Numerical Simulation Analysis of Cu2+ Concentration for Marine Biological Control Based on Seawater Lifting Pump

Abstract

1. Introduction

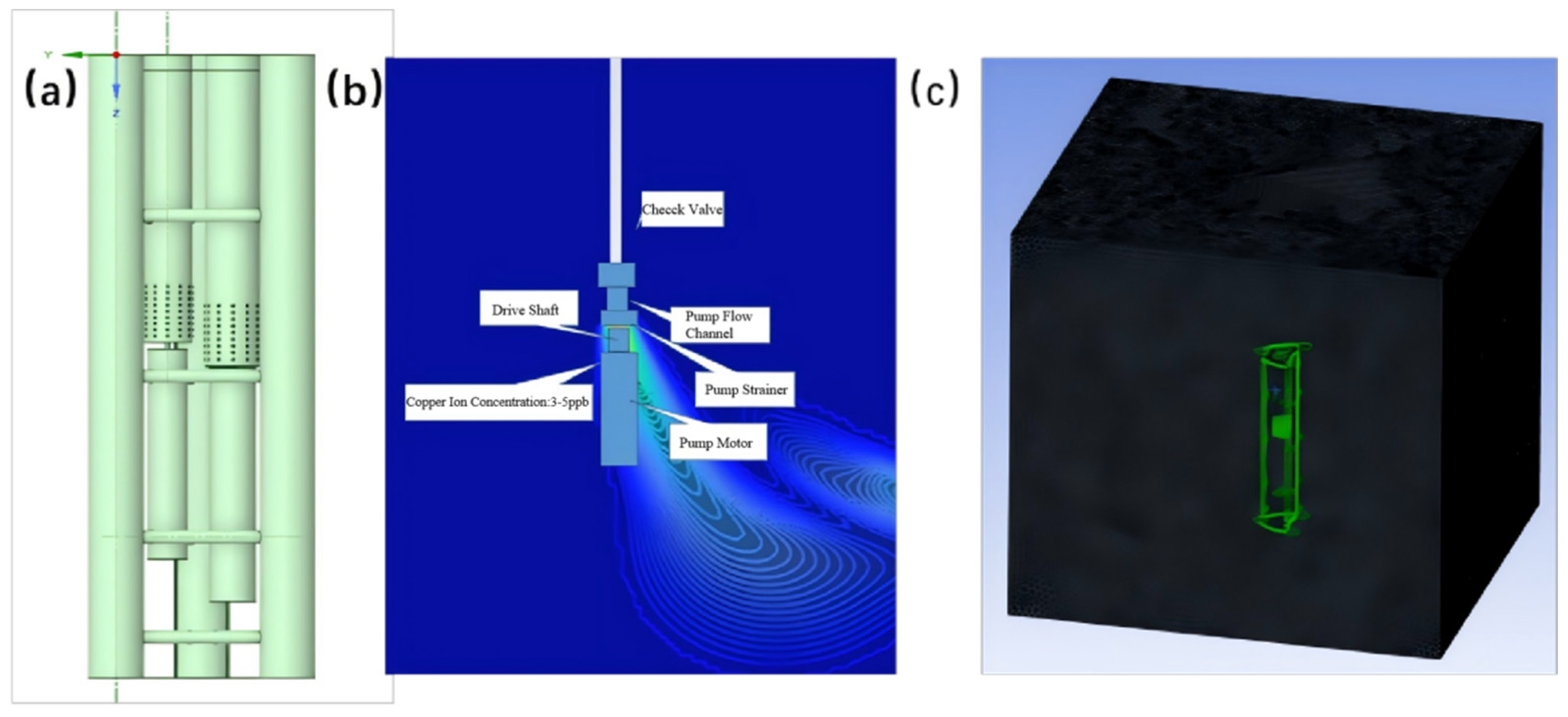

2. Mathematical Calculation Model

- (1)

- Continuity equation

- (2)

- Momentum equation

- (3)

- Energy equation

- (4)

- Bernoulli equation

3. Physical Model

4. Results and Discussion

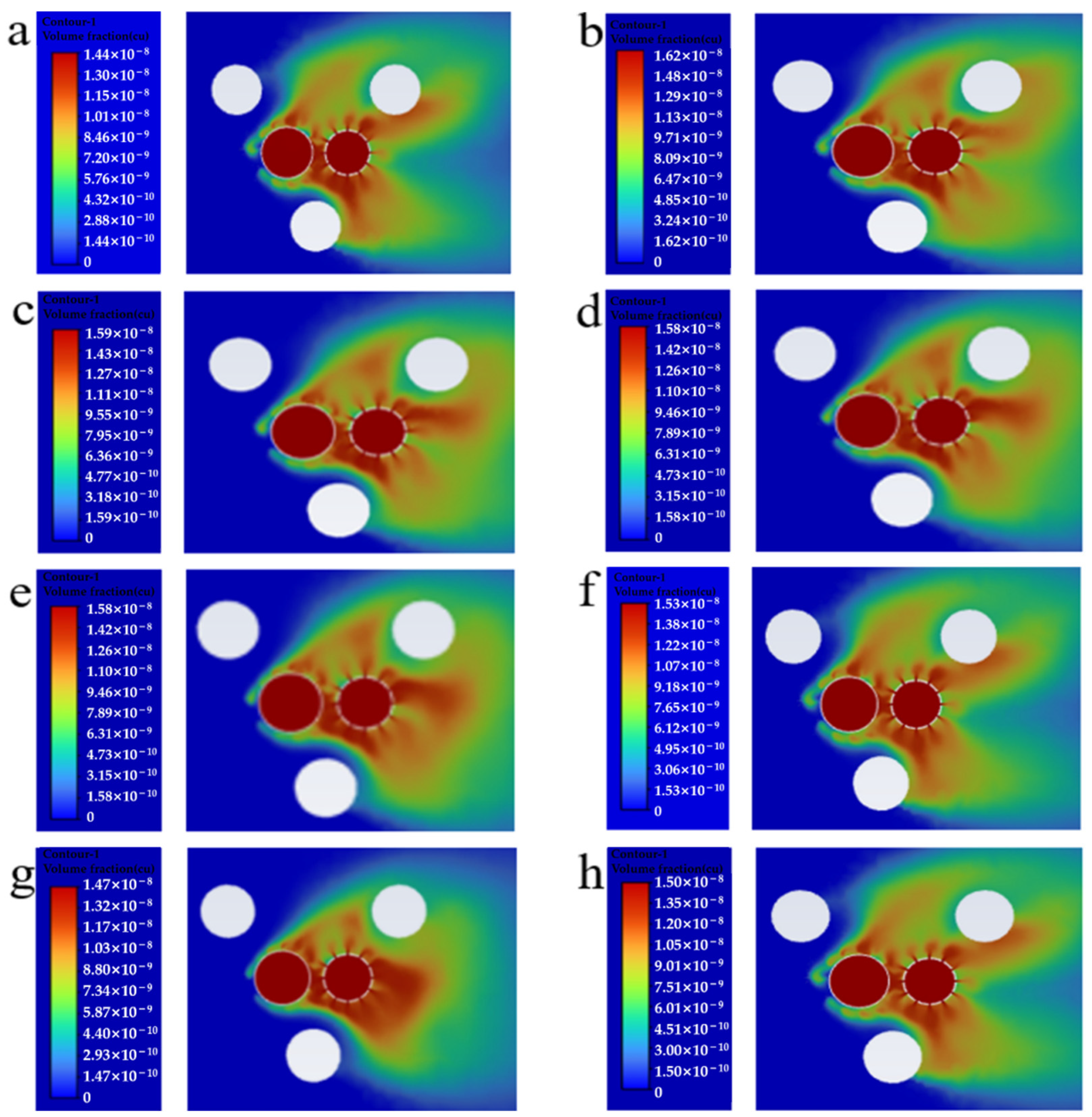

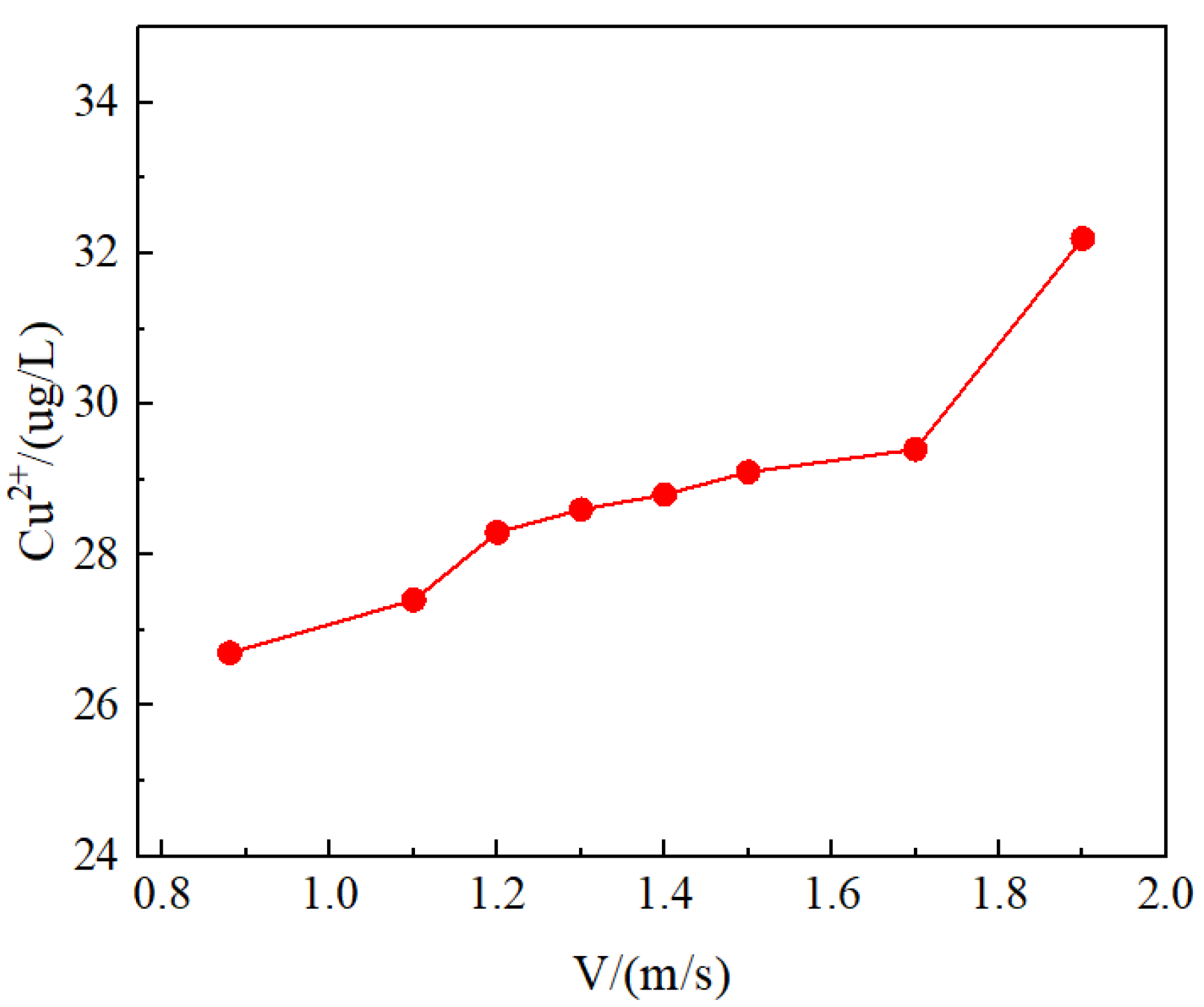

4.1. Influence of Seawater Flow Rate on Concentration of Injected Cu2+

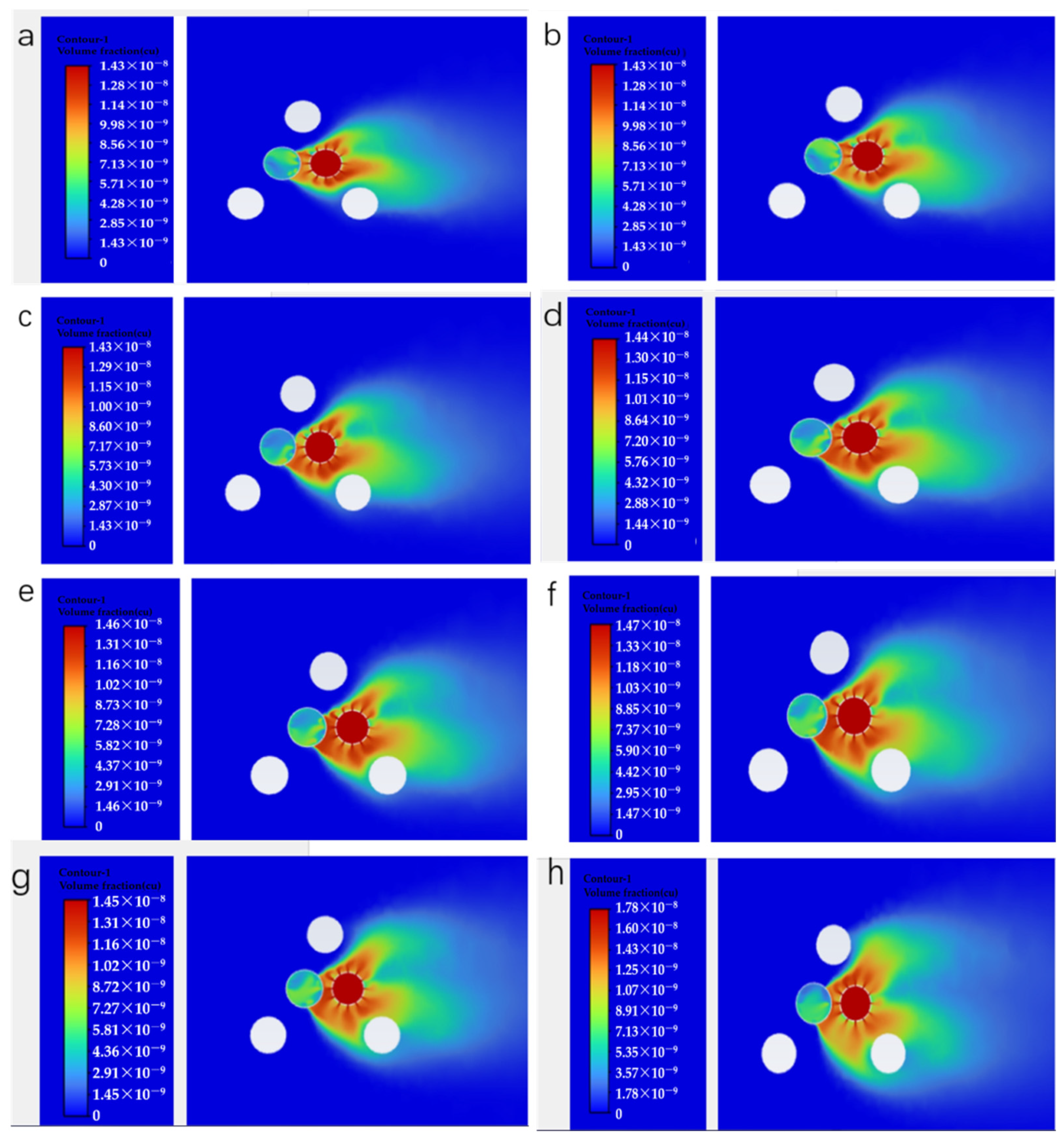

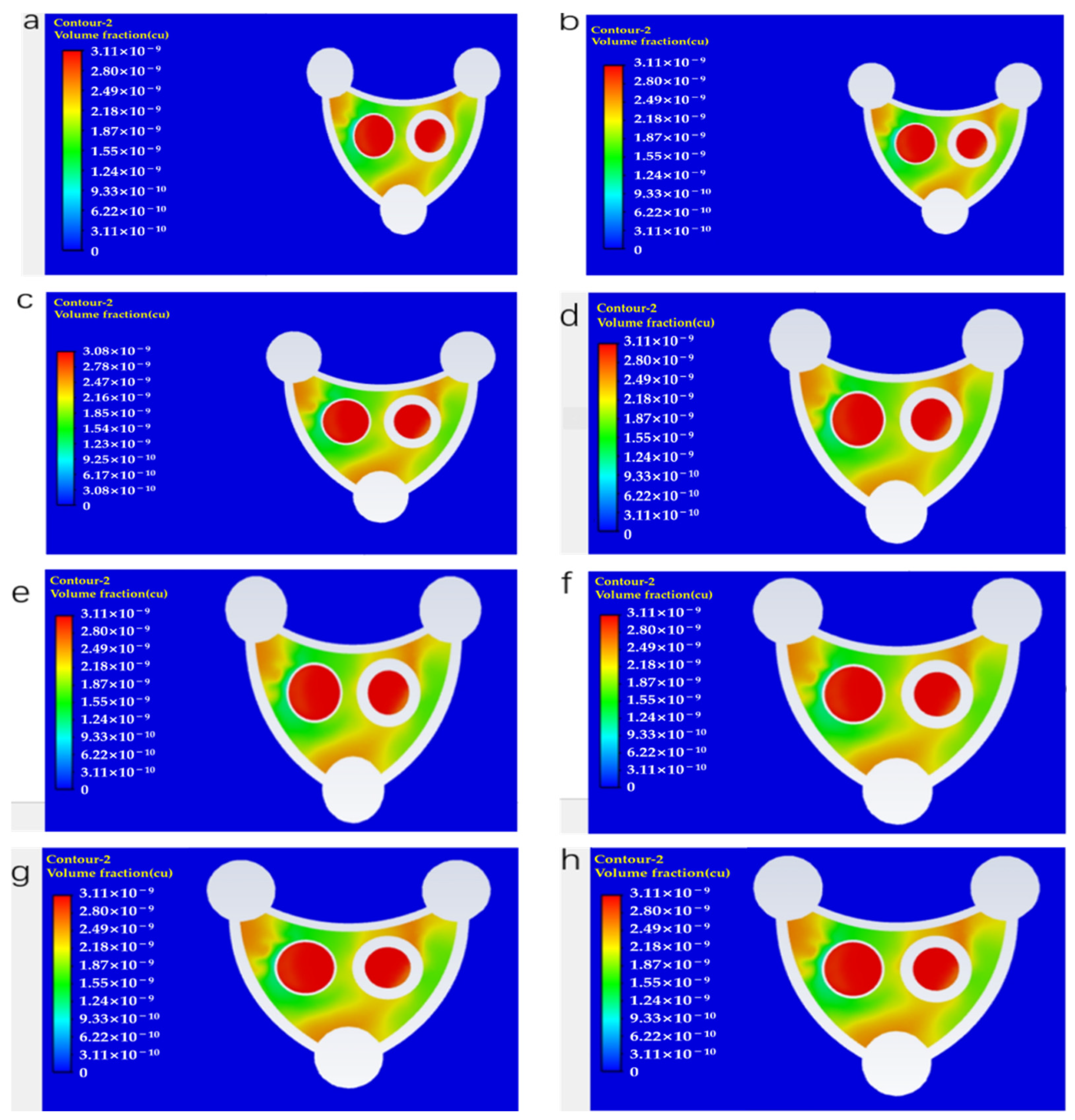

4.2. Effect of Large Pump Operation on Injecting Cu2+ Concentration

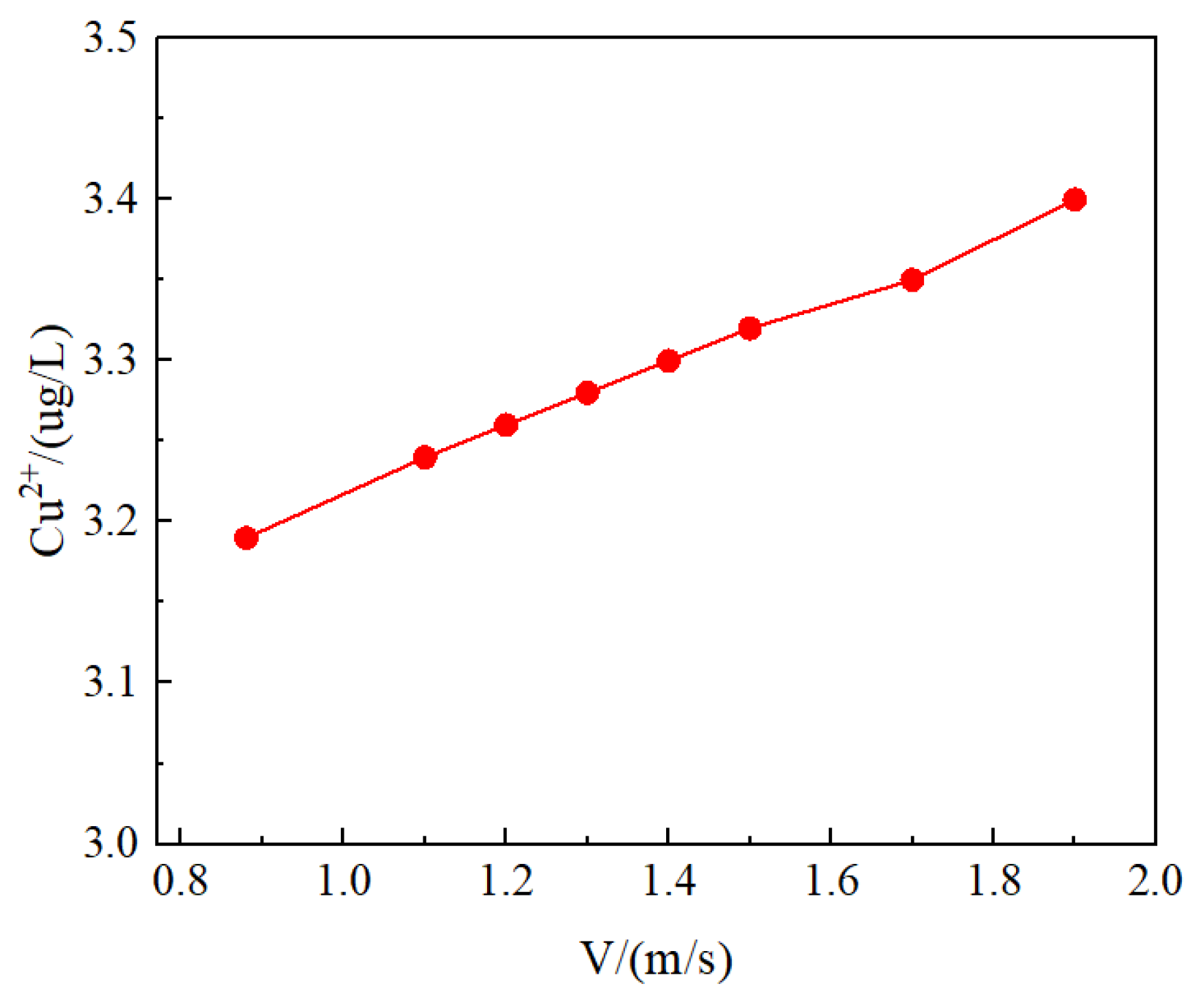

4.3. Effect of Small Pump Operation on Injecting Cu2+ Concentration

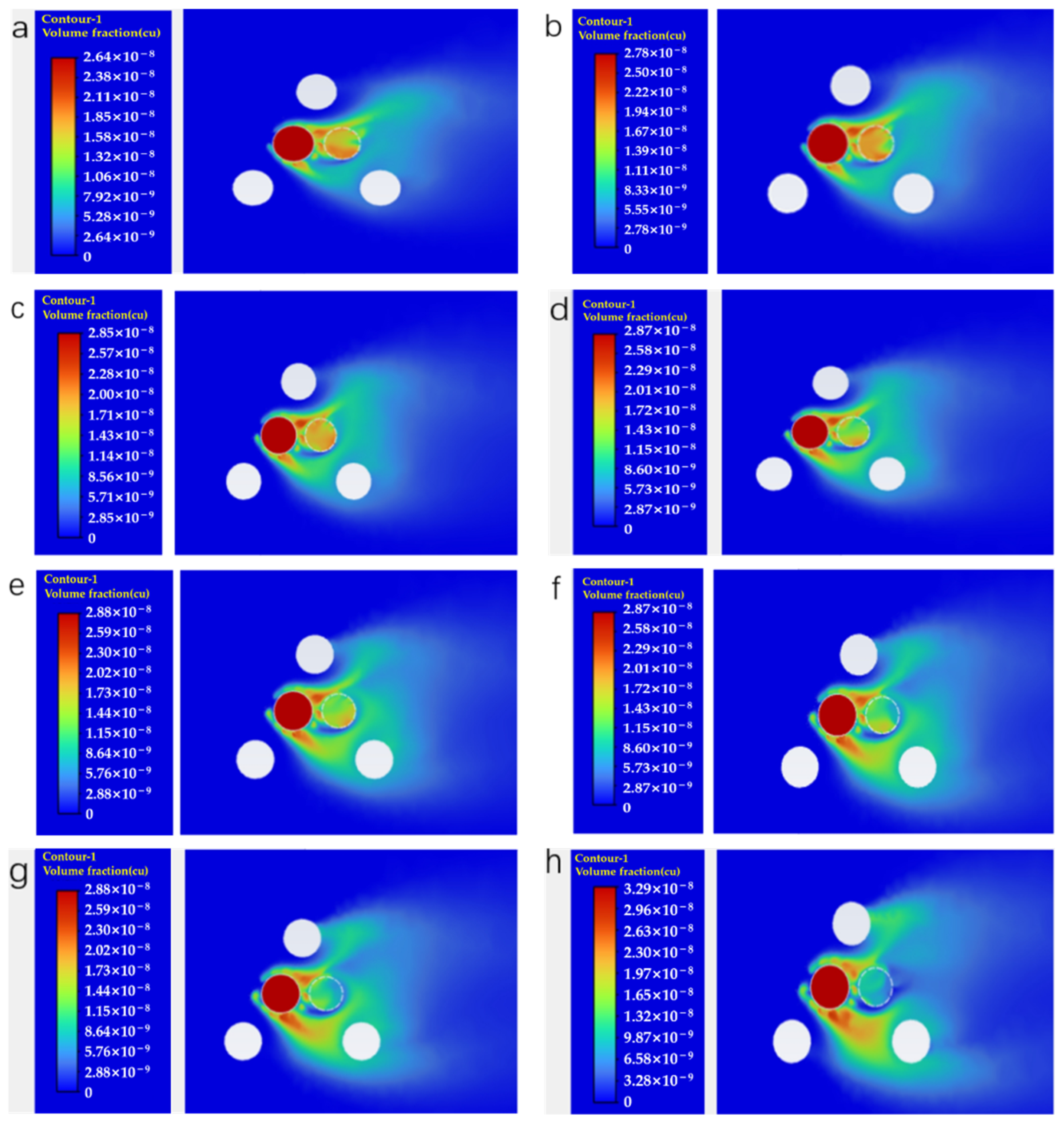

4.4. Effect of Installing Baffles on Injecting Cu2+ Concentration

4.5. Comparative Analysis with On-Site Data

5. Conclusions

- (1)

- Based on CFD, it is possible to accurately simulate the concentration of Cu2+ injected into electrolytic seawater. To ensure that the Cu2+ concentration within a 10 cm range around the lifting pump can reach 3 ppb, it is necessary to analyse the upstream range data due to the influence of the seawater flow direction.

- (2)

- Upon cessation of the lift pump, the Cu2+ concentration in the 10 cm area surrounding the pump is observed to reach the requisite level of 3 ppb. As the seawater flow rate increases, the required Cu2+ concentration for injection gradually increases. The maximum permissible seawater flow rate is 1.9 m/s, and the requisite Cu2+ concentration for injection is 41.9 ug/L.

- (3)

- In circumstances where the lifting pump is operated in an alternating manner, the concentration of Cu2+ within a 10 cm radius of the pump is elevated to the requisite level of 3 ppb. As the seawater flow rate increases, the required Cu2+ concentration for injection gradually increases. The seawater’s upward flow, driven by the pump’s position, results in a lower required Cu2+ concentration for injection when compared to the downstream pumps.

- (4)

- The installation of baffles in the vicinity of the lifting pump was demonstrated to be an effective measure for mitigating the impact of seawater flow on the concentration of Cu2+ injected into electrolytic seawater. This approach was shown to result in a substantial reduction in the required Cu2+ concentration.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Li, Y.; Lu, H.; Pan, Z.; Dai, P.; Sun, G.; Yang, Q. A Full-Scale Process for Produced Water Treatment on Offshore Oilfield: Reduction of Organic Pollutants Dominated by Hydrocarbons. J. Clean. Prod. 2021, 296, 126511. [Google Scholar] [CrossRef]

- Onishi, S.; Itagaki, Y.; Nakatani, N.; Ohara, K.; Katayama, H.; Yamazaki, T. An Experimental Study of Pulp-Lift Characteristics Using a High-Viscous Fluid Simulating Deep Muddy Seawater. J. Mar. Sci. Eng. 2024, 12, 1448. [Google Scholar] [CrossRef]

- Zuo, J.; Li, F.; Zhang, N.; He, D.; Wang, W.; Zhang, J. Experimental Study on Hydraulic Characteristics of Pneumatic Lifting Pump. Water 2020, 12, 388. [Google Scholar] [CrossRef]

- Zhang, Z.; Tan, M.; Wu, X.; Liu, H.; Shao, C.; Qu, B. The Effect of Particle Size on the Reflux Performance of the Lifting Pumps. Comput. Part. Mech. 2024, 11, 1837–1847. [Google Scholar] [CrossRef]

- Li, B.; Guo, Z.; Zheng, L.; Du, M.; Han, J.; Yang, C. Effect of modified eva-gmx bionic nanocomposite pour point depressants on the rheological properties of waxy crude oil. Fuel 2026, 403, 136025. [Google Scholar] [CrossRef]

- Zhou, X.; Zheng, B. Surface Modification for Improving Immunoassay Sensitivity. Lab Chip 2023, 23, 1151–1168. [Google Scholar] [CrossRef] [PubMed]

- Tian, S.; Li, Y.; Zhang, H.; Lu, G.; Li, R.; Yu, J.; Zhao, C.; Yang, J.; Zhang, L. Amphiphilic Marine Antifouling Coatings Based on Zwitterion-Modified Silicone Polymers. Langmuir 2025, 41, 1037–1046. [Google Scholar] [CrossRef] [PubMed]

- Salta, M.; Goodes, L.R.; Maas, B.J.; Dennington, S.P.; Secker, T.J.; Leighton, T.G. Bubbles versus Biofilms: A Novel Method for the Removal of Marine Biofilms Attached on Antifouling Coatings Using an Ultrasonically Activated Water Stream. Surf. Topogr. Metrol. Prop. 2016, 4, 034009. [Google Scholar] [CrossRef]

- Schultz, M.P.; Walker, J.M.; Steppe, C.N.; Flack, K.A. Impact of Diatomaceous Biofilms on the Frictional Drag of Fouling-Release Coatings. Biofouling 2015, 31, 759–773. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Duan, Y.; Cui, M.; Huang, R.; Su, R.; Qi, W.; He, Z. Biomimetic Surface Coatings for Marine Antifouling: Natural Antifoulants, Synthetic Polymers and Surface Microtopography. Sci. Total Environ. 2021, 766, 144469. [Google Scholar] [CrossRef] [PubMed]

- Şimşek, Ü.; Çoğun, C.; Esen, Z. Effects of Electrolytic Copper and Copper Alloy Electrodes on Machining Performance in Electrical Discharge Machining (EDM). Mach. Sci. Technol. 2022, 26, 229–244. [Google Scholar] [CrossRef]

- Chen, X.; Li, T.; Li, B.; Wang, M.; Guo, L.; Tian, P.; Meng, L.; Yang, M. Supramolecular Hydrogels Based on Boroxine and Application in Self-Healing Superhydrophobic Coating. Prog. Org. Coat. 2025, 204, 109248. [Google Scholar] [CrossRef]

- Yarmolenko, M.; Mogilei, S. Iron, Copper, and Aluminium Electrochemical Corrosion in Motionless and Moving Electrolytes Investigation during Electrolysis. Results Mater. 2023, 20, 100479. [Google Scholar] [CrossRef]

- Aoki, S.; Shimabukuro, M.; Kishida, R.; Kyuno, K.; Noda, K.; Yokoi, T.; Kawashita, M. Electrochemical Deposition of Copper on Bioactive Porous Titanium Dioxide Layer: Antibacterial and Pro-Osteogenic Activities. ACS Appl. Bio Mater. 2023, 6, 5759–5767. [Google Scholar] [CrossRef] [PubMed]

- Szewczuk-Karpisz, K.; Kukowska, S.; Grygorczuk-Płaneta, K.; Kondracki, B.; Jerin, K.; Kovačević, D. Scavenging of Copper(II) Ions, Phosphate(V) Ions, and Diuron from Aqueous Media by Goethite Modified with Chitosan or Poly(Acrylic Acid). Environ. Sci. Pollut. Res. 2023, 30, 79980–80000. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Shakibi, A.; Grandhi, M.; Liu, Z.; Ning, F. Wire-Influenced Particle Dynamics and Fluid Flow Behaviors of Melt Pool in Coaxial Wire-Powder Fed Directed Energy Deposition of Metal Matrix Composites. J. Mater. Res. Technol. 2025, 36, 2909–2924. [Google Scholar] [CrossRef]

- Chen, H.; Li, W.; Cui, W.; Yang, P.; Chen, L. Multi-objective multidisciplinary design optimization of a robotic fish system. J. Mar. Sci. Eng. 2021, 9, 478. [Google Scholar] [CrossRef]

| Maximum Grid Size (mm) | Minimum Local Grid Size (mm) | Total Number of Units | Cu2+ Concentration (mg/L) | Relative Error/ % |

|---|---|---|---|---|

| 120 | 120 | 50,000 | 28.3 | 23.7 |

| 60 | 20 | 300,000 | 25.1 | 11.2 |

| 30 | 8 | 1,200,000 | 23.4 | 5.8 |

| 15 | 2 | 4,500,000 | 22.5 | - |

| Operating Conditions | CFD Simulation Data/(ug·L−1) | Actual Production Data/(ug·L−1) | Relative Error/% |

|---|---|---|---|

| When Two Pumps are Shut Down with Baffles Around the Pumps | 41.9 | 45 | 6.9 |

| When Two Pumps are Shut Down without Baffles Around the Pumps | 3.6 | 3.4 | 5.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Liu, J.; Li, L.; Yang, Q.; Meng, L.; Li, Z. Numerical Simulation Analysis of Cu2+ Concentration for Marine Biological Control Based on Seawater Lifting Pump. Processes 2025, 13, 2440. https://doi.org/10.3390/pr13082440

Zhang Z, Liu J, Li L, Yang Q, Meng L, Li Z. Numerical Simulation Analysis of Cu2+ Concentration for Marine Biological Control Based on Seawater Lifting Pump. Processes. 2025; 13(8):2440. https://doi.org/10.3390/pr13082440

Chicago/Turabian StyleZhang, Zhishu, Jie Liu, Lei Li, Qingmiao Yang, Longqi Meng, and Zhaoxuan Li. 2025. "Numerical Simulation Analysis of Cu2+ Concentration for Marine Biological Control Based on Seawater Lifting Pump" Processes 13, no. 8: 2440. https://doi.org/10.3390/pr13082440

APA StyleZhang, Z., Liu, J., Li, L., Yang, Q., Meng, L., & Li, Z. (2025). Numerical Simulation Analysis of Cu2+ Concentration for Marine Biological Control Based on Seawater Lifting Pump. Processes, 13(8), 2440. https://doi.org/10.3390/pr13082440