Challenges and Prospects of Enhanced Oil Recovery Using Acid Gas Injection Technology: Lessons from Case Studies

Abstract

1. Introduction

2. Gas Injection Fundamentals and Controlling Factors

2.1. Displacement Mechanisms

2.2. Phase Behavior and Minimum Miscibility Pressure (MMP)

2.3. Reservoir Properties

2.4. Geochemical and Geomechanical Interactions

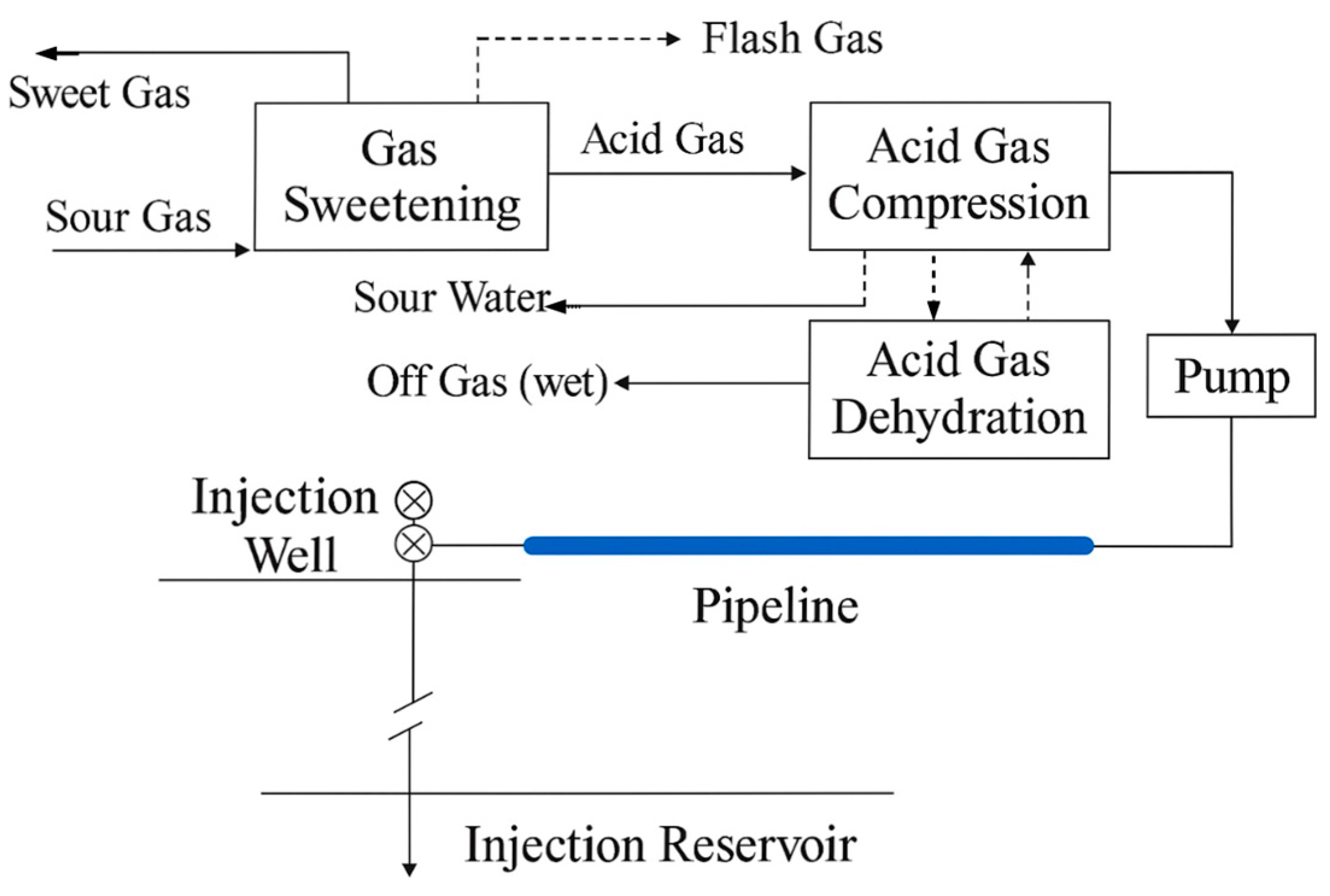

2.5. Operational Considerations

3. Case Studies

3.1. Acid Gas Injection in Western Canada (Alberta Basin)

3.2. Expansion of the Strasshof Tief Sour Gas Reservoir

3.3. Sour Gas Injection in Oman

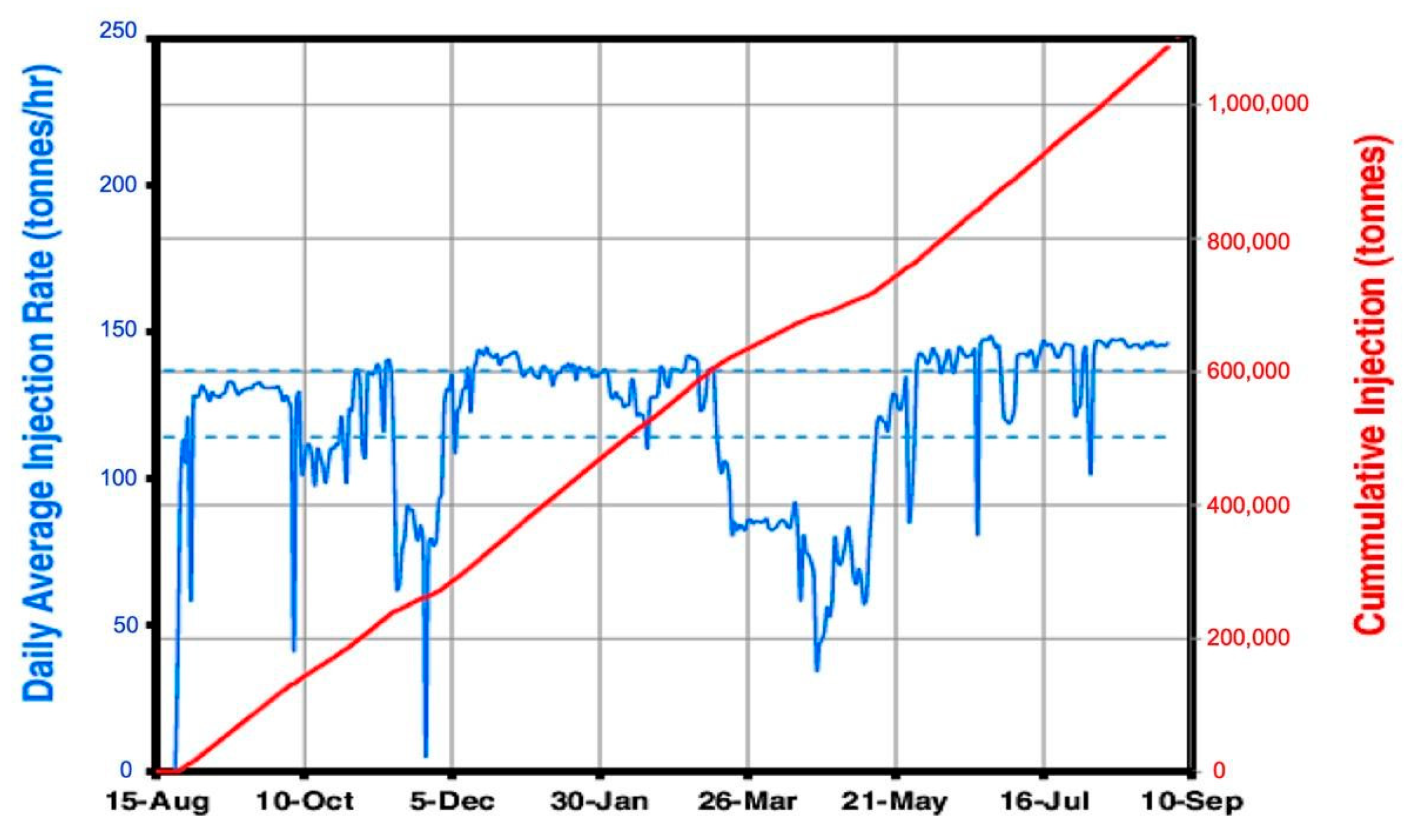

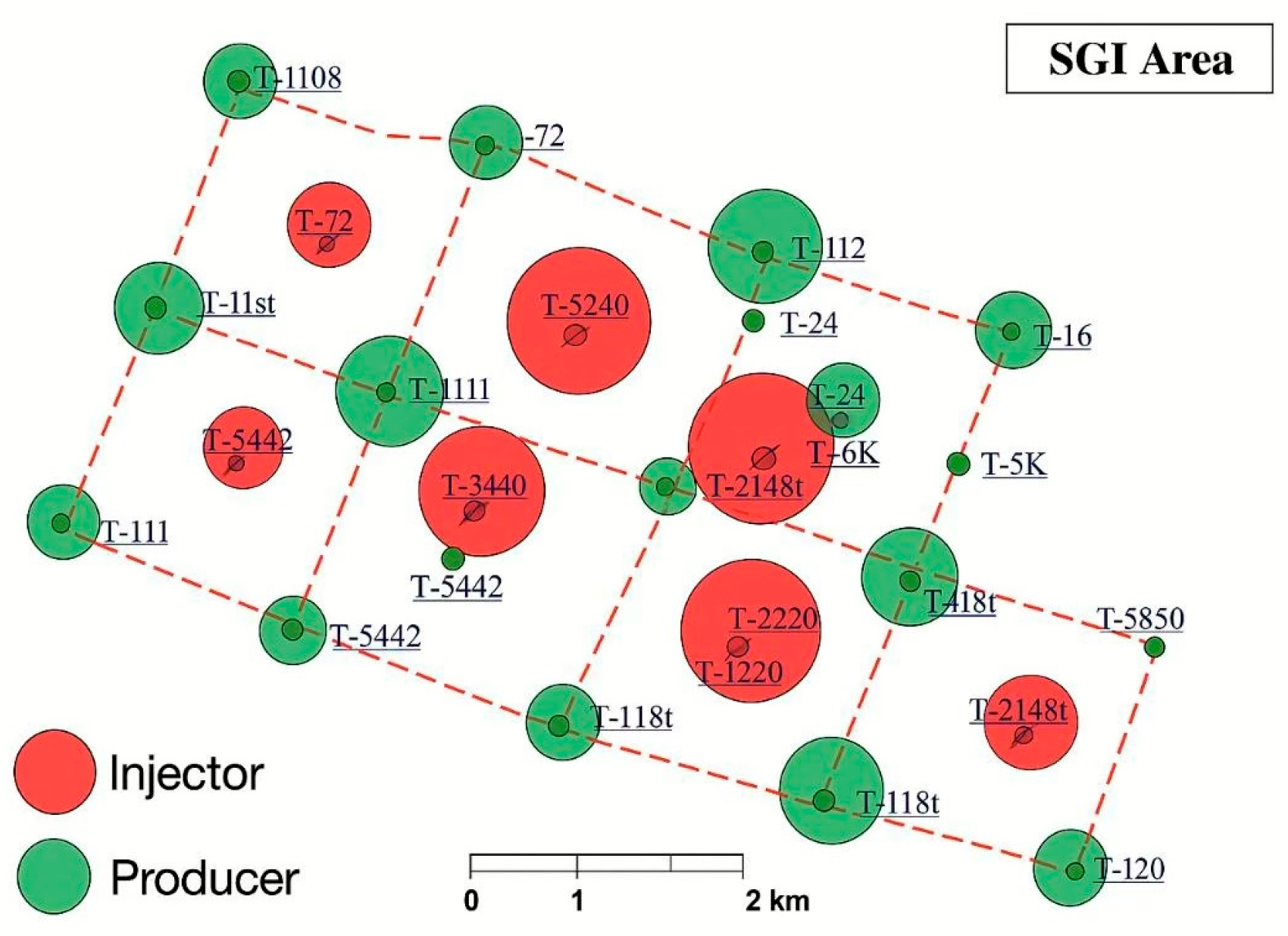

3.4. Sour Gas Injection Operations at the Tengiz Field, Kazakhstan

3.5. Feasibility Study of AGI in Iran and Its Neighboring Regions in West Asia

3.6. Cross-Case Comparisons and Geographic Insights

| Ref. | Field/Country | Formation Type | Permeability (md) | Porosity (%) | Purpose | Outcome |

|---|---|---|---|---|---|---|

| [43] | Zama, Canada | Carbonate | 150 | 6 | CO2 sequestration | Positive |

| [26] | Brazeau NiskuQ, Canada | Carbonate | 60 | 6.6 | Reservoir repressuring | Positive |

| [44] | West Stoddart, Canada | Sandstone | 5 | 11 | Geological sequestration | Technically feasible |

| [45] | Thompson Lake, Canada | Carbonate | --- | --- | Enhanced oil recovery (EOR) | Negative |

| [28] | Wabamun2, Canada | Unknown | 67 | 14.8 | Leakage risk assessment | Smaller leakage rate |

| [37] | Reyersdorfer, Canada | Dolomite | 6 | 4 | Gas recovery | Recommended |

| [30] | Birba A4C, Oman | Carbonate | 2 | 8 | Pressure maintenance, oil recovery | Positive dynamic model |

| [36] | Tengiz, Kazakhstan | Carbonate | Single-digit | 10–15 | Enhanced reservoir performance | Successful |

| [32] | Cluster, Oman | Carbonate | --- | --- | EOR, reduced uncertainty | Reduced uncertainties |

4. Results and Discussion

4.1. Results

4.2. Discussion

4.2.1. Key Outcomes from AGI Case Studies

4.2.2. Technical and Operational Considerations

4.2.3. Economic and Policy Considerations

4.3. Challenges of AGI in Enhanced Oil Recovery (EOR)

4.3.1. Operational Challenges

- Corrosion: Gaseous corrosive materials, such as hydrogen sulfide (H2S) and carbon dioxide (CO2), pose a significant corrosion threat to subsurface wellbore facilities, pipeline networks, and surface equipment. To effectively avoid such corrosion, highly resistant materials must be used in corrosive environments, along with advanced corrosion management systems [50].

- Safety risks: The handling and injecting of toxic gases, such as hydrogen sulfide (H2S), poses a serious health and safety concern. A risk of gas leakage risk exists, with the potential for toxic exposure; therefore, rigorous safety protocols, a good emergency response system, and constant monitoring are all of the utmost importance.

- Gas distribution and injection control: Navigating the complications of subsurface structures, especially those which exhibit variability in their properties, continues to present a lot of challenges in achieving gas injection velocities and a spread of gas throughout the reservoir.

- Hydrate formation: Under specific thermodynamic-pressure and temperature conditions, gas hydrates may be nucleated and grown by the introduction of gaseous molecules. Gas hydrates pose a severe operating threat in pipeline systems via the formation of occluding blockages [50].

4.3.2. Economic Challenges

- High capital costs: Gas injection calls for a large initial capital outlay. This entails the establishment of large compression facilities, redesign of existing wells, and the utilization of specialized corrosion-resistant equipment and materials.

- Uncertain recovery efficiency: The effectiveness of gas injection for oil recovery is very variable, depending on the specific characteristics of the subsurface reservoir. Such variability in reservoir properties creates uncertainty in predictions of ultimate recovery.

- Operating costs: Operational costs include ongoing surveillance and maintenance, in addition to the implementation of chemical agents specially crafted to prevent corrosion and the formation of hydrates.

- Gas sourcing and availability: Availability of a low-cost and reliable supply of suitable injection gas (CO2, N2, or acid gas) can be a significant financial barrier [52].

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| AGI | Acid Gas Injection |

| CO2 | Carbon Dioxide |

| H2S | Hydrogen Sulfide |

| EOR | Enhanced Oil Recovery |

| BHP | Bottom-Hole Pressure |

| MMP | Minimum Miscibility Pressure |

References

- Bennion, D.B.; Thomas, F.B.; Bennion, D.W.; Bietz, R.F. Formation Screening to Minimize Permeability Impairment Associated With Acid Gas Or Sour Gas Injection/Disposal. J. Can. Pet. Technol. 1999, 38, 1–12. [Google Scholar] [CrossRef]

- Duncan, G.J.; Hartford, C.A. Get Rid of Greenhouse Gases by Downhole Disposal Guidelines for Acid Gas Injection Wells; SPE: Richardson, TX, USA, 1998. [Google Scholar]

- Bou-Hamdan, K.F.; Sufyan, F.; Hashim Abbas, A. Carbon Capture, Utilization, and Storage in the MENA Region: A Regional Review of Projects and Challenges. Arab. J. Sci. Eng. 2025, 50, 4529–4549. [Google Scholar] [CrossRef]

- Lagalaye, Y.; Nectoux, A.; James, N. Characterization of Acid Gas Diffusion in a Carbonate Fractured Reservoir Through Experimental Studies, Numerical Simulation and Field Pilots; SPE: Richardson, TX, USA, 2002. [Google Scholar]

- Guo, X.; Feng, J.; Wang, P.; Kong, B.; Wang, L.; Dong, X.; Guo, S. Review on the Mechanism of CO2 Storage and Enhanced Gas Recovery in Carbonate Sour Gas Reservoir. Processes 2023, 11, 164. [Google Scholar] [CrossRef]

- Kutchko, B.G.; Strazisar, B.R.; Hawthorne, S.B.; Lopano, C.L.; Miller, D.J.; Hakala, J.A.; Guthrie, G.D. H2S–CO2 reaction with hydrated Class H well cement: Acid-gas injection and CO2 Co-sequestration. Int. J. Greenh. Gas Control 2011, 5, 880–888. [Google Scholar] [CrossRef]

- Vickerd, M.A.; Thring, R.W.; Arocena, J.M.; Li, J.B.; Heck, R.J. Changes in Porosity Due to Acid Gas Injection As Determined by X-Ray Computed Tomography. J. Can. Pet. Technol. 2006, 45, 17–22. [Google Scholar] [CrossRef]

- Khan, C.; Amin, R.; Madden, G. Effects of CO2 and acid gas injection on enhanced gas recovery and storage. J. Pet. Explor. Prod. Technol. 2013, 3, 55–60. [Google Scholar] [CrossRef]

- Snippe, J.; Wei, L. An Efficient and Internally Consistent Reactive Transport Modelling Scheme for Sour Gas Injection Simulations; SPE: Richardson, TX, USA, 2014. [Google Scholar]

- Haristyawan, R.B.; Yuliatri, M.; Sugiarto, I.T.; Ringoringo, A.F.; Adhi, T.P. Conceptual Study for Sour Gas Processing Emphasized on Acid Gas Injection; SPE: Richardson, TX, USA, 2016. [Google Scholar]

- van Vark, W.; Masalmeh, S.K.; van Dorp, J.; Al Nasr, M.A.; Al-Khanbashi, S. Simulation Study of Miscible Gas Injection for Enhanced Oil Recovery in Low Permeable Carbonate Reservoirs in Abu Dhabi; SPE: Richardson, TX, USA, 2004. [Google Scholar]

- Bennion, D.B.; Thomas, F.B.; Schulmeister, B.E.; Imer, D.; Shtepani, E.; Becker, L. The Phase Behaviour of Acid Disposal Gases and the Potential Adverse Impact on Injection or Disposal Operations. J. Can. Pet. Technol. 2004, 43, 24–29. [Google Scholar] [CrossRef]

- Li, Q.; Liu, X.; Du, L.; Bai, B.; Fang, Z.; Jing, M.; Li, X. Economics of Acid Gas Injection with Comparison to Sulfur Recovery in China. Energy Procedia 2013, 37, 2505–2510. [Google Scholar] [CrossRef]

- Hashemizadeh, A.; Ju, Y.; Zareian Baghdad Abadi, F. Policy design for renewable energy development based on government support: A system dynamics model. Appl. Energy 2024, 376, 124331. [Google Scholar] [CrossRef]

- Abou-Sayed, A.S.; Zaki, K.S.; Sarfare, M.D. An Assessment of Engineering, Economical and Environmental Drivers of Sour Gas Management by Injection; SPE: Richardson, TX, USA, 2005. [Google Scholar]

- Cardu, M.; Farzay, O.; Shakouri, A.; Jamali, S.; Jamali, S. Feasibility Assessment of Acid Gas Injection in an Iranian Offshore Aquifer. Appl. Sci. 2023, 13, 10776. [Google Scholar]

- Ofori, K.; Barifcani, A.; Phan, C.M. Effect of higher H2S concentration over CO2 in acid gas mixtures during geosequestration. Discov. Chem. Eng. 2023, 3, 18. [Google Scholar] [CrossRef]

- Zambrano, J.; Gómez, F.; Lozano-Martín, D.; Martín, M.; Segovia, J. Volumetric behaviour of (carbon dioxide + hydrocarbon) mixtures at high pressures. J. Supercrit. Fluids 2016, 110, 103–109. [Google Scholar]

- Alvarado, V.; Manrique, E. Enhanced Oil Recovery: An Update Review. Energies 2010, 3, 1529–1575. [Google Scholar] [CrossRef]

- Choudhary, N.; Narayanan Nair, A.K.; Che Ruslan, M.F.A.; Sun, S. Bulk and interfacial properties of decane in the presence of carbon dioxide, methane, and their mixture. Sci. Rep. 2019, 9, 19784. [Google Scholar] [CrossRef]

- Thomas, S. Enhanced Oil Recovery—An Overview. Oil Gas Sci. Technol.—Rev. D’ifpen 2007, 63, 9–19. [Google Scholar] [CrossRef]

- Zhou, Y.; Guan, W.; Sun, Q.; Zou, X.; He, Z. Effect of multi-scale rough surfaces on oil-phase trapping in fractures: Pore-scale modeling accelerated by wavelet decomposition. Comput. Geotech. 2025, 179, 106951. [Google Scholar] [CrossRef]

- Shabdirova, A.; Kozhagulova, A.; Samenov, Y.; Merbayev, R.; Niyazbayeva, A.; Shabdirov, D. Core Flooding Experiments on the Impact of CO2-EOR on the Petrophysical Properties and Oil Recovery Parameters of Reservoir Sandstones in Kazakhstan. Geosciences 2024, 14, 185. [Google Scholar] [CrossRef]

- Duong, C.; Bower, C.; Hume, K.; Rock, L.; Tessarolo, S. Quest carbon capture and storage offset project: Findings and learnings from 1st reporting period. Int. J. Greenh. Gas Control 2019, 89, 65–75. [Google Scholar] [CrossRef]

- Rock, L.; O’Brien, S.; Tessarolo, S.; Duer, J.; Bacci, V.; Hirst, B.; Randell, D.; Helmy, M.; Blackmore, J.; Duong, C.; et al. The Quest CCS Project: 1st Year Review Post Start of Injection. Energy Procedia 2017, 114, 5320–5328. [Google Scholar] [CrossRef]

- Gunter, W.D.; Pratt, A.; Buschkuehle, B.E.; Perkins, E.H. Acid gas injection in the Brazeau Nisku Q carbonate reservoir: Geochemical reactions as a result of the injection of an H2S-CO2 waste stream. In Greenhouse Gas Control Technologies 7; Rubin, E.S., Keith, D.W., Gilboy, C.F., Wilson, M., Morris, T., Gale, J., Thambimuthu, K., Eds.; Elsevier Science Ltd.: Oxford, UK, 2005; pp. 469–477. [Google Scholar]

- Bachu, S.; Watson, T.L. Review of failures for wells used for CO2 and acid gas injection in Alberta, Canada. Energy Procedia 2009, 1, 3531–3537. [Google Scholar] [CrossRef]

- LeNeveu, D.M. Analysis of potential acid gas leakage from wellbores in Alberta, Canada. Int. J. Greenh. Gas Control 2011, 5, 862–879. [Google Scholar] [CrossRef]

- Raza, A.; Gholami, R.; Rezaee, R.; Rasouli, V.; Rabiei, M. Significant aspects of carbon capture and storage–A review. Petroleum 2019, 5, 335–340. [Google Scholar] [CrossRef]

- Behrend, J.; Chugh, S.; McKishnie, R.A. Development of the Strasshof Tief Sour-Gas Field Including Acid-Gas Injection Into Adjacent Producing Sour-Gas Reservoirs. SPE Reserv. Eval. Eng. 2007, 10, 572–579. [Google Scholar] [CrossRef]

- Haynes, B.; Kaura, N.C.; Faulkner, A. Life Cycle of a depletion drive and sour gas injection development: Birba A4C Reservoir, South Oman. In Proceedings of the IPTC 2008: International Petroleum Technology Conference, Kuala Lumpur, Malaysia, 3–5 December 2008. [Google Scholar]

- Al-Hadhrami, A.K.; Davis, D.W.; Deinum, G.; Soek, H. The Design of the First Miscible Sour Gasflood Project in Oman; IPTC: Dubai, UAE, 2007. [Google Scholar]

- Bachu, S.; Gunter, W.D. Overview of acid-gas injection operations in Western Canada. In Greenhouse Gas Control Technologies 7; Rubin, E.S., Keith, D.W., Gilboy, C.F., Wilson, M., Morris, T., Gale, J., Thambimuthu, K., Eds.; Elsevier Science Ltd.: Oxford, UK, 2005; pp. 443–448. [Google Scholar]

- Mandhari, A.; Maskari, M.; Al, A.; Mihajlov, R.; Omairi, N.; Kindi, Z.; Bawdekar, M.; Al Mandhari, S.; Kiyumi, N. Unexpected Formation of Elemental Sulphur in Critical Sour Plant. In Proceedings of the SPE Conference at Oman Petroleum & Energy Show, Muscat, Oman, 22–24 April 2024. [Google Scholar]

- Kazemi, A.; Esmaeili, M. Reservoir Surrogate Modeling Using U-Net with Vision Transformer and Time Embedding. Processes 2025, 13, 958. [Google Scholar] [CrossRef]

- Darmentaev, S.; Yessaliyeva, A.; Azhigaliyeva, A.; Belanger, D.; Sullivan, M.; King, G.; Feyijimi, T.; Bateman, P. Tengiz Sour Gas Injection Project; SPE: Richardson, TX, USA, 2010. [Google Scholar]

- Bachu, S.; Haug, K.; Michael, K.; Buschkuehle, B.E.; Adams, J.J. Deep Injection of Acid Gas in Western Canada. In Developments in Water Science; Tsang, C.-F., Apps, J.A., Eds.; Elsevier: Amsterdam, The Netherlands, 2005; Volume 52, pp. 623–635. [Google Scholar]

- Koyanbayev, M.; Wang, L.; Wang, Y.; Hashmet, M.R.; Hazlett, R.D. Impact of gas composition and reservoir heterogeneity on miscible sour gas flooding—A simulation study. Fuel 2023, 346, 128267. [Google Scholar] [CrossRef]

- Hashemizadeh, A.; Bahonar, E.; Chahardowli, M.; Kheirollahi, H.; Simjoo, M. Analysis of rate of penetration prediction in drilling using data-driven models based on weight on hook measurement. Earth Sci. Inform. 2022, 15, 2133–2153. [Google Scholar]

- Rad, H.S.; Rajabi, M.; Masoudian, M.S. A Numerical Study of Gas Injection and Caprock Leakage from Yort-e-Shah Aquifer in Iran. Eng. Technol. Appl. Sci. Res. 2017, 7, 1843–1849. [Google Scholar] [CrossRef]

- Tang, Y.; Xiang, S.; Wang, J.; Tian, Y.; Wang, J.-Z.; Wang, F. Study on the erosion patterns of high-strength injection-production strings under alternating operating conditions in gas storage reservoirs. Phys. Fluids 2025, 37, 033329. [Google Scholar]

- Jafari Raad, S.M.; Azin, R.; Osfoury, S.; Fatehi, R. Simulation of Natural Convection in Acid Gas Disposal into Saline Aquifers. J. Pet. Res. 2014, 24, 100–109. [Google Scholar] [CrossRef]

- Smith, S.A.; Sorensen, J.A.; Steadman, E.N.; Harju, J.A. Acid gas injection and monitoring at the Zama oil field in Alberta, Canada: A case study in demonstration-scale carbon dioxide sequestration. Energy Procedia 2009, 1, 1981–1988. [Google Scholar] [CrossRef]

- Michael, K.; Buschkuehle, B.E. Acid-gas injection at West Stoddart, British Columbia: An analogue for the detailed hydrogeological characterization of a CO2 sequestration site. J. Geochem. Explor. 2006, 89, 280–283. [Google Scholar] [CrossRef]

- Bachu, S.; Gunter, W.D. Acid-gas injection in the Alberta basin, Canada: A CO2-storage experience. Geol. Soc. Lond. Spec. Publ. 2004, 233, 225. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Q.; Zheng, L.; Li, X.; Xu, L. Numerical simulation and feasibility assessment of acid gas injection in a carbonate formation of the Tarim Basin, China. Oil Gas Sci. Technol.—Rev. IFP Energ. Nouv. 2020, 75, 28. [Google Scholar]

- Zhao, X.; Qi, X. Exploration and Application of Natural Gas Injection, Water Injection and Fracturing Technologies in Low-Permeability Reservoirs in China. Processes 2025, 13, 855. [Google Scholar] [CrossRef]

- Kanakaki, E.M.; Samnioti, A.; Koffa, E.; Dimitrellou, I.; Obetzanov, I.; Tsiantis, Y.; Kiomourtzi, P.; Gaganis, V.; Stamataki, S. Prospects of an Acid Gas Re-Injection Process into a Mature Reservoir. Energies 2023, 16, 7989. [Google Scholar] [CrossRef]

- Aghakhani Emamqeysi, M.R.; Fatehi Marji, M.; Hashemizadeh, A.; Abdollahipour, A.; Sanei, M. Prediction of elastic parameters in gas reservoirs using ensemble approach. Environ. Earth Sci. 2023, 82, 269. [Google Scholar]

- Song, G.-L.; Zhang, J. Corrosion Control in CO2 Enhanced Oil Recovery From a Perspective of Multiphase Fluids. Front. Mater. 2019, 6, 272. [Google Scholar] [CrossRef]

- Gan, B.; Li, Z.; Huo, W.; Zhang, Y.; Li, Z.; Fan, R.; Zhang, H.; Xu, Y.; He, Y. Phase transitions of CH4 hydrates in mud-bearing sediments with oceanic laminar distribution: Mechanical response and stabilization-type evolution. Fuel 2025, 380, 133185. [Google Scholar] [CrossRef]

- Zekri, A.; Jerbi, K. Economic Evaluation of Enhanced Oil Recovery. Oil Gas Sci. Technol.—Rev. IFP 2002, 57, 259–267. [Google Scholar] [CrossRef]

| Ref. | Fluid Type (Crude Oil/Natural Gas) | Formation Type | Permeability | Porosity |

|---|---|---|---|---|

| [43] | Crude oil | Dolomite reservoir | --- | --- |

| [26] | Natural gas | Carbonate reservoir | 60 md | 6.6% |

| [44] | Crude oil | Sediments and sandstones | 5 md | 11% |

| [45] | Natural gas | Sandstone | 10 md | 30% |

| [45] | Crude oil | Carbonate | 150 md | 6% |

| [28] | Natural gas | Unknown | 67 md | 14.8% |

| [37] | Crude oil and natural gas | Sandstone | 5 to 4250 md | 4–30% |

| [30] | Natural gas | Dolomite | 6 md | 4% |

| [30] | Natural gas | Dolomite | 1 md | 4% |

| [31] | Sour crude oil | Carbonate | 2 md | 8% |

| [33] | Crude oil and natural gas | 29 cases of carbonate and 19 cases of siliciclastics | 1 to 4250 md | 4–30% |

| [36] | Crude oil | Carbonate | Single digit | 10–15% |

| [32] | Crude oil | Carbonate | --- | --- |

| Ref. | Country | Field Name | Purpose of AGI | Results |

|---|---|---|---|---|

| [43] | Canada | Zama | CO2 sequestration within mixed gas streams | Confirmed |

| [26] | Canada | Brazeau NiskuQ Pool | Repressuring of the reservoir | Positive |

| [44] | Canada | West Stoddart | Geological sequestration of CO2, | Technically feasible |

| [45] | Canada | Thompson Lake | EOR | Negative |

| [28] | Canada | Wabamun2 | Reduced rate of leakage through wellbores, repressuring of the reservoir | Reduced leakage rate |

| [37] | Canada | Western Canada | Safe disposal of acid and greenhouse gases | Successfully injected |

| [30] | Canada | Reyersdorfer-schonkirchen | Improved gas recovery | Recommended |

| [31] | Oman | A4C reservoir | Pressure maintenance, increased oil recovery | Led to past dynamic model |

| [33] | Canada | Western Canada | Reduction in atmospheric emissions of hydrogen sulfide | Successfully injected |

| [27] | Canada | Alberta | Storage of CO2, EOR | Acid gas wells showed greater reliability compared to CO2 injection wells |

| [36] | Kazakhstan | Tengiz | Increasing reservoir performance | Gas injection project was successful |

| [32] | Oman | Cluster | Reduction in uncertainties, EOR | Certainly helped in reducing uncertainties |

| Ref. | Name | Advantages | Disadvantages |

|---|---|---|---|

| [43] | Zama | Economically viable, with limited impact on current oil extraction operations | Needs a lot of monitoring |

| [26] | Brazeau NiskuQ Pool | Increased reservoir pressure, storage of acid gas | Hydrogeological traps, solubility trapping, mineral trapping |

| [44] | West Stoddart | Reduced emissions into the atmosphere | Acid gas solubility, saturation of remaining gas |

| [45] | Thompson Lake | Desulphurization was uneconomic | Requires complex facility design and operation; acid gas leaks can cause fatalities, dehydration, and hydrate blockages |

| [28] | Wabamun2 | Carbon storage achieved in the area | Acid gas leakage, risk of detriment |

| [37] | Western | Increased capacity and decreased buoyancy, increased injectivity | Corrosion, cavitation |

| [30] | Reyersdorfer-schonkirchen | Favorable mobility ratio, higher recovery of natural gas, premature watering out of producing well prevented | Risk scenarios must be evaluated, needs extensive modeling of operation |

| [31] | A4C | Low level of produced GOR, increased reservoir pressure, absence of corrosion when carbon-steel materials used | Reliability problems with compressor |

| [33] | Western Canada | Potential for future use at sites for geological sequestration and storage of CO2, EOR, gas recovery, no safety incidents recorded over the past 15 years | Key concerns that require attention moving forward include ensuring long-term containment of injected gases underground and maintaining the safety of large-scale injection operations |

| [27] | Alberta, Canada | Enhanced oil recovery | Common issues involve surface-casing venting, casing or tubing rupture, packer integrity loss, compromised zonal isolation, gas migration |

| [36] | Tengiz | Due to the absence of fractures, the platform was ideal for gas injection. Injection wells demonstrated good performance, with consistent injectivity and no significant change in well skin over time, | Probability of breakthrough of gas |

| [32] | Cluster | Execution of miscible gas flood project required substantial resources, and was sometimes a complex undertaking, but did lead to sustainable production and high recovery; increased RF | Needs highly advanced monitoring and modeling. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hashemizadeh, A.; Aliasgharzadeh Olyaei, A.; Sedighi, M.; Hashemizadeh, A. Challenges and Prospects of Enhanced Oil Recovery Using Acid Gas Injection Technology: Lessons from Case Studies. Processes 2025, 13, 2203. https://doi.org/10.3390/pr13072203

Hashemizadeh A, Aliasgharzadeh Olyaei A, Sedighi M, Hashemizadeh A. Challenges and Prospects of Enhanced Oil Recovery Using Acid Gas Injection Technology: Lessons from Case Studies. Processes. 2025; 13(7):2203. https://doi.org/10.3390/pr13072203

Chicago/Turabian StyleHashemizadeh, Abbas, Amirreza Aliasgharzadeh Olyaei, Mehdi Sedighi, and Ali Hashemizadeh. 2025. "Challenges and Prospects of Enhanced Oil Recovery Using Acid Gas Injection Technology: Lessons from Case Studies" Processes 13, no. 7: 2203. https://doi.org/10.3390/pr13072203

APA StyleHashemizadeh, A., Aliasgharzadeh Olyaei, A., Sedighi, M., & Hashemizadeh, A. (2025). Challenges and Prospects of Enhanced Oil Recovery Using Acid Gas Injection Technology: Lessons from Case Studies. Processes, 13(7), 2203. https://doi.org/10.3390/pr13072203