3.2. Shear and Elastic Moduli

Shear modulus measurements were conducted using the TA.XT Plus texture analyzer from SMS (

Figure 2), equipped with an HDP/WBV 60° V-shaped cutter for shear testing. The experimental data for the three materials are presented in

Figure 3. Based on the data in

Figure 3, the average shear moduli were calculated as follows: 1.19 MPa for diced chicken, 13.37 MPa for peanuts, and 7.88 MPa for diced scallions.

The relationship between the elastic modulus, Poisson’s ratio, and shear modulus is as follows:

where S is the shear modulus (MPa), E is the elastic modulus (MPa), and P is the Poisson’s ratio. P was taken as 0.450 for diced chicken, 0.362 for peanuts, and 0.360 for diced scallions. Based on this, the calculated elastic moduli were 3.45 MPa for diced chicken, 36.42 MPa for peanuts, and 21.43 MPa for diced scallions.

The static friction coefficient was determined using the inclined plane method [

27]. The experimental setup is shown in

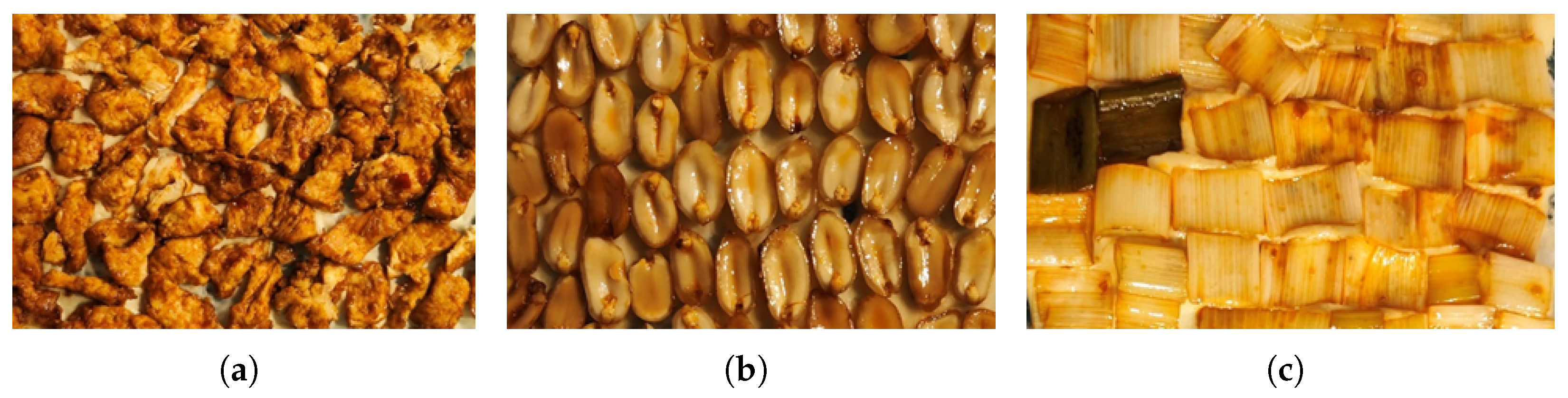

Figure 4a, which consisted of an angle control wheel, protractor, inclined platform, and sheet of coordinate paper. The experiment involved placing the test surface on an inclined platform, positioning the material to be tested on the surface, and slowly adjusting the angle of inclination. A high-frame-rate camera was used to record the motion of the material, and the angle of the surface at which the material began to slide was measured. The experiment used diced chicken, peanuts, and diced scallions as the test materials, with PMMA, diced chicken cluster boards, peanut cluster boards, and diced scallion cluster boards as the test surfaces, as shown in

Figure 5.

The experiment was conducted on the inclined plane testing platform shown in

Figure 4a, with a total of 12 sets of measurements, and 20 measurements per set. The static friction coefficient was calculated using the following equations, and the average value was taken from the results:

where

is the reaction force of the friction between the test material and the test surface (N),

is the pressure exerted by the test material on the test surface (N),

G is the gravitational force acting on the test material (N),

f is the frictional force between the test material and the test surface (N),

N is the supporting force exerted by the test surface on the test material (N),

is the coefficient of friction between the test surface and the test material, and

is the critical angle at which sliding occurred.

In the EDEM static friction test shown in

Figure 4b, all the contact coefficients except for static friction were set to 0. The accurate sliding angle (

) was used as the independent variable, and the static friction coefficient was the test variable. The range of the static friction coefficient was set between 0.1 and 0.5, with an interval of 0.05. A total of 12 sets of simulation tests were performed, with each set repeated 10 times, and the average value was taken. Data fitting was used to determine the relationship between the static friction coefficient (

) and the critical sliding angle (

).

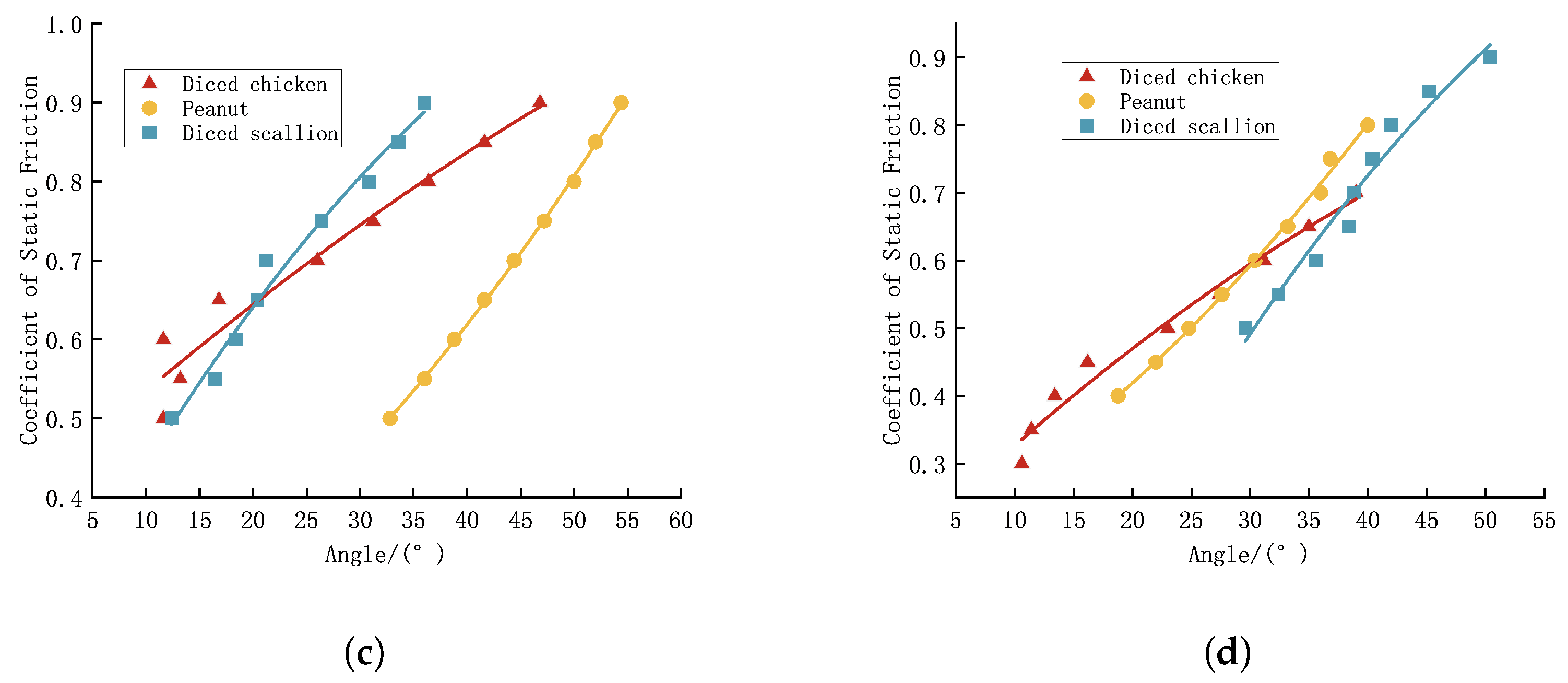

3.2.1. Poly(methyl methacrylate) (PMMA) Board Experiment and Simulation Results

The average sliding friction angles for the three different test materials were as follows: 18.6° for diced chicken, 25.8° for peanuts, and 46.1° for diced scallions. The corresponding average static friction coefficients between the three materials and the PMMA board were as follows: 0.337 for diced chicken, 0.483 for peanuts, and 1.039 for diced scallions.

In the EDEM simulation experiments, the following fitted equations for diced chicken, peanuts, and diced scallions were, respectively, obtained, with the corresponding fitting curves displayed in

Figure 6a:

When the sliding friction angles were set to 18.6° for diced chicken, 25.8° for peanuts, and 46.1° for diced scallions, the friction coefficients between the test materials and the PMMA board were calculated as 0.308 for diced chicken, 0.448 for peanuts, and 0.789 for diced scallions.

3.2.2. Diced Chicken Cluster Board Experiment and Simulation Results

The average sliding friction angles for the three different test materials were as follows: 51.0° for diced chicken, 34.0° for peanuts, and 38.8° for diced scallions. The corresponding average static friction coefficients between the three materials and the diced chicken cluster board were 1.234 for diced chicken, 0.675 for peanuts, and 0.804 for diced scallions.

In the EDEM simulation experiments, the following fitted equations for diced chicken, peanuts, and diced scallions were, respectively, obtained with the corresponding fitting curves displayed in

Figure 6b:

When the sliding friction angles were set to 51.0° for diced chicken, 34.0° for peanuts, and 38.8° for diced scallions, the friction coefficients between the test materials and the diced chicken cluster board were calculated as 0.758 for diced chicken, 0.667 for peanuts, and 0.768 for diced scallions.

3.2.3. Peanut Cluster Board Experiment and Simulation Results

The average sliding friction angles for the three different test materials were as follows: 41.6° for diced chicken, 43° for peanuts, and 41.8° for diced scallions. The corresponding average static friction coefficients for the three materials were 0.888 for diced chicken, 0.933 for peanuts, and 0.894 for diced scallions.

In the EDEM simulation experiments, the following fitted equations for diced chicken, peanuts, and diced scallions were, respectively, obtained with the corresponding fitting curves presented in

Figure 6c:

When the sliding friction angles were set to 41.6° for diced chicken, 43° for peanuts, and 41.8° for diced scallions, the friction coefficients between the test materials and the peanut cluster board were calculated as 0.851 for diced chicken, 0.673 for peanuts, and 0.944 for diced scallions.

3.2.4. Diced Scallion Cluster Board Experiment and Simulation Results

The average sliding friction angles for the three different test materials were as follows: 30.6° for diced chicken, 36.6° for peanuts, and 44.2° for diced scallions. The corresponding average static friction coefficients for the three materials were 0.591 for diced chicken, 0.743 for peanuts, and 0.972 for diced scallions.

In the EDEM simulation experiments, the following fitted equations for diced chicken, peanuts, and diced scallions were, respectively, obtained with the corresponding fitting curves displayed in

Figure 6d:

When the sliding friction angles were set to 30.6° for diced chicken, 36.6° for peanuts, and 44.2° for diced scallions, the friction coefficients between the test materials and the diced scallion cluster board were calculated as 0.602 for diced chicken, 0.727 for peanuts, and 0.809 for diced scallions.

3.2.5. Static Friction Coefficient Calibration Conclusions

The results of the experimental and simulation calibration showed that the static friction coefficients between the PMMA board and the diced chicken, peanuts, and diced scallions were 0.308, 0.448, and 0.789, respectively. The static friction coefficients between the diced chicken, peanuts, and diced scallions were as follows: 0.758 for diced chicken, 0.673 for peanuts, and 0.809 for diced scallions.

Two friction coefficient values were measured for each material pair, and the results are shown in

Table 2. The pairs with smaller relative errors are indicated with an asterisk. The static friction coefficients with the minimum errors compared to the actual experimental measurements were selected and are shown as follows:

Diced chicken–Peanuts: 0.667

Diced chicken–Diced scallions: 0.602

Peanuts–Diced scallions: 0.727

3.3. Rolling Friction Coefficient

The rolling friction coefficient was determined using the rolling distance method [

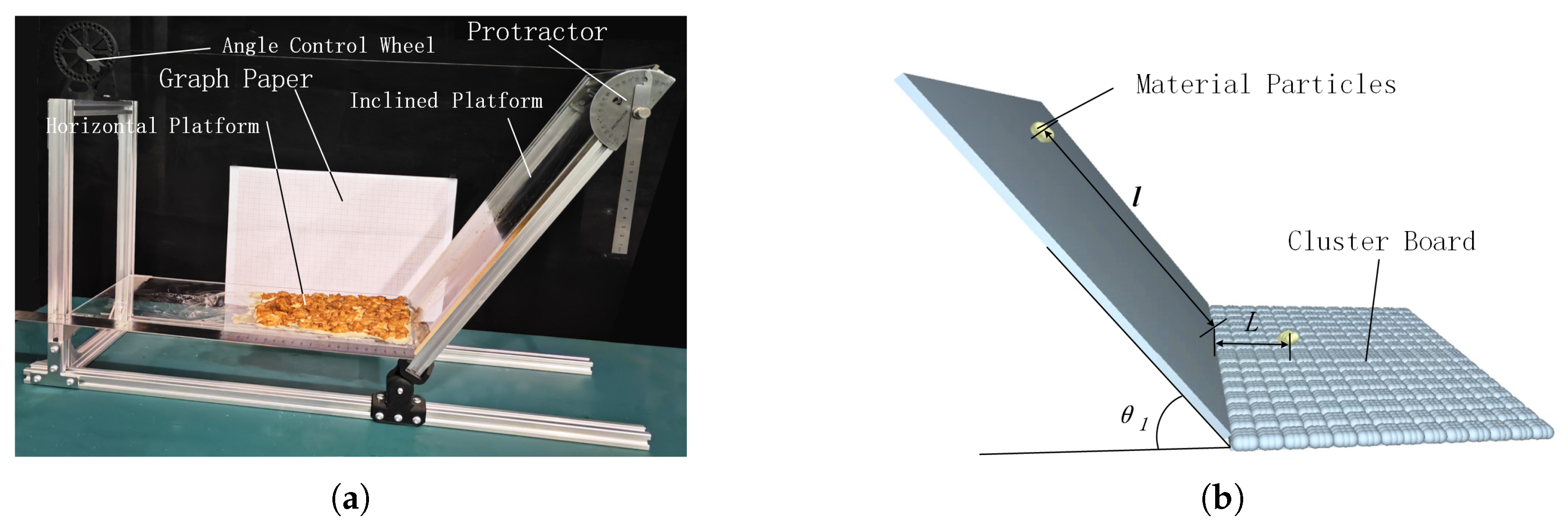

28]. The experimental setup shown in

Figure 7 consisted of an angle control wheel, protractor, flat platform, inclined platform, and sheet of coordinate paper. The experiment involved placing the test surface on the flat platform, positioning the material to be tested on the inclined platform at a specified angle and distance, and recording the rolling process and distance of the material using a high-frame-rate camera. The rolling friction coefficient between the material and the surface was then calculated. Diced chicken, peanuts, and diced scallions were used as test materials, while PMMA, diced chicken cluster boards, peanut cluster boards, and diced scallion cluster boards were used as test surfaces.

After multiple preliminary experiments, the actual experimental parameters were set to

= 60° and

l = 200 mm. A total of 12 sets of measurements were conducted, with 20 measurements per set. The rolling friction coefficient was calculated using the following equation, and the average value was taken:

where

G is the gravitational force on the test material (N),

l is the linear distance from the test material to the base of the inclined plane (mm),

is the angle between the inclined plane and the horizontal surface (°),

L is the rolling distance of the test material on the flat surface (mm), and

is the rolling friction coefficient of the test material.

The EDEM rolling friction test, as shown in

Figure 7b, involved setting all the contact coefficients to 0 except for the rolling friction coefficient and the static friction coefficient. The sliding distance

L on the plane was used as the test indicator, with the rolling friction coefficient as the test variable. The rolling friction coefficient ranged from 0.02 to 0.40, with an interval of 0.02, and 10 points were taken for each set. A total of 12 simulation tests were performed, each repeated 10 times, and the average value was calculated. Data fitting was used to determine the relationship between the static friction coefficient

and the sliding distance

L.

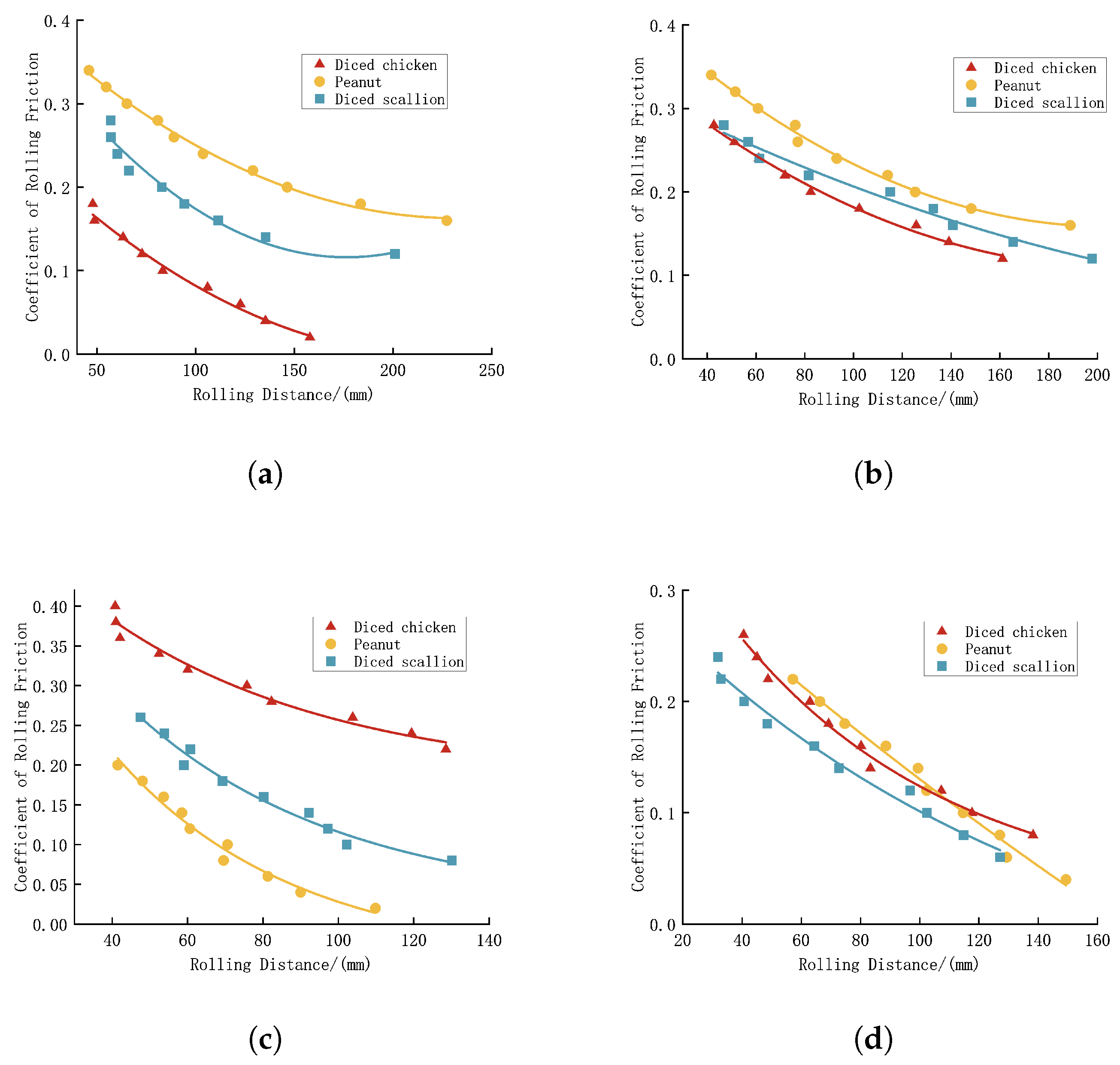

3.3.1. PMMA Board Experiment and Simulation Results

The average rolling distances for the three different test materials were as follows: 135.3 mm for diced chicken, 121.1 mm for peanuts, and 104 mm for diced scallions. The corresponding average static friction coefficients between the three materials and the PMMA board were 0.045 for diced chicken, 0.227 for peanuts, and 0.163 for diced scallions.

In the EDEM simulation experiments, the following fitted equations for diced chicken, peanuts, and diced scallions were, respectively, obtained, with the corresponding fitting curves presented in

Figure 8a:

When the sliding distances were set to 135.3 mm for diced chicken, 121.1 mm for peanuts, and 104 mm for diced scallions, the friction coefficients between the test materials and the PMMA board were calculated as 0.042 for diced chicken, 0.224 for peanuts, and 0.159 for diced scallions.

3.3.2. Diced Chicken Cluster Board Experiment and Simulation Results

The average rolling distances for the three different test materials were as follows: 88.5 mm for diced chicken, 98.5 mm for peanuts, and 111.3 mm for diced scallions. The corresponding average static friction coefficients between the three materials and the diced chicken cluster board were 0.161 for diced chicken, 0.247 for peanuts, and 0.189 for diced scallions.

In the EDEM simulation experiments, the following fitted equations for the diced chicken, peanuts, and diced scallions were, respectively, derived with the corresponding fitting curves presented in

Figure 8b:

When the sliding distances were set to 88.5 mm for diced chicken, 98.5 mm for peanuts, and 111.3 mm for diced scallions, the friction coefficients between the test materials and the diced chicken cluster board were calculated as 0.196 for diced chicken, 0.235 for peanuts, and 0.191 for diced scallions.

3.3.3. Peanut Cluster Board Experiment and Simulation Results

The average rolling distances for the three different test materials were as follows: 92 mm for diced chicken, 94 mm for peanuts, and 122.5 mm for diced scallions. The corresponding average static friction coefficients between the three materials and the peanut cluster board were 0.251 for diced chicken, 0.154 for peanuts, and 0.083 for diced scallions.

In the EDEM simulation experiments, the following fitted equations for diced chicken, peanuts, and diced scallions were, respectively, derived with the corresponding fitting curves presented in

Figure 8c:

When the sliding distances were set to 92 mm for diced chicken, 94 mm for peanuts, and 122.5 mm for diced scallions, the friction coefficients between the test materials and the peanut cluster board were calculated as follows: 0.262 for diced chicken, 0.146 for peanuts, and 0.085 for diced scallions.

3.3.4. Diced Scallion Cluster Board Experiment and Simulation Results

The average rolling distances for the three different test materials were as follows: 88.5 mm for diced chicken, 112.5 mm for peanuts, and 111.7 mm for diced scallions. The corresponding average static friction coefficients between the three materials and the diced scallion cluster board were as follows: 0.137 for diced chicken, 0.096 for peanuts, and 0.071 for diced scallions.

In the EDEM simulation experiments, the following fitted equations for the diced chicken, peanuts, and diced scallions were, respectively, obtained with the corresponding fitting curves presented in

Figure 8d:

When the sliding distances were set to 88.5 mm for diced chicken, 112.5 mm for peanuts, and 111.7 mm for diced scallions, the friction coefficients between the test materials and the diced scallion cluster board were calculated as 0.141 for diced chicken, 0.103 for peanuts, and 0.085 for diced scallions.

3.3.5. Rolling Friction Coefficient Calibration Conclusions

The results of the experimental and simulation calibration showed that the dynamic friction coefficients between the PMMA board and the diced chicken, peanuts, and diced scallions were 0.042, 0.224, and 0.159, respectively. The dynamic friction coefficients between the diced chicken, peanuts, and diced scallions were 0.196 for diced chicken, 0.146 for peanuts, and 0.085 for diced scallions.

Two friction coefficient values were measured for each material pair, and the results are summarized in

Table 3. Pairs with smaller relative errors are marked with an asterisk. The static friction coefficients selected, based on the minimal error compared with the actual experimental measurements, were as follows:

Diced chicken–Peanuts: 0.247

Diced chicken–Diced scallions: 0.189

Peanuts–Diced scallions: 0.083

3.4. Coefficient of Restitution

The coefficient of restitution was determined using the rebound height method [

29,

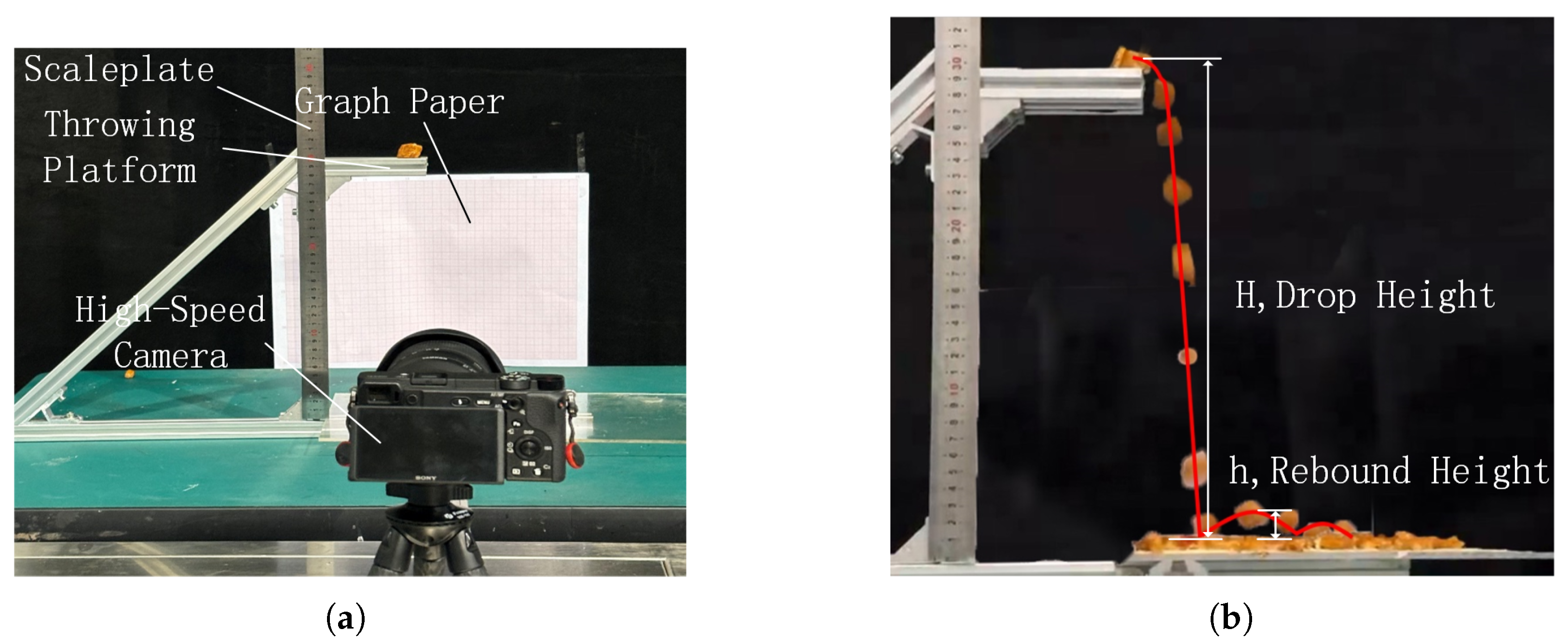

30]. The experimental setup, as shown in

Figure 9, consisted of a support stand, drop platform, flat platform, sheet of coordinate paper, and high-speed camera. The experiment involved placing the test surface on the flat platform, positioning the test material on the drop platform, and recording the drop process using a high-frame-rate camera. The coefficient of restitution between the material and the test surface was then calculated. Diced chicken, peanuts, and diced scallions were used as test materials, with PMMA, diced chicken cluster boards, peanut cluster boards, and diced scallion cluster boards used as the test surfaces.

After multiple preliminary experiments, the drop height was set to

H = 300 mm. A total of 12 sets of measurements were conducted, with 20 measurements per set. The coefficient of restitution was calculated as follows, and the average value was taken:

where

e is the coefficient of restitution,

is the relative velocity during rebound (mm/s),

is the relative velocity during impact (mm/s), g is the acceleration due to gravity (m/

),

h is the maximum rebound height (mm), and

H is the drop height (mm).

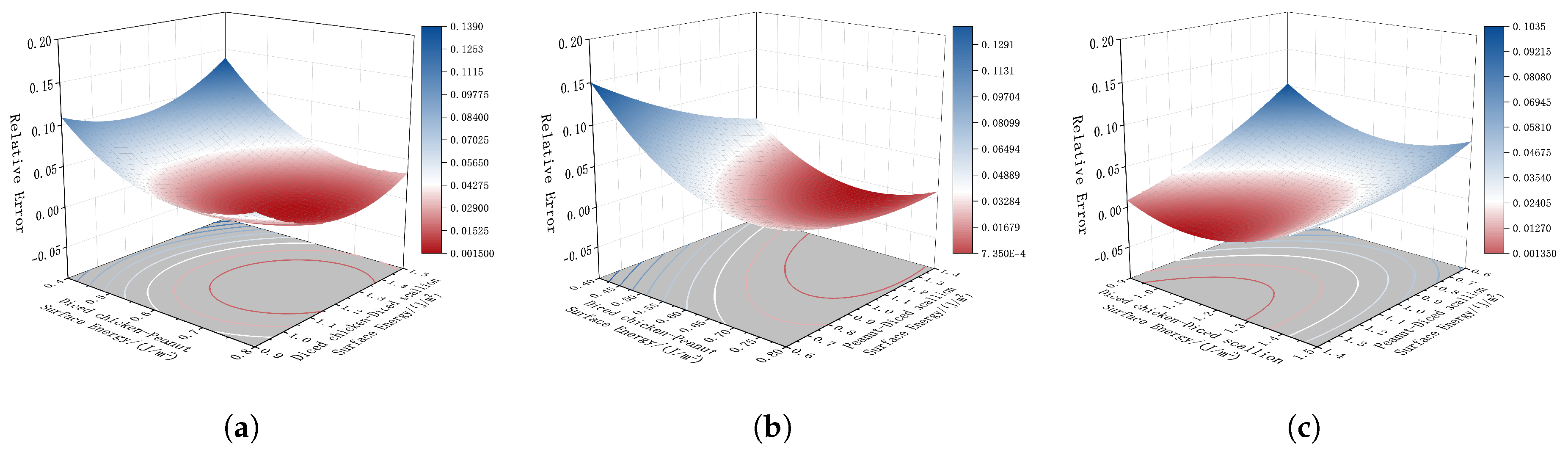

In the EDEM rebound height tests, the rolling friction coefficients and static friction coefficients were set according to the calibration results from

Section 3.3 and

Section 3.4, respectively. The maximum rebound height

h was used as the test indicator, with the coefficient of restitution as the test variable. Ten points were taken for each group. A total of nine simulation tests were performed, with each set repeated 10 times, and the average value was calculated. Data fitting was used to determine the relationship between the coefficient of restitution

e and the maximum rebound height

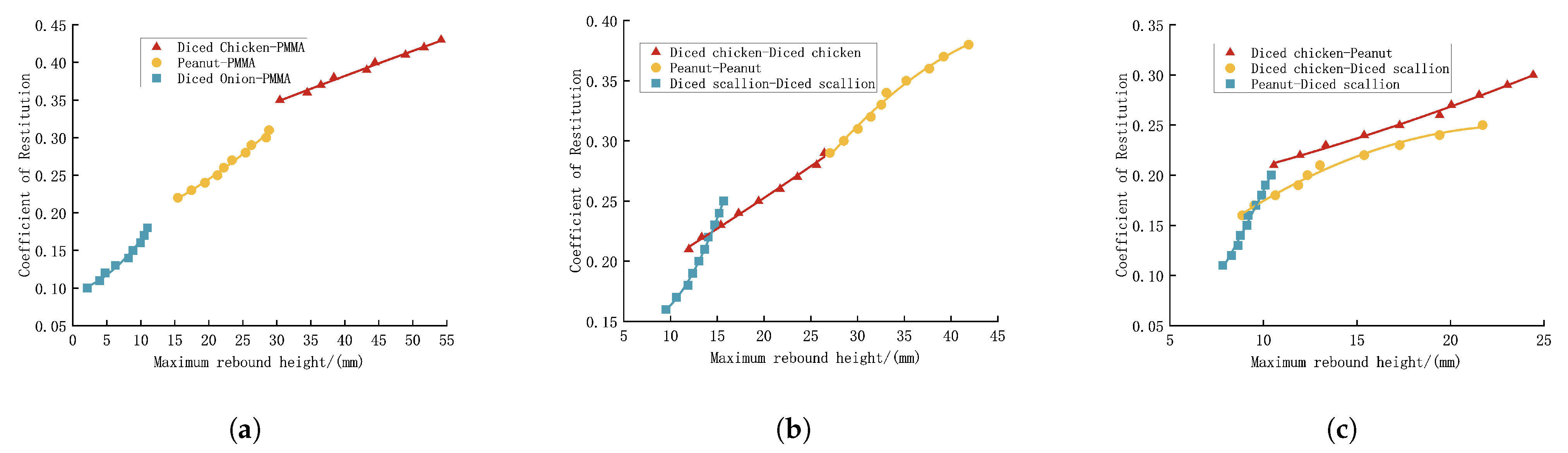

h. The fitting curves shown in

Figure 10 corresponded to the following equations. The results are summarized in

Table 4.