Research on Damage Characteristics of Clean Fracturing Fluid in Deep Coal Seam

Abstract

1. Introduction

2. Materials and Methods

2.1. Experimental Materials

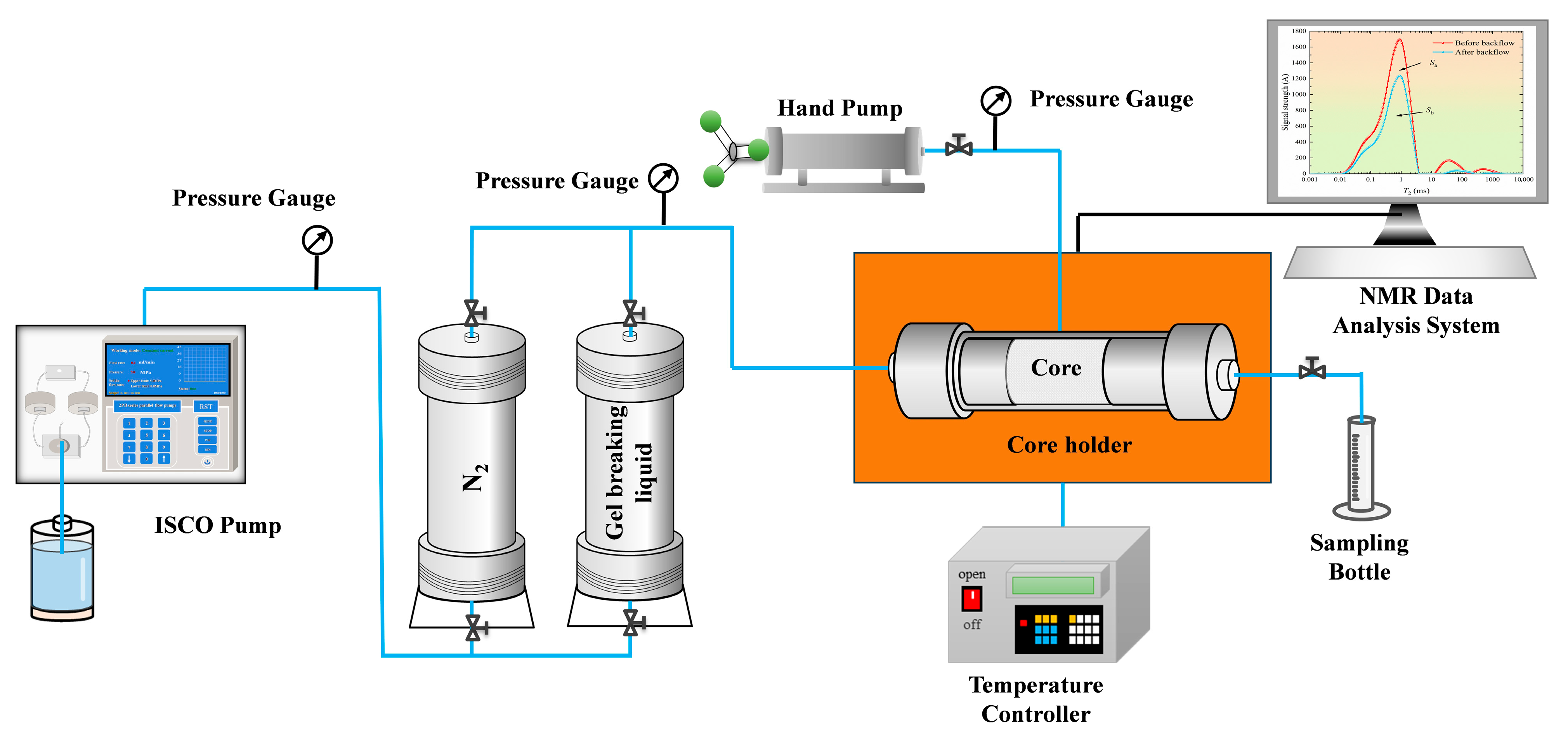

2.2. Experimental Device

2.3. Experimental Process

2.4. Experimental Principle

3. Results and Discussion

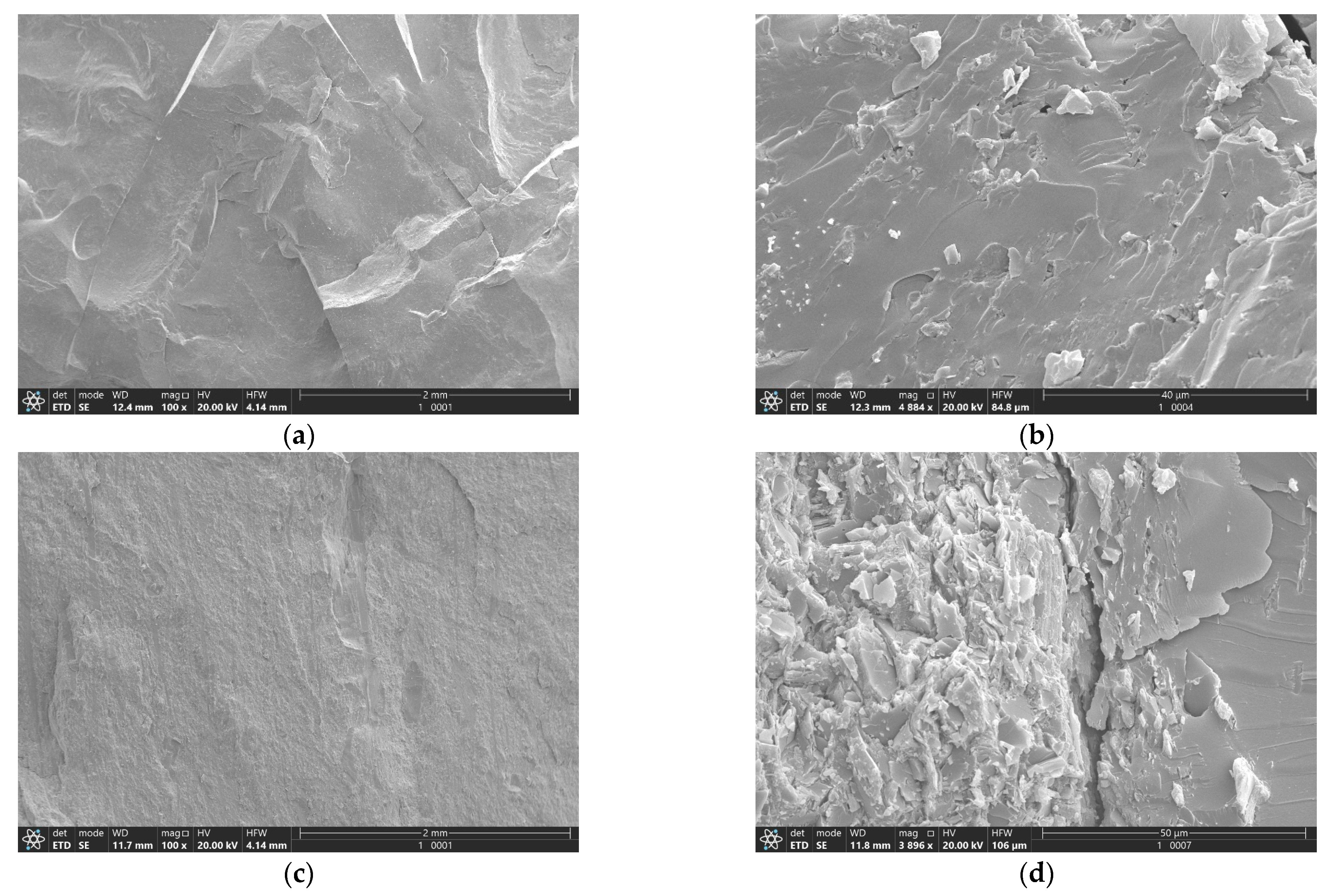

3.1. Characteristics of Coal and Rock Samples

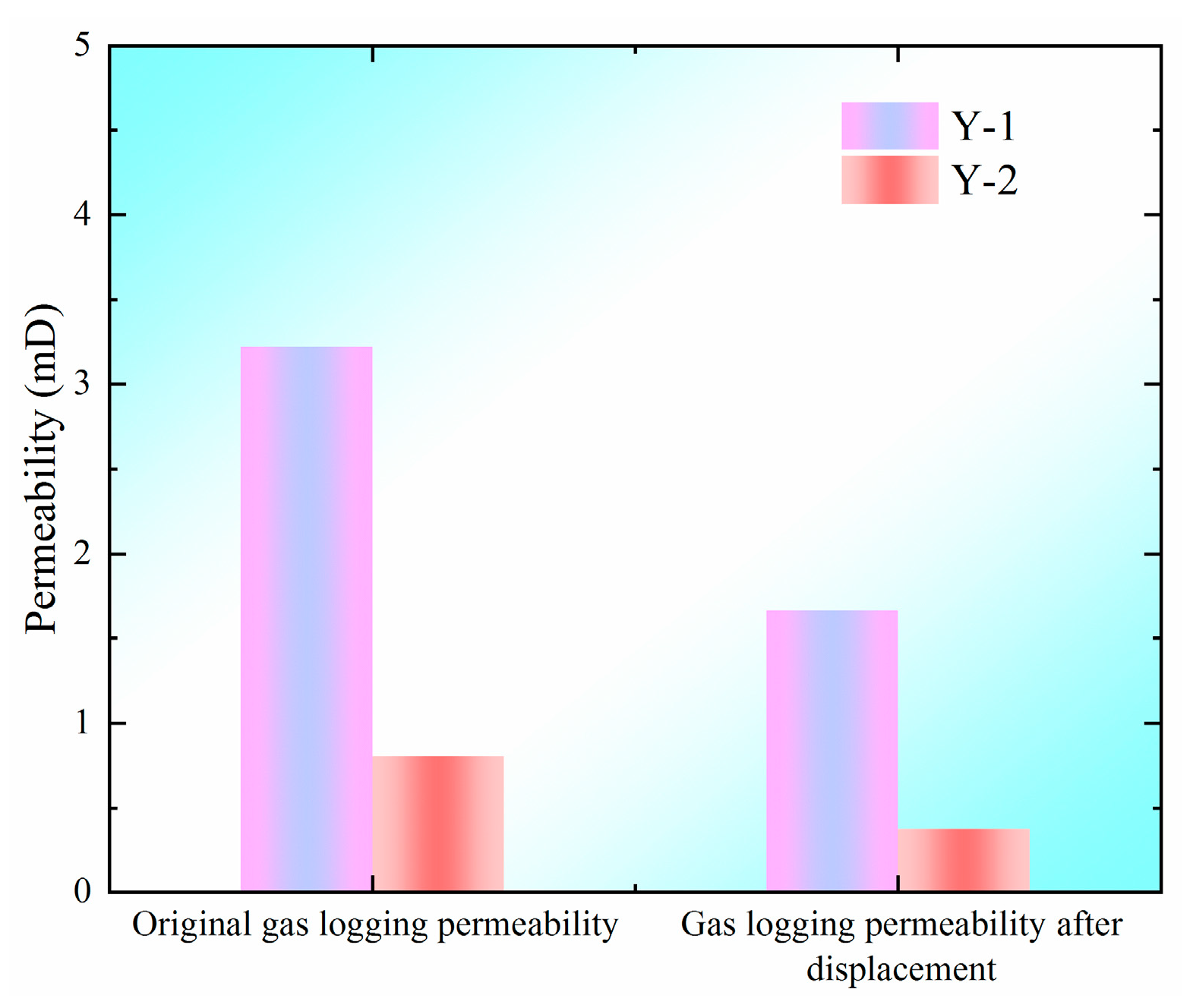

3.2. Damage to the Matrix Caused by Fracturing Fluid

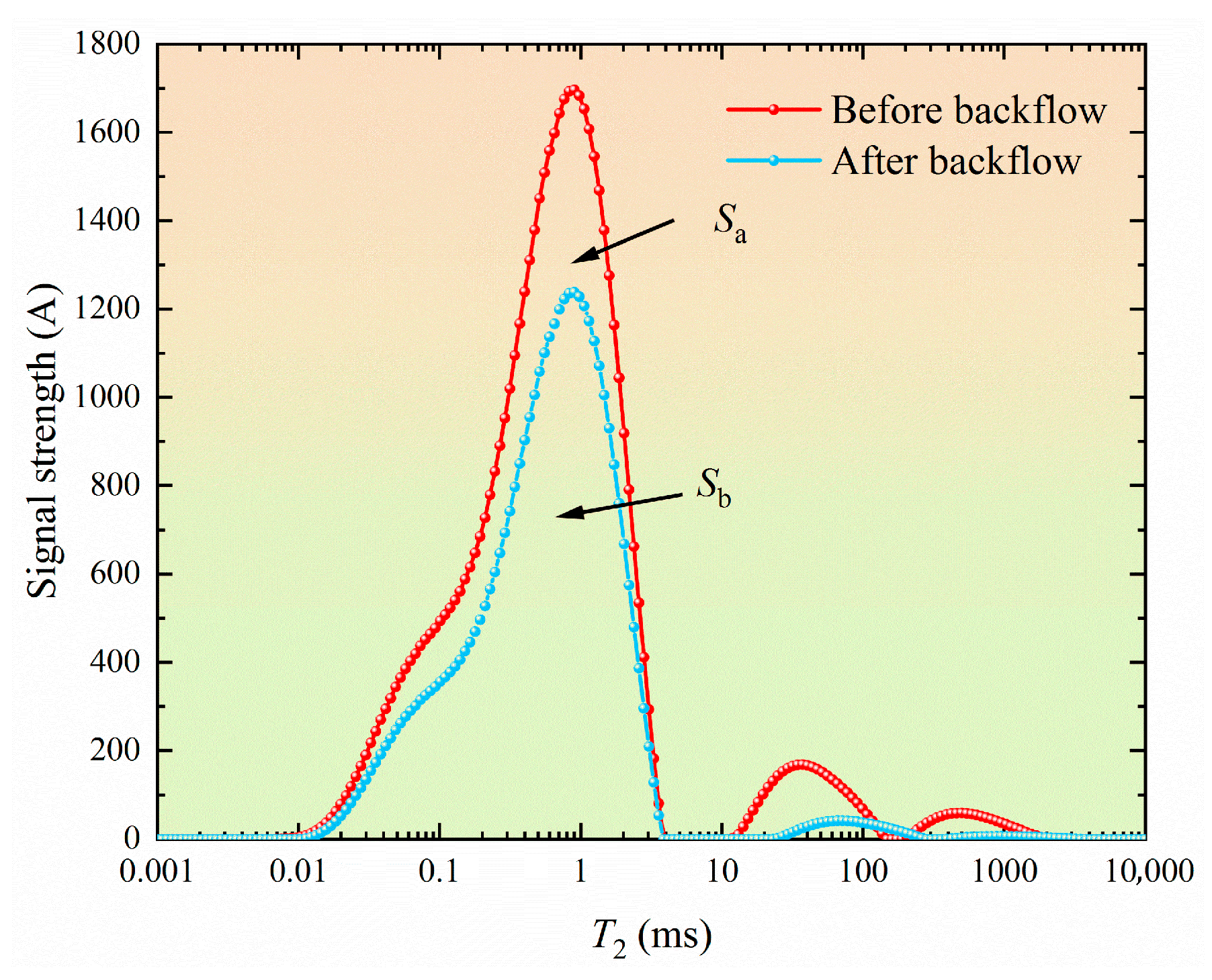

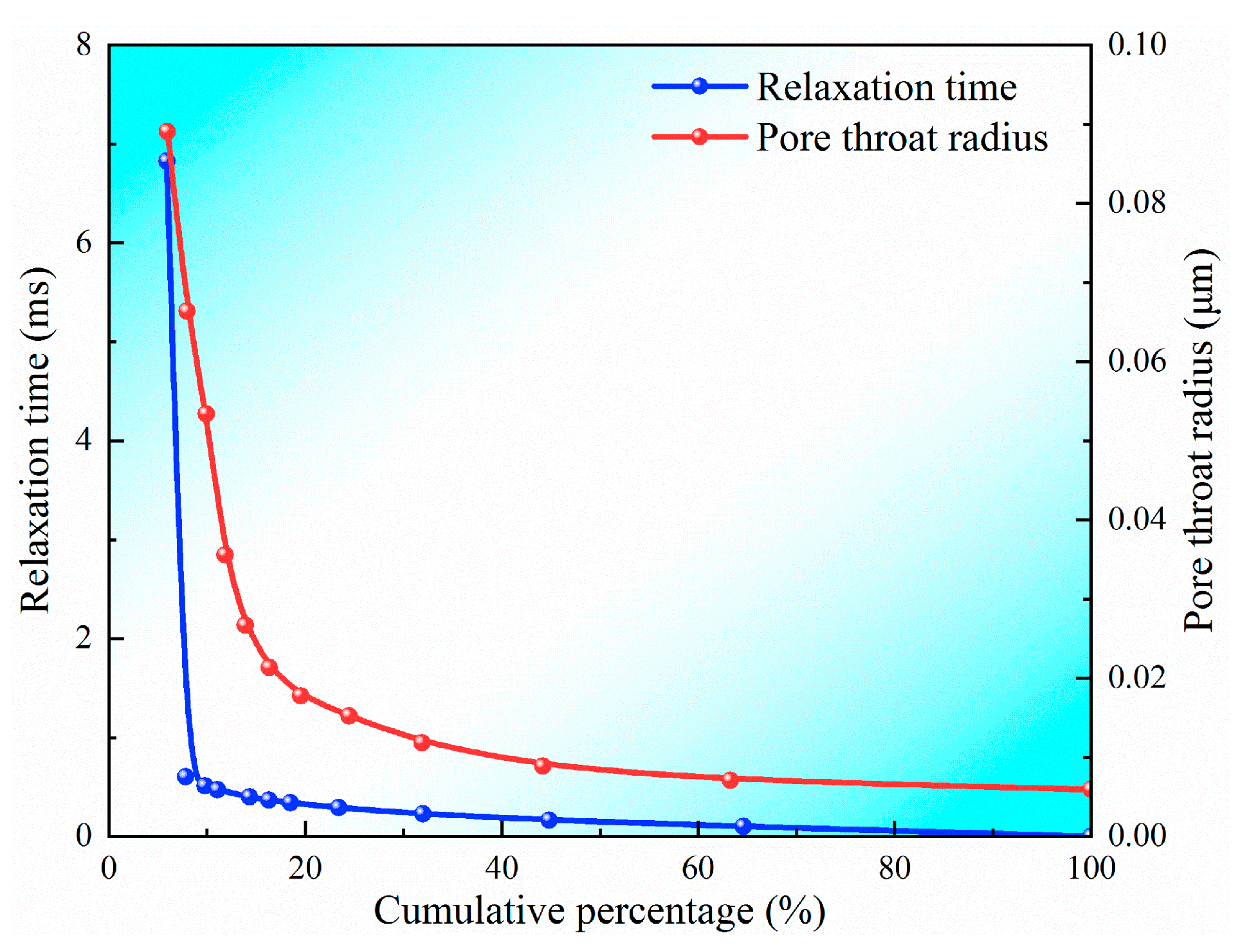

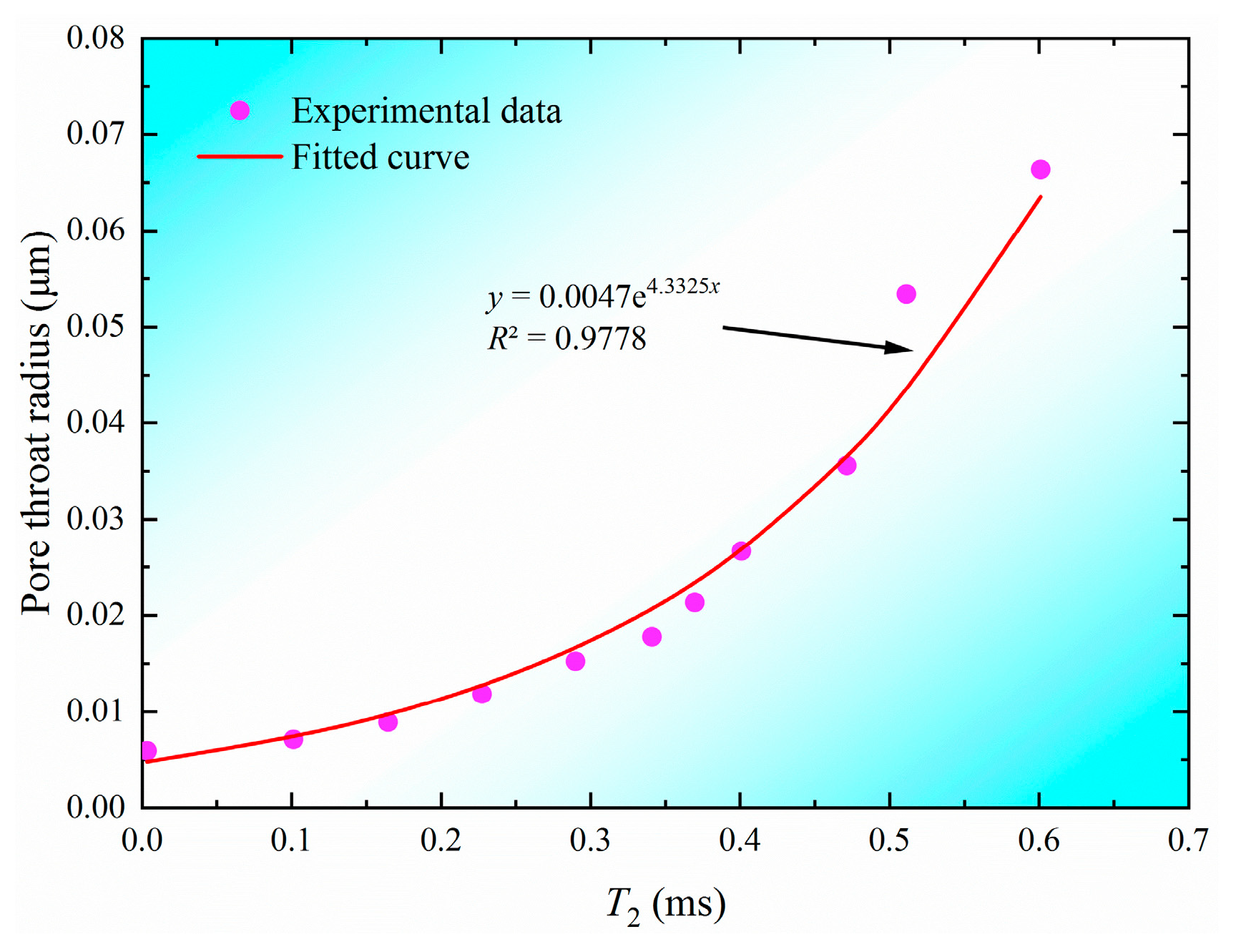

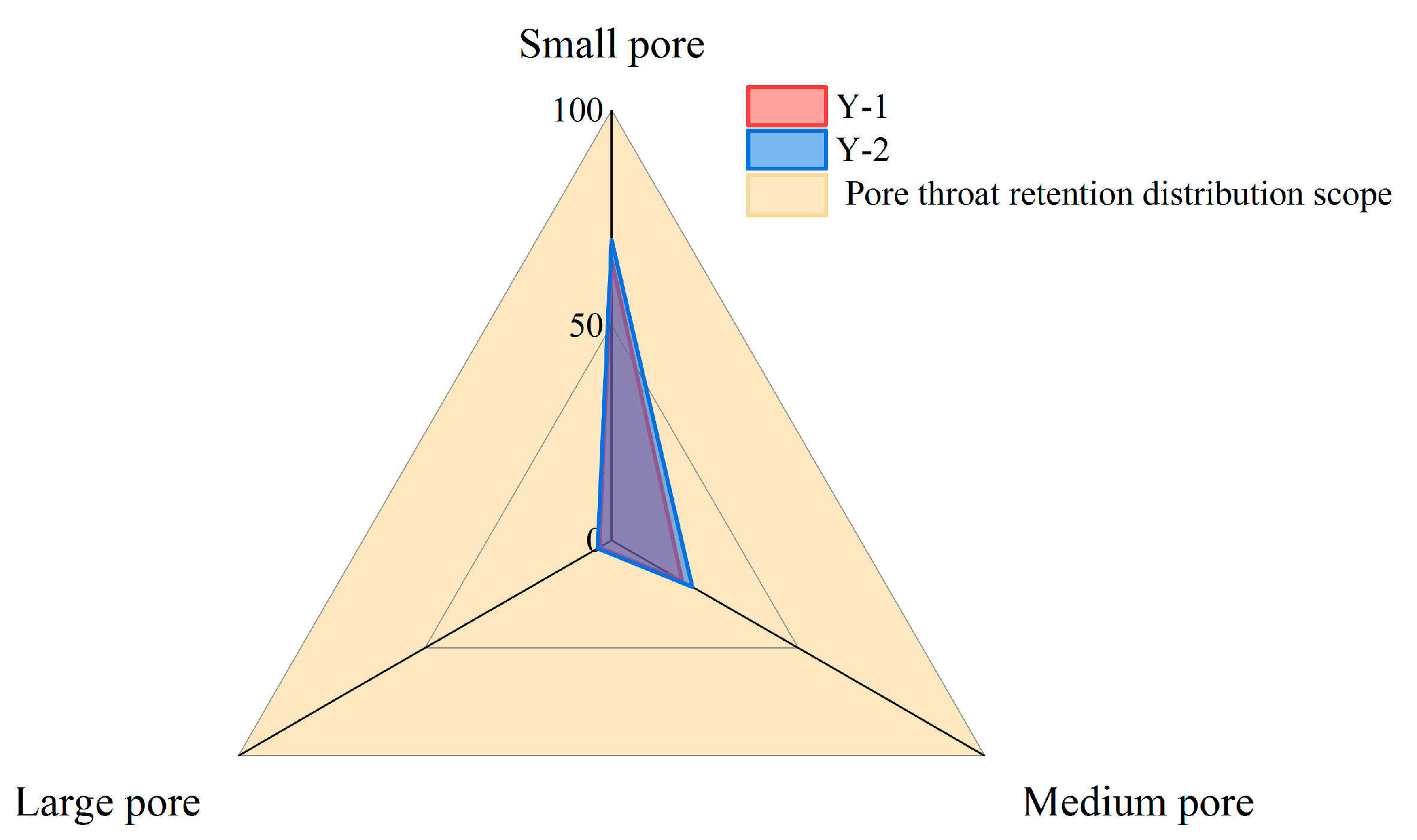

3.3. Analysis of Pore Throat Retention Characteristics of Fracturing Fluid with Different Scales Based on NMR

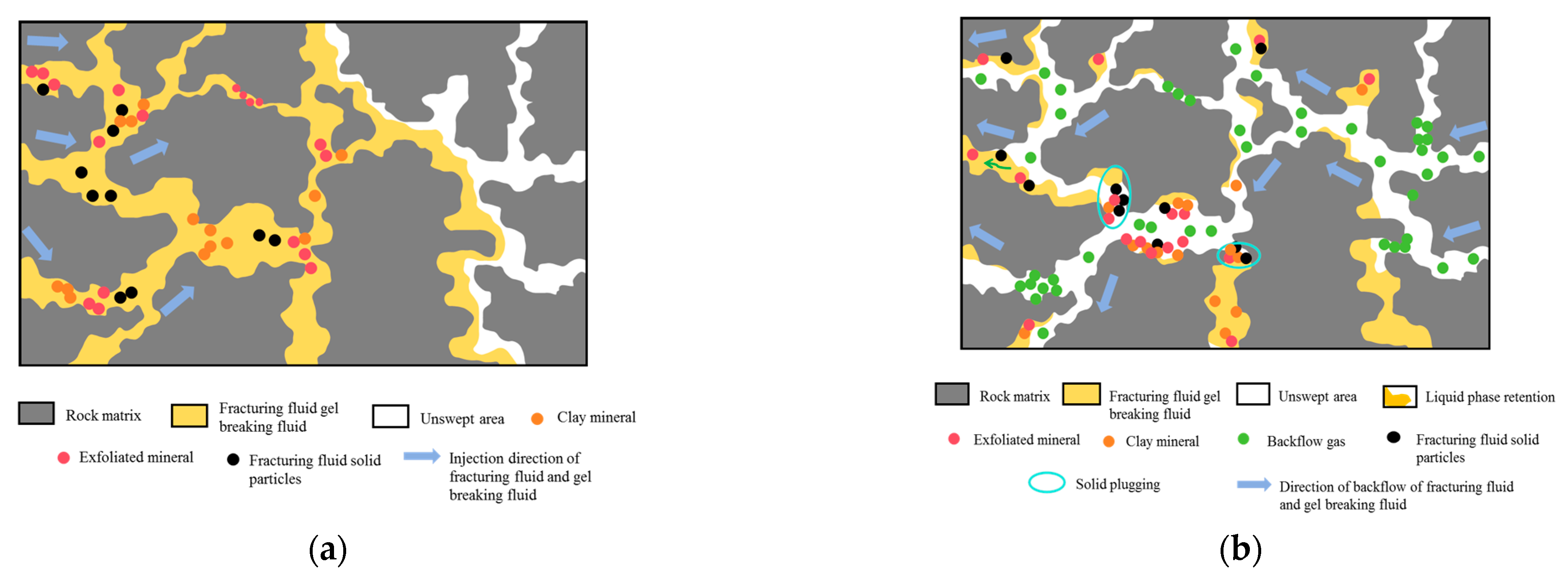

3.4. Microscopic Damage Mechanisms of Environmentally Friendly Fracturing Fluids

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Feng, G.; Wang, G.; Xie, H.; Hu, Y.; Meng, T.; Li, G. A Review of Exploration and Development Technologies for Coal, Oil, and Natural Gas. Energies 2024, 17, 3600. [Google Scholar] [CrossRef]

- Dreger, M. Methane emissions in selected hard-coal mines of the Upper Silesian Coal Basin in 1997–2016. Geol. Geophys. Environ. 2019, 45, 121–132. [Google Scholar] [CrossRef]

- Huang, Q.; Liu, S.; Cheng, W.; Wang, G. Fracture Permeability Damage and Recovery Behaviors with Fracturing Fluid Treatment of Coal: An Experimental Study. Fuel 2020, 282, 118809. [Google Scholar] [CrossRef]

- Jiang, Z.; Li, Q.; Hu, Q.; Chen, J.; Li, X.; Wang, X.; Xu, Y. Underground Microseismic Monitoring of a Hydraulic Fracturing Operation for CBM Reservoirs in a Coal Mine. Energy Sci. Eng. 2019, 7, 986–999. [Google Scholar] [CrossRef]

- Gao, D.; Bi, Y.; Xian, B. Technical Advances in Well Type and Drilling & Completion for High-Efficient Development of Coalbed Methane in China. Nat. Gas Ind. B 2022, 9, 561–577. [Google Scholar] [CrossRef]

- Li, L.; Liu, D.; Cai, Y.; Wang, Y.; Jia, Q. Coal Structure and Its Implications for Coalbed Methane Exploitation: A Review. Energy Fuels 2021, 35, 86–110. [Google Scholar] [CrossRef]

- Li, C.; Sun, L.; Zhao, Z.; Zhang, J.; Li, Y.; Meng, Y.; Wang, L. A Method for Evaluating Coalbed Methane Reservoir Productivity Considering Drilling Fluid Damage. Energies 2024, 17, 1686. [Google Scholar] [CrossRef]

- Tao, X.; Zheng, Z.; Yu, H.; Liu, H.; Li, Y.; Zhang, J.; Liu, J.; Zheng, L. Internal Blocking and Bonding to Strengthen the Mechanical Properties and Prevent Collapse and Leakage of Fragmented Coalbed Methane (CBM) Reservoirs by Cohesive Drilling Fluids. Geoenergy Sci. Eng. 2024, 241, 213136. [Google Scholar] [CrossRef]

- Huang, W.; Lei, M.; Qiu, Z.; Leong, Y.-K.; Zhong, H.; Zhang, S. Damage Mechanism and Protection Measures of a Coalbed Methane Reservoir in the Zhengzhuang Block. J. Nat. Gas Sci. Eng. 2015, 26, 683–694. [Google Scholar] [CrossRef]

- Pan, J.; Mou, P.; Ju, Y.; Wang, K.; Zhu, Q.; Ge, T.; Yu, K. Micro-Nano-Scale Pore Stimulation of Coalbed Methane Reservoirs Caused by Hydraulic Fracturing Experiments. J. Pet. Sci. Eng. 2022, 214, 110512. [Google Scholar] [CrossRef]

- Wang, F.; Huang, F.; Guan, Y.; Xu, Z. Mitigation of Fracturing Fluid Leak-off and Subsequent Formation Damage Caused by Coal Fine Invasion in Fractures: An Experimental Study. Processes 2024, 12, 1711. [Google Scholar] [CrossRef]

- Lyu, S.; Wang, S.; Li, J.; Chen, X.; Chen, L.; Dong, Q.; Zhang, X.; Huang, P. Massive Hydraulic Fracturing to Control Gas Outbursts in Soft Coal Seams. Rock Mech. Rock. Eng. 2022, 55, 1759–1776. [Google Scholar] [CrossRef]

- Zhou, M.; Yang, X.; Gao, Z.; Wu, X.; Li, L.; Guo, X.; Yang, Y. Preparation and Performance Evaluation of Nanoparticle Modified Clean Fracturing Fluid. Colloids Surf. A Physicochem. Eng. Asp. 2022, 636, 128117. [Google Scholar] [CrossRef]

- Sun, N.; Gao, M.; Liu, J.; Zhao, G.; Ding, F.; You, Q.; Dai, C. A Novel Temperature-Resistant Fracturing Fluid for Tight Oil Reservoirs: CO2-Responsive Clean Fracturing Fluid. Colloids Surf. A Physicochem. Eng. Asp. 2023, 665, 131247. [Google Scholar] [CrossRef]

- Zhao, J.; Fan, J.; Mao, J.; Yang, X.; Zhang, H.; Zhang, W. High Performance Clean Fracturing Fluid Using a New Tri-Cationic Surfactant. Polymers 2018, 10, 535. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, Q.; Xia, T.; Ji, Q.; Liu, J.; Liu, X.; Wang, L.; Wang, L. Development and Study of a Salt Tolerance Gemini Cationic Viscoelastic Surfactant with Spacer of Neopentyl-Glycol Applied in Seawater-Based Clean Fracturing Fluid. Colloid Polym. Sci. 2025, 303, 547–561. [Google Scholar] [CrossRef]

- Zuo, S.; Wang, C.; Si, J.; Zhang, L.; Tian, F.; Peng, S.; Li, Z. The Effect of Temperature and Ultrasonic Power on the Microstructure Evolution of Coal Modified by Clean Fracturing Fluid: An Experimental Study. Energy 2024, 306, 132436. [Google Scholar] [CrossRef]

- Li, Z.; Liu, D.; Cai, Y.; Wang, Y.; Si, G. Evaluation of Coal Petrophysics Incorporating Fractal Characteristics by Mercury Intrusion Porosimetry and Low-Field NMR. Fuel 2020, 263, 116802. [Google Scholar] [CrossRef]

- Zuo, W.; Zhang, W.; Liu, Y.; Han, H.; Huang, C.; Jiang, W.; Mitri, H. Pore Structure Characteristics and Adsorption and Desorption Capacity of Coal Rock after Exposure to Clean Fracturing Fluid. ACS Omega 2022, 7, 21407–21417. [Google Scholar] [CrossRef]

- Liu, D.; Lin, C.; Guo, B.; Liu, Q.; Ma, F.; Wang, Q.; Wei, C.; Wang, L.; Jia, D. Experimental Evaluation of Working Fluid Damage to Gas Transport in a High-Rank Coalbed Methane Reservoir in the Qinshui Basin, China. ACS Omega 2023, 8, 13733–13740. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Yang, F.; Ge, Z.; Wang, Q.; Wang, S. Influence of Viscoelastic Surfactant Fracturing Fluid on Permeability of Coal Seams. Fuel 2017, 194, 1–6. [Google Scholar] [CrossRef]

- Wu, H.; Kong, X. Analysis of Geological Characteristics and Potential Factors of Formation Damage in Coalbed Methane Reservoir in Northern Qinshui Basin. Sci. Rep. 2025, 15, 3025. [Google Scholar] [CrossRef]

- Liu, Y.; Tang, D.; Xu, H.; Tao, S.; Li, S. Quantitative Characterization of Middle-High Ranked Coal Reservoirs in the Hancheng Block, Eastern Margin, Ordos Basin, China: Implications for Permeability Evolution with the Coal Macrolithotypes. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 201–215. [Google Scholar] [CrossRef]

- Wang, G.; Huang, T.; Yan, S.; Liu, X. Experimental Study of the Fracturing-Wetting Effect of VES Fracturing Fluid for the Coal Seam Water Injection. J. Mol. Liq. 2019, 295, 111715. [Google Scholar] [CrossRef]

- You, L.; Xie, B.; Yang, J.; Kang, Y.; Han, H.; Wang, L.; Yang, B. Mechanism of Fracture Damage Induced by Fracturing Fluid Flowback in Shale Gas Reservoirs. Nat. Gas Ind. B 2019, 6, 366–373. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Q.; Liu, P.; Li, T.; Liu, G.; Liu, Z.; Zhao, H. Investigation on the Microscopic Damage Mechanism of Fracturing Fluids to Low-Permeability Sandstone Oil Reservoir by Nuclear Magnetic Resonance. J. Pet. Sci. Eng. 2022, 209, 109821. [Google Scholar] [CrossRef]

- Da, Q.; Yao, C.; Zhang, X.; Li, L.; Lei, G. Reservoir Damage Induced by Water-Based Fracturing Fluids in Tight Reservoirs: A Review of Formation Mechanisms and Treatment Methods. Energy Fuels 2024, 38, 18093–18115. [Google Scholar] [CrossRef]

- Guo, J.-C.; Zhou, H.-Y.; Zeng, J.; Wang, K.-J.; Lai, J.; Liu, Y.-X. Advances in Low-Field Nuclear Magnetic Resonance (NMR) Technologies Applied for Characterization of Pore Space inside Rocks: A Critical Review. Pet. Sci. 2020, 17, 1281–1297. [Google Scholar] [CrossRef]

- Gao, H.; Luo, K.-Q.; Wang, C.; Li, T.; Cheng, Z.-L.; Dou, L.-B.; Zhao, K.; Zhang, N.; Liu, Y.-L. Impact of Dissolution and Precipitation on Pore Structure in CO2 Sequestration within Tight Sandstone Reservoirs. Pet. Sci. 2025, 22, 868–883. [Google Scholar] [CrossRef]

- Elsayed, M.; Isah, A.; Hiba, M.; Hassan, A.; Al-Garadi, K.; Mahmoud, M.; El-Husseiny, A.; Radwan, A.E. A Review on the Applications of Nuclear Magnetic Resonance (NMR) in the Oil and Gas Industry: Laboratory and Field-Scale Measurements. J. Pet. Explor. Prod. Technol. 2022, 12, 2747–2784. [Google Scholar] [CrossRef]

- Wang, C.; Gao, H.; Gao, Y.; Fan, H. Influence of Pressure on Spontaneous Imbibition in Tight Sandstone Reservoirs. Energy Fuels 2020, 34, 9275–9282. [Google Scholar] [CrossRef]

- Zhao, S.; Sun, Y.; Wang, H.; Li, Q.; Guo, W. Modeling and Field-Testing of Fracturing Fluid Back-Flow after Acid Fracturing in Unconventional Reservoirs. J. Pet. Sci. Eng. 2019, 176, 494–501. [Google Scholar] [CrossRef]

- Lenci, A.; Chiapponi, L.; Longo, S.; Di Federico, V. Experimental Investigation on Backflow of Power-Law Fluids in Planar Fractures. Phys. Fluids 2021, 33, 083111. [Google Scholar] [CrossRef]

- Qu, Z.; Wang, J.; Guo, T.; Shen, L.; Liao, H.; Liu, X.; Fan, J.; Hao, T. Optimization on Fracturing Fluid Flowback Model after Hydraulic Fracturing in Oil Well. J. Pet. Sci. Eng. 2021, 204, 108703. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, J.; Yang, Y.; Liu, D.; Jiang, R.; Huang, S.; Sun, Y.; Dai, C. Distribution Characteristics and Backflow Flow Pattern of a Slickwater Fracturing Fluid in Shale Based on Low-Field Nuclear Magnetic Resonance. Energy Fuels 2024, 38, 2001–2009. [Google Scholar] [CrossRef]

- Wang, M.; Leung, J.Y. Numerical Investigation of Fluid-Loss Mechanisms during Hydraulic Fracturing Flow-Back Operations in Tight Reservoirs. J. Pet. Sci. Eng. 2015, 133, 85–102. [Google Scholar] [CrossRef]

- Bai, Z.; Wang, Q.; Song, W. Lower Limits of Pore Throat Producing in Natural Gas Drive Reservoirs Based on Nuclear Magnetic Resonance. Xinjiang Pet. Geol. 2023, 44, 58–63. [Google Scholar] [CrossRef]

- Connolly, P.R.J.; Yan, W.; Zhang, D.; Mahmoud, M.; Verrall, M.; Lebedev, M.; Iglauer, S.; Metaxas, P.J.; May, E.F.; Johns, M.L. Simulation and Experimental Measurements of Internal Magnetic Field Gradients and NMR Transverse Relaxation Times (T2) in Sandstone Rocks. J. Pet. Sci. Eng. 2019, 175, 985–997. [Google Scholar] [CrossRef]

- Hu, D.; Wang, R.; Liu, B.; Bai, X.; Zhu, L. A Rigid Double-tailed Surfactant Preparation Method and Its Application in Clean Fracturing Fluid. J. Surfactants Deterg. 2023, 26, 703–709. [Google Scholar] [CrossRef]

- Xu, Z.; Zhao, M.; Liu, J.; Zhang, Y.; Gao, M.; Song, X.; Sun, N.; Li, L.; Wu, Y.; Dai, C. Study on Formation Process and Reservoir Damage Mechanism of Blockages Caused by Polyacrylamide Fracturing Fluid in Production Wells. Fuel 2024, 358, 130154. [Google Scholar] [CrossRef]

- Luo, M.-L.; Si, X.-D.; Li, M.-Z.; Jia, X.-H.; Yang, Y.-L.; Zhan, Y.-P. Experimental Study on the Drag Reduction Performance of Clear Fracturing Fluid Using Wormlike Surfactant Micelles and Magnetic Nanoparticles under a Magnetic Field. Nanomaterials 2021, 11, 885. [Google Scholar] [CrossRef] [PubMed]

- Fan, M.; Lai, X.; Tang, M.; Li, J.; Wang, L.; Gao, J. Preparation and Properties of a Clean, Low-damage Waterproof Locking Damage Multifunctional Integrated Water-based Fracturing Fluid. J. Appl. Polym. Sci. 2022, 139, e53207. [Google Scholar] [CrossRef]

- Fu, L.; Liao, K.; Ge, J.; Huang, W.; Chen, L.; Sun, X.; Zhang, S. Study on the Damage and Control Method of Fracturing Fluid to Tight Reservoir Matrix. J. Nat. Gas Sci. Eng. 2020, 82, 103464. [Google Scholar] [CrossRef]

- Yu, X.; Hong, L.; Zhai, C.; Cheng, Z.; Zhao, N.; Sun, P.; Regenauer-Lieb, K. Quantification of the Effects of the Clean Fracturing Fluid of Mixed Anion-Zwitterionic VES on Methane Sorption Behavior in Bituminous and Anthracite Coals. J. Energy Eng. 2025, 151, 04025011. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, G.; Jiang, W.; Niu, C.; Xue, Y. Preparation and Performance Analysis of Bisamido-Based Cationic Surfactant Fracturing Fluid for Coal Seam Water Injection. J. Mol. Liq. 2021, 332, 115806. [Google Scholar] [CrossRef]

- Li, L.; Sun, Y.; Li, Y.; Wang, R.; Chen, J.; Wu, Y.; Dai, C. Interface Properties Evolution and Imbibition Mechanism of Gel Breaking Fluid of Clean Fracturing Fluid. J. Mol. Liq. 2022, 359, 118952. [Google Scholar] [CrossRef]

- Huang, S.; Jiang, G.; Wang, Q.; Zhu, L.; Yang, J.; Guo, C.; Dong, T.; He, Y.; Yang, L. Preparation and Performance Evaluation of Viscoelastic Zwitterionic Surfactant for Cleaning Fracturing Fluids. J. Mol. Liq. 2024, 416, 126495. [Google Scholar] [CrossRef]

- Fang, X.; Wu, C.; Gao, B.; Zhang, S.; Zhou, D.; Jiang, X.; Liu, N. Effects of active hydraulic fracturing fluid on the fracture propagation and structural damage of coal: Phenomena and mechanisms. Nat. Resour. Res. 2023, 32, 1761–1775. [Google Scholar] [CrossRef]

| Core Number | Length/cm | Diameter/cm | Porosity/% | Gas Permeability/mD |

|---|---|---|---|---|

| Y-1 | 4.99 | 2.50 | 2.035 | 3.2241 |

| Y-2 | 4.95 | 2.49 | 4.183 | 0.8066 |

| Sample Number | Fracturing Fluid System | Length/cm | Diameter/cm | K1/mD | K2/mD | Damage Rate (%) |

|---|---|---|---|---|---|---|

| Y-1 | 0.4%SlickwoA Dose + 0.2%Slickwo-B Dose | 4.99 | 2.50 | 3.2241 | 1.6643 | 48.4 |

| Y-2 | 0.5%SlickwoA Dose + 0.2%Slickwo-B Dose | 4.95 | 2.49 | 0.8066 | 0.3743 | 53.6 |

| Pore Throat Type | Pore Throat Radius Range (μm) |

|---|---|

| Small pore | <0.01 |

| Medium pore | 0.01–0.1 |

| Large pore | >0.1 |

| Sample Number | Pore Throat Type | Retention Degree/% |

|---|---|---|

| Y-1 | Small pore | 65.18 |

| Medium pore | 18.87 | |

| Large pore | 3.26 | |

| Entirety | 62.24 | |

| Y-2 | Small pore | 69.81 |

| Medium pore | 21.63 | |

| Large pore | 3.77 | |

| Entirety | 68.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Liu, A.; Zhang, F.; Liu, Y.; Yan, L.; Jie, Y.; Wang, C. Research on Damage Characteristics of Clean Fracturing Fluid in Deep Coal Seam. Processes 2025, 13, 2669. https://doi.org/10.3390/pr13092669

Wu J, Liu A, Zhang F, Liu Y, Yan L, Jie Y, Wang C. Research on Damage Characteristics of Clean Fracturing Fluid in Deep Coal Seam. Processes. 2025; 13(9):2669. https://doi.org/10.3390/pr13092669

Chicago/Turabian StyleWu, Jinqiao, Anbang Liu, Fengsan Zhang, Yiting Liu, Le Yan, Yenan Jie, and Chen Wang. 2025. "Research on Damage Characteristics of Clean Fracturing Fluid in Deep Coal Seam" Processes 13, no. 9: 2669. https://doi.org/10.3390/pr13092669

APA StyleWu, J., Liu, A., Zhang, F., Liu, Y., Yan, L., Jie, Y., & Wang, C. (2025). Research on Damage Characteristics of Clean Fracturing Fluid in Deep Coal Seam. Processes, 13(9), 2669. https://doi.org/10.3390/pr13092669