailings ponds, laden with heavy metals, were found to have destroyed arable land and polluted local water sources, causing irreversible ecological damage [105]. The data reveals that multiple heavy metals in tailings from different regions of Hunan Province exceed standards [106]. In the sediments of the Dongting Lake Area, cadmium (Cd) is the main pollutant, with concentrations ranging from 0.54 to 79.9 mg/kg and an average value 64.2 times the background value; the pollution stems from upstream mining activities. Furthermore, in the water system of the Huangmuxi River in the Realgar Mining Area of Shimen County, the concentration of arsenic (As) reaches 0.28–10.43 mg/L, far surpassing the national standard (0.01 mg/L) with an excess of 1043 times, and this pollution originates from the mining and accumulation of realgar ore [106]. Moreover, in the soil around tailings in the Xiangtan Manganese Mining Area, manganese (Mn) pollution is the most severe, with an average content of 1020.98 mg/kg, 441 times the background value, followed by zinc (Zn) with an average value 95 times the background value. These heavy metals migrate through soil and water, posing long-term threats to ecosystems and human health.

Table 7.

Typical pollutants and their contents in tailings from different regions of Hunan Province.

Additionally, several major accidents highlight the severity of this issue caused by tailings. On 10 April 2010, a tailings dam collapse in Huayuan County, Xiangxi Tujia and Miao Autonomous Prefecture, resulted in six fatalities [111]. On 16 November 2015, the tailings pond at the Wuchangping Tin Mine in Chenzhou City collapsed, releasing water and tailings through a drainage culvert, with four individuals reported missing downstream [112]. Such tragedies underscore the urgent need for strengthened management, enhanced safety protocols, and more sustainable tailings disposal practices in Hunan’s mining sector.

These alarming cases underscore the urgent need for systematic and effective tailings management. Addressing these environmental hazards is not only critical for restoring ecological balance but also for safeguarding public health and ensuring the sustainable development of both the region and its population.

5.2. Resources Utilization of Mine Tailings in Hunan Province

Through the efforts of researchers, Hunan Province has made initial progress in tailings reduction and resource recovery. The province’s mineral resources are typically characterized by low grades, fine particle sizes, and high impurity content, which complicates beneficiation [113]. In the early stages of mining development, outdated beneficiation technologies and inefficient processes led to the selective extraction of only high-grade or easily recoverable ores. As a result, large quantities of low-grade or refractory minerals were discarded as tailings, causing substantial resource waste. It is estimated that such losses amount to tens of billions of yuan annually. With the ongoing advancement of beneficiation technologies and the modernization of processing equipment, many of the valuable components previously lost in tailings can now be recovered. In recent years, the Hunan Provincial Government, in collaboration with mining enterprises, has made notable progress in several areas, including the reprocessing of tailings to extract valuable elements, the use of tailings in the production of construction materials, the backfilling of abandoned mining sites, and land reclamation efforts. Table 8 gives the typical resources utilization of mine tailings in Hunan Province.

Table 8.

Representative cases and effectiveness of tailings recycling in Hunan mines.

In the area of resource recovery from tailings, the China Minmetals Corporation has successfully implemented the project titled “Key Technology Research and Demonstration of Fluorite Resource Utilization from Typical Non-ferrous Metal Tailings in the Shizhuyuan Mine and Surrounding Areas of Chenzhou, China.” This initiative overcame key technical barriers in the recovery and application of low-grade fluorite, paving the way for more efficient resource conservation and sustainable development in China’s fluorine chemical and metallurgical industries [114].

In the field of building materials production, the Shaodong Lead-Zinc Concentrator (Shaodong, Hunan, China) has utilized lead-zinc tailings to manufacture refractory bricks, while Hunan Nonferrous Metals Holding Group Co., Ltd. (Changsha, Hunan, China). developed lightweight foamed building materials from tailings. These efforts have collectively reduced tailings storage by 200,000 tons annually, moving toward near-zero tailings discharge [115,116].

For mine backfilling, Hunan Gold Baoshan Mining (Chenzhou, Hunan, China) has adopted a high-concentration full-tailings paste backfill technology, which involves processing tailings before reintroducing them into abandoned mine areas [117]. This not only reduces the discharge of solid mining waste but also enables the recycling of tailings wastewater, enhancing resource efficiency.

In terms of land reclamation, the Shizhuyuan Mine Park (Chenzhou, Hunan, China)—once a barren tailings pond and waste rock dump—has undergone extensive ecological restoration. Through sustained efforts in land reclamation and mine greening, the site has added 3431 acres of forest, green space, and farmland, along with 281 acres of construction land, reclaiming 87.5% of the originally affected area [118,119]. The heavily polluted former mining zone has now been transformed into the largest national mine park in Hunan Province, serving as a recreational space for local residents and yielding significant ecological, economic, and social benefits.

6. Analysis of Scientific Fund Support Related to Tailings Management in Hunan Province

The number of approved scientific fund projects serves as a strong indicator of the region’s strategic emphasis and policy support for a given field. In recent years, to mitigate the environmental risks associated with tailings and to promote the coordinated development of mineral resource extraction and ecological protection, the Hunan Provincial Science Fund has significantly increased its investment in tailings utilization research. This growing support aims to drive technological advancement and innovation in the field.

According to statistics on scientific funding for tailings utilization in Hunan Province between 2018 and 2023 (Table 9), a total of 120 project applications were submitted over the five-year period. Of these, 25 projects were funded, reflecting an overall approval rate of 20.8%. General and Youth Fund Projects accounted for the largest share, with 75 applications and 16 approvals, yielding a success rate of 21.3%. Outstanding Youth Projects saw 9 applications and 3 approvals, with a funding rate of 33.3%. Meanwhile, none of the 8 Excellent Youth Project applications were approved. Key Project proposals numbered 28, of which 6 were funded, reflecting a 21.4% approval rate.

Table 9.

Analysis of funding of science foundation projects in Hunan Province from 2018 to 2023.

With this funding support, universities and research institutions in Hunan have carried out extensive studies in areas such as tailings recycling technologies, safe disposal methods, and resource recovery strategies. A review of these funded projects reveals several core scientific challenges currently being addressed in tailings research across the province:

- (1)

- Development of pre-disposal separation technologies and high-efficiency flotation reagents and processes to enhance ore grade, improve beneficiation efficiency, and reduce processing costs;

- (2)

- Advancement of cascade utilization technologies aimed at reducing the load on tailings ponds, mitigating disposal risks, and increasing tailings reuse rates;

- (3)

- Design of selective collectors and specialized equipment for the recovery of fine-grained minerals to enhance mineral grade and recovery efficiency;

- (4)

- Investigation of the migration mechanisms of hazardous elements in tailings, coupled with the development of effective containment and remediation strategies to reduce environmental risks and ensure ecological safety;

- (5)

- Application of pyrometallurgical and hydrometallurgical processes to transform tailings into environmentally friendly, high-value secondary materials, achieving both harmless treatment and value-added reuse;

- (6)

- Development of microbial-induced calcium carbonate precipitation (MICP) techniques to improve the solidification performance of radioactive tailings, such as uranium tailings, and validate their field-scale applicability in tailings ponds [95,120].

These research themes represent key frontiers in tailings treatment technology and offer valuable guidance for the continued evolution of comprehensive tailings utilization in Hunan Province and beyond.

7. Outlook

Hunan Province, one of China’s most mineral-rich regions, relies heavily on its mining economy. However, the environmental and management challenges posed by tailings have become increasingly pressing. In the context of ecological civilization and green development, the comprehensive utilization of tailings has gained significant attention. Despite this, several obstacles persist, including a low utilization rate of tailings, outdated mining and beneficiation technologies, and a prevailing focus on extraction over remediation among mining enterprises. These issues hinder the sustainable and green development of Hunan’s mining sector.

To address these challenges, a coordinated approach integrating resource management, economic growth, and environmental protection is essential. Efforts should focus on promoting a circular mining economy and ensuring the sustainable use of mineral resources. Increased investment in research and development is crucial to advancing tailings treatment technologies, enhancing resource recovery, and minimizing waste generation at the source. Furthermore, improving regulatory frameworks and accelerating the implementation of comprehensive tailings management policies will be key to driving progress. Strengthened policy support and clear guidance are also needed to shift the mining industry toward a more sustainable growth model—one that balances resource exploitation with ecological responsibility and long-term economic resilience.

In summary, this review underscores that tailings are not merely waste but a significant resource reservoir, whose valorization hinges on technological innovation and policy synergy. The experience from Hunan Province highlights the critical need for integrated approaches that combine advanced recovery techniques with robust environmental governance. future research in China and global mining regions should prioritize three directions: first, strengthening cross-regional collaboration on low-grade mineral separation technologies to address technical bottlenecks in resource recovery; second, integrating tailings utilization with carbon neutrality goals to develop low-carbon activation and recycling processes; and third, establishing international standards for tailings environmental risk prevention to promote green mining practices worldwide, thereby achieving a dynamic balance between mineral resource development and ecological protection.

Author Contributions

X.J.: writing—original draft preparation, validation, formal analysis, investigation, data curation. Y.Z.: writing—review and editing, software, visualization. X.T.: Conceptualization, methodology, resources, supervision, project administration, funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Natural Science Foundation of Hunan Province (Grant No. 2023JJ40042), and Scientific Research Foundation of Hunan Provincial Education Department (22B0335) for which the authors are grateful.

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

Xiaoling Jia was employed by the Hunan Science and Technology Affairs Center. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Yu, J.; Liu, X.; Yang, B.; Li, X.; Wang, P.; Yuan, B.; Wang, M.; Liang, T.; Shi, P.; Li, R.; et al. Major influencing factors identification and probabilistic health risk assessment of soil potentially toxic elements pollution in coal and metal mines across China: A systematic review. Ecotoxicol. Environ. Saf. 2024, 274, 116231. [Google Scholar] [CrossRef]

- Yıldız, T.D. Considering the development levels of countries, contributions of mineral recovery from mining tailings and urban mining wastes to sustainability criteria—A review. Resour. Policy 2024, 99, 105399. [Google Scholar] [CrossRef]

- Feng, Z.; Zhang, Z.; Li, W.; Hao, G.; Xia, X.; Li, P.; Zhu, K. Recent advances in tailings waste as geopolymers for construction: Current challenges and prospects. Miner. Eng. 2025, 230, 109439. [Google Scholar] [CrossRef]

- Kossoff, D.; Dubbin, W.E.; Alfredsson, M.; Edwards, S.J.; Macklin, M.G.; Hudson-Edwards, K.A. Mine tailings dams: Characteristics, failure, environmental impacts, and remediation. Appl. Geochem. 2014, 51, 229–245. [Google Scholar] [CrossRef]

- Krishna, R.S.; Shaikh, F.; Mishra, J.; Lazorenko, G.; Kasprzhitskii, A. Mine tailings-based geopolymers: Properties, applications and industrial prospects. Ceram. Int. 2021, 47, 17826–17843. [Google Scholar] [CrossRef]

- Jamieson, H.E.; Walker, S.R.; Parsons, M.B. Mineralogical characterization of mine waste. Appl. Geochem. 2015, 57, 85–105. [Google Scholar] [CrossRef]

- Lindsay, M.B.J.; Moncur, M.C.; Bain, J.G.; Jambor, J.L.; Ptacek, C.J.; Blowes, D.W. Geochemical and mineralogical aspects of sulfide mine tailings. Appl. Geochem. 2015, 57, 157–177. [Google Scholar] [CrossRef]

- Li, S.; Chen, J.; Gao, W.; Lyu, X.; Liang, Z.; Zhou, W. Current situation and prospects for the clean utilization of gold tailings. Waste Manag. 2024, 180, 149–161. [Google Scholar] [CrossRef]

- Sun, E.; Zhang, X.; Li, Z.; Wang, Y. Tailings Dam Flood Overtopping Failure Evolution Pattern. Procedia Eng. 2012, 28, 356–362. [Google Scholar] [CrossRef]

- Qaidi, S.M.A.; Tayeh, B.A.; Zeyad, A.M.; de Azevedo, A.R.G.; Ahmed, H.U.; Emad, W. Recycling of mine tailings for the geopolymers production: A systematic review. Case Stud. Constr. Mater. 2022, 16, e00933. [Google Scholar] [CrossRef]

- Edraki, M.; Baumgartl, T.; Manlapig, E.; Bradshaw, D.; Franks, D.M.; Moran, C.J. Designing mine tailings for better environmental, social and economic outcomes: A review of alternative approaches. J. Clean. Prod. 2014, 84, 411–420. [Google Scholar] [CrossRef]

- Dimitrova, R.S.; Yanful, E.K. Factors affecting the shear strength of mine tailings/clay mixtures with varying clay content and clay mineralogy. Eng. Geol. 2012, 125, 11–25. [Google Scholar] [CrossRef]

- Adewuyi, S.O.; Anani, A.; Luxbacher, K. Advancing sustainable and circular mining through solid-liquid recovery of mine tailings. Process Saf. Environ. Prot. 2024, 189, 31–46. [Google Scholar] [CrossRef]

- Ertugrul, G.; Goz, E.; Ucar, A. Analysis of Geological, Mechanical and Characteristics of Aggregates Used in Tailings Ponds. Int. J. Econ. Environ. Geol. 2017, 8, 1–7. [Google Scholar] [CrossRef]

- Fisonga, M.; Wang, F.; Mutambo, V. Sustainable utilization of copper tailings and tyre-derived aggregates in highway concrete traffic barriers. Constr. Build. Mater. 2019, 216, 29–39. [Google Scholar] [CrossRef]

- Abbadi, A.; Mucsi, G. A review on complex utilization of mine tailings: Recovery of rare earth elements and residue valorization. J. Environ. Chem. Eng. 2024, 12, 113118. [Google Scholar] [CrossRef]

- Sherlock, E.J.; Lawrence, R.W.; Poulin, R. On the neutralization of acid rock drainage by carbonate and silicate minerals. Environ. Geol. 1995, 25, 43–54. [Google Scholar] [CrossRef]

- Jurjovec, J.; Ptacek, C.J.; Blowes, D.W. Acid neutralization mechanisms and metal release in mine tailings: A laboratory column experiment. Geochim. Cosmochim. Acta 2002, 66, 1511–1523. [Google Scholar] [CrossRef]

- Shi, J.; Pan, W.; Kang, J.; Yu, Z.; Sun, G.; Li, J.; Zheng, K.; Shen, J. Properties of Ultra-High Performance Concrete incorporating iron tailings powder and iron tailings sand. J. Build. Eng. 2024, 83, 108442. [Google Scholar] [CrossRef]

- Song, X.; Xu, H.; Zhou, D.; Yao, K.; Tao, F.; Jiang, P.; Wang, W. Mechanical performance and microscopic mechanism of coastal cemented soil modified by iron tailings and nano silica. Crystals 2021, 11, 1331. [Google Scholar] [CrossRef]

- Onuaguluchi, O.; Eren, Ö. Recycling of copper tailings as an additive in cement mortars. Constr. Build. Mater. 2012, 37, 723–727. [Google Scholar] [CrossRef]

- Ghazi, A.B.; Jamshidi-Zanjani, A.; Nejati, H. Clinkerisation of copper tailings to replace Portland cement in concrete construction. J. Build. Eng. 2022, 51, 104275. [Google Scholar] [CrossRef]

- Çelik, Ö.; Elbeyli, I.Y.; Piskin, S. Utilization of gold tailings as an additive in Portland cement. Waste Manag. Res. 2006, 24, 215–224. [Google Scholar] [CrossRef]

- De Andrade Lima, L.R.P.; Bernardez, L.A.; Barbosa, L.A.D. Characterization and treatment of artisanal gold mine tailings. J. Hazard Mater. 2008, 150, 747–753. [Google Scholar] [CrossRef]

- Chang, N.; Heymann, G.; Clayton, C. The effect of fabric on the behaviour of gold tailings. Géotechnique 2011, 61, 187–197. [Google Scholar] [CrossRef]

- Mashifana, T.; Sithole, T. Clean production of sustainable backfill material from waste gold tailings and slag. J. Clean. Prod. 2021, 308, 127357. [Google Scholar] [CrossRef]

- Zhao, J.; Ni, K.; Su, Y.; Shi, Y. An evaluation of iron ore tailings characteristics and iron ore tailings concrete properties. Constr. Build. Mater. 2021, 286, 122968. [Google Scholar] [CrossRef]

- Cheng, Y.; Huang, F.; Li, W.; Liu, R.; Li, G.; Wei, J. Test research on the effects of mechanochemically activated iron tailings on the compressive strength of concrete. Constr. Build. Mater. 2016, 118, 164–170. [Google Scholar] [CrossRef]

- Carmignano, O.R.; Vieira, S.S.; Teixeira, A.P.C.; Lameiras, F.S.; Brandão, P.R.G.; Lago, R.M. Iron ore tailings: Characterization and applications. J. Braz. Chem. Soc. 2021, 32, 1895–1911. [Google Scholar] [CrossRef]

- Huang, Y.; Hu, N.; Ye, Y.; Ou, Z.; Shi, X. Preparation and pore-forming mechanism of MgO–Al2O3–CaO-based porous ceramics using phosphorus tailings. Ceram. Int. 2022, 48, 29882–29891. [Google Scholar] [CrossRef]

- Yu, Y.; Du, C. Leaching of phosphorus from phosphate tailings and extraction of calcium phosphates: Toward comprehensive utilization of tailing resources. J. Environ. Manag. 2023, 347, 119159. [Google Scholar] [CrossRef]

- Hartikainen, S.H.; Hartikainen, H.H. Phosphorus retention by phlogopite-rich mine tailings. Appl. Geochem. 2008, 23, 2716–2723. [Google Scholar] [CrossRef]

- Li, R.; Yin, Z.; Lin, H. Research status and prospects for the utilization of lead–zinc tailings as building materials. Buildings 2023, 13, 150. [Google Scholar] [CrossRef]

- Shu, W.S.; Ye, Z.H.; Lan, C.Y.; Zhang, Z.Q.; Wong, M.H. Acidification of lead/zinc mine tailings and its effect on heavy metal mobility. Environ. Int. 2001, 26, 389–394. [Google Scholar] [CrossRef]

- Chen, B.; Pang, L.; Zhao, Y.; Fu, P.; Chang, Q.; Sun, L. Effect of activated gold tailings replacing fly ash on the properties of cement-based grouting material. J. Mater. Civ. Eng. 2022, 34, 04022066. [Google Scholar] [CrossRef]

- Panayotova, M. Control of Non-Ferrous Metal-Sulfide Minerals’ Flotation via Pulp Potential. Minerals 2023, 13, 1512. [Google Scholar] [CrossRef]

- Niu, H.; Abdulkareem, M.; Sreenivasan, H.; Kantola, A.M.; Havukainen, J.; Horttanainen, M.; Telkki, V.-V.; Kinnunen, P.; Illikainen, M. Recycling mica and carbonate-rich mine tailings in alkali-activated composites: A synergy with metakaolin. Miner. Eng. 2020, 157, 106535. [Google Scholar] [CrossRef]

- Alcalde, J.; Kelm, U.; Vergara, D. Historical assessment of metal recovery potential from old mine tailings: A study case for porphyry copper tailings, Chile. Miner. Eng. 2018, 127, 334–338. [Google Scholar] [CrossRef]

- Indraratna, B. Geotechnical characterization of blended coal tailings for construction and rehabilitation work. Q. J. Eng. Geol. Hydrogeol. 1994, 27, 353–361. [Google Scholar] [CrossRef]

- Parviainen, A.; Soto, F.; Caraballo, M.A. Revalorization of Haveri Au-Cu mine tailings (SW Finland) for potential reprocessing. J. Geochem. Explor. 2020, 218, 106614. [Google Scholar] [CrossRef]

- Sarker, S.K.; Haque, N.; Bhuiyan, M.; Bruckard, W.; Pramanik, B.K. Recovery of strategically important critical minerals from mine tailings. J. Environ. Chem. Eng. 2022, 10, 107622. [Google Scholar] [CrossRef]

- Lottermoser, B.G. Recycling, reuse and rehabilitation of mine wastes. Elements 2011, 7, 405–410. [Google Scholar] [CrossRef]

- Abaka-Wood, G.B.; Quast, K.; Zanin, M.; Addai-Mensah, J.; Skinner, W. A study of the feasibility of upgrading rare earth elements minerals from iron-oxide-silicate rich tailings using Knelson concentrator and Wilfley shaking table. Powder Technol. 2019, 344, 897–913. [Google Scholar] [CrossRef]

- Falagán, C.; Grail, B.M.; Johnson, D.B. New approaches for extracting and recovering metals from mine tailings. Miner. Eng. 2017, 106, 71–78. [Google Scholar] [CrossRef]

- Xie, L.; van Zyl, D. Distinguishing reclamation, revegetation and phytoremediation, and the importance of geochemical processes in the reclamation of sulfidic mine tailings: A review. Chemosphere 2020, 252, 126446. [Google Scholar] [CrossRef]

- Sabreena; Hassan, S.; Bhat, S.A.; Kumar, V.; Ganai, B.A.; Ameen, F. Phytoremediation of heavy metals: An indispensable contrivance in green remediation technology. Plants 2022, 11, 1255. [Google Scholar] [CrossRef] [PubMed]

- Begum, S.; Rath, S.K.; Rath, C.C. Applications of microbial communities for the remediation of industrial and mining toxic metal waste: A review. Geomicrobiol. J. 2022, 39, 282–293. [Google Scholar] [CrossRef]

- Thavamani, P.; Samkumar, R.A.; Satheesh, V.; Subashchandrabose, S.R.; Ramadass, K.; Naidu, R.; Venkateswarlu, K.; Megharaj, M. Microbes from mined sites: Harnessing their potential for reclamation of derelict mine sites. Environ. Pollut. 2017, 230, 495–505. [Google Scholar] [CrossRef]

- Bednarek, P.S.; Zawala, J.; Kowalczuk, P.B. Polymer-based collectors in flotation: A review. Adv. Colloid Interface Sci. 2025, 335, 103351. [Google Scholar] [CrossRef]

- Bilal, M.; Ito, M.; Akishino, R.; Bu, X.; Hassan, F.U.; Park, I.; Jeon, S.; Aikawa, K.; Hiroyoshi, N. Heterogenous carrier flotation technique for recovering finely ground chalcopyrite particles using coarse pyrite particles as a carrier. Miner. Eng. 2022, 180, 107518. [Google Scholar] [CrossRef]

- Zhou, W.; Sun, Y.; Han, Y.; Gao, P.; Li, Y. Recycling iron from oolitic hematite via microwave fluidization roasting and magnetic separation. Miner. Eng. 2021, 164, 106851. [Google Scholar] [CrossRef]

- Schippers, A.; Hedrich, S.; Vasters, J.; Drobe, M.; Sand, W.; Willscher, S. Biomining: Metal Recovery from Ores with Microorganisms. In Geobiotechnology I: Metal-Related Issues; Schippers, A., Glombitza, F., Sand, W., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; pp. 1–47. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Wang, W.Z.; Yang, C.G. Comprehensive utilization and resources of gold mining tailings. Key Eng. Mater. 2011, 480, 1438–1441. [Google Scholar] [CrossRef]

- Wu, D.; Zhao, R.; Xie, C.; Liu, S. Effect of curing humidity on performance of cemented paste backfill. Int. J. Miner. Metall. Mater. 2020, 27, 1046–1053. [Google Scholar] [CrossRef]

- Sun, W.; Ji, B.; Khoso, S.A.; Tang, H.; Liu, R.; Wang, L.; Hu, Y. An extensive review on restoration technologies for mining tailings. Environ. Sci. Pollut. Res. 2018, 25, 33911–33925. [Google Scholar] [CrossRef]

- Liu, L.; Ruan, S.; Qi, C.; Zhang, B.; Tu, B.; Yang, Q.; Song, K.-I. Co-disposal of magnesium slag and high-calcium fly ash as cementitious materials in backfill. J. Clean Prod. 2021, 279, 123684. [Google Scholar] [CrossRef]

- Maruthupandian, S.; Chaliasou, A.; Kanellopoulos, A. Recycling mine tailings as precursors for cementitious binders–Methods, challenges and future outlook. Constr. Build. Mater. 2021, 312, 125333. [Google Scholar] [CrossRef]

- Carrasco, E.V.M.; Magalhaes, M.D.C.; Santos, W.J.D.; Alves, R.C.; Mantilla, J.N.R. Characterization of mortars with iron ore tailings using destructive and nondestructive tests. Constr. Build. Mater. 2017, 131, 31–38. [Google Scholar] [CrossRef]

- Yinghao, Z.H.O.; Xingyu, L.I.; Ying, L.; Zebao, T.A.; Haoyu, W.U.; Xiaolong, B.I.N.; Zhiya, Q.I.; Liyun, Z.H.N. Application of a composite microbial agent in the restoration of ecologically damaged areas in typical coal mines in Northwest China. Microbiology China 2024, 51, 1391–1404. [Google Scholar]

- Ivannikov, A.L.; Kongar-Syuryun, C.; Rybak, J.; Tyulyaeva, Y. The Reuse of Mining and Construction Waste for Backfill as one of the Sustainable Activities. In IOP Conference Series Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; p. 012130. [Google Scholar]

- Kiventerä, J.; Perumal, P.; Yliniemi, J.; Illikainen, M. Mine tailings as a raw material in alkali activation: A review. Int. J. Miner. Metall. Mater. 2020, 27, 1009–1020. [Google Scholar] [CrossRef]

- Dong, L.; Tong, X.; Li, X.; Zhou, J.; Wang, S.; Liu, B. Some developments and new insights of environmental problems and deep mining strategy for cleaner production in mines. J. Clean. Prod. 2019, 210, 1562–1578. [Google Scholar] [CrossRef]

- Wu, A.; Wang, Y.; Ruan, Z.; Xiao, B.; Wang, J.; Wang, L. Key theory and technology of cemented paste backfill for green mining of metal mines. Green Smart Min. Eng. 2024, 1, 27–39. [Google Scholar] [CrossRef]

- Han, D.; Ferron, R.D. Effect of mixing method on microstructure and rheology of cement paste. Constr. Build. Mater. 2015, 93, 278–288. [Google Scholar] [CrossRef]

- Gou, M.; Zhou, L.; Then, N.W.Y. Utilization of tailings in cement and concrete: A review. Sci. Eng. Compos. Mater. 2019, 26, 449–464. [Google Scholar] [CrossRef]

- Akinyemi, B.A.; Alaba, P.A.; Rashedi, A. Selected performance of alkali-activated mine tailings as cementitious composites: A review. J. Build. Eng. 2022, 50, 104154. [Google Scholar] [CrossRef]

- Illikainen, M.; Kiventerä, J. Chapter 10 Mine Tailings as Precursors for Alkali-Activated Materials and Ettringite Binders. In Characterization, Modification and Applications of Residues; Pöllmann, H., Ed.; De Gruyter: Berlin, Germany, 2021; pp. 345–360. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, J.; Fu, Y.; Long, W.; Dong, B. Synthesis of one-part geopolymers from alkaline-activated molybdenum tailings: Mechanical properties and microstructural evolution. J. Clean. Prod. 2024, 443, 141129. [Google Scholar] [CrossRef]

- Jaabay, D.; Yi, Y.; Ablimityaxar, J.; Li, C.; Chang, X. Fabrication of porous geopolymers from coal fly ash and spodumene flotation tailings through a novel combined saponification/hydrogen peroxide process. Environ. Res. 2025, 269, 120900. [Google Scholar] [CrossRef]

- Jiang, T.; Liu, Z.; Tian, X.; Wu, J.; Wang, L. Review on the impact of metakaolin-based geopolymer’s reaction chemistry, nanostructure and factors on its properties. Constr. Build. Mater. 2024, 412, 134760. [Google Scholar] [CrossRef]

- Singh, N.B.; Middendorf, B. Geopolymers as an alternative to Portland cement: An overview. Constr. Build. Mater. 2020, 237, 117455. [Google Scholar] [CrossRef]

- Tailby, J.; MacKenzie, K.J.D. Structure and mechanical properties of aluminosilicate geopolymer composites with Portland cement and its constituent minerals. Cem. Concr. Res. 2010, 40, 787–794. [Google Scholar] [CrossRef]

- Duxson, P.; Lukey, G.C.; van Deventer, J.S.J. Evolution of gel structure during thermal processing of Na-geopolymer gels. Langmuir 2006, 22, 8750–8757. [Google Scholar] [CrossRef]

- Wan, Q.; Rao, F.; Song, S.; Morales-Estrella, R.; Xie, X.; Tong, X. Chemical forms of lead immobilization in alkali-activated binders based on mine tailings. Cem. Concr. Compos. 2018, 92, 198–204. [Google Scholar] [CrossRef]

- Shvarzman, A.; Kovler, K.; Grader, G.S.; Shter, G.E. The effect of dehydroxylation/amorphization degree on pozzolanic activity of kaolinite. Cem. Concr. Res. 2003, 33, 405–416. [Google Scholar] [CrossRef]

- Tironi, A.; Trezza, M.; Irassar, E.; Scian, A.N. Thermal Treatment of Kaolin: Effect on the Pozzolanic Activity. Procedia Mater. Sci. 2012, 1, 343–350. [Google Scholar] [CrossRef]

- Snellings, R.; Suraneni, P.; Skibsted, J. Future and emerging supplementary cementitious materials. Cem. Concr. Res. 2023, 171, 107199. [Google Scholar] [CrossRef]

- Liu, X.; Liu, X.; Zhang, Z.; Wei, C.; Zeng, Q.; Li, Y.; Ma, S. Investigation of the Pozzolanic Activity Improvement of Yellow Phosphorus Slag with Thermal Activation. Materials 2023, 16, 6047. [Google Scholar] [CrossRef]

- Brittain, H.G. Effects of mechanical processing on phase composition. J. Pharm. Sci. 2002, 91, 1573–1580. [Google Scholar] [CrossRef]

- Chen, B.; Pang, L.; Zhou, Z.; Chang, Q.; Fu, P. Study on the activation mechanism and hydration properties of gold tailings activated by mechanical-chemical-thermal coupling. J. Build. Eng. 2022, 48, 104014. [Google Scholar] [CrossRef]

- Mendes, B.C.; Pedroti, L.G.; Vieira, C.M.F.; Marvila, M.; Azevedo, A.R.G.; De Carvalho, J.M.F.; Ribeiro, J.C.L. Application of eco-friendly alternative activators in alkali-activated materials: A review. J. Build. Eng. 2021, 35, 102010. [Google Scholar] [CrossRef]

- China Nonferrous Metals News. Luoyang Molybdenum Group and Government Jointly Achieve Comprehensive Recovery of Scheelite in Luanchuan. 2010. Available online: https://www.cnmn.com.cn/ShowNews1.aspx?id=168053 (accessed on 1 May 2025).

- Ruixin, Z.; Yanyan, L. Start of Luoyang Molybdenum Group’s Comprehensive Utilization Project of Low-Grade Scheelite. Luoyang Network. 2015. Available online: https://news.lyd.com.cn/system/2015/10/27/010472229.shtml (accessed on 1 May 2025).

- Hongzhao, L.; Hongli, Z. Investigation and Comprehensive Utilization of Mine Tailings of Six Important Mineral Species. Website of China Geological Survey. Zhengzhou Institute of Multipurpose Utilization of Mineral Resources, China Geological Survey. 2019. Available online: http://www.imu.cgs.gov.cn/cgkx/201903/t20190327_477849.html (accessed on 1 May 2025).

- Ministry of Industry and Information Technology. Catalogue of Advanced and Applicable Technologies for Comprehensive Utilization of Industrial Solid Wastes. First Batch. 2013. Available online: https://www.miit.gov.cn/cms_files/filemanager/oldfile/miit/n1146295/n1652858/n1652930/n4509607/c4512849/part/4512851.pdf (accessed on 1 May 2025).

- Yajun, M.; Xiaoyu, L.; Chengxiu, L.; Xing, L. Re-election of Spodumene from Lithium Processing Tailings in Keeryin, Sichuan. Multipurp. Util. Miner. Resour. 2023, 44, 83–87. Available online: https://www.cgsjournals.com/article/doi/10.3969/j.issn.1000-6532.2023.04.013 (accessed on 1 May 2025).

- Xueru, F.; Shuping, L.; Chao, L. Comprehensive Utilization of Sulfur Separation Tailings of High Sulfur Rare Metal Complex Ore in Coal Measure. Multipurp. Util. Miner. Resour. 2023, 44, 169–173. [Google Scholar] [CrossRef]

- Xu, W.; Shen, K.; Cao, Z.; Liu, F.; Zhang, Y.; Zhang, T.; Wu, N.; Ouyang, S. Crystallization and thermal stability effects on tailings glass-ceramics by various heat treating processes. Mater. Chem. Phys. 2021, 263, 124334. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, C.; Li, J.; Wang, W.; Zhao, H.; Li, Y.; Luo, J. Sintering conversion to porous diopside ceramic from geopolymer fabricated by iron tailings and steel slag. Ceram. Int. 2025, 51, 15687–15698. [Google Scholar] [CrossRef]

- Fereydouni, H.; Naseri, T.; Mousavi, S.M. Synergistic recovery of Pr, Eu, and Ce from gold mine tailings using bioleaching and oxalic acid pretreatment. Sci. Rep. 2025, 15, 4478. [Google Scholar] [CrossRef]

- Hunan Provincial Department of Natural Resources. The Song of Xiang People Reso-nates: Geological Strength in Hunan’s Economic and Social Development. 2024. Available online: https://zrzyt.hunan.gov.cn/zrzyt/xxgk/gzdt/zhxw_1/202404/t20240418_33280406.html (accessed on 1 May 2025).

- Hunan Provincial Emergency Management Department. Hunan Province Has Achieved Zero Tailings Ponds Within 3 Kilometers of the Yangtze River Mainstream Shoreline. 2023. Available online: https://www.hunan.gov.cn/topic/fsz/fszyw/202311/t20231116_32406348.html (accessed on 1 May 2025).

- National Bureau of Statistics of China. Office of the Leading Group of the State Coun-cil for the Seventh National Population Census. Major Figures on 2020 Population Census of China. 2021. Available online: https://www.stats.gov.cn/sj/pcsj/rkpc/d7c/202303/P020230301403217959330.pdf (accessed on 1 May 2025).

- Guo, D.; Hou, H.; Long, J.; Guo, X.; Xu, H. Underestimated environmental benefits of tailings resource utilization: Evidence from a life cycle perspective. Environ. Impact Assess. Rev. 2022, 96, 106832. [Google Scholar] [CrossRef]

- Hunan Coal Mine Safety Supervision Bureau. Standardizing Remediation Standards to Ensure Ecological and Environmental Safety of Tailings Ponds. Website of Hunan Coal Mine Safety Supervision Bureau. 2022. Available online: http://www.hunanmj.org.cn/articles/2016/2022-6/75185.html (accessed on 1 May 2025).

- Hua Jing Industrial Research Institute. Analysis on Output Trend, Utilization Rate and Key Enterprises of China’s Tailings Comprehensive Utilization Industry in 2025. Toutiao. 2025. Available online: https://www.toutiao.com/article/7488229918019617295/ (accessed on 1 May 2025).

- Miao, Y. Hunan Successfully Applied for National Demonstration Projects for Three Consecutive Years: Accelerating Ecological Restoration of Legacy Abandoned Mines. Hunan Daily (Electronic Edition). 2024. Available online: https://epaper.voc.com.cn/hnrb/html/2024-06/17/content_1690456.htm (accessed on 1 May 2025).

- Department of Natural Resources of Hunan Province. Overall Plan for Mineral Resources of Hunan Province (2021–2025). 2022. Available online: https://zrzyt.hunan.gov.cn/zrzyt/xxgk/ghjh/202301/29178583/files/4f3a9a31a62e4c17be9909710db7a7bb.pdf (accessed on 1 May 2025).

- Hunan Provincial People’s Government. Outline of the 14th Five-Year Plan for National Economic and Social Development and Long-Term Goals for 2035 of Hunan Province. 2021. Available online: https://www.hunan.gov.cn/szf/hnzb_18/2021/202108/szfwj_98718_88_1rdehshdhnksrcethtptpbuggr/202104/t20210430_16521827.html (accessed on 1 May 2025).

- CCTV. News 1+1 Program Team. Exceeding Standard Rice: It’s More Than Just Talk. 2013. Available online: https://tv.cctv.com/2013/05/20/VIDE1369061639505444.shtml (accessed on 1 May 2025).

- Jian, T.; Weiyan, S.; Tiantian, B. Ten-Year Report Card on Xiangjiang River Pollution Control. CCTV Eco Channel. 2022. Available online: https://eco.cctv.com/2022/08/14/ARTIqmTeb3SulhpEdMeN3DUK220814.shtml (accessed on 1 May 2025).

- People’s Government of Hunan Province. Overall Plan for Mineral Resources of Hunan Province (2000—2010). Website of Yueyang Municipal People’s Government. 2022. Available online: https://zygh.yueyang.gov.cn/30279/content_1616757.html (accessed on 1 May 2025).

- EHS Environment, Health and Safety Network. Hunan: 28,000 Hectares of Land Contaminated by Heavy Metals, Cadmium Exceedance in Xiangjiang River Reaches 1800 Times the Standard. EHS Environment, Health and Safety Network. 2012. Available online: https://www.ehs.cn/article-14099-1.html (accessed on 1 May 2025).

- CCTV. Economic Half-Hour Program Team. “Black Tailings” in Huayuan County. 2018. Available online: https://tv.cctv.com/2018/06/25/VIDEtvnolnqzan4902D48ih6180625.shtml (accessed on 1 May 2025).

- GB 3838-2002; State Environmental Protection Administration, Inspection and Quarantine of the People’s Republic of China. Environmental Quality Standards for Surface Water. Ministry of Ecology and Environment: Beijing, China, 2002.

- Qingyang, X.U.; Liangliang, D.; Zhigang, P.; Jun, Z.; Kaiqi, X.; Hao, G.; Huanhuan, W. Characteristics and health risk evaluation of soil heavy metals in Longshan County, Hunan Province. Geol. China 2025, 52, 834–848. [Google Scholar]

- Guanggui, Z.; Yinan, X.; Yongtao, M. Spatial Distribution Characteristics and Potential Ecological Risk Assessment of Heavy Metals in Typical Water Surface Sediments of Dongting Lake. Res. Environ. Sci. 2015, 28, 1545–1552. [Google Scholar] [CrossRef]

- Li, W.; He, J.; Liu, J.; Chen, S. Environmental Geochemistry and Transportation Behavior of Arsenic and Bacterial Community Analysis in Huangshui Creek. Res. Environ. Sci. 2019, 32, 966–973. [Google Scholar] [CrossRef]

- Jiawen, Z.; Yanci, X.; Guanghui, Y. Study on Spatial Distribution of Heavy Metal Pollution in Xiangtan Manganese Mining Land. Environ. Sci. Manag. 2019, 44, 35–38. [Google Scholar] [CrossRef]

- China Daily. Investigation into the Dam Break Incident of Huayuan Manganese Slag Reservoir in Western Hunan: Tragedy Caused by Ineffective Rectification. 2010. Available online: https://www.chinadaily.com.cn/dfpd/2010-04/14/content_9725506.htm (accessed on 1 May 2025).

- Hunan Provincial People’s Government. Collapse of the Upper Part of the Drainage Shaft of a Tailings Pond in Chenzhou Resulting in 4 People Missing. 2015. Available online: https://www.hunan.gov.cn/hnszf/xxgk/yjgl/tfsj/201511/t20151120_4694596.html (accessed on 1 May 2025).

- Li, H.; Feng, Y.; Li, H.; Liu, Z. Microbial pretreatment of microfine-grained low-grade zinnwaldite tailings for enhanced flotation to recover lithium and rubidium resources. Miner. Eng. 2022, 181, 107503. [Google Scholar] [CrossRef]

- China Nonferrous Metals News. Shizhuyuan Company’s Two Technologies Win First Prize of Science and Technology Progress in Nonferrous Metals Industry. 2021. Available online: https://www.cnmn.com.cn/ShowNews1.aspx?id=425246 (accessed on 1 May 2025).

- Yu, Z. Progress in Research on Lead-Zinc Tailings Resourcing Utilization. 2017. Available online: https://max.book118.com/html/2017/1210/143610256.shtm (accessed on 1 May 2025).

- China Nonferrous Metals News. Facing the New Sun—A Record of Hunan Nonferrous Environmental Protection Building Materials Co., Ltd. 2014. Available online: https://www.cnmn.com.cn/ShowNews1.aspx?id=287620 (accessed on 1 May 2025).

- China Nonferrous Metals News. Serving Green Mine Backfilling, Boosting the Development of ‘Two-Type Construction’—A Review of the High-Quality Development of Feiyi Co., Ltd. 2019. Available online: https://www.cnmn.com.cn/ShowNews1.aspx?id=417820 (accessed on 1 May 2025).

- China Geological Survey. Win-Win Between Beauty and Development—Documentary of Hunan Shizhuyuan Company’s Strengthening of Environmental Protection and Governance. 2018. Available online: http://www.kyb.cgs.gov.cn/ksqy/through/202004/t20200402_620856.html (accessed on 1 May 2025).

- Hunan Provincial Department of Natural Resources. Reply to Proposal No. 1506 of the Second Session of the 13th Hunan Provincial People’s Congress (Xiang Natural Resources Construction Reply [2019] No. 109). 2019. Available online: https://zrzyt.hunan.gov.cn/zrzyt/ztzl/jytabl/jydfnr/201907/t20190731_9371775.html (accessed on 1 May 2025).

- Lazorenko, G.; Kasprzhitskii, A.; Shaikh, F.; Krishna, R.S.; Mishra, J. Utilization potential of mine tailings in geopolymers: Physicochemical and environmental aspects. Process Saf. Environ. Prot. 2021, 147, 559–577. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).