Remote Monitoring and Energy Grade Evaluation for Water-Based Centrifugal Pumps Based on Browser/Server Architecture

Abstract

1. Introduction

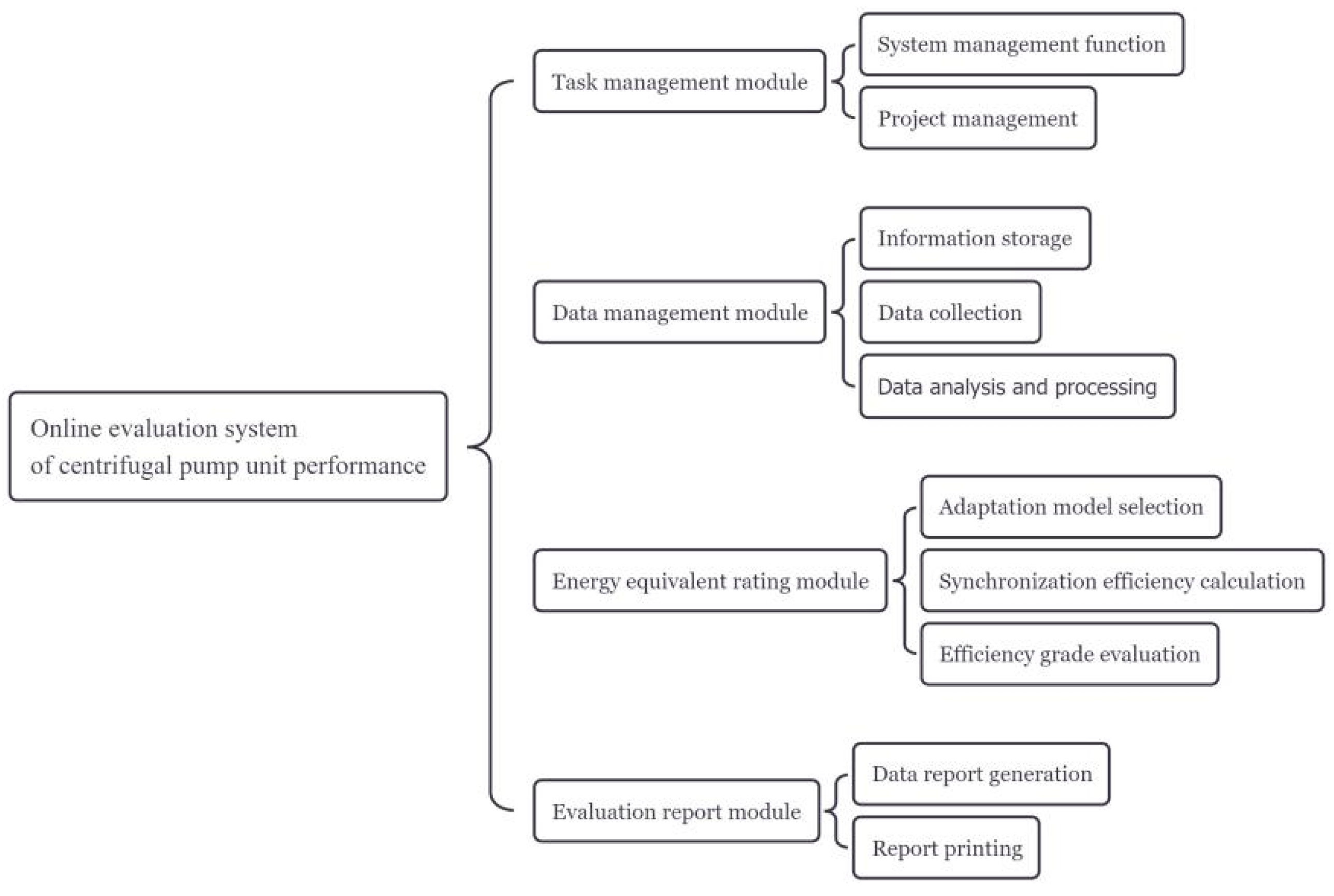

2. Overall System Design

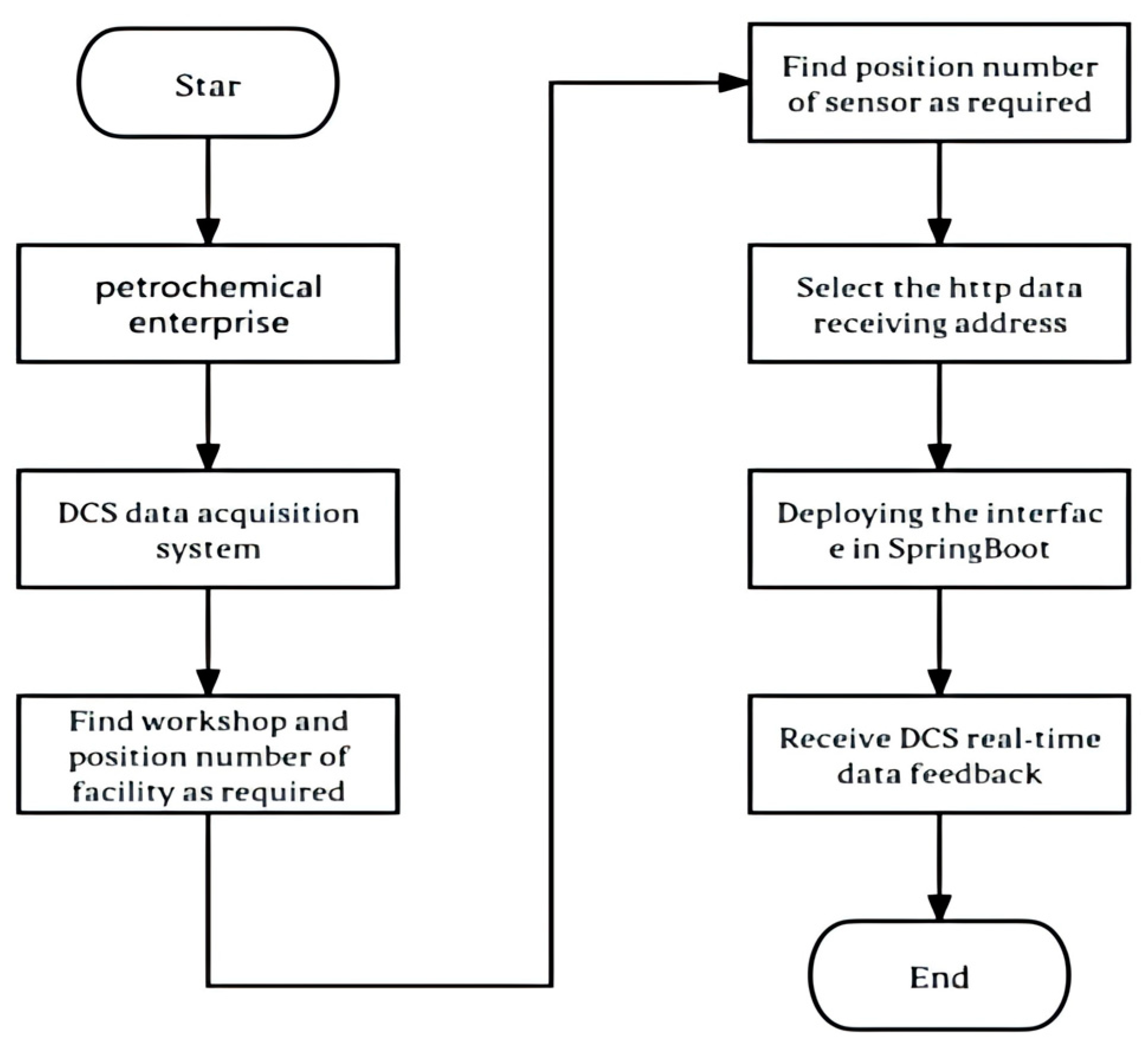

3. Development of Energy Efficiency Rating System

3.1. Centrifugal Pump Energy Level Formula

- (1)

- The equation for calculating the specific rotational speed of the centrifugal pump is shown below:

- (2)

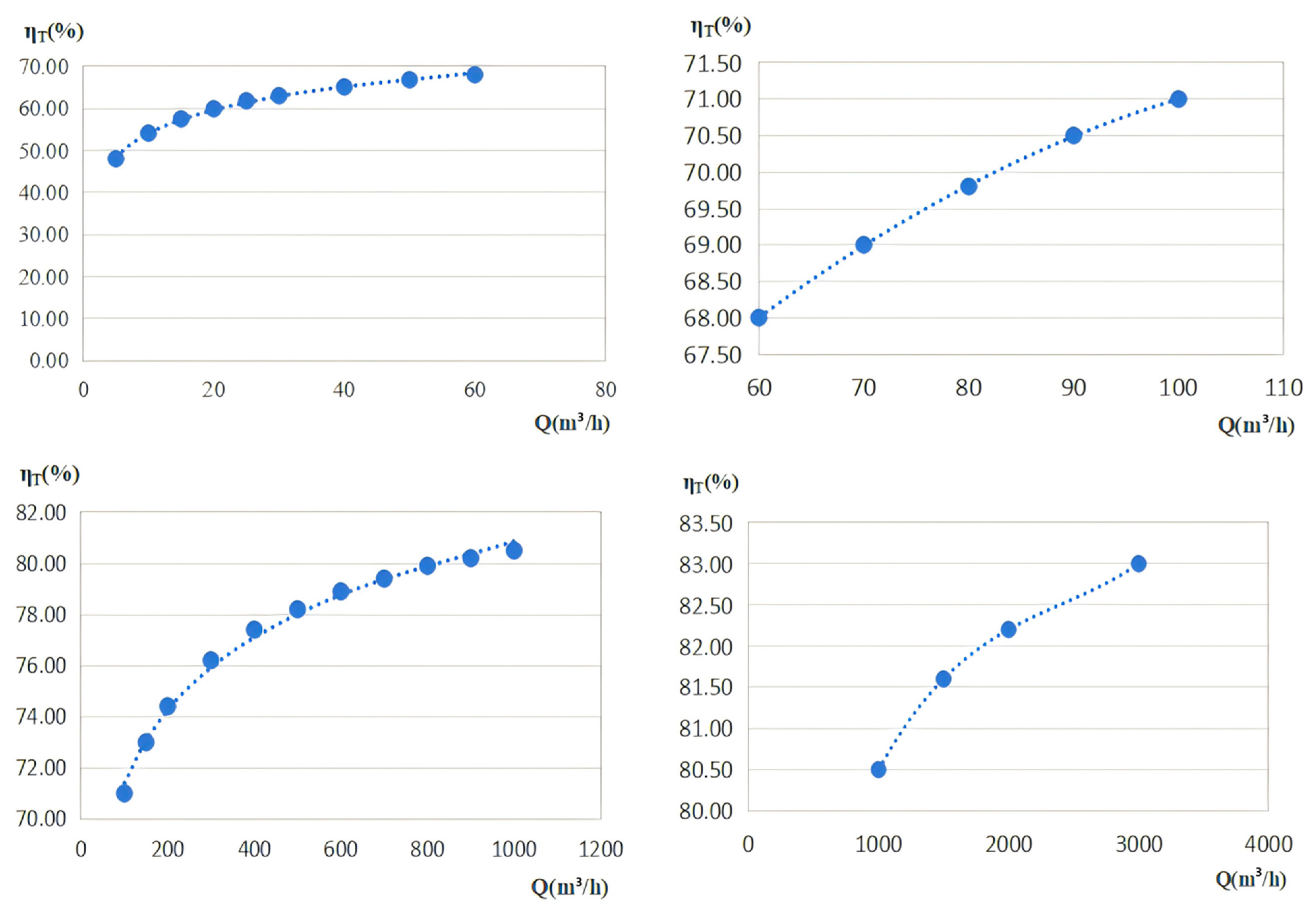

- According to the value provided by the manufacturer, the flow rate (Q) and efficiency reference value (η) can be obtained, as shown in Figure 3. In order to prevent overfitting [19], we limit the highest degree of the fitted polynomial to 0 to 3. The segment function of the reference efficiency (η) is shown in Equation (2):

- (3)

- Figure 4 is a graph of the flow rate and the target energy efficiency limits. The segment function obtained from this fitting is shown in Equation (3):

- (4)

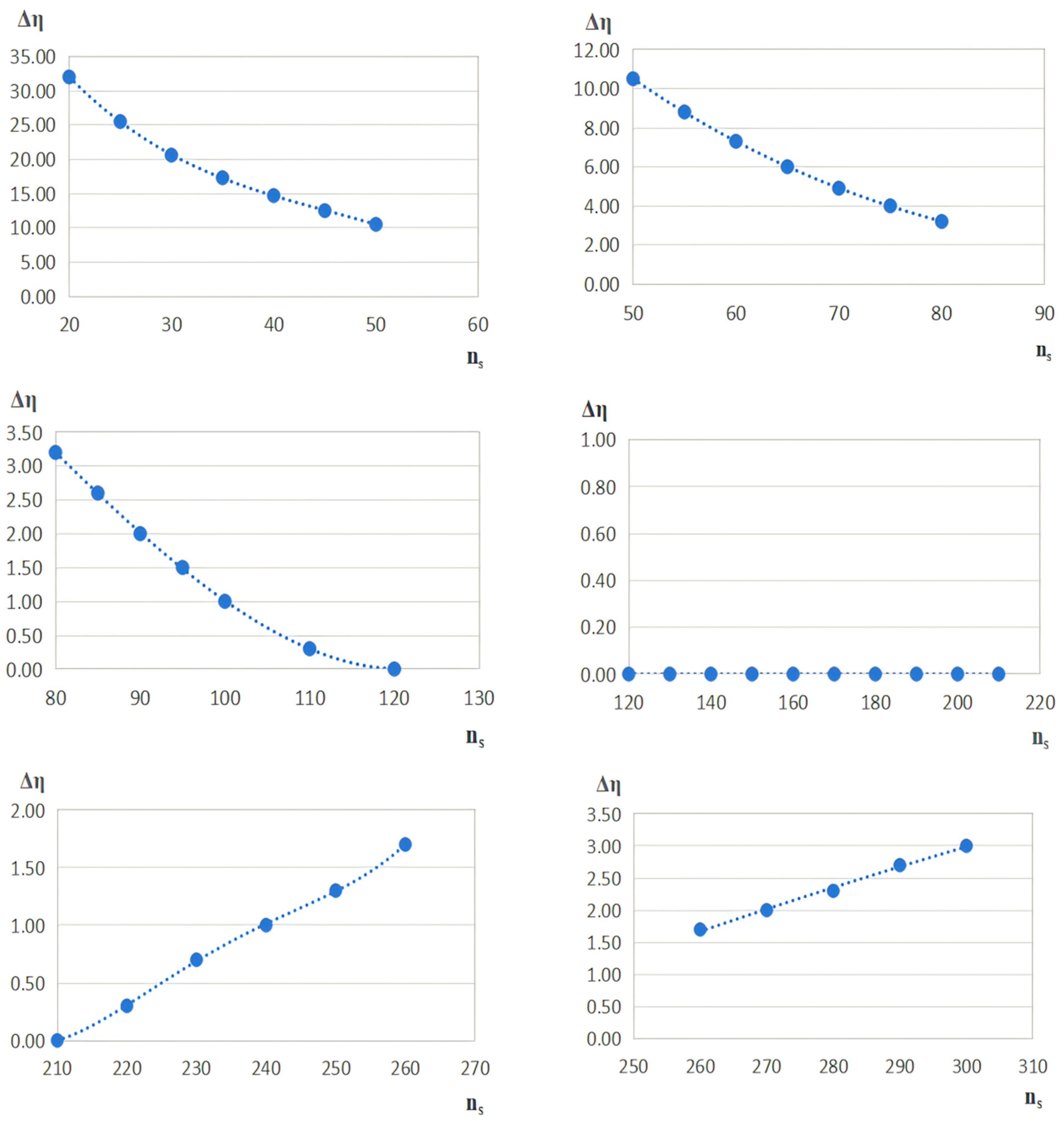

- Table 1 is the energy efficiency grade evaluation table [20]. According to the real-time flow Q, specific speed ns, efficiency reference value η, target energy efficiency limit value ηT, and efficiency correction value Δη, the first level energy efficiency, second level energy efficiency, and third level energy efficiency of the centrifugal pump are determined.

- (5)

- The system evaluates the energy efficiency grade of the centrifugal pump according to the fitting results and the actual efficiency of the centrifugal pump ηP:

3.2. Three-Phase Asynchronous Electromotor Energy Level Standard

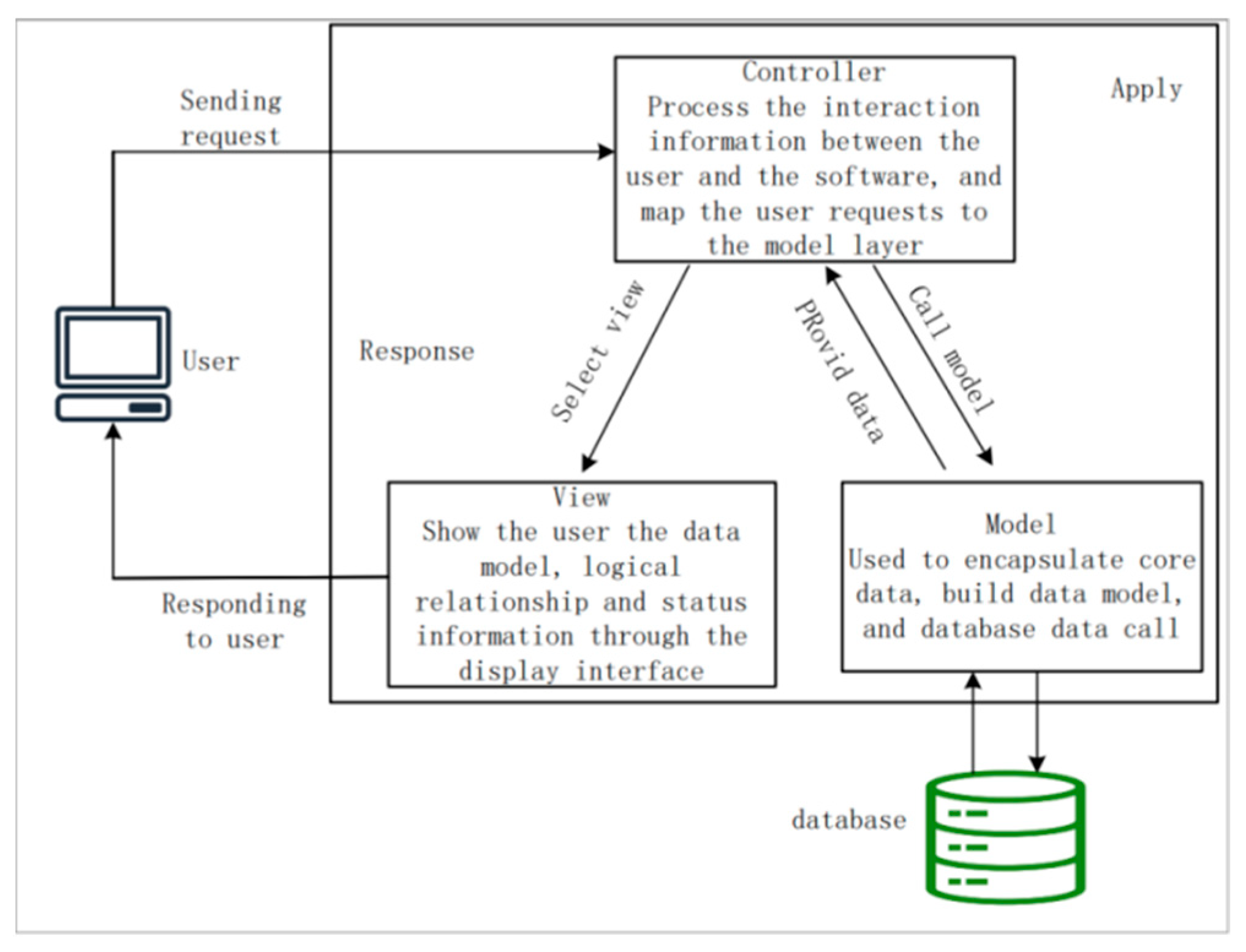

4. Browser/Server-Based System Development

4.1. System Development Architecture

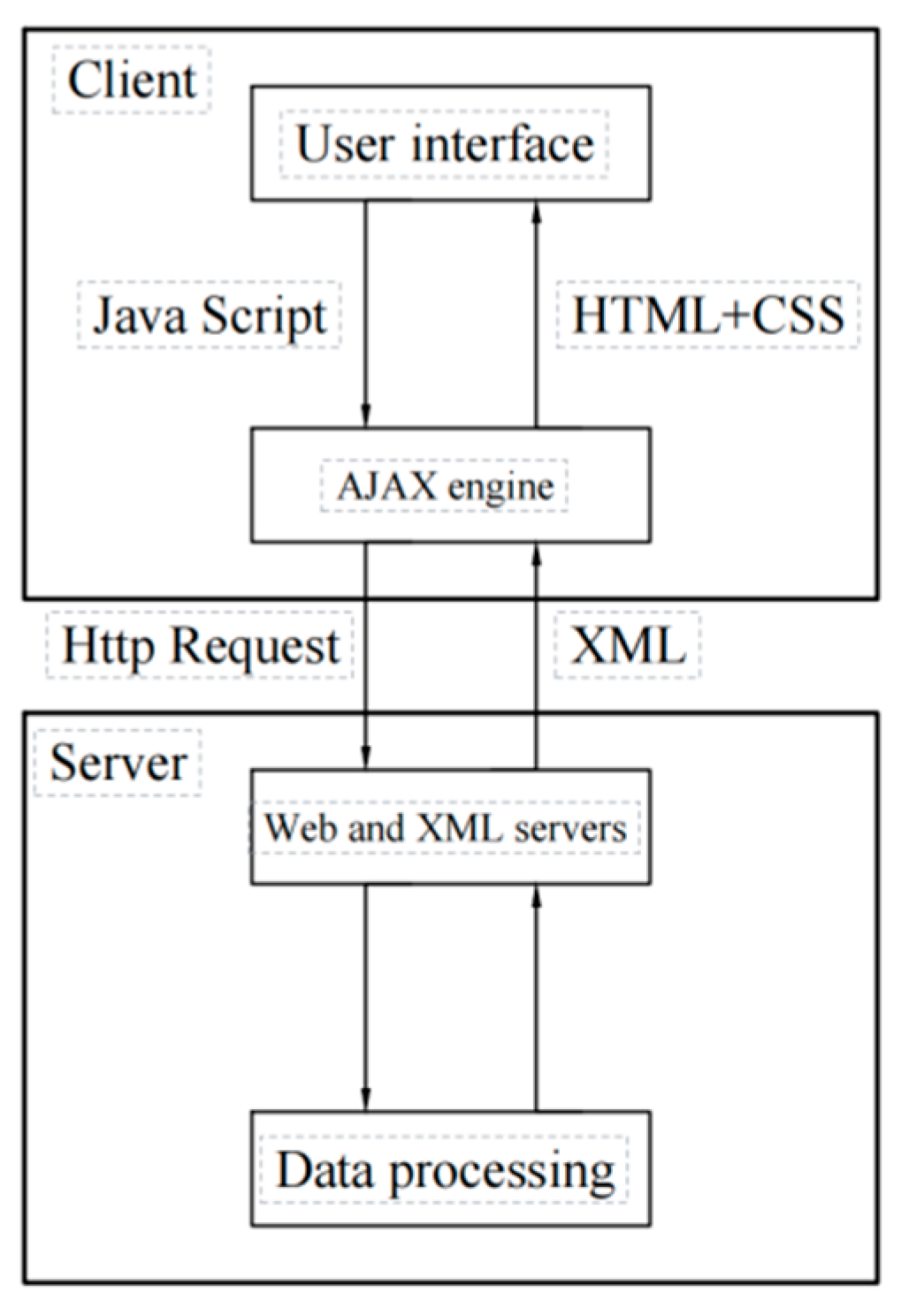

4.2. System Front-End Design

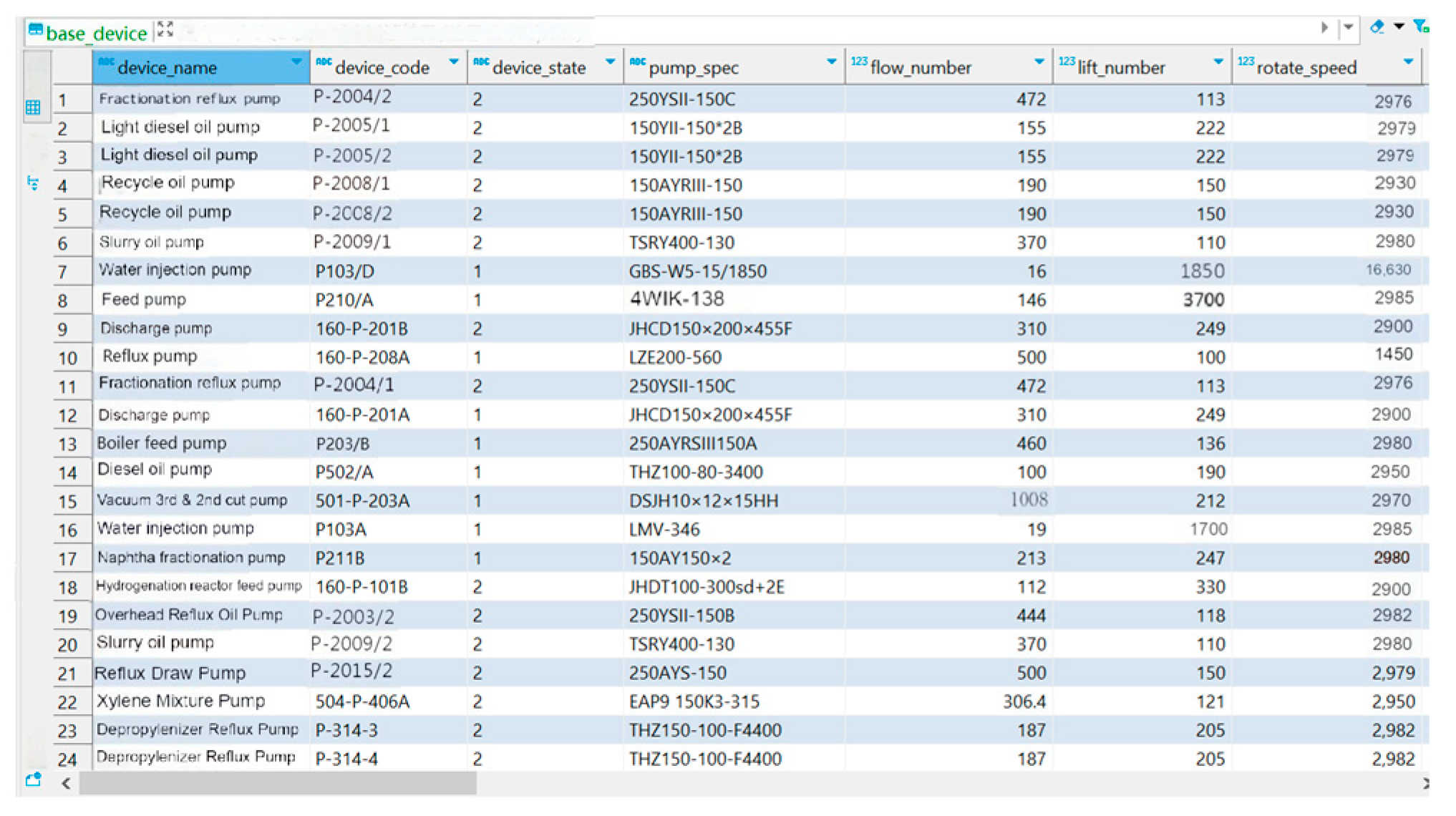

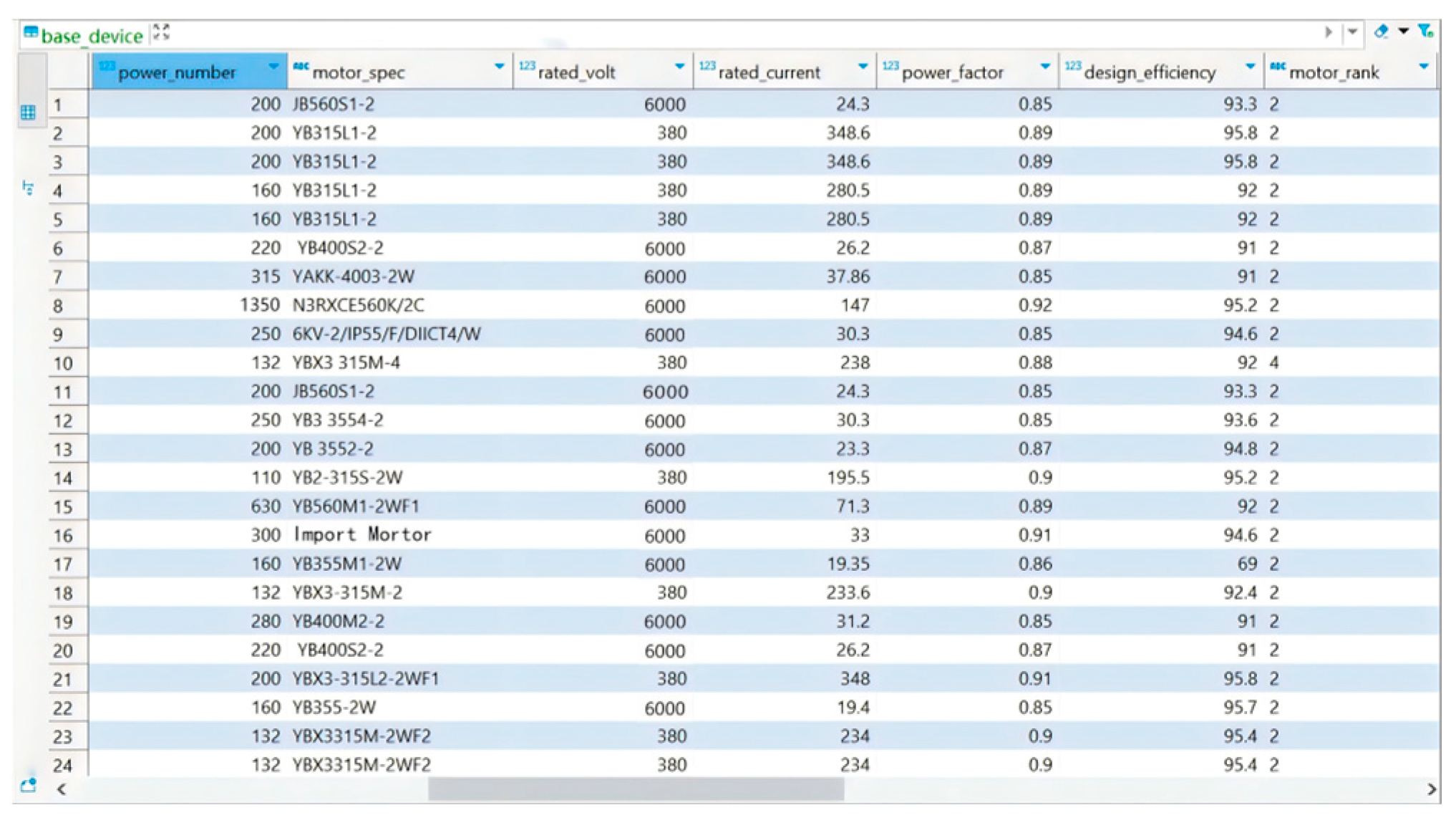

4.3. Database Technology

4.4. RESTful API Data Interface Technology

5. Main Functional Test of the System

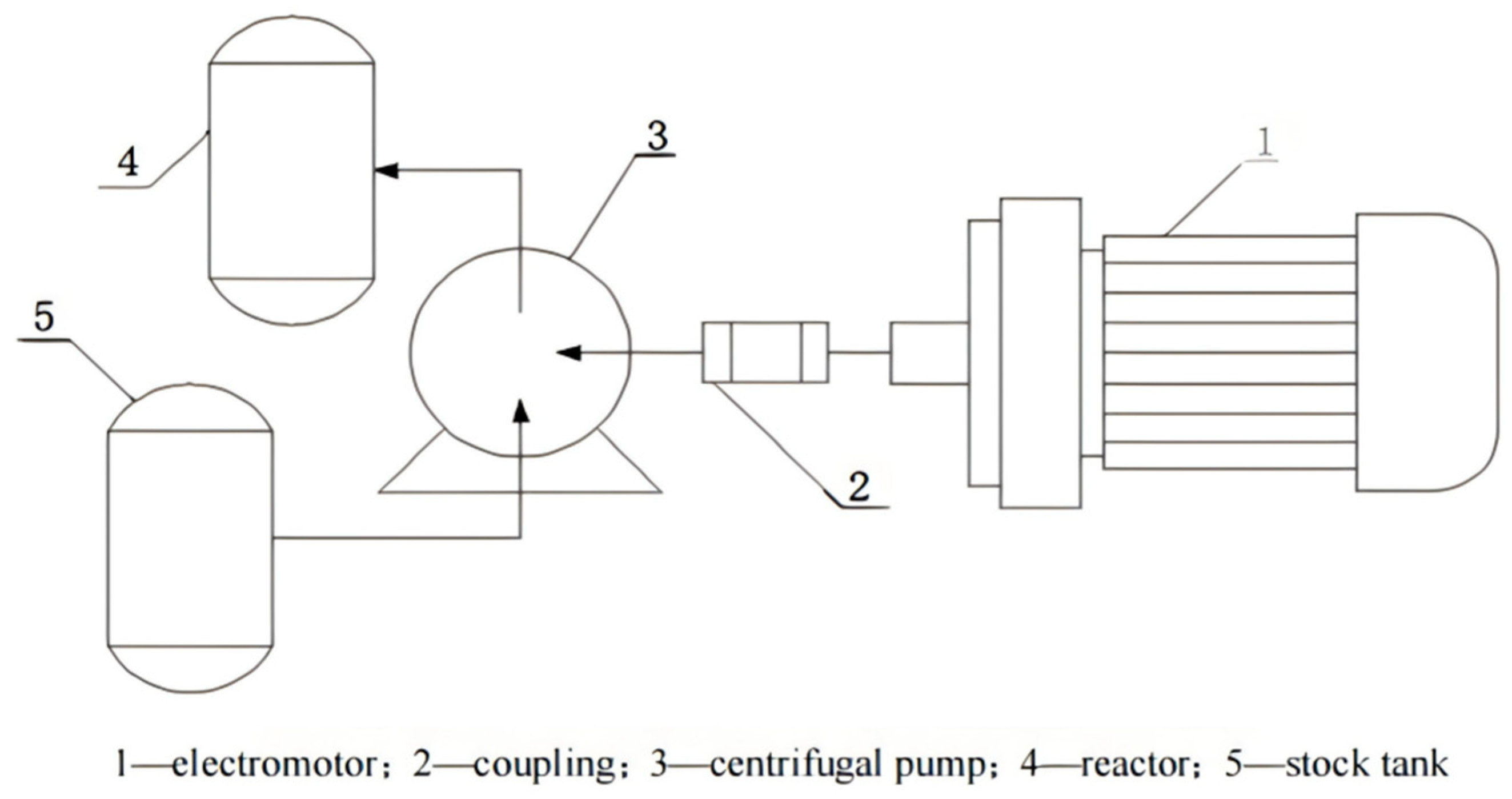

5.1. Basic Parameters of the Centrifugal Pump Unit

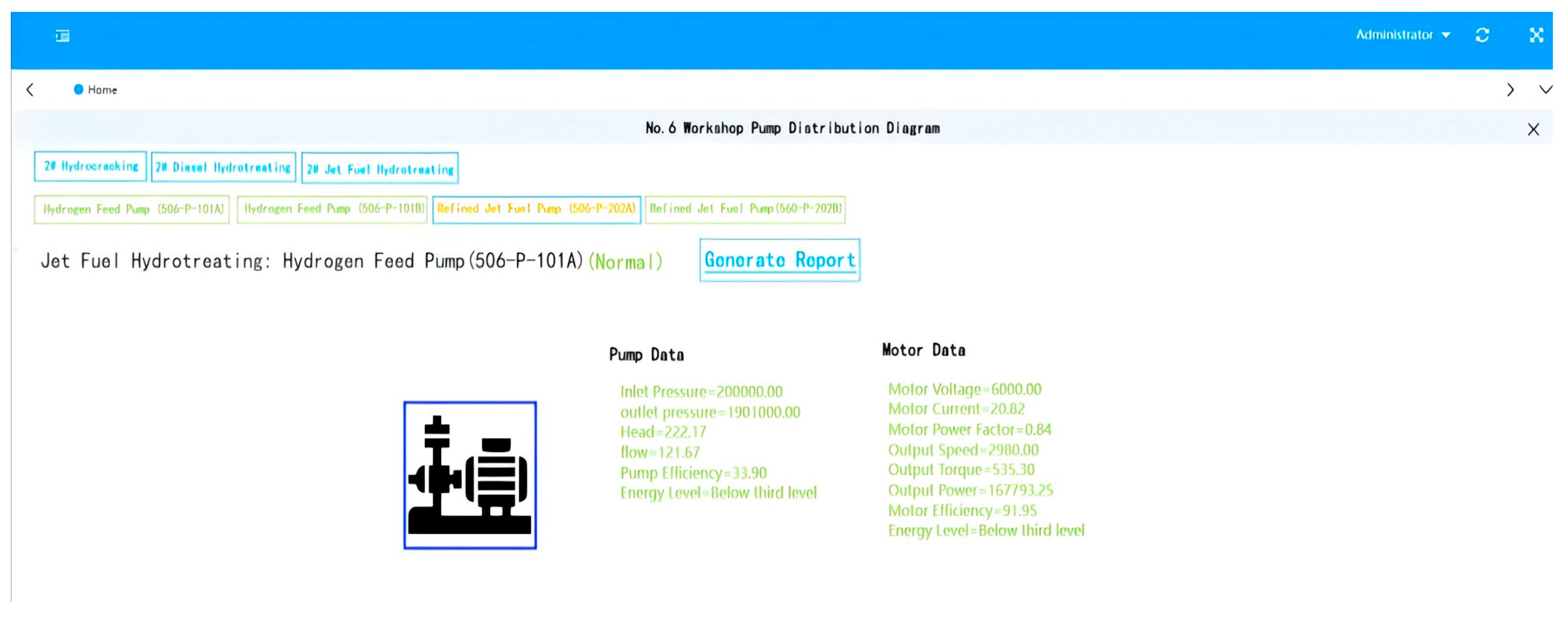

5.2. Implementation of the Equipment Monitoring Function

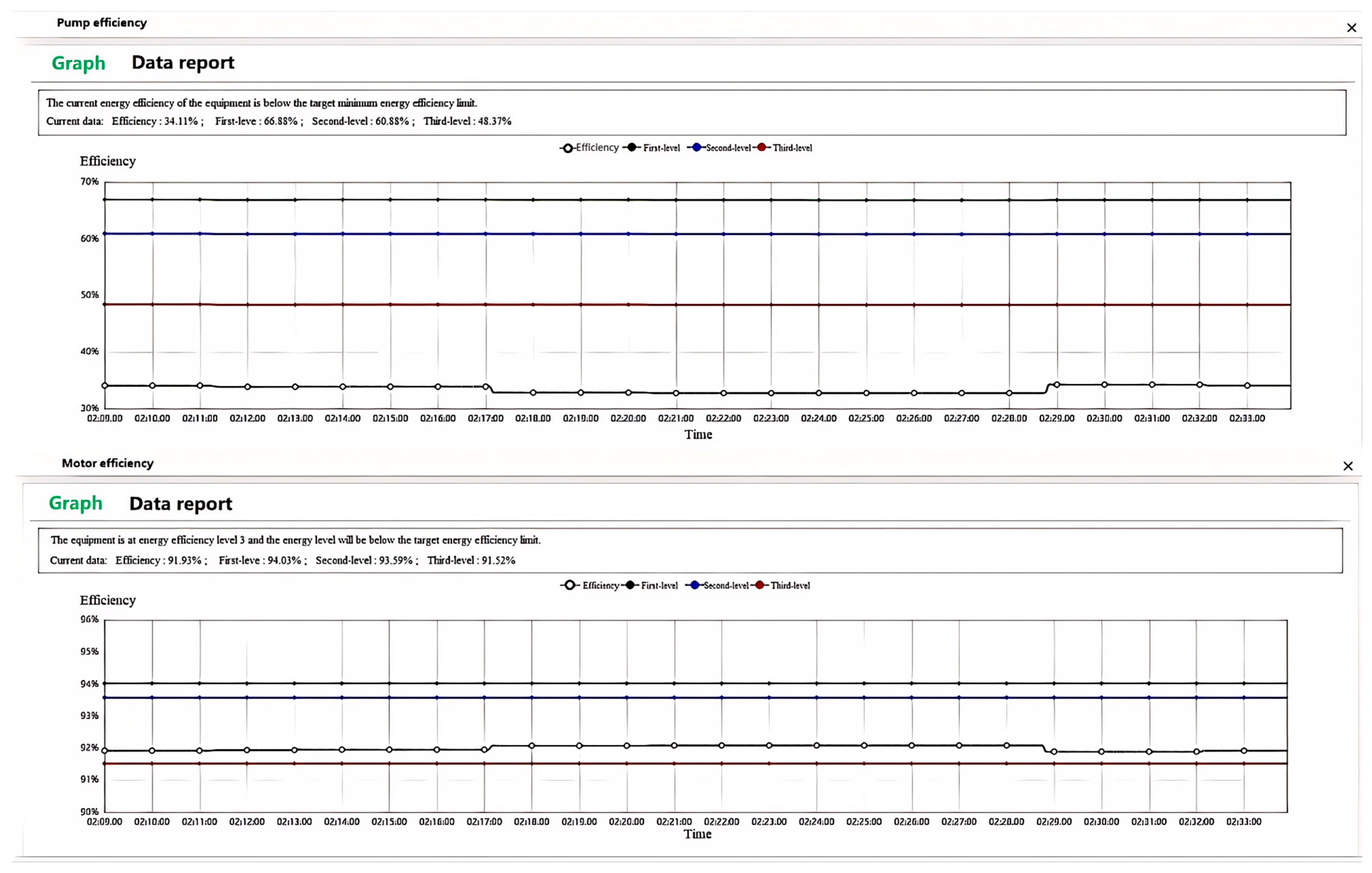

5.3. Realization of the Online Evaluation Function of Energy Efficiency Grade

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- De Almeida, A.; Fong, J.; Brunner, C.U.; Werle, R.; Van Werkhoven, M. New technology trends and policy needs in energy efficient motor systems-A major opportunity for energy and carbon savings. Renew. Sustain. Energy Rev. 2019, 115, 109384. [Google Scholar] [CrossRef]

- Miao, C.; Fang, D.; Sun, L.; Luo, Q. Natural resources utilization efficiency under the influence of green technological innovation. Resour. Conserv. Recycl. 2017, 126, 153–161. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, C.; Shou, B.; Zhou, W.; Zhang, Z.; Wang, S.; Bai, B. A quantitative energy efficiency evaluation and grading of plate heat exchangers. Energy 2018, 142, 228–233. [Google Scholar] [CrossRef]

- Muralidhar, K.; Rajasekar, N. A review of various components of solar water-pumping system: Configuration, characteristics, and performance. Int. Trans. Electr. Energy Syst. 2021, 31, e13002. [Google Scholar] [CrossRef]

- Vikhlyantsev, A.A.; Volkov, A.V.; Ryzhenkov, A.V.; Druzhinin, A.A.; Šoukal, J.; Sedlař, M.; Komárek, M.; Pochylý, F.; Rudolf, P.; Fialová, S. Increasing Efficiency for MicroHPP Hydroturbines Operating under Variable Head Pressure Using an Aperiodic Blade System. Therm. Eng. 2020, 67, 922–930. [Google Scholar] [CrossRef]

- Emami, S.A.; Emami, M.H. Design and Implementation of an Online Precise Monitoring and Performance Analysis System for Centrifugal Pumps. IEEE Trans. Ind. Electron. 2018, 65, 1636–1644. [Google Scholar] [CrossRef]

- Chen, L.; Wei, L.; Wang, Y.; Wang, J.; Li, W. Monitoring and Predictive Maintenance of Centrifugal Pumps Based on Smart Sensors. Sensors 2022, 22, 2106. [Google Scholar] [CrossRef]

- Zhang, M. Research on Flowrate Control and Lifecycle Prediction Method of Centrifugal Pump Based on Condition Monitoring System. Master’s Thesis, Jiangsu University, Zhenjiang, China, 2022. [Google Scholar]

- Feng, F.; Cai, D.; Chang, Z.; Wu, J.; Bamisile, O.; Huang, Q. Exploring the Performance Test of Smart Substation Auxiliary Control System Test Platform Based on B/S Architecture. In Proceedings of the International Conference on Power and Electrical Engineering, Singapore, 3–5 November 2023; Springer Nature Singapore: Singapore, 2023; pp. 175–185. [Google Scholar]

- Li, D. Green Logistics Supply Chain System Based on B/S Architecture and Mileage Saving Algorithm. Sustain. Oper. Comput. 2025, in press. [Google Scholar] [CrossRef]

- Zhao, Y. Research on energy evaluation system of transfer pump unit based on combination model. Energy Conserv. Meas. Pet. Petrochem. Ind. 2023, 13, 61–65. [Google Scholar]

- Hammo, S.; Viholainen, J. Testing the accuracy of pump flow calculation without metering. World Pumps 2005, 2005, 36–39. [Google Scholar] [CrossRef]

- Frequency-converter-based hybrid estimation method for the centrifugal pump operational state. IEEE Trans. Ind. Electron. 2011, 59, 4803–4809.

- Ahonen, T.; Tamminen, J.; Ahola, J.; Viholainen, J.; Aranto, N.; Kestilä, J. Estimation of pump operational state with model-based methods. Energy Convers. Manag. 2010, 51, 1319–1325. [Google Scholar] [CrossRef]

- Heo, M.W.; Ma, S.B.; Shim, H.S.; Kim, K.Y. High-efficiency design optimization of a centrifugal pump. J. Mech. Sci. Technol. 2016, 30, 3917–3927. [Google Scholar] [CrossRef]

- Hieninger, T.; Schmidt-Vollus, R.; Schlücker, E. Improving energy efficiency of individual centrifugal pump systems using model-free and on-line optimization methods. Appl. Energy 2021, 304, 117311. [Google Scholar] [CrossRef]

- Bordeasu, D.; Dragan, F.; Filip, I.; Szeidert, I.; Tirian, G.O. Estimation of Centrifugal Pump Efficiency at Variable Frequency for Irrigation Systems. Sustainability 2024, 16, 4134. [Google Scholar] [CrossRef]

- GB 32284-2015; Minimum Allowable Values of Energy Efficiency and Energy Efficiency Grades for Petrochemical Centrifugal Pumps. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China; Standardization Administration of the People’s Republic of China: Beijing, China, 2015.

- Khan, A.; Bradshaw, C.R.; Schmitt, J.; Langebach, R. Predicting vapor injected compressor performance using artificial neural networks. In Proceedings of the International Compressor Engineering Conference, West Lafayette, IN, USA, 15–18 July 2024. [Google Scholar]

- GB 30254-2013; Minimum Allowable Values of Energy Efficiency and the Energy Efficiency Grades for Cage Three-Phase High Voltage Induction Motor. Standardization Administration of the People’s Republic of China; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2013.

- Liu, J.P.; Cai, S.Q.; Liu, S.Y.; Ren, X.L.; Xie, Z.P. Visual management method and system for station assets. Softw. Guide 2024, 1–10. Available online: https://kns.cnki.net/kcms2/article/abstract?v=9oehDy4zW5b75J_-QaNlTdCq-yAo9yQZyVJwLFAigIoiPzbHNUuq4dddFIpV-zdT9qYdgXpO2wfv-nmqGeVR6CNyiD2eU9qf4hMI5r25tezCCpAdReO2oGHjfdMBWj9eRF5Y2NsYymfNlryetrrdPtCbIHM7-G5G4cJxvi1cWfVLH0PdcIwHnL9UrLKJHUpghiOqLGsx9lE=&uniplatform=NZKPT (accessed on 15 August 2025).

- Jain, P.; Munjal, Y.; Gera, J.; Gupta, P. Performance analysis of various server hosting techniques. Procedia Comput. Sci. 2020, 173, 70–77. [Google Scholar] [CrossRef]

- Nyabuto, M.G.M.; Mony, V.; Mbugua, S. Architectural review of client-server models. Int. J. Sci. Res. Eng. Trends 2024, 10, 139–143. [Google Scholar] [CrossRef]

- Hu, P.F.; Yu, Q. Remote-control system of space station high temperature cabinet foundation experiment based on B/S architecture. Comput. Appl. Softw. 2023, 40, 9–15+78. [Google Scholar]

- Jani, Y. Spring boot for microservices: Patterns, challenges, and best practices. Eur. J. Adv. Eng. Technol. 2020, 7, 73–78. [Google Scholar]

- Subari, A.; Manan, S.; Ariyanto, E. Implementation of MVC (Model-View-Controller) architecture in online submission and reporting process at official travel warrant information system based on web application. J. Phys. Conf. Ser. 2021, 1918, 042145. [Google Scholar] [CrossRef]

- Song, J.H.; Cao, Y. The Design and Implementation of ASP.NET AJAX Technology Based Online Test System. Comput. Knowl. Technol. 2009, 5, 7161–7163. [Google Scholar]

- Qin, W.R. Construction and Application Multi-Source Geographic Information Map Supporting Compound Condition Query. Master’s thesis, Beijing University of Posts and Telecommunications, Beijing, China, 2022. [Google Scholar]

- Jiang, C.; Bao, Z.; Li, C. A Brief Analysis of the Application of MyBatis in Java Development. J. Theory Pract. Eng. Technol. 2024, 1, 25–32. [Google Scholar]

- Wang, R. Web-Based Chinese Musical Instrument Digital Museum System. Master’s thesis, Huazhong University of Science and Technology, Wuhan, China, 2018. [Google Scholar]

| Flow Q (m2/h) | Specific Speed (ns) | First Level η1(%) | Second Level η2(%) | Third Level η3(%) |

|---|---|---|---|---|

| 5 ≤ Q ≤ 300 | 20 ≤ ns < 60 | η − Δη + 10 | η − Δη + 5 | ηT − Δη |

| 5 ≤ Q ≤ 300 | 60 ≤ ns < 120 | η − Δη + 4 | η − Δη + 1 | ηT − Δη |

| 5 ≤ Q ≤ 300 | 120 ≤ ns < 210 | η + 3 | η − Δη + 1 | ηT |

| 5 ≤ Q ≤ 300 | 210 ≤ ns < 300 | η − Δη + 3 | η − Δη + 5 | ηT − Δη |

| Q > 300 | 20 ≤ ns < 60 | η − Δη + 11 | η − Δη + 1 | ηT − Δη |

| Q > 300 | 60 ≤ ns < 120 | η − Δη + 5 | η − Δη + 1 | ηT − Δη |

| Q > 300 | 120 ≤ ns < 210 | η + 3 | η − Δη + 2 | ηT |

| Q > 300 | 210 ≤ ns < 300 | η − Δη + 3 | η − Δη + 2 | ηT − Δη |

| Rated Power (KW) | First Level η1 (%) | Second Level η2 (%) | Third Level η3 (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Motor Pole Number | 2 | 4 | 6 | 8 | 2 | 4 | 6 | 8 | 2 | 4 | 6 | 8 |

| 710 | 96.0 | 95.9 | 96.0 | 95.9 | 95.1 | 95.0 | 95.2 | 95.0 | 94.1 | 94.0 | 94.2 | 94.0 |

| 800 | 96.1 | 96.1 | 96.1 | 96.0 | 95.3 | 95.3 | 95.4 | 95.2 | 94.3 | 94.3 | 94.4 | 94.2 |

| 900 | 96.3 | 96.2 | 96.3 | 96.1 | 95.5 | 95.4 | 95.5 | 95.3 | 94.5 | 94.4 | 94.5 | 94.3 |

| 1000 | 96.3 | 96.3 | 96.3 | 96.2 | 95.5 | 95.5 | 95.5 | 95.4 | 94.6 | 94.5 | 94.6 | 94.4 |

| 1120 | 96.4 | 96.3 | 96.4 | 96.3 | 95.6 | 95.5 | 95.6 | 95.5 | 94.7 | 94.6 | 94.7 | 94.5 |

| 1250 | 96.5 | 96.4 | 96.5 | 96.3 | 95.8 | 95.7 | 95.8 | 95.6 | 94.9 | 94.8 | 94.9 | 94.7 |

| The Parameter Name | Symbol | Unit | Numeric |

|---|---|---|---|

| rated flow | 142 | ||

| rated head | m | 388 | |

| Designed speed | 2980 |

| The Parameter Name | Symbol | Unit | Numeric |

|---|---|---|---|

| power rating | KW | 200 | |

| rated voltage | V | 6000 | |

| rated current | A | 27.2 | |

| design efficiency | % | 92.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, S.; Zhao, M.; Liu, J.; Huang, Q.; Liu, Y.; Liu, J.; Sun, T. Remote Monitoring and Energy Grade Evaluation for Water-Based Centrifugal Pumps Based on Browser/Server Architecture. Processes 2025, 13, 2650. https://doi.org/10.3390/pr13082650

Gao S, Zhao M, Liu J, Huang Q, Liu Y, Liu J, Sun T. Remote Monitoring and Energy Grade Evaluation for Water-Based Centrifugal Pumps Based on Browser/Server Architecture. Processes. 2025; 13(8):2650. https://doi.org/10.3390/pr13082650

Chicago/Turabian StyleGao, Shenlong, Mengjiao Zhao, Jingming Liu, Qiang Huang, Yang Liu, Jie Liu, and Tie Sun. 2025. "Remote Monitoring and Energy Grade Evaluation for Water-Based Centrifugal Pumps Based on Browser/Server Architecture" Processes 13, no. 8: 2650. https://doi.org/10.3390/pr13082650

APA StyleGao, S., Zhao, M., Liu, J., Huang, Q., Liu, Y., Liu, J., & Sun, T. (2025). Remote Monitoring and Energy Grade Evaluation for Water-Based Centrifugal Pumps Based on Browser/Server Architecture. Processes, 13(8), 2650. https://doi.org/10.3390/pr13082650