Evaluation of Temperature- and Salt-Resistant Foam Acid and Study of Foam Diversion Mechanism

Abstract

1. Introduction

2. Experimental Section

2.1. Experimental Materials

2.2. Preparation of the Foam Acid System

2.3. Foamability and Foam Stability Measurement

2.4. Test of Temperature and Salt Resistance of the Foam Acid System

2.4.1. Salinity Resistance Test

2.4.2. Temperature Resistance Test

2.5. Retarding Performance Test of the Foam Acid System

2.6. Scanning Electron Microscopy Testing of Cores

2.7. Experimental Study of Foam Diversion

2.7.1. Plugging Experiment of Foam in Single Core

2.7.2. Divided-Flow Experiment of Foam in Parallel Cores

3. Results and Discussion

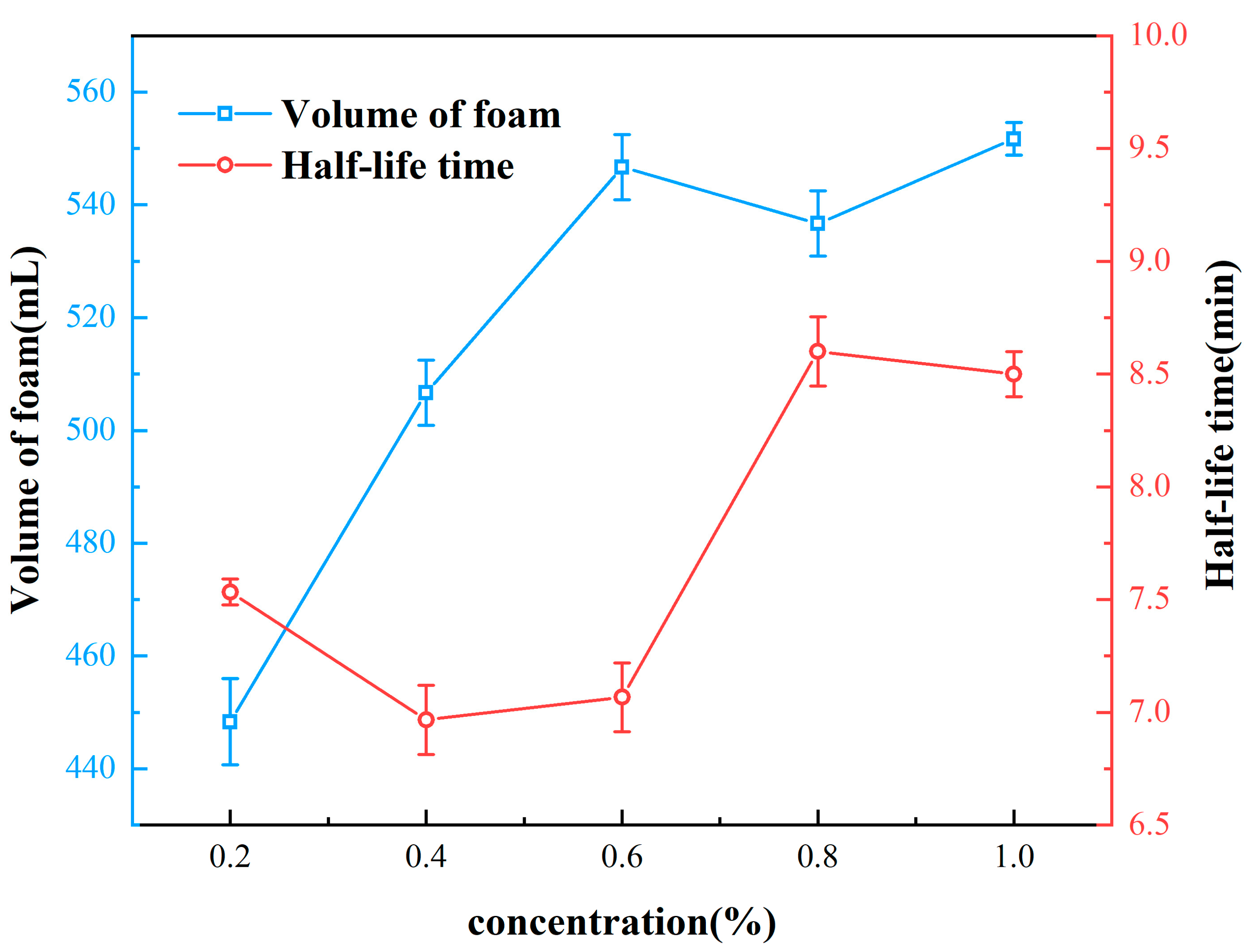

3.1. Foamability and Foam Stability of the Foam Acid System

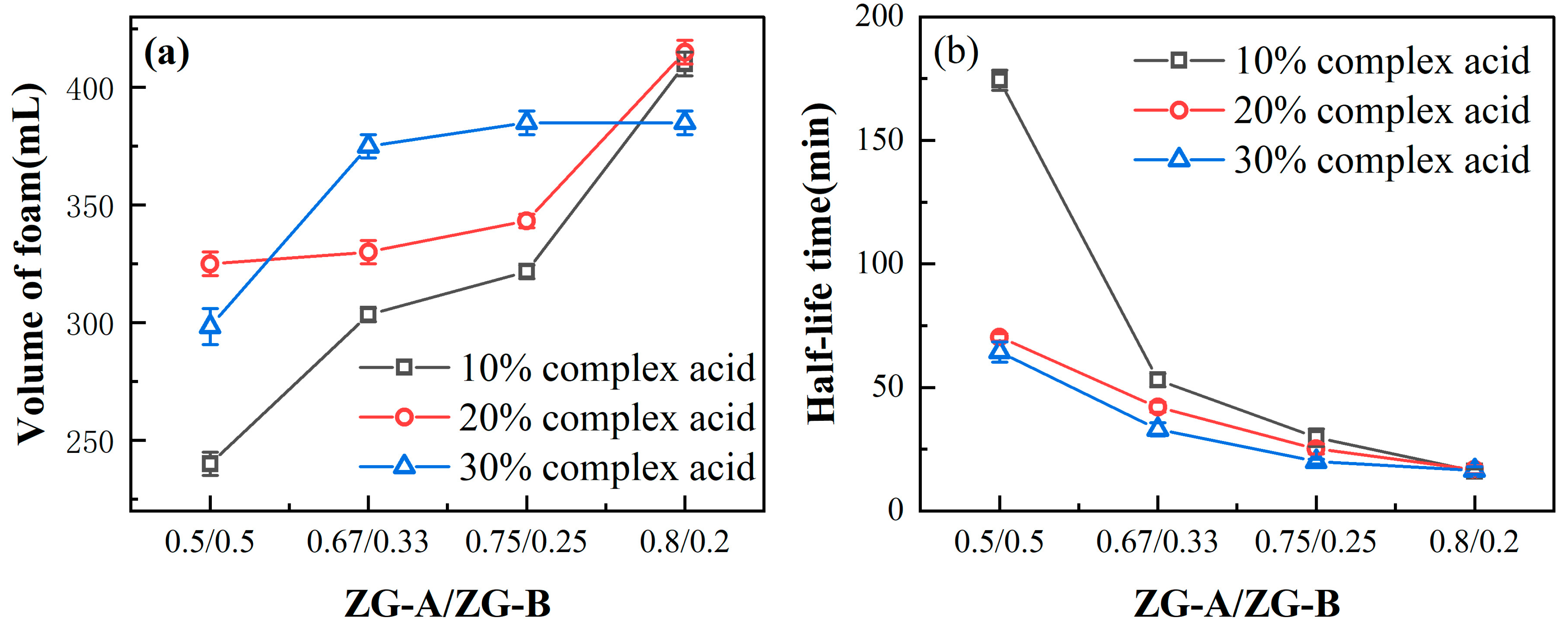

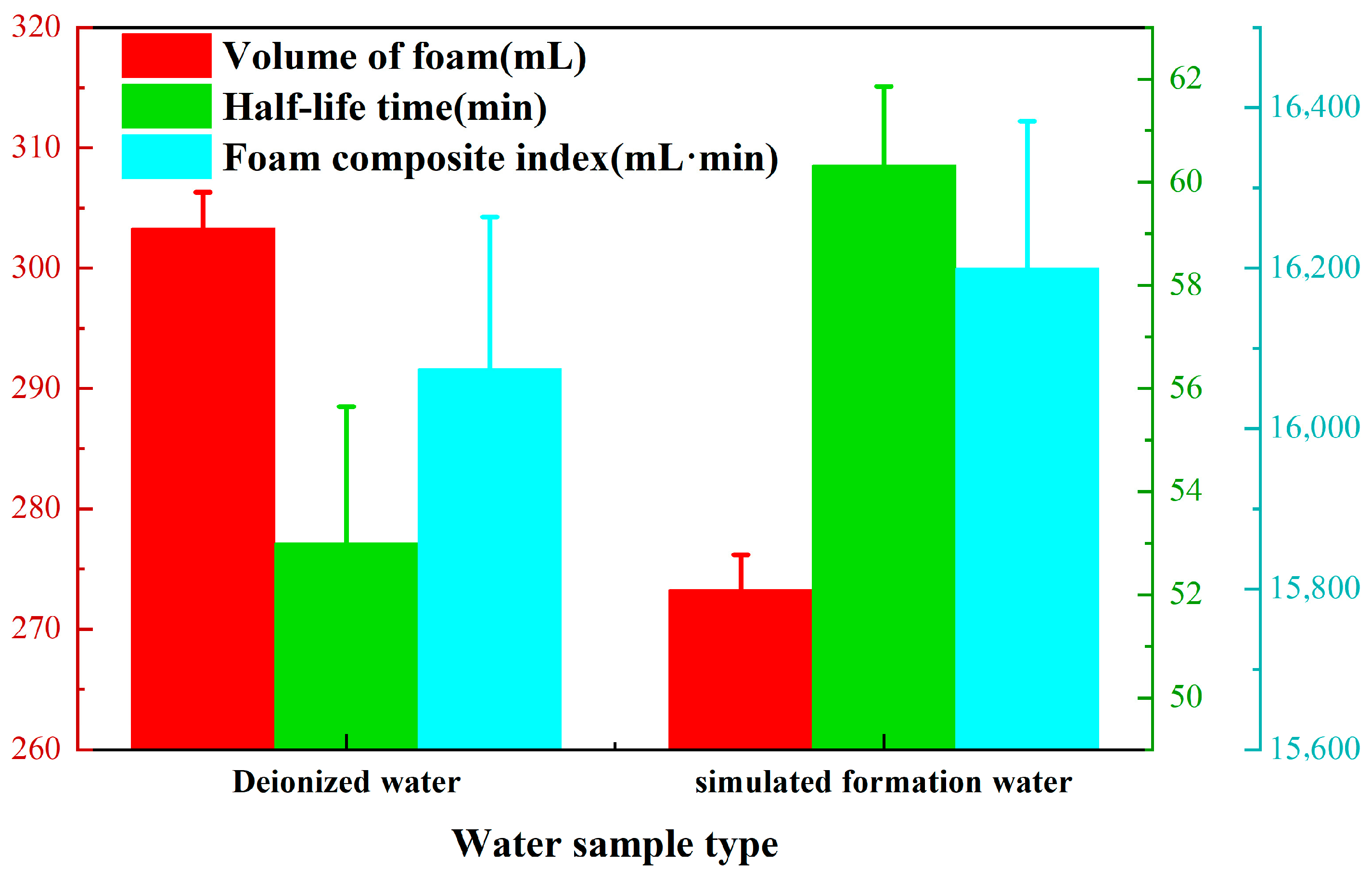

3.2. Temperature and Salt Resistance of the Foam Acid System

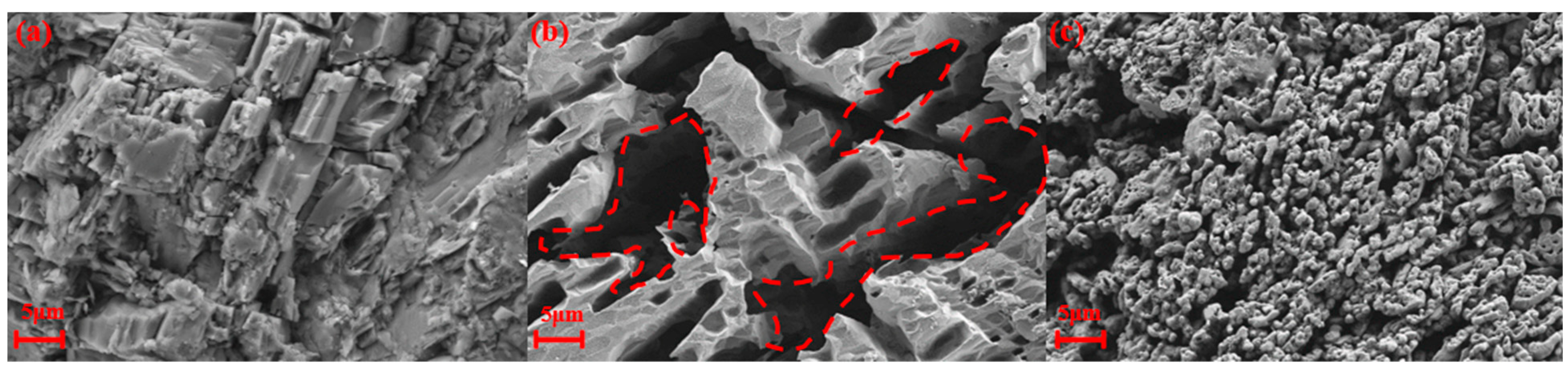

3.3. Retarding Performance of the Foam Acid System

3.4. Study of the Mechanism of Foam Fluid Divided Flow

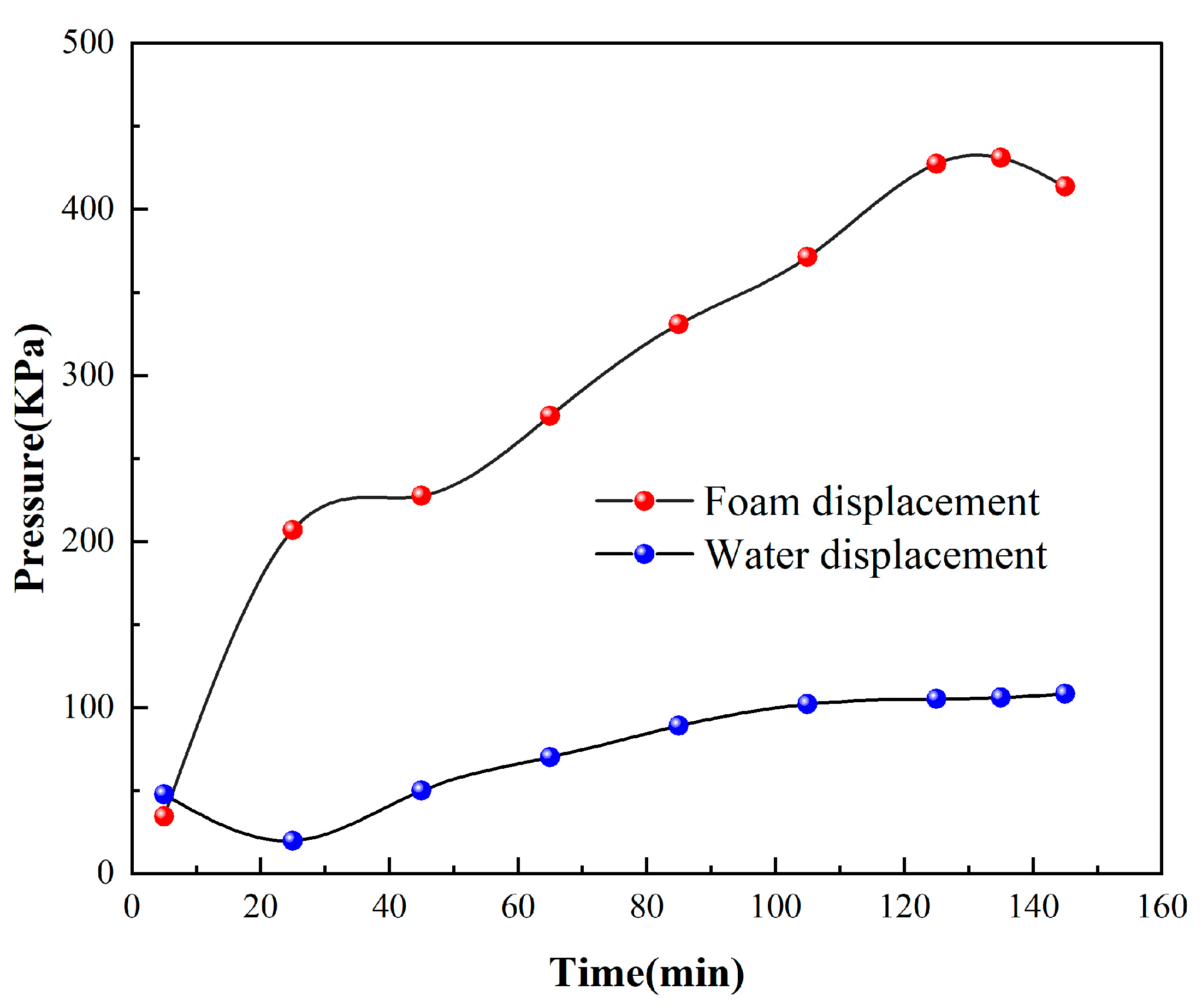

3.4.1. Plugging Performance of Foam in Single Core

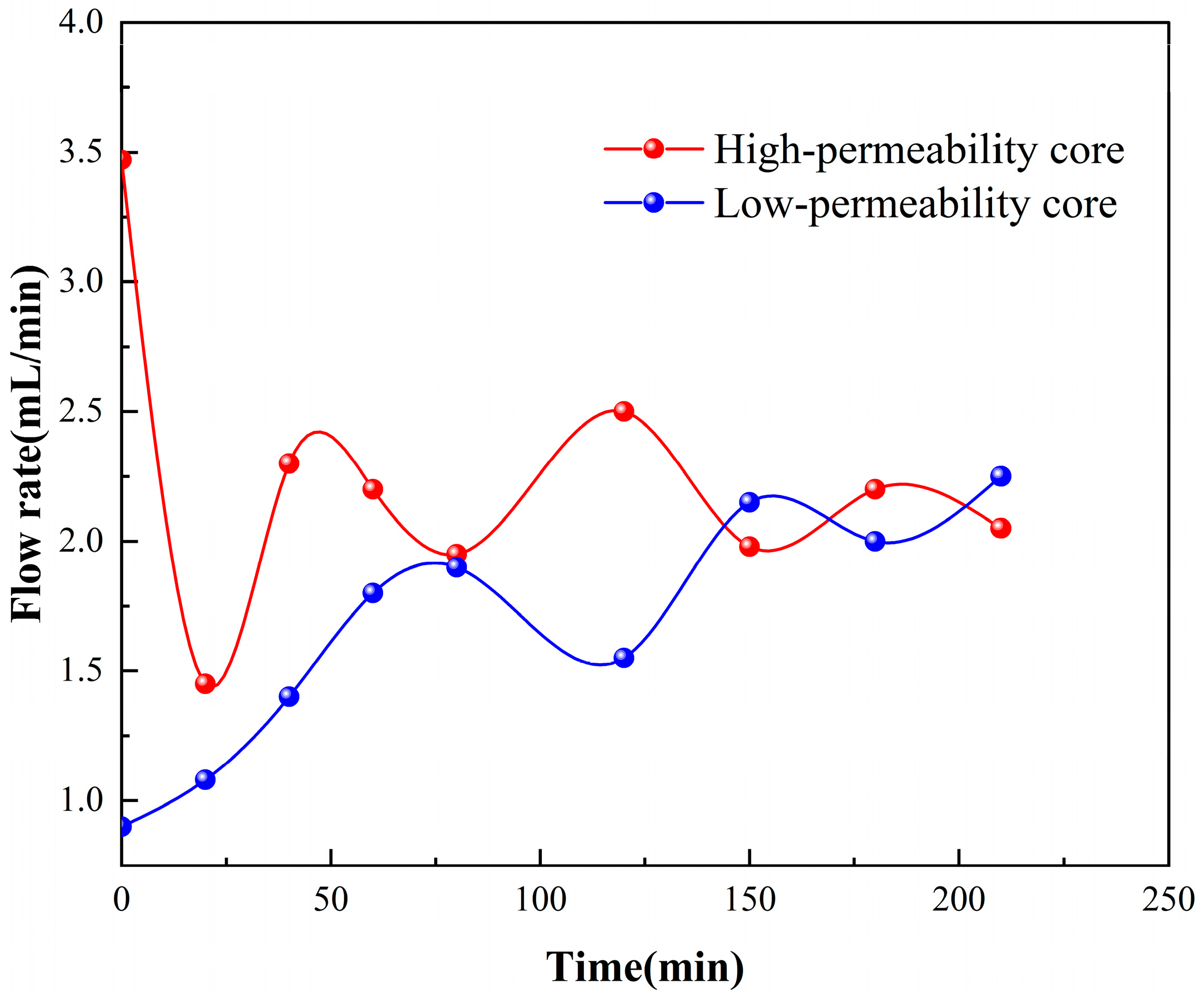

3.4.2. Divided-Flow Performance of Foam in Parallel Cores

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Kumar, R.; He, J.; Bataweel, M.; Nasr-El-Din, H. New Insights on the Effect of Oil Saturation on the Optimal Acid-Injection Rate in Carbonate Acidizing. SPE J. 2017, 23, 969–984. [Google Scholar] [CrossRef]

- Wang, Y.; Fan, Y.; Zhou, C.; Luo, Z.; Chen, W.; He, T.; Fang, H.; Fu, Y. Research and Appli-cation of Segmented Acid Fracturing by Temporary Plugging in Ultradeep Carbonate Reservoirs. ACS Omega 2021, 6, 28620–28629. [Google Scholar] [CrossRef] [PubMed]

- Kang, S.; Pu, C.; Wang, K.; Li, X.; Zhang, N.; Yan, D.; Huang, F. Investigation of the Oil-Soluble Particulate Temporary Plugging Agent-Assisted Water Huff ‘n’ Puff Enhanced Oil Recovery in Tight Oil Reservoirs. SPE J. 2023, 28, 2346–2364. [Google Scholar] [CrossRef]

- Yuan, Y.; Du, J.; Liu, P.; Wang, M.; Liu, J.; Chen, X. Research on acidizing blockage removal and perfusion enhancement technology for sandstone geothermal reservoir recharge wells. Ge-Othermics 2025, 125, 103200. [Google Scholar] [CrossRef]

- Luo, Z.-F.; Zhao, L.-Q.; Liu, P.-L.; Wang, Z.-K. Integrated Technology of Water Plugging and Acidizing of Hydrofractured Oil Wells. Chem. Technol. Fuels Oils 2015, 51, 190–198. [Google Scholar] [CrossRef]

- Song, W.; Zhang, K.; Feng, D.; Jiang, Q.; Lin, H.; Liao, L.; Kang, R.; Ou, B.; Du, J.; Wang, Y.; et al. Study on Stable Loose Sandstone Reservoir and Corresponding Acidizing Technology. Coatings 2024, 14, 667. [Google Scholar] [CrossRef]

- Wang, Y.; Zhou, F.; Zou, Y.; Wang, Z.; Wang, Y. Preparation and Performance Study of Mi-croemulsion Acid for Comprehensive Plugging Removal in Carbonate Reservoir. Molecules 2023, 28, 5606. [Google Scholar] [CrossRef]

- Dang, F.; Li, S.; Feng, S. Greening strategy for heavy oil thermal recovery assisted by en-vironmental-friendly solvent dimethyl ether. Geoenergy Sci. Eng. 2025, 251, 213889. [Google Scholar] [CrossRef]

- Feng, Q.; Liu, H.; Peng, Z.; Zheng, Y. Preparation of a Cationic Hyperbranched Polymer for Inhibiting Clay Hydration Swelling in the Process of Oilfield Waterflooding. Energy Fuels 2019, 33, 12202–12212. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, J.; Feng, Z.; Fang, W.; Wang, F. Characteristics of remaining oil viscosity in water- and polymer-flooding reservoirs in Daqing Oilfield. Sci. China Ser. D Earth Sci. 2010, 53, 72–83. [Google Scholar] [CrossRef]

- Bader, M.S.H. Seawater versus produced water in oil-fields water injection operations. Desalination 2007, 208, 159–168. [Google Scholar] [CrossRef]

- Dang, F.; Li, S.; Feng, S.; Li, S.; Liu, L.; Su, L. Innovative Soaking-Enhanced Carbonated Water Flooding for EOR and CO2 Storage. Geoenergy Sci. Eng. 2025, 252, 213922. [Google Scholar] [CrossRef]

- Liu, X.; Feng, Y.; Xu, X.; Dang, F.; Li, S. Experimental Study on Viscosity-Reducing Foam Flooding in Fractured-Vuggy Reservoirs. ACS Omega 2025, 10, 14602–14615. [Google Scholar] [CrossRef] [PubMed]

- Rahman, A.; Torabi, F.; Shirif, E. Surfactant and nanoparticle synergy: Towards improved foam stability. Petroleum 2023, 9, 255–264. [Google Scholar] [CrossRef]

- Ding, B.; Guan, B.; Liu, W.; Chen, B.; Sun, J.; Li, M.; Wu, W.; Hua, S.; Geng, X.; Chen, W.; et al. Mechanism of Improving Water Flooding Using the Nanofluid Permeation Flooding System for Tight Reservoirs in Jilin Oilfield. Energy Fuels 2021, 35, 17389–17395. [Google Scholar] [CrossRef]

- O’Reilly, D.; Haghighi, M.; Sayyafzadeh, M.; Flett, M. Analytical Rate-Transient Analysis and Production Performance of Waterflooded Fields with Delayed Injection Support. SPE Reserv. Eval. Eng. 2021, 24, 639–661. [Google Scholar] [CrossRef]

- Wang, Z.; Li, S.; Dang, F.; Li, M.; Husein, M.M. Rheological behavior and flow characteristics of oil-based CO2 foam under varying petroleum industry conditions. Fuel 2025, 385, 134086. [Google Scholar] [CrossRef]

- Sun, J.; Xiu, Z.; Li, L.; Lv, K.; Zhang, X.; Wang, Z.; Dai, Z.; Xu, Z.; Huang, N.; Liu, J. Application status and prospect of ionic liquids in oilfield chemistry. Petroleum 2024, 10, 11–18. [Google Scholar] [CrossRef]

- Jiang, O.; Zhang, P.; Jia, H.; Liang, J.; Zheng, X. A retarded foam acid fluid system for low-temperature dolomite geothermal reservoir stimulation and its action mechanisms. Colloids Surf. A Physicochem. Eng. Asp. 2025, 705, 135717. [Google Scholar] [CrossRef]

- Chen, H.; Wei, P.; Qi, Y.; Xie, Y.; Huang, X. Water-Induced Cellulose Nanofibers/Poly(vinyl alcohol) Hydrogels Regulated by Hydrogen Bonding for In Situ Water Shutoff. ACS Appl. Mater. Interfaces 2023, 15, 39883–39895. [Google Scholar] [CrossRef] [PubMed]

- Alooghareh, M.H.; Kabipour, A.; Ghazavi, M.; Sisakht, S.M.M.; Razavifar, M. Effects of different gases on the performance of foams stabilized by Cocamidopropyl betaine surfactant and silica nanoparticles: A comparative experimental study. Petroleum 2022, 8, 546–551. [Google Scholar] [CrossRef]

- Yan, Y.-L.; Xi, Q.; Una, C.-C.; He, B.-C.; Wu, C.-S.; Dou, L.-L. A novel acidizing technology in carbonate reservoir: In-Situ formation of CO2 foamed acid and its self-diversion. Colloids Surf. A Physicochem. Eng. Asp. 2019, 580, 123787. [Google Scholar] [CrossRef]

- Li, Z.; Huang, X.; Lu, H.; Lv, K.; Geng, Y.; Ren, L.; Zhang, C. Synthesis and plugging per-formance evaluation of micro-nano polymeric high-temperature resistant plugging agent for water-based drilling fluids. Geoenergy Sci. Eng. 2025, 246, 213604. [Google Scholar] [CrossRef]

- Cheng, L.; Kam, S.I.; Delshad, M.; Rossen, W. Simulation of Dynamic Foam-Acid Diversion Processes. SPE J. 2002, 7, 316–324. [Google Scholar] [CrossRef]

- Yuan, H.; Chen, X.; Li, N.; Zhou, H.; Gong, Y.; Wang, Y. Numerical simulation of foam diversion acidizing in heterogeneous reservoirs. Petroleum 2022, 8, 516–521. [Google Scholar] [CrossRef]

- Xin, Y.; Li, B.; Song, Y.; Wang, J.; Zhang, M.; Zhang, J.; Xu, Z.; Li, Z. Visualization study on migration characteristics of high-stability gel foam in fractures of fractured-vuggy reservoirs. Colloids Surf. A Physicochem. Eng. Asp. 2025, 717, 136892. [Google Scholar] [CrossRef]

- Cheng, Q.; Li, B.; Shi, Z.; Shao, G.; Li, B.; Kang, N.; Wang, X. Preparation and plugging characteristics investigation of a high temperature induced calcium salt precipitation system for profile control in high temperature reservoirs. Colloids Surf. A Physicochem. Eng. Asp. 2025, 711, 136413. [Google Scholar] [CrossRef]

- Wang, Z.; Li, S.; Wei, Y.; Dang, F.; Li, M. Investigation of oil-based CO2 foam EOR and carbon mitigation in a 2D visualization physical model: Effects of different injection strategies. Energy 2024, 313, 133800. [Google Scholar] [CrossRef]

- Al-Darweesh, J.; Aljawad, M.S.; Alyousef, Z.; BinGhanim, A.; Kamal, M.S.; Mahmoud, M.; Al-Shehri, D. Investigation of amine-based surfactants for foamed acid stimulation at high temperature, pressure, and salinity. Geoenergy Sci. Eng. 2023, 229, 212094. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, H.; Zhou, F.; Mou, J. Numerical Simulation of Wormhole Propagation with Foamed-Viscoelastic-Surfactant Acid in Carbonate Acidizing. Processes 2023, 11, 1839. [Google Scholar] [CrossRef]

- Singh, R.; Panthi, K.; Mohanty, K.K. Microencapsulation of Acids by Nanoparticles for Acid Treatment of Shales. Energy Fuels 2017, 31, 11755–11764. [Google Scholar] [CrossRef]

- Wang, Z.; Li, S.; Li, M.; Husein, M.M. Enhanced oil recovery and carbon sequestration in low-permeability reservoirs: Comparative analysis of CO2 and oil-based CO2 foam. Fuel 2025, 381, 133319. [Google Scholar] [CrossRef]

- Al-Ameri, A.; Gamadi, T. Optimization of acid fracturing for a tight carbonate reservoir. Petroleum 2020, 6, 70–79. [Google Scholar] [CrossRef]

- Xu, Z.; Li, Z.; Liu, Z.; Li, B.; Zhang, Q.; Zheng, L.; Song, Y.; Husein, M.M. Characteristics of CO2 foam plugging and migration: Implications for geological carbon storage and utilization in fractured reservoirs. Sep. Purif. Technol. 2022, 294, 121190. [Google Scholar] [CrossRef]

- Xu, B.; Yang, Y.; Long, W.; Yang, J.; Liu, T. Mechanism of plugging high permeability core and decreasing reservoir heterogeneity with ultra-dry CO2-in-water foam. Fuel 2024, 364, 131148. [Google Scholar] [CrossRef]

- Xin, Y.; Li, B.; Li, Z.; Li, Z.; Wang, B.; Wang, X.; Zhang, M.; Li, W. Gas channeling control with CO2-responsive gel system in fractured low-permeability reservoirs: Enhancing oil recovery during CO2 flooding. Sep. Purif. Technol. 2025, 353, 128475. [Google Scholar] [CrossRef]

- Li, S.; Yao, Z.; Shang, F.; Li, M.; Wei, Y.; Li, S. Improving CO2 storage efficiency in saline aquifers through wettability-optimized nanoparticle foam. Phys. Fluids 2025, 37, 013351. [Google Scholar] [CrossRef]

- Li, S.; Wang, Z.; Li, S.; Liu, D. Enhancing the Stability and Practical Application of CO2-Responsive Foam with Nanoparticles: The Role of Salt Ions. Energy Fuels 2024, 38, 20384–20396. [Google Scholar] [CrossRef]

- Lai, N.; He, X.; Wang, J.; Tang, L. Study on the Stabilization Mechanism of Wormlike Micelle-CO2 Foams in High-Temperature and High-Salt Oil Reservoirs. Energy Fuels 2023, 37, 10939–10950. [Google Scholar] [CrossRef]

- SY/T 7494-2020; Experimental Evaluation Method of Foaming Agents in Oil and Gas Field. National Energy Board: Beijing, China, 2020.

- SY/T 6526-2019; Measuring Method of Dynamic Reaction Rate for Hydrochloric Acid with Carbonate Rock. National Energy Board: Beijing, China, 2019.

- Han, W.; Fan, J.; Lv, H.; Yan, Y.; Liu, C.; Dong, S. Excellent foaming properties of anionic-zwitterionic-Gemini cationic compound surfactants for gas well deliquification: Experimental and computational investigations. Colloids Surf. A Physicochem. Eng. Asp. 2022, 653, 129944. [Google Scholar] [CrossRef]

- Li, N.; Dai, J.; Liu, P.; Luo, Z.; Zhao, L. Experimental study on influencing factors of acid-fracturing effect for carbonate reservoirs. Petroleum 2015, 1, 146–153. [Google Scholar] [CrossRef]

- Miguet, J.; Dorbolo, S.; Scheid, B. Antibubble column: A mean to measure and enhance liquid–gas mass transfer through surfactant-laden interfaces. Chem. Eng. J. 2024, 498, 153276. [Google Scholar] [CrossRef]

- Staples, E.; Thompson, L.; Tucker, I.; Penfold, J.; Thomas, R.K.; Lu, J.R. The Influence of Sorbitol on the Adsorption of Surfactants at the Air–Liquid Interface. J. Colloid Interface Sci. 1996, 184, 391–398. [Google Scholar] [CrossRef]

- Han, W.; Fan, J.; Qiang, T.; Liu, C.; Ji, Y.; Dong, S. A novel salt and condensate–resistant foam co-stabilized by mixtures of surfactants and citric acid for gas well deliquification. J. Mol. Liq. 2023, 385, 122426. [Google Scholar] [CrossRef]

- Wang, B.; Luo, Y.; Li, X.; Liu, Y.Z.; Xu, C.R.; Zheng, Y.X.; Zhang, Y.H.; Zhou, Y.R. Water–Rock reactions in the acid leaching of Uranium: Hydrochemical characteristics and reaction mechanisms. J. Hydrol. 2024, 641, 131798. [Google Scholar] [CrossRef]

- Xue, H.; Huang, Z.; Zhao, L.; Wang, H.; Kang, B.; Liu, P.; Liu, F.; Cheng, Y.; Xin, J. Influence of acid-rock reaction heat and heat transmission on wormholing in carbonate rock. J. Nat. Gas Sci. Eng. 2018, 50, 189–204. [Google Scholar] [CrossRef]

- Hu, M.; Niu, Q.; Yuan, W.; Wang, W.; Chang, J.; Du, Z.; Wang, Q.; Zheng, Y.; Shangguan, S.; Qi, X.; et al. Evolution characteristic and mechanism of microstructure, hydraulic and mechanical behaviors of sandstone treated by ac-id-rock reaction: Application of in-situ leaching of uranium deposits. J. Hydrol. 2024, 643, 131948. [Google Scholar] [CrossRef]

- Gao, B.; Mou, J.; Lu, P.; Zhang, S.; Sun, X.; Li, S.; Zhang, X.; Wang, X. Numerical investigation into the acid flow and reaction behavior in the tight, naturally fractured carbonate reservoir during acid fracturing. Phys. Fluids 2024, 36, 113614. [Google Scholar] [CrossRef]

- Shen, X.; Wang, S.; Guo, J.; Chen, F.; Xu, B.; Wang, Z.; Liu, Y. Effect of carbon chain lengths of cationic surfactant on inhibition rate of acid-rock reaction. J. Pet. Sci. Eng. 2021, 196, 107793. [Google Scholar] [CrossRef]

- Niu, Q.; Dong, Z.; Lv, Q.; Zhang, F.; Shen, H.; Yang, Z.; Lin, M.; Zhang, J.; Xiao, K. Role of interfacial and bulk properties of long-chain viscoelastic surfactant in stabilization mechanism of CO2 foam for CCUS. J. CO2 Util. 2022, 66, 102297. [Google Scholar] [CrossRef]

- Lv, M.; Liu, Z.; Jia, L.; Ji, C. Visualizing pore-scale foam flow in micromodels with different permeabilities. Colloids Surf. A Physicochem. Eng. Asp. 2020, 600, 124923. [Google Scholar] [CrossRef]

| Number | Length/mm | Diameter/mm | Hydrometric Permeability/μm2 |

|---|---|---|---|

| 1 | 300 | 25 | 2.100 |

| 2 | 300 | 25 | 0.705 |

| Reaction Condition | Rock Core Surface Area/cm2 | Rock Core Reaction Quality/mg | Average Reaction Rate ( )/mg/(cm2·s) | Retarding Rate (K)/% |

|---|---|---|---|---|

| 10% compound acid | 38.78 | 32.50 | 1.412 × 10−3 | / |

| 38.69 | 33.01 | |||

| 38.19 | 32.8 | |||

| 0.67% ZG-A + 0.33% ZG-B + 10% compound acid | 41.20 | 1.60 | 6.622 × 10−5 | 95.31 |

| 42.03 | 1.71 | |||

| 41.78 | 1.70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, X.; Ma, H.; Xu, Y.; Chang, F.; Fan, J.; Zhang, C. Evaluation of Temperature- and Salt-Resistant Foam Acid and Study of Foam Diversion Mechanism. Processes 2025, 13, 2704. https://doi.org/10.3390/pr13092704

Hu X, Ma H, Xu Y, Chang F, Fan J, Zhang C. Evaluation of Temperature- and Salt-Resistant Foam Acid and Study of Foam Diversion Mechanism. Processes. 2025; 13(9):2704. https://doi.org/10.3390/pr13092704

Chicago/Turabian StyleHu, Xiangsong, Hui Ma, Ya Xu, Fuhua Chang, Jiabao Fan, and Chao Zhang. 2025. "Evaluation of Temperature- and Salt-Resistant Foam Acid and Study of Foam Diversion Mechanism" Processes 13, no. 9: 2704. https://doi.org/10.3390/pr13092704

APA StyleHu, X., Ma, H., Xu, Y., Chang, F., Fan, J., & Zhang, C. (2025). Evaluation of Temperature- and Salt-Resistant Foam Acid and Study of Foam Diversion Mechanism. Processes, 13(9), 2704. https://doi.org/10.3390/pr13092704