Creep Deformation Mechanisms of Gas-Bearing Coal in Deep Mining Environments: Experimental Characterization and Constitutive Modeling

Abstract

1. Introductory

2. Experimental Methods

2.1. Experiment Procedure

2.2. Experimental Procedures

- (1)

- Assemble and place the three-axis gripper on the operating table and connect the pressure system, sonic collector, and gas transmission unit.

- (2)

- Create a new loading control file, select the pressure control system–rock triaxial test module, and select manual control. Input the initial axial pressure and confining pressure parameters and start loading until the stress reaches the initial values. The confining pressure and gas pressure conditions of each coal sample are shown in Table 1.

- (3)

- Open the outlet valve, close the inlet valve, and evacuate for 15 min.

- (4)

- Close the outlet valve, open the inlet valves and the cylinder valve and fill with gas. Adjust the gas cylinder pressure, reducing the valve to the set value, inflate for 2 h; let the coal sample and gas achieve full adsorption, to achieve an adsorption equilibrium.

- (5)

- According to the site conditions of the coal seam, load the samples up to an axial pressure of 20 MPa, a loading rate of 2 MPa/min, and a constant loading time of 60 min. After that, increase the loading pressure by 2 MPa at each stage.

- (6)

- At the end of the experiment, make a record. Then, close the gas cylinder, the pressure reducing valve and the inlet valve of the gripper, and open the outlet valve until the gas pressure in the gripper drops to 0, and then stop the press loading.

- (7)

- According to different experimental programs, change the gas pressure, loading mode, repeat steps (1)~(6), to apply different conditions to the stress–gas coupling damage experiments.

3. Experimental Results

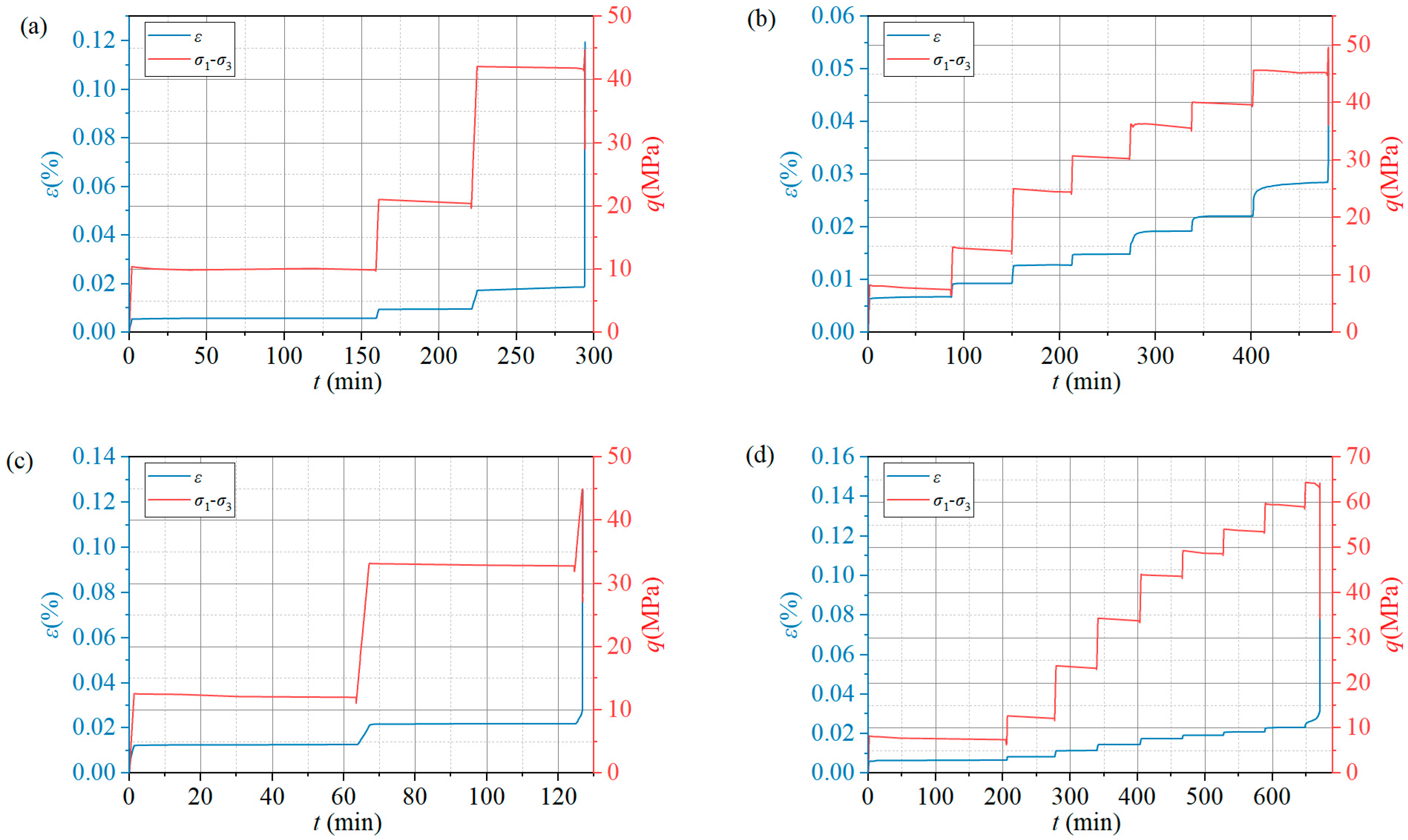

3.1. Mechanical Loading Results

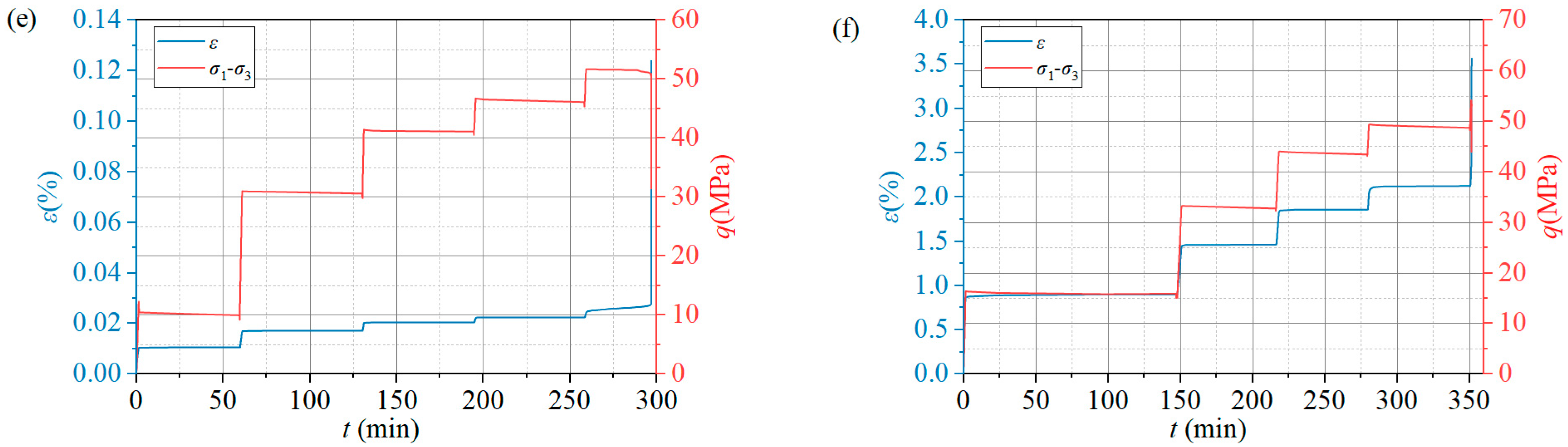

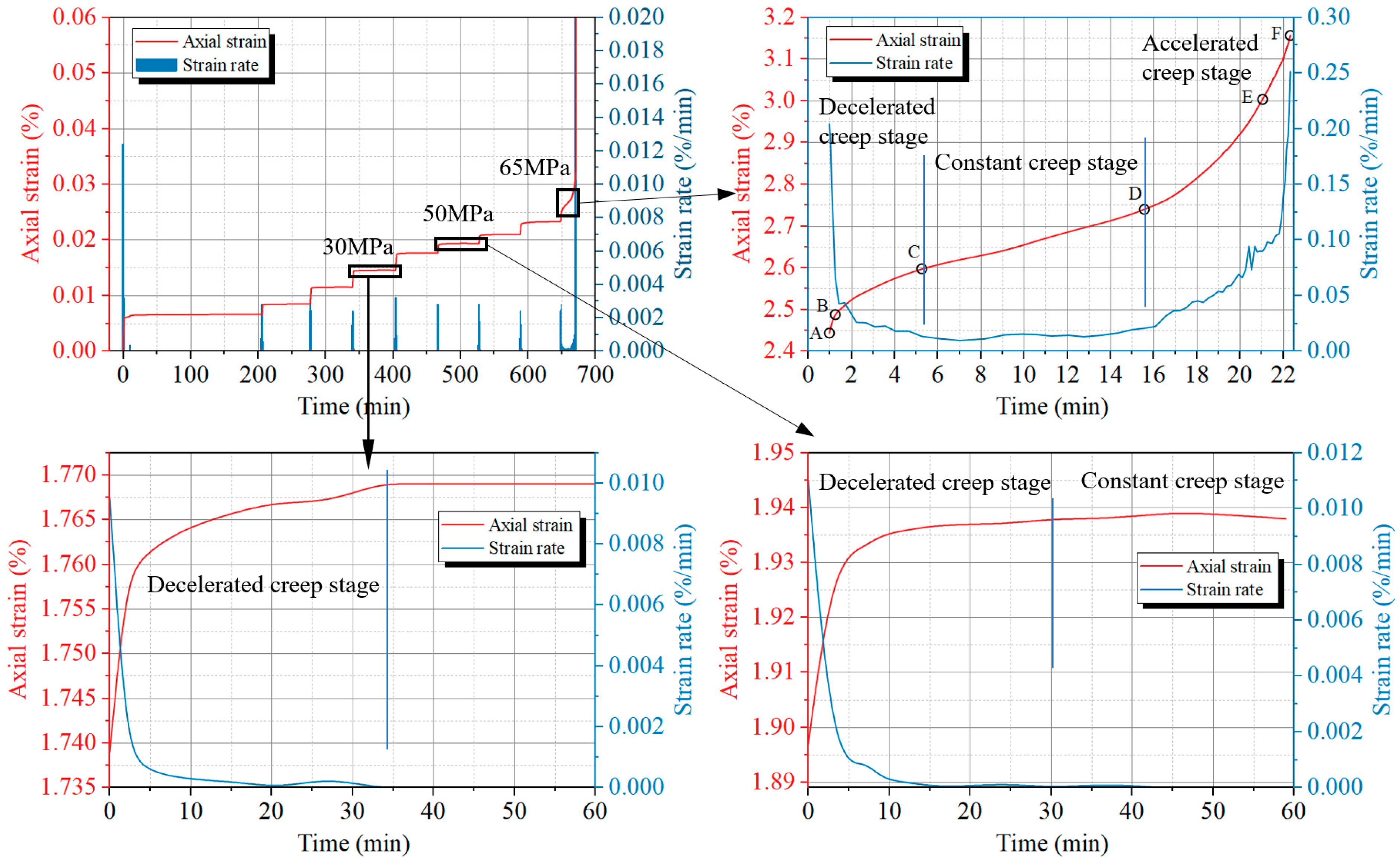

3.2. Characteristics of Loading Creep Damage

3.3. Analysis of Typical Creep Phenomena

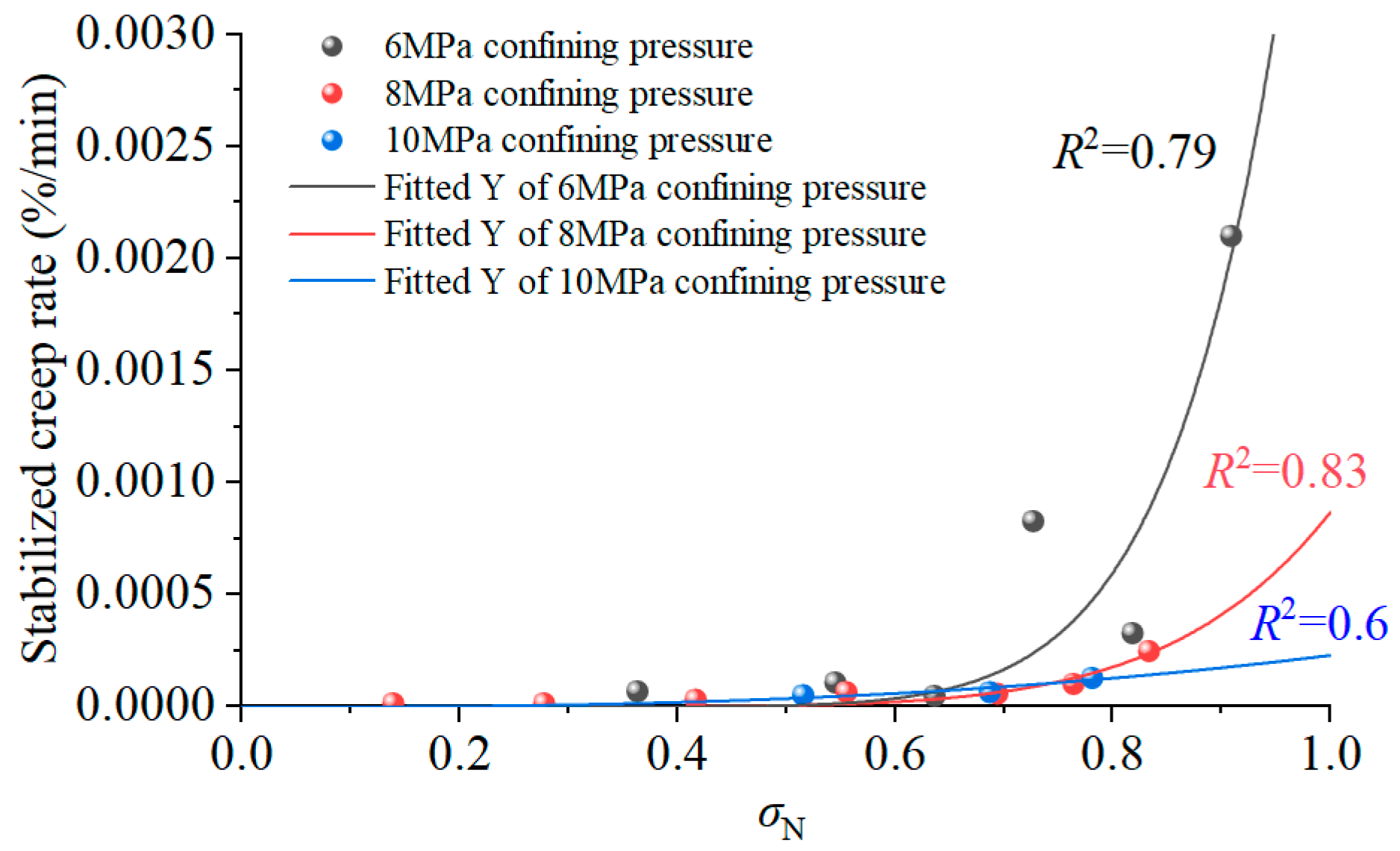

3.4. Variation in Creep Rate of Gas-Bearing Coal Bodies

4. Discussion

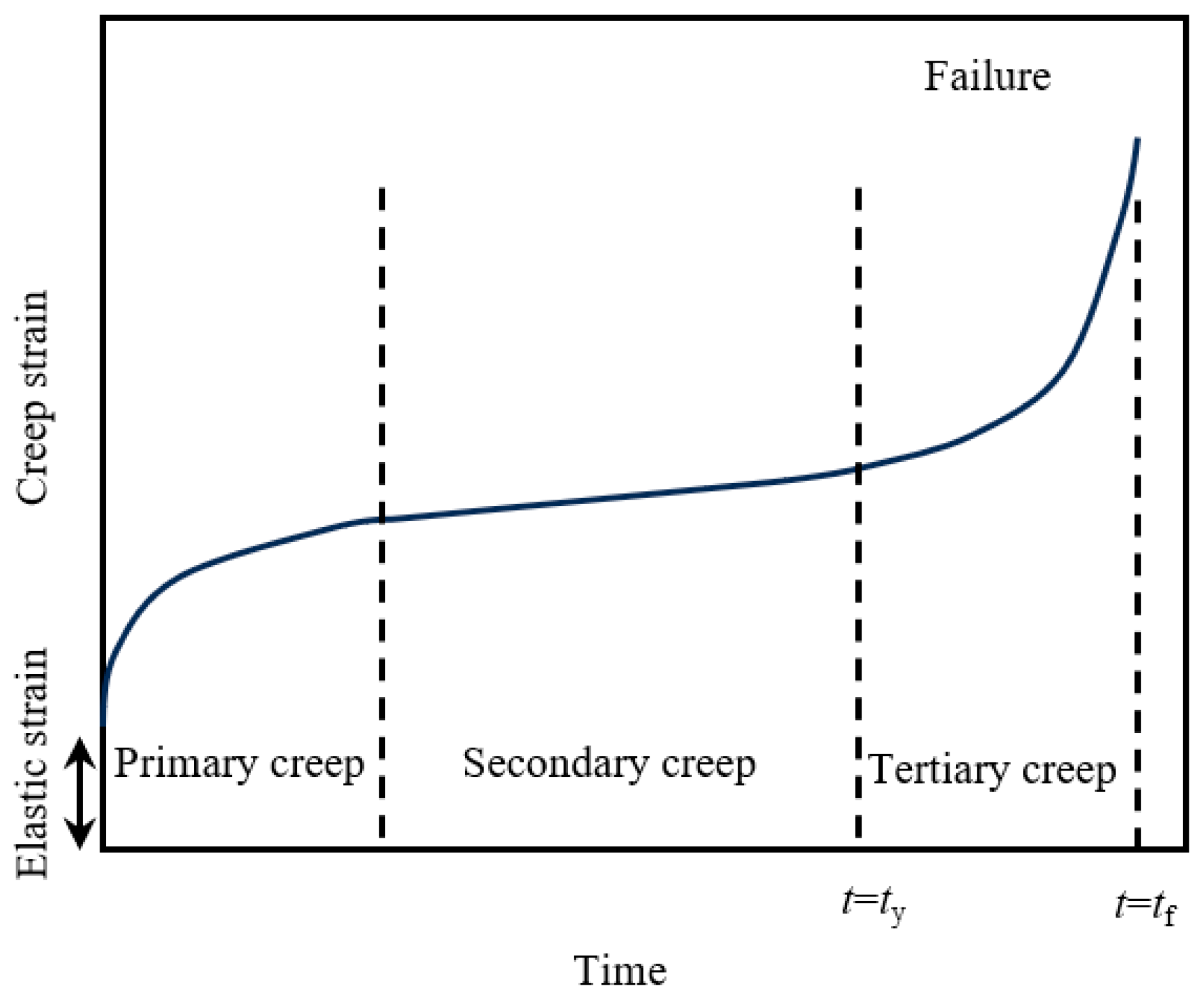

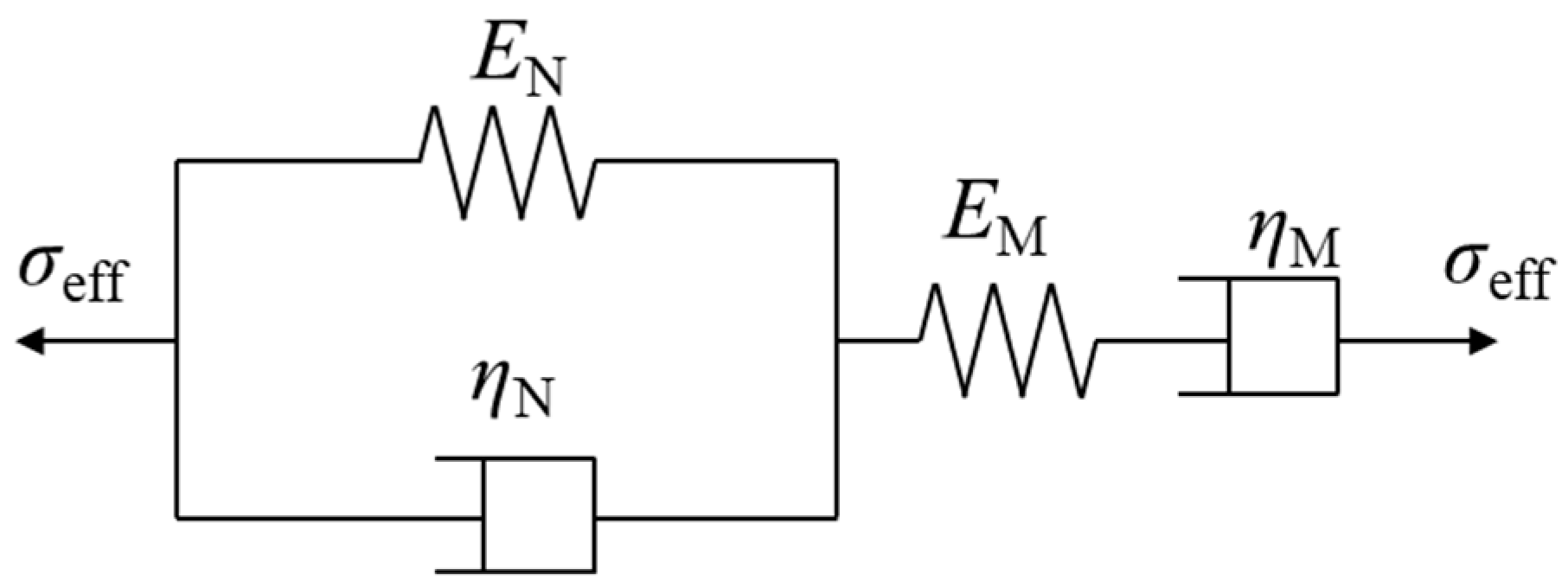

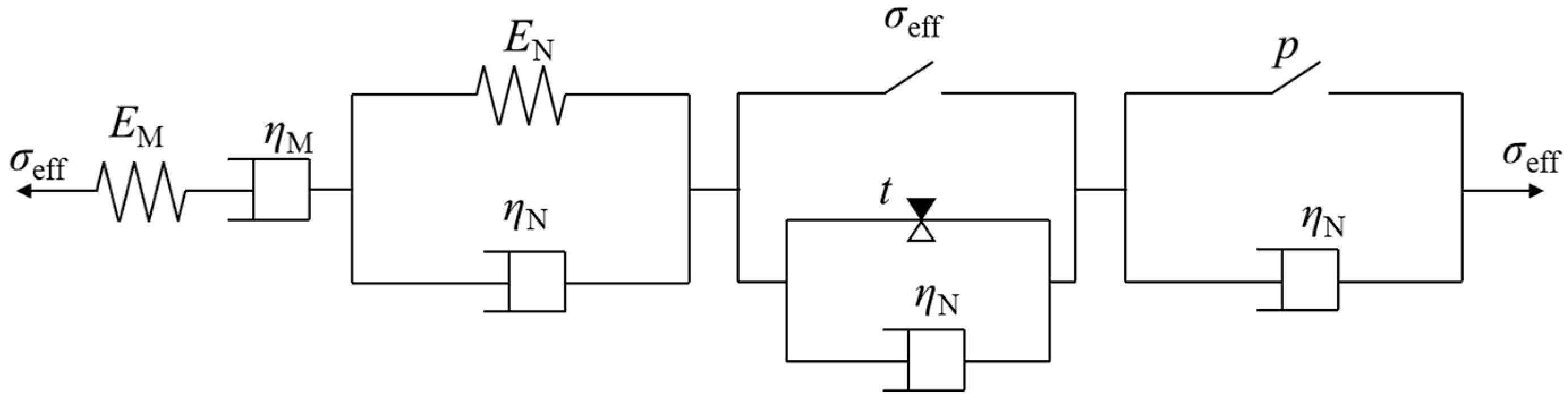

4.1. Creep Strain in Coal

4.2. The Effect of Gas Action on the Creep of Coal Bodies

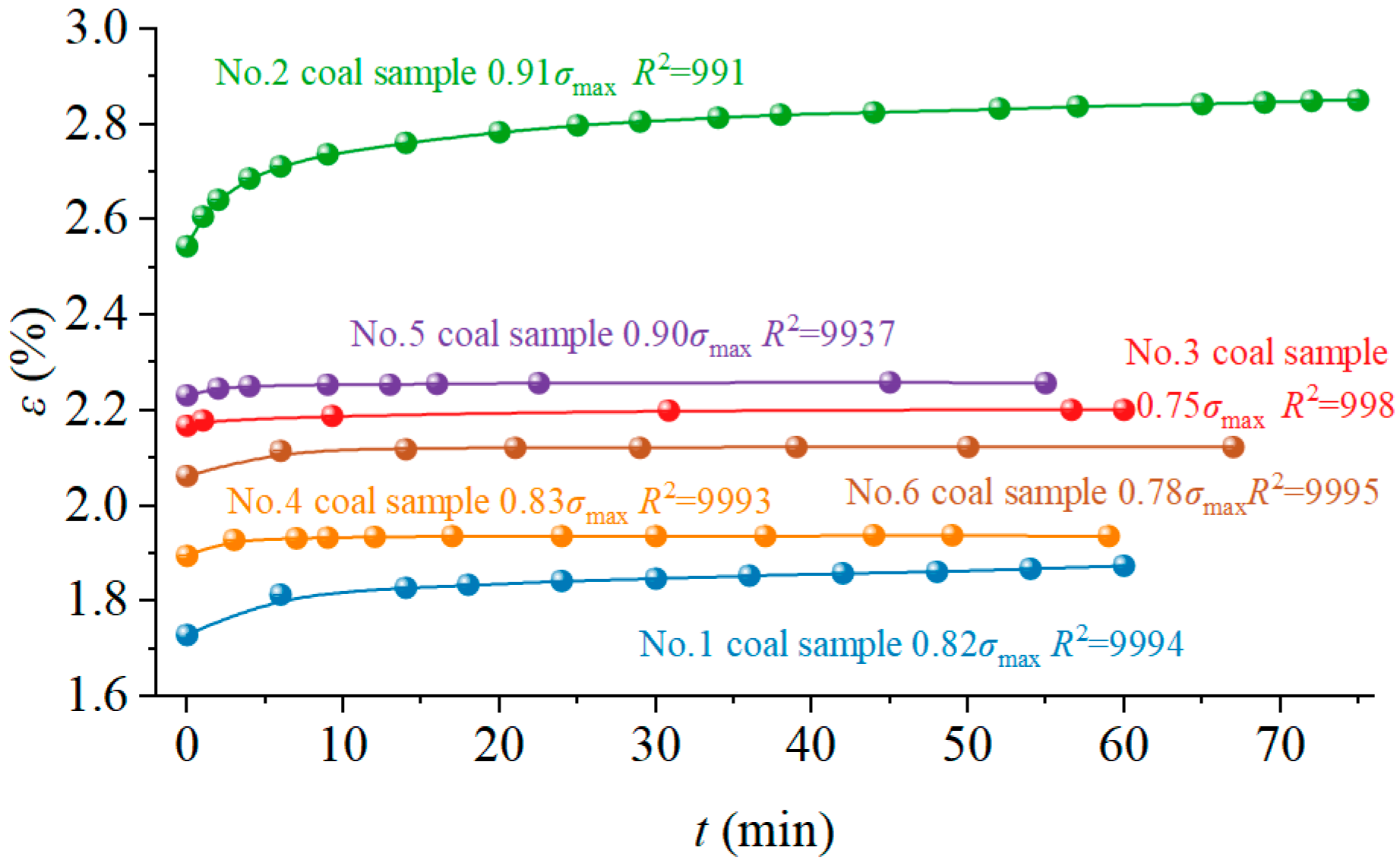

4.3. Validation of the Model

5. Conclusions

- (1)

- Coal body creep appears as a decelerating creep stage at low stress levels, begins to show decelerating and constant creep stages as stress levels increase, and shows distinctive features of decelerating, constant, and accelerating stages at the highest stress levels. The strain values for coal specimens without gas pressure (0 MPa) are lower than those for gas-filled coal of 0.5 MPa, and the gas causes unequal time to failure, and the gas accelerates the creep process.

- (2)

- The primary creep rate is 0.002–0.011%/min and, then, secondary creep gradually decreases to below 0.001%/min. The stable creep rate of gas-containing coals at each stress stage is small at the low stress stage and gradually becomes larger at the high stress stage. The relationship between the stable creep rate and partial stress is in accordance with the power function law.

- (3)

- On the basis of the Burgers model, the creep damage constitutive model of gas-containing coal considering the role of adsorption–expansion stress was established according to the principle of effective stress in porous media. The comparison results show that the experimental data after inversion using the above model parameters do not differ much from the original experimental data, and the R2 of the correlation coefficients are all greater than 0.991, which verifies the correctness of the constitutive model.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| import numpy as np |

| import pandas as pd |

| from scipy.optimize import curve_fit |

| # Experimental data |

| t_data = [ ] |

| strain_data = [ ] |

| # module |

| def staged_creep_model(t, E_M, E_K, eta_M, eta_K, eps_max, p_L, alpha, sigma_y0, k, epsilon_0): |

| sigma_applied = 50 # Current level stress |

| p = 0.5 # gas pressure |

| sigma_eff = sigma_applied - alpha * p |

| sigma_y = sigma_y0 * np.exp(-k * p) |

| # Maxwell strains |

| epsilon_M = sigma_eff / E_M + sigma_eff / eta_M * t |

| # Kelvin strains |

| tau_K = eta_K / E_K |

| epsilon_K = sigma_eff / E_K * (1 - np.exp(-t / tau_K)) |

| # Adsorption expansion strain |

| epsilon_s = eps_max * p / (p + p_L) * (1 - np.exp(-t/30)) |

| return epsilon_0 + epsilon_M + epsilon_K + epsilon_s |

| # Parameter boundaries and initial values |

| p0 = [ ] |

| bounds = ( ) |

| params, cov = curve_fit(staged_creep_model, t_data, strain_data, p0=p0, bounds=bounds) |

| # Generate fitted data table |

| df = pd.DataFrame({ |

| ’Time (min)’: t_data, |

| ’Experimental Strain (0.01)’: (strain_data / 0.01) + 2.063, # Restore to the original unit |

| ’Fitted Strain (0.01)’: (staged_creep_model(t_data, *params) / 0.01) + 2.063, |

| ’Residual (0.01)’: (staged_creep_model(t_data, *params) - strain_data) / 0.01 |

| }) |

| # Calculate R2 |

| ss_res = np.sum((strain_data - staged_creep_model(t_data, *params))**2) |

| ss_tot = np.sum((strain_data - np.mean(strain_data))**2) |

| r2 = 1 - (ss_res / ss_tot) |

References

- Asif, M.; Wang, L.; Naveen, P.; Longinos, S.N.; Hazlett, R.; Ojha, K.; Panigrahi, D. Influence of competitive adsorption, diffusion, and dispersion of CH4 and CO2 gases during the CO2-ecbm process. Fuel 2024, 358, 130065. [Google Scholar] [CrossRef]

- Zhou, A.; Wang, K.; Fan, L.; Kiryaeva, T.A. Gas-solid coupling laws for deep high-gas coal seams. Int. J. Min. Sci. Technol. 2017, 27, 675–679. [Google Scholar] [CrossRef]

- Liu, X.S.; Tan, Y.L.; Ning, J.G.; Lu, Y.W.; Gu, Q.H. Mechanical properties and damage constitutive model of coal in coal-rock combined body. Int. J. Rock. Mech. Min. Sci. 2018, 110, 140–150. [Google Scholar] [CrossRef]

- Liu, Z.B.; Xie, S.Y.; Shao, J.F.; Conil, N. Effects of deviatoric stress and structural anisotropy on compressive creep behavior of a clayey rock. Appl. Clay Sci. 2015, 114, 491–496. [Google Scholar] [CrossRef]

- Guo, J.; Zong, D.; Ma, L. Creep damage characteristics and constitutive model of pre-damage coal. Eng. Fail. Anal. 2024, 158, 108002. [Google Scholar] [CrossRef]

- Hamza, O.; Stace, R. Creep properties of intact and fractured muddy siltstone. Int. J. Rock. Mech. Min. Sci. 2018, 106, 109–116. [Google Scholar] [CrossRef]

- Yang, Y.; Huang, G.; Zhang, Y.; Yuan, L. An improved burgers creep model of coal based on fractional-order. Front. Earth Sci. 2023, 11, 1277147. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, W.; Lv, H. Creep energy damage model of rock graded loading. Results Phys. 2019, 12, 1119–1125. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, J.; Wang, J.; Li, F.; Zhou, Y. Research on nonlinear damage hardening creep model of soft surrounding rock under the stress of deep coal resources mining. Energy Rep. 2022, 8, 1493–1507. [Google Scholar] [CrossRef]

- Li, X.; Yin, Z. Study of creep mechanical properties and a rheological model of sandstone under disturbance loads. Processes 2021, 9, 1291. [Google Scholar] [CrossRef]

- Yin, J.; Cheng, Y.; Cheng, M.; Wang, C.; Huang, Y.; Shen, S. The effect of insufficient creep of tectonic coal under hydrostatic pressure on deformation energy measurements. Powder Technol. 2024, 447, 120183. [Google Scholar] [CrossRef]

- Li, X.; Liu, X.; Tan, Y.; Ma, Q.; Wu, B.; Wang, H. Creep constitutive model and numerical realization of coal-rock combination deteriorated by immersion. Minerals 2022, 12, 292. [Google Scholar] [CrossRef]

- Zhou, H.W.; Zhang, L.; Wang, X.Y.; Rong, T.L.; Wang, L.J. Effects of matrix-fracture interaction and creep deformation on permeability evolution of deep coal. Int. J. Rock. Mech. Min. Sci. 2020, 127, 104236. [Google Scholar] [CrossRef]

- Zhao, W.; Dong, H.; Wang, K.; Liu, S.; Yan, Z. Evolution from gas outburst to coal outburst: An analysis from the perspective of asynchronous transfer difference of gas mass and coal deformation. Int. J. Heat Mass Transf. 2023, 217, 124736. [Google Scholar] [CrossRef]

- Qiu, L.; Li, Z.; Wang, E.; Liu, Z.; Ou, J.; Li, X.; Ali, M.; Zhang, Y.; Xia, S. Characteristics and precursor information of electromagnetic signals of mining-induced coal and gas outburst. J. Loss Prev. Process Ind. 2018, 54, 206–215. [Google Scholar] [CrossRef]

- Li, X.; Yang, C.; Ren, T.; Nie, B.; Zhao, C.; Liu, S.; Jiang, T. Creep behaviour and constitutive model of coal filled with gas. Int. J. Min. Sci. Technol. 2017, 27, 847–851. [Google Scholar] [CrossRef]

- Danesh, N.N.; Chen, Z.; Connell, L.D.; Kizil, M.S.; Pan, Z.; Aminossadati, S.M. Characterisation of creep in coal and its impact on permeability: An experimental study. Int. J. Coal Geol. 2017, 173, 200–211. [Google Scholar] [CrossRef]

- Song, D.; Liu, Q.; Qiu, L.; Zhang, J.; Khan, M.; Peng, Y.; Zhao, Y.; Wang, M.; Guo, M.; Hong, T. Experimental study on resistivity evolution law and precursory signals in the damage process of gas-bearing coal. Fuel 2024, 362, 130798. [Google Scholar] [CrossRef]

- Liu, J.; Chen, L.; Wang, C.; Man, K.; Wang, L.; Wang, J.; Su, R. Characterizing the mechanical tensile behavior of Beishan granite with different experimental methods. Int. J. Rock Mech. Min. Sci. 2014, 69, 50–58. [Google Scholar] [CrossRef]

- Yin, G.; Wang, D.; Zhang, D.; Wei, Z. Research on triaxial creep properties and creep model of coal containing gas. Chin. J. Rock Mech. Eng. 2008, 27, 2631–2636. [Google Scholar]

- Xue, E.; Zhang, X.; He, X.; Zhao, F.; Liu, X.; Guo, J.; Li, H. Coupling study between rheology and electromagnetic emission of coal or rock dynamic catastrophe. Procedia Eng. 2011, 26, 1571–1575. [Google Scholar] [CrossRef]

- Zhang, L. Theoretical and Experimental Research on the Evolution of Creep-Seepage for Coal Containing Gas. Doctoral Thesis, China University of Mining and Technology-Beijing, Beijing, China, 2021. [Google Scholar]

- Qiu, L.; Dang, J.; Zhang, J.; Wang, M.; Liu, Q.; Si, L.; Jiang, Z.; Khan, M. Investigating nonlinear resistivity characteristics and mechanisms of coal during various loading stages. J. Appl. Geophys. 2025, 238, 105705. [Google Scholar] [CrossRef]

- Zhou, A.; Hu, J.; Gong, W.; Wang, K.; Deng, N.; Wu, J. The instability criticality and safety factor of coal-gas outburst induced by shear failure based on limit analysis. Fuel 2021, 303, 121245. [Google Scholar] [CrossRef]

- Du, F.; Wang, K.; Zhang, X.; Xin, C.; Shu, L.; Wang, G. Experimental study of coal–gas outburst: Insights from coal–rock structure, gas pressure and adsorptivity. Nat. Resour. Res. 2020, 29, 2481–2493. [Google Scholar] [CrossRef]

- Du, F.; Wang, K. Unstable failure of gas-bearing coal-rock combination bodies: Insights from physical experiments and numerical simulations. Process Saf. Environ. Prot. 2019, 129, 264–279. [Google Scholar] [CrossRef]

| Number | Confining Pressure σ3 (MPa) | Gas Pressure pg (MPa) | Number | Confining Pressure σ3 (MPa) | Gas Pressure pg (MPa) |

|---|---|---|---|---|---|

| No. 1 | 6 | 0 | No. 2 | 6 | 0.5 |

| No. 3 | 8 | 0 | No. 4 | 8 | 0.5 |

| No. 5 | 10 | 0 | No. 6 | 10 | 0.5 |

| Parameter | EM/MPa | EK/MPa | ηM | ηK | εmax | pL | α | σy0 | k | ε0 |

|---|---|---|---|---|---|---|---|---|---|---|

| No. 1 | 2987.35 | 6.98 × 104 | 1.97 × 106 | 1984 | 0.00395 | 0.079 | 1.19 | 49.8 | 0.049 | 0.00183 |

| No. 2 | 2850.12 | 7.23 × 104 | 1.85 × 106 | 2107 | 0.00428 | 0.067 | 1.32 | 48.6 | 0.053 | 0.00175 |

| No. 3 | 4125.37 | 4.86 × 104 | 3.15 × 106 | 1472 | 0.00297 | 0.048 | 1.53 | 55.2 | 0.038 | 0.00185 |

| No. 4 | 3278.54 | 6.23 × 104 | 1.78 × 106 | 1865 | 0.00431 | 0.076 | 1.15 | 52.4 | 0.047 | 0.0019 |

| No. 5 | 3562.84 | 5.78 × 104 | 2.41 × 106 | 1823 | 0.00265 | 0.061 | 1.38 | 52.4 | 0.044 | 0.00178 |

| No. 6 | 3256.71 | 6.24 × 104 | 2.78 × 106 | 2015 | 0.00352 | 0.059 | 1.27 | 51.9 | 0.047 | 0.00181 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, X.; He, X.; Qiu, L.; Liu, Q.; Qie, L.; Sun, Q. Creep Deformation Mechanisms of Gas-Bearing Coal in Deep Mining Environments: Experimental Characterization and Constitutive Modeling. Processes 2025, 13, 2466. https://doi.org/10.3390/pr13082466

Sun X, He X, Qiu L, Liu Q, Qie L, Sun Q. Creep Deformation Mechanisms of Gas-Bearing Coal in Deep Mining Environments: Experimental Characterization and Constitutive Modeling. Processes. 2025; 13(8):2466. https://doi.org/10.3390/pr13082466

Chicago/Turabian StyleSun, Xiaolei, Xueqiu He, Liming Qiu, Qiang Liu, Limin Qie, and Qian Sun. 2025. "Creep Deformation Mechanisms of Gas-Bearing Coal in Deep Mining Environments: Experimental Characterization and Constitutive Modeling" Processes 13, no. 8: 2466. https://doi.org/10.3390/pr13082466

APA StyleSun, X., He, X., Qiu, L., Liu, Q., Qie, L., & Sun, Q. (2025). Creep Deformation Mechanisms of Gas-Bearing Coal in Deep Mining Environments: Experimental Characterization and Constitutive Modeling. Processes, 13(8), 2466. https://doi.org/10.3390/pr13082466