Current State of Development of Demand-Driven Biogas Plants in Poland

Abstract

1. Introduction

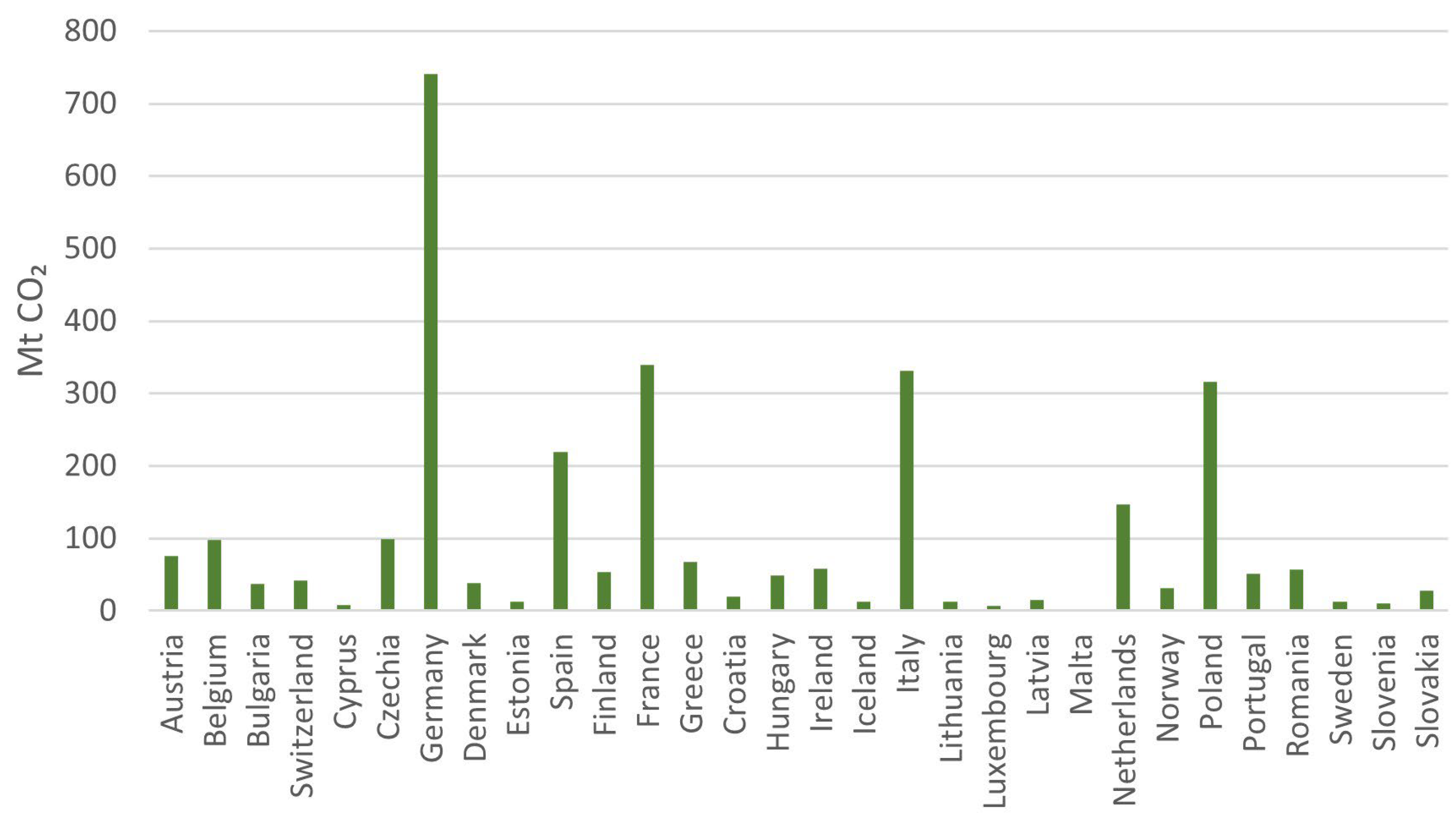

2. Current Situation in the Polish Energy Sector

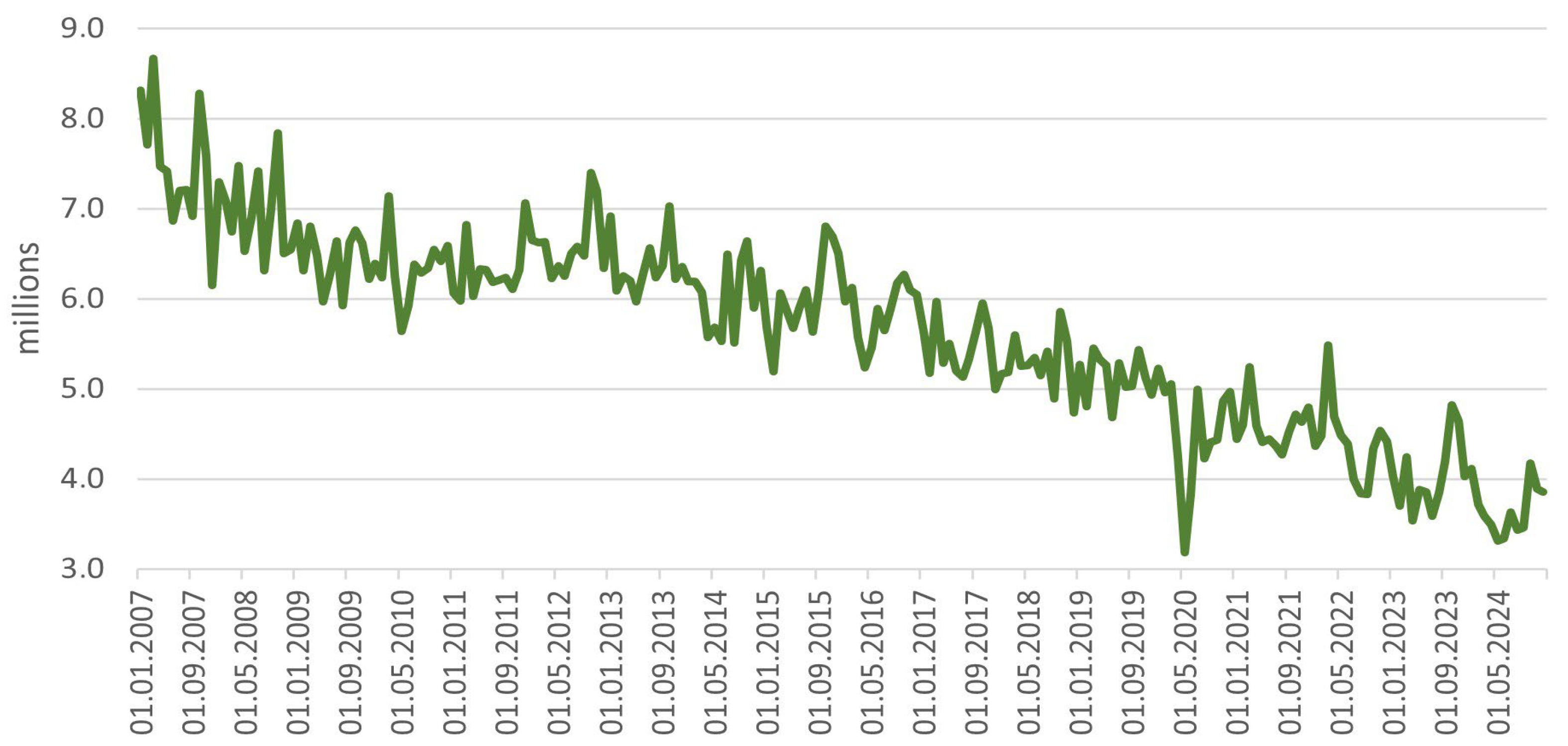

2.1. Historical Background and Coal Dependency

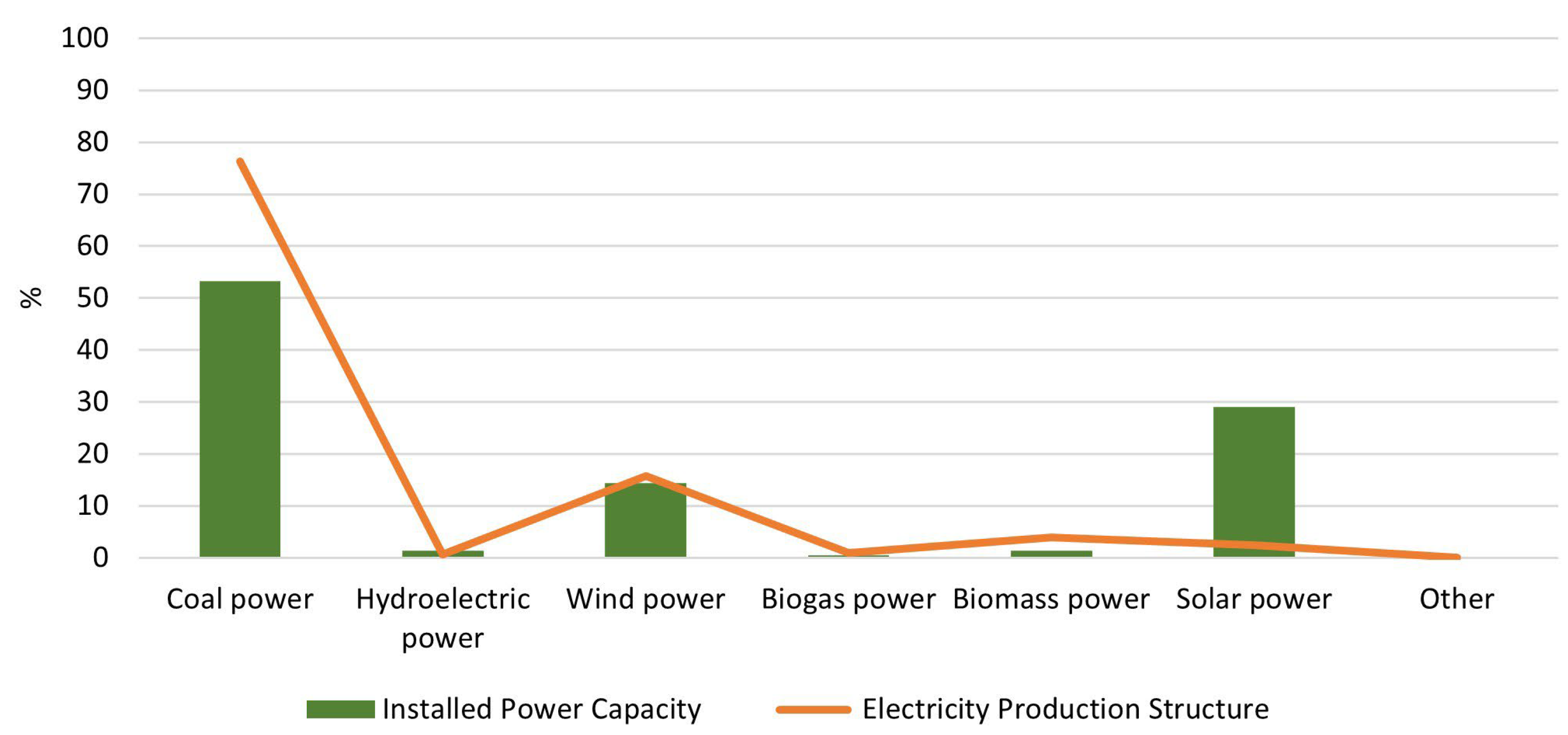

2.2. Current Energy Mix

2.3. Flexibility Gaps in the Polish Power Sector

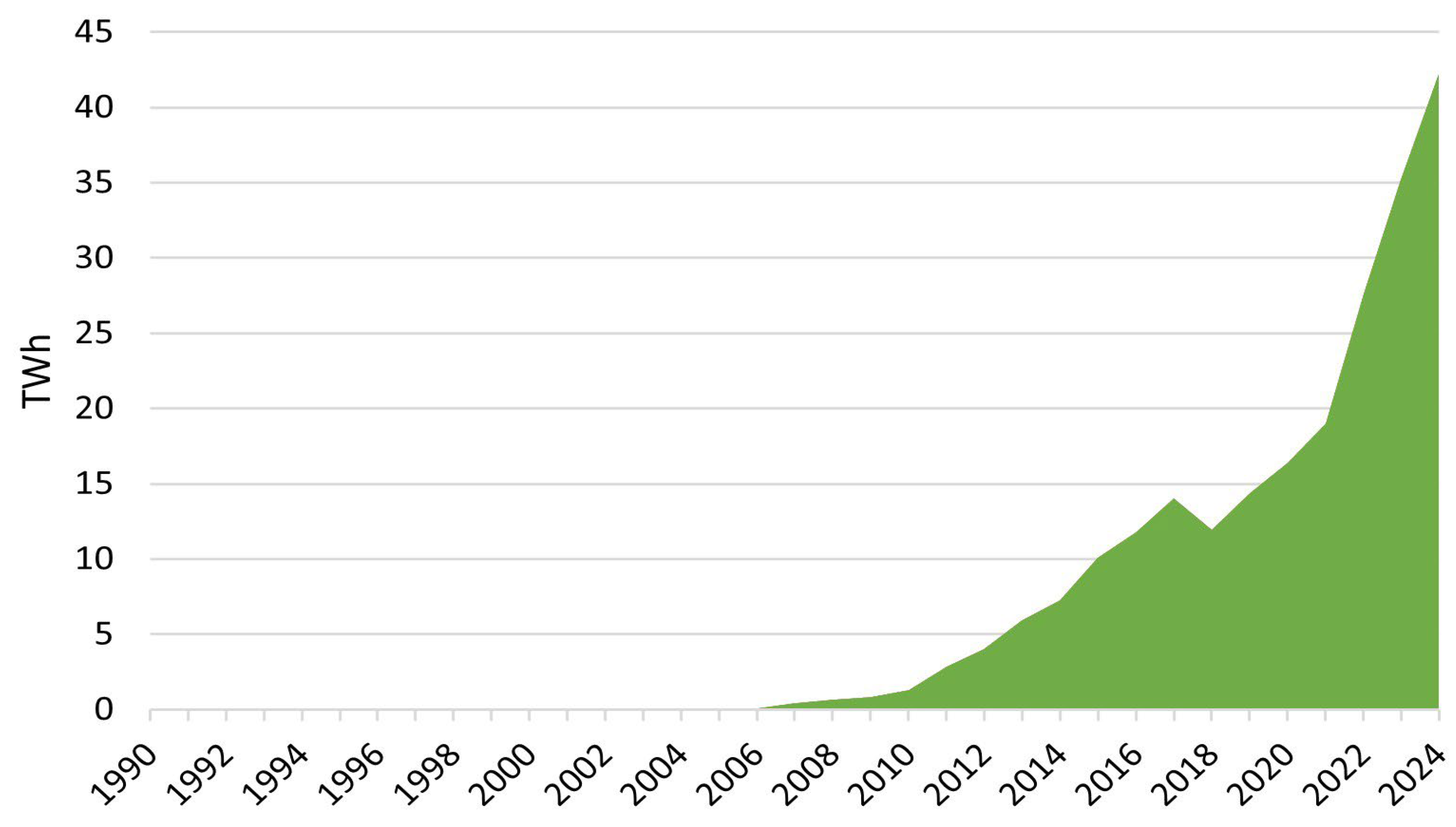

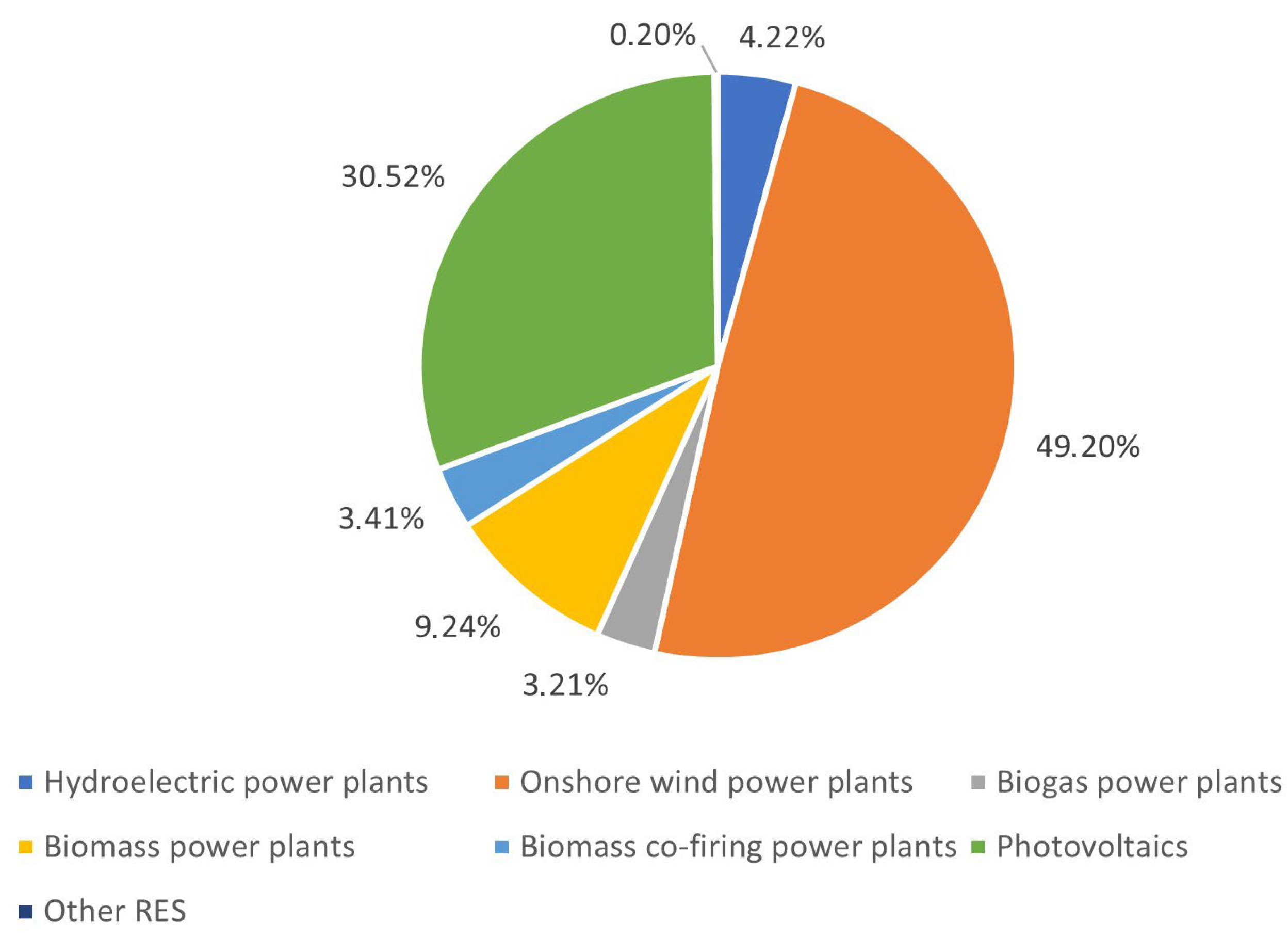

3. Development of Renewable Energy in Poland

4. Biogas as the Key Component of a Stable Renewable Energy System

4.1. Biogas Plants as Part of a Circular Economy

- Energy recovery in the form of biogas, alongside reduced methane emissions into the atmosphere;

- Soil enrichment through the use of stable organic fractions (digestate, compost);

- Reduced environmental pressure by cutting down on landfilled waste volumes;

- Promotion of the local economy, wherein waste becomes a valuable resource in subsequent stages of the production chain [42].

4.2. Technical and Technological Challenges

- Maintaining the technical condition of installations by sealing fermenter tanks and gas storage covers, as well as controlling system pressure.

- Conducting leak surveys that enable swift detection and mitigation of localized CH4 emissions.

- Optimizing storage conditions and duration for digestate (e.g., storing it in sealed containers) to further reduce methane and nitrous oxide (N2O) formation during storage [38].

- Lowering methane emissions from the conventional storage of slurry by several tens of percent annually [43].

- Reducing N2O emissions—this gas primarily originates from storing and applying manure and digestate, but with proper digestate management, emissions can be significantly curtailed [46].

- Replacing fossil fuels: biogas can be used to generate energy for on-farm needs; any surplus can be sold or supplied as heat in local grids [45].

- Recycling nutrients: the digestate serves as an organic fertilizer, supplying readily available nitrogen and phosphorus to soil, reducing the demand for mineral fertilizers and thus lowering the carbon footprint of agricultural production [39].

4.3. Benefits from Biogas Production

5. The Potential of Demand-Driven Biogas Plants

5.1. Advantages of Flexible Electricity Production

- (1)

- Flexible Power Output Control

- (2)

- Reducing the Need to Curtail Other Renewables

- (3)

- Minimizing System Losses

- Can ramp up power generation within just a few hours, as demonstrated by full-scale industrial experiences in Germany [58].

- Improve resource efficiency by minimizing the need to expand conventional backup capacity.

- Enhance the balancing of electricity markets by allowing biogas facilities to secure higher revenues for production during peak-price periods.

5.2. Determining the Capacity of the Biogas Plant

6. The Operation of Demand-Driven Biogas Plants

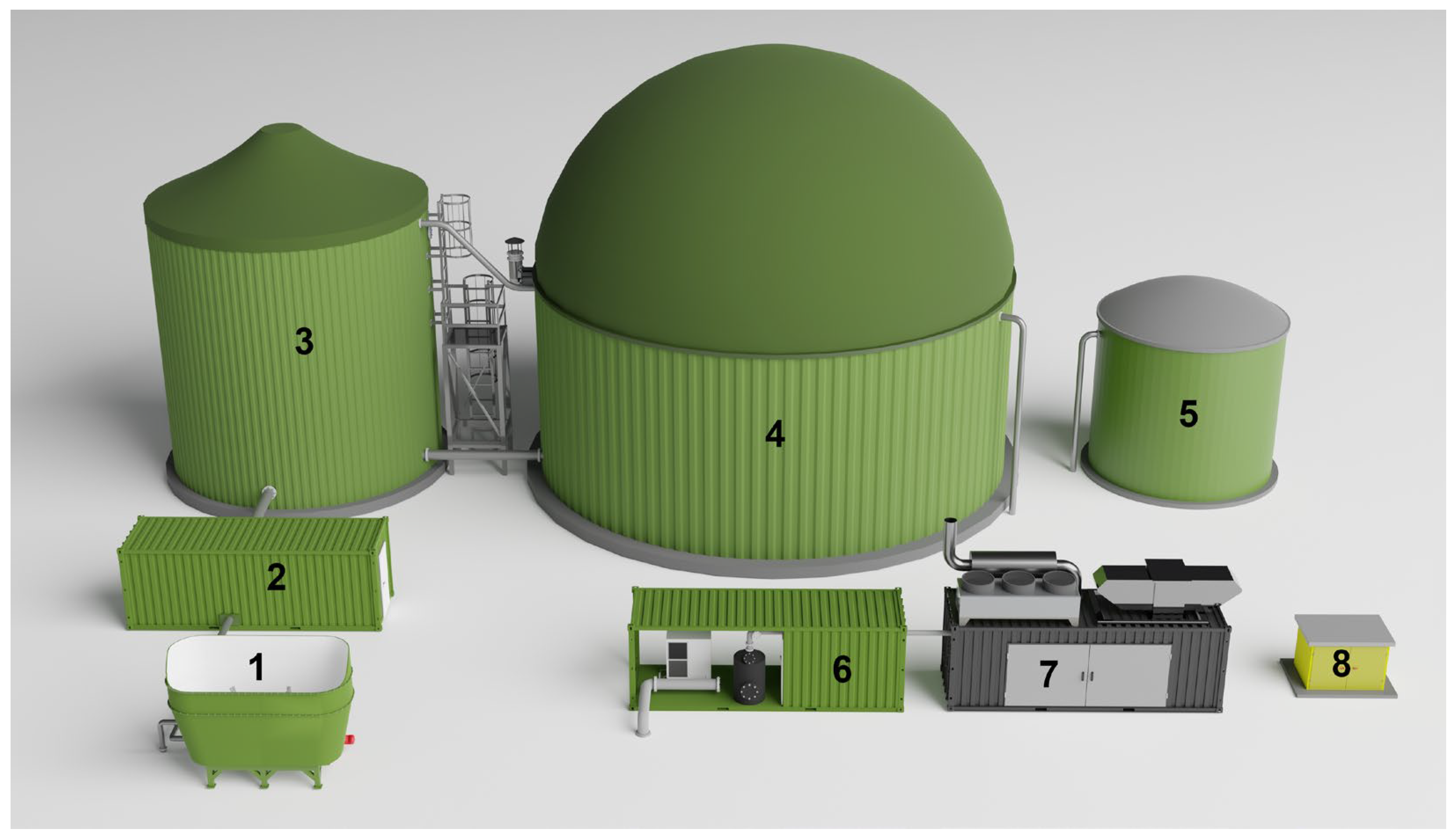

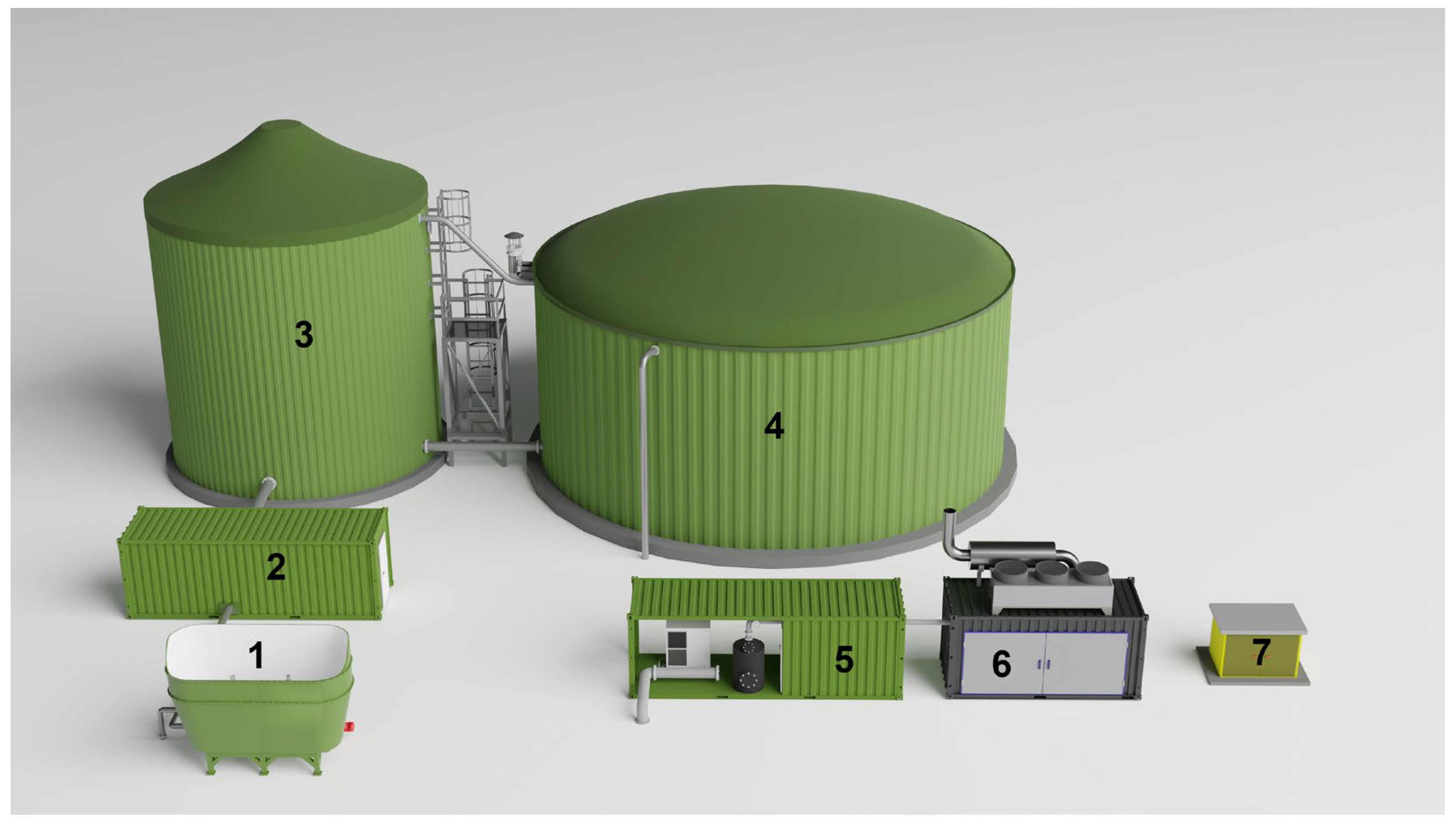

6.1. Comparison Between Traditional and Demand-Driven Biogas Plant

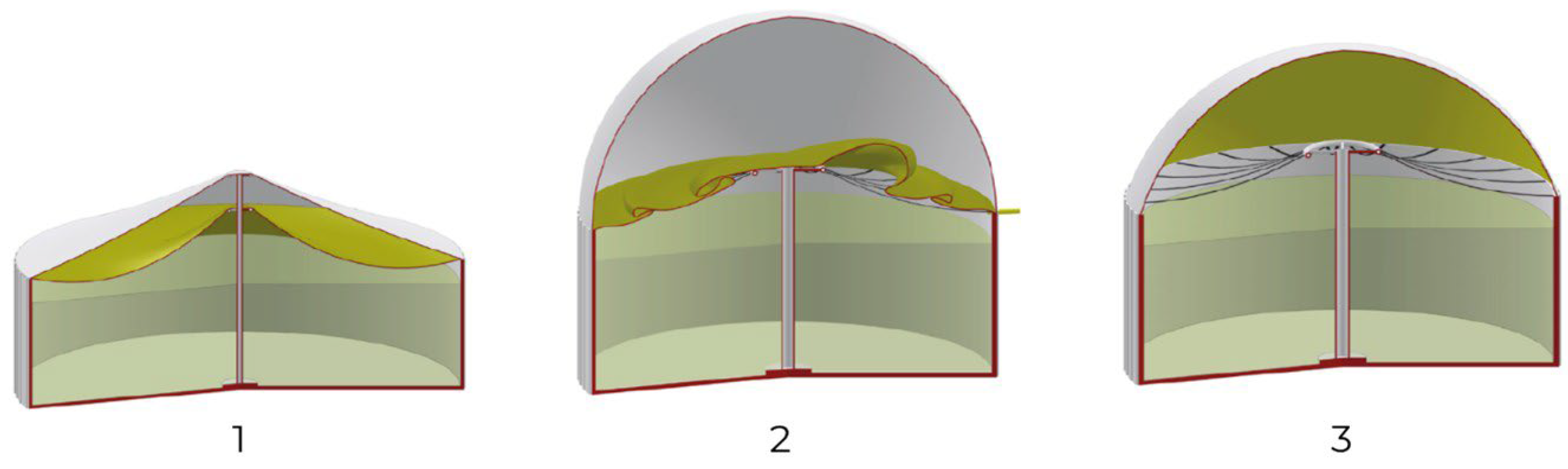

6.2. Storage of Biogas

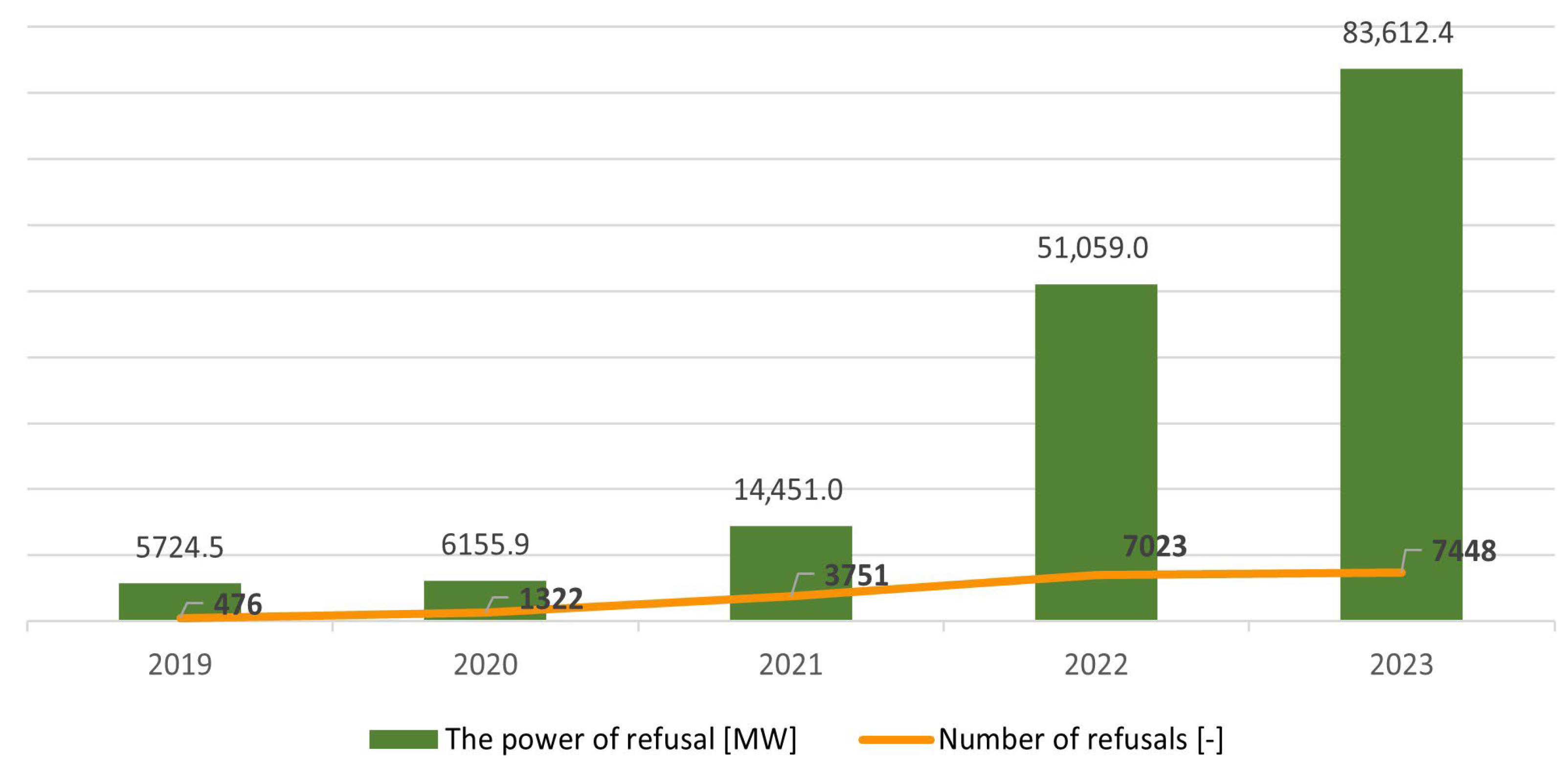

6.3. Challenges in Connecting New RES to the Power Grid

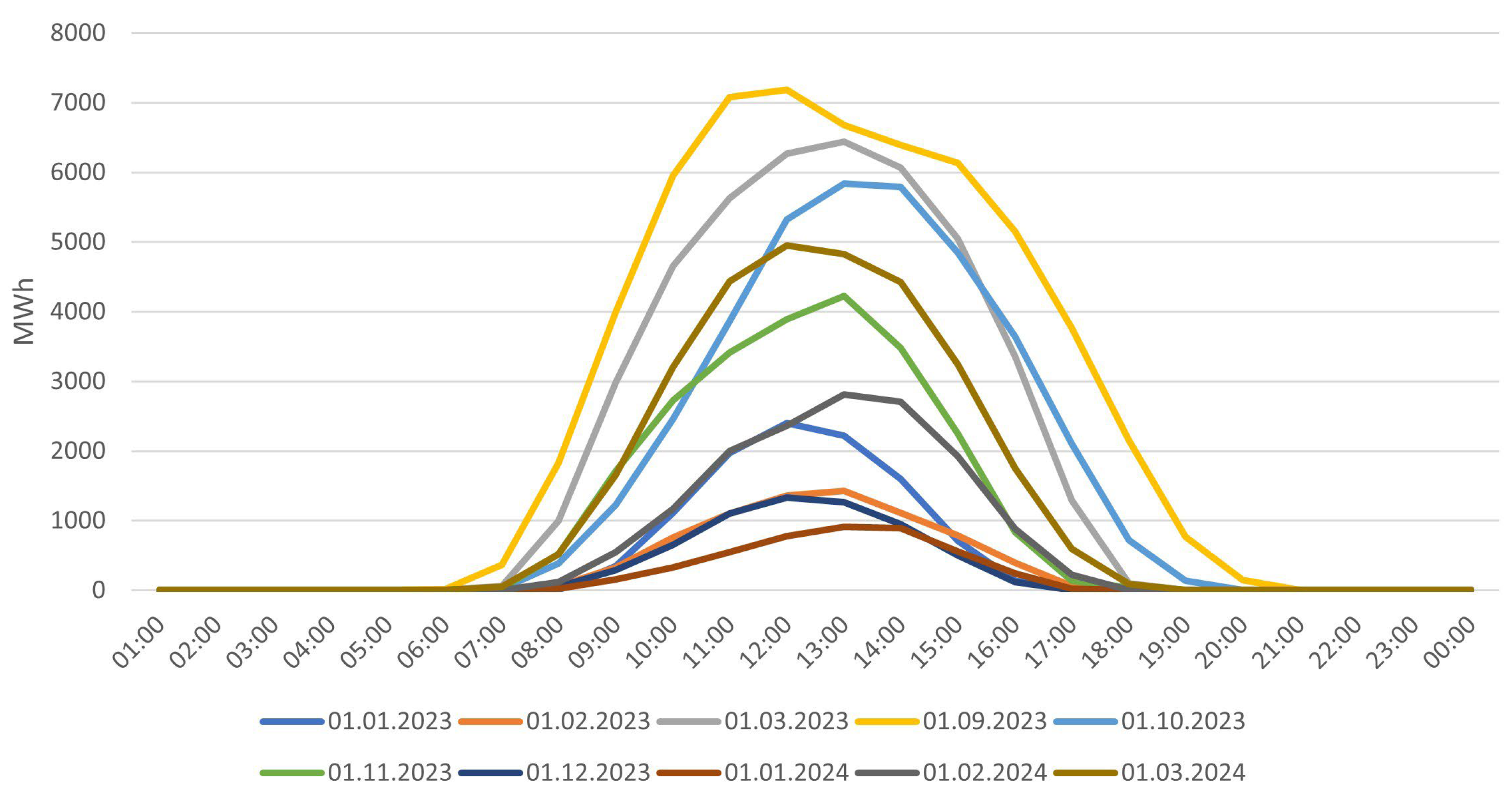

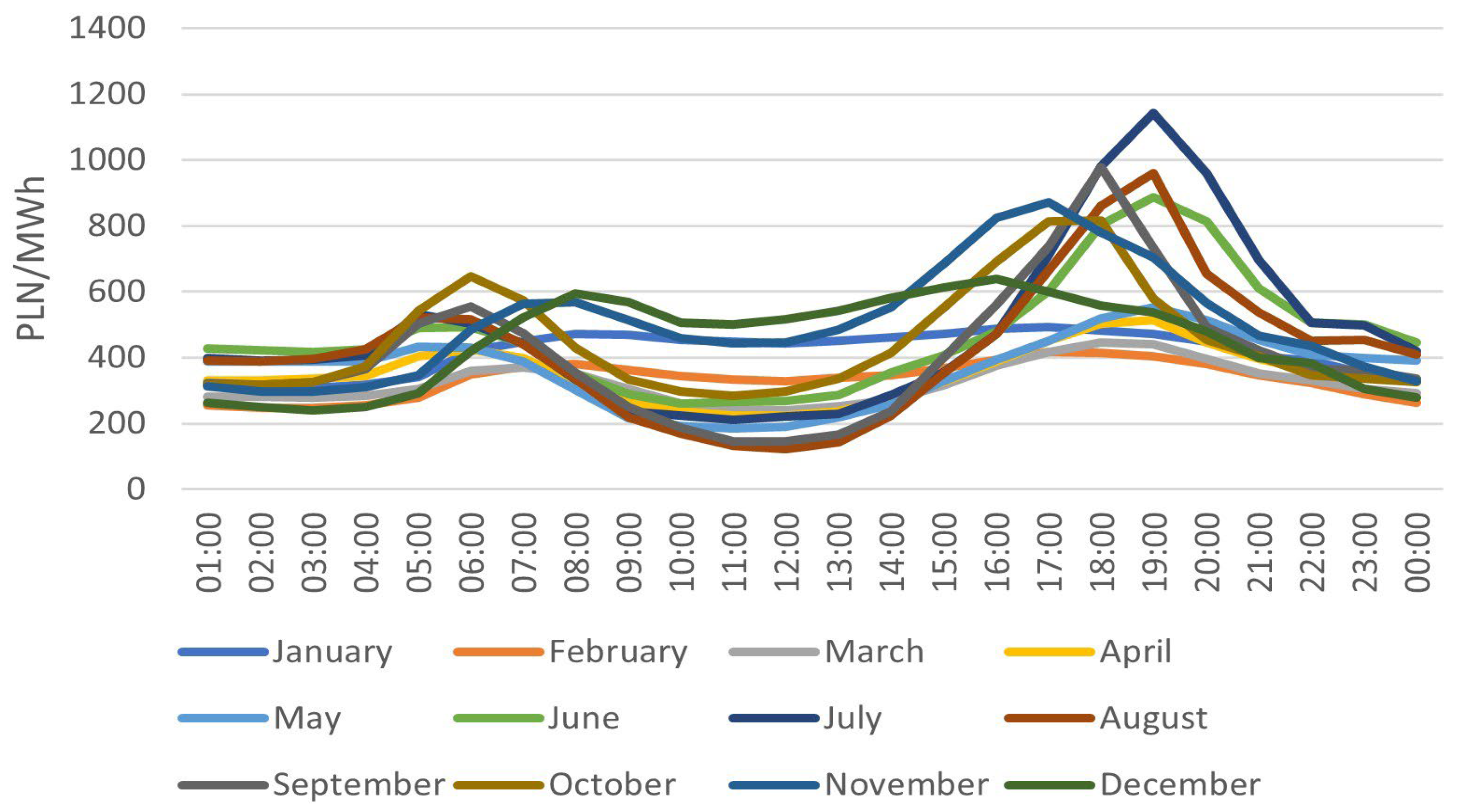

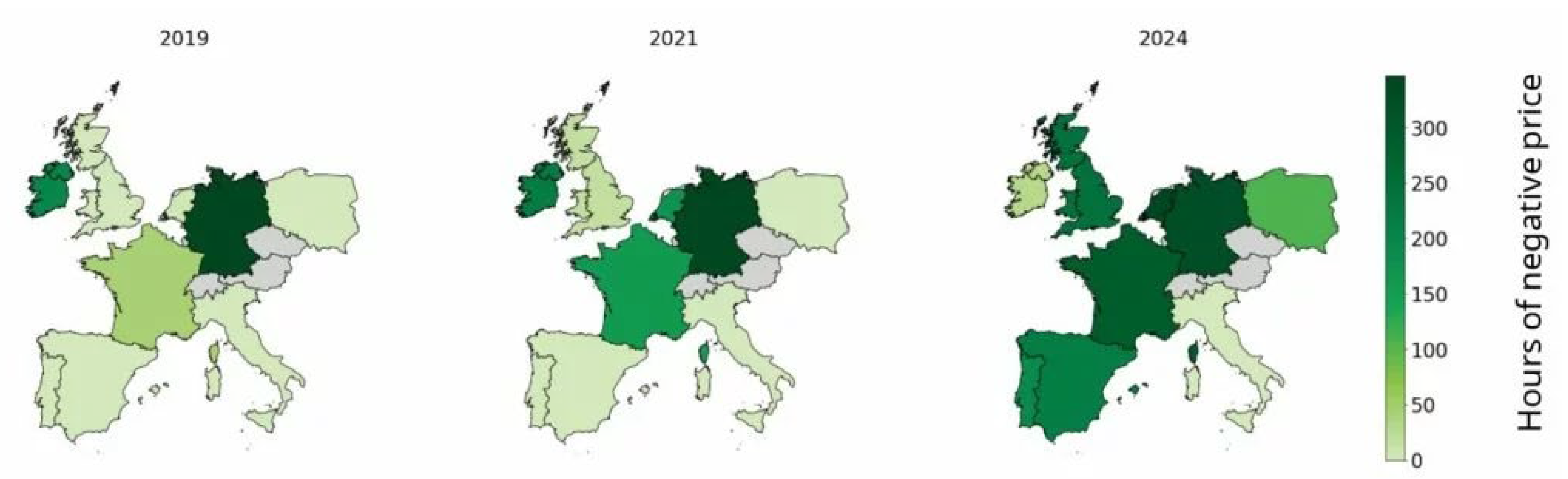

6.4. Schedule of Operation of Demand-Driven Biogas Plants

- Stage 1—fundamental analysis, assuming whole power generation from all RES (including PV) by their rated power. If the analysis results indicate that the biogas plant cannot be connected, operators proceed to the next stage.

7. Factors Inhibiting the Development of Demand-Driven Biogas Plants

- Installation of an additional cogeneration engine or increasing the capacity of the existing one;

- Construction of a biogas storage facility;

- Construction of a heat storage facility.

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Statista. Distribution of Energy Sector Greenhouse Gas Emissions in the European Union (EU-27) in 2021. Available online: https://www.statista.com/statistics/1000061/ghg-emissions-sources-energy-sector-european-union-eu/ (accessed on 30 May 2025).

- Hafner, M.; Raimondi, P.P. Priorities and Challenges of the EU Energy Transition: From the European Green Package to the New Green Deal. Russ. J. Econ. 2020, 6, 374–389. [Google Scholar] [CrossRef]

- Tomaszewski, K. The Polish Road to the New European Green Deal—Challenges and Threats to the National Energy Policy. Polityka Energ.—Energy Policy J. 2020, 23, 5–18. [Google Scholar] [CrossRef]

- International Renewable Energy Agency (IREA). Geopolitics of the Energy Transition: Energy Security. Available online: https://www.apeg.pt/folder/documento/ficheiro/869_IRENA_Geopolitics_transition_energy_security_2024.pdf (accessed on 30 May 2025).

- Saleh, H.M.; Hassan, A.I. The Challenges of Sustainable Energy Transition: A Focus on Renewable Energy. Appl. Chem. Eng. 2024, 7, 2084. [Google Scholar] [CrossRef]

- Ang, T.-Z.; Salem, M.; Kamarol, M.; Das, H.S.; Nazari, M.A.; Prabaharan, N. A Comprehensive Study of Renewable Energy Sources: Classifications, Challenges and Suggestions. Energy Strategy Rev. 2022, 43, 100939. [Google Scholar] [CrossRef]

- Rybak, A.; Rybak, A.; Kolev, S.D. The Import of Energy Raw Materials and the Energy Security of the European Union—The Case of Poland. Gospod. Surowcami Miner.—Miner. Resour. Manag. 2023, 38, 29–48. [Google Scholar] [CrossRef]

- Stankovski, A.; Gjorgiev, B.; Locher, L.; Sansavini, G. Power Blackouts in Europe: Analyses, Key Insights, and Recommendations from Empirical Evidence. Joule 2023, 7, 2468–2484. [Google Scholar] [CrossRef]

- Hodgson, R. Norwegian Finance Minister Blames EU Energy Policy for Government Collapse. Available online: https://www.euronews.com/my-europe/2025/01/30/norwegian-finance-minister-blames-eu-energy-policy-for-government-collapse (accessed on 30 May 2025).

- Energy Market Agency (ARE). Statistical Information About Electricity. Available online: https://www.are.waw.pl/oferta/wydawnictwa (accessed on 30 May 2025). (In Polish).

- Pochwatka, P.; Rozakis, S.; Kowalczyk-Juśko, A.; Czekała, W.; Qiao, W.; Nägele, H.-J.; Janczak, D.; Mazurkiewicz, J.; Mazur, A.; Dach, J. The Energetic and Economic Analysis of Demand-Driven Biogas Plant Investment Possibility in Dairy Farm. Energy 2023, 283, 129165. [Google Scholar] [CrossRef]

- Łukomska, A.; Pulka, J.; Broński, M.; Dach, J. Demand-Driven Biogas Plants in Poland—Potential and Growth Perspectives. J. Ecol. Eng. 2024, 25, 236–248. [Google Scholar] [CrossRef]

- Kuchler, M.; Bridge, G. Down the Black Hole: Sustaining National Socio-Technical Imaginaries of Coal in Poland. Energy Res. Soc. Sci. 2018, 41, 136–147. [Google Scholar] [CrossRef]

- Szpringer, Z. Problems of Polish Mining in the Light of EU Climate Policy. Available online: https://www.ceeol.com/search/article-detail?id=1293333 (accessed on 30 May 2025).

- Instrat Energy & Climate. Hard Coal Production in Poland in the Years 2007–2024. Available online: https://energy.instrat.pl/en/mining/production-sales-hard-coal/ (accessed on 28 May 2025).

- European Environment Agency (EEA). Total Greenhouse Gas Emissions in EU Member States. Available online: https://www.eea.europa.eu/en/analysis/maps-and-charts/greenhouse-gases-viewer-data-viewers (accessed on 30 May 2025).

- Forum Energii. Energy Transformation in Poland. Available online: https://www.forum-energii.eu/transformacja-edycja-2024 (accessed on 28 May 2025). (In Polish).

- Kubiczek, P. Basic Work. Modeling the Costs of Low Flexibility of the Polish Power System. Available online: https://instrat.pl/wp-content/uploads/2023/08/Praca-w-podstawie_28.08.pdf (accessed on 30 May 2025).

- Fiebrandt, M.; Röder, J.; Wagner, H. Minimum Loads of Coal-fired Power Plants and the Potential Suitability for Energy Storage Using the Example of Germany. Int. J. Energy Res. 2022, 46, 4975–4993. [Google Scholar] [CrossRef]

- Gonzalez-Salazar, M.A.; Kirsten, T.; Prchlik, L. Review of the Operational Flexibility and Emissions of Gas- and Coal-Fired Power Plants in a Future with Growing Renewables. Renew. Sustain. Energy Rev. 2018, 82, 1497–1513. [Google Scholar] [CrossRef]

- Chenna, A.; Aouzellag, D.; Ghedamsi, K. Study and Control of a Pumped Storage Hydropower System Dedicated to Renewable Energy Resources. J. Eur. Syst. Autom. 2020, 53, 95–102. [Google Scholar] [CrossRef]

- Nikolaos, P.C.; Marios, F.; Dimitris, K. A Review of Pumped Hydro Storage Systems. Energies 2023, 16, 4516. [Google Scholar] [CrossRef]

- Kałuża, T.; Hämmerling, M.; Zawadzki, P.; Czekała, W.; Kasperek, R.; Sojka, M.; Mokwa, M.; Ptak, M.; Szkudlarek, A.; Czechlowski, M.; et al. The Hydropower Sector in Poland: Barriers and the Outlook for the Future. Renew. Sustain. Energy Rev. 2022, 163, 112500. [Google Scholar] [CrossRef]

- Grira, S.; Alkhedher, M.; Abu Khalifeh, H.; Ramadan, M.; Ghazal, M. Using Algae in Li-Ion Batteries: A Sustainable Pathway toward Greener Energy Storage. Bioresour. Technol. 2024, 394, 130225. [Google Scholar] [CrossRef] [PubMed]

- Stan, A.-I.; Swierczynski, M.; Stroe, D.-I.; Teodorescu, R.; Andreasen, S.J. Lithium Ion Battery Chemistries from Renewable Energy Storage to Automotive and Back-up Power Applications—An Overview. In Proceedings of the 2014 International Conference on Optimization of Electrical and Electronic Equipment (OPTIM), Bran, Romania, 22–24 May 2014; pp. 713–720. [Google Scholar] [CrossRef]

- Gaines, L. Profitable Recycling of Low-Cobalt Lithium-Ion Batteries Will Depend on New Process Developments. One Earth 2019, 1, 413–415. [Google Scholar] [CrossRef]

- Luo, G.; Zhang, Y.; Tang, A. Capacity Degradation and Aging Mechanisms Evolution of Lithium-Ion Batteries under Different Operation Conditions. Energies 2023, 16, 4232. [Google Scholar] [CrossRef]

- Polish Electricity Transmission System Operator. Report 2024 Polish Power System. Available online: https://www.pse.pl/dane-systemowe/funkcjonowanie-kse/raporty-roczne-z-funkcjonowania-kse-za-rok/raporty-za-rok-2024#r6_3 (accessed on 15 July 2025).

- Świdyńska, N. Renewable Energy Sources in Poland in 2014–2023 and the Perspective of Their Development until 2030. A Contribution to the Discussion. Olszt. Econ. J. 2024, 19, 31–44. [Google Scholar] [CrossRef]

- Bachanek, K.H.; Drożdż, W.; Kolon, M. Development of Renewable Energy Sources in Poland and Stability of Power Grids—Challenges, Technologies, and Adaptation Strategies. Energies 2025, 18, 2036. [Google Scholar] [CrossRef]

- Evro, S.; Wade, C.; Tomomewo, O. Solar PV Technology Cost Dynamics and Challenges for US New Entrants. Am. J. Energy Res. 2023, 11, 15–26. [Google Scholar] [CrossRef]

- Mazurek-Czarnecka, A.; Rosiek, K.; Salamaga, M.; Wąsowicz, K.; Żaba-Nieroda, R. Study on Support Mechanisms for Renewable Energy Sources in Poland. Energies 2022, 15, 4196. [Google Scholar] [CrossRef]

- Hebda, W.; Leśniak, K.; Stolorz, M. Wind Energy in Poland. In EU Energy and Climate Policy After COVID-19 and the Invasion of Ukraine; Routledge: London, UK, 2024; pp. 195–210. [Google Scholar] [CrossRef]

- Baltic Power. Baltic Power Confirms First Successful Installations of the Offshore Wind Turbines for Poland’s First Offshore Wind Farm. Available online: https://balticpower.pl/news/baltic-power-confirms-first-successful-installations-of-the-offshore-wind-turbines-for-poland-s-first-offshore-wind-farm/ (accessed on 16 July 2025).

- Smolinski, P.R.; Januszewicz, J.; Pawlowska, B.; Winiarski, J. Nuclear Energy Acceptance in Poland: From Societal Attitudes to Effective Policy Strategies—Network Modeling Approach. PLoS ONE 2024, 19, e0305115. [Google Scholar] [CrossRef]

- Mrozowska, S.; Wendt, J.A.; Tomaszewski, K. The Challenges of Poland’s Energy Transition. Energies 2021, 14, 8165. [Google Scholar] [CrossRef]

- Cucina, M. Integrating Anaerobic Digestion and Composting to Boost Energy and Material Recovery from Organic Wastes in the Circular Economy Framework in Europe: A Review. Bioresour. Technol. Rep. 2023, 24, 101642. [Google Scholar] [CrossRef]

- Lehtokunnas, T. The Circular Economy Futures in the Making: Transformativity and Object Ontologies in Food Waste Practices in Finnish Households, Supermarkets and Biogas Plants. Futures 2023, 153, 103241. [Google Scholar] [CrossRef]

- Burg, V.; Rolli, C.; Schnorf, V.; Scharfy, D.; Anspach, V.; Bowman, G. Agricultural Biogas Plants as a Hub to Foster Circular Economy and Bioenergy: An Assessment Using Substance and Energy Flow Analysis. Resour. Conserv. Recycl. 2023, 190, 106770. [Google Scholar] [CrossRef]

- Zabochnicka, M.; Wolny, L.; Zawieja, I.; Lozano Sanchez, F.D. Biogas Production from Waste Food as an Element of Circular Bioeconomy in the Context of Water Protection. Desalination Water Treat. 2023, 301, 289–295. [Google Scholar] [CrossRef]

- Emmanuel, J.K.; Juma, M.J.; Mlozi, S.H. Biogas Generation from Food Waste through Anaerobic Digestion Technology with Emphasis on Enhancing Circular Economy in Sub-Saharan Africa—A Review. Energy Rep. 2024, 12, 3207–3217. [Google Scholar] [CrossRef]

- Kuo, T.-C.; Chen, H.-Y.; Chong, B.; Lin, M. Cost Benefit Analysis and Carbon Footprint of Biogas Energy through Life Cycle Assessment. Clean. Environ. Syst. 2024, 15, 100240. [Google Scholar] [CrossRef]

- Michael Fredenslund, A.; Gudmundsson, E.; Maria Falk, J.; Scheutz, C. The Danish National Effort to Minimise Methane Emissions from Biogas Plants. Waste Manag. 2023, 157, 321–329. [Google Scholar] [CrossRef]

- Thrän, D.; Adetona, A.; Borchers, M.; Cyffka, K.-F.; Daniel-Gromke, J.; Oehmichen, K. Potential Contribution of Biogas to Net Zero Energy Systems—A Comparative Study of Canada and Germany. Biomass Bioenergy 2025, 193, 107561. [Google Scholar] [CrossRef]

- Ferrari, G.; Shi, Z.; Marinello, F.; Pezzuolo, A. From Biogas to Biomethane: Comparison of Sustainable Scenarios for Upgrading Plant Location Based on Greenhouse Gas Emissions and Cost Assessments. J. Clean. Prod. 2024, 478, 143936. [Google Scholar] [CrossRef]

- Lehtoranta, S.; Tampio, E.; Rasi, S.; Laakso, J.; Vikki, K.; Luostarinen, S. The Implications of Management Practices on Life Cycle Greenhouse Gas Emissions in Biogas Production. J. Environ. Manag. 2024, 366, 121884. [Google Scholar] [CrossRef] [PubMed]

- Lamidi, R.O.; Jiang, L.; Wang, Y.D.; Pathare, P.B.; Roskilly, A.P. Techno-Economic Analysis of a Biogas Driven Poly-Generation System for Postharvest Loss Reduction in a Sub-Saharan African Rural Community. Energy Convers. Manag. 2019, 196, 591–604. [Google Scholar] [CrossRef]

- Buonomano, A.; Del Papa, G.; Giuzio, G.F.; Palombo, A.; Russo, G. Future Pathways for Decarbonization and Energy Efficiency of Ports: Modelling and Optimization as Sustainable Energy Hubs. J. Clean. Prod. 2023, 420, 138389. [Google Scholar] [CrossRef]

- Nadaleti, W.C. Utilization of Residues from Rice Parboiling Industries in Southern Brazil for Biogas and Hydrogen-Syngas Generation: Heat, Electricity and Energy Planning. Renew. Energy 2019, 131, 55–72. [Google Scholar] [CrossRef]

- Achinas, S.; Euverink, G.J.W. Rambling Facets of Manure-Based Biogas Production in Europe: A Briefing. Renew. Sustain. Energy Rev. 2020, 119, 109566. [Google Scholar] [CrossRef]

- Loboichenko, V.; Iranzo, A.; Casado-Manzano, M.; Navas, S.J.; Pino, F.J.; Rosa, F. Study of the Use of Biogas as an Energy Vector for Microgrids. Renew. Sustain. Energy Rev. 2024, 200, 114574. [Google Scholar] [CrossRef]

- Agonafer, T.D.; Eremed, W.B.; Adem, K.D. Biogas-Based Trigeneration System: A Review. Results Eng. 2022, 15, 100509. [Google Scholar] [CrossRef]

- Qin, M.; Yang, Y.; Chen, S.; Xu, Q. Bi-Level Optimization Model of Integrated Biogas Energy System Considering the Thermal Comfort of Heat Customers and the Price Fluctuation of Natural Gas. Int. J. Electr. Power Energy Syst. 2023, 151, 109168. [Google Scholar] [CrossRef]

- Reinelt, T.; Liebetrau, J.; Nelles, M. Analysis of Operational Methane Emissions from Pressure Relief Valves from Biogas Storages of Biogas Plants. Bioresour. Technol. 2016, 217, 257–264. [Google Scholar] [CrossRef]

- Dotzauer, M.; Pfeiffer, D.; Lauer, M.; Pohl, M.; Mauky, E.; Bär, K.; Sonnleitner, M.; Zörner, W.; Hudde, J.; Schwarz, B.; et al. How to Measure Flexibility—Performance Indicators for Demand Driven Power Generation from Biogas Plants. Renew. Energy 2019, 134, 135–146. [Google Scholar] [CrossRef]

- Dittmer, C.; Krümpel, J.; Lemmer, A. Power Demand Forecasting for Demand-Driven Energy Production with Biogas Plants. Renew. Energy 2021, 163, 1871–1877. [Google Scholar] [CrossRef]

- Lemmer, A.; Krümpel, J. Demand-Driven Biogas Production in Anaerobic Filters. Appl. Energy 2017, 185, 885–894. [Google Scholar] [CrossRef]

- Ohnmacht, B.; Lemmer, A.; Oechsner, H.; Kress, P. Demand-Oriented Biogas Production and Biogas Storage in Digestate by Flexibly Feeding a Full-Scale Biogas Plant. Bioresour. Technol. 2021, 332, 125099. [Google Scholar] [CrossRef]

- Polish Central Statistical Office. Statistical Yearbook of the Republic of Poland. 2024. Available online: https://stat.gov.pl/obszary-tematyczne/roczniki-statystyczne/roczniki-statystyczne/rocznik-statystyczny-rzeczypospolitej-polskiej-2024,2,24.html (accessed on 16 July 2025).

- Polish Central Statistical Office. Statistical Yearbook of Agriculture. 2024. Available online: https://stat.gov.pl/obszary-tematyczne/roczniki-statystyczne/roczniki-statystyczne/rocznik-statystyczny-rolnictwa-2024,6,18.html (accessed on 16 July 2025).

- Kozłowski, K.; Dach, J.; Lewicki, A.; Malińska, K.; do Carmo, I.E.P.; Czekała, W. Potential of Biogas Production from Animal Manure in Poland. Arch. Environ. Prot. 2023, 45, 99–108. [Google Scholar] [CrossRef]

- DIN 38414-8; Deutsche Einheitsverfahren Zur Wasser-, Abwasser- und Schlammuntersuchung; Schlamm und Sedimente (Gruppe S); Bestimmung des Faulverhaltens (S 8). Beuth Verlag GmbH: Berlin, Germany, 1985.

- VDI 4630; Vergärung Organischer Stoffe Substratcharakterisierung, Probenahme, Stoffdatenerhebung, Gärversuche. VDI Verein Deutscher Ingenieure: Düsseldorf, Germany, 2016.

- Pochwatka, P.; Kowalczyk-Juśko, A.; Sołowiej, P.; Wawrzyniak, A.; Dach, J. Biogas Plant Exploitation in a Middle-Sized Dairy Farm in Poland: Energetic and Economic Aspects. Energies 2020, 13, 6058. [Google Scholar] [CrossRef]

- Rokicki, T.; Perkowska, A.; Ziółkowska, P. Changes in the Concentration of Animal Production in Poland. Ann. Pol. Assoc. Agric. Agribus. Econ. 2020, 22, 175–186. [Google Scholar] [CrossRef]

- Bożek, J.; Szewczyk, J. Area Structure of Farms in Poland against the Background of Other European Union Countries. Wiad. Stat. Pol. Stat. 2020, 65, 48–62. [Google Scholar] [CrossRef]

- Kusz, D.; Nowakowski, T.; Kusz, B. The Capacity of Power of Biogas Plants and Their Technical Efficiency: A Case Study of Poland. Energies 2024, 17, 6256. [Google Scholar] [CrossRef]

- Kusz, D.; Kusz, B.; Wicki, L.; Nowakowski, T.; Kata, R.; Brejta, W.; Kasprzyk, A.; Barć, M. The Economic Efficiencies of Investment in Biogas Plants—A Case Study of a Biogas Plant Using Waste from a Dairy Farm in Poland. Energies 2024, 17, 3760. [Google Scholar] [CrossRef]

- Jarrar, L.; Ayadi, O.; Al Asfar, J. Techno-Economic Aspects of Electricity Generation from a Farm Based Biogas Plant. J. Sustain. Dev. Energy Water Environ. Syst. 2020, 8, 476–492. [Google Scholar] [CrossRef]

- Trypolska, G.; Kyryziuk, S.; Krupin, V.; Wąs, A.; Podolets, R. Economic Feasibility of Agricultural Biogas Production by Farms in Ukraine. Energies 2021, 15, 87. [Google Scholar] [CrossRef]

- Dalpaz, R.; Konrad, O.; Cândido da Silva Cyrne, C.; Panis Barzotto, H.; Hasan, C.; Guerini Filho, M. Using Biogas for Energy Cogeneration: An Analysis of Electric and Thermal Energy Generation from Agro-Industrial Waste. Sustain. Energy Technol. Assess. 2020, 40, 100774. [Google Scholar] [CrossRef]

- Stürmer, B.; Theuretzbacher, F.; Saracevic, E. Opportunities for the Integration of Existing Biogas Plants into the Austrian Electricity Market. Renew. Sustain. Energy Rev. 2021, 138, 110548. [Google Scholar] [CrossRef]

- Mauky, E.; Jacobi, H.F.; Liebetrau, J.; Nelles, M. Flexible Biogas Production for Demand-Driven Energy Supply—Feeding Strategies and Types of Substrates. Bioresour. Technol. 2015, 178, 262–269. [Google Scholar] [CrossRef]

- Hahn, H.; Krautkremer, B.; Hartmann, K.; Wachendorf, M. Review of Concepts for a Demand-Driven Biogas Supply for Flexible Power Generation. Renew. Sustain. Energy Rev. 2014, 29, 383–393. [Google Scholar] [CrossRef]

- Barchmann, T.; Mauky, E.; Dotzauer, M.; Stur, M.; Weinrich, S.; Jacobi, H.F.; Liebetrau, J.; Nelles, M. Erweiterung Der Flexibilität von Biogas-Anlagen—Substratmanagement, Fahrplan-Synthese Und Ökonomische Bewertun. Landtechnik 2016, 71, 233–251. [Google Scholar] [CrossRef]

- Nassereddine, M.; Nassreddine, G.; El Arid, A. Hybrid Photovoltaic and Biogas System for Stable Power System. Next Energy 2024, 5, 100172. [Google Scholar] [CrossRef]

- Kube, J. Management of Gas Storages in Biogas Plants. Chem. Eng. Technol. 2018, 41, 702–710. [Google Scholar] [CrossRef]

- Stur, M.; Pohl, M.; Krebs, C.; Mauky, E. Characterisation of Biogas Storages: Influences and Comparison of Methods. Landtechnik 2022, 77, 21–45. [Google Scholar]

- Circular Renewables. Membrane Replacement. Available online: https://www.circularrenewables.co.uk/maximising-efficiency-with-flexible-biogas/ (accessed on 17 July 2025).

- Wang, Y.; Zhang, H.; Wang, W.; Wu, Z.; Xu, X.; Kang, X.; Zhan, O.; Lü, F.; He, P. Double Membrane Gasholder for Biogas Storage: Odor Pollution Risk and Permeation Characteristics. J. Clean. Prod. 2022, 352, 131644. [Google Scholar] [CrossRef]

- DIN 4102; Fire Behaviour of Building Materials and Components. Beuth Verlag GmbH: Berlin, Germany, 1981.

- DIN EN 1876-1; Thermal Insulating Products for Building Equipment and Industrial Installations—Determination of Steady-State Thermal Transmission Properties—Part 1: Guarded Hot Plate Method. Beuth Verlag GmbH: Berlin, Germany, 1998.

- DIN 53359; Testing of Plastics—Determination of Resistance to Repeated Bending. Beuth Verlag GmbH: Berlin, Germany, 2006.

- ASTM D1434; Standard Test Method for Determining Gas Permeability Characteristics of Plastic Film and Sheeting. ASTM International: West Conshohocken, PA, USA, 2023.

- Urząd Regulacji Energetyki. Report on the Activities of the President of the Energy Regulatory Office in 2023. Available online: https://www.ure.gov.pl/pl/urzad/informacje-ogolne/aktualnosci/11948,Sprawozdanie-z-dzialalnosci-Prezesa-URE-w-2023-r-jak-realniewyglada-kwestia-odm.html (accessed on 31 May 2025). (In Polish)

- Kryszk, H.; Kurowska, K.; Marks-Bielska, R.; Bielski, S.; Eźlakowski, B. Barriers and Prospects for the Development of Renewable Energy Sources in Poland during the Energy Crisis. Energies 2023, 16, 1724. [Google Scholar] [CrossRef]

- Bednarek, A.; Klepacka, A.; Siudek, A. Development Barriers of Agricultural Biogas Plants in Poland. Econ. Environ. 2023, 84, 229–258. [Google Scholar] [CrossRef]

- Tauron Dystrybucja. Connection Feasibility Assessment Criteria and Technical Requirements for Energy Sources Connected to the Medium-Voltage Grid of the Distribution System Operator. Available online: https://www.tauron-dystrybucja.pl/przylaczenie-do-sieci/przylaczenie/zrodla-wytworcze (accessed on 9 July 2025).

- PGE Dystrybucja. Connection Feasibility Assessment Criteria and Technical Requirements for Energy Sources Connected to the Medium-Voltage Grid of the Distribution System Operator. Available online: https://pgedystrybucja.pl/przylaczenia/przydatne-dokumenty (accessed on 9 July 2025).

- Energa Operator. Connection Feasibility Assessment Criteria and Technical Requirements for Energy Sources Connected to the Medium-Voltage Grid of the Distribution System Operator. Available online: https://energa-operator.pl/przylaczenie-do-sieci/przylaczanie-wytworcy-energii/kryteria-oceny-mozliwosci-przylaczenia (accessed on 9 July 2025).

- Kościelny, M.; Olczak, P. Comparative LCOE/LCA and Maintenance/Service Analysis of Renewable Energy Sources in the Context of Curtailment with the Regional Diversity in Poland. Polityka Energetyczna—Energy Policy J. 2025, 28, 5–22. [Google Scholar] [CrossRef]

- Pijarski, P.; Kacejko, P.; Belowski, A. Rescheduling Renewable Energy Installations in Practice—Necessity versus Consequence. Rynek Energii 2025, 177, 3–10. [Google Scholar]

- Körber, M.; Weinrich, S.; Span, R.; Gerber, M. Demand-Oriented Biogas Production to Cover Residual Load of an Electricity Self-Sufficient Community Using a Simple Kinetic Model. Bioresour. Technol. 2022, 361, 127664. [Google Scholar] [CrossRef]

- Fichtner, S.; Meyr, H. Biogas Plant Optimization by Increasing Its Flexibility Considering Uncertain Revenues. Available online: https://wiso.uni-hohenheim.de/fileadmin/einrichtungen/wiso/Forschungsdekan/Papers_BESS/DP_2019-07_online.pdf (accessed on 18 July 2025).

- Polish Electricity Transmission System Operator. PPS Operation—Generation of Wind and Photovoltaic Sources. Available online: https://www.pse.pl/dane-systemowe/funkcjonowanie-kse/raporty-dobowe-z-pracy-kse/generacja-zrodel-wiatrowych (accessed on 15 July 2025).

- Lauven, L.-P.; Geldermann, J.; Desideri, U. Estimating the Revenue Potential of Flexible Biogas Plants in the Power Sector. Energy Policy 2019, 128, 402–410. [Google Scholar] [CrossRef]

- Next Kraftwerke GmbH. Biogas & Control Energy—The Optimal System. Available online: https://www.next-kraftwerke.de/energie-blog/biogas-regelenergie-optimale-anlage (accessed on 15 July 2025).

- Lehna, M.; Scheller, F.; Herwartz, H. Forecasting Day-Ahead Electricity Prices: A Comparison of Time Series and Neural Network Models Taking External Regressors into Account. Energy Econ. 2022, 106, 105742. [Google Scholar] [CrossRef]

- Prokhorov, O.; Dreisbach, D. The Impact of Renewables on the Incidents of Negative Prices in the Energy Spot Markets. Energy Policy 2022, 167, 113073. [Google Scholar] [CrossRef]

- Timera Energy. Strong Growth in Negative Prices: A German Case Study. Available online: https://timera-energy.com/blog/strong-growth-in-negative-prices-a-german-case-study/ (accessed on 30 May 2025).

- Warnecke, H.-J.; Kampa, H. Flexible Production Systems in the Federal Republic of Germany. IFAC Proc. Vol. 1982, 15, 191–206. [Google Scholar] [CrossRef]

| Mass | Biogas Efficiency | Ch4 Content | Amount of Biogas | Amount of Methane | |

|---|---|---|---|---|---|

| Type of substrate | million Mg | m3/Mg FM | % | million m3 | million m3 |

| manure (including poultry manure) | 70 | 80 | 62 | 5600.0 | 3472.0 |

| slurry | 20 | 18 | 64 | 360.0 | 230.4 |

| maize straw | 4 | 420 | 52 | 1680.0 | 873.6 |

| beet leaves | 4.5 | 70 | 54 | 315.0 | 170.1 |

| beet pulp | 4.5 | 42 | 52 | 189.0 | 98.3 |

| cereal straw and others | 8 | 520 | 54 | 4160.0 | 2246.4 |

| non-feed hay | 1.6 | 420 | 54 | 672.0 | 362.9 |

| waste animal tissue | 0.4 | 300 | 66 | 120.0 | 79.2 |

| sediments from processing plants | 0.14 | 80 | 65 | 11.2 | 7.3 |

| pomace and residues from processing | 0.95 | 150 | 56 | 142.5 | 79.8 |

| waste from dairy industry | 0.15 | 40 | 56 | 6.0 | 3.4 |

| stillages and musts | 1.32 | 45 | 60 | 59.4 | 35.6 |

| cellulose waste | 1.08 | 140 | 56 | 151.2 | 84.7 |

| refood | 0.36 | 160 | 64 | 57.6 | 36.9 |

| Sum: | 117.0 | 13,523.9 | 7780.5 |

| Mass | Biogas Efficiency | Ch4 Content | Amount of Biogas | Amount of Methane | |

|---|---|---|---|---|---|

| Type of substrate | million Mg | m3/Mg FM | % | million m3 | million m3 |

| sewage sludge | 0.58 | 192.2 | 62 | 111.5 | 69.1 |

| kitchen waste | 3.75 | 103.5 | 58 | 388.1 | 225.1 |

| grass leaves | 1.25 | 88 | 52 | 110.0 | 57.2 |

| green waste from PSZOK | 0.4 | 80 | 50 | 32.0 | 16.0 |

| Sum: | 6.0 | 641.6 | 367.4 |

| Available Biomass | Available Biogas | Amount of Methane | Amount of Electricity | Power of Linear Biogas Plants | Power of Demand-Driven Biogas Plants |

|---|---|---|---|---|---|

| million Mg | million m3 | million m3 | GWh | GW | GW |

| 117 | 13,523.9 | 7780.6 | 3.7 | 7.4 |

| Parameters | Generation Capacity | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 25 kW | 50 kW | 100 kW | 150 kW | 350 kW | 500 kW | 1 MW | 10 MW | 20 MW | |

| Investments, EUR/kW | 8400 | 8400 | 6000 | 5000 | 4500 | 4500 | 3500 | 1800 | 2000 |

| Levelized generation cost, EUR/kWh | 0.837 | 0.837 | 0.603 | 0.500 | 0.465 | 0.465 | 0.370 | 0.220 | 0.145 |

| Simple return period, years | 16.5 | 16.5 | 11.8 | 9.8 | 8.9 | 8.9 | 6.9 | 3.5 | 2.0 |

| Simple return period (in case of potential feed-in tariff at 0.3 EUR kWh), years | 8.4 | 8.4 | 6.0 | 5 | 4.5 | 4.5 | 3.5 | 1.8 | 1.4 |

| Month | I | II | III | IV | V | VI | VII | VIII | IX | X | XI | XII |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| On time | 16:00 | 16:00 | 16:00 | 18:00 | 18:00 | 18:00 | 18:00 | 18:00 | 16:00 | 16:00 | 16:00 | 16:00 |

| Off time | 9:00 | 9:00 | 9:00 | 9:00 | 9:00 | 9:00 | 9:00 | 9:00 | 9:00 | 9:00 | 9:00 | 9:00 |

| Time of work | 17 | 17 | 17 | 14 | 14 | 14 | 14 | 14 | 17 | 17 | 17 | 17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Łukomska, A.; Witaszek, K.; Dach, J. Current State of Development of Demand-Driven Biogas Plants in Poland. Processes 2025, 13, 2369. https://doi.org/10.3390/pr13082369

Łukomska A, Witaszek K, Dach J. Current State of Development of Demand-Driven Biogas Plants in Poland. Processes. 2025; 13(8):2369. https://doi.org/10.3390/pr13082369

Chicago/Turabian StyleŁukomska, Aleksandra, Kamil Witaszek, and Jacek Dach. 2025. "Current State of Development of Demand-Driven Biogas Plants in Poland" Processes 13, no. 8: 2369. https://doi.org/10.3390/pr13082369

APA StyleŁukomska, A., Witaszek, K., & Dach, J. (2025). Current State of Development of Demand-Driven Biogas Plants in Poland. Processes, 13(8), 2369. https://doi.org/10.3390/pr13082369