An Integrated Synthesis Approach for Emergency Logistics System Optimization of Hazardous Chemical Industrial Parks

Abstract

1. Introduction

2. Research Problem and Assumptions

- (1)

- Scenario 1—Incremental Optimization: This involves supplementing an existing logistics system by adding new supply nodes to alleviate dispatch pressure and reduce operating costs while maintaining the current facility layout.

- (2)

- Scenario 2—Full Reconstruction: This includes redesigning the emergency network entirely in the aftermath of large-scale infrastructure failure or policy-driven transformation.

- All facilities are modeled as dimensionless points to simplify spatial relationships and distance calculations.

- The set of candidate supply facility locations is finite, with activation decisions determined by the model.

- Emergency resource demand gaps, consumption rates, and existing inventories at each demand point are known and constant.

- Partial shipments are permitted, allowing a single demand point to be served by multiple facilities.

- Transportation time is estimated using the straight-line (Euclidean) distance and average vehicle speed, ignoring real-time congestion or dynamic routing adjustments.

- Each demand point has a maximum allowable response time, and failure to meet this threshold is considered a disruption.

- Activated supply facilities must maintain minimum safety distances to mitigate spatial conflicts and comply with safety regulations.

- The objective function includes facility activation costs, per-unit storage costs, and transportation costs, while loading/unloading and administrative costs are not considered.

- The emergency logistics area is represented as a rectangular region with known boundaries, with its diagonal intersection as the coordinate system origin.

- The area is subdivided into subregions based on facility coordinates, reflecting spatial variations in land costs and storage fees to capture economic trade-offs in facility location decisions.

- The transportation paths consider only the straight-line (Euclidean) distance, ignoring complex road conditions, traffic congestion, and road quality factors.

- The emergency supplies are an abstract single commodity, meaning all emergency supplies have the same characteristics and handling procedures, without considering the differences between different types of supplies.

3. Mathematical Models and Computational Complexity

3.1. Mathematical Models

3.2. Computational Complexity and Scalability

- Linearizing nonlinear expressions where possible;

- Decomposing the problem structure using Benders decomposition or column generation;

- Relaxing integer variables;

- Applying metaheuristic algorithms such as Genetic Algorithms (GAs), Simulated Annealing (SA), or Particle Swarm Optimization (PSO) to find high-quality near-optimal solutions within limited time frames.

4. Case Study

- (1)

- Scenario 1: Incremental Optimization—This involves adding new supply nodes to supplement the existing logistics system, alleviate dispatch bottlenecks, enhance redundancy, and reduce total system costs, without modifying the original facility layout.

- (2)

- Scenario 2: Full Reconstruction—This involves redesigning the emergency supply network in the event of large-scale infrastructure failure or the need for system-wide reconstruction.

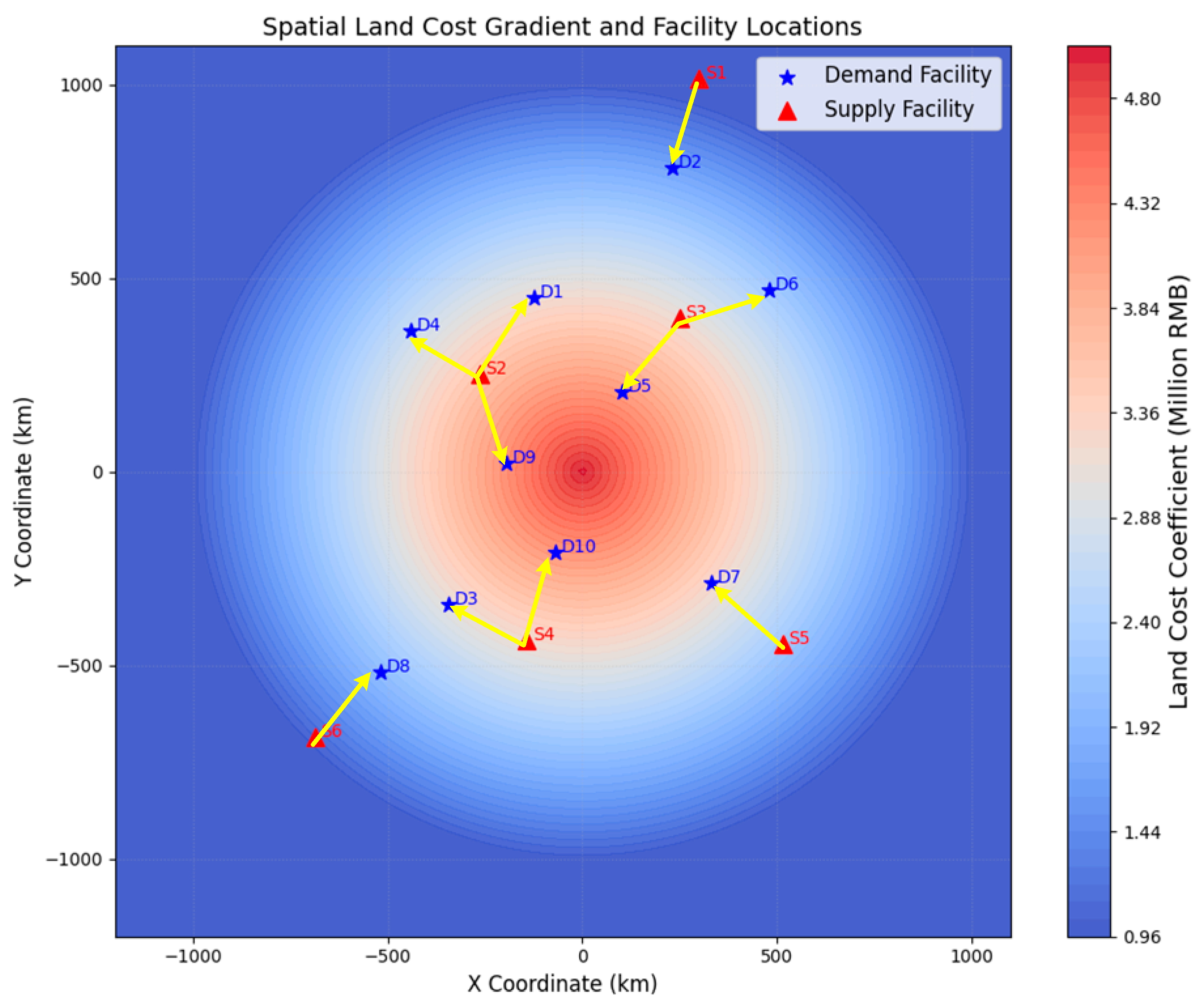

4.1. Case 1: Incremental Optimization Under Stable Logistics Systems

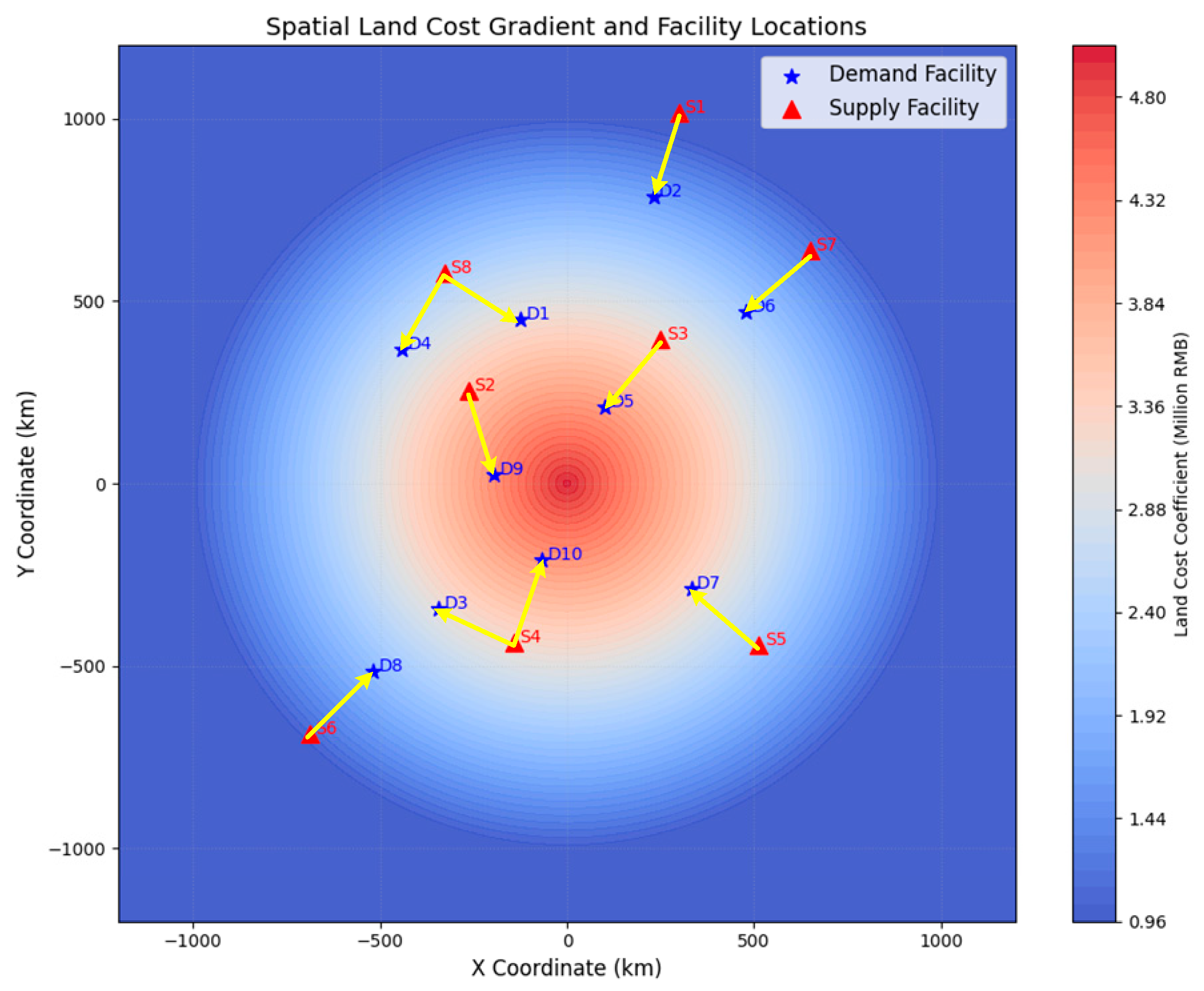

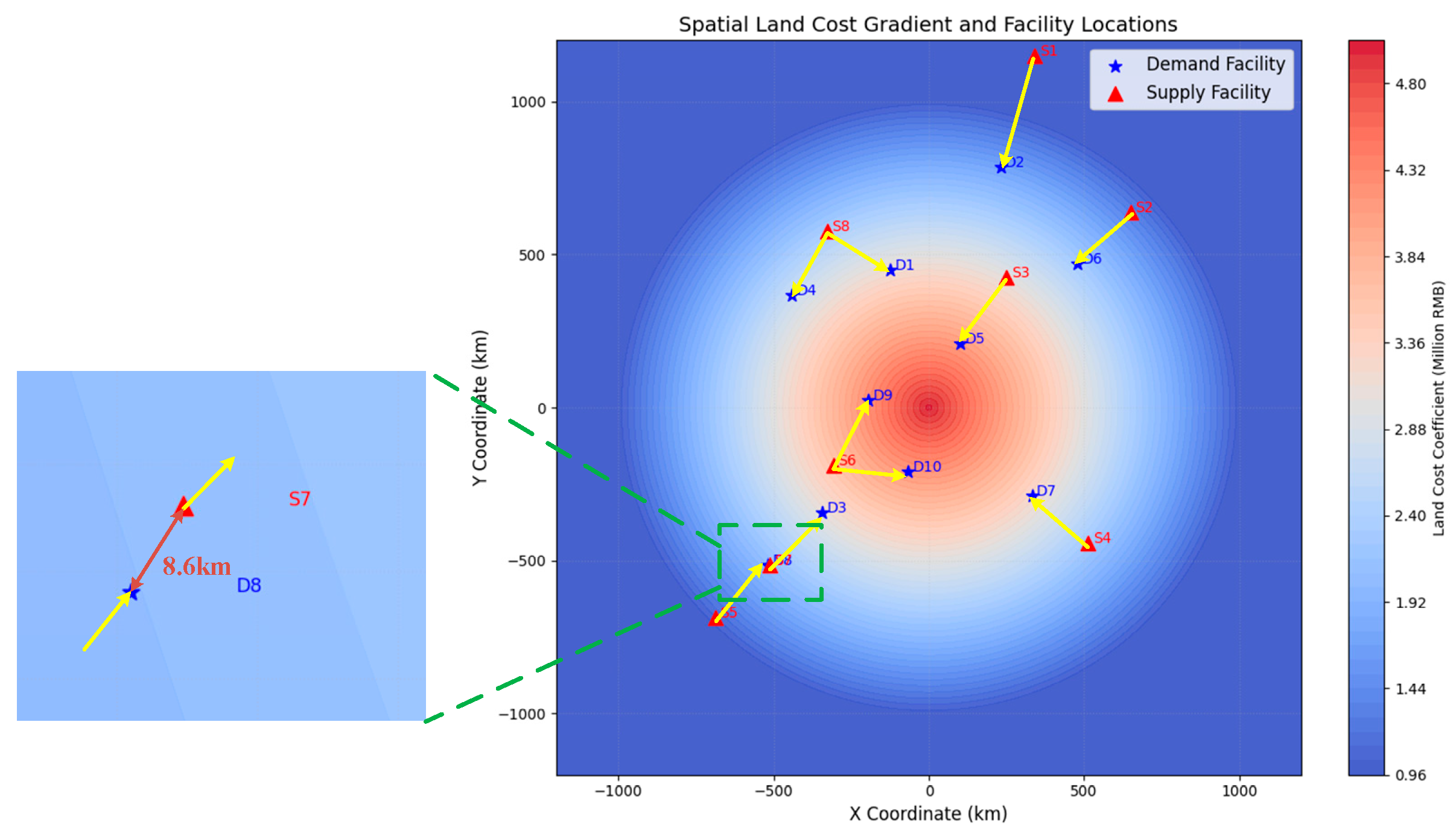

4.2. Case 2: Network Reconstruction Under Systemic Failure

5. Discussion and Conclusions

- (a)

- Scenario adaptability: The framework applies to both incremental optimization and full network redesign, offering flexibility for diverse emergency-preparedness needs.

- (b)

- Economic–spatial synergy: The integration of radial land cost gradients reduces infrastructure investment without compromising safety, as demonstrated in both case scenarios.

- (c)

- Operational resilience: By enforcing domino safety distances and dynamically reallocating supply–demand assignments, the model enhances resource utilization while adhering to spatial risk controls.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Symbol | Definition | Unit |

| cap | Land cost factor | million dollars |

| cbp | Unit emergency supplies’ purchase and management costs | tons·dollars−1 |

| costp | Total emergency dispatch cost at supply point p | million dollars |

| D | Set of emergency supply demand points | — |

| Dsdmin | Minimum safety distance constraint between two facilities | km |

| fdloq | Quantity of emergency supplies required at demand point q | tons |

| fsp | Total amount of emergency resources stored at supply point p | tons |

| fstdp, q | Quantity of emergency supplies transported from supply point p to demand point q | tons |

| kL | Rate of cost decline with distance | million dollars km−1 |

| Land0 | Baseline land price at the origin | million dollars |

| M1 | Sufficiently large positive number in “Big-M” | — |

| M2 | Large constant to deactivate constraint when zf (p,q) = 0 | — |

| M3 | Sufficiently large positive value | — |

| M4 | Small positive constant to avoid numerical instability | — |

| p | Emergency supply point index | — |

| q | Emergency demand point index | — |

| rsdp | Euclidean distance from origin to facility location | km |

| S | Set of emergency supply points | — |

| sdp, q | Euclidean distance between facilities p and q | km |

| svq | Emergency supply consumption rate at demand point q | tons·hour−1 |

| tsq | Support time for stored emergency supplies at demand point q | hours |

| Tcost | Total of all supply point dispatch costs | million dollars |

| Ttp, q | Transportation time from p to q | hours |

| xap | Horizontal coordinate of supply facility p | — |

| xaq | Horizontal coordinate of demand facility q | — |

| yap | Vertical coordinate of supply facility p | — |

| yaq | Vertical coordinate of demand facility q | — |

| zfp, q | Binary variable: whether supply point p serves demand point q | 0 or 1 |

| ztp | Binary variable: whether supply point p is activated | 0 or 1 |

References

- Yang, P.; Zhang, L.; Tao, G. Smart Chemical Industry Parks in China: Current Status, Challenges, and Pathways for Future Sustainable Development. J. Loss Prev. Process Ind. 2023, 83, 105105. [Google Scholar] [CrossRef]

- Hou, J.; Gai, W.-M.; Cheng, W.-Y.; Deng, Y.-F. Hazardous Chemical Leakage Accidents and Emergency Evacuation Response from 2009 to 2018 in China: A Review. Saf. Sci. 2021, 135, 105101. [Google Scholar] [CrossRef]

- Wang, B.; Wu, C.; Reniers, G.; Huang, L.; Kang, L.; Zhang, L. The Future of Hazardous Chemical Safety in China: Opportunities, Problems, Challenges and Tasks. Sci. Total Environ. 2018, 643, 1–11. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Han, J.; Lei, C.; Ding, W.; Li, B.; Zhang, L. The Challenges and Countermeasures in Emergency Management after the Establishment of the Ministry of Emergency Management of China: A Case Study. Int. J. Disaster Risk Reduct. 2021, 55, 102075. [Google Scholar] [CrossRef]

- Ding, Z.; Xu, X.; Jiang, S.; Yan, J.; Han, Y. Emergency Logistics Scheduling with Multiple Supply-Demand Points Based on Grey Interval. J. Saf. Sci. Resil. 2022, 3, 179–188. [Google Scholar] [CrossRef]

- Kundu, T.; Sheu, J.B.; Kuo, H.T. Emergency Logistics Management—Review and Propositions for Future Research. Transp. Res. E Logist. Transp. Rev. 2022, 164, 102789. [Google Scholar] [CrossRef]

- Duan, W.; He, B. Emergency Response System for Pollution Accidents in Chemical Industrial Parks, China. Int. J. Environ. Res. Public Health 2015, 12, 7868–7885. [Google Scholar] [CrossRef]

- Du, Y.; Sun, J.; Duan, Q.; Qi, K.; Xiao, H.; Liew, K.M. Optimal Assignments of Allocating and Scheduling Emergency Resources to Accidents in Chemical Industrial Parks. J. Loss Prev. Process Ind. 2020, 65, 104148. [Google Scholar] [CrossRef]

- Jiang, Y.; Xu, K.; Gai, W.; Salhi, S. Emergency Response for Tackling Major Accidental Toxic Gas Releases: What Should Be Done and When? Saf. Sci. 2022, 154, 105819. [Google Scholar] [CrossRef]

- Xu, Z.; Zheng, C.; Zheng, S.; Ma, G.; Chen, Z. Multimodal Transportation Route Optimization of Emergency Supplies Under Uncertain Conditions. Sustainability 2024, 16, 10905. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.; Pettet, G.; Vazirizade, S.M.; Lu, D.; Jaimes, A.; El Said, S.; Baroud, H.; Vorobeychik, Y.; Kochenderfer, M.; Dubey, A. A Review of Incident Prediction, Resource Allocation, and Dispatch Models for Emergency Management. Accid. Anal. Prev. 2022, 165, 106501. [Google Scholar] [CrossRef]

- Xu, F.; Ma, Y.; Liu, C.; Ji, Y. Emergency Logistics Facilities Location Dual-Objective Modeling in Uncertain Environments. Sustainability 2024, 16, 1361. [Google Scholar] [CrossRef]

- Wang, W.; Wu, S.; Wang, S.; Zhen, L.; Qu, X. Emergency Facility Location Problems in Logistics: Status and Perspectives. Transp. Res. E Logist. Transp. Rev. 2021, 154, 102465. [Google Scholar] [CrossRef]

- Boonmee, C.; Arimura, M.; Asada, T. Facility Location Optimization Model for Emergency Humanitarian Logistics. Int. J. Disaster Risk Reduct. 2017, 24, 485–498. [Google Scholar] [CrossRef]

- Yao, J.; Zhang, X.; Murray, A.T. Location Optimization of Urban Fire Stations: Access and Service Coverage. Comput. Environ. Urban. Syst. 2019, 73, 184–190. [Google Scholar] [CrossRef]

- Dantrakul, S.; Likasiri, C.; Pongvuthithum, R. Applied P-Median and p-Center Algorithms for Facility Location Problems. Expert. Syst. Appl. 2014, 41, 3596–3604. [Google Scholar] [CrossRef]

- Karatas, M.; Razi, N.; Tozan, H. A Comparison of P-Median and Maximal Coverage Location Models with Q-Coverage Requirement. Procedia Eng. 2016, 149, 169–176. [Google Scholar] [CrossRef]

- Carnero Quispe, M.F.; Couto, A.S.; de Brito Junior, I.; Cunha, L.R.A.; Siqueira, R.M.; Yoshizaki, H.T.Y. Humanitarian Logistics Prioritization Models: A Systematic Literature Review. Logistics 2024, 8, 60. [Google Scholar] [CrossRef]

- Akgün, I.; Gümüşbuğa, F.; Tansel, B. Risk Based Facility Location by Using Fault Tree Analysis in Disaster Management. Omega 2015, 52, 168–179. [Google Scholar] [CrossRef]

- Hu, H.; He, J.; He, X.; Yang, W.; Nie, J.; Ran, B. Emergency Material Scheduling Optimization Model and Algorithms: A Review. J. Traffic Transp. Eng. (Engl. Ed.) 2019, 6, 441–454. [Google Scholar] [CrossRef]

- Yuan, Y.; Wang, F. An Emergency Supplies Scheduling for Chemical Industry Park: Based on Super Network Theory. Environ. Sci. Pollut. Res. 2022, 29, 39345–39358. [Google Scholar] [CrossRef]

- Bodaghi, B.; Shahparvari, S.; Fadaki, M.; Lau, K.H.; Ekambaram, P.; Chhetri, P. Multi-Resource Scheduling and Routing for Emergency Recovery Operations. Int. J. Disaster Risk Reduct. 2020, 50, 101780. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Li, J.; Wang, J.; Yuan, N. Research on Location-Inventory-Routing Optimization of Emergency Logistics Based on Multiple Reliability under Uncertainty. Comput. Ind. Eng. 2025, 200, 110826. [Google Scholar] [CrossRef]

- Pu, X.; Zhao, X. Post-Earthquake Emergency Logistics Location-Routing Optimization Considering Vehicle Three-Dimensional Loading Constraints. Symmetry 2024, 16, 1080. [Google Scholar] [CrossRef]

- Caunhye, A.M.; Zhang, Y.; Li, M.; Nie, X. A Location-Routing Model for Prepositioning and Distributing Emergency Supplies. Transp. Res. E Logist. Transp. Rev. 2016, 90, 161–176. [Google Scholar] [CrossRef]

- Sun, H.; Huang, Y.; Chang, Q.; Li, J. A Robust and Multi-Period Model for an Emergency Logistics Network Considering the Risk of Disruptions. RAIRO-Oper. Res. 2025, 59, 1501–1525. [Google Scholar] [CrossRef]

- Liu, L.; Tian, T.; Wang, R.; Li, S. Time Varying Route Optimization of Hazardous Materials Transportation Considering Risk Equity. Preprints 2025. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, J.; Yang, Y.; Wang, Y. Research on Optimization and Intelligent Upgrading Strategies for Emergency Logistics Systems. In Proceedings of the 2024 6th Management Science Informatization and Economic Innovation Development Conference (MSIEID 2024), Guangzhou, China, 6–8 December 2024; Atlantis Press: Dordrecht, The Netherlands, 2025; pp. 605–612. [Google Scholar] [CrossRef]

| Demand Facility ID | X Coordinate | Y Coordinate |

|---|---|---|

| D1 | −125.00 | 450.00 |

| D2 | 231.00 | 787.00 |

| D3 | −343.00 | −344.00 |

| D4 | −441.00 | 366.00 |

| D5 | 101.00 | 208.00 |

| D6 | 479.00 | 469.00 |

| D7 | 332.00 | −287.00 |

| D8 | −518.00 | −516.00 |

| D9 | −195.00 | 24.00 |

| D10 | −68.00 | −208.00 |

| Demand Facility ID | Additional Emergency Supply Demand (Tons) | Consumption Rate of Emergency Supplies (Tons/Hour) | Self-Reserve of Emergency Supplies (Tons) |

|---|---|---|---|

| D1 | 830 | 30 | 90 |

| D2 | 1050 | 40 | 120 |

| D3 | 2390 | 90 | 270 |

| D4 | 980 | 30 | 90 |

| D5 | 3130 | 110 | 330 |

| D6 | 1590 | 60 | 180 |

| D7 | 1620 | 60 | 180 |

| D8 | 3310 | 120 | 360 |

| D9 | 1400 | 50 | 150 |

| D10 | 2030 | 70 | 210 |

| Supply Facility ID | X Coordinate | Y Coordinate | Emergency Reserve Stockpile |

|---|---|---|---|

| S1 | 298.59 | 1017.28 | 1050 |

| S2 | −263.51 | 254.00 | 3210 |

| S3 | 250.44 | 395.79 | 4720 |

| S4 | −142.58 | −436.12 | 4420 |

| S5 | 513.56 | −443.95 | 1620 |

| S6 | −688.03 | −685.38 | 3310 |

| D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 | D9 | D10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 1050 | |||||||||

| S2 | 830 | 980 | 1400 | |||||||

| S3 | 3130 | 1590 | ||||||||

| S4 | 2390 | 2030 | ||||||||

| S5 | 1620 | |||||||||

| S6 | 3310 |

| Supply Facility ID | X Coordinate | Y Coordinate | Emergency Reserve Stockpile |

|---|---|---|---|

| S1 | 298.59 | 1017.28 | 1050 |

| S2 | −263.51 | 254.00 | 1400 |

| S3 | 250.44 | 395.79 | 3130 |

| S4 | −142.58 | −436.12 | 4420 |

| S5 | 513.56 | −443.95 | 1620 |

| S6 | −688.03 | −685.38 | 3310 |

| S7 | 650.00 | 637.04 | 1590 |

| S8 | −328.12 | 578.14 | 1810 |

| D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 | D9 | D10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 1050 | |||||||||

| S2 | 1400 | |||||||||

| S3 | 3130 | |||||||||

| S4 | 2390 | 2030 | ||||||||

| S5 | 1620 | |||||||||

| S6 | 3310 | |||||||||

| S7 | 1590 | |||||||||

| S8 | 830 | 980 |

| Supply Facility ID | X Coordinate | Y Coordinate | Emergency Reserve Stockpile (Tons) |

|---|---|---|---|

| S1 | 341.58 | 1200.00 | 1050 |

| S2 | 650.48 | 636.90 | 1590 |

| S3 | 250.83 | 423.89 | 3130 |

| S4 | 513.56 | −443.95 | 1620 |

| S5 | −688.03 | −685.38 | 3130 |

| S6 | −307.18 | −188.17 | 3430 |

| S7 | −510.46 | −511.95 | 2390 |

| S8 | −328.14 | −577.80 | 1810 |

| D1 | D2 | D3 | D4 | D5 | D6 | D7 | D8 | D9 | D10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| S1 | 1050 | |||||||||

| S2 | 1590 | |||||||||

| S3 | 3130 | |||||||||

| S4 | 1620 | |||||||||

| S5 | 3130 | |||||||||

| S6 | 1400 | 2030 | ||||||||

| S7 | 2390 | |||||||||

| S8 | 830 | 980 |

| Example | |

|---|---|

| Number of equations | 1431 |

| Number of variables | 791 |

| Number of discrete variables | 116 |

| CPU time (s) | 26 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, D.; Yang, F.; Chen, Z.; Liu, F.; Ye, H.; Bi, M. An Integrated Synthesis Approach for Emergency Logistics System Optimization of Hazardous Chemical Industrial Parks. Processes 2025, 13, 2513. https://doi.org/10.3390/pr13082513

Ma D, Yang F, Chen Z, Liu F, Ye H, Bi M. An Integrated Synthesis Approach for Emergency Logistics System Optimization of Hazardous Chemical Industrial Parks. Processes. 2025; 13(8):2513. https://doi.org/10.3390/pr13082513

Chicago/Turabian StyleMa, Daqing, Fuming Yang, Zhongwang Chen, Fengyi Liu, Haotian Ye, and Mingshu Bi. 2025. "An Integrated Synthesis Approach for Emergency Logistics System Optimization of Hazardous Chemical Industrial Parks" Processes 13, no. 8: 2513. https://doi.org/10.3390/pr13082513

APA StyleMa, D., Yang, F., Chen, Z., Liu, F., Ye, H., & Bi, M. (2025). An Integrated Synthesis Approach for Emergency Logistics System Optimization of Hazardous Chemical Industrial Parks. Processes, 13(8), 2513. https://doi.org/10.3390/pr13082513