Insulation Ability and Morphological Effect of ZrO2 Spacer Layer in Carbon-Based Multiporous Layered Electrode Perovskite Solar Cells

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of ZrO2 Paste for Mesoporous ZrO2 Layer

2.3. Preparation of Perovskite Precursor Solution

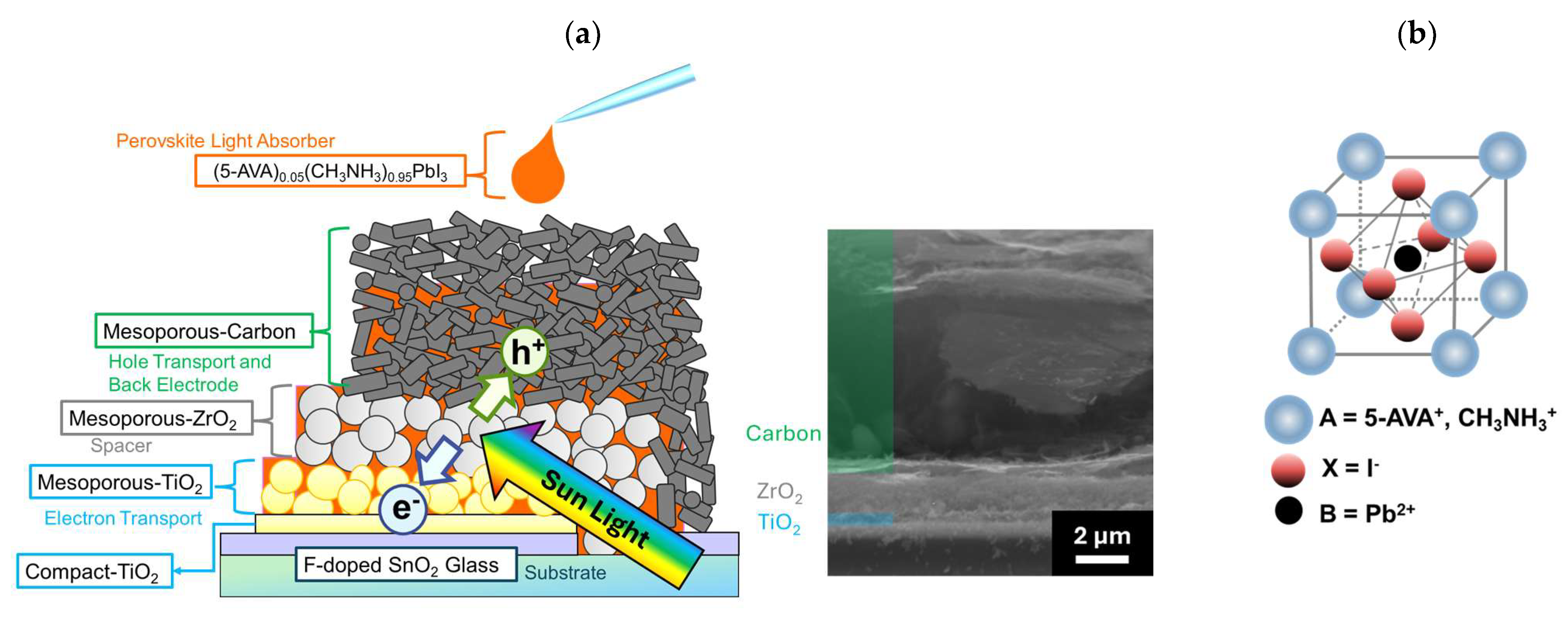

2.4. Fabrication of MPLE−PSCs

2.5. Characterization

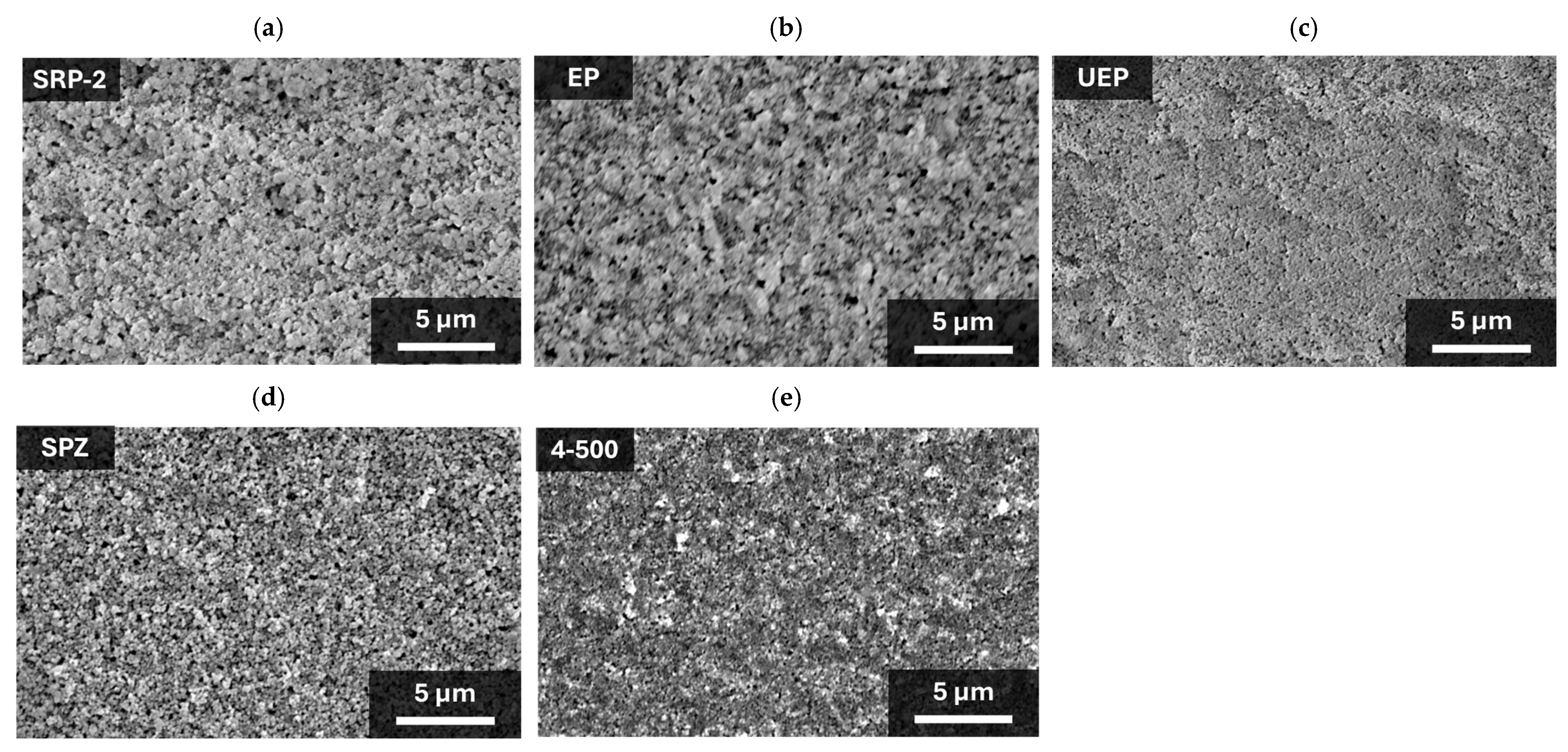

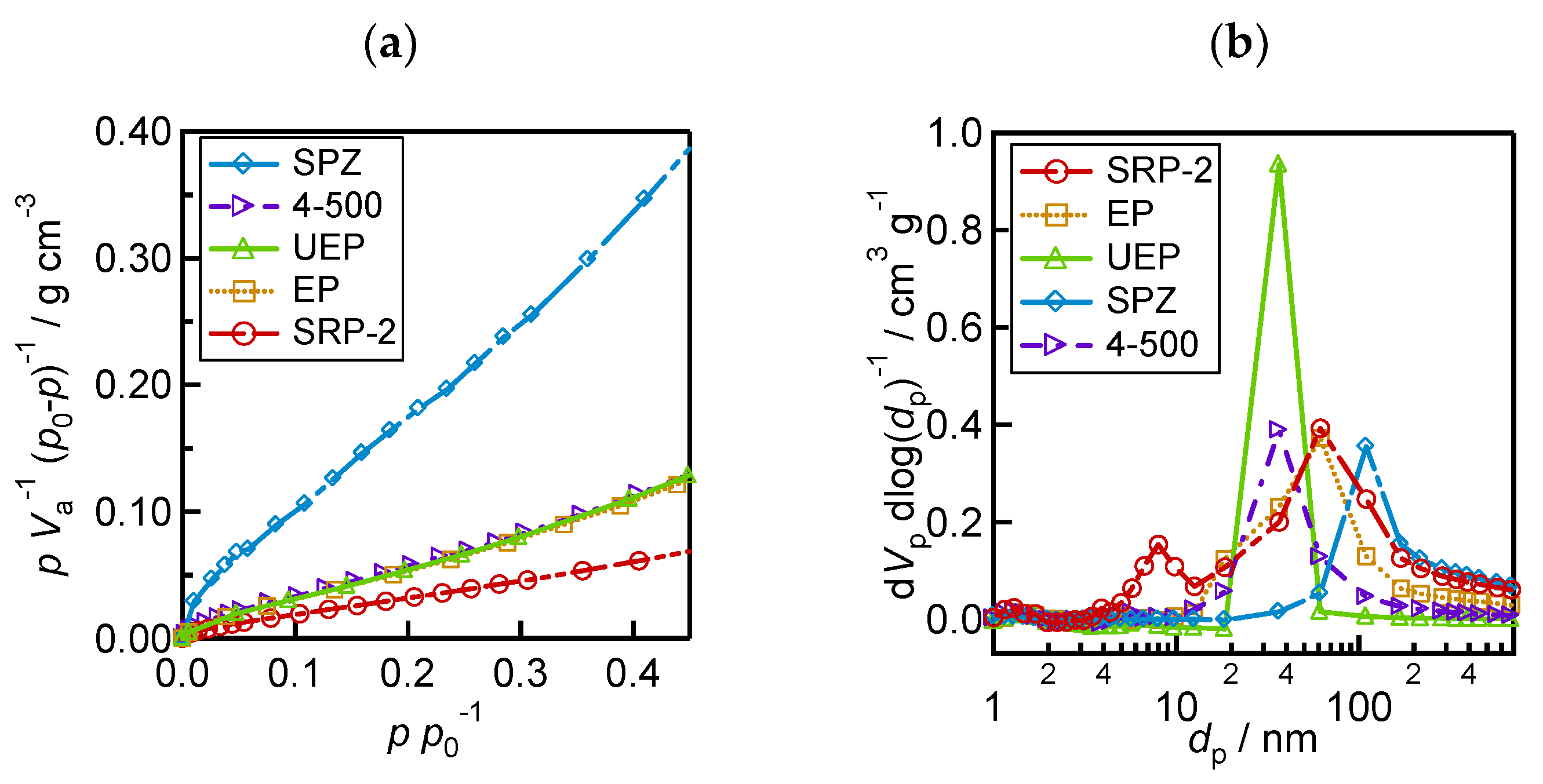

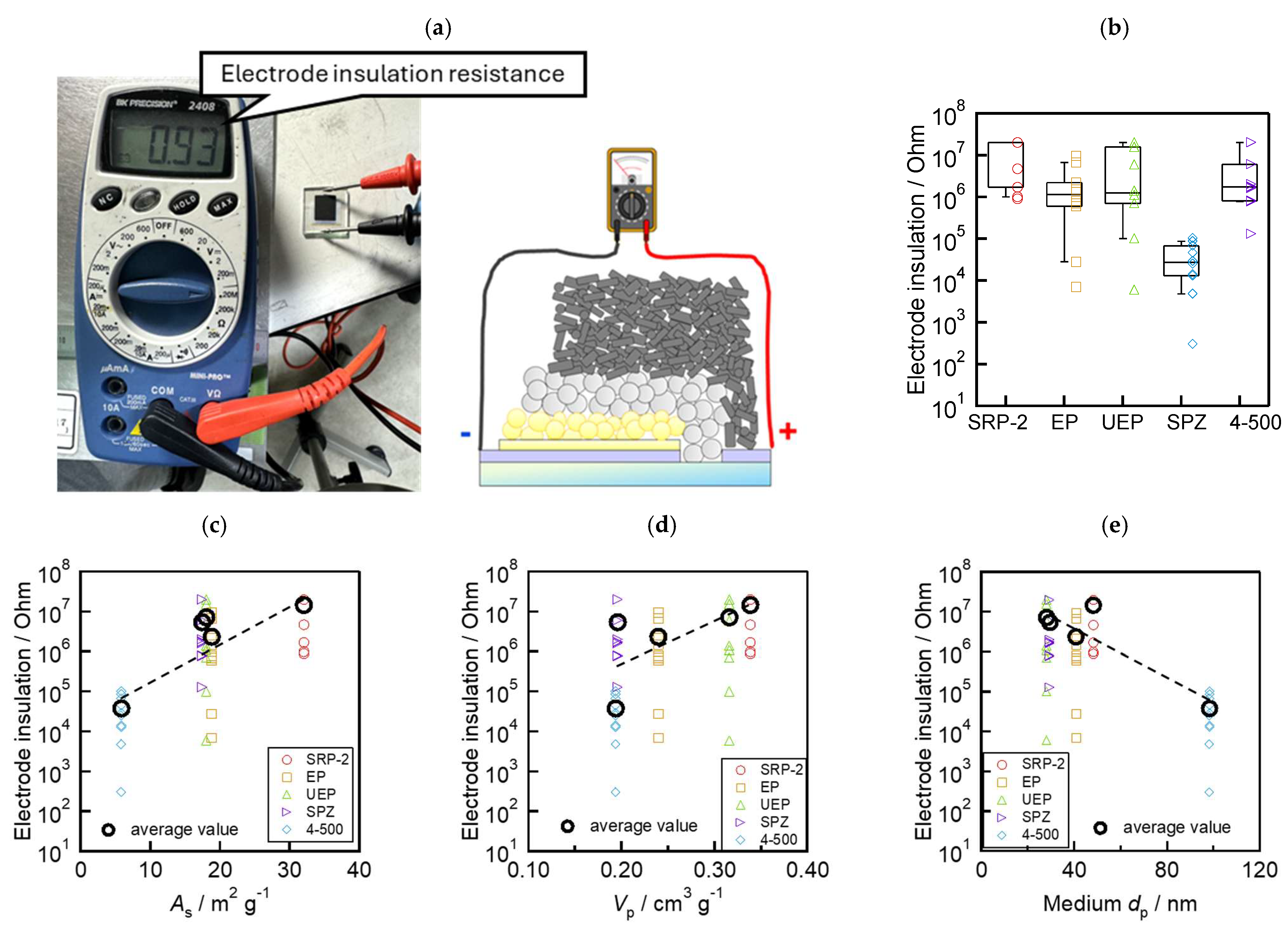

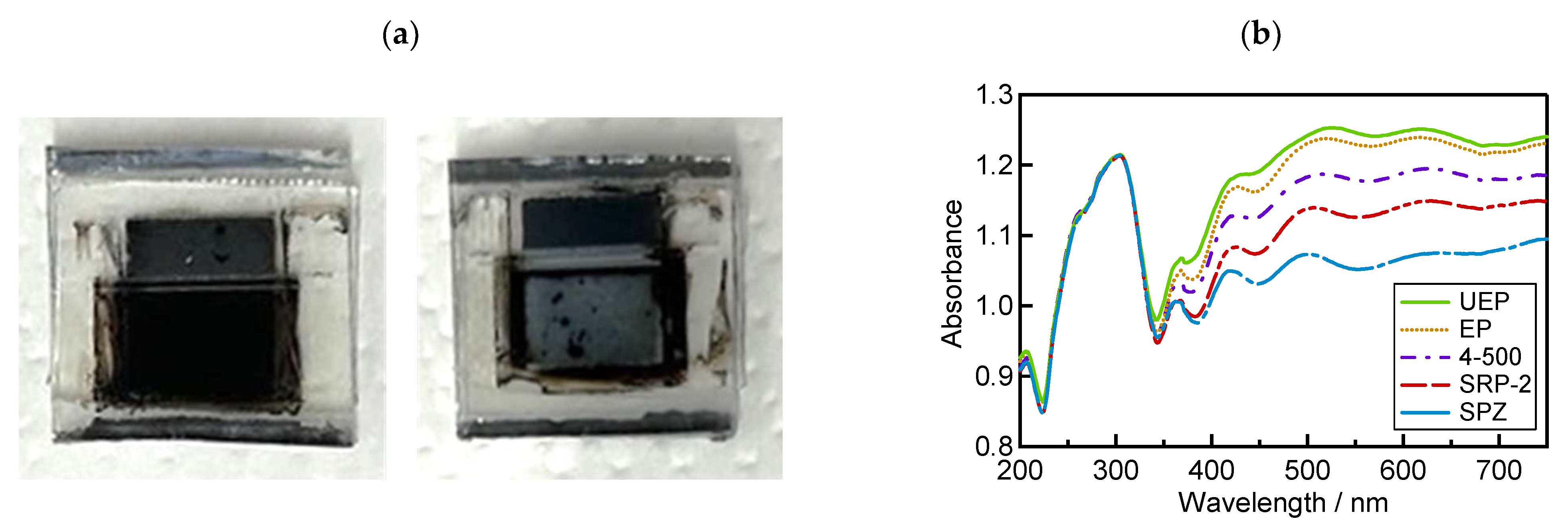

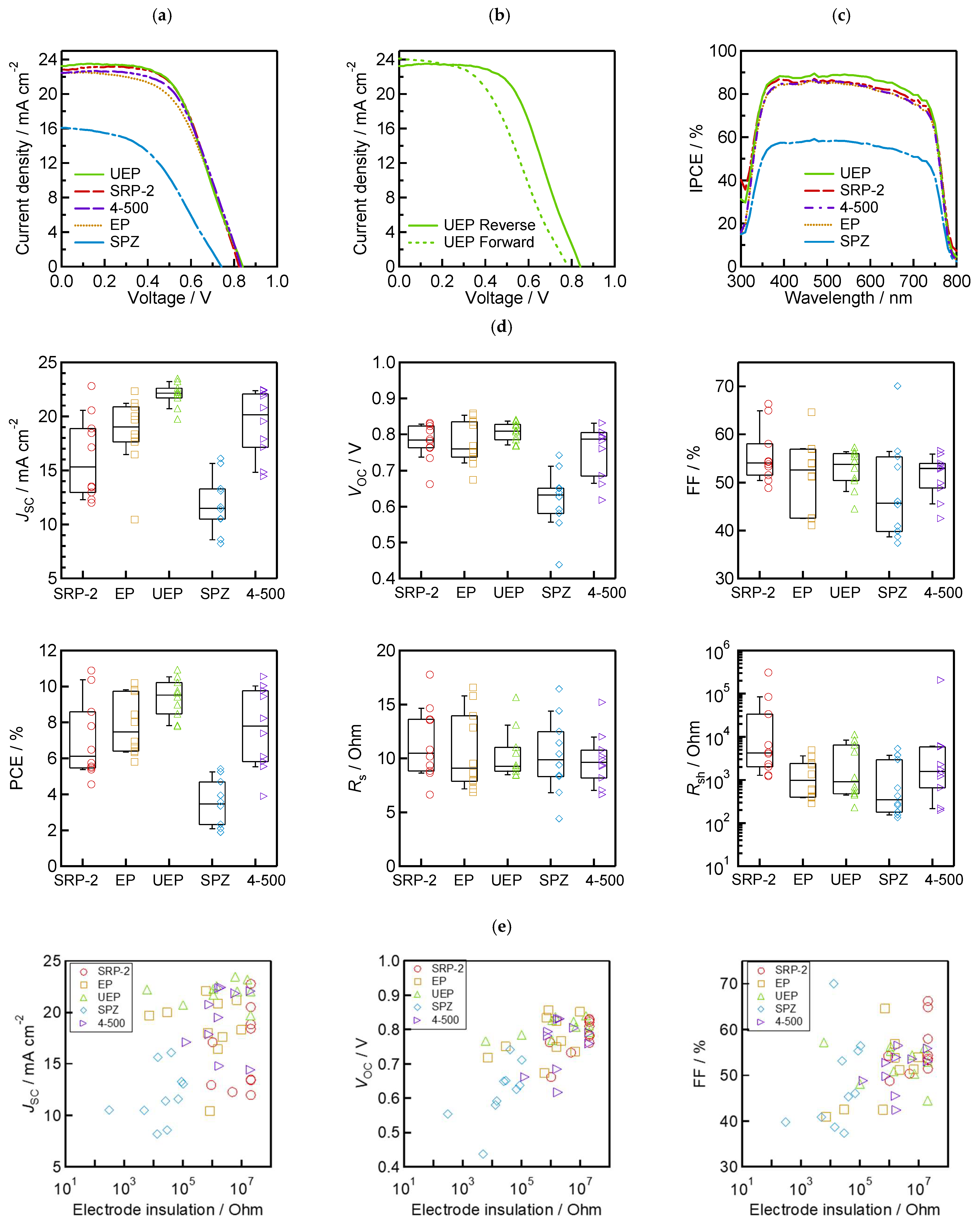

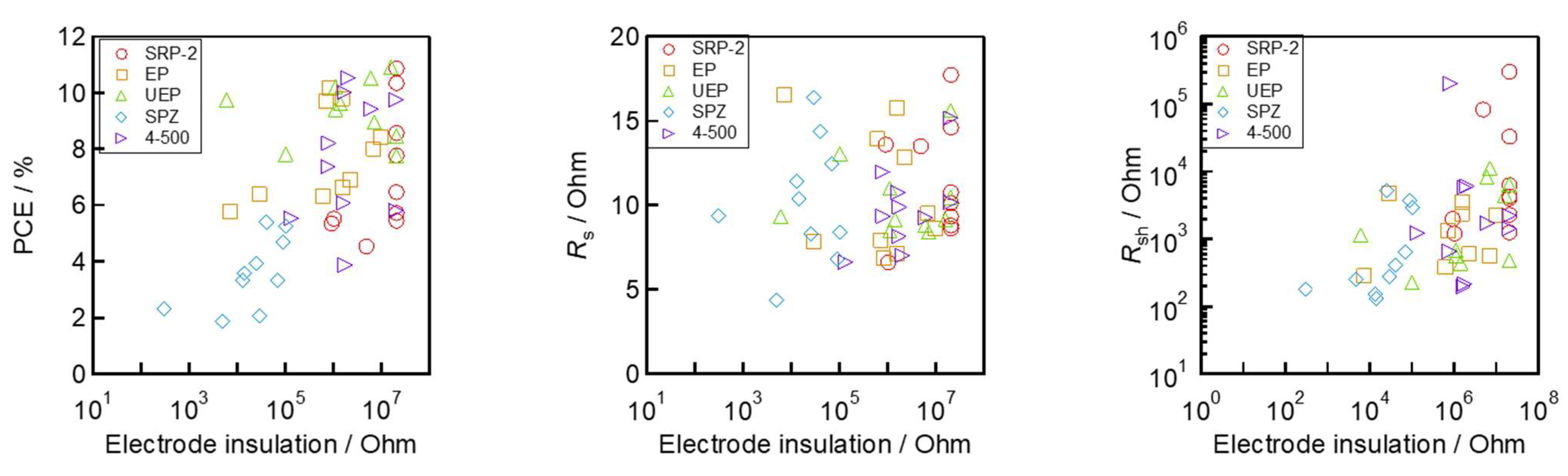

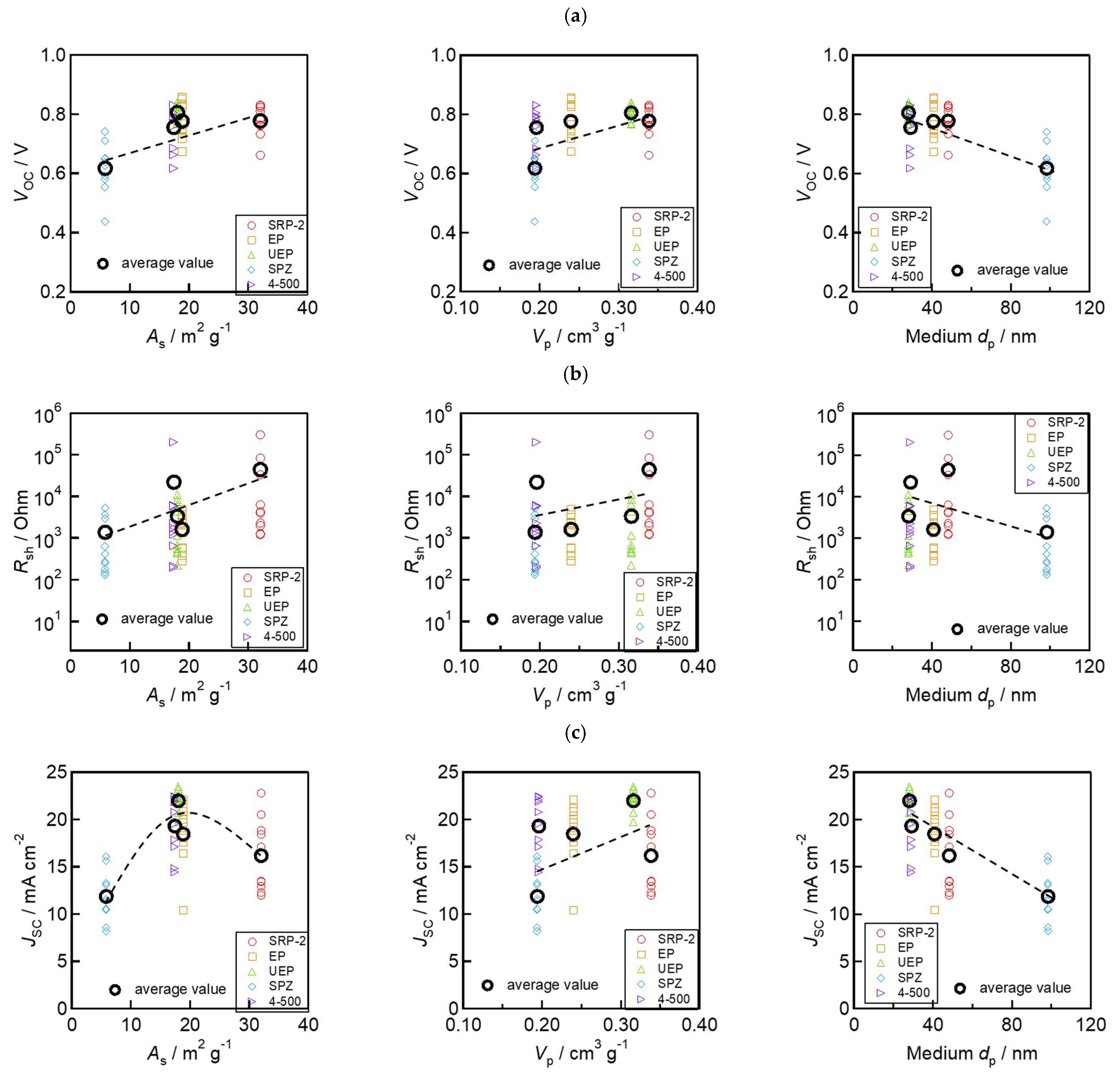

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PSCs | Perovskite solar cells |

| MPLE−PSCs | Multiporous layered electrode perovskite solar cells |

| FTO | Fluorine-doped tin oxide |

| SEM | Scanning electron microscope |

| BET | Brunauer–Emmett–Teller |

| BJH | Barrett–Joyner–Halenda |

| As | Specific surface area |

| Vp | Total pore volume |

| Medium dp | Medium pore diameter |

| PCE | Photoelectric conversion efficiency |

| JSC | Short-circuit current density |

| VOC | Open circuit voltage |

| FF | Fill factor |

| Rs | Series resistance |

| Rsh | Shunt resistance |

References

- Kojima, A.; Teshima, K.; Shirai, Y.; Miyasaka, T. Organometal Halide Perovskites as Visible-Light Sensitizers for Photovoltaic Cells. J. Am. Chem. Soc. 2009, 131, 6050–6051. [Google Scholar] [CrossRef] [PubMed]

- Arora, N.; Dar, M.I.; Abdi-Jalebi, M.; Giordano, F.; Pellet, N.; Jacopin, G.; Friend, R.H.; Zakeeruddin, S.M.; Grätzel, M. Intrinsic and Extrinsic Stability of Formamidinium Lead Bromide Perovskite Solar Cells Yielding High Photovoltage. Nano Lett. 2016, 16, 7155–7162. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Zhang, W.; Zhang, W.; Du, J.; Zhang, C.; Xu, G.; Mei, A.; Rong, Y.; Hu, Y.; Han, H. Cl-Assisted Perovskite Crystallization Pathway in the Confined Space of Mesoporous Metal Oxides Unveiled by in Situ Grazing Incidence Wide-Angle X-Ray Scattering. Chem. Mater. 2022, 34, 2231–2237. [Google Scholar] [CrossRef]

- Nakamura, T.; Yakumaru, S.; Truong, M.A.; Kim, K.; Liu, J.; Hu, S.; Otsuka, K.; Hashimoto, R.; Murdey, R.; Sasamori, T.; et al. Sn(IV)-free tin perovskite films realized by in situ Sn(0) nanoparticle treatment of the precursor solution. Nat. Commun. 2020, 11, 3008. [Google Scholar] [CrossRef] [PubMed]

- Ito, N.; Kamarudin, M.A.; Hirotani, D.; Zhang, Y.; Shen, Q.; Ogomi, Y.; Iikubo, S.; Minemoto, T.; Yoshino, K.; Hayase, S. Mixed Sn-Ge Perovskite for Enhanced Perovskite Solar Cell Performance in Air. J. Phys. Chem. Lett. 2018, 9, 1682–1688. [Google Scholar] [CrossRef] [PubMed]

- Jong, U.G.; Yu, C.J.; Kim, Y.S.; Kye, Y.H.; Kim, C.H. First-principles study on the material properties of the inorganic perovskite Rb1-XCsxPbI3 for solar cell applications. Phys. Rev. B 2018, 98, 125116. [Google Scholar] [CrossRef]

- Nam, J.K.; Chai, S.U.; Cha, W.; Choi, Y.J.; Kim, W.; Jung, M.S.; Kwon, J.; Kim, D.; Park, J.H. Potassium Incorporation for Enhanced Performance and Stability of Fully Inorganic Cesium Lead Halide Perovskite Solar Cells. Nano Lett. 2017, 17, 2028–2033. [Google Scholar] [CrossRef] [PubMed]

- Sun, H.; Zhang, J.; Gan, X.; Yu, L.; Yuan, H.; Shang, M.; Lu, C.; Hou, D.; Hu, Z.; Zhu, Y.; et al. Pb-Reduced CsPb0.9Zn0.1I2Br Thin Films for Efficient Perovskite Solar Cells. Adv. Energy Mater. 2019, 9, 1900896. [Google Scholar] [CrossRef]

- Bi, D.; Tress, W.; Dar, M.I.; Gao, P.; Luo, J.; Renevier, C.; Schenk, K.; Abate, A.; Giordano, F.; Correa Baena, J.P.; et al. Efficient luminescent solar cells based on tailored mixed-cation perovskites. Sci. Adv. 2016, 2, e1501170. [Google Scholar] [CrossRef] [PubMed]

- Jeon, N.J.; Noh, J.H.; Kim, Y.C.; Yang, W.S.; Ryu, S.; Seok, S. Il Solvent engineering for high-performance inorganic-organic hybrid perovskite solar cells. Nat. Mater. 2014, 13, 897–903. [Google Scholar] [CrossRef] [PubMed]

- Jeon, N.J.; Noh, J.H.; Yang, W.S.; Kim, Y.C.; Ryu, S.; Seo, J.; Seok, S., II. Compositional engineering of perovskite materials for high-performance solar cells. Nature 2015, 517, 476–480. [Google Scholar] [CrossRef] [PubMed]

- Lapotre, M.G.A.; Ewing, R.C.; Lamb, M.P.; Fischer, W.W.; Grotzinger, J.P.; Rubin, D.M.; Lewis, K.W.; Ballard, M.J.; Day, M.; Gupta, S.; et al. Large wind ripples on Mars: A record of atmospheric evolution. Science 2016, 353, 55–58. [Google Scholar] [CrossRef] [PubMed]

- Etgar, L.; Gao, P.; Xue, Z.; Peng, Q.; Chandiran, A.K.; Liu, B.; Nazeeruddin, M.K.; Grätzel, M. Mesoscopic CH3NH3PbI3/TiO2 Heterojunction Solar Cells. J. Am. Chem. Soc. 2012, 134, 17396–17399. [Google Scholar] [CrossRef] [PubMed]

- NREL Best Research-Cell PV Efficiency Chart. Available online: https://www.nrel.gov/pv/cell-efficiency.html (accessed on 17 February 2025).

- Lee, M.M.; Teuscher, J.; Miyasaka, T.; Murakami, T.N.; Snaith, H.J. Efficient Hybrid Solar Cells Based on Meso-Superstructured Organometal Halide Perovskites. Science 2012, 338, 643–647. [Google Scholar] [CrossRef] [PubMed]

- Liu, M.; Johnston, M.B.; Snaith, H.J. Efficient planar heterojunction perovskite solar cells by vapour deposition. Nature 2013, 501, 395–398. [Google Scholar] [CrossRef] [PubMed]

- Burschka, J.; Pellet, N.; Moon, S.J.; Humphry-Baker, R.; Gao, P.; Nazeeruddin, M.K.; Grätzel, M. Sequential deposition as a route to high-performance perovskite-sensitized solar cells. Nature 2013, 499, 316–319. [Google Scholar] [CrossRef] [PubMed]

- Heo, J.H.; Im, S.H.; Noh, J.H.; Mandal, T.N.; Lim, C.S.; Chang, J.A.; Lee, Y.H.; Kim, H.J.; Sarkar, A.; Nazeeruddin, M.K.; et al. Efficient inorganic-organic hybrid heterojunction solar cells containing perovskite compound and polymeric hole conductors. Nat. Photonics 2013, 7, 486–491. [Google Scholar] [CrossRef]

- Xing, G.; Mathews, N.; Sun, S.; Lim, S.S.; Lam, Y.M.; Grätzel, M.; Mhaisalkar, S.; Sum, T.C. Long-Range Balanced Electron- and Hole-Transport Lengths in Organic-Inorganic CH3NH3PbI3. Science 2013, 342, 344–347. [Google Scholar] [CrossRef] [PubMed]

- Noh, J.H.; Im, S.H.; Heo, J.H.; Mandal, T.N.; Seok, S., II. Chemical Management for Colorful, Efficient, and Stable Inorganic-Organic Hybrid Nanostructured Solar Cells. Nano Lett. 2013, 13, 1764–1769. [Google Scholar] [CrossRef] [PubMed]

- Eperon, G.E.; Stranks, S.D.; Menelaou, C.; Johnston, M.B.; Herz, L.M.; Snaith, H.J. Formamidinium lead trihalide: A broadly tunable perovskite for efficient planar heterojunction solar cells. Energy Environ. Sci. 2014, 7, 982–988. [Google Scholar] [CrossRef]

- Pang, S.; Hu, H.; Zhang, J.; Lv, S.; Yu, Y.; Wei, F.; Qin, T.; Xu, H.; Liu, Z.; Cui, G. NH2CH=NH2PbI3: An Alternative Organolead Iodide Perovskite Sensitizer for Mesoscopic Solar Cells. Chem. Mater. 2014, 26, 1485–1491. [Google Scholar] [CrossRef]

- Rong, Y.; Liu, L.; Mei, A.; Li, X.; Han, H. Beyond Efficiency: The Challenge of Stability in Mesoscopic Perovskite Solar Cells. Adv. Energy Mater. 2015, 5, 1501066. [Google Scholar] [CrossRef]

- Wang, Z.; Shi, Z.; Li, T.; Chen, Y.; Huang, W. Stability of Perovskite Solar Cells: A Prospective on the Substitution of the A Cation and X Anion. Angew. Chem. Int. Ed. 2017, 56, 1190–1212. [Google Scholar] [CrossRef] [PubMed]

- Ku, Z.; Rong, Y.; Xu, M.; Liu, T.; Han, H. Full Printable Processed Mesoscopic CH3NH3PbI3/TiO2 Heterojunction Solar Cells with Carbon Counter Electrode. Sci. Rep. 2013, 3, 3132. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.Q.; Wang, Q.; Fang, Y.; Shao, Y.; Tang, S.; Deng, Y.; Lu, H.; Liu, Y.; Li, T.; Yang, Z.; et al. Molecular doping enabled scalable blading of efficient hole-transport-layer-free perovskite solar cells. Nat. Commun. 2018, 9, 1625. [Google Scholar] [CrossRef] [PubMed]

- Hwang, K.; Jung, Y.S.; Heo, Y.J.; Scholes, F.H.; Watkins, S.E.; Subbiah, J.; Jones, D.J.; Kim, D.Y.; Vak, D. Toward large scale roll-to-roll production of fully printed perovskite solar cells. Adv. Mater. 2015, 27, 1241–1247. [Google Scholar] [CrossRef] [PubMed]

- Worsley, C.; Potts, S.J.; Hughes, D.; Tsoi, W.C.; Watson, T. Age-Induced Excellence with Green Solvents: The Impact of Residual Solvent and Post-Treatments in Screen-Printed Carbon Perovskite Solar Cells and Modules. Mater. Adv. 2024, 5, 4354–4365. [Google Scholar] [CrossRef]

- Liu, S.; Li, J.; Xiao, W.; Chen, R.; Sun, Z.; Zhang, Y.; Lei, X.; Hu, S.; Kober-Czerny, M.; Wang, J.; et al. Buried Interface Molecular Hybrid for Inverted Perovskite Solar Cells. Nature 2024, 632, 536–542. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Jiang, Y.; Xu, J.; Wang, D.; Ding, Z.; Zhu, T.; Chen, B.; Yang, Y.; Wei, M.; Guo, R.; et al. High-Efficiency and Thermally Stable FACsPbI3 Perovskite Photovoltaics. Nature 2024, 635, 82–88. [Google Scholar] [CrossRef] [PubMed]

- Thangavel, N.R.; Koh, T.M.; Chee, Z.Q.; Tay, D.J.J.; Lee, M.J.; Mhaisalkar, S.G.; Ager, J.W.; Mathews, N. Printable Low-Temperature Carbon for Highly Efficient and Stable Mesoscopic Perovskite Solar Cells. Energy Technol. 2022, 10, 2200559. [Google Scholar] [CrossRef]

- Park, S.J.; Eng, J.L.; Pethe, S.D.; Tay, D.J.J.; Yantara, N.; Mathews, N. Investigating the Effects of a High Boiling Point Solvent in Slot Die-Coated Halide Perovskite Solar Cells. ChemSusChem 2025, 18, e202402499. [Google Scholar] [CrossRef] [PubMed]

- Rana, P.J.S.; Febriansyah, B.; Koh, T.M.; Muhammad, B.T.; Salim, T.; Hooper, T.J.N.; Kanwat, A.; Ghosh, B.; Kajal, P.; Lew, J.H.; et al. Alkali Additives Enable Efficient Large Area (>55 cm2) Slot-Die Coated Perovskite Solar Modules. Adv. Funct. Mater. 2022, 32, 2113026. [Google Scholar] [CrossRef]

- Mei, A.; Li, X.; Liu, L.; Ku, Z.; Liu, T.; Rong, Y.; Xu, M.; Hu, M.; Chen, J.; Yang, Y.; et al. A hole-conductor–free, fully printable mesoscopic perovskite solar cell with high stability. Science 2014, 345, 295–298. [Google Scholar] [CrossRef] [PubMed]

- Kobayashi, E.; Tsuji, R.; Martineau, D.; Hinsch, A.; Ito, S. Light-induced performance increase of carbon-based perovskite solar module for 20-year stability. Cell Rep. Phys. Sci. 2021, 2, 100648. [Google Scholar] [CrossRef]

- Grancini, G.; Roldán-Carmona, C.; Zimmermann, I.; Mosconi, E.; Lee, X.; Martineau, D.; Narbey, S.; Oswald, F.; De Angelis, F.; Graetzel, M.; et al. One-Year stable perovskite solar cells by 2D/3D interface engineering. Nat. Commun. 2017, 8, 15684. [Google Scholar] [CrossRef] [PubMed]

- Baranwal, A.K.; Kanda, H.; Shibayama, N.; Masutani, H.; Peiris, T.A.N.; Kanaya, S.; Segawa, H.; Miyasaka, T.; Ito, S. Thermal Degradation Analysis of Sealed Perovskite Solar Cell with Porous Carbon Electrode at 100 °C for 7000 h. Energy Technol. 2019, 7, 245–252. [Google Scholar] [CrossRef]

- Liu, J.; Chen, X.; Chen, K.; Tian, W.; Sheng, Y.; Jiang, Y.; Zhang, D.; Liu, Y.; Qi, J.; Chen, K.; et al. Electron injection and defect passivation for high-efficiency mesoporous perovskite solar cells. Science 2024, 383, 1198–1204. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Zhang, Z.; Huang, T.; She, B.; Liu, B.; Chen, Y.; Wang, L.; Wu, C.; Xiong, J.; Huang, Y.; et al. Crystallization Kinetics Control Enabled by a Green Ionic Liquid Additive toward Efficient and Stable Carbon-Based Mesoscopic Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2022, 14, 9161–9171. [Google Scholar] [CrossRef] [PubMed]

- Srisamran, N.; Sudchanham, J.; Sriprachuabwong, C.; Srisawad, K.; Pakawatpanurut, P.; Lohawet, K.; Kumnorkaew, P.; Krajangsang, T.; Tuantranont, A. Enhanced Performance and Stability of Fully Printed Perovskite Solar Cells and Modules by Ternary Additives under High Humidity. Energy Fuels 2023, 37, 6049–6061. [Google Scholar] [CrossRef]

- Tao, Y.; Chen, Y.; Shao, W.; Zhu, W.; Guo, R.; Zhang, Z.; Huang, Y.; Xiong, J.; Xiang, D.; Wang, D.; et al. Natural molecule niacin enables printable carbon-based mesoscopic perovskite solar cells with 17.3% efficiency. J. Mater. Sci. Mater. Electron. 2024, 35, 930. [Google Scholar] [CrossRef]

- Keremane, K.S.; Prathapani, S.; Haur, L.J.; Bruno, A.; Priyadarshi, A.; Adhikari, A.V.; Mhaisalkar, S.G. Improving the Performance of Carbon-Based Perovskite Solar Modules (70 cm2) by Incorporating Cesium Halide in Mesoporous TiO2. ACS Appl. Energy Mater. 2021, 4, 249–258. [Google Scholar] [CrossRef]

- Cheng, Y.; Xiang, J.; Li, X.; Zhang, G.; Xia, M.; Han, C.; Zheng, Z.; Chen, L.; Chen, K.; Ma, Y.; et al. Wettability Sequence Optimization and Interface Strain Buffering in Triple Mesoporous Layer-Based Printable Perovskite Solar Cells for Enhanced Performance. Adv. Mater. 2025, 37, 2413151. [Google Scholar] [CrossRef] [PubMed]

- Qiu, Z.; Liu, J.; Han, C.; Wang, C.; Xiang, J.; Zheng, Z.; Xia, M.; Zhou, Y.; Mei, A.; Han, H. Decylammonium Sulfate Post-Treatment for Efficient Hole-Conductor-Free Printable Perovskite Solar Cells with Reduced Voltage Loss. Commun. Mater. 2024, 5, 221. [Google Scholar] [CrossRef]

- Xiang, J.; Cheng, Y.; Zhang, G.; Liu, Z.; Han, C.; Gao, Q.; Wang, C.; Xie, J.; Li, S.; Zhou, Z.; et al. Efficient Carbon-Based Hole-Conductor-Free Printable Mesoscopic Perovskite Solar Cells via a Multifunctional Fluorinated Molecule. Adv. Funct. Mater. 2024, 34, 2402816. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, D.; Sheng, Y.; Zhang, W.; Qin, Z.; Qin, M.; Li, S.; Wang, Y.; Gao, C.; Wang, Q.; et al. Highly oriented MAPbI3 crystals for efficient hole-conductor-free printable mesoscopic perovskite solar cells. Fundam. Res. 2022, 2, 276–283. [Google Scholar] [CrossRef] [PubMed]

- Ko, S.G.; Ryu, G., II; Kim, B.; Cha, G.J.; Ri, J.H.; Sonu, G.S.; Kim, U.C. Effects of Thiourea on the Perovskite Crystallization for Fully Printable Solar Cells. Sol. Energy Mater. Sol. Cells 2019, 196, 105–110. [Google Scholar] [CrossRef]

- Hashmi, S.G.; Martineau, D.; Li, X.; Ozkan, M.; Tiihonen, A.; Dar, M.I.; Sarikka, T.; Zakeeruddin, S.M.; Paltakari, J.; Lund, P.D.; et al. Air Processed Inkjet Infiltrated Carbon Based Printed Perovskite Solar Cells with High Stability and Reproducibility. Adv. Mater. Technol. 2017, 2, 1600183. [Google Scholar] [CrossRef]

- Meroni, S.; Mouhamad, Y.; De Rossi, F.; Pockett, A.; Baker, J.; Escalante, R.; Searle, J.; Carnie, M.; Jewell, E.; Oskam, G.; et al. Homogeneous and Highly Controlled Deposition of Low Viscosity Inks and Application on Fully Printable Perovskite Solar Cells. Sci. Technol. Adv. Mater. 2018, 19, 1–9. [Google Scholar] [CrossRef]

- Tsuji, R.; Bogachuk, D.; Martineau, D.; Wagner, L.; Kobayashi, E.; Funayama, R.; Matsuo, Y.; Mastroianni, S.; Hinsch, A.; Ito, S. Function of Porous Carbon Electrode during the Fabrication of Multiporous-Layered-Electrode Perovskite Solar Cells. Photonics 2020, 7, 133. [Google Scholar] [CrossRef]

- Tsuji, R.; Tanaka, K.; Oishi, K.; Shioki, T.; Satone, H.; Ito, S. Role and Function of Polymer Binder Thickeners in Carbon Pastes for Multiporous-Layered-Electrode Perovskite Solar Cells. Chem. Mater. 2023, 35, 8574–8589. [Google Scholar] [CrossRef]

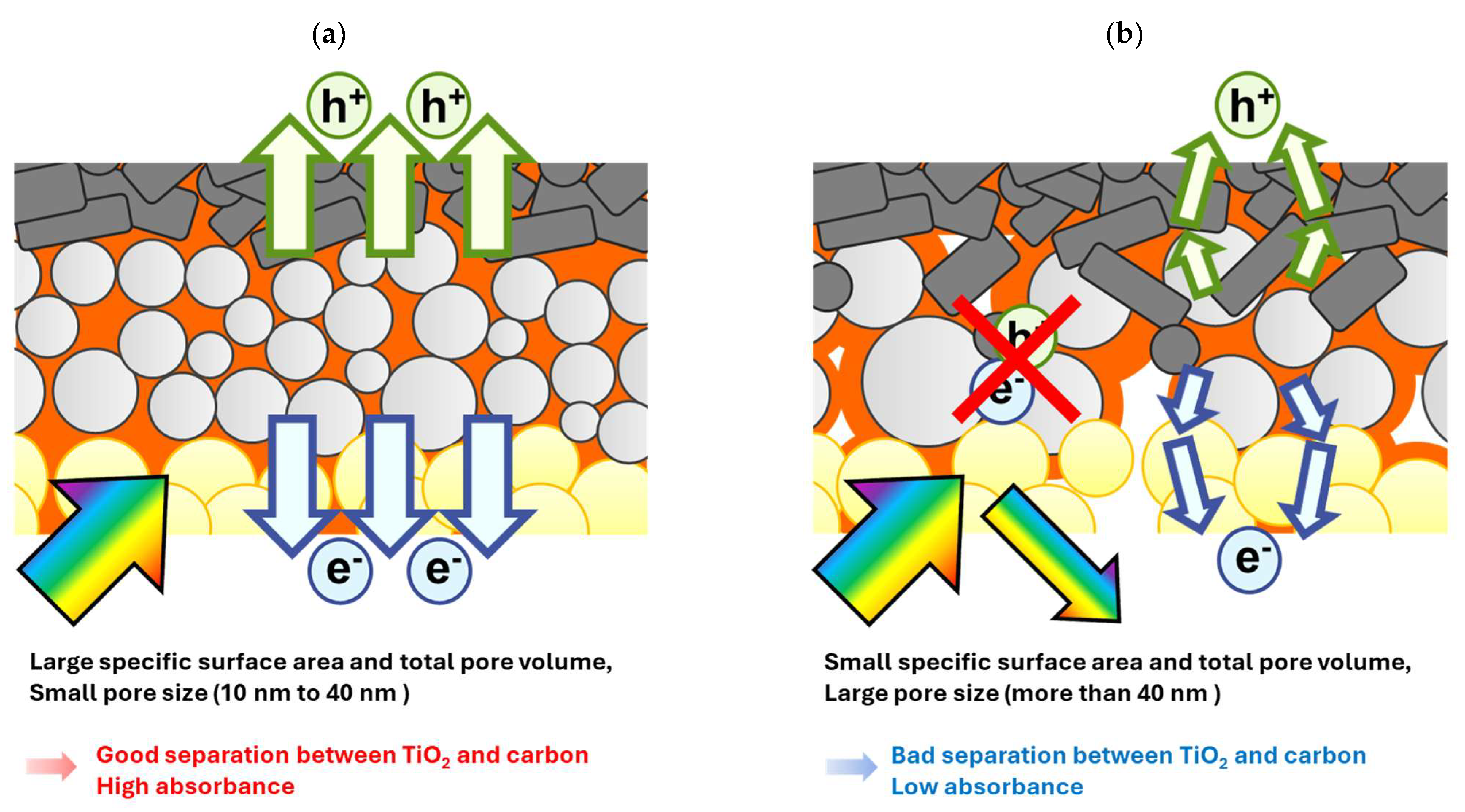

- Shioki, T.; Tsuji, R.; Oishi, K.; Fukumuro, N.; Ito, S. Designed Mesoporous Architecture by 10–100 nm TiO2 as Electron Transport Materials in Carbon-Based Multiporous-Layered-Electrode Perovskite Solar Cells. Photonics 2024, 11, 236. [Google Scholar] [CrossRef]

- Hu, Y.; Si, S.; Mei, A.; Rong, Y.; Liu, H.; Li, X.; Han, H. Stable Large-Area (10 × 10 cm2) Printable Mesoscopic Perovskite Module Exceeding 10% Efficiency. Solar RRL 2017, 1, 1600019. [Google Scholar] [CrossRef]

- Liu, T.; Xiong, Y.; Mei, A.; Hu, Y.; Rong, Y.; Xu, M.; Wang, Z.; Lou, L.; Du, D.; Zheng, S.; et al. Spacer layer design for efficient fully printable mesoscopic perovskite solar cells. RSC Adv. 2019, 9, 29840–29846. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Liu, S.; Ming, Y.; Guan, Y.; Li, D.; Zhang, C.; Wang, Z.; Rong, Y.; Hu, Y.; Han, H. Improvements in printable mesoscopic perovskite solar cells: Via thinner spacer layers. Sustain. Energy Fuels 2018, 2, 2412–2418. [Google Scholar] [CrossRef]

- Liu, T.; Liu, L.; Hu, M.; Yang, Y.; Zhang, L.; Mei, A.; Han, H. Critical parameters in TiO2/ZrO2/Carbon-based mesoscopic perovskite solar cell. J. Power Sources 2015, 293, 533–538. [Google Scholar] [CrossRef]

- Cao, K.; Zuo, Z.; Cui, J.; Shen, Y.; Moehl, T.; Zakeeruddin, S.M.; Grätzel, M.; Wang, M. Efficient screen printed perovskite solar cells based on mesoscopic TiO2/Al2O3/NiO/carbon architecture. Nano Energy 2015, 17, 171–179. [Google Scholar] [CrossRef]

- Liu, S.; Cao, K.; Li, H.; Song, J.; Han, J.; Shen, Y.; Wang, M. Full printable perovskite solar cells based on mesoscopic TiO2/Al2O3/NiO (carbon nanotubes) architecture. Solar Energy 2017, 144, 158–165. [Google Scholar] [CrossRef]

- Meng, Z.; Guo, D.; Yu, J.; Fan, K. Investigation of Al2O3 and ZrO2 spacer layers for fully printable and hole-conductor-free mesoscopic perovskite solar cells. Appl. Surf. Sci. 2018, 430, 632–638. [Google Scholar] [CrossRef]

- Cheng, N.; Liu, P.; Bai, S.; Yu, Z.; Liu, W.; Guo, S.S.; Zhao, X.Z. Application of mesoporous SiO2 layer as an insulating layer in high performance hole transport material free CH3NH3PbI3 perovskite solar cells. J. Power Sources 2016, 321, 71–75. [Google Scholar] [CrossRef]

- Liu, H.; Yang, B.; Chen, H.; Li, K.; Liu, G.; Yuan, Y.; Gao, Y.; Zhou, C. Efficient and stable hole-conductor-free mesoscopic perovskite solar cells using SiO2 as blocking layer. Org. Electron. 2018, 58, 69–74. [Google Scholar] [CrossRef]

- Bhandari, S.; Valsalakumar, S.; Ali, M.S.; Mallick, T.K.; Hinshelwood, J.; Sundaram, S. Influence of Adjustable CeO2 Morphology on the Performance of Ambient Hole Transport Layer-Free Carbon-Based Perovskite Solar Cells. Energy Fuels 2025, 39, 9566–9575. [Google Scholar] [CrossRef] [PubMed]

- Perrin, L.; Planes, E.; Shioki, T.; Tsuji, R.; Honore, J.C.; Farha, C.; Ito, S.; Flandin, L. How Ammonium Valeric Acid Iodide Additive Can Lead to More Efficient and Stable Carbon-Based Perovskite Solar Cells: Role of Microstructure and Interfaces? Solar RRL 2024, 8, 2400393. [Google Scholar] [CrossRef]

- Tsuji, R.; Shioki, T.; Izumoto, N.; Oshita, S.; Kondo, T.; Ito, S. Hysteresis in Carbon-Based Multiporous Layered Electrode Perovskite Solar Cells with 5-AVA-MAPbI3 and CsFAPbI3. ACS Energy Lett. 2025, 10, 1275–1283. [Google Scholar] [CrossRef]

- Ito, S.; Chen, P.; Comte, P.; Nazeeruddin, M.K.; Liska, P.; Péchy, P.; Grätzel, M. Fabrication of screen-printing pastes from TiO2 powders for dye-sensitised solar cells. Progress. Photovolt. Res. Appl. 2007, 15, 603–612. [Google Scholar] [CrossRef]

- Ito, S.; Takahashi, K. Fabrication of Monolithic Dye-Sensitized Solar Cell Using Ionic Liquid Electrolyte. Int. J. Photoenergy 2012, 2012, 915352. [Google Scholar] [CrossRef]

- Tsuji, R.; Bogachuk, D.; Luo, B.; Martineau, D.; Kobayashi, E.; Funayama, R.; Mastroianni, S.; Hinsch, A.; Ito, S. Activation of Weak Monochromic Photocurrents by White Light Irradiation for Accurate IPCE Measurements of Carbon-Based Multi-Porous-Layered-Electrode Perovskite Solar Cells. Electrochemistry 2020, 88, 418–422. [Google Scholar] [CrossRef]

| ZrO2 | Specific Surface Area: As [m2/g] | Total Pore Volume: Vp [cm3/g] | Medium Pore Diameter: dp [nm] |

|---|---|---|---|

| SRP−2 | 32.0 | 0.338 | 48.1 |

| EP | 18.8 | 0.239 | 40.7 |

| UEP | 18.0 | 0.316 | 28.0 |

| SPZ | 5.80 | 0.194 | 98.2 |

| 4−500 | 17.4 | 0.196 | 29.4 |

| ZrO2 | JSC [mA cm−2] | VOC [V] | FF [%] | PCE [%] | HI [%] | |

|---|---|---|---|---|---|---|

| SRP−2 | Reverse | 22.80 | 0.823 | 58.0 | 10.88 | 13.2 |

| Forward | 23.79 | 0.783 | 50.7 | 9.44 | ||

| EP | Reverse | 22.38 | 0.831 | 53.9 | 10.03 | 17.0 |

| Forward | 23.17 | 0.780 | 46.1 | 8.32 | ||

| UEP | Reverse | 23.22 | 0.840 | 56.0 | 10.92 | 22.8 |

| Forward | 24.10 | 0.783 | 44.7 | 8.43 | ||

| SPZ | Reverse | 16.08 | 0.741 | 45.3 | 5.40 | 17.2 |

| Forward | 16.54 | 0.700 | 38.6 | 4.47 | ||

| 4−500 | Reverse | 22.43 | 0.831 | 56.5 | 10.54 | 17.7 |

| Forward | 23.14 | 0.779 | 48.1 | 8.67 |

| ZrO2 | JSC [mA cm−2] | VOC [V] | FF [%] | PCE [%] |

|---|---|---|---|---|

| SRP−2 | 16.20 ± 3.85 | 0.778 ± 0.052 | 55.6 ± 5.9 | 7.08 ± 2.22 |

| EP | 18.48 ± 3.33 | 0.777 ± 0.062 | 51.5 ± 7.5 | 7.83 ± 1.63 |

| UEP | 22.00 ± 1.11 | 0.806 ± 0.027 | 52.6 ± 4.1 | 9.35 ± 1.08 |

| SPZ | 11.88 ± 2.66 | 0.618 ± 0.085 | 48.3 ± 10.4 | 3.58 ± 1.26 |

| 4−500 | 19.33 ± 3.10 | 0.756 ± 0.074 | 51.2 ± 4.5 | 7.67 ± 2.27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shioki, T.; Izumoto, N.; Iwakura, F.; Tsuji, R.; Ito, S. Insulation Ability and Morphological Effect of ZrO2 Spacer Layer in Carbon-Based Multiporous Layered Electrode Perovskite Solar Cells. Processes 2025, 13, 2264. https://doi.org/10.3390/pr13072264

Shioki T, Izumoto N, Iwakura F, Tsuji R, Ito S. Insulation Ability and Morphological Effect of ZrO2 Spacer Layer in Carbon-Based Multiporous Layered Electrode Perovskite Solar Cells. Processes. 2025; 13(7):2264. https://doi.org/10.3390/pr13072264

Chicago/Turabian StyleShioki, Takaya, Naonari Izumoto, Fumitaka Iwakura, Ryuki Tsuji, and Seigo Ito. 2025. "Insulation Ability and Morphological Effect of ZrO2 Spacer Layer in Carbon-Based Multiporous Layered Electrode Perovskite Solar Cells" Processes 13, no. 7: 2264. https://doi.org/10.3390/pr13072264

APA StyleShioki, T., Izumoto, N., Iwakura, F., Tsuji, R., & Ito, S. (2025). Insulation Ability and Morphological Effect of ZrO2 Spacer Layer in Carbon-Based Multiporous Layered Electrode Perovskite Solar Cells. Processes, 13(7), 2264. https://doi.org/10.3390/pr13072264