Study on the Microscopic Mechanism of Supercritical CO2 and Active Water Alternating Flooding in a Tight Oil Reservoir

Abstract

1. Introduction

2. Experimental Equipment and Design

2.1. Experimental Samples

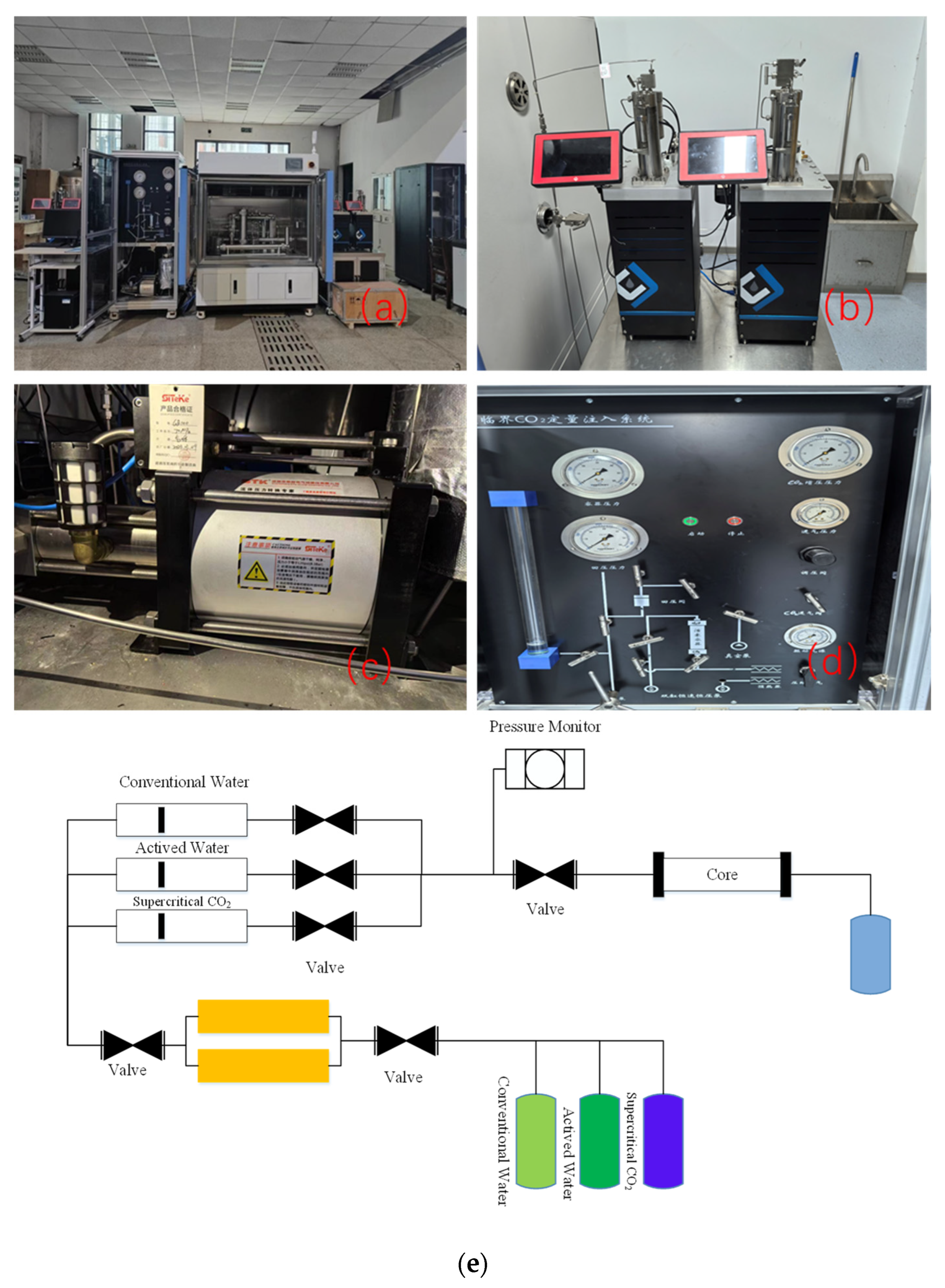

2.2. Experimental Equipment

2.3. Experimental Procedure

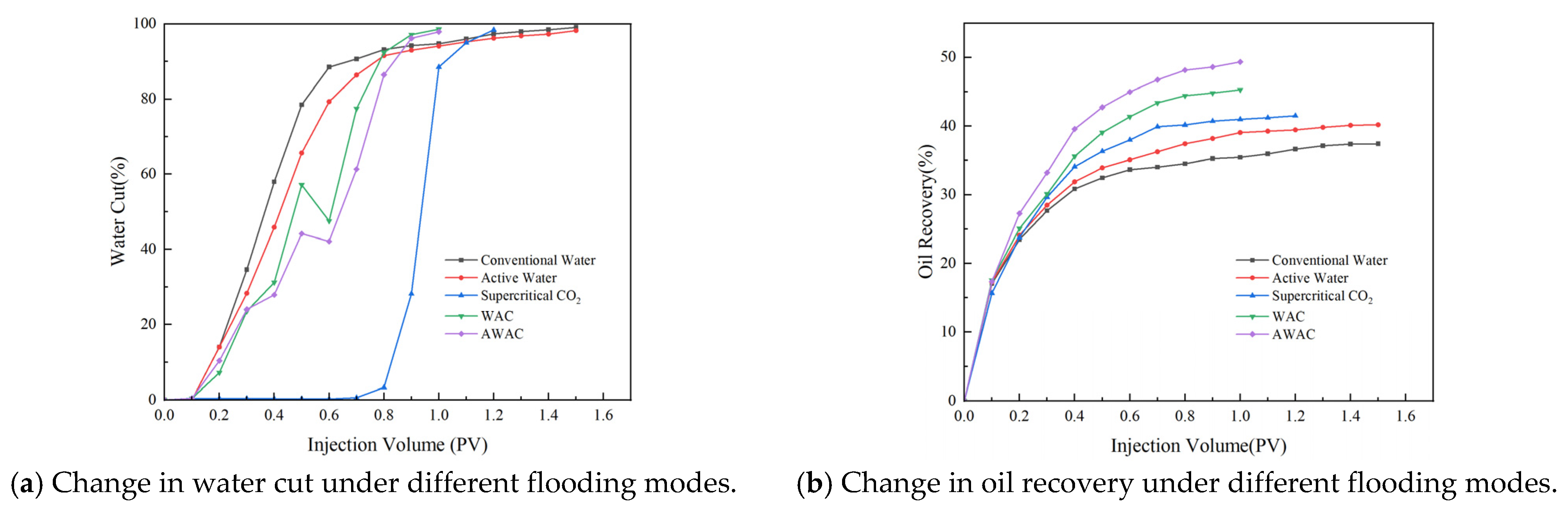

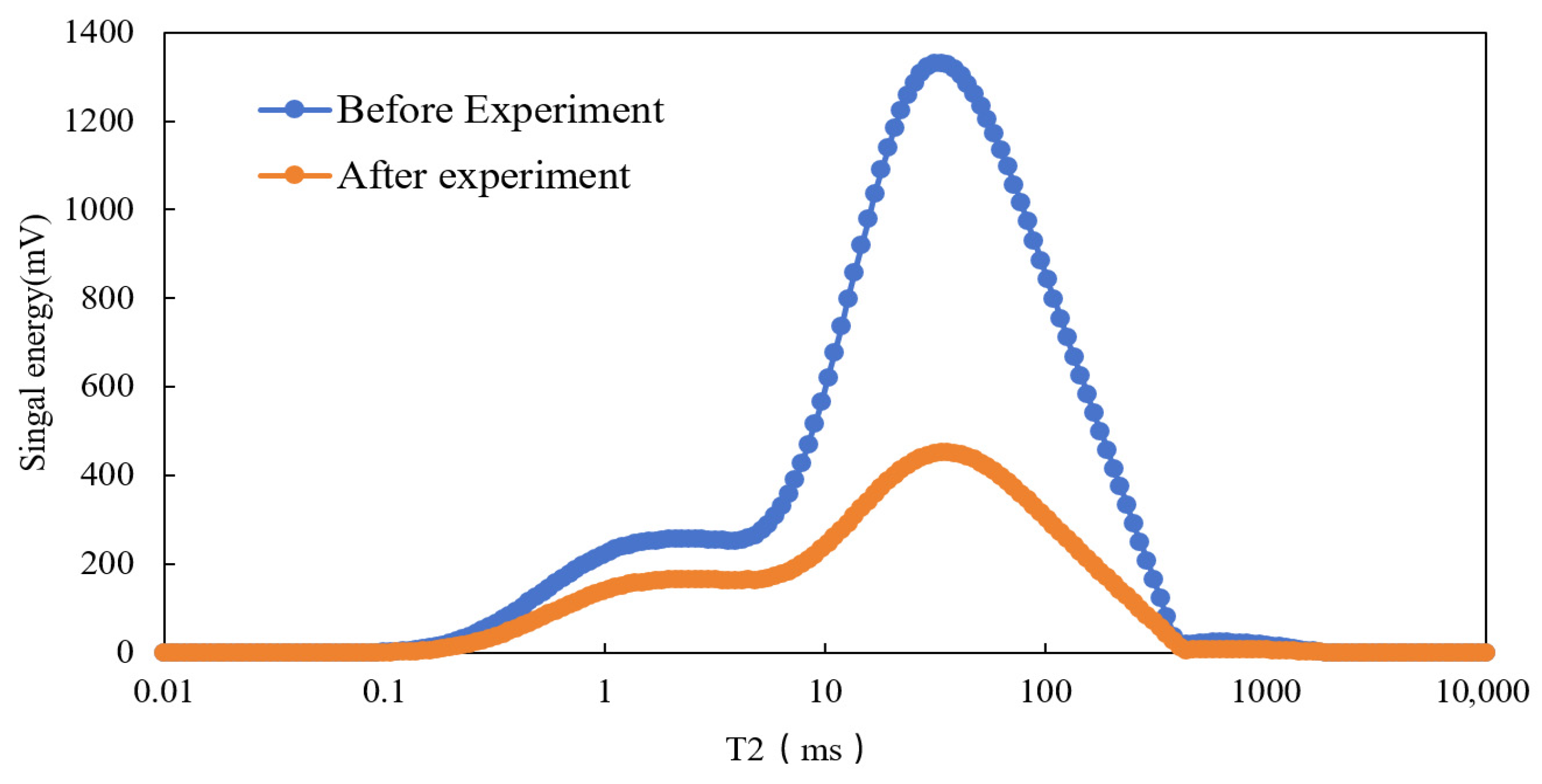

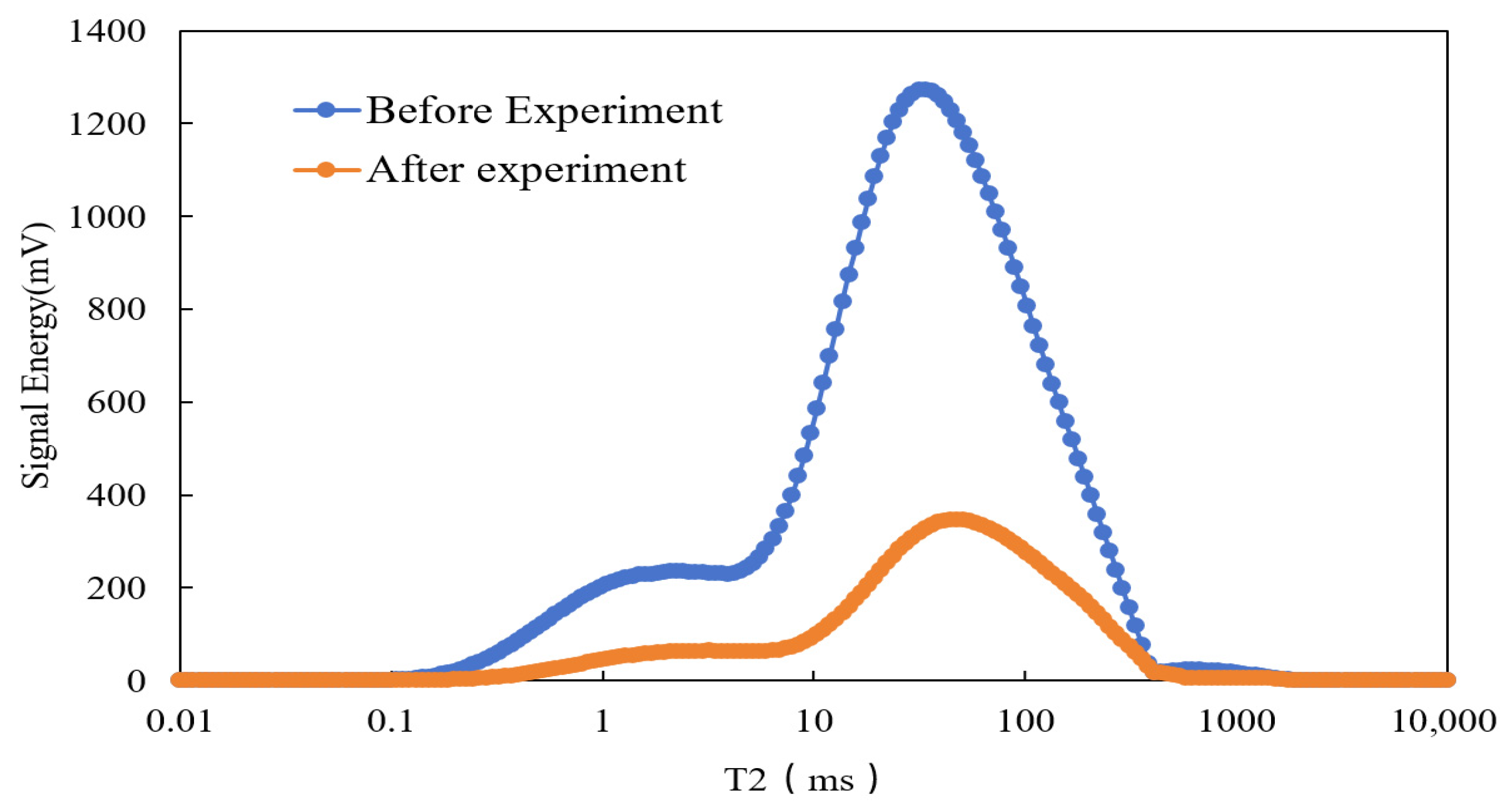

3. Experimental Results

4. Discussion

- (1)

- Comparing the initial and remaining oil saturation shows that the initial oil saturation was influenced by the pore structure; oil was mainly distributed in the pore throat range of 0.1–1.0 μm, and oil in the pore throat range of 0.001–0.01 m was rare. After the displacement process, the remaining oil saturation in all pore throats was up to 6.0% lower than the irreducible water saturation, which indicates that using supercritical CO2 and active water can effectively improve oil displacement.

- (2)

- Comparing the different types of pore throats, the utilization of pore throats in five rock samples shows consistency. The highest utilization was found for type III (0.1–1 µm), followed by type IV (1–10 µm), type II (0.01–0.1 µm), and type I (0.001–0.01 µm).

- (3)

- In terms of oil recovery, the active water flooding recovery is 39.14%, while the water flooding recovery is 36.58%, having increased by 7.01%. The greatest increase in active water flooding was achieved for pore throat type II (0.01–0.1 m), with an increase of 5.48%, followed by type IV (1.0–10.0 m), with an increase of 3.36%. This shows that active water flooding can effectively improve the displacement effect in the pore throat range of 0.01–0.1 µm.

- (4)

- Comparing CO2 flooding with water flooding, it was found that supercritical CO2 can increase oil recovery by 13.26%. Supercritical CO2 had the most obvious effect on pore throats of 0.001~0.01 µm, with an increase of 9.25%, followed by type II (0.01~0.1 µm) pore throats, with an increase of 8.30%. This indicates that supercritical CO2 flooding can effectively improve oil recovery in pore throats of 0.001~0.1 µm.

- (5)

- Comparing water + CO2 alternating flooding, active water + CO2 alternating flooding, and water flooding, the highest utilization of water + CO2 alternating flooding occurs in pore throats in the 0.001~0.01 µm range, while when using active water + CO2 alternating flooding, a corresponding recovery process of different types of pore throats is found. This shows that the oil displacement effect is primarily improved by active water flooding in pores with a throat radius of 0.01~0.1 m, while supercritical CO2 flooding can effectively improve oil recovery in pore throats of 0.001~0.1 µm.

5. Conclusions

- (1)

- Compared with water flooding, active water flooding, supercritical CO2 flooding, water + CO2 alternating flooding, and active water + CO2 staggered flooding, the experimental results suggest that active water with CO2 alternating flooding shows great advantages in terms of increasing oil recovery and decreasing water production. The experiments showed that the oil recovery increased by more than 16.4%, while the water cut decreased by 37.8%, which can effectively reduce the propulsion speed of the water drive leading edge due to the enhanced Jamin effect.

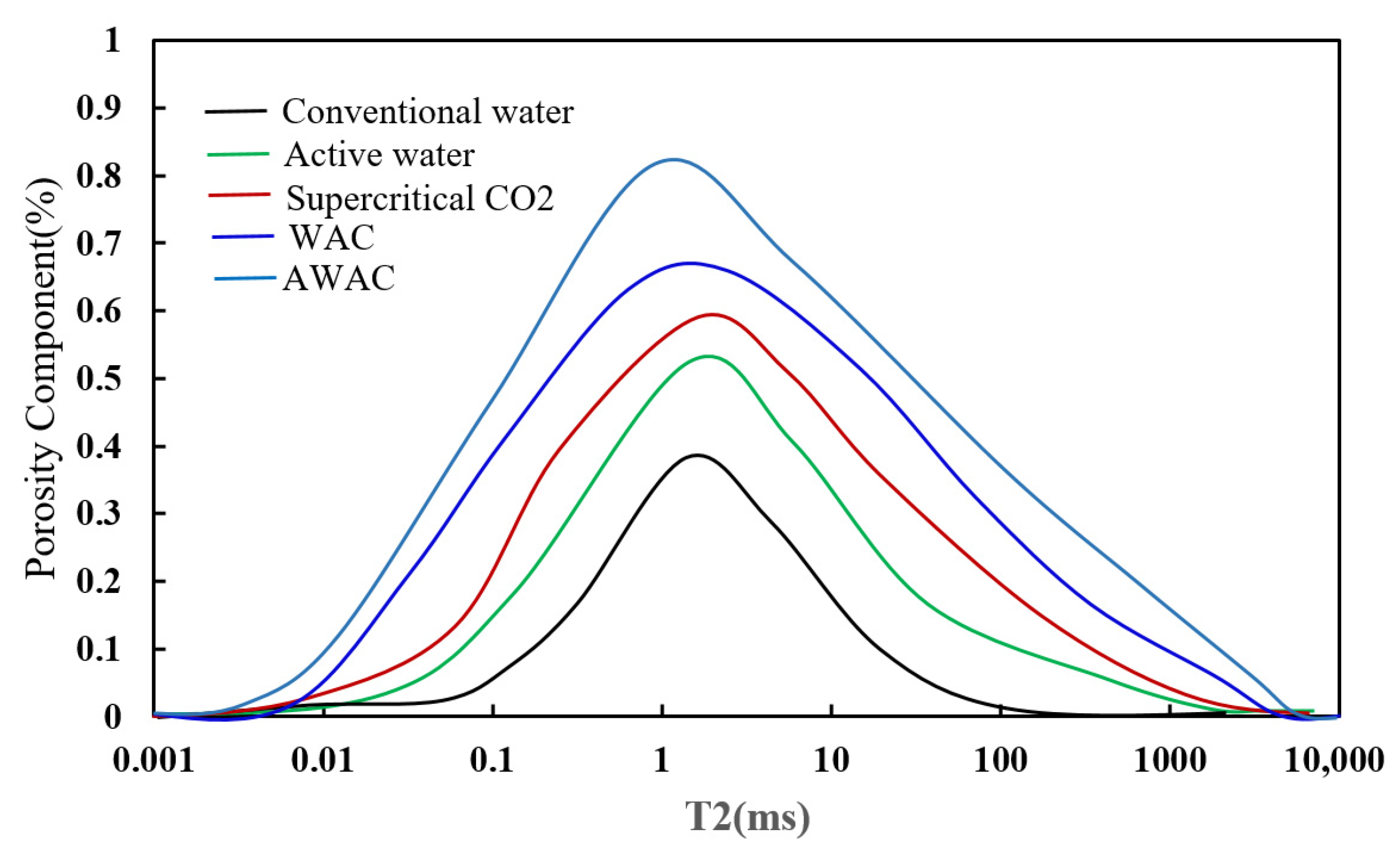

- (2)

- Nuclear magnetic resonance detection under five different displacement modes showed consistency in the utilization of pore throat oil among the five different displacement modes. The highest utilization rate was in type III (0.1~1 µm), followed by types IV (1~10 µm), II (0.01~0.1 µm), and I (0.001~0.01 µm).

- (3)

- Comparing the oil utilization of pore throats under different displacement methods, it was found that active water injection can effectively improve the oil recovery rate of 0.01~0.1 µm pore throats, while supercritical CO2 displacement can effectively improve the oil recovery rate of 0.001~0.1 µm pore throats. At the same time, it was found that conventional water + CO2 alternating flooding can effectively improve the oil recovery effect of type I pore throats, while active water + CO2 alternating flooding can effectively increase the recovery rate of different types of reservoirs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nakagawa, S.; Kneafsey, T.; Daley, T.M.; Freifeld, B.M.; Rees, E.V. Laboratory seismic monitoring of supercritical CO2 flooding in sandstone cores using the Split Hopkinson Resonant Bar technique with concurrent x-ray Computed Tomography imaging. Geophys. Prospect. 2013, 61, 254–269. [Google Scholar] [CrossRef]

- Wang, Z.; Cates, E.; Langa, T.R. Seismic Monitoring of CO2 Flooding in a Carbonate Reservoir: Rock Physics Study; Society of Exploration Geophysicists: Houston, TX, USA, 1996; pp. 1886–1889. [Google Scholar]

- Alemu, B.L.; Aker, E.; Soldal, M.; Johnsen, Ø.; Aagaard, P. Influence of CO2 on rock physics properties in typical reservoir rock: A CO2 flooding experiment of brine saturated sandstone in a CT-scanner. Energy Procedia 2011, 4, 4379–4386. [Google Scholar] [CrossRef]

- Zhou, Y.; Yin, D.; Cao, R.; Zhang, C. The mechanism for pore-throat scale emulsion displacing residual oil after water flooding. J. Pet. Sci. Eng. 2018, 163, 519–525. [Google Scholar] [CrossRef]

- Jiang, L.; Nishizawa, O.; Zhang, Y.; Park, H.; Xue, Z. A novel high-pressure vessel for simultaneous observations of seismic velocity and in situ CO2 distribution in a porous rock using a medical X-ray CT scanner. J. Appl. Geophys. 2016, 135, 67–76. [Google Scholar] [CrossRef]

- Zhang, Y.; Kogure, T.; Nishizawa, O.; Xue, Z. Different flow behavior between 1-to-1 displacement and co-injection of CO2 and brine in Berea sandstone: Insights from laboratory experiments with X-ray CT imaging. Int. J. Greenh. Gas Control 2017, 66, 76–84. [Google Scholar] [CrossRef]

- Kuo, C.-W.; Benson, S.M. Numerical and analytical study of effects of small scale heterogeneity on CO2/brine multiphase flow system in horizontal corefloods. Adv. Water Resour. 2015, 79, 1–17. [Google Scholar] [CrossRef]

- Perrin, J.-C.; Krause, M.; Kuo, C.-W.; Miljkovic, L.; Charoba, E.; Benson, S.M. Core-scale experimental study of relative permeability properties of CO2 and brine in reservoir rocks. Energy Procedia 2009, 1, 3515–3522. [Google Scholar] [CrossRef]

- Chiquet, P.; Daridon, J.-L.; Broseta, D.; Thibeau, S. CO2/water interfacial tensions under pressure and temperature conditions of CO2 geological storage. Energy Convers. Manag. 2007, 48, 736–744. [Google Scholar] [CrossRef]

- Akbarabadi, M.; Piri, M. Relative permeability hysteresis and capillary trapping characteristics of supercritical CO2/brine systems: An experimental study at reservoir conditions. Adv. Water Resour. 2013, 52, 190–206. [Google Scholar] [CrossRef]

- Pini, R.; Benson, S.M. Capillary pressure heterogeneity and hysteresis for the supercritical CO2/water system in a sandstone. Adv. Water Resour. 2017, 108, 277–292. [Google Scholar] [CrossRef]

- Burnside, N.M.; Naylor, M. Review and implications of relative permeability of CO2/brine systems and residual trapping of CO2. Int. J. Greenh. Gas Control 2014, 23, 1–11. [Google Scholar] [CrossRef]

- Tenney, C.M.; Dewers, T.; Chaudhary, K.; Matteo, E.N.; Cardenas, M.B.; Cygan, R.T. Experimental and simulation study of carbon dioxide, brine, and muscovite surface interactions. J. Pet. Sci. Eng. 2017, 155, 78–88. [Google Scholar] [CrossRef]

- Rasmusson, K.; Rasmusson, M.; Tsang, Y.; Benson, S.; Hingerl, F.; Fagerlund, F.; Niemi, A. Residual trapping of carbon dioxide during geological storage—Insight gained through a pore-network modeling approach. Int. J. Greenh. Gas Control 2018, 74, 62–78. [Google Scholar] [CrossRef]

- Jing, G.; Tang, S.; Li, X.; Wang, H. The analysis of scaling mechanism for water-injection pipe columns in the Daqing Oilfield. Arab. J. Chem. 2017, 10, S1235–S1239. [Google Scholar] [CrossRef]

- Mou, J.; Yam, X.; Zhang, S.; Shi, L.; Li, D.; Ma, X. Research on CO2 Matrix Penetration Distance in Tight Reservoirs. Xinjiang Oil Gas 2024, 20, 64–71. [Google Scholar] [CrossRef]

- Xiao, W.; Chen, S.; Yi, Y.; Chen, H.; Ren, J. NMR-Based Experiments of Fracturing Fluid Assisted CO2 Huff-n-Puff for Enhancing Shale Oil Recovery. Xinjiang Oil Gas 2024, 20, 83–90. [Google Scholar] [CrossRef]

- Buckley, J.S.; Hirasaki, G.J.; Liu, Y.; Von Drasek, S.; Wang, J.X.; Gill, B.S. ASPHALTENE PRECIPITATION AND SOLVENT PROPERTIES OF CRUDE OILS. Pet. Sci. Technol. 1998, 16, 251–285. [Google Scholar] [CrossRef]

- Cameron, D.A.; Durlofsky, L.J. Optimization of well placement, CO2 injection rates, and brine cycling for geological carbon sequestration. Int. J. Greenh. Gas Control 2012, 10, 100–112. [Google Scholar] [CrossRef]

- Nielsen, L.C.; Bourg, I.C.; Sposito, G. Predicting CO2–water interfacial tension under pressure and temperature conditions of geologic CO2 storage. Geochim. Cosmochim. Acta 2012, 81, 28–38. [Google Scholar] [CrossRef]

- Ma, X.; Li, X.; Yang, G.; Huang, W.; Diao, Y.; Hu, L.; Zhang, H.; Wei, S. Study on Field-scale of CO2 Geological Storage Combined with Saline Water Recovery: A Case Study of East Junggar Basin of Xinjiang. Energy Procedia 2018, 154, 36–41. [Google Scholar] [CrossRef]

- Shabaninejad, M.; Middlelton, J.; Fogden, A. Systematic pore-scale study of low salinity recovery from Berea sandstone analyzed by micro-CT. J. Pet. Sci. Eng. 2017, 163, S092041051731029X. [Google Scholar] [CrossRef]

- Honari, V.; Underschultz, J.; Wang, X.; Garnett, A.; Wang, X.; Gao, R.; Liang, Q. CO2 sequestration-EOR in Yanchang oilfield, China: Estimation of CO2 storage capacity using a two-stage well test. Energy Procedia 2018, 154, 9–14. [Google Scholar] [CrossRef]

- Oh, J.; Kim, K.-Y.; Han, W.S.; Park, E.; Kim, J.-C. Migration behavior of supercritical and liquid CO2 in a stratified system: Experiments and numerical simulations. Water Resour. Res. 2015, 51, 7937–7958. [Google Scholar] [CrossRef]

- Perrin, J.-C.; Benson, S. An Experimental Study on the Influence of Sub-Core Scale Heterogeneities on CO2 Distribution in Reservoir Rocks. Transp. Porous Media 2010, 82, 93–109. [Google Scholar] [CrossRef]

- Park, H.; Jiang, L.; Kiyama, T.; Zhang, Y.; Ueda, R.; Nakano, M.; Xue, Z. Influence of Sedimentation Heterogeneity on CO2 Flooding. Energy Procedia 2017, 114, 2933–2941. [Google Scholar] [CrossRef]

- Gonçalves, S.I.; Ligneul, C.; Shemesh, N. Short echo time relaxation-enhanced MR spectroscopy reveals broad downfield resonances. Magn. Reson. Med. 2019, 82, 1266–1277. [Google Scholar] [CrossRef] [PubMed]

- Coskun, S.B.; Wardlaw, N.C. Image analysis for estimating ultimate oil recovery efficiency by waterflooding for two sandstone reservoirs. J. Pet. Sci. Eng. 1996, 15, 237–250. [Google Scholar] [CrossRef]

- Kewen, W.; Ning, L. Numerical simulation of rock pore-throat structure effects on NMR T2 distribution. Appl. Geophys. 2008, 5, 86–91. [Google Scholar] [CrossRef]

| Na++K+ | Mg2+ | Ca2+ | SO42− | Cl− | CO32− | HCO3− | Total Salinity/ mg/L |

|---|---|---|---|---|---|---|---|

| 14,570.00 | 336.0 | 471.2 | 336.2 | 15,470.2 | 669.0 | 332.1 | 32,184.7 |

| No. | Core Size Length × Diameter /cm | Permeability /mD | Porosity /% | Dry Weight /g |

|---|---|---|---|---|

| 1 | 60 × 2.54 | 1.4 | 7.32 | 426.8 |

| 2 | 60 × 2.54 | 1.4 | 7.32 | 427.4 |

| 3 | 60 × 2.54 | 1.4 | 7.32 | 426.4 |

| 4 | 60 × 2.54 | 1.4 | 7.32 | 426.7 |

| 5 | 60 × 2.54 | 1.4 | 7.32 | 428.1 |

| Sample | Experimental Scheme |

|---|---|

| Sample 1 | Conventional water flooding (0.8 PV) |

| Sample 2 | Active water flooding (0.8 PV) |

| Sample 3 | CO2 flooding (0.8 PV) |

| Sample 4 | 0.15 PV conventional water + 0.15 PV CO2 + 0.15 PV conventional water + 0.15 PV CO2 + 0.10 PV conventional water + 0.10 PV CO2 + conventional water flooding |

| Sample 5 | Active water (0.15 PV) + 0.15 PV CO2 + active water (0.15 PV) + 0.15 PV CO2 + active water (0.1 PV) + 0.1 PV CO2 |

| Flooding Mode | Water Cut/% | Oil Recovery/% |

|---|---|---|

| Conventional water flooding | 99.06 | 37.42 |

| Active water flooding | 98.22 | 40.21 |

| Supercritical CO2 flooding | 98.42 | 41.5 |

| Supercritical CO2 + conventional water flooding | 98.58 | 45.29 |

| Supercritical CO2 + active water flooding | 97.89 | 49.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Dong, J.; Zhou, P.; Liu, K. Study on the Microscopic Mechanism of Supercritical CO2 and Active Water Alternating Flooding in a Tight Oil Reservoir. Processes 2025, 13, 2535. https://doi.org/10.3390/pr13082535

Wang B, Dong J, Zhou P, Liu K. Study on the Microscopic Mechanism of Supercritical CO2 and Active Water Alternating Flooding in a Tight Oil Reservoir. Processes. 2025; 13(8):2535. https://doi.org/10.3390/pr13082535

Chicago/Turabian StyleWang, Bin, Jingfeng Dong, Peiyao Zhou, and Kaixin Liu. 2025. "Study on the Microscopic Mechanism of Supercritical CO2 and Active Water Alternating Flooding in a Tight Oil Reservoir" Processes 13, no. 8: 2535. https://doi.org/10.3390/pr13082535

APA StyleWang, B., Dong, J., Zhou, P., & Liu, K. (2025). Study on the Microscopic Mechanism of Supercritical CO2 and Active Water Alternating Flooding in a Tight Oil Reservoir. Processes, 13(8), 2535. https://doi.org/10.3390/pr13082535