Evaluation of Tight Gas Reservoirs and Characteristics of Fracture Development: A Case Study of the He 8 Member in the Western Sulige Area, Ordos Basin

Abstract

1. Introduction

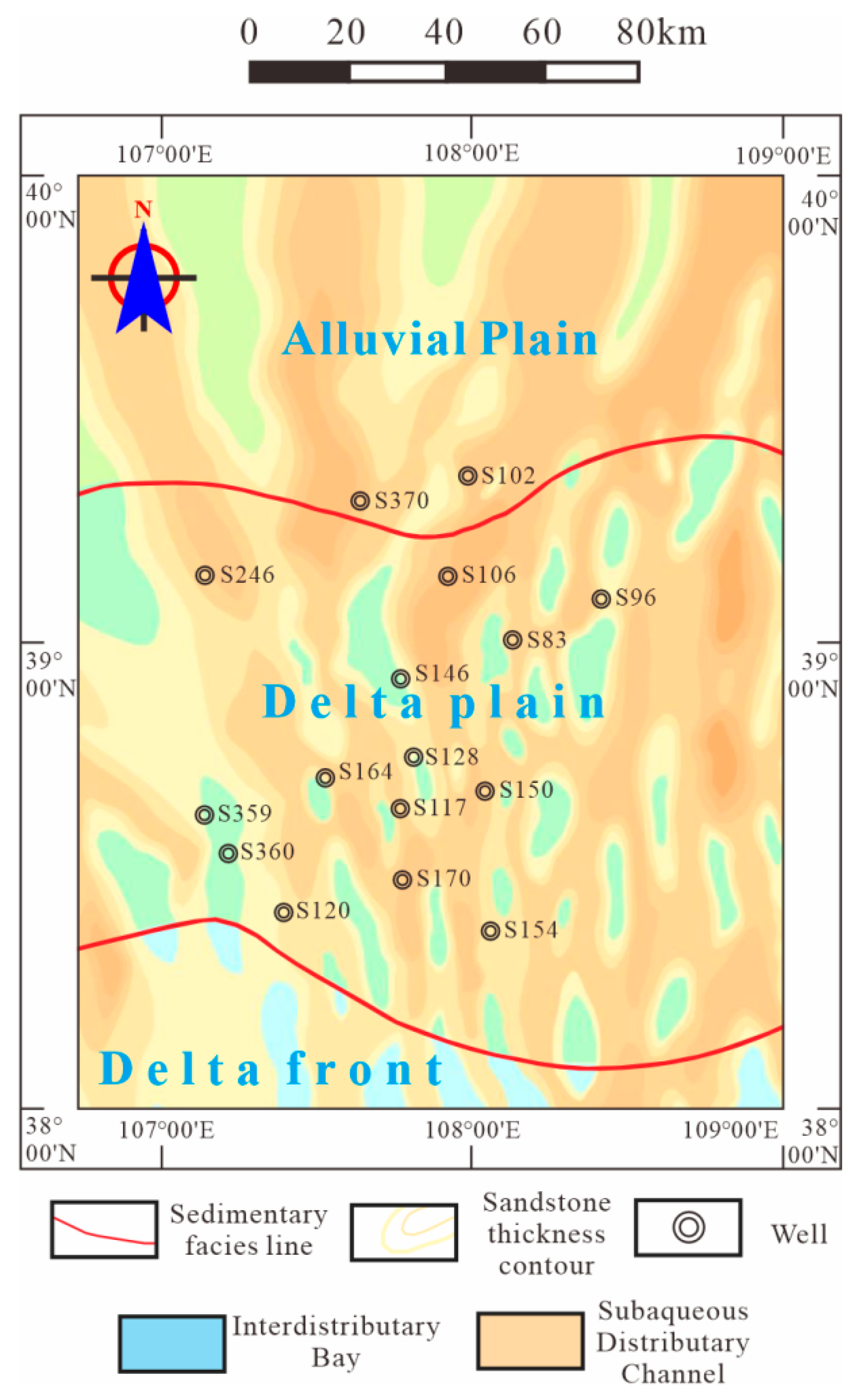

2. Geological Overview of the Study Area

3. Materials and Methods

3.1. Sample Selection

3.2. Core Observation

3.3. Microstructural Characterization

3.4. X-Ray Diffraction (XRD) Analysis

3.5. Uniaxial and Triaxial Rock Stress Sensitivity Experiments

4. Results

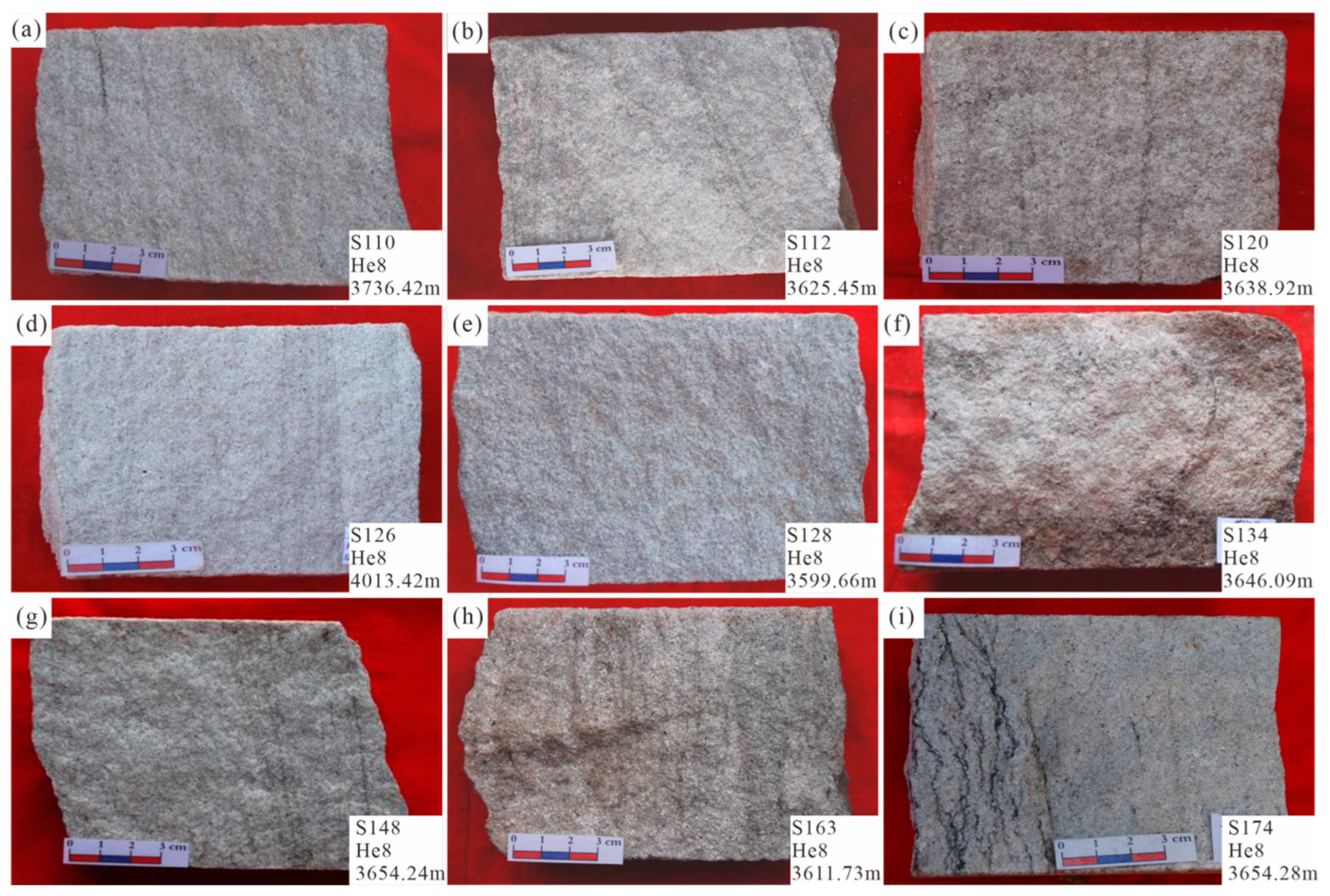

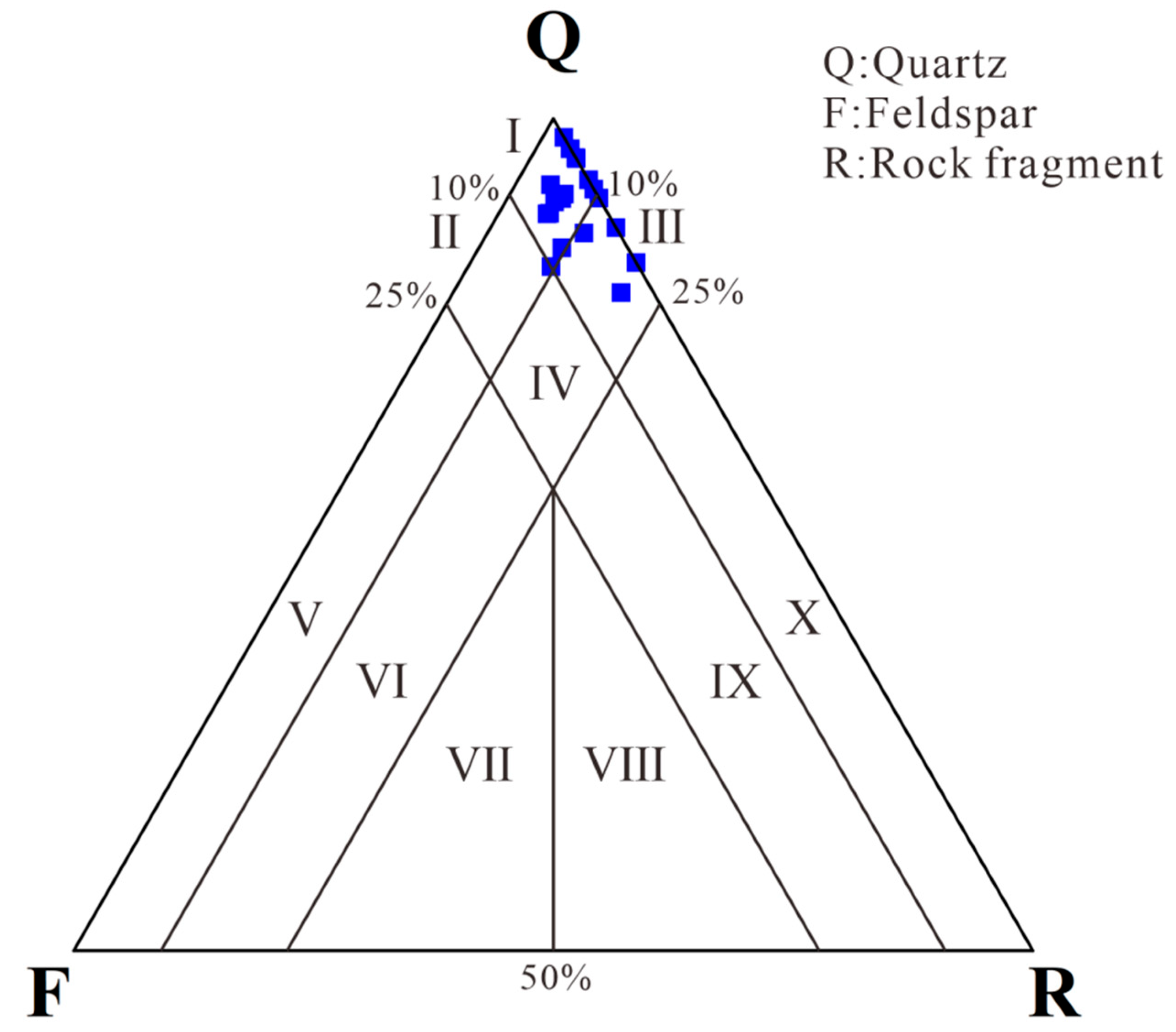

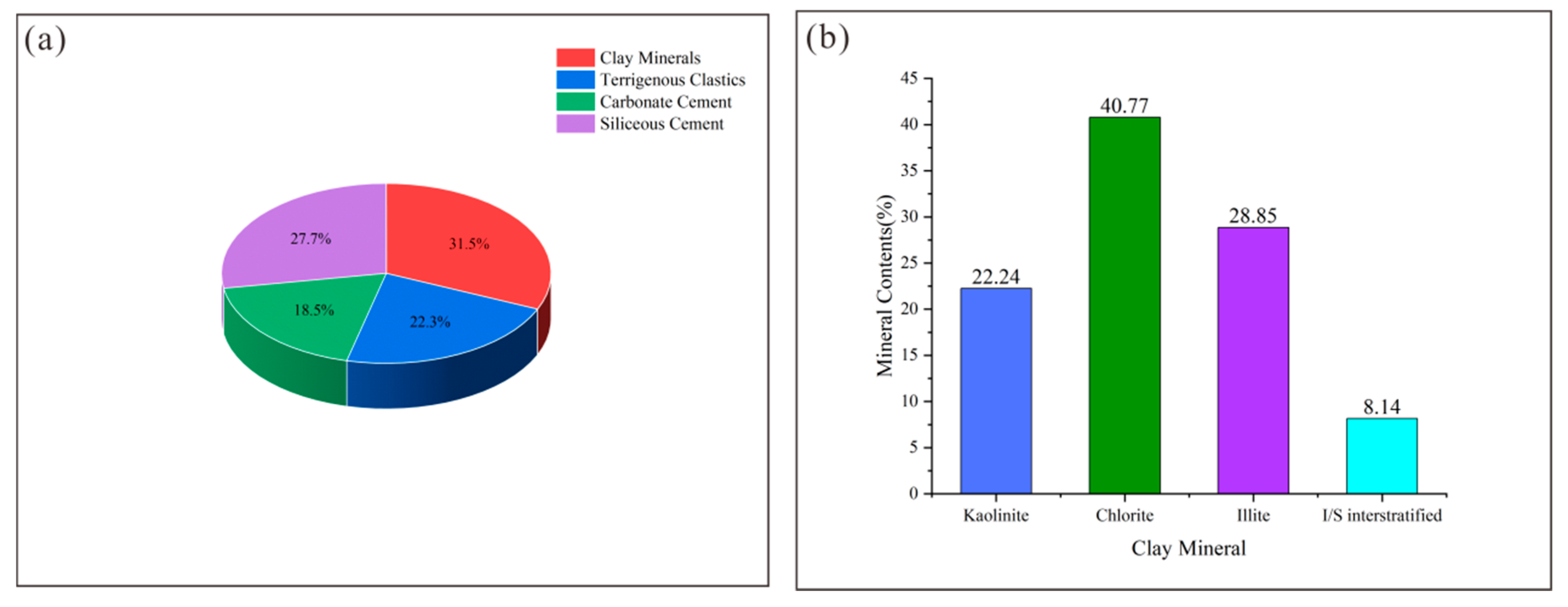

4.1. Lithological Characteristics of Reservoir Rocks

4.2. Microstructural Characteristics of the Reservoir

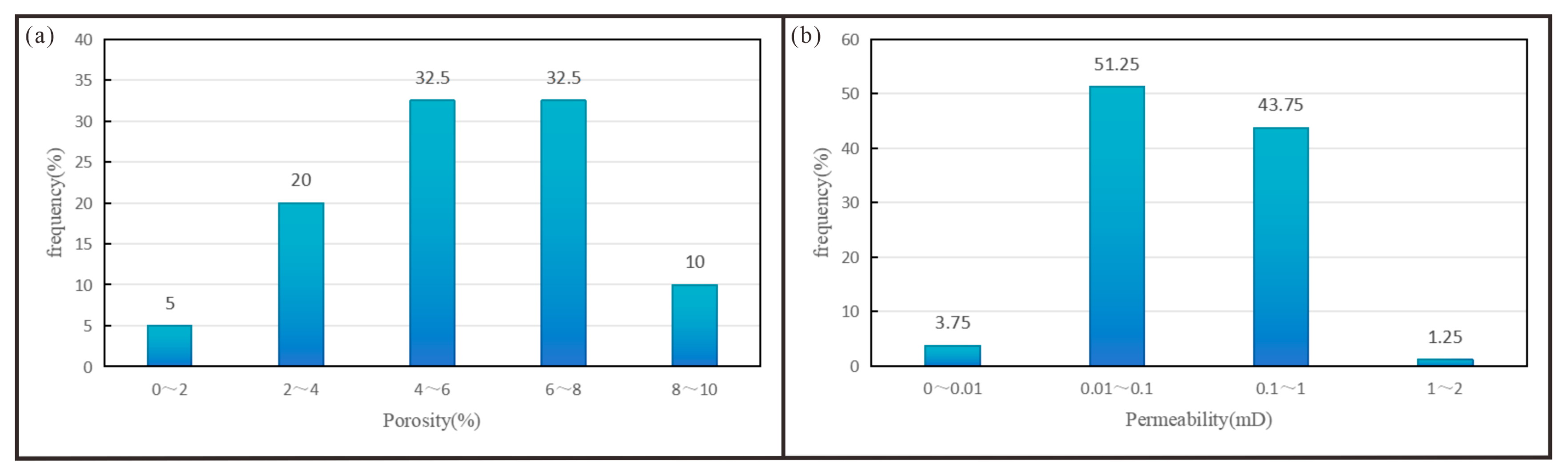

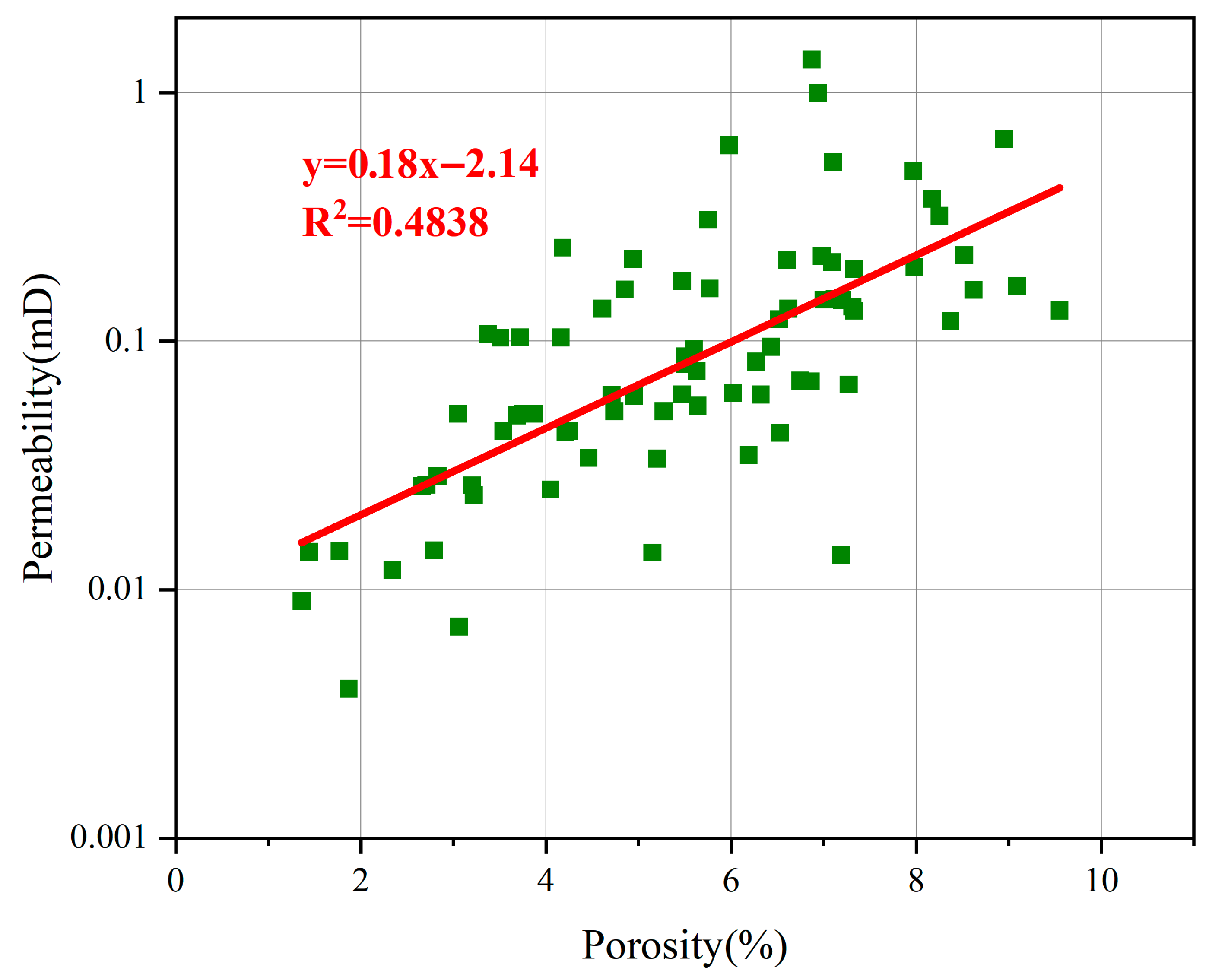

4.3. Reservoir Physical Properties

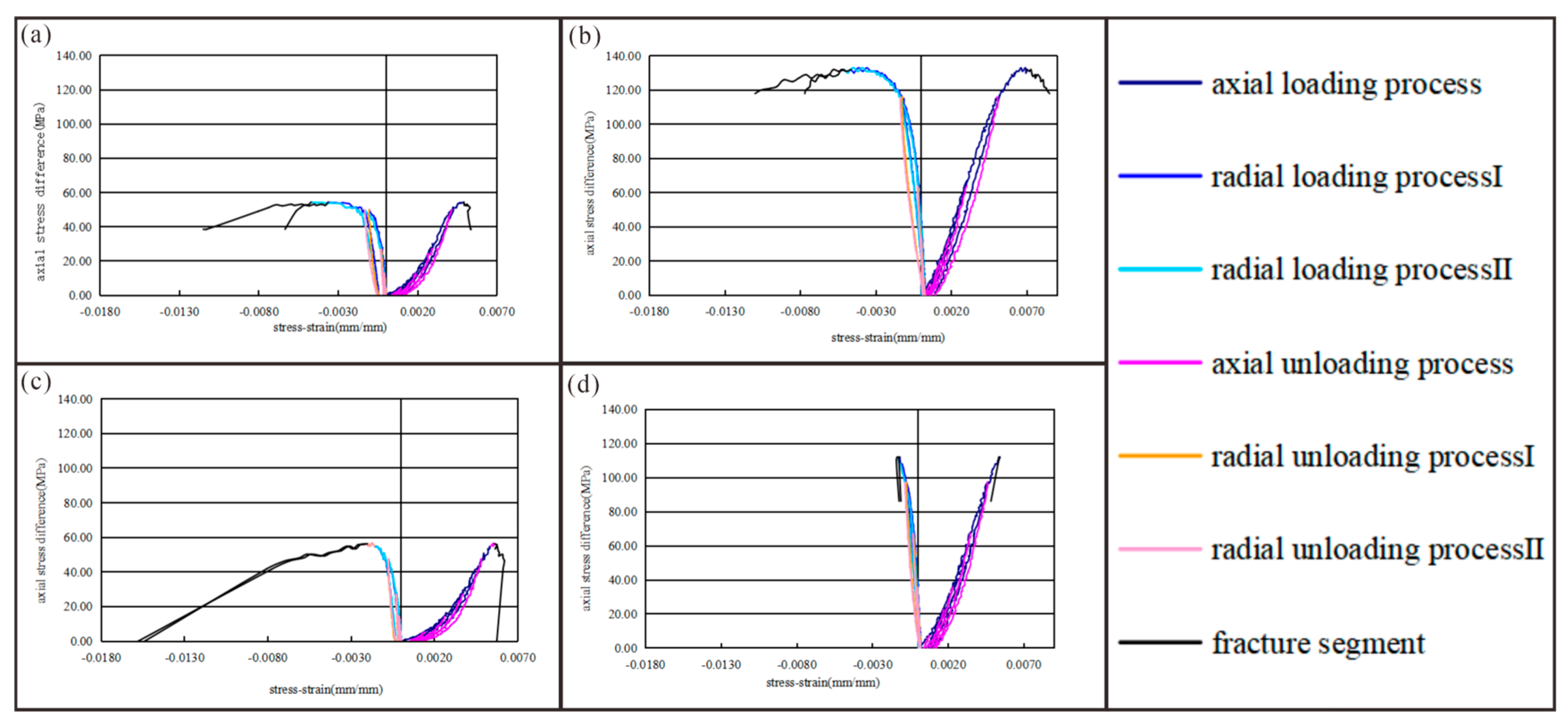

4.4. Rock Mechanical Characteristics

5. Discussion

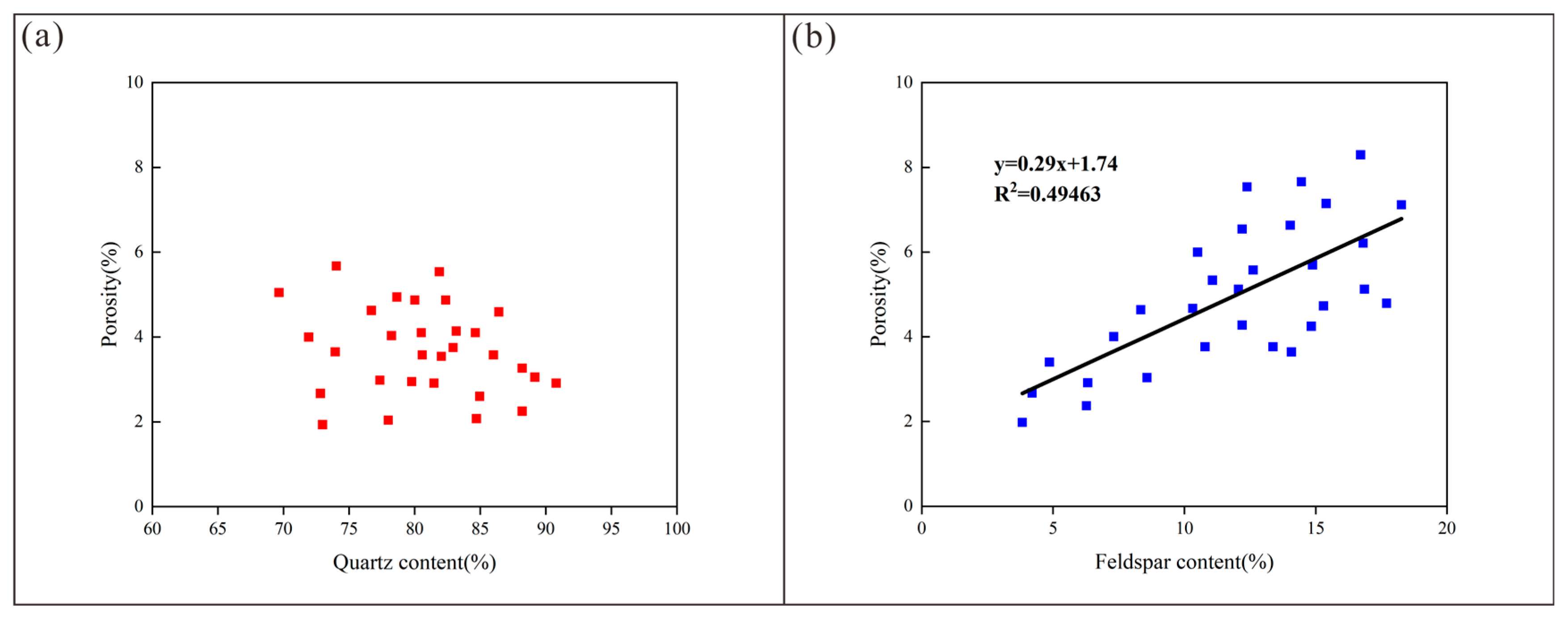

5.1. Influence of Lithology on Reservoir Properties

5.2. Sedimentary Facies Controls on Reservoir Development

5.3. Effect of Diagenesis on Reservoir

5.4. Fracture Formation Characteristics of Tight Reservoir

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, Y.; Cai, X.; Zhao, P. Theoretical understandings and practices of shale gas exploration and development in China. Pet. Explor. Dev. 2018, 45, 561–574. [Google Scholar] [CrossRef]

- Zhao, J. Concepts, classification, and resource potential of unconventional oil and gas. Nat. Gas Geosci. 2012, 23, 393–406. [Google Scholar]

- He, X.; Zhang, P.; Ren, J.; Wang, W.; Lu, B. Exploration and development practices of normal-pressure shale gas in the Dongsheng structural zone, Nanchuan area, southeastern Chongqing. Pet. Geol. Exp. 2023, 45, 1057–1066. [Google Scholar]

- Jia, C.; Pang, X.; Song, Y. Mechanisms of unconventional hydrocarbon accumulation: Hydrocarbon self-sealing and intermolecular forces. Pet. Explor. Dev. 2021, 48, 437–452. [Google Scholar] [CrossRef]

- Fu, J.; Dong, G.; Zhou, X.; Hui, X.; Dan, W.; Fan, L.; Wang, Y.; Zhang, H.; Gu, Y.; Zhou, G. Research progress of petroleum geology and exploration technology in Ordos Basin. China Pet. Explor. 2021, 26, 19. [Google Scholar]

- Yang, H.; Fu, J.; Wei, X. Characteristics of natural gas accumulation in the Ordos Basin. Nat. Gas Ind. 2005, 25, 5–8. [Google Scholar]

- Jin, X.; Mao, C.; Chen, Y.; Chen, Z. Analysis of reservoir characteristics and main controlling factors of He 8 member in Sudong area of The Sulige Gas Field. Miner. Explor. 2024, 15, 53–59. [Google Scholar]

- Yang, T.; Zhang, G.; Liang, K.; Zheng, M.; Guo, B. Global progress in tight gas exploration and development and forecast of China’s trends. Strateg. Study CAE 2012, 14, 64–68+76. [Google Scholar]

- He, D.; Li, D.; Tong, X.; Wu, X. Theory of three-dimensional integrated hydrocarbon exploration in sedimentary basins of China. Oil Gas Geol. 2021, 42, 265–284. [Google Scholar]

- Sun, L.; Zou, C.; Jia, A.; Wei, Y.; Zhu, R.; Wu, S.; Guo, Z. Development characteristics and orientation of tight oil and gas in China. Pet. Explor. Dev. 2019, 46, 1015–1026. [Google Scholar] [CrossRef]

- Tian, B.; Yuan, Y.; Duan, Z.; Tang, J.; Qiu, S.; Zhang, J.; Guo, C. Sandy braided river tight sandstone reservoir characteristics and its main controlling factors-Taking the 8th member of Shihezi Formation in The Sulige Gas Field as an example. Fault Block Oil Gas Field 2024, 31, 387–394+402. [Google Scholar]

- Sun, C.; Huang, W.; Liang, J.; Qian, L.; Zuo, Y.; Liu, F.; Liu, C. Tight sandstone reservoir characteristics and main controlling factors of He 8 member in Block 46 of The Sulige Gas Field. Fault Block Oil Gas Field 2024, 31, 97–206+215. [Google Scholar]

- Yao, J.; Bao, H.; Ren, J.; Sun, L.; Ma, Z. Natural gas exploration under Ordovician salt beds in Ordos Basin. China Pet. Explor. 2015, 20, 1–12. [Google Scholar]

- He, X.; Liu, C.; Wang, J.; Zhao, H.; Wang, F. Paleostructures of the Late Paleozoic in Ordos Basin. J. Palaeogeogr. 2011, 13, 677–686. [Google Scholar]

- Zhao, Z.; Guo, Y.; Wang, Y.; Lin, D. Research progress on tectonic evolution and paleogeographic characteristics of Ordos Basin. Spec. Oil Gas Reserv. 2012, 19, 15–20+151. [Google Scholar]

- Lu, S.; Yan, R.; Yuan, X. Reservoir characteristics and main controlling factors of He8 gas reservoir in southern The Sulige Gas Field. Gas Explor. Dev. 2012, 35, 1–4+81. [Google Scholar]

- SY/T 5368-2016; Identification for Thin Section of Rocks. National Energy Administration: Beijing, China, 2016.

- SY/T 5163-2010; Analysis Method for Clay Minerals and Ordinary Non-Clay Minerals in Sedimentary Rocks by the X-Ray Diffraction. Geology Exploration: Beijing, China, 2010.

- Zhu, X. Sedimentary Petrology; Petroleum Industry Press: Beijing, China, 2008; pp. 109–114. [Google Scholar]

- Liu, X.; Li, S.; Zhou, X.; Chen, X.; Liu, J.; Guo, Q.; Wei, J.; Liao, Y. New fields, new types and resource potential of oil exploration in Ordos Basin. Pet. J. 2023, 44, 2070–2090. [Google Scholar]

| Parameter | Axial Stress Difference | Confining Pressure | Pore Pressure | Simulated Temperature |

|---|---|---|---|---|

| Unit | σd ≤ 1470 KN | Pc ≤ 140 MPa | Pp ≤ 103 MPa | T ≤ 200 °C |

| Sandstone Classification | Quartz Sandstone | Feldspar Quartz Sandstone | Lithic Quartz Sandstone | Feldspar Lithic Quartz Sandstone |

|---|---|---|---|---|

| Proportion | 78% | 27% | 5% | <1% |

| Well | Lithology | Depth (m) | Orientation (H-Parallel to Bedding Plane; V-Perpendicular to Bedding Plane) | Porosity (%) | Air Permeability (mD) |

|---|---|---|---|---|---|

| S117 | Coarse-grained quartz arenite | 3711.64 | IH-1 | 13.4 | 1.33 |

| IV-1 | 13.2 | 1.65 | |||

| IH-2 | 14.9 | 1.61 | |||

| IV-2 | 14.4 | 1.92 | |||

| S128 | Medium-grained quartz arenite | 3256.57 | IIH-1 | 6.0 | 0.136 |

| IIV-1 | 10.1 | 0.183 | |||

| IIH-2 | 5.9 | 0.0755 | |||

| IIV-2 | 6.4 | 0.0825 | |||

| S150 | Mica-bearing fine sandstone | 3469.15 | IIIH-1 | 1.3 | 0.0486 |

| IIIV-1 | 1.3 | 0.0492 | |||

| IIIH-2 | 1.9 | 0.0391 | |||

| IIIV-2 | 2.4 | 0.0317 | |||

| S164 | Siltstone | 3654.18 | IVH-1 | 1.4 | 0.019 |

| IVV-1 | 0.7 | 0.022 | |||

| IVH-2 | 1.6 | 0.019 | |||

| IVV-2 | 0.8 | 0.016 |

| Well | Lithology | Depth (m) | Rock Structural Characteristics (Vertical-to-Bedding) | Orientation H-Parallel to Bedding Plane; V-Perpendicular to Bedding Plane) | Unconfining Pressure Fracture Strength (MPa) | High Confining Pressure Fracture Strength (MPa) | Parallel-to-Bedding vs. Vertical-to-Bedding Strength Comparison | Porosity (%) | Permeability (mD) |

|---|---|---|---|---|---|---|---|---|---|

| S117 | Coarse-grained quartz arenite | 3711.64 | Rocks with Strong Homogeneity | IH-1 | 48.4 | H1 > V1 | 13.4 | 1.33 | |

| IV-1 | 45.4 | 13.2 | 1.65 | ||||||

| IH-2 | 119.1 | H2 > V2 | 14.9 | 1.61 | |||||

| IV-2 | 116.3 | 14.4 | 1.92 | ||||||

| S128 | Medium-grained quartz arenite | 3256.57 | Rocks with Strong Homogeneity | IIH-1 | 72.7 | H1 > V1 | 6.0 | 0.136 | |

| IIV-1 | 54.5 | 10.1 | 0.183 | ||||||

| IIH-2 | 145.3 | H2 > V2 | 5.9 | 0.0755 | |||||

| IIV-2 | 129.2 | 6.4 | 0.0825 | ||||||

| S150 | Mica-bearing fine sandstone | 3469.15 | Rocks with Strong Heterogeneity | IIIH-1 | 34.5 | H1 < V1 | 1.3 | 0.0486 | |

| IIIV-1 | 43.9 | 1.3 | 0.0492 | ||||||

| IIIH-2 | 94.4 | H2 < V2 | 1.9 | 0.0391 | |||||

| IIIV-2 | 120.5 | 2.4 | 0.0317 | ||||||

| S164 | Siltstone | 3654.18 | Rocks with Strong Heterogeneity | IVH-1 | 43.6 | H1 < V1 | 1.4 | 0.019 | |

| IVV-1 | 63.2 | 0.7 | 0.022 | ||||||

| IVH-2 | 120.2 | H2 < V2 | 1.6 | 0.019 | |||||

| IVV-2 | 129.3 | 0.8 | 0.016 |

| Microfacies | Lithology | Sedimentary Structures | Porosity (%) | Permeability (mD) |

|---|---|---|---|---|

| Subaqueous Distributary Channel | Coarse Sandstone | Parallel Lamination | 6.73 | 1.320 |

| Medium Sandstone | Massive Bedding | 5.65 | 0.263 | |

| Mouth Bar | Medium-Fine Sandstone | Massive Bedding | 4.37 | 0.214 |

| Medium-Fine Sandstone | Massive Bedding | 4.26 | 0.148 | |

| Fine Sandstone | Massive Bedding | 3.82 | 0.073 | |

| Interdistributary Bay | Silty Sandstone | Horizontal Lamination | 2.74 | 0.026 |

| Delta Front | Siltstone, Mudstone | Horizontal Lamination | 2.37 | 0.016 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Zhang, J.; Chen, Z.; Wang, W. Evaluation of Tight Gas Reservoirs and Characteristics of Fracture Development: A Case Study of the He 8 Member in the Western Sulige Area, Ordos Basin. Processes 2025, 13, 2838. https://doi.org/10.3390/pr13092838

Zhang Z, Zhang J, Chen Z, Wang W. Evaluation of Tight Gas Reservoirs and Characteristics of Fracture Development: A Case Study of the He 8 Member in the Western Sulige Area, Ordos Basin. Processes. 2025; 13(9):2838. https://doi.org/10.3390/pr13092838

Chicago/Turabian StyleZhang, Zhaoyu, Jingong Zhang, Zhiqiang Chen, and Wanting Wang. 2025. "Evaluation of Tight Gas Reservoirs and Characteristics of Fracture Development: A Case Study of the He 8 Member in the Western Sulige Area, Ordos Basin" Processes 13, no. 9: 2838. https://doi.org/10.3390/pr13092838

APA StyleZhang, Z., Zhang, J., Chen, Z., & Wang, W. (2025). Evaluation of Tight Gas Reservoirs and Characteristics of Fracture Development: A Case Study of the He 8 Member in the Western Sulige Area, Ordos Basin. Processes, 13(9), 2838. https://doi.org/10.3390/pr13092838