Cultivation and Analysis of White Mutant Antrodia cinnamomea with Differing Carbon Sources from Solid and Submerged Culture

Abstract

1. Introduction

2. Materials and Methods

2.1. A. cinnamomea Strains and Preparation

2.2. A. cinnamomea Culture

2.3. Triterpenoid Extraction and Analysis

2.4. Statistical Analysis

3. Results

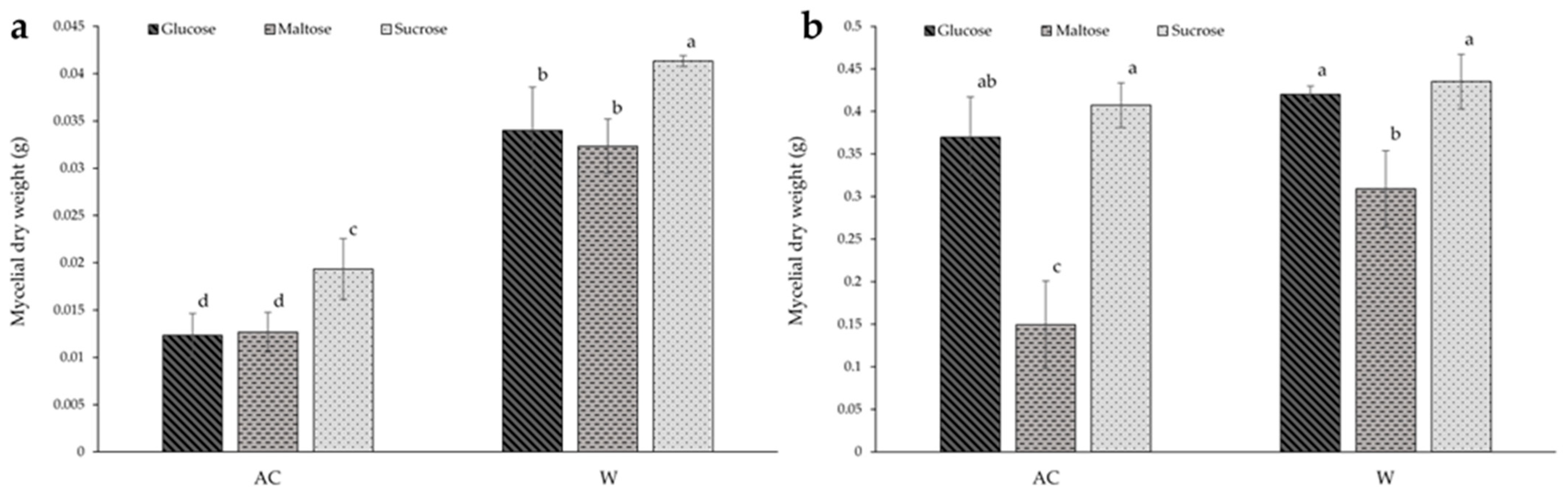

3.1. Effect of Culture Method and Carbohydrate Source on Biomass

3.2. Effect of Culture Method and Carbohydrate Source on Total Triterpenoid Content

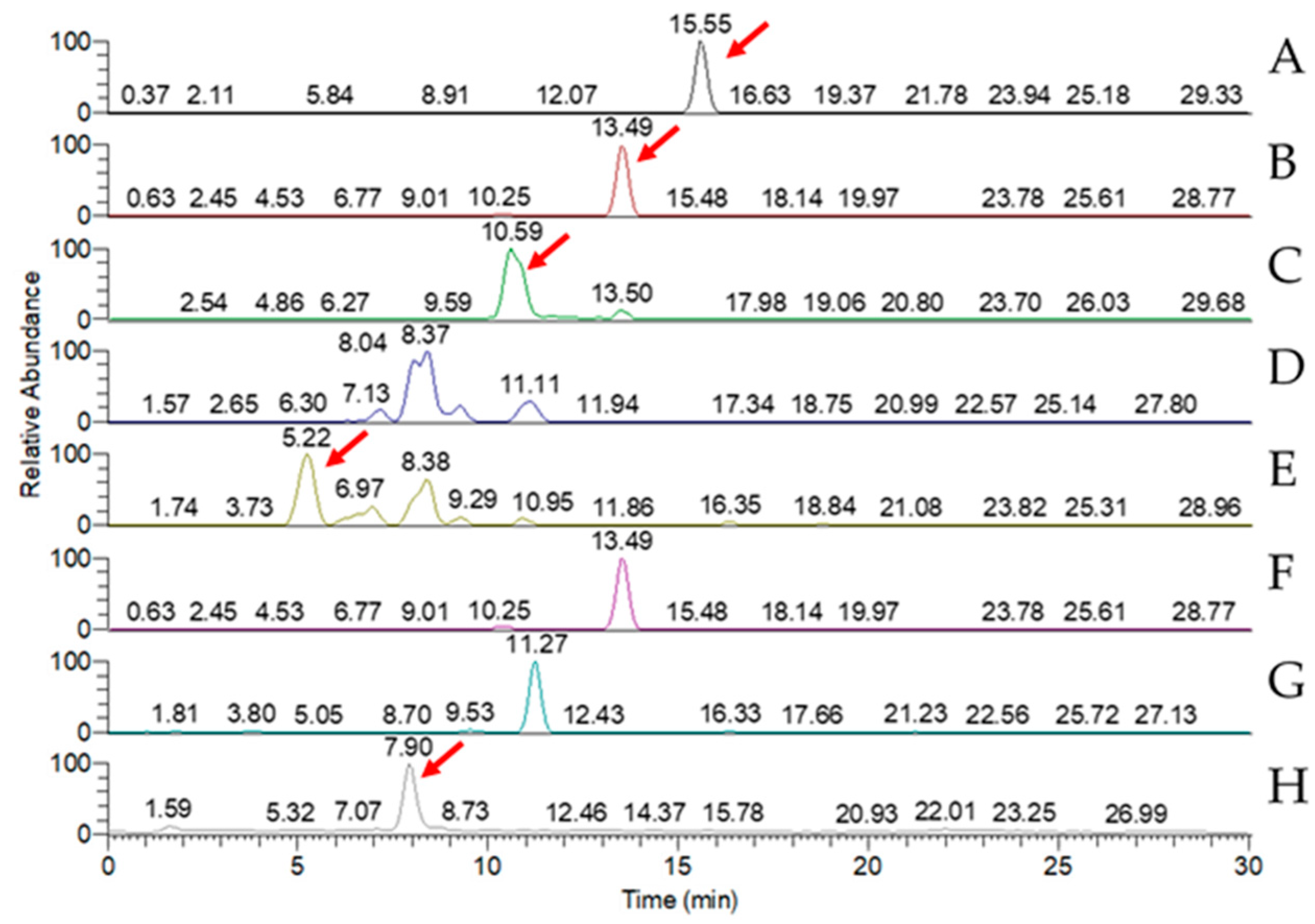

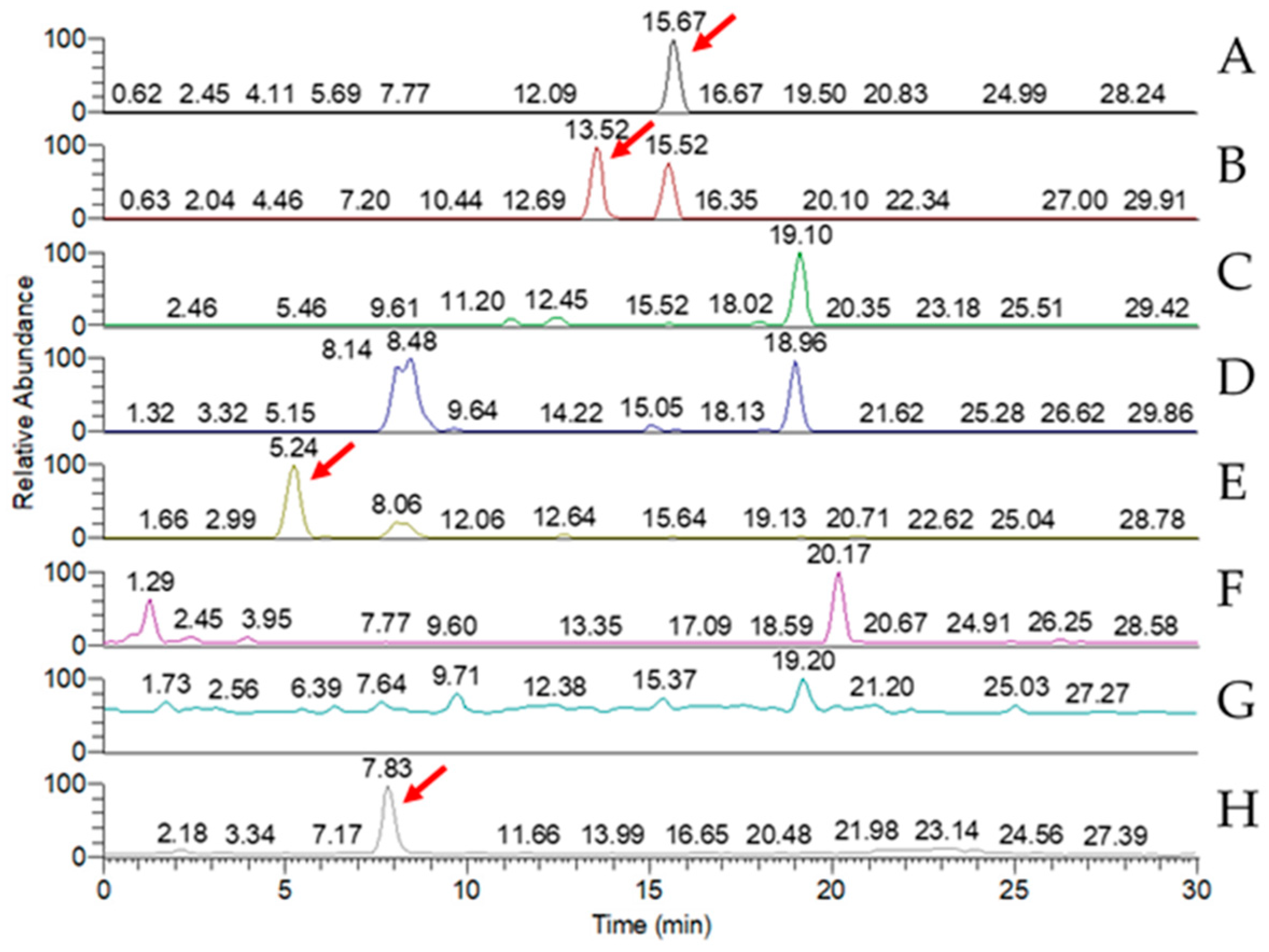

3.3. Effect of Culture Method on Triterpenoid Profiles

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shu, C.H.; Wu, H.J.; Ko, Y.H.; Lin, W.H.; Jaiswal, R. Effects of Red Light and Addition of Monoterpenes and Tangerine oil on the Production of Biomass and Triterpenoids of Antrodia cinnamomea in Submerged Cultures. J. Taiwan Inst. Chem. Eng. 2016, 67, 140–147. [Google Scholar] [CrossRef]

- Senthil Kumar, K.J.; Gokila Vani, M.; Chen, C.Y.; Hsiao, W.W.; Li, J.; Lin, Z.X.; Chu, F.H.; Yen, G.C.; Wang, S.Y. A Mechanistic and Empirical Review of Antcins, A New Class of Phytosterols of Formosan Fungi Origin. J. Food Drug Anal. 2020, 28, 38–59. [Google Scholar] [CrossRef]

- Ma, T.W.; Lai, Y.T.; Chen, L.T.; Yang, F.C. The Cultivation Strategy of Enhancing Triterpenoid Production in Submerged Cultures of Antrodia cinnamomea by Adding Monoterpenes. J. Taiwan Inst. Chem. Eng. 2016, 58, 210–218. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Y.; Yuan, X.L.; Luo, Y.N.; Luo, M.N.; Zheng, Y. Effects of Culture Mechanism of Cinnamomum kanehirae and C. camphora on the Expression of Genes Related to Terpene Biosynthesis in Antrodia cinnamomea. Mycobiology 2022, 50, 121–131. [Google Scholar] [CrossRef]

- Ma, T.W.; Chiu, M.Y.; Yang, F.C. Enhancement of Triterpenoids Formation of Antrodia cinnamomea in thin Stillage-submerged Culture by Shifting the Shaking Rate and Adding Soybean Oil. Asian J. Biotechnol. Bioresour. Technol. 2018, 4, 1–13. [Google Scholar] [CrossRef]

- Chen, Y.T.; Shen, Y.C.; Chang, M.C.; Lu, M.K. Precursor-Feeding Strategy on the Triterpenoid Production and Anti-Inflammatory Activity of Antrodia cinnamomea. Process Biochem. 2016, 51, 941–949. [Google Scholar] [CrossRef]

- Tien, A.J.; Chien, C.Y.; Chen, Y.H.; Lin, L.C.; Chien, C.T. Fruiting Bodies of Antrodia cinnamomea and Its Active Triterpenoid, Antcin K, Ameliorates N-Nitrosodiethylamine-Induced Hepatic Inflammation, Fibrosis and Carcinogenesis in Rats. Am. J. Chin. Med. 2017, 45, 173–198. [Google Scholar] [CrossRef]

- Zhao, S.S.; Leung, K.S. Quality Evaluation of Mycelial Antrodia camphorata using High-Performance Liquid Chromatography (HPLC) Coupled with Diode Array Detector and Mass Spectrometry (DAD-MS). Chin. Med. 2010, 5, 4. [Google Scholar] [CrossRef] [PubMed]

- Chang, T.T.; Wang, W.R. Basidiomatal Formation of Antrodia cinnamomea on Artificial Agar Media. Bot. Bull. Acad. Sin. 2005, 46, 151–154. [Google Scholar]

- Lin, J.Y.; Wu, T.Z.; Chou, J.C. In Vitro Induction of Fruiting Body in Antrodia cinnamomea-A Medicinally Important Fungus. Bot. Stud. 2006, 47, 267–272. [Google Scholar]

- Chu, Y.C.; Yang, R.M.; Chang, T.T.; Chou, J.C. Fructification of Antrodia cinnamomea Was Strain Dependent in Malt Extract Media and Involved Specific Gene Expression. J. Agric. Food Chem. 2010, 58, 257–261. [Google Scholar] [CrossRef]

- He, Y.C.; He, K.Z.; Pu, Q.; Li, J.; Zhao, Z.J. Optimization of Cultivating Conditions for Triterpenoids Production from Antrodia cinnamomea. Indian J. Microbiol. 2012, 52, 648–653. [Google Scholar] [CrossRef]

- Moore-Landecker, E. Effects of Medium Composition and Light on Formation of Apothecia and Sclerotia by Pyronema domesticum. Can. J. Bot. 1987, 65, 2276–2279. [Google Scholar] [CrossRef]

- Lee, I.H.; Chen, C.T.; Chen, H.C.; Hsu, W.C.; Lu, M.K. Sugar Flux in Response to Carbohydrate-Feeding of Cultured Antrodia camphorata, a Recently Described Medicinal Fungus in Taiwan. J. Chin. Med. 2002, 13, 21–31. [Google Scholar] [CrossRef]

- Chang, C.Y.; Lee, C.L.; Pan, T.M. Statistical Optimization of Medium Components for the Production of Antrodia cinnamomea AC0623 in Submerged Cultures. Appl. Microbiol. Biotechnol. 2006, 72, 654–661. [Google Scholar] [CrossRef] [PubMed]

- Yang, F.C.; Huang, H.C.; Yang, M.J. The Influence of Environmental Conditions on the Mycelial Growth of Antrodia cinnamomea in Submerged Cultures. Enzym. Microb. Technol. 2003, 33, 395–402. [Google Scholar] [CrossRef]

- Lin, E.S.; Wang, C.C.; Sung, S.C. Cultivating Conditions Influence Lipase Production by the Edible Basidiomycete Antrodia cinnamomea in Submerged Culture. Enzym. Microb. Technol. 2006, 39, 98–102. [Google Scholar] [CrossRef]

- Geng, Y.; He, Z.; Lu, Z.M.; Xu, H.Y.; Xu, G.H.; Shi, J.S.; Xu, Z.H. Antrodia camphorata ATCC 200183 Sporulates Asexually in Submerged Culture. Appl. Microbiol. Biotechnol. 2013, 97, 2851–2858. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.L. Chemical Variation of White Antrodia cinnamomea from Regular Antrodia cinnamomea; National Dong Hwa University: Hualien, Taiwan, 2013. [Google Scholar]

- Chung, C.H.; Yeh, S.C.; Tseng, H.C.; Siu, M.L.; Lee, K.T. Chemical Quality Evaluation of Antrodia cinnamomea Fruiting Bodies using Phytomics Similarity Index Analysis. J. Food Drug Anal. 2016, 24, 173–178. [Google Scholar] [CrossRef] [PubMed]

- Chen, W.L.; Ho, Y.P.; Chou, J.C. Phenologic Variation of Major Triterpenoids in Regular and White Antrodia cinnamomea. Bot. Stud. 2016, 57, 33. [Google Scholar] [CrossRef]

- Liu, K.C. The Effect of Different Solid Plate Medium Culture on Mycelium Growth and Polysaccharides Content of White Antrodia cinnamomea; National Pingtung University of Science and Technology: Pingtung, Taiwan, 2019. [Google Scholar]

- Chen, Y.; Xie, M.Y.; Gong, X.F. Microwave-assisted extraction used for the isolation of total triterpenoid saponins from. J. Food Eng. 2007, 81, 162–170. [Google Scholar] [CrossRef]

- Fazenda, M.L.; Seviour, R.; McNeil, B.; Harvey, L.M. Submerged Culture Fermentation of “Higher Fungi”: The Macrofungi. Adv. Appl. Microbiol. 2008, 63, 33–103. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.B.; Guan, Y.Y.; Hu, P.F.; Chen, L.; Xu, G.R.; Liu, L.M.; Cheung, P.C.K. Production of Bioactive Metabolites by Submerged Fermentation of the Medicinal Mushroom Antrodia cinnamomea: Recent Advances and Future Development. Crit. Rev. Biotechnol. 2019, 39, 541–554. [Google Scholar] [CrossRef]

- Gibbs, P.A.; Seviour, R.J.; Schmid, F. Growth of Filamentous Fungi in Submerged Culture: Problems and Possible Solutions. Crit. Rev. Biotechnol. 2000, 20, 17–48. [Google Scholar] [CrossRef] [PubMed]

- Stark, B.C.; Dikshit, K.L.; Pagilla, K.R. Recent Advances in Understanding the Structure, Function, and Biotechnological Usefulness of the Hemoglobin from the bacterium Vitreoscilla. Biotechnol. Lett. 2011, 33, 1705–1714. [Google Scholar] [CrossRef]

- Wei, X.X.; Chen, G.Q. Applications of the VHb Gene for Improved Microbial Fermentation Processes. Method Enzym. 2008, 436, 273–287. [Google Scholar] [CrossRef]

- Barrios-González, J.; Tarragó-Castellanos, M.R. Solid-State Fermentation: Special Physiology of Fungi. In Fungal metabolites; Reference Series in Phytochemistry; Merillon, J.M., Ramawat, K., Eds.; Springer: Cham, Switzerland, 2015; pp. 319–347. [Google Scholar] [CrossRef]

- Barrios-González, J. Solid-State Fermentation: Physiology of Solid Medium, Its Molecular Basis and Applications. Process Biochem. 2012, 47, 175–185. [Google Scholar] [CrossRef]

- Rahardjo, Y.S.P.; Tramper, J.; Rinzema, A. Modeling Conversion and Transport Phenomena in Solid-State Fermentation: A Review and Perspectives. Biotechnol. Adv. 2006, 24, 161–179. [Google Scholar] [CrossRef]

- Acuña-Argüelles, M.E.; Gutiérrez-Rojas, M.; Viniegra-González, G.; Favela-Torres, E. Production and Properties of Three Pectinolytic Activities Produced by Aspergillus niger in Submerged and Solid-State Fermentation. Appl. Microbiol. Biotechnol. 1995, 43, 808–814. [Google Scholar] [CrossRef]

- Shih, I.L.; Pan, K.; Hsieh, C.Y. Influence of Nutritional Components and Oxygen Supply on the Mycelial Growth and Bioactive Metabolites Production in Submerged Culture of Antrodia cinnamomea. Process Biochem. 2006, 41, 1129–1135. [Google Scholar] [CrossRef]

- Magel, E.; Einig, W.; Hampp, R. Carbohydrates in Trees. In Developments in Crop Science; Gupta, A.K., Kaur, N., Eds.; Elsevier: Amsterdam, The Netherlands, 2000; Volume 26, pp. 317–336. [Google Scholar]

- Shen, Y.C.; Chou, C.J.; Wang, Y.H.; Chen, C.F.; Chou, Y.C.; Lu, M.K. Anti-Inflammatory Activity of the Extracts from Mycelia of Antrodia camphorata Cultured with Water-Soluble Fractions from Five Different Cinnamomum Species. FEMS Microbiol. Lett. 2004, 231, 137–143. [Google Scholar] [CrossRef]

- Hsu, F.L.; Chou, C.J.; Chang, Y.C.; Chang, T.T.; Lu, M.K. Promotion of Hyphal Growth and Underlying Chemical Changes in Antrodia camphorata by Host Factors from Cinnamomum camphora. Int. J. Food Microbiol. 2006, 106, 32–38. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Yuan, X.; Wang, J.; Yang, Y.; Zheng, Y. Transcriptome Profiling of Antrodia cinnamomea Fruiting Bodies Grown on Cinnamomum kanehirae and C. camphora Wood Substrates. Res. Square, 2023; preprint. [Google Scholar] [CrossRef]

- Noushahi, H.A.; Khan, A.H.; Noushahi, U.F.; Hussain, M.; Javed, T.; Zafar, M.; Batool, M.; Ahmed, U.; Liu, K.; Harrison, M.T.; et al. Biosynthetic Pathways of Triterpenoids and Strategies to Improve their Biosynthetic Efficiency. Plant Growth Regul. 2022, 97, 439–454. [Google Scholar] [CrossRef]

- Pietrocola, F.; Galluzzi, L.; Bravo-San Pedro, J.M.; Madeo, F.; Kroemer, G. Acetyl Coenzyme A: A Central Metabolite and Second Messenger. Cell Metab. 2015, 21, 805–821. [Google Scholar] [CrossRef]

- Su, C.H.; Hsieh, Y.C.; Chng, J.Y.; Lai, M.N.; Ng, L.T. Metabolomic Profiling of Different Antrodia cinnamomea Phenotypes. J. Fungi 2023, 9, 97. [Google Scholar] [CrossRef]

- Qiao, X.; Song, W.; Wang, Q.; Liu, K.D.; Zhang, Z.X.; Bo, T.; Li, R.Y.; Liang, L.N.; Tzeng, Y.M.; Guo, D.A.; et al. Comprehensive Chemical Analysis of Triterpenoids and Polysaccharides in the Medicinal Mushroom Antrodia cinnamomea. RSC Adv. 2015, 5, 47040–47052. [Google Scholar] [CrossRef]

- Chang, T.T.; Wang, W.R.; Chou, C.J. Differentiation of Mycelia and Basidiomes of Antrodia cinnamomea using Certain Chemical Components. Taiwan J. For. Sci. 2011, 26, 125–133. [Google Scholar]

- Lin, T.Y.; Chen, C.Y.; Chien, S.C.; Hsiao, W.W.; Chu, F.H.; Li, W.H.; Lin, C.C.; Shaw, J.F.; Wang, S.Y. Metabolite Profiles for Antrodia cinnamomea Fruiting Bodies Harvested at Different Culture Ages and from Different Wood Substrates. J. Agric. Food Chem. 2011, 59, 7626–7635. [Google Scholar] [CrossRef] [PubMed]

- Lu, Z.M.; Geng, Y.; Li, H.X.; Sun, Q.; Shi, J.S.; Xu, Z.H. Alpha-Terpineol Promotes Triterpenoid Production of Antrodia cinnamomea in Submerged Culture. FEMS Microbiol. Lett. 2014, 358, 36–43. [Google Scholar] [CrossRef]

- Li, H.X.; Lu, Z.M.; Geng, Y.; Gong, J.S.; Zhang, X.J.; Shi, J.S.; Xu, Z.H.; Ma, Y.H. Efficient Production of Bioactive Metabolites from Antrodia camphorata ATCC 200183 by Asexual Reproduction-Based Repeated Batch Fermentation. Bioresour. Technol. 2015, 194, 334–343. [Google Scholar] [CrossRef] [PubMed]

- Zeng, W.W.; Chen, T.C.; Liu, C.H.; Wang, S.Y.; Shaw, J.F.; Chen, Y.T. Identification and Isolation of an Intermediate Metabolite with Dual Antioxidant and Anti-Proliferative Activity Present in the Fungus Antrodia cinnamomea Cultured on an Alternative Medium with Cinnamomum kanehirai Leaf Extract. Plants 2021, 10, 737. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.C.; Wu, T.Y.; Hsu, T.H.; Lai, M.N.; Wu, Y.C.; Ng, L.T. Chemical Composition and Chronic Toxicity of Disc-Cultured Antrodia cinnamomea Fruiting Bodies. Toxics 2022, 10, 587. [Google Scholar] [CrossRef] [PubMed]

| Culture Method | Triterpenoid Content (µg/g) | ||||

|---|---|---|---|---|---|

| Antcin A | Antcin B | Antcin C | Antcin K | DMMB | |

| Solid-State | 0.46 ± 0.01 | 3.58 ± 0.19 | 1.09 ± 0.01 | 0.14 ± 0.01 | 0.21 ± 0.01 |

| Submerged | 0.02 ± 0.01 | 0.03 ± 0.01 | - | 0.02 ± 0.01 | 0.26 ± 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mu, S.Y.; Sheng, C.R.; Li, P. Cultivation and Analysis of White Mutant Antrodia cinnamomea with Differing Carbon Sources from Solid and Submerged Culture. Processes 2025, 13, 2732. https://doi.org/10.3390/pr13092732

Mu SY, Sheng CR, Li P. Cultivation and Analysis of White Mutant Antrodia cinnamomea with Differing Carbon Sources from Solid and Submerged Culture. Processes. 2025; 13(9):2732. https://doi.org/10.3390/pr13092732

Chicago/Turabian StyleMu, Shu Yu, Cheng Ren Sheng, and Pomin Li. 2025. "Cultivation and Analysis of White Mutant Antrodia cinnamomea with Differing Carbon Sources from Solid and Submerged Culture" Processes 13, no. 9: 2732. https://doi.org/10.3390/pr13092732

APA StyleMu, S. Y., Sheng, C. R., & Li, P. (2025). Cultivation and Analysis of White Mutant Antrodia cinnamomea with Differing Carbon Sources from Solid and Submerged Culture. Processes, 13(9), 2732. https://doi.org/10.3390/pr13092732