Discrete-Time Internal Model Control with Equal-Order Fractional Butterworth Filter for Multivariable Systems

Abstract

1. Introduction

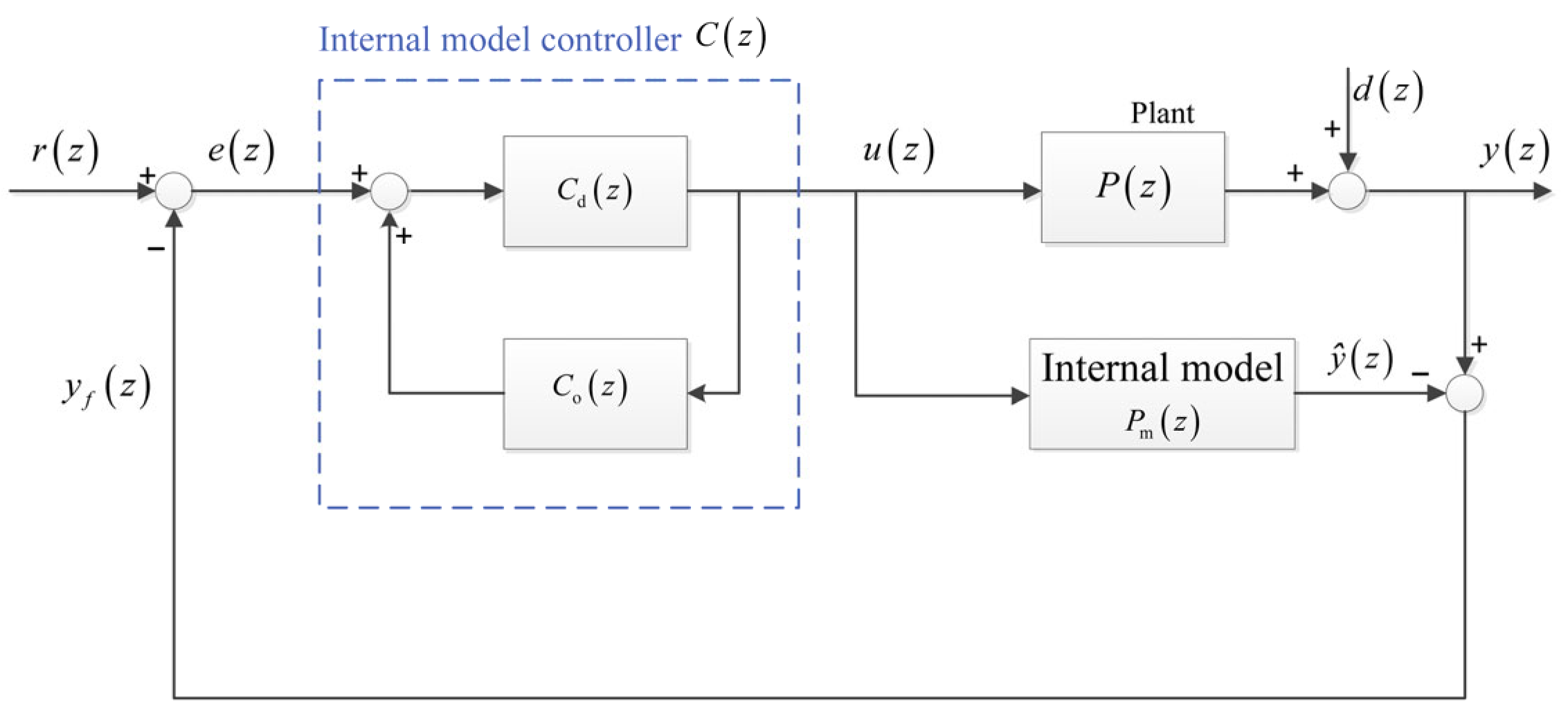

2. Discrete-Time Internal Model Control with Inverted Decoupling

2.1. Structure of the Discrete-Time ID-IMC

2.2. Design of and

2.3. Realizability and the Closed-Loop Performance

- Stability. The controller must generate a bounded response to bounded inputs; therefore, all poles of and must lie inside the unit circle of the z-plane;

- Causality. The controller must be causal, which means that the controller must make no prediction;

- Properness. A strictly proper transfer function has a denominator order equal to/greater than the numerator order.

2.3.1. Multiple Time-Delays

2.3.2. Zeros Outside the Unit Circle

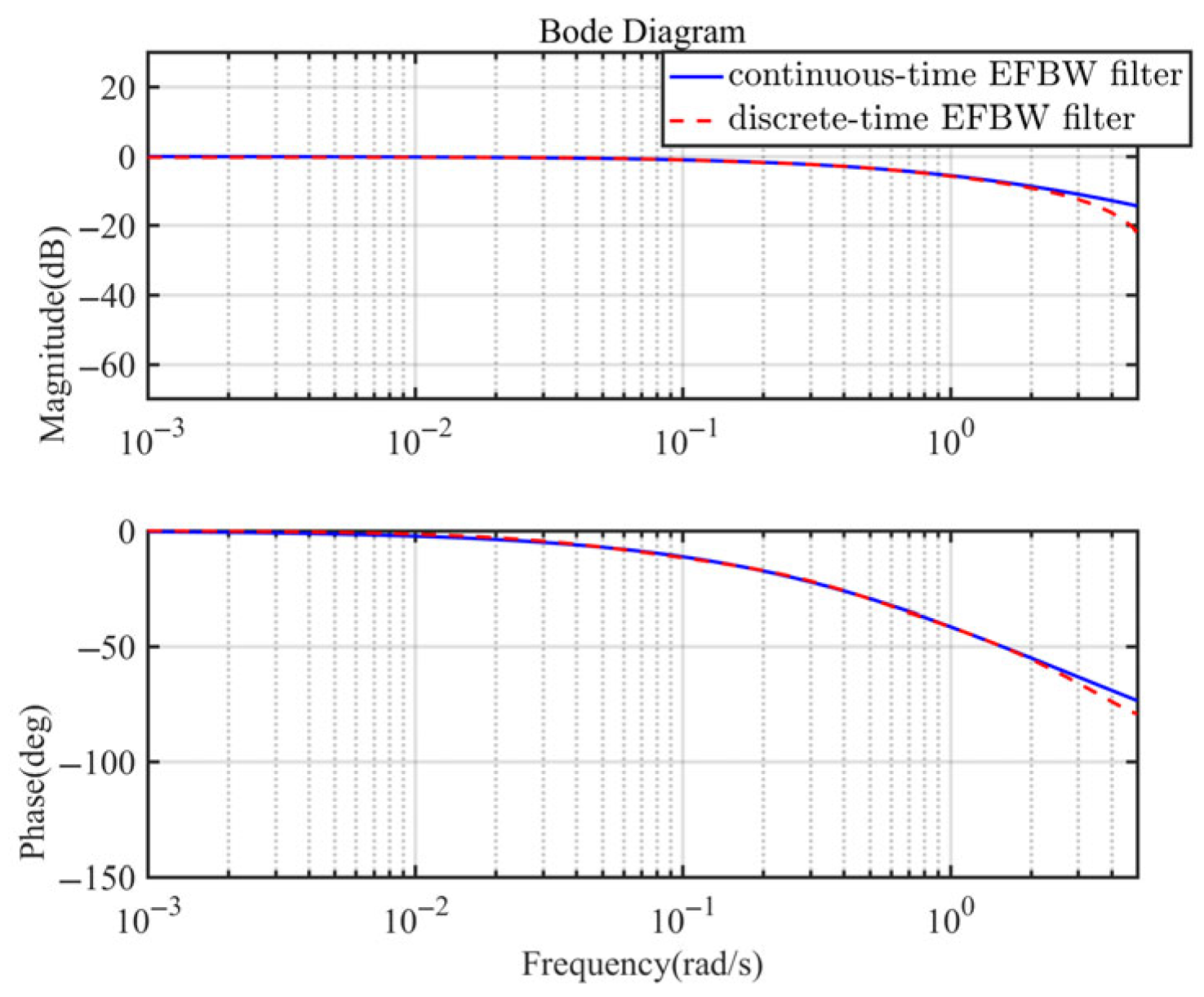

3. Discrete-Time Equal-Order Fractional Butterworth Filter

3.1. Definitions of the Fractional Calculus

3.2. Design of Continuous-Time Equal-Order Fractional Butterworth Filter

3.3. Design Advantages of EFBW Filter

3.4. Discretization Algorithm

- Euler transformation:

- Tustin transformation:

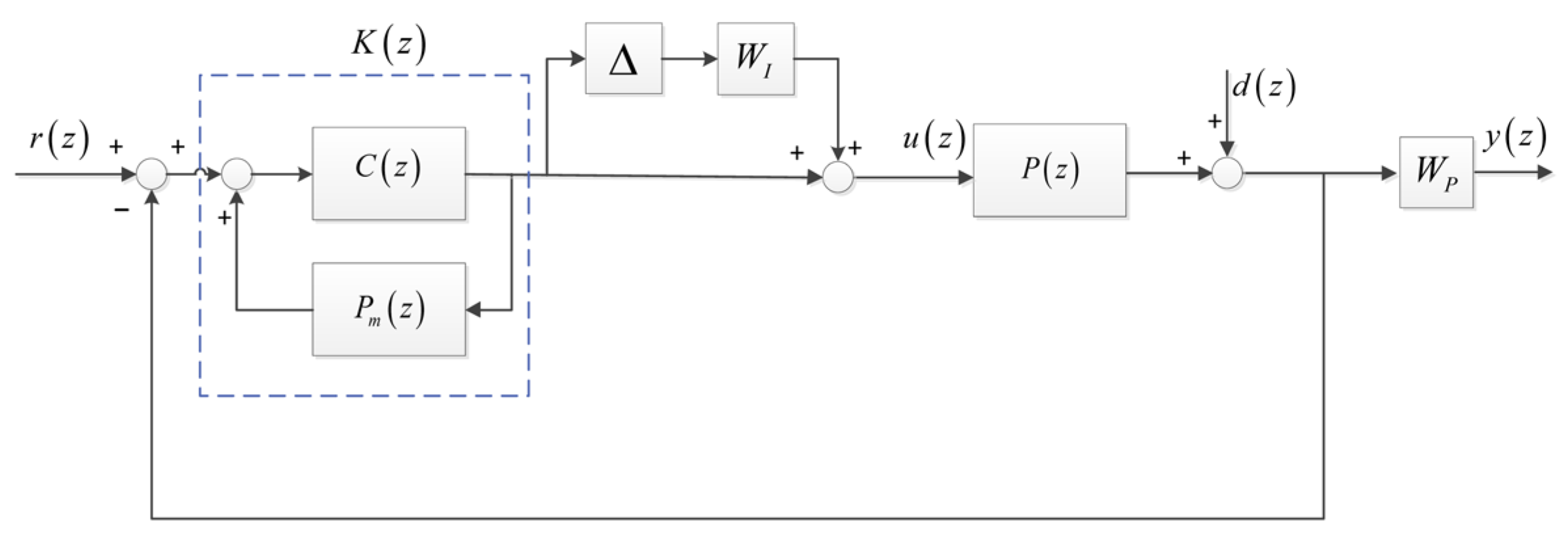

4. Stability Analysis

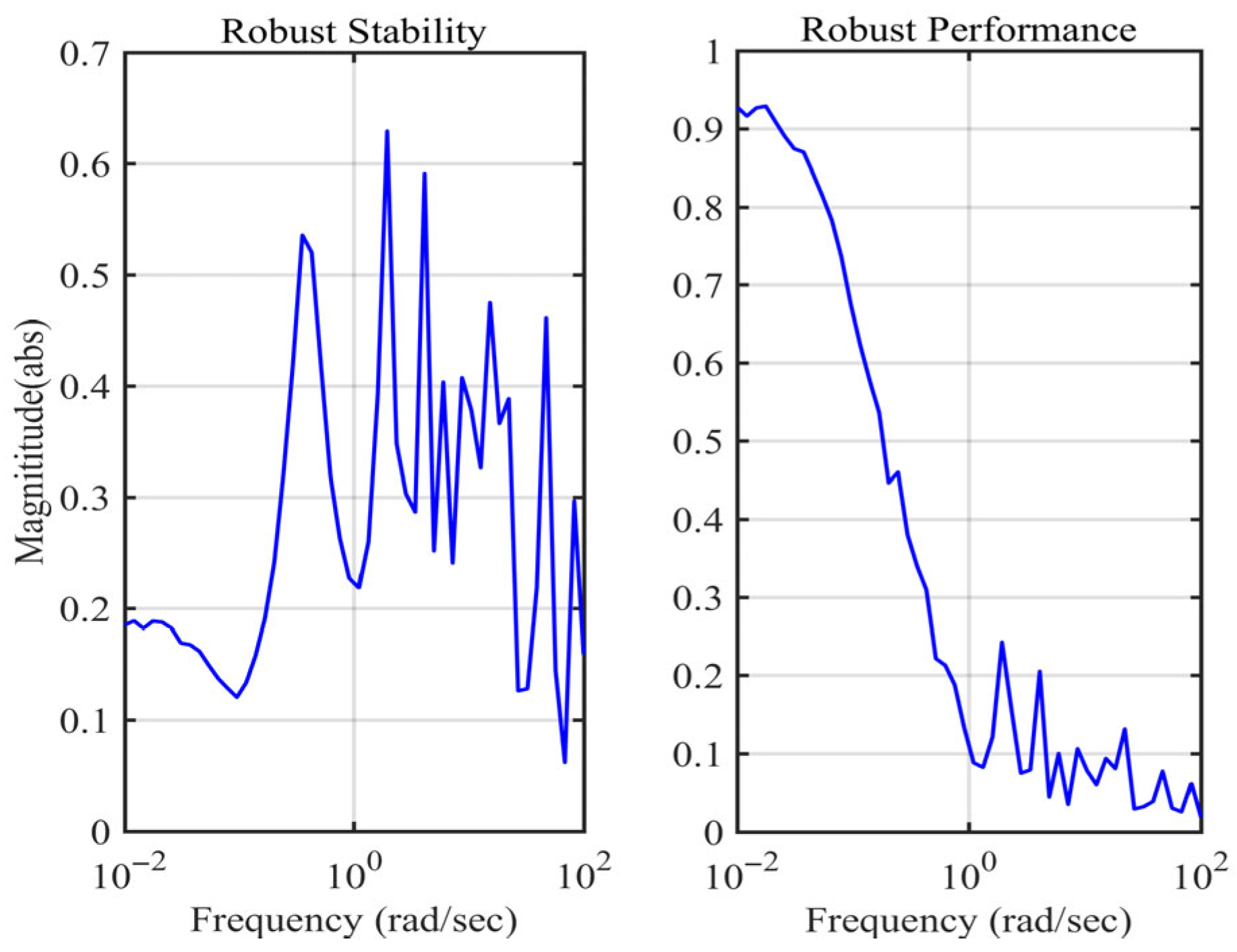

5. Robustness Analysis

6. Simulations

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Garcia, C.E.; Morari, M. Internal model control. A unifying review and some new results. Ind. Eng. Chem. Process Des. Dev. 1982, 21, 308–323. [Google Scholar] [CrossRef]

- Garcia, C.E.; Morari, M. Internal model control. 2. Design procedure for multivariable systems. Ind. Eng. Chem. Process Des. Dev. 1985, 24, 472–484. [Google Scholar] [CrossRef]

- Ouardani, D.; Bodian, A.; Cardenas, A. Comparative Analysis of PID and Robust IMC Control in Cascaded Processes with Time-Delay. IEEE Access 2024, 12, 14199–142014. [Google Scholar] [CrossRef]

- Xie, J.; Bonassi, F.; Scattolini, R. Learning Control Affine Neural NARX Models for Internal Model Control Design. IEEE Trans. Autom. Sci. Eng. 2025, 22, 8137–8149. [Google Scholar] [CrossRef]

- Maamar, B.; Rachid, M. IMC-PID-fractional-order-filter controllers design for integer order systems. ISA Trans. 2014, 53, 1620–1628. [Google Scholar] [CrossRef]

- Bettayeb, M.; Mansouri, R. Fractional IMC-PID-filter controllers design for non integer order systems. J. Process Control 2014, 24, 261–271. [Google Scholar] [CrossRef]

- Li, D.; Liu, L.; Jin, Q.; Hirasawa, K. Maximum sensitivity based fractional IMC–PID controller design for non-integer order system with time delay. J. Process Control 2015, 31, 17–29. [Google Scholar] [CrossRef]

- Cui, J.; Chen, Y.; Liu, T. Discrete-time domain IMC-based PID control design for industrial processes with time delay. In Proceedings of the 2016 35th Chinese Control Conference (CCC), Chengdu, China, 27–29 July 2016; IEEE: New York, NY, USA; pp. 5946–5951. [Google Scholar]

- De Keyser, R.; Copot, C.; Hernandez, A.; Ionescu, C. Discrete-time internal model control with disturbance and vibration rejection. J. Vib. Control 2017, 23, 3–15. [Google Scholar] [CrossRef]

- Silva, G.J.; Datta, A. Adaptive internal model control: The discrete-time case. Int. J. Adapt. Control Signal Process. 2001, 15, 15–36. [Google Scholar] [CrossRef]

- Hannachi, M.; Soudani, D. Internal model control of multivariable discrete-time systems. In Proceedings of the 2015 7th International Conference on Modelling, Identification and Control (ICMIC), Sousse, Tunisia, 18–20 December 2015; IEEE: New York, NY, USA; pp. 1–6. [Google Scholar]

- Touati, N.; Saidi, I. Dahlin Deadbeat Internal Model Control for Discrete MIMO Systems. Int. J. Electr. Comput. Eng. Syst. 2024, 15, 483–490. [Google Scholar] [CrossRef]

- Mondal, R.; Dey, J. On Non-Integer Order Internal Model Control of Non-Minimum Phase Systems and Plants with Transport Delay. In Proceedings of the 2024 IEEE 3rd International Conference on Control, Instrumentation, Energy & Communication (CIEC), Kolkata, India, 25–27 January 2024; IEEE: New York, NY, USA; pp. 37–42. [Google Scholar]

- Ogunba, K.S.; Fakunle, A.A.; Ogunfunmi, T.; Taiwo, O. Extended Approach to Analytical Triangular Decoupling Internal Model Control of Square Stable Multivariable Systems with Delays and Right-Half-Plane Zeros. IEEE Access 2023, 11, 32201–32228. [Google Scholar] [CrossRef]

- Kumar, A.; Anwar, M.N.; Huba, M. Load Frequency Controller Design Based on the Direct Synthesis Approach Using a 2DoF-IMC Scheme for a Multi-Area Power System. Symmetry 2022, 14, 1994. [Google Scholar] [CrossRef]

- Kumar, K.; Patwardhan, S.C.; Noronha, S. Development of an adaptive and explicit dual model predictive controller based on generalized orthogonal basis filters. J. Process Control 2019, 83, 196–214. [Google Scholar] [CrossRef]

- Hasan, M.J.; Bashar, N.; Sarker, S.; Lopa, S.A.; Hamim, T. Harmonic reduction of second order sallen and key lowpass filter and second order MFB lowpass filter through closed loop PID controlled method. Int. J. Inf. Technol. 2024, 16, 2635–2645. [Google Scholar] [CrossRef]

- Speakman, J.; Papasavvas, A.; Francois, G. A robust modifier adaptation method via Hessian augmentation using model uncertainties. J. Process Control 2021, 99, 28–40. [Google Scholar] [CrossRef]

- Gnaneshwar, K.; Trivedi, R.; Sharma, S.; Padhy, P.K. A frequency domain fractional order tilted integral derivative controller design for fractional order time delay processes. Asian J. Control 2025, 27, 1384–1404. [Google Scholar]

- Zhou, Y.; Sun, H.; Xu, J.; Rui, X.; Li, J.; Shi, Y.; Qian, Y. Multisim-based Optimized Design of Butterworth Low-pass Filters. In Proceedings of the 2024 7th International Conference on Electronics, Communications, and Control Engineering (ICECC), Kuala Lumpur, Malaysia, 22–24 March 2024; IEEE: New York, NY, USA; pp. 33–40. [Google Scholar]

- Dahake, V.R.; Patil, M.D.; Vyawahare, V.A. Analysis of networked control system with integer-order and fractional-order PID controllers. Int. J. Control Autom. Syst. 2024, 22, 373–386. [Google Scholar] [CrossRef]

- Joshi, M.; Bhosale, S.R.; Vyawahare, V.A. Fractional-order artificial neural network models for linear systems. Int. J. Dyn. Control 2025, 13, 118. [Google Scholar] [CrossRef]

- Maurya, P.; Paul, N.; Prasad, D.; Singh, R.S. Modified Fractional-Order PID Controller Design for the Mixing Tank Process. Chem. Eng. Technol. 2025, 48, e70026. [Google Scholar] [CrossRef]

- Medjili, F.; Bouguerra, A.; Ladjal, M.; Babes, B.; Ali, E.; Ghoneim, S.S.; Aeggegn, D.B.; Sharaf, A.B.A. HIL co-simulation of an optimal hybrid fractional-order type-2 fuzzy PID regulator based on dSPACE for quadruple tank system. Sci. Rep. 2025, 15, 7583. [Google Scholar] [CrossRef]

- Gnaneshwar, K.; Padhy, P.K. A TDF Fractional Order Controller Design for Time Delay Systems Using IMC Approach. In Proceedings of the 2023 Ninth Indian Control Conference (ICC), Visakhapatnam, India, 18–20 December 2023; IEEE: New York, NY, USA; pp. 425–430. [Google Scholar]

- Znidi, A.; Nouri, A.S. Discrete adaptive sliding mode control for uncertain fractional-order Hammerstein system. Trans. Inst. Meas. Control 2025. [Google Scholar] [CrossRef]

- Morari, M.; Zafiriou, E. Robust Process Control; Prentice Hall: Englewood Cliffs, NJ, USA, 1989. [Google Scholar]

- Acharya, A.; Das, S.; Pan, I.; Das, S. Extending the concept of analog Butterworth filter for fractional order systems. Signal Process. 2014, 94, 409–420. [Google Scholar] [CrossRef]

- Liu, K.; Chen, J. Internal Model Control with Improved Butterworth Filter Based on Inverted Decoupling for Multivariable Systems. In Proceedings of the 2019 IEEE International Conference on Systems, Man and Cybernetics (SMC), Bari, Italy, 6–9 October 2019; pp. 511–517. [Google Scholar]

- De Keyser, R.; Muresan, C.I.; Ionescu, C.M. An efficient algorithm for low-order direct discrete-time implementation of fractional order transfer functions. ISA Trans. 2018, 74, 229–238. [Google Scholar] [CrossRef] [PubMed]

- Aouiche, E.M.; Liu, X.; Aouiche, A.; Hassan, M.A.; Aguida, M.E.; Khan, J.A.; Cao, Y. Dynamic Decoupled Current Control 674 for Smooth Torque of the Open-Winding Variable Flux Reluctance Motor Using Integrated Torque Harmonic Extended State Observer. Processes 2025, 13, 263. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, X.; Han, X.; Ren, Y.; Zhang, B.; Wang, P. A Transformerless Converter with Common-Mode Decoupling in Low-Voltage Hybrid Grids. Processes 2024, 12, 507. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y. Dual-band dual-polarized antenna using a simple radiation restoration and decoupling structure. IEEE Antennas Wirel. Propag. Lett. 2023, 22, 709–713. [Google Scholar] [CrossRef]

- Tran, D.N.V.; Tran, H.H.; Park, H.C.; Nguyen-Trong, N. Simple Decoupling Structure for Dual-Sense CP MIMO Antenna. In Proceedings of the 2022 International Conference on Advanced Technologies for Communications (ATC), Hanoi Capital, Vietnam, 20–22 October 2022; IEEE: New York, NY, USA; pp. 35–38. [Google Scholar]

- Fu, B.; You, B.; Hu, G. Layered Composite Decoupling Control Based on Regional Dynamic Sparrow Search Algorithm. Processes 2023, 11, 3350. [Google Scholar] [CrossRef]

- Lara, M.; Ruz, M.L.; Mulders, S.P.; Vázquez, F.; Garrido, J. Individual pitch controller with static inverted decoupling for periodic blade load reduction on monopile offshore wind turbines. Ocean Eng. 2025, 334, 121608. [Google Scholar] [CrossRef]

- Huairong, C.; Xi, W.; Haonan, W.; Nannan, G.; Meiyin, Z.; Shubo, Y. Inverted decoupling and LMI-based controller design for a turboprop engine with actuator dynamics. Chin. J. Aeronaut. 2020, 33, 1774–1787. [Google Scholar]

- Shen, L.; Chen, Z.; He, J. Multi-zone integrated iterative-decoupling control of temperature ffeld of large-scale vertical quenching furnaces based on ESRNN. Processes 2023, 11, 2106. [Google Scholar] [CrossRef]

- Song, M.; Liu, H.; Xu, Y.; Wang, D.; Huang, Y. Decoupling adaptive smith prediction model of ffatness closed-loop control and its application. Processes 2020, 8, 895. [Google Scholar] [CrossRef]

- Liu, K.; Chen, J. Internal model control design based on equal order fractional Butterworth filter for multivariable systems. IEEE Access 2020, 8, 84667–84679. [Google Scholar] [CrossRef]

- Liu, K.; Wang, R.; Lyu, S. Inverted decoupling internal model control for MIMO time-delay systems based on improved Butterworth Filter. IEEE Access 2024, 12, 193241–193253. [Google Scholar] [CrossRef]

- Wade, H.L. Inverted decoupling: A neglected technique. ISA Trans. 1997, 36, 3–10. [Google Scholar] [CrossRef]

- Miller, K.S.; Ross, B. An Introduction to the Fractional Calculus and Fractional Differential Equations; Wiley: New York, NY, USA, 1993. [Google Scholar]

- Das, S. Functional Fractional Calculus; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Butterworth, S. On the theory of filter amplifiers. Wirel. Eng. 1930, 7, 536–541. [Google Scholar]

- Said, L.A.; Ismail, S.M.; Radwan, A.G.; Madian, A.H.; Abu El-Yazeed, M.F.; Soliman, A.M. On the optimization of fractional order low-pass filters. Circuits Syst. Signal Process. 2016, 35, 2017–2039. [Google Scholar] [CrossRef]

- Manolakis, D.G.; Ingle, V.K. Applied Digital Signal Processing: Theory and Practice; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar]

- Stoica, P.; Soderstrom, T. The Steiglitz-McBride identification algorithm revisited–Convergence analysis and accuracy aspects. IEEE Trans. Autom. Control 1981, 26, 712–717. [Google Scholar] [CrossRef]

- Skogestad, S.; Postlethwaite, I. Multivariable Feedback Control: Analysis and Design; John Wiley & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Wood, R.; Berry, M. Terminal composition control of a binary distillation column. Chem. Eng. Sci. 1973, 28, 1707–1717. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, K.; Lyu, S.; Wang, R.; Gao, C.; Yang, X.; Liu, Y. Discrete-Time Internal Model Control with Equal-Order Fractional Butterworth Filter for Multivariable Systems. Processes 2025, 13, 2161. https://doi.org/10.3390/pr13072161

Liu K, Lyu S, Wang R, Gao C, Yang X, Liu Y. Discrete-Time Internal Model Control with Equal-Order Fractional Butterworth Filter for Multivariable Systems. Processes. 2025; 13(7):2161. https://doi.org/10.3390/pr13072161

Chicago/Turabian StyleLiu, Kaiyue, Shuke Lyu, Rui Wang, Chenkang Gao, Xiangyu Yang, and Yongtao Liu. 2025. "Discrete-Time Internal Model Control with Equal-Order Fractional Butterworth Filter for Multivariable Systems" Processes 13, no. 7: 2161. https://doi.org/10.3390/pr13072161

APA StyleLiu, K., Lyu, S., Wang, R., Gao, C., Yang, X., & Liu, Y. (2025). Discrete-Time Internal Model Control with Equal-Order Fractional Butterworth Filter for Multivariable Systems. Processes, 13(7), 2161. https://doi.org/10.3390/pr13072161