1. Introduction

Conventional reserves are becoming increasingly difficult to access, leading to a growing need for enhanced oil recovery (EOR) techniques in ultra-tight carbonate reservoirs [

1]. These reservoirs present serious difficulties for traditional stimulation methods due to their complex mineralogy, low matrix permeability, and sour conditions. Due to uncontrolled wormhole propagation, poor penetration depth, and rapid acid spending, conventional acidizing techniques usually result in suboptimal performance in such environments [

2]. In contrast to traditional emulsified acid systems, the Polymer-free Delayed Acid System utilizes a special retardation mechanism based on encapsulation that prolongs acid reactivity, maximizes radial penetration, and promotes the development of wormholes in tight formations. The deployment of the Polymer-free Delayed Acid System in a candidate well situated in an onshore Gulf region is thoroughly examined in this study [

3]. A history of unstable production led to the selection of the well, and diagnostic techniques, including pressure transient analysis, mineralogical evaluation, and core-based capillary profiling, verified the presence of near-wellbore damage. A meticulously planned stimulation sequence, real-time injectivity monitoring, and post-job evaluation through flowback and multi-phase testing were all part of the field implementation. Additionally, the extended shutdown time brought on by surface infrastructure delays presents a special chance to assess the acid-induced wormhole network’s resilience in less-than-ideal circumstances.

In addition to comparing the efficacy of the Polymer-free Delayed Acid System to more conventional techniques, this study proposes a scalable stimulation framework that can be applied to comparable tight carbonate reservoirs worldwide [

4]. A significant advancement in the field of carbonate reservoir stimulation is the integration of sophisticated chemical engineering, data-driven design, and diagnostics. The enhanced acid stimulation strategy was rigorously constructed over two stages to achieve optimal reservoir response and long-term productivity enhancement. The first stage focused on preconditioning the formation by injecting tailored pre-flush slugs that prepared the reservoir matrix before acid contact. This included the use of specialist fluids such as the following:

An acid pickling procedure was also used to remove inorganic scaling and residual drilling damage, thereby lowering the skin factor and allowing for better fluid intake.

This extensive preparation step was very important in changing the near-wellbore environment to allow deeper acid propagation. After successfully implementing the pre-treatment stage, the second phase involved deploying the engineered single-phase, Polymer-free Delayed Acid System, a polymer-free retarded formulation particularly designed to give controlled reaction kinetics between HCl and carbonate rocks. Amphoteric surfactants, which have both cationic and anionic functional groups depending on pH, was used for their distinct surface activity, stability across a wide pH range, and compatibility with divalent ions present in carbonate deposits.

In this formulation, the amphoteric surfactant functions as a reaction retarder by producing a transitory interfacial coating on the rock surface and partially enclosing acid molecules, limiting their immediate availability to react with the formation. This delay in acid–rock interaction allows for deeper acid penetration before considerable spending occurs, especially in low-permeability or tight carbonate reservoirs. The single-phase nature allows for easy preparation, constant distribution, and reduces the risk of emulsion formation or phase separation during pumping promoted as single-homogenous phase acid retarder (

Figure 1). The retardation mechanism guarantees that minimal acid is spent near the wellbore, allowing for long-term acid reactivity deep within the matrix. This results in the production of dominating conductive wormholes that extend into previously unstimulated zones, circumventing formation dams and improving hydrocarbon flow pathways. This sequential, integrated stimulation approach enhanced acid penetration and treatment uniformity while also improving reservoir injectivity and skin removal, resulting in a demonstrable improvement in post-treatment well performance.

This paper aims to provide a comprehensive examination of the Polymer-free Delayed Acid System’s post-stimulation performance, chemical formulation, and operational methodology. The geological environment is reviewed, the stimulation job design is broken down, the difficulties encountered during the execution phase are discussed, and the production uplift observed is examined. To get around these restrictions, new retarded acid systems have been developed “recently” in stimulation chemistry [

5]. Among these, the Polymer-free Delayed Acid System is a cutting-edge solution designed especially for use in hostile reservoir conditions, such as those with high temperatures, with H

2S concentrations, and low permeability or tight formation.

2. Materials and Methods

This research focuses on a potential well located within a mature carbonate reservoir in the onshore Gulf region. The reservoir is highly heterogeneous due to its complex diagenetic development, consisting mostly of tight micritic limestone interbedded with dolomitic streaks, small anhydrite inclusions, and indications of siliceous minerals. Given the formation’s mineralogical heterogeneity and damage profile, a standard high-concentration acid treatment was found to be insufficient to achieve the targeted stimulation depth and production increase.

To address this, a unique acid solution was created with a customized reaction kinetics profile that achieves extended retardation, outperforms near-wellbore damage (skin), and allows deep live acid penetration into the reservoir matrix [

6]. The formulation deviated from the standard acid-concentration-based design and instead depended on regulated acid–rock interaction rates that could be changed based on mineralogical composition and reservoir temperature.

Retarded acid systems are designed to slow down the interaction rate between acid and carbonate rock, allowing for deeper acid penetration, better wormhole propagation, and more effective stimulation of low-permeability or heterogeneous reservoirs.

Table 1 presents several types of acid retardation technologies have been developed, including viscous acid systems, which use high molecular weight polymers or gelling agents to increase acid viscosity and slow reaction kinetics; emulsified acid systems, which physically entrap acid droplets in an oil-continuous external phase using surfactants and emulsifiers, thereby reducing acid reactivity at the rock surface; and gelled or crosslinked acids, which use polymer crosslinking. While these technologies provide variable degrees of retardation, they frequently have operational limitations such as mixing complexity, limited heat stability, emulsion instability, formation damage risk, and cleanup challenges.

In contrast, the chemically retarded acid system is a next-generation solution that serves as an enhanced improvement to classic emulsified acid technology while being developed in a single-phase acid format. Rather than relying on physical barriers such as emulsions or viscosity control, this system employs amphoteric or reactive surfactants and additives that interact at the molecular level to temporarily shield acid molecules and adsorb on the rock surface, chemically delaying the acid–rock interaction while retaining the fluid’s phase behavior and flow characteristics. This single-phase formulation eliminates the dangers associated with phase separation, emulsion breakdown, and complex field blending.

It remains stable over a wide temperature range and is compatible with common acid additives including corrosion inhibitors, scale inhibitors, and iron control agents. Compared to all other retarded acid systems as demonstrated in

Table 1, chemically retarded single-phase acid provides superior operational simplicity, predictable retardation behavior, cleaner post-treatment flowback, and improved wormhole efficiency, making it an ideal and versatile candidate for full-field application, particularly in complex carbonate reservoirs like those in Abu Dhabi.

Given the inherent limitations associated with rapid acid spending during conventional acidizing, particularly near the wellbore, the newly developed single-phase Delayed Acid System with an amphoteric surfactant base was carefully chosen and deployed to address critical challenges in carbonate stimulation. Traditional acid systems frequently react too quickly with formation minerals, resulting in significant acid loss, restricted penetration, and inefficient wormholing. The novel retarded acid formulation reduces these losses by dramatically decreasing the acid–rock interaction rate, allowing for deeper penetration, more uniform contact with the reservoir, and improved stimulation coverage—particularly in heterogeneous intervals.

Unlike viscoelastic diverting agents (VDAs), which work by increasing fluid viscosity to seal thief zones or preferentially open pathways and divert subsequent acid stages to less reactive zones, amphoteric-based delayed acid achieves stimulation uniformity intrinsically—without the need for an external diversion stage. It lowers acid reactivity in naturally higher-permeability zones, allowing unspent acid to spread into previously under-stimulated or tighter zones, resulting in balanced reservoir contact. This reactivity-driven diversion method allows for simultaneous treatment of various permeability layers, reducing the possibility of under-stimulation or over-flushing.

In contrast to VDAs, which frequently require tight temperature conditions for activation, specialized mixing equipment, and the possibility of partial cleanup or formation damage, the novel single-phase delayed acid is easier to use and more reliable. It is simple to prepare, handle, and mix in the field, requires no special equipment or pre-treatment, and may be smoothly pumped at conventional flow rates without plugging or shear degradation. It also avoids the viscosity-related pressure drop caused by viscoelastic chemicals, allowing for more control over injection profiles and lowering the risk of exceeding formation fracture pressures.

From a strategic field-wide perspective, the single-phase acid retarder offers numerous distinct advantages over conventional diversion-based treatments:

Inherent response control rather than mechanical or viscosity-based diversion.

Stimulation contact is uniform, with no need for many phases or complex sequencing.

Operating simplicity: there is no need for separate mixing units, breakers, or additional cleanup steps.

Compatible with all carbonate lithologies, including limestone and dolomite.

Reduced operational costs and risk by using fewer additives, pumping pressures, and formation damage potential.

Given these advantages, this acid system represents a universal and field-ready solution—ideal for deployment across Abu Dhabi’s carbonate reservoirs, where formation mineralogy (limestone and dolomite) and permeability profiles necessitate a flexible, effective, and low-risk stimulation strategy.

Extensive laboratory work aided the design process, including compatibility testing, solubility studies, and core flood evaluations on several core samples to evaluate the novel system’s performance under actual conditions [

7]. These experiments confirmed that the acid system was effective across a wide variety of mineral compositions and reservoir properties, indicating its robustness and suitability for field application. The next subsections provide extensive material specifications, testing methodologies, and experimental settings to assure reproducibility and allow future researchers to build on these findings.

2.1. Oilfield Potential and Capacity

The oilfield in question, located approximately 290 km from the borders of three oil-exporting countries in the Gulf region—namely, the United Arab Emirates, Saudi Arabia, and Oman—is an important asset in the Operator’s Southeast Cluster, which also comprises the nearby fields. This field is strategically important in the Operator’s larger plan to increase onshore oil production capacity [

7]. In 2015, the operator granted a Chinese company an EPC contract worth 334 million USD USD 334 to build the field’s infrastructure, which included collection stations, pipelines, power transmission, and sewage facilities. This oilfield has a peak production capacity of 20,000 barrels per day (bpd), and production is scheduled to continue until it reaches its economic limit in 2077. Current projections indicate that peak output will occur around 2032, with approximately 20.38% of its total recoverable reserves already extracted. A major oil and gas company in the Gulf region operates the field. It involves several international stakeholders, including BP, CNPC, China Zhen Hua Oil, GS Energy, Inpex, and TotalEnergies. Additionally, a Phase 2 expansion is underway, with an expected operational date of 2027. As part of the wider Southeast Full Field Development project, this oilfield support operator’s goal of increasing its production by 143,000 bpd, highlighting its significant contribution to the Gulf country’s long-term energy security and economic growth.

2.2. Well Selection and Reservoir Characteristics

The selection of field falls in a mature, onshore Gulf region reservoir noted for its ultra-tight carbonate formations made up mostly of micritic limestone with moderate dolomitization. Historically, this field has been hampered by low productivity due to considerable formation heterogeneity, few natural fractures, and severe near-wellbore damage. These qualities have resulted in consistently high skin values and low injectivity for the majority of producers and injectors in the formation.

The candidate well for this study is a vertical producer that has shown persistently inconsistent and irregular oil production behavior for more than two years.

A detailed petrophysical examination using high-resolution wireline logs and core analysis found an average matrix permeability of less than 0.3 millidarcies (mD), classifying the reservoir as ultra-tight. This poor permeability, along with high capillary entry pressures and a heterogeneous pore throat distribution, greatly limits hydrocarbon movement. The formation mineralogy is mostly composed of fine-grained, micritic limestone mixed with fossiliferous pieces and distributed pyrite nodules, which complicate acid–rock interaction and effective stimulation. The petrophysical dataset, compiled from multiple logging suites, included porosity, permeability, formation resistivity, and saturation profiles. Reservoir condition data, including bottomhole temperature, pressure (exceeding 120 °C in some intervals), and gas content (with measurable concentrations of H

2S and CO

2), were analyzed to tailor a safe and compatible treatment design. Previous intervention data showed that several stimulations opertaions with conventional acids resulted in only minor improvements, with upper perforated intervals generating little oil production. Deeper reservoir layers, on the other hand, showed large log reactions and pressure differentials, indicating the presence of bypassed hydrocarbons that had previously gone untapped due to typical acid systems’ inability to penetrate and react beyond the damaged epidermis and tight matrix. This diagnostic knowledge, together with reservoir heterogeneity and residual damage from drilling and completion fluids, supported the choice of this well for advanced stimulation [

8]. The need to improve contact with these isolated hydrocarbon-bearing layers drove the development of a novel acid formulation that provided controlled retardation, deep live-acid penetration, and skin bypassing, addressing both the candidate well’s geological complexity and operational constraints.

2.3. Introduction of Single-Phase Acid Retarder (Polymer-Free Delayed Acid System)

The Polymer-free Delayed Acid System single-phase retarded acid system is a deliberate departure from traditional acid treatments, providing significant benefits in performance and operational simplicity. The Polymer-free Delayed Acid System uses a novel kinetic retardation mechanism to increase acid–rock contact duration, unlike typical hydrochloric or emulsified acid systems that can cause shallow etching or acid diversion issues near the wellbore. This controlled reactivity allows acid to penetrate deeper into ultra-tight formations and create highly conductive wormholes that bypass both skin injury and matrix flow constraints. The Polymer-free Delayed Acid System is unique among retarded systems because to its single-phase formulation, which eliminates the need for sophisticated emulsification processes and co-surfactants. This reduces the blending time, on-site handling concerns, and emulsifier-related incompatibility. The fluid’s stability under high temperature and pressure conditions, such as those found in the Gulf offshore region and ultra-deep carbonate wells in Brazil, has been extensively validated through field trials, demonstrating consistent post-treatment production enhancement with minimal risk to completion equipment. The Polymer-free Delayed Acid System, unlike conventional acids, provides long-term productivity benefits by initiating dominant wormhole pathways that maintain conductivity even under drawdown pressure. This has been demonstrated in previous successful applications in offshore Gulf assets and complex carbonate systems in Brazil [

9]. The Polymer-free Delayed Acid System outperforms traditional and emulsified acid systems in treating deep, tight, and damaged reservoir intervals because to its simplicity of logistics, pumpability, and thermal stability.

2.4. Materials and Mixture Composition

2.4.1. Chemical Composition of Retarder Additive

Baker Hughes’ polymer-free delayed acid technology is a chemically engineered breakthrough in matrix acidizing that accurately controls the reactivity of hydrochloric acid (HCl) with carbonate deposits. The Polymer-free Delayed Acid System, a patented blend of low-molecular-weight organic compounds, chelating agents, surface-active modifiers, and acid corrosion inhibitors, achieves kinetic control without using viscous or residue-forming additives, unlike traditional polymer-based retarders. The system’s retardation mechanism is based on changing the mass transfer dynamics between the acid and the rock surface—specifically, by controlling the availability of free hydrogen ions and lowering their immediate reactivity via adsorption-limited reaction control [

10]. Chelating chemicals bind to calcium ions after breakdown, delaying secondary precipitation and facilitating deeper acid propagation [

11].

Specialty surfactants are used to reduce interfacial tension and enhance wettability, resulting in improved fluid distribution and reduced acid face diversion. The Polymer-free Delayed Acid System enables live acid to go deeper into the formation, creating high-conductivity wormholes that circumvent near-wellbore damage and access restricted pore structures that fast-acting acids cannot. Its polymer-free composition promotes clean breakback, prevents post-treatment permeability impairment, and is compatible with artificial lift systems such as ESPs. The system maintains consistent performance at high bottomhole temperatures (up to ~300 °F), resulting in extended acid–rock contact duration, increased stimulation radius, enhanced reservoir drainage, and long-term productivity gains.

2.4.2. Laboratory Equipment and Testing

Emulsion Stability Test

The Baker Hughes Polymer-free Delayed Acid System, a single-phase, polymer-free formulation, offers remarkable emulsion stability when blended with hydrochloric acid. It forms a single-phase, homogenous solution that remains stable over a wide temperature range. Mixing the Polymer-free Delayed Acid System retarder additive with the acid recipe (15–28% HCl) results in no phase separation, stratification, or precipitation, even after extended holding times.

To imitate downhole conditions, laboratory-based emulsion stability experiments were performed under both static and dynamic circumstances at ambient temperature and gradually increasing temperatures up to 325 °F (163 °C). These assessments validated the system’s chemical integrity and thermal robustness, with no signs of component incompatibility, salt dropout, or viscosity degradation. The mixture exhibited optical clarity and uniformity, indicating steady molecular dispersion. This thermal durability is an important advantage in high-temperature carbonate reservoirs, where traditional acid systems frequently demonstrate emulsion instability, resulting in ineffective wormholing and probable formation damage. Emulsion stability tests were conducted in Superior Abu Dhabi laboratory based in Abu Dhabi in laboratory glass testing tubes by mixing the Polymer-free Delayed Acid System retarder with HCl acid. The tubes were subsequently stored at ambient temperature and in high-temperature aging cells at 94 °C to 163 °C (200 °F to 325 °F) under 200 psi pressure. During the tests, the mixtures remained single phase and homogeneous, with no evident separation, precipitation, or phase stratification [

11].

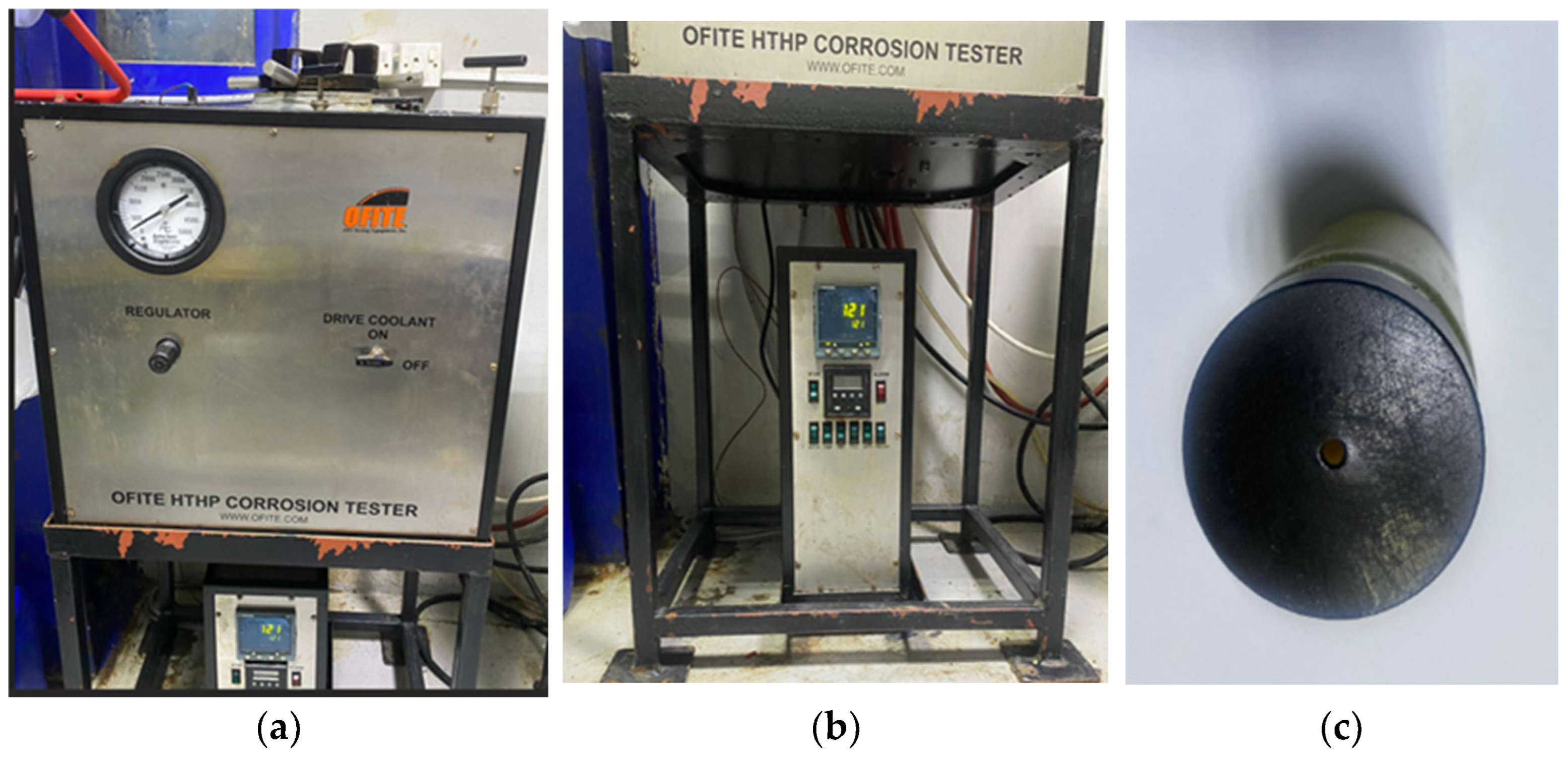

The single-phase acid retarder system’s laboratory preparation and corrosion assessment procedure are shown in detail in

Figure 1. Following the progressive addition of all required additives, such as corrosion inhibitor, surfactant, anti-sludge agent, iron sequestering agent, and other performance enhancers, the final blended acid system is depicted in

Figure 1a. With no indications of phase separation or precipitation, the resultant mixture seems uniform and stable, demonstrating the effective formulation of a suitable single-phase system. For safe handling and dependable field performance, this visual compatibility validation is essential. To replicate operational exposure conditions, the formulated acid retarder is placed into a testing tube in

Figure 1b. The testing tube is placed in an agent cell, which is completely sealed and pressurized up to 200 Psi to meet client requirements. After running the test for a 6 or 12 h exposure period, the testing tubes are retrieved for visual inspection of the stability of the treatment and its homogenous one-phase mixture without any precipitation from the top or at the bottom.

Polymer-free Delayed Acid System’s polymer-free nature removes the chance of post-treatment residue, assuring clean breakback, low-filter cake development, and full permeability. The formulation’s high-temperature emulsion stability emphasizes its dependability for deep matrix penetration and extended acid–rock interaction, making it an excellent choice for demanding stimulation conditions.

Corrosion Test

The Baker Hughes Polymer-free Delayed Acid System™ single-phase retarded acid system was tested for compatibility with downhole equipment in HPHT conditions, using a comprehensive corrosion testing technique. Dynamic corrosion studies were carried out with the OFITE HPHT corrosion tester, which faithfully replicates acid flow and turbulence inside the wellbore during real-world stimulation operations [

12].

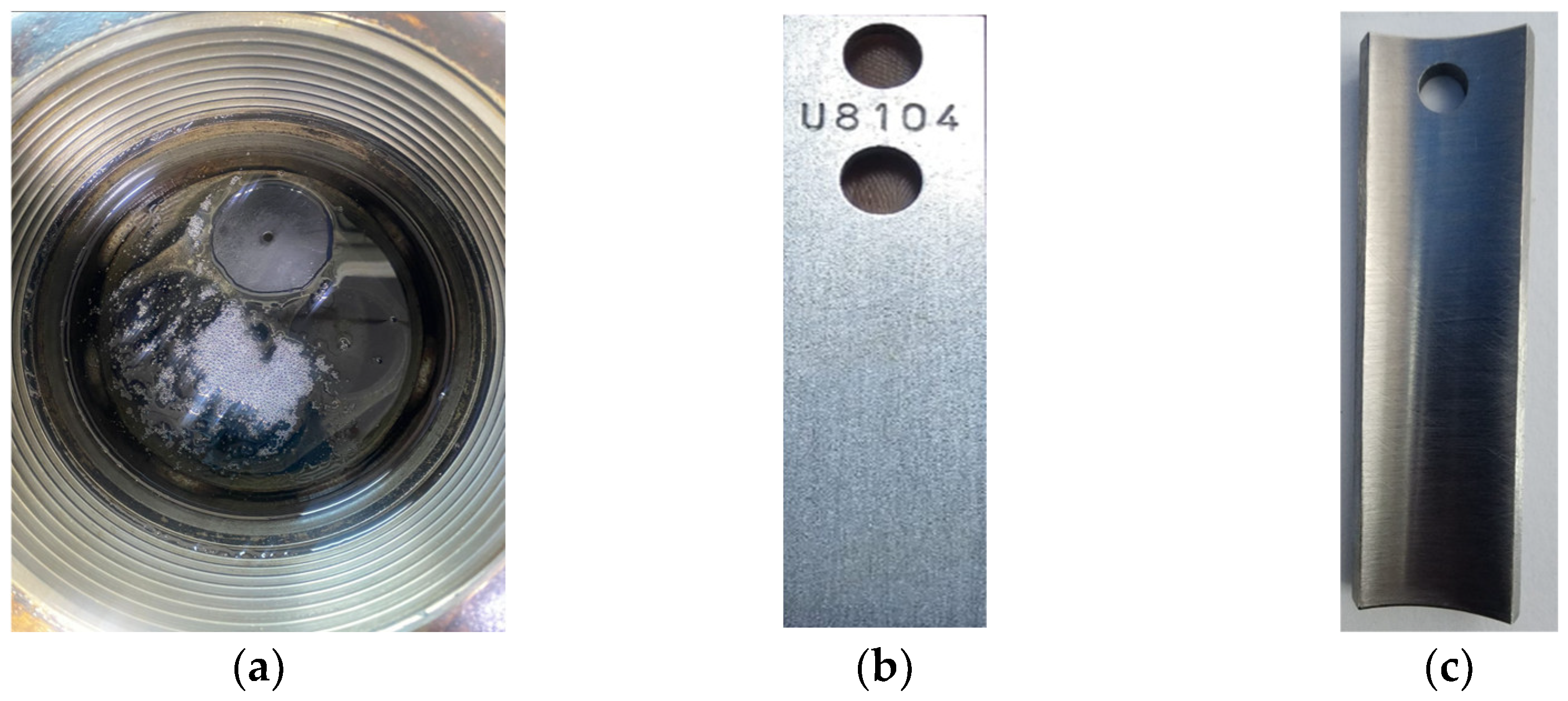

A High-Pressure High-Temperature (HPHT) OFITE corrosion testing system is used to test the single-phase retarder acid formulation for corrosion, as shown in the presented figures. The corrosion tester equipment depicted in the illustration is an OFITE High-Pressure High Temperature (HPHT) apparatus that was specifically built for corrosion testing utilizing the weight loss (gravimetric) approach presented in

Figure 2. This machine is divided into two primary sections: mechanical (or driving) and electronic control. The mechanical part contains a heat exchanger and a chamber that can hold up to four corrosion specimens at once, allowing for more efficient and regulated testing. The electronic part acts as an interface for programming and monitoring test parameters, allowing users to accurately define and manage the heating duration, target temperature, test pressure, treatment exposure time, and cooling phase. The system may operate at pressures of up to 5000 psi; however, in this case, the client specified a corrosion testing pressure of 200 psi. The following configuration allows for exact simulation of downhole conditions to assess the corrosive effects of treatment fluids in realistic high-pressure, high-temperature situations [

13].

In

Figure 3, the acid recipe is put inside a high-integrity corrosion test bottle after being previously mixed with necessary additives (such as corrosion inhibitors, surfactants, anti-sludge agents, and iron sequestering agents). A metallic coupon is positioned and secured precisely within the bottle to be exposed to the acid in a downhole simulation. The gravimetry method, a proven corrosion assessment methodology that measures the weight loss of the metallic coupon before and after testing, is used in this testing procedure to quantify the severity of corrosion. The initial weight of the coupon is carefully noted before testing. The coupon is cleansed of any corrosion byproducts, dried, and reweighed after being subjected to the acid inside the HPHT corrosion cell at high temperatures and pressures (to mimic reservoir conditions). The corrosion rate in grams per square meter (g/m

2), which represents the material loss as a result of acid contact, is computed using the weight difference. The L-80 and QT-800 standard coupons, which each represent tubular steel grades frequently used in oilfield applications, are employed for this test. A corrosion rate of less than 244 g/m

2 is the industry-accepted passing standard for corrosion resistance in such testing. This standard confirms that the acid system is secure and will not harm downhole equipment or well tubulars, confirming its suitable for field trials [

14].

Corrosion Test Procedure

The corrosion testing approach was meticulously devised to reproduce reservoir-specific operational circumstances utilizing the gravimetric corrosion analysis method in dynamic high-pressure, high-temperature (HPHT) settings. The OFITE HPHT corrosion tester machine was used for the testing, which is a specialized device that allows for controlled rotation of test cells to imitate the dynamic flow of acid within the wellbore during stimulation operations. This approach is consistent with both client-standard testing protocols and actual reservoir conditions, assuring great relevance and dependability of results.

In

Figure 4a, specifically made high-temperature-resistant testing bottles are used in the corrosion testing procedure. These bottles are designed to properly hold acid solutions in demanding testing environments, especially when reservoir pressures and temperatures are being simulated. The bottles are sealed with a precisely designed cap that keeps the temperature constant during the test and guarantees a safe, leak-proof environment. With this configuration, the acid formulation is heated consistently without losing its reactive components or being exposed to outside oil surrounding solution, which helps to ensure head transfer from the coil surrounding the acid testing bottle to the HCl system in place for a constant temperature and accuracy of the test. A metal coupon, either L-80 or QT-800, is completely immersed in the acid solution inside the testing container in

Figure 4b. A suspension mechanism is used to gently place the coupon so that the entire surface is exposed to the acid. When using the gravimetry method to undertake corrosion tests under controlled conditions, this setup is crucial. The corrosion rate is determined by weighing the metal coupon after exposure, which provides important information about how well the acid system works with downhole metallurgy. This test makes it so that the acid mix preserves equipment integrity during field application in addition to meeting client corrosion standards [

15].

The test setup comprised inserting corrosion metal coupons—specifically QT-800 grade, representing coiled tubing, and L-80 low-carbon steel, matching downhole production tube materials—into glass testing bottles holding the acid–retarder mixture. These bottles were sealed with specific lids and placed in the rotating HPHT corrosion cell at reservoir temperature. The QT-800 coupons were evaluated for 12 h of inhibition, whereas the L-80 coupons were tested for 6 h. The corrosion cells were subjected to controlled continuous movement at extreme temperatures ranging from 94 °C to 163 °C (200 °F to 325 °F) and pressures of 200 psi to simulate downhole operational stress. Post-test analysis demonstrated negligible weight loss and surface deterioration, validating the retarded acid system’s effective corrosion inhibition properties, even in harsh temperature and dynamic conditions.

An important step in ensuring that the acid system is compatible with downhole metallurgy and that it complies with stringent client criteria is the corrosion test, which is carried out over an 8 h inhibition and exposure period. The acid formulation must not, under simulated reservoir conditions, exceed a corrosion rate of 244 g/m

2 (0.05 lb/ft

2), per the client’s specifications. During acid stimulation operations, this restriction protects tubing, casing, and completion equipment from accelerated degradation. This was accomplished by meticulously adding a number of acid solutions with varying proportions of surfactants, corrosion inhibitors, iron control agents, and other additions to maximize performance. The chemical stability and synergy of the additives in each blend were carefully assessed. Only the top three acid formulations that showed the best compatibility and stability after the first screening were chosen for corrosion testing. In

Table 2, test number 3 demonstrates good corrosion rate with passing rate. Using the gravimetry method, these experiments were conducted under high-pressure, high-temperature (HPHT) conditions, exposing L-80 and QT-800 metal coupons to the acid for eight hours. The technique allowed for an accurate calculation of the corrosion rate by estimating the weight loss of each coupon both before and after exposure. Only formulations with shown integrity and reduced corrosive impact were taken into consideration for field application thanks to this methodical approach.

The Polymer-free Delayed Acid System can be safely deployed in sensitive hardware situations, including coiled tubing and production tubing, without affecting equipment integrity.

Compatibility Test

An important stage in the validation of acid stimulation fluids, particularly when aiming for ultra-tight or complex formations, is the compatibility test between the retarder acid formula and the crude oil unique to the candidate well. The purpose of this test is to assess how the native reservoir fluids and the acid system interact under high-temperature simulations. It guarantees complete homogeneity between the acid and crude oil at first contact and, more crucially, that phase separation happens quickly when heated. The retarder acid recipe’s specific surfactant additions, which lower interfacial tension and inhibit the development of stable emulsions, are primarily responsible for this behavior. These emulsions may affect oil movement or reduce formation’s production. The test’s quick and thorough separation verifies that the acid will not encapsulate oil droplets or change the wettability in a way that might impede the flow of hydrocarbons. Rather, the acid system is designed to clean the pore throats while preserving the integrity of oil-bearing zones, deeply penetrate the formation as a living acid because of its delayed reaction kinetics, and selectively remove damaged skin [

16]. This compatibility is a crucial validation step for any acidizing operation since it guarantees that the treatment increases reservoir production without causing secondary harm.

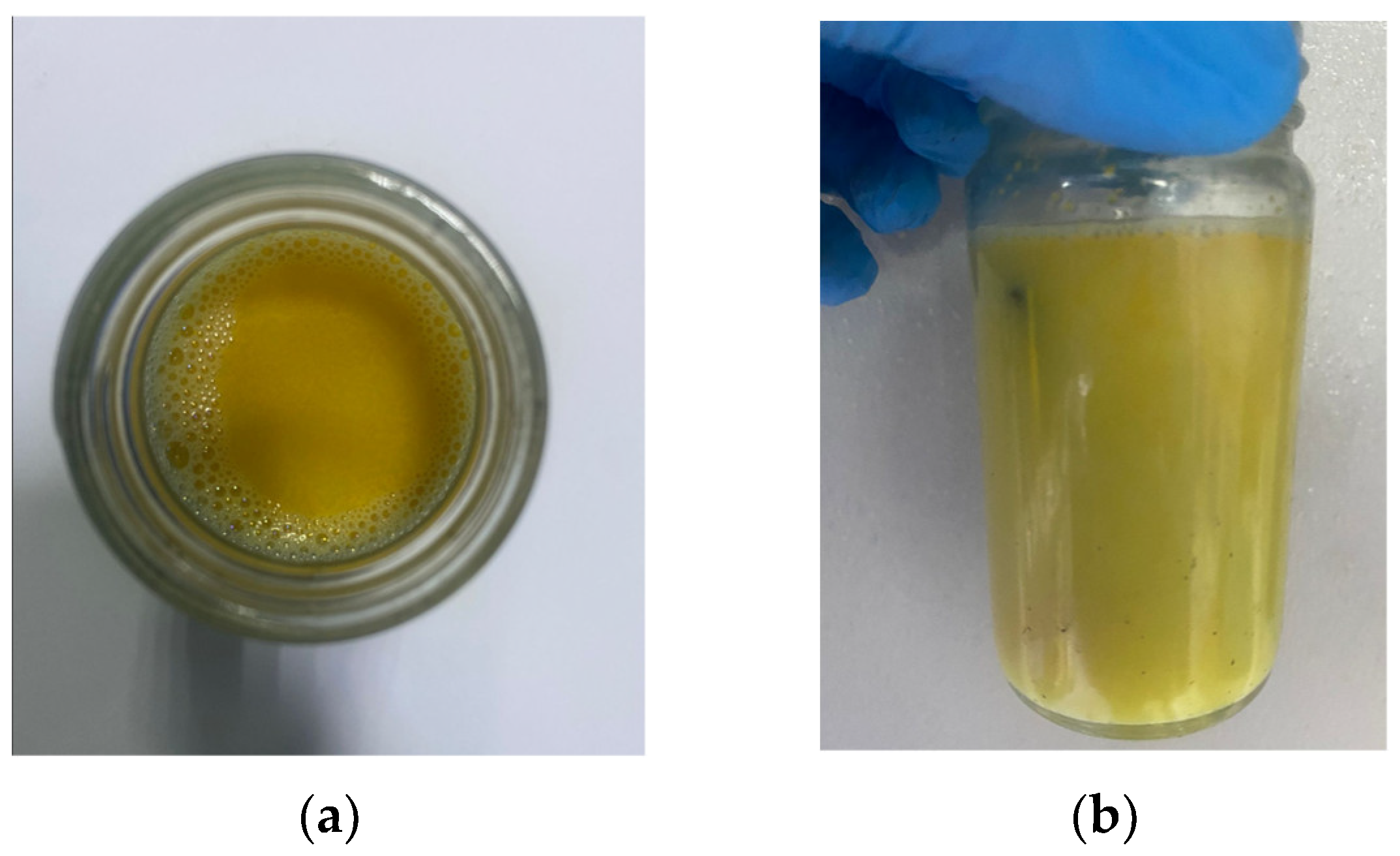

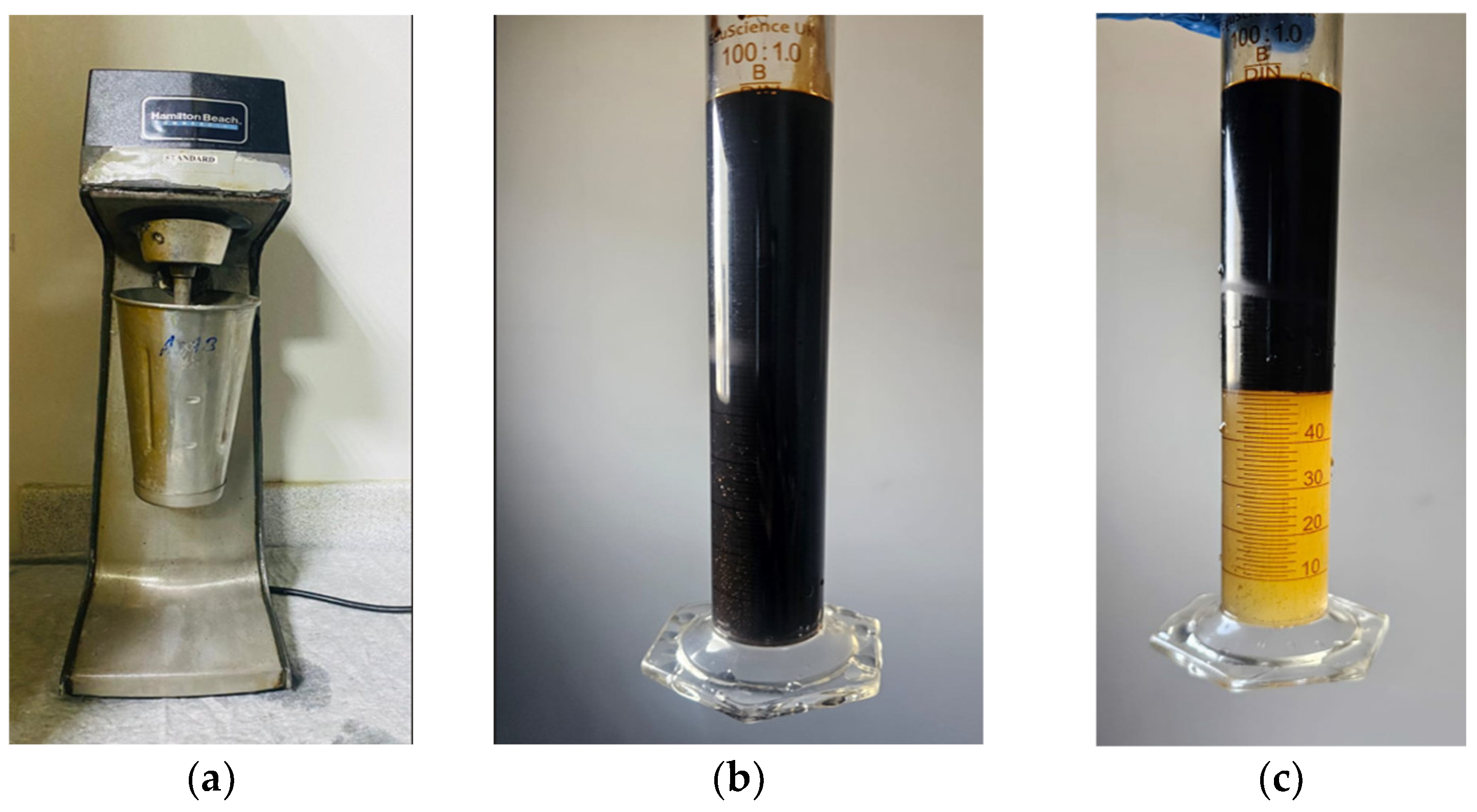

A significant point in ensuring that no stable emulsions form during acidizing operations is the compatibility and emulsion separation test, which assesses how the reservoir-specific crude oil and the acid retarder recipe interact. Using a Hamilton high-speed batch mixer present in

Figure 5, 50 mL of freshly extracted crude oil from the candidate well and 50 mL of the prepared acid formula are combined to start the test. In order to produce a single-phase 100 mL acid–crude oil mixture that faithfully replicates actual reservoir conditions after acid injection, this procedure guarantees strong agitation and uniform blending. To enable accurate visual monitoring of any phase separation, the resultant solution is carefully poured into a graduated glass measuring cylinder after mixing. The measuring cylinder holding the acid–crude oil mixture is submerged in a water bath that has been preheated and stabilized to 82 °C, which is the reservoir’s minimum downhole temperature, in order to conduct the emulsion stability test. Throughout the test, the temperature is continuously tracked and maintained to replicate the thermal conditions that would be present in the field. The setup is left alone for no more than half an hour. The mixture is visually examined during this period to look for indications of layering or emulsion formation. Excellent compatibility and a low emulsion propensity were confirmed by the results, which in this particular instance showed a clear and quick separation between the acid and crude oil phases. The presence of surface-active compounds in the acid formula, which encourage phase segregation and inhibit emulsification, is responsible for this advantageous result. The test verifies that the acid will efficiently remove damaged skin while preserving formation productivity and will not negatively interact with oil-bearing areas; it also proves the strong structure of homogenous acid recipe under high temperature without creating emulsion with the crude oil.

2.4.3. Single-Phase Acid Retarder Mixture

The Polymer-free Delayed Acid System is a breakthrough in matrix stimulation technology, designed to address the challenges of ultra-tight carbonate reserves where traditional acid treatments have been ineffective. The Polymer-free Delayed Acid System, unlike standard emulsified or polymer-based retarders, is a polymer-free, single-phase formulation designed using patented chemical encapsulation technology. This method reduces the reaction rate between hydrochloric acid (HCl) and carbonate rock, enabling precise control of acid–rock kinetics while maintaining a low viscosity profile that is ideal for deep reservoir penetration. The Polymer-free Delayed Acid System stabilizes the acid phase at both surface and reservoir conditions, reducing acid expenditure near the wellbore and increasing contact time with the formation [

17].

This regulated reaction mechanism promotes the formation of conductive wormholes, allowing the acid to skip damaged near-wellbore zones and travel deeper into the reservoir matrix. The system is thermally stable up to 163 °C (325 °F), allowing for consistent performance over a wide temperature range without precipitation, emulsification, or phase separation. The Polymer-free Delayed Acid System is a safer and more efficient alternative to emulsified acid systems, reducing handling complexity and formation damage hazards. It is also easier to pump and less affected by operational fluctuations.

3. Stimulation Job Design

The job design was carefully developed to match the reservoir’s specific features, following a thorough examination of the well’s historical performance and stimulation records. The candidate well had previously had two independent acid stimulation treatments with typical 15% hydrochloric acid (HCl) systems. Although these treatments initially led to a minor increase in injectivity, the benefits were fleeting, with a quick drop in performance and unpredictable output profiles. These findings emphasized the difficulties of typical acid systems in overcoming the ultra-tight matrix and complicated damage processes present in the formation. The operating company submitted a comprehensive collection of well and reservoir data, including petrophysical logs, core analysis, pressure and temperature profiles, previous intervention outcomes, and fluid characteristics in order to develop a more effective stimulation strategy. These data were thoroughly analyzed to determine the core causes of stimulation failure, which included poor acid propagation, rapid acid spending near the wellbore, and ineffective wormhole creation. Based on the study, a unique acidizing strategy was designed and verified through simulation utilizing Baker Hughes’ Matrix-Acidizing Modeling Software 2024 version, which represented the acid system behavior under real reservoir circumstances. The goal was to produce deeper penetration and longer-lasting stimulation efficiency by creating a treatment that was compatible with the reservoir’s mineralogical heterogeneity, permeability limits, and capillary barriers, resulting in maximum hydrocarbon recovery and long-term well performance [

18].

Table 3 depicts important reservoir data for a horizontal barefoot well undergoing single-phase acid retarder treatment. The well has an open-hole section of 2303 feet, a maximum reservoir pressure of 2000 psi, and a temperature of 200 °F—conditions that necessitate a reliable and effective acid system. The flowing period includes stimulation, clean-up, downhole sampling (SDT), and surface sampling, all of which follow actual operational sequences. The projected maximum oil production rate is 350 barrels per day, indicating a productive formation that will benefit from optimal stimulation. The well environment comprises 0.35 mol% H

2S and 2.5 mol% CO

2, emphasizing the importance of corrosion-resistant components and chemical formulations. This data collection is critical for developing the acid retarder system, assuring effective matrix penetration, less corrosion, and improved hydrocarbon recovery under real-world conditions.

Table 4 depicts precise petrophysical and reservoir data for an oil-producing well designed for acid stimulation using a single-phase acid retarder. The candidate well, drilled to an 8½” section, demonstrates promising characteristics for the proposed treatment. The reservoir has a maximum depth of 5037 feet and a total measured depth (TMD) of 7340 feet. The formation pressure is 2600 psi, and the reservoir temperature is approximately 200 °F, enabling controlled reaction kinetics in a single-phase retarded acid system. The fracture gradient of 0.7 psi/ft indicates a relatively stable formation pressure range for acid placement, which avoids unexpected fracturing. Petrophysical investigation reveals an average hydrocarbon saturation of 48%, a permeability of 1.6 millidarcies (mD), and a porosity of 30%, indicating a large pore space volume and good fluid flow potential. These properties make the formation ideal for single-phase acid retarder stimulation, which is predicted to improve matrix contact and hydrocarbon productivity due to increased acid penetration and delayed reactivity with the rock matrix.

The design structure started with a complex, multi-stage pre-flush procedure specifically designed to maximize the performance of the subsequent retarded acid treatment in this ultra-tight carbonate reservoir. This preparatory step included sequential treatments to address near-wellbore degradation and prepare the reservoir for optimum acid penetration. SUP-NE, a specific surfactant blend, was first injected to alter surface wettability and reduce interfacial tension, thereby enhancing acid mobility and minimizing fluid bypass. This was followed by SUP-Asphalt 1, an organic solvent designed to dissolve and disperse asphaltenic and organic matter deposits that commonly clog pore throats in mature carbonate formations [

19]. A customized acid pickling phase was then carried out using diluted HCl to remove inorganic scales and mud filtrates, therefore, cleansing the near-wellbore environment of leftover drilling and completion damage. This integrated pre-flush process was carried out with precisely controlled pumping parameters to achieve optimal distribution and effectiveness over the target interval.

After a successful pre-flush, Baker Hughes’ Polymer-free Delayed Acid System was used for the main acid treatment. The Polymer-free Delayed Acid System™ method promotes controlled reactivity by extending acid–rock contact duration. This allows live acid to penetrate deeper into the matrix without prematurely spending at the wellbore. The tailored acid composition, which includes patented retarders to regulate HCl kinetics, facilitated the creation of dominant conductive wormholes and significantly reduced the severity of damaged skin. Pumping was carried out over 8 h under monitored conditions, with NOV CTES recording equipment tracking injection performance in real time. The treatment resulted in a considerable increase in injectivity, from 2.5 bpm during pre-flush testing to 7.1 bpm at only 300 psi post-acid, indicating stimulation effectiveness. Baker Hughes’ Matrix-Acidizing Modeling Software predicted wormhole penetration depths of up to 3 feet, which matched the observed reservoir performance gains. The combination of a meticulously customized pre-flush and a tailored retarded acid treatment allowed for a high-efficiency matrix stimulation operation that restored the reservoir connections and liberated the previously untapped hydrocarbons.

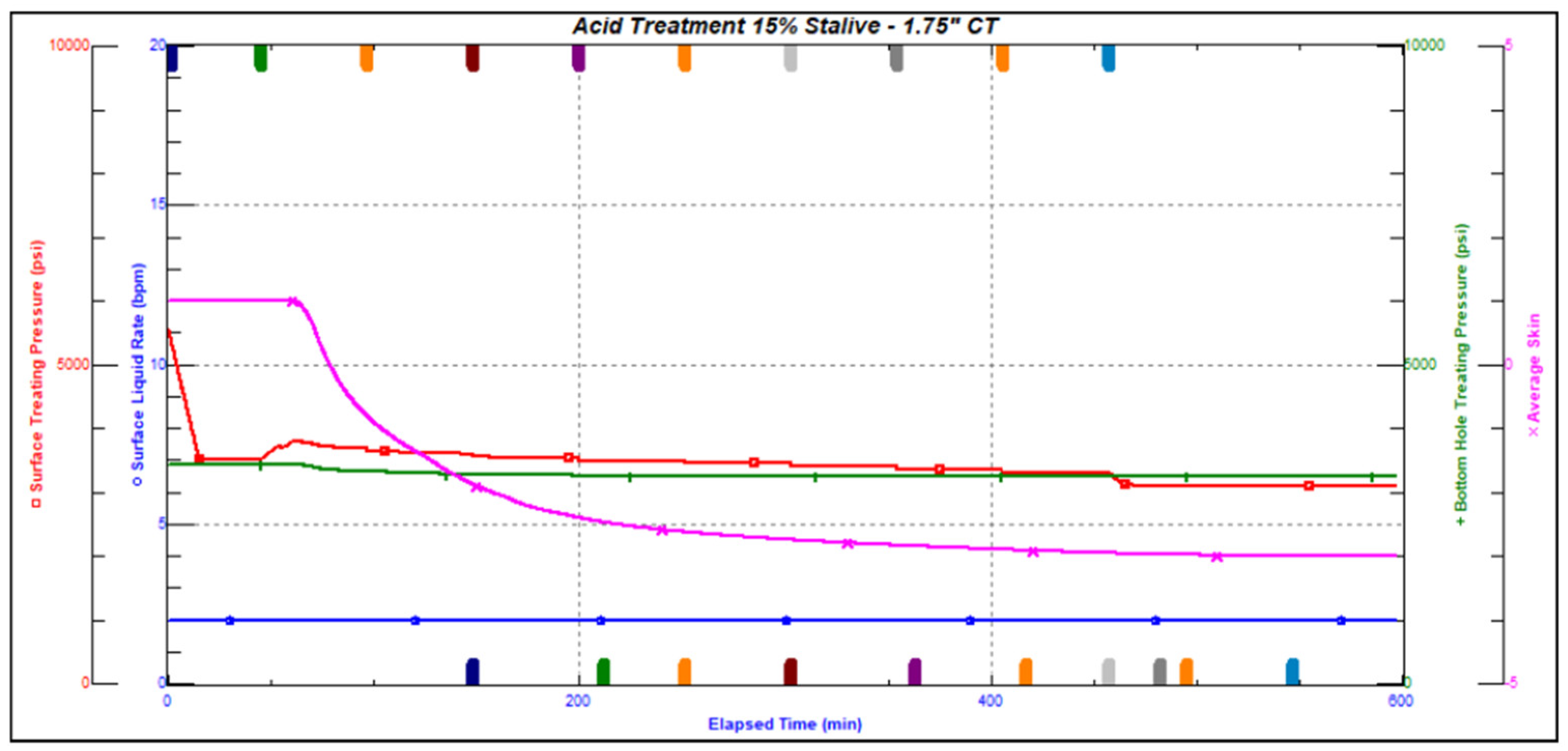

The attached plot in

Figure 6 depicts the simulated performance monitoring of a 15% Polymer-free Delayed Acid System acid treatment injected into the reservoir using 1.75” coiled tubing (CT), with considerable improvement evident through skin reduction and improved injectivity. The surface treatment pressure (red curve, left

y-axis) immediately rises as acid enters the formation, peaking at almost 6000 psi. the pressure progressively decreases, showing a steady reduction in near-wellbore resistance as the acid reacts with the formation damage. Simultaneously, the bottomhole treatment pressure (green curve, right

y-axis) stabilizes at a moderate level, indicating regulated acid propagation and long-term formation contact. The surface liquid rate (blue curve, left

y-axis) remained constant throughout the job, indicating consistent pumping conditions. Notably, the average skin (magenta curve, right

y-axis) declines sharply from around +4 to nearly 0, indicating the treatment’s efficacy in removing harmful deposits and increasing wormholing, a sign of effective carbonate stimulation. The relatively low-end pressure profile, with less skin, indicates increased permeability and a reservoir connection. The colored marks at the top of the figure most likely represent operational stages or tool movement logs that are synced with the elapsed time (

x-axis), providing useful context for analyzing dynamic pressure and rate behavior. This single-phase retarded acid system allowed for longer contact time with the formation, increasing acid–rock interaction, reducing face dissolving, and accelerating deep wormhole penetration, ultimately restoring and enhancing well productivity [

11].

Figure 7 depicts a full post-treatment evaluation of the Polymer-free Delayed Acid System single-phase retarded acid stimulation, with three essential parameters displayed against depth (vertical axis, in feet). The skin factor track (left) shows a significant reduction over the treated interval, with values ranging from about −0.2 to less than −5, indicating significant elimination of near-wellbore damage and increased permeability. Negative skin values indicate successful stimulation as they reflect increased fluid flow and effective acid contact with injured areas. The middle track displays the length of the wormhole, which is a clear indicator of the acid’s capacity to penetrate and etch conductive channels into the carbonate deposit. Wormhole propagation varies across the interval, reaching up to 8 ft in some zones, indicating heterogeneous rock reaction and acid distribution influenced by mineralogy and permeability differential. Deeper wormholes correspond to zones of greater initial damage, resulting in lower skin values after therapy. The treatment invasion profile (rightmost track) depicts acid penetration into the formation, with multi-colored pixelation showing acid front distribution over radial invasion depths of up to 5 feet. The main blue zones exhibit base invasion levels, while warmer colors (orange, red, and purple) indicate stronger localized acid transport. This multi-modal design demonstrates effective acid placement and conformity control, which are crucial for increasing matrix interaction and minimizing face disintegration. Overall, these plots demonstrate that the Polymer-free Delayed Acid System retarded acid system accomplished deep, effective wormholing with uniform radial penetration and little skin, considerably enhancing formation conductivity and treatment efficiency.

In

Table 5, the acid stimulation treatment using the Polymer-free Delayed Acid System single-phase retarded acid system showed effective penetration and formation interaction, as evidenced by a post-acidifying average skin factor reduction from +1.00 to −3.00, indicating a significant decrease in near-wellbore damage and a clear transition from a damaged to a stimulated regime. Using a retarded acid like Polymer-free Delayed Acid System, which has regulated H

+ ion release kinetics, allows for deeper matrix penetration while limiting premature reaction with carbonate minerals near the wellbore. This control over the reaction rate increases the acid’s effective radial reach, allowing for an average wormhole propagation of 4.46 ft and indicating a dominant conductive channel into the formation.

The wormhole shape indicates a dominating wormholing regime, most likely defined by ramified channels rather than face dissolving, which is aided by ideal injection rate, temperature, and acid contact time. The 4.46-foot wormhole length indicates effective acid placement outside the invaded damaged zone, assuring contact with new reservoir material. The initial skin of +1.00 most likely represents permeability deterioration caused by fines migration, scale, or residual drilling fluid invasion, whereas the post-treatment skin of −3.00 represents the creation of high-conductivity wormholes, which reduce the pressure drop across the near-wellbore region. The statistics show that Polymer-free Delayed Acid System’s delayed process assures radial acid coverage, increased conductivity, and reduced near-wellbore reprecipitation, resulting in high stimulation efficiency.

4. Results

This section presents the Polymer-free Delayed Acid System, which was evaluated for matrix stimulation in ultra-tight carbonate reservoirs, both in the laboratory and in the field. The proposed polymer-free, single-phase acid retarder system has showed exceptional field performance, particularly in challenging reservoir conditions where conventional acid systems have failed. In the recent candidate well with unpredictable injectivity and low productivity, the Delayed Acid System considerably improved well performance, raising the production rate from 1.2 bpm to 7.1 bpm while lowering the wellhead pressure from 1100 psi to only 300 psi. Notably, this same well had previously undergone two acid stimulation attempts utilizing identical acid volumes and concentrations in a conventional HCl system, with no detectable improvement in either case. Following the successful retarded acid treatment, the operator asked for additional monitoring and production evaluation to validate the results. The data acquired revealed a consistent output rate of 509 barrels per day over a four-month period, demonstrating the treatment’s long-term sustainability and efficiency. This exceptional performance demonstrates that the polymer-free delayed acid achieves improved penetration and homogenous stimulation. Building on this success, current efforts are focused on validating the retarded acid system’s efficacy in dolomite-rich carbonate reservoirs, with the goal of establishing it as a universal acidizing solution for all carbonate formations in Abu Dhabi, regardless of mineralogical variability or reservoir complexity.

The study links experimental findings such as emulsion stability, corrosion resistance, solubility kinetics, and coreflood performance—to the petrophysical restrictions and production metrics unique to the candidate well. The study focuses on comparing reservoir behavior before and after treatment, as measured by real-time injection patterns and persistent post-stimulation output increases. Detailed pressure and rate data were gathered and evaluated during the operative period to track the progression of improvement through the treatment stages [

11].

The pre-flush phase enhanced matrix accessibility, and the primary acid treatment with a Polymer-Free Delayed Acid System resulted in a significant shift in injectivity and fluid penetration behavior. The Polymer-free Delayed Acid System’s controlled kinetics and prolonged acid–rock interaction allowed for deeper wormholing beyond the damaged near-wellbore region, unlike previous conventional or emulsified acid systems, which have limited stimulation radius and premature spent. This greatly bypassed the reservoir’s damaged skin, allowing access to previously inaccessible hydrocarbon-bearing zones. Post-treatment results showed a significant increase in well productivity, demonstrating the longevity and greater stimulation reach of the Polymer-free Delayed Acid System formulation in challenging formation conditions [

20]. This section aims to connect lab-proven efficacy with real-world field results, establishing a clear performance baseline for next-generation acidizing systems in similar reservoir settings.

4.1. Detailed Experimental Laboratory Results

The newly designed single-phase, Polymer-free Delayed Acid System underwent thorough laboratory evaluation and key tests to ensure its technical robustness and field compatibility. Each test was designed to replicate real reservoir and operational conditions to demonstrate fluid stability, compatibility with downhole metallurgy, and the effectiveness of corrosion mitigation. All laboratory test results met or surpassed the expected performance levels.

Emulsion stability experiments were carried out in glass test tubes and aging cells under both ambient and enhanced settings. Over a wide temperature range, the acid–retarder blend remained homogeneous and single-phase, with no evidence of phase separation or precipitation. At the reservoir goal temperature of 94 °C (201 °F), the formulation demonstrated outstanding thermal stability, maintaining its uniform consistency for more than 24 h in static settings and demonstrating its appropriateness for use in high-temperature carbonate formations.

Dynamic corrosion tests were performed on the OFITE HPHT corrosion testing equipment under circumstances that simulated genuine wellbore environments, such as high pressure, higher temperature, and continuous motion. Gravimetric corrosion tests were performed on three types of metal coupons: low-carbon steel L-80 (typical of production tubing) and QT-800 (coiled tubing grade). The tests were conducted for 6, 8, and 12 h to evaluate time-dependent corrosion rates and inhibitor efficacy. The Polymer-free Delayed Acid System’s inhibitor package proved effective as corrosion rates remained below 0.05 lb/ft2 across all test intervals, meeting client criteria.

The client’s technical team formally examined and validated all test data and processes, independently replicating select tests to ensure they met internal requirements. Following mutual validation and final approval, preparations for the candidate’s well treatment began. This involved organizing logistics for surface equipment, setting up real-time monitoring systems and ensuring that all treatment chemicals and testing kits were available on-site.

The successful laboratory and client-verification phases instilled a high level of trust in the operational execution and stimulated zone penetration envisaged from this enhanced acid system.

4.2. Field Application

The operational preparation for the advanced acid stimulation treatment was methodically planned and executed over two days to achieve optimal reservoir reaction and treatment efficiency. On Day One, the emphasis was on conditioning the formation in preparation for the primary acid stimulus. The procedure began with the sequential injection of customized chemical slugs through coiled tubing, which were designed to solve specific reservoir issues. Initially, a slug of SUP-NE, a surface tension-reducing chemical, was used to change the surface wettability and improve acid interaction with the rock matrix. This was followed by SUP-Asphalt 1, a potent organic solvent specifically designed to dissolve tough organic deposits, such as paraffin and asphaltenes, which frequently restrict flow channels in mature carbonate reservoirs. Finally, a gentle acid pickling treatment with diluted hydrochloric acid was used to target and remove inorganic scale and mineral accumulation, rounding off the multi-layered pre-flush program [

21].

This sequence was developed and implemented in partnership with Superior Abu Dhabi Company, whose customized pre-flush method was important in overcoming near-wellbore damage and enhancing formation receptivity. Following completion of the pre-flush, pre- and post-injectivity tests were performed utilizing coiled tubing. The results showed a remarkable improvement in injectivity—from 1.2 bpm at 1100 psi to 2.5 bpm at 800 psi—demonstrating effective formation damage removal and reduction in near-wellbore skin, as well as a noticeable drop in wellhead pressure, indicating better fluid acceptance and enhanced permeability in the treated zone [

22].

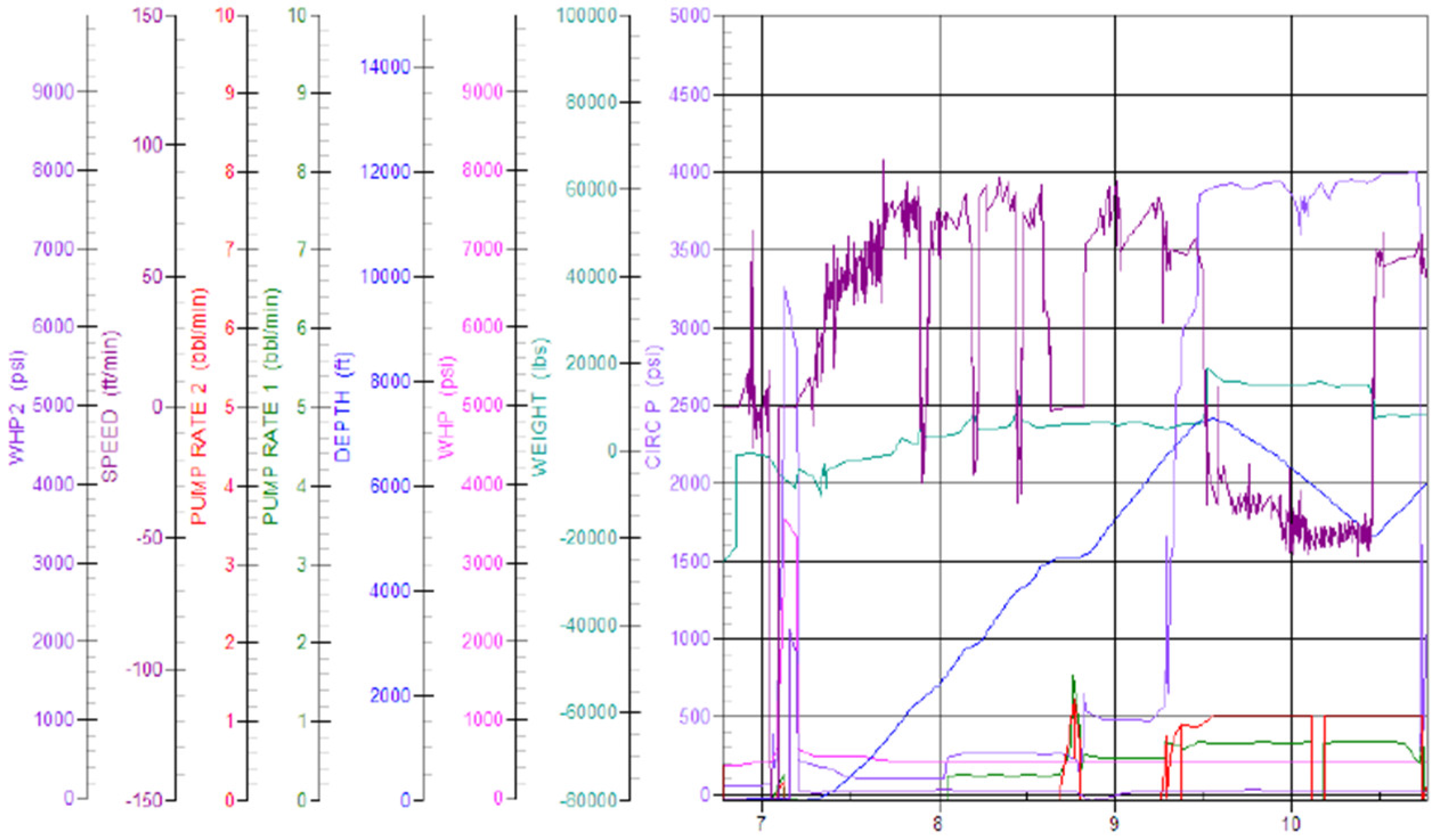

The graph in

Figure 8 illustrates the overall pumping rate during the first stage of the stimulation operation, which precedes the pre-flush treatment and acid injection. Pumping Rate 1 (green) maintains a rate of approximately 0.6 barrels per minute (bpm), while Pumping Rate 2 (red) averages around 0.6 bpm, resulting in a total pumping rate of 1.2 bpm. Notably, the graph shows oscillations in individual and overall pumping rates, indicating heterogeneity within the reservoir rock. These differences indicate the presence of formation damage and a positive skin factor, which operate as impediments to consistent fluid injection. Such instability highlights the vital necessity for a targeted pre-flush step that cleans out the near-wellbore region, dissolves particles and organic materials, and reduces damaged skin. By doing so, the pre-flush improves the formation’s receptivity to the upcoming acid treatment, resulting in more uniform penetration and effective stimulation.

Figure 9 illustrates the overall pumping rate during the pre-flush treatment phase of the stimulation operation. The combined total pumping rate is roughly 2.5 barrels per minute (bpm), with Pumping Rate 1 (green) maintaining an average rate of 1.4 bpm and Pumping Rate 2 (red) averaging about 1.1 bpm. At this stage, tailored chemical slugs are injected, including acid pickling solutions to target initial inorganic scaling, organic dissolvers to break down hydrocarbon-based deposits, and nano-surfactants to alter the reservoir’s wettability. As the pre-flush successfully cleaned the near-wellbore area, a discernible increase in the pumping rate was seen during this phase, indicating the gradual improvement in injectivity. In addition to improving the formation’s permeability, this treatment significantly reduced skin damage, thereby enhancing the reservoir’s preparedness for the primary acidizing step that followed.

On Day Two, Baker Hughes’ Polymer-free Delayed Acid System was used to continue the successful acid treatment. The formula was co-engineered and authorized by the client, taking into account the reservoir’s ultra-tight permeability and unique mineralogy. A startup injectivity test was run to measure baseline reservoir reaction, with all data acquired and logged using the NOV CTES real-time acquisition system. As pumping continued during an 8 h operational window, the formation’s permeability gradually improved, demonstrated by smoother acid propagation and stable downhole pressure profiles, where acid concentration and dosage were similar to the conventional acid treatment, allowing for the operator to compare the results. The Polymer-free Delayed Acid System’s controlled reactivity enables deeper acid penetration and wormhole creation, circumventing residual skin damage and uncovering hitherto untouched zones. After a three-hour soak time, a final post-injectivity test was performed. A total of 23,030 gals of the Polymer-free Delayed Acid System demonstrated outstanding effectiveness, raising injectivity to 7.1 bpm at 300 psi pressure, significantly above the pre-treatment baseline considering operator standard dosage for horizontal well of 10 gal of mixed acid per foot. This improvement confirmed the polymer-free, kinetically retarded acid system’s deep-reaching stimulating action, wormhole conductivity, and long-term flow enhancement potential. The two-day operation highlighted the synergistic benefit of a strategic pre-flush followed by a next-generation acid system, which resulted in transformative injectivity gains and paved the road for better hydrocarbon recovery from an underperforming ultra-tight carbonate reservoir [

23].

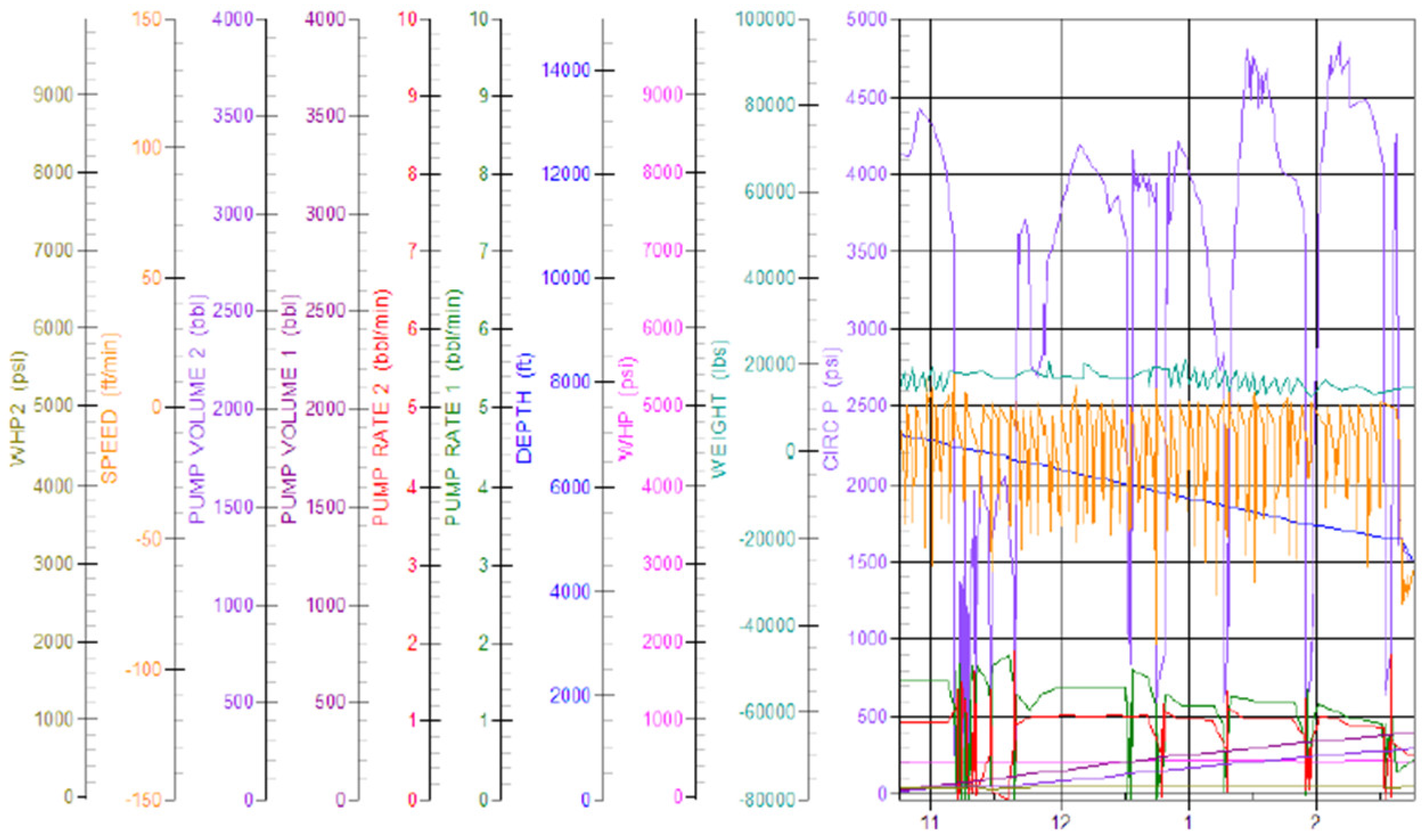

Figure 10 shows the overall acid pumping rate during the primary stimulation period, which is when a single-phase acid retarder system is being implemented. The overall acid injection rate is roughly 7.1 bpm, with Pumping Rate 1 (green) recording a constant rate of 3.5 barrels per minute (bpm) and Pumping Rate 2 (yellow) registering an average of 3.6 bpm. The effective spread of the acid into the reservoir matrix is shown in this high and steadily rising pumping rate. The acid system effectively removed the skin, started deep acid invasion into the formation, and overcome near-wellbore damage, as evidenced by operational indicators like declining wellhead and circulation pressures. Delaying the acid–rock reaction is a major benefit of the single-phase acid retarder since it permits deeper wormhole formation and increased live acid penetration. The single-phase retarder ensures uniform distribution and improved stimulation coverage by maintaining acid reactivity over longer distances than conventional acid systems, which have a tendency to spend quickly close to the wellbore. This results in increased permeability enhancement, better reservoir contact, and long-term production gains. The acid is guaranteed to reach deeper damaged zones due to the combination of high injection efficiency and retarded reaction kinetics, which efficiently restores flow channels and maximizes reservoir performance.

4.3. Accuracy of Simulation Run

Baker Hughes conducted a simulation study using their proprietary Matrix-Acidizing Modeling Software to visualize the behavior and effectiveness of the Polymer-free Delayed Acid System within the ultra-tight carbonate formation. This advanced simulation technique, which combines reactive transport modeling and reservoir fluid dynamics, enabled the engineering team to virtually recreate the complicated acid–rock interaction mechanisms under reservoir-specific conditions. The simulation included a variety of input data, including extensive petrophysical logs, formation mineralogy, porosity–permeability relationships, core analysis, pore throat distribution, fluid composition, and temperature-pressure gradients. These datasets allowed the software to estimate the acid invasion profile precisely, anticipate the reduction in formation skin, and map the spread of dominating wormholes caused by regulated acid expenditure and retardation kinetics [

24,

25,

26].

Simulated outcomes from the Matrix-Acidizing Modeling Software and field data from the single-phase, Polymer-free Delayed Acid System (SPRA) stimulation demonstrate a strong correlation, indicating the software’s predicted robustness and practical applicability. The simulation (

Figure 6 and

Figure 7) predicted a decrease in skin factor from +1.00 to −3.00, a wormhole length of approximately 4.46 ft, and a stable bottomhole pressure profile, all of which indicate successful deep acid penetration and improved near-wellbore conductivity. These predictions were remarkably reflected in the field as real-time measurements revealed a post-treatment skin drop from +1.0 to −3.0 and injectivity improvement from 1.2 bpm at 1100 psi to 7.1 bpm at 300 psi, which closely matched the simulated acid–rock interaction model. Furthermore, the actual acid propagation pattern—recorded via NOV CTES—exhibited the same pressure and rate dynamics as those calculated, including an initial surface pressure surge to ~6000 psi, followed by a controlled decline indicative of skin loss and wormhole growth. The convergence of the simulation and field results demonstrates the software’s high-resolution accuracy in modeling complex carbonate stimulation behavior, as well as its predictive ability to identify dominant wormholing regimes, estimate acid coverage depth, and forecast post-stimulation flow improvements. These predictive capabilities allowed for exact project design, avoided operational guesswork, and significantly reduced non-productive time (NPT) by eliminating the need for several trial treatments.

As a result, the Matrix-Acidizing Modeling Software significantly improved cost optimization, treatment placement, and reservoir management by accurately forecasting treatment efficiency and formation response prior to execution, making it an essential tool for designing high-efficiency matrix acidizing in ultra-tight carbonate formations.

5. Discussion

Baker Hughes’ proprietary matrix-acidizing design and evaluation software, StimVision™, was used to simulate the effectiveness of the single-phase, Polymer-free Delayed Acid System in an ultra-tight carbonate reservoir. Using a large set of formation-specific data, including petrophysical logs, mineralogical composition, pressure-temperature profiles, and permeability–porosity relationships, the software effectively predicted acid invasion behavior and reactive transport dynamics. The model outputs showed the formation of well-structured wormholes with a predicted radial penetration of about 4.45 feet, significantly above what is generally obtained with traditional acid systems. This result represents the increased retardation kinetics of the Polymer-free Delayed Acid System, which lowers the acid reaction rate near the wellbore and allows further propagation before depletion, thus enhancing the acid’s live contact with previously unreachable hydrocarbon-bearing zones. The simulation demonstrated that higher acid penetration improved formation permeability and reduced damaged skin. This supports the idea that the Polymer-free Delayed Acid System promotes deeper and more uniform stimulation in heterogeneous and damage-prone carbonate formations. These findings are consistent with prior research highlighting the difficulties of acid placement and early expenditure in confined reservoirs, and they show how advanced modeling techniques can improve fluid design and treatment execution. Furthermore, the significant increase in injection rate—from 1.2 bpm to more than 7.1 bpm post-treatment—confirms the modeling projections and underscores the treatment’s long-term benefits to reservoir production, as shown in

Table 6.

These findings support the use of data-integrated stimulation planning and digital simulation tools, such as the Matrix-Acidizing Modeling Software, to improve decision-making. The high-fidelity prediction of acid distribution and wormhole morphology enables operators to fine-tune recipes and operational parameters to address reservoir-specific issues. Future study could focus on expanding the simulation framework to include real-time downhole monitoring data, dynamically updating stimulation models, and allowing for real-time optimization during acidizing operations. This forward-thinking mix of simulation and field analytics shows significant promise for improving stimulation efficiency in complicated carbonate systems.

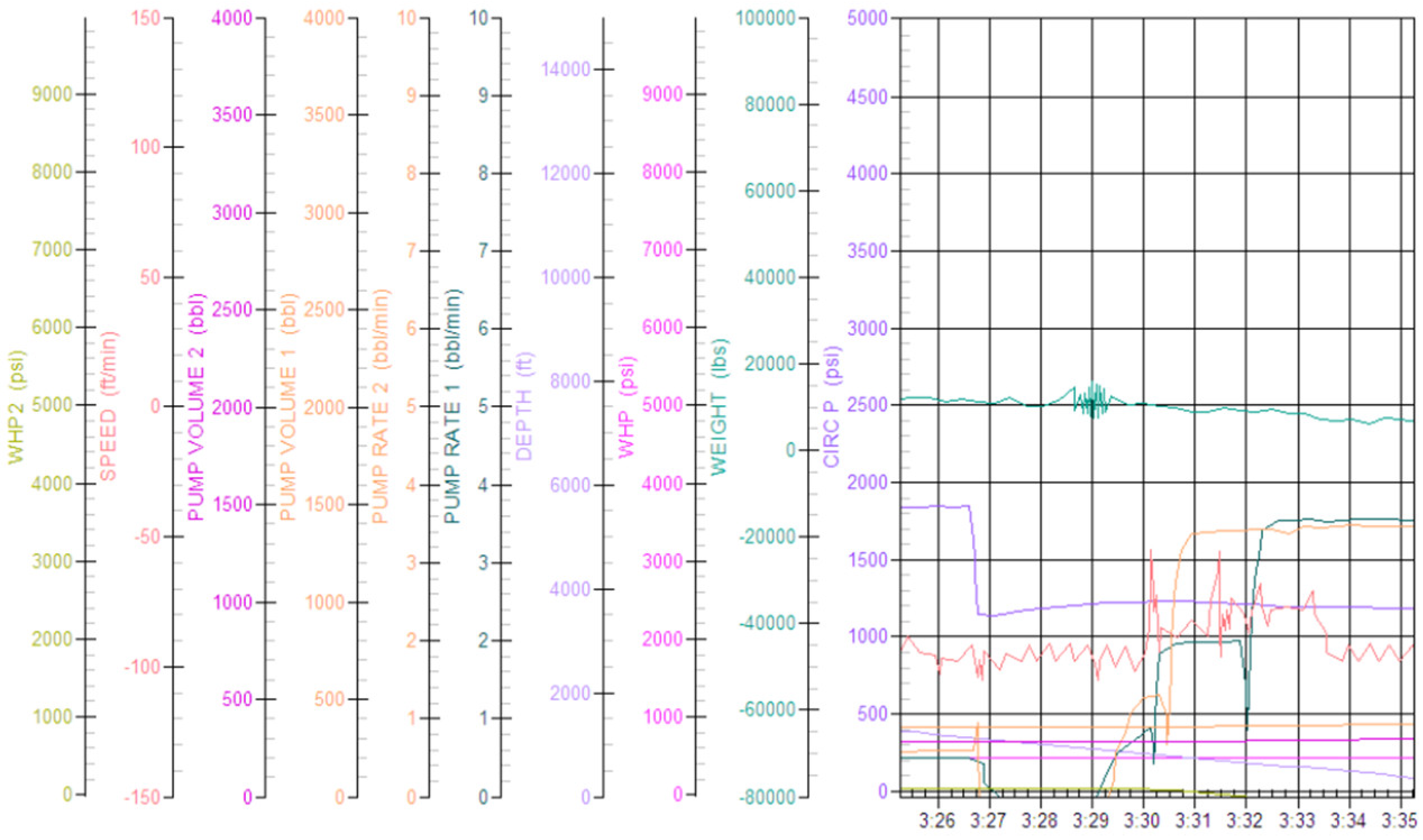

The acidizing treatment with the single-phase, Polymer-free Delayed Acid System was carried out effectively in the field, outperforming traditional hydrochloric acid (HCl) systems in terms of reservoir stimulation and productivity enhancement. The treatment design, based on previous coreflood and wormholing simulation studies, targeted deep matrix penetration with controlled acid spending, and the simulation projected an average wormhole length of 4.45 ft, which was confirmed during field execution. Real-time surface data collected during acid injection revealed clear signs of in situ wormhole propagation, such as significant fluctuations in pumping rate, a consistent drop in wellhead pressure, and a decrease in circulating pressure, all of which indicate acid breakthrough into lower-pressure zones and enhanced injectivity, consistent with wormhole formation dynamics.

These pressure and rate fluctuations, when connected with the acid contact time and injection profile, demonstrate the successful radial propagation of conductive wormholes into the carbonate matrix, as well as the reduction in near-wellbore flow resistance.

Following stimulation, the operator conducted a methodical, multi-stage production testing program with four distinct flow phases, each spaced approximately one month apart. This long-term test design enabled high-resolution tracking of the well’s production behavior under various reservoir conditions and fluid extraction rates. Each stage featured shut-in buildup followed by controlled flowback, and flow rates of oil and generated water were measured daily, allowing for a detailed assessment of the treatment’s performance over time.

Following the successful implementation of the recently introduced Polymer-free Delayed Acid System SPRA on the OP candidate well, the operator carried out a systematic and monitored four-stage production testing schedule to assess the long-term impact of the stimulation on reservoir performance. Each test was conducted approximately one month apart over a four-month post-treatment period (January to April 2025), allowing for extensive analysis of production stability, reservoir pressure behavior, and fluid responsiveness under dynamic flow circumstances. The well demonstrated a large and steady increase in average oil production, producing 496, 505, 520, and 515 barrels per day (bbl/day) in January, February, March, and April, respectively, culminating in a four-month continuous average of 509 bbl/day. This performance represents a 46% increase over the pre-stimulation baseline, when production was limited to an unstable and intermittent 350 barrels per day, sometimes hindered by rapid pressure drops and poor reservoir deliverability due to significant near-wellbore formation degradation.

The organized testing regime included gradual choke management and consistent production drawdowns to ensure that transitory flow circumstances did not influence the results. In

Table 7, the stark difference in flow behavior before and after stimulation demonstrates the efficiency of the Delayed Acid System in overcoming severe epidermal degradation, which previously impeded inflow due to pore-throat obstructions and limited effective permeability. The Polymer-free Delayed Acid System, designed for controlled H

+ ion release and minimal face dissolution, allows for deep acid penetration and uniform wormhole generation in tight carbonate reservoirs, unlike conventional HCl systems that cause localized dissolution and early acid spending near the wellbore. The acid treatment’s effectiveness was further demonstrated by increasing injection rates during execution (from 1.2 to 5.6 bpm) and real-time surface indicators such as lowering wellhead and circulation pressures, which confirmed wormhole propagation and an increase in stimulated volume. Each of the four production assessments not only verified the acidized zone’s strength and over-time efficacy but also verified the pre-job simulation findings, which predicted an average wormhole length of 4.45 feet, enough to pass through the damaged skin radius and connect to less-invaded matrix regions. Importantly, the production tests found no evidence of early water breakthrough, indicating great zonal coverage, acid diversion efficiency, and consistent coning management. These findings confirm that the single-phase retarded acid system met its goals:

- ✓

Deep radial stimulation beyond the damaged zone.

- ✓

Sustained skin reduction and permeability enhancement.

- ✓

Consistent, high-rate oil production with improved reservoir connectivity.

This case study not only confirms the technical viability and operational durability of the Polymer-free Delayed Acid System but also establishes a solid foundation for its wider field deployment in similar tight and damage-prone carbonate formations.

Table 7.

Production rate summary performed on the candidate well.

Table 7.

Production rate summary performed on the candidate well.

| Operational Parameters | Jan-25 | Feb-25 | Mar-25 | Apr-25 |

|---|

| Average production data (bpd) | 496 | 505 | 520 | 515 |

| Average wellhead pressure (Psi) | 800 | 780 | 750 | 780 |

The field deployment of this Delayed Acid System has clearly proved its urgent need in several carbonate fields where conventional acid systems failed to offer adequate stimulation due to high reaction rates, limited penetration, or inadequate wormholing efficiency. The amphoteric-surfactant-based retarder has demonstrated superiority by allowing for better diversion in heterogeneous forms, greatly increasing injectivity, and providing more uniform and deeper stimulation coverage.

This method has performed especially well in tight carbonate rocks, when standard acid systems failed due to premature spending. The delayed acid successfully formed conductive wormholes and expanded the stimulation radius, resulting in higher productivity and better post-treatment well performance.

The use of a retardation system should be expanded to dolomitic formations, where its performance has proven particularly helpful. In testing conducted on carbonate limestone formations, where injectivity could not be increased despite several treatments with 28% HCl, the addition of the delayed acid resulted in a substantial improvement in injectivity, demonstrating its potential as a game-changing solution. Given the geological composition of the Abu Dhabi fields, which are primarily limestone with varied degrees of dolomite presence depending on the field, this method offers a field-wide potential for consistent implementation. Its efficiency across all lithologies strengthens the case for implementing this method in all wells in Abu Dhabi, ensuring consistent stimulation success independent of mineralogical variation.

Following the successful implementation of the polymer-free, chemically retarded acid system in both limestone and dolomite-based carbonate formations, and with its efficiency validated across a wide range of reservoir lithologies, the next phase will concentrate on systematic data collection and performance monitoring. A series of scheduled stimulation operations should be performed on several wells to capture high-resolution statistics such as pre- and post-stimulation production rates, pressure behavior, injectivity profiles, and reservoir reaction characteristics. These datasets will be combined and fed into AI and machine learning models, where advanced algorithms will be employed to build predictive tools that can link stimulation inputs to post-treatment results. This technique attempts to improve our capacity to estimate stimulation effectiveness and production benefits, allowing for improved acid job designs adapted to unique reservoir features [

27].

Ultimately, this data-driven methodology will allow the operation to identify high-impact candidates, eliminate non-productive treatments, and minimize cost while maximizing stimulation return on investment, establishing a new, intelligent framework for acid stimulation planning across the entire field.

Finally, this data-driven methodology will enable the operation to identify high-impact candidates, eliminate ineffective treatments, and reduce costs while increasing stimulation return on investment, resulting in a new, intelligent framework for acid stimulation planning across the entire field [

28].

6. Conclusions

The acid stimulation operation, which utilized the single-phase, Polymer-free Delayed Acid System, was completed with great precision and resulted in a significant improvement in both reservoir performance and oil production capacity. Before stimulation, the well faced significant productivity issues, with an unpredictable and intermittent production rate of only 350 barrels per day (bpd), frequent shut-ins due to high skin damage, limited reservoir contact, and insufficient fluid mobility around the wellbore. These characteristics are often indicative of formation degradation produced by drilling fluid invasion, scale deposition, or fines migration, which results in increased skin values and limited hydrocarbon flow.

To address the limitations of conventional HCl acid systems in low-permeability carbonate environments, a retarded acid system with controlled H+ ion release was implemented. This system allows for deeper matrix penetration and targeted wormhole propagation.

The treatment program began with a pre-flush phase designed to remove remaining drilling fluids and create a clean interface for acid contact. The main treatment phase then used the Polymer-free Delayed Acid System single-phase retarder, and real-time surface data showed a gradual increase in injection rate from 1.2 barrels per minute (bpm) to 2.5 bpm and finally to 7.1 bpm. This stepwise increase in injection rate mirrored the gradual removal of near-wellbore damage and the real-time evolution of formation conductivity, confirming the theoretical model predictions. The increased injectivity also showed a shift from face dissolving to dominating wormhole propagation, which is typical of appropriate acid placement in carbonate matrices. These field results were consistent with simulation studies conducted prior to execution, which predicted the production of conductive wormholes with an average radial length of 4.45 feet—a critical design goal to ensure acid reached beyond the damaged zone.

Following stimulation, the well was temporarily shut in due to midstream infrastructure restrictions, providing a unique chance to evaluate the acid treatment’s longevity and sustainability without rapid flowback interference. Following the resumption of production, the well was continually monitored over a four-month production testing program, during which it displayed excellent performance stability, with an average sustained production rate of 509 bpd. The production response fluctuated minimally and showed no signs of early water breakthrough, indicating successful acid placement, zonal selectivity, and promotion of oil-rich periods without unwanted water coning or channeling. When compared to the pre-treatment average of 350 bpd, this result shows a 46% increase in production performance, confirming the treatment’s effectiveness in repairing and improving the well’s deliverability.

The performance uplift can be directly ascribed to multiple interconnected processes:

Controlled acid reactions of the Polymer-free Delayed Acid System, which enabled live acid to penetrate deeper into the reservoir before reacting with the formation.

Effective wormhole generating that extended beyond the damaged zone, creating high-conductivity paths for hydrocarbon flow.

Improved contact with unstimulated reservoir volumes, so allowing a more efficient drainage area.

This instance demonstrates the engineering and practical advantages of single-phase retarded acid systems in tight carbonate reservoirs, particularly where traditional acid systems fail to provide a sufficient stimulation level and production stability. The findings not only confirm the pre-job design and simulation models but also serve as a standard for future acidizing treatments in similar geological contexts, emphasizing the importance of specialized acid chemistries and reaction transport modeling to improve reservoir stimulation outcomes.

Author Contributions

Conceptualization, R.G.R. and C.R.; methodology, R.G.R., C.R., A.D., C.C.M., E.Y.Z., S.N. and M.T.; validation, R.G.R.; formal analysis, R.G.R., C.R., A.D., C.C.M., E.Y.Z., S.N., A.M. and M.T., investigation, R.G.R., C.R., A.D., C.C.M., E.Y.Z., S.N., A.M. and M.T.; resources, C.R.; writing—original draft preparation, R.G.R., C.R., A.D., C.C.M., D.A.H., C.S., E.Y.Z., S.N., A.M. and M.T.; writing—review and editing, R.G.R., C.R., A.D., C.C.M., E.Y.Z., S.N., and M.T.; visualization, R.G.R.; supervision, R.G.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Acknowledgments