Abstract

This research assesses the impacts of five cleaner production (CP) profiles of soap products and the overall equipment effectiveness (OEE) of liquid detergent production lines. A simulation model was built to depict the “As-Is” condition, and then the overall equipment effectiveness was calculated. Results showed high rejection rates and bottlenecks, resulting in long average cycle times and waiting times, as well as low production rates and machine utilization. Consequently, lean, agile, and resilient actions were utilized to enhance the OEE of the line’s processes. The improvement results showed that the bottle placement, filling, labeling, and taping processes were enhanced by 237%, 4.67%, 5.41%, and 26.02%, respectively. Moreover, the smallest percentages of availability, quality, and performance were 97.46%, 99.82%, and 81.56%, respectively, indicating a considerable enhancement in the performance of the line’s processes. Further, cleaner production assessment was performed on soap products to estimate environmental profile indices for raw material, energy, product, waste, and packaging. The estimated overall environmental index was 107.93, with liquid waste contributing the largest index value. Therefore, a proposal for a water treatment system was suggested and then assessed. In conclusion, lean, agile, and resilient actions were found to be effective in enhancing the OEE of production processes. Moreover, cleaner production provided valuable support to decision-makers in determining the appropriate actions for improving the OEE and environmental performance of the technological processes and products of detergent production lines.

1. Introduction

Uncertain and unexpected changes in demand and processes/products have urged firms to adopt effective improvement practices. Lean, agile, resilient, and cleaner production comprise effective practices that can improve the capability and efficiency of manufacturing processes [1,2,3]. Hence, this research employs applicable improvement practices to enhance the performance of the detergent production system.

Lean management focuses on eliminating eight types of waste, including overproduction, waiting, transportation, overprocessing, inventory, motion, defects, and non-utilized talent [4,5,6]. Lean practices can significantly reduce production lead and cycle times, waiting times, and the number of units in queues [7,8]. Further, industrial firms are facing rapid and unanticipated changes in demand. Agility is defined as the ability of a production system to reconfigure its operating status quickly, flexibly, and adequately to respond cost-effectively to unpredictable and ever-changing product demand [9]. Furthermore, agile manufacturing can enhance the capabilities of manufacturing processes and improve a firm’s competitive advantage [10]. Finally, resilience represents the ability of manufacturing systems to cope with disturbances that negatively impact product quality and process performance, such as unexpected machine breakdowns, product queues, and process variations [11,12,13]. It also prevents manufacturing systems from shifting to an undesirable state without incurring significant additional costs. Resilient systems have been considered in various manufacturing applications [14,15,16].

Furthermore, the growing recognition of environmental issues necessitates immediate reductions in the negative impacts caused by manufacturing processes and products. Therefore, production engineers are challenged to enhance the efficiency and productivity of manufacturing processes without attributing negative environmental impacts [17,18,19]. Conceptually, Cleaner Production (CP) seeks to integrate the continuous utilization of preventive environmental approaches to processes, products, and services, aiming to enhance efficiency, minimize negative environmental impacts, and achieve sustainable development goals [20,21]. CP practices collaborate in preserving raw materials and power, ensure the reduction or elimination of toxic materials, and minimize the toxicity of emissions and residues during the production processes [22,23]. Several studies have implemented CP to achieve the environmental goals of manufacturing processes [24,25,26]. Additionally, some studies aimed to enhance quality and reduce carbon emissions [27,28], whereas other studies examined the conceptual relationships between quality improvement techniques [29,30,31,32]. This research focuses on enhancing the OEE components and environmental performance of the technological processes and products of the detergent and soup production lines.

In this regard, this research aims to (1) enhance the OEE of liquid detergent production processes utilizing lean, agile, and resilient practices and (2) assess the environmental performance of the technological processes for soap products using cleaner production. The results of this research provide valuable support to production engineers on how to enhance the operational and environmental performance of the technological processes and products. Compared to previous studies, this research contributes to ongoing research by combining lean, agile, and resilient practices, and environmental assessment to improve the efficiency of technological processes and the sustainability of the produced products. The remainder of this research is outlined in the following sections. Section 2 describes the research methodology and application. Section 3 presents the improvement actions. Section 4 presents research results. Section 5 summarizes research conclusions.

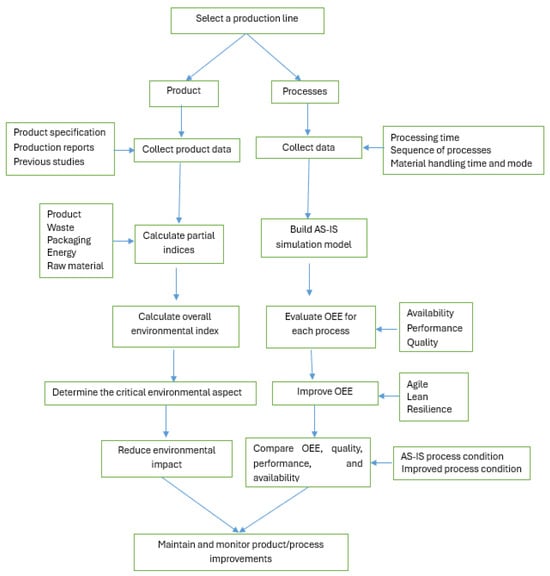

2. Research Methodology and Application

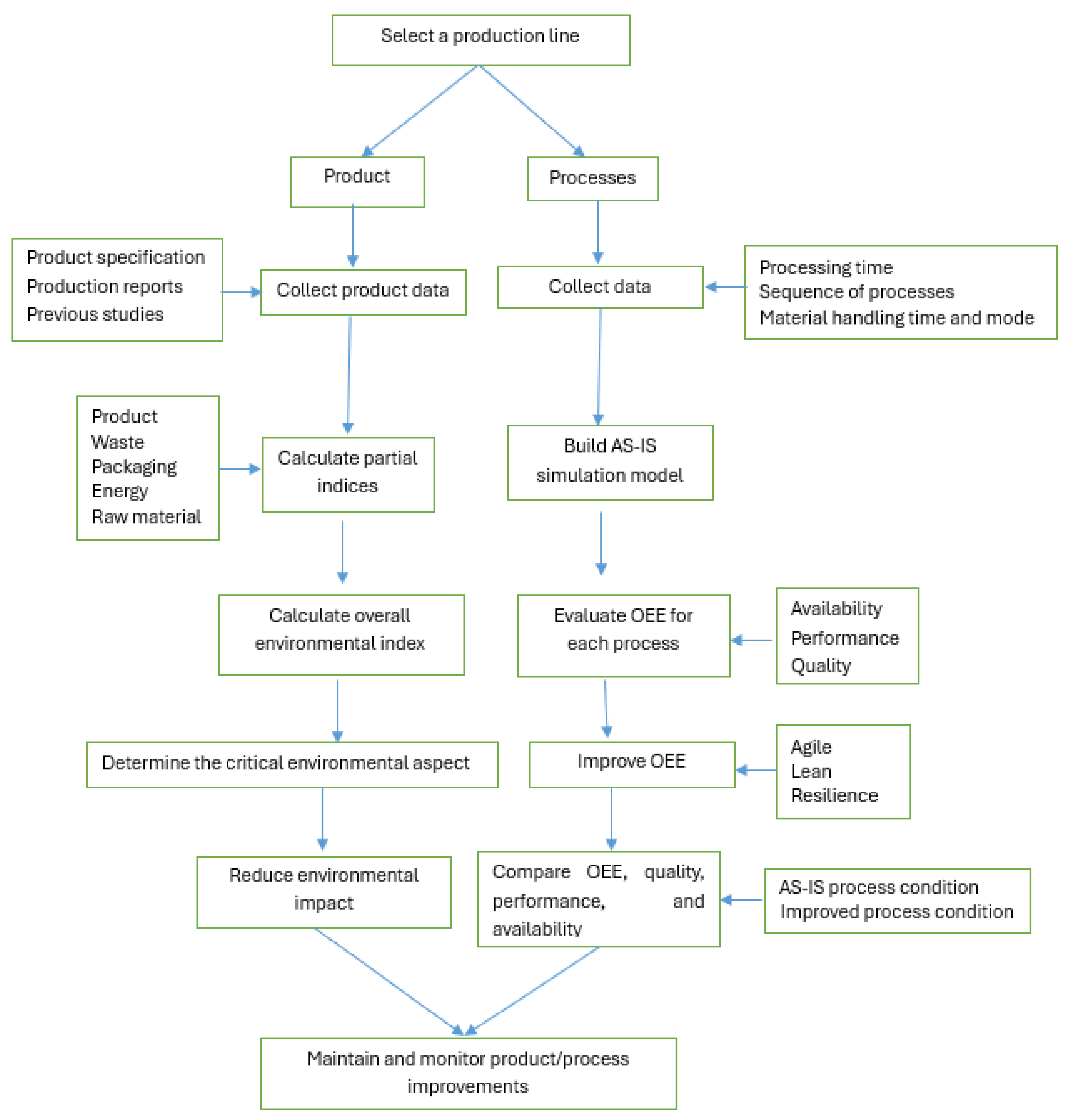

The methodology to achieve the objectives of this research is depicted in Figure 1. Initially, the key production line is selected based on production experience with processes that need significant improvement to achieve the firm’s goals. Next, the main product is chosen, and the relevant technological processes are mapped. Data collection for processing times, handling characteristics, and product specifications is performed. Evaluation of the OEE at the current process conditions and assessment of the environmental impacts for five environmental profiles based on the existing product characteristics are then conducted. Improvement opportunities are then identified for manufacturing processes and products. Finally, appropriate improvement actions utilizing the practices of lean, agile, resilient, and CP are conducted, and then improvements in process OEE and environmental performance are assessed. Finally, improvements are implemented and maintained.

Figure 1.

Research methodology.

2.1. As-Is Simulation Model

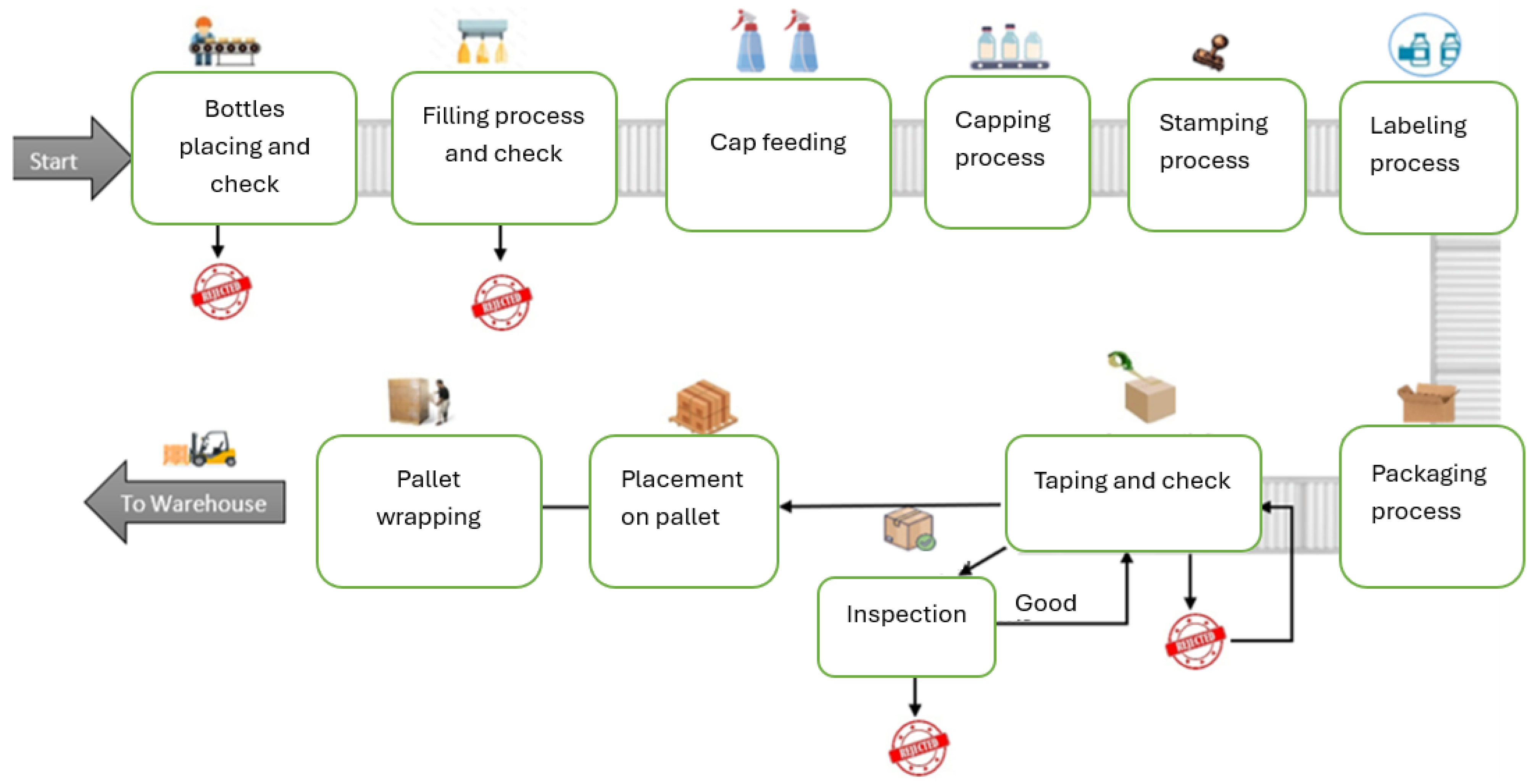

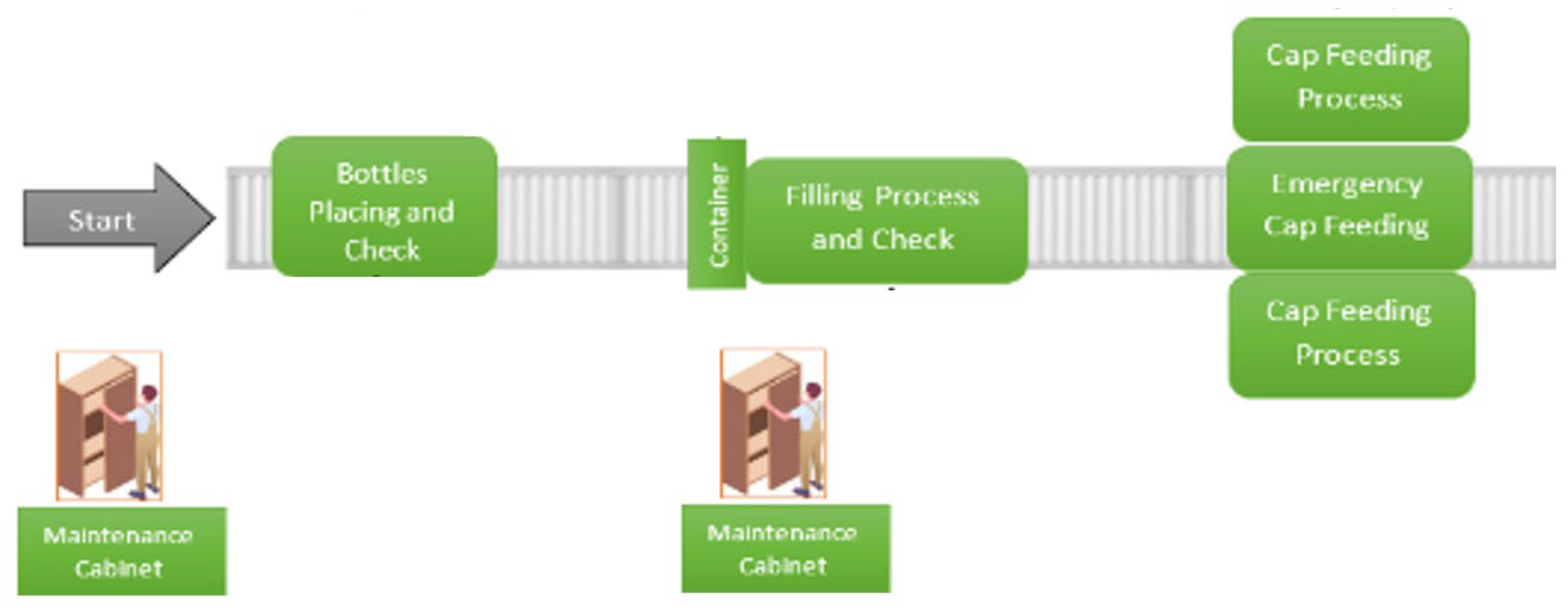

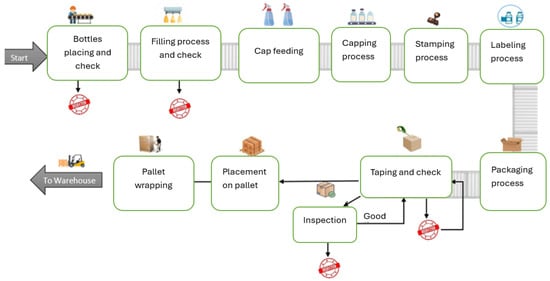

Figure 2 shows the production line of liquid detergents, which contains various processes, including bottle placing, filling, cap feeding, stamping, labeling, packaging, and taping. Time and motion studies were conducted to collect process data, which were then fitted to appropriate distributions, as shown in Table 1. The conveyor characteristics are presented in Table 2.

Figure 2.

Production line segments.

Table 1.

Process time fitting distributions (in seconds).

Table 2.

Conveyor characteristics.

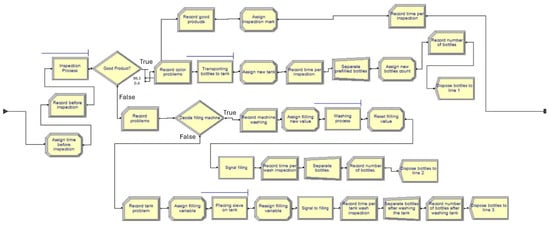

The As-Is model consists of the following Sub-models.

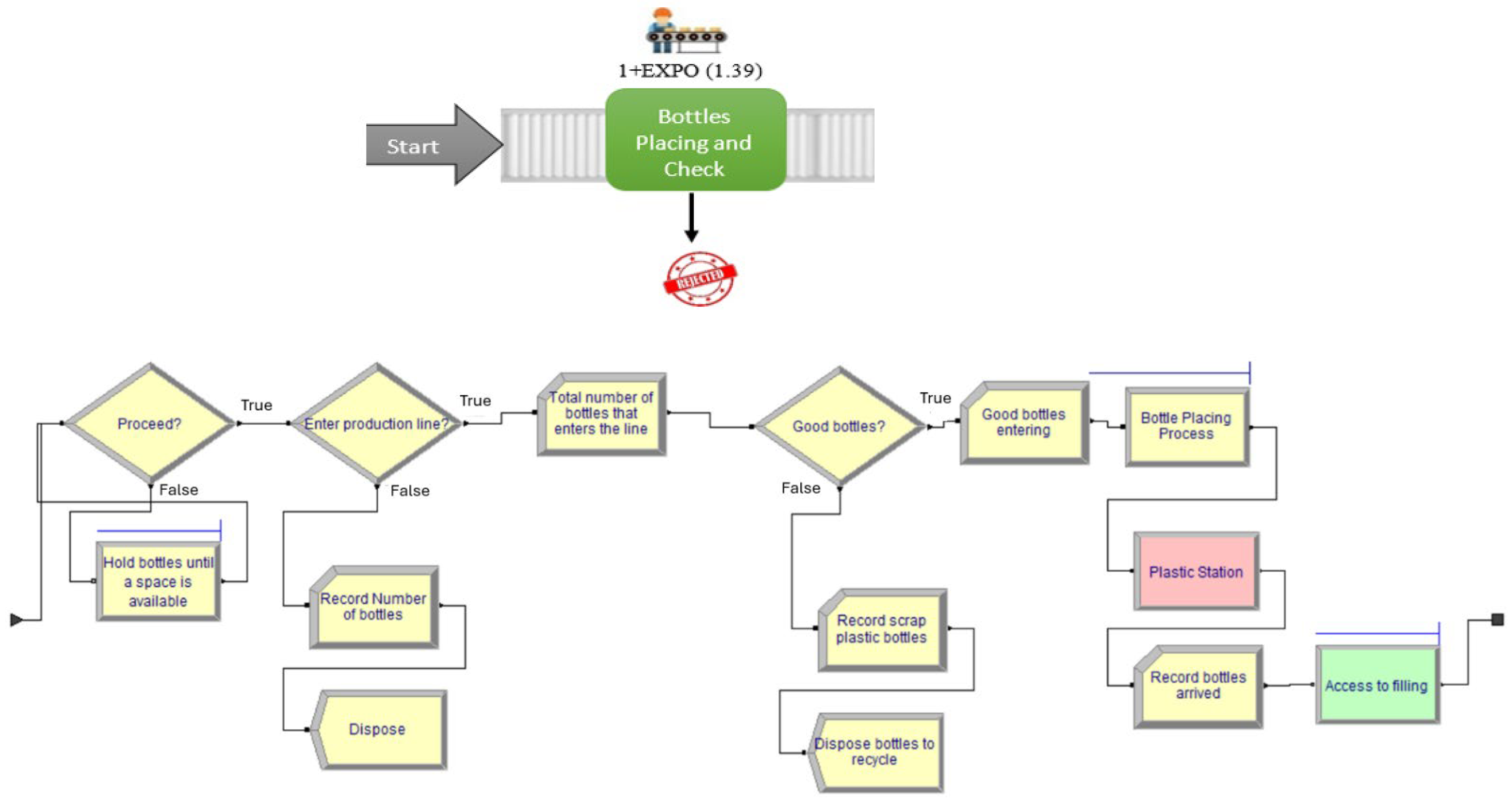

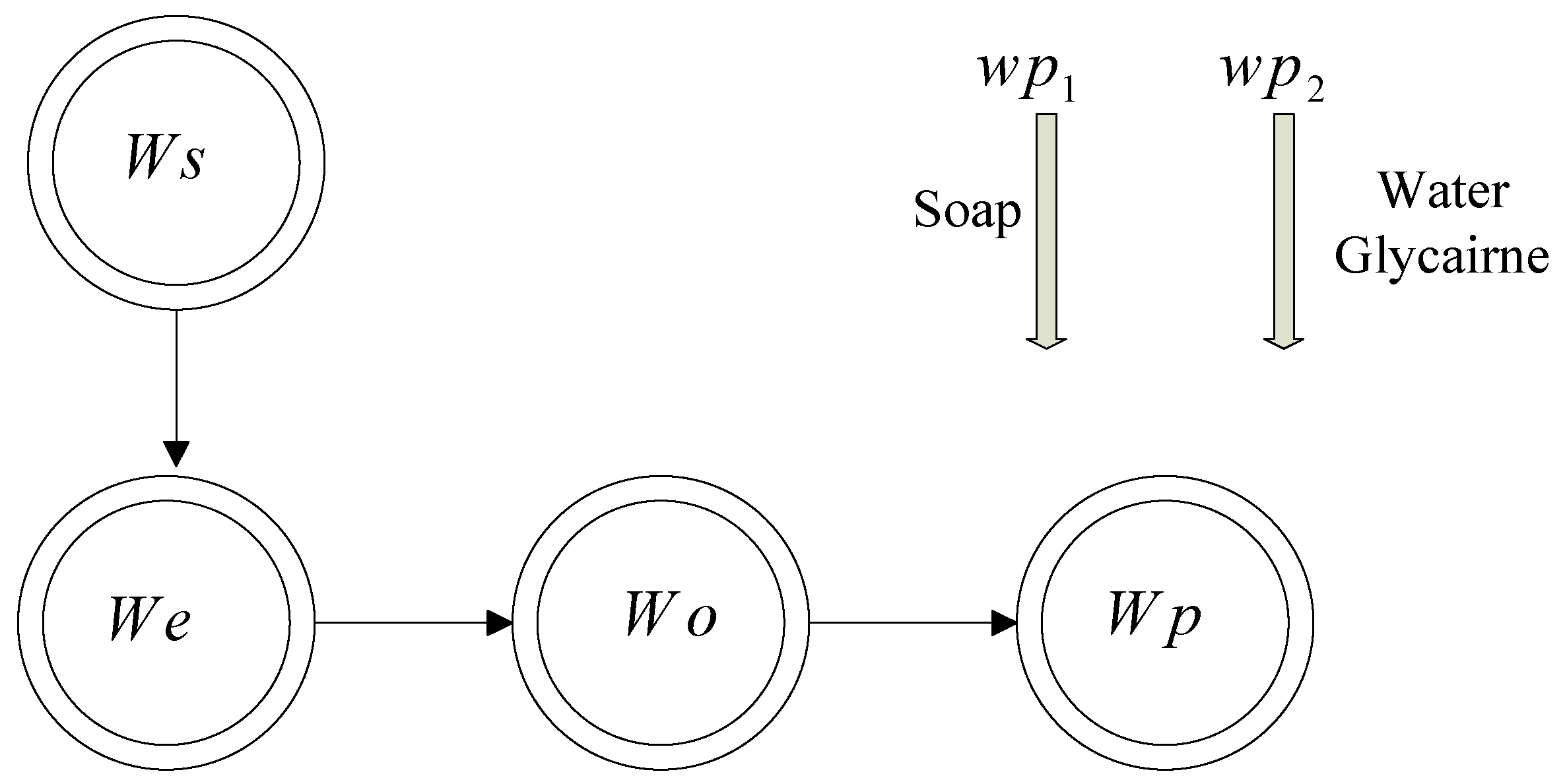

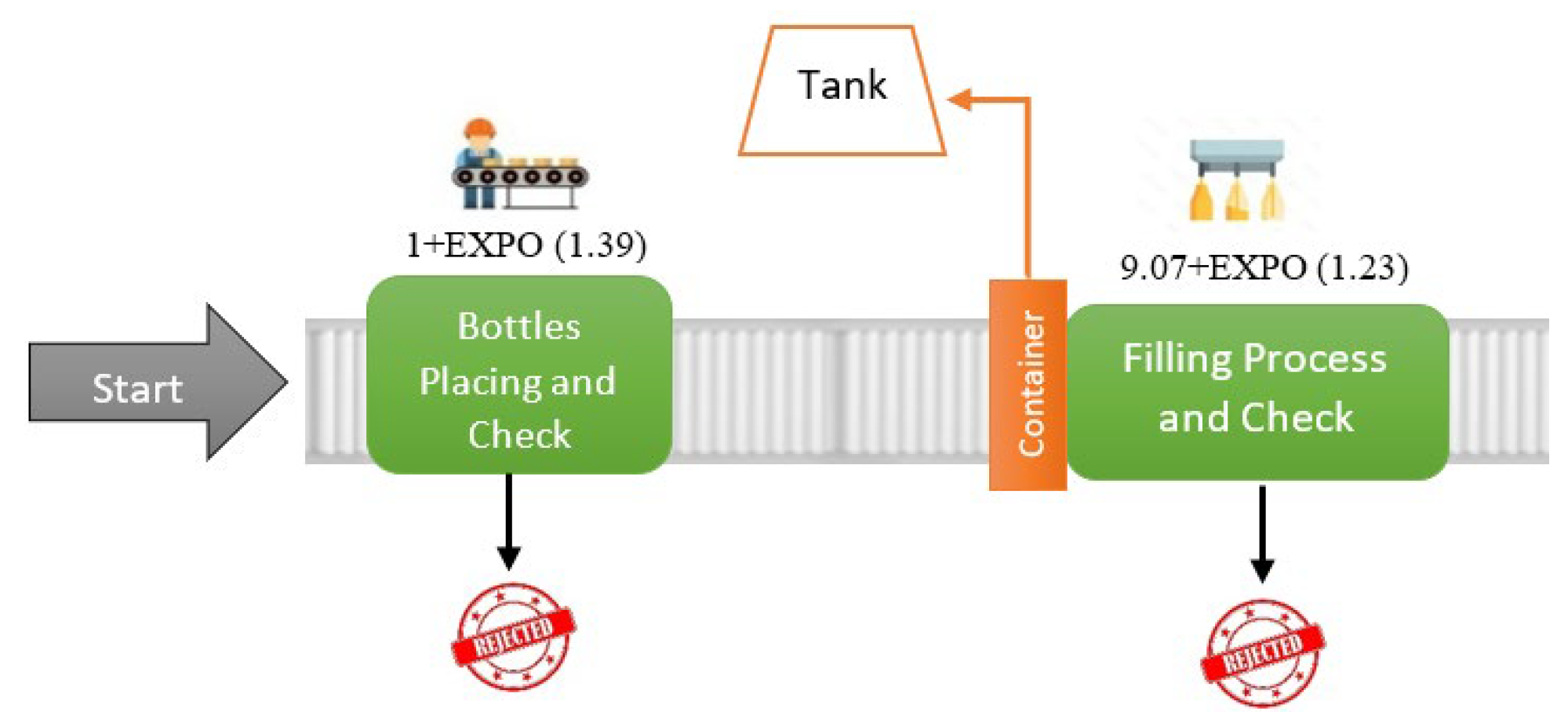

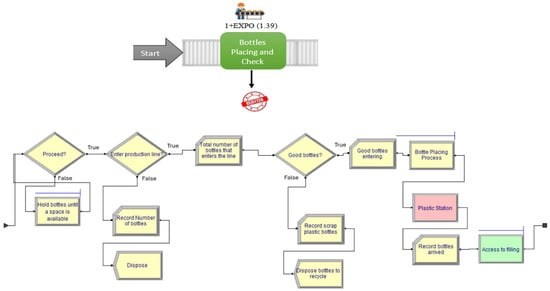

2.1.1. Bottle Arrival Sub-Model

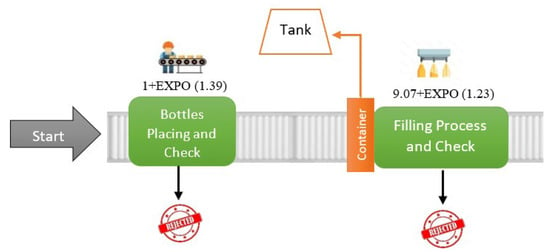

The bottle arrival sub-model is depicted in Figure 3. A pallet of nine plastic bags of 165 bottles is fed manually to the production line. The interarrival time between the bottles is defined as 1 + EXPO (1.39) seconds. Once a bottle has entered the production line, an operator checks the conformity of the bottles. The non-conforming bottles are returned to the plastic factory to be recycled, whereas acceptable ones access the plastic station and are transported by conveyor to the filling machine.

Figure 3.

Bottle arrival sub-model.

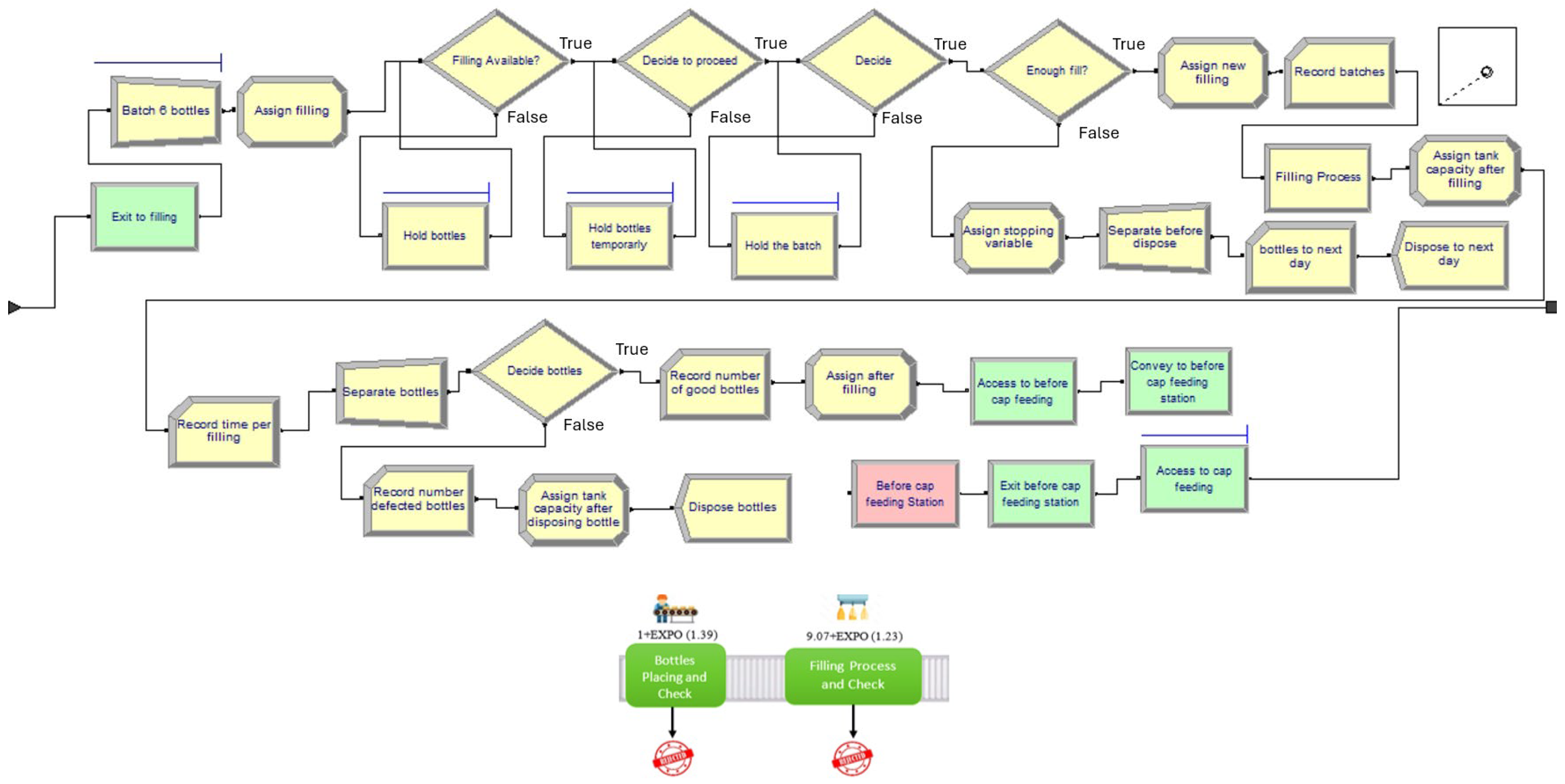

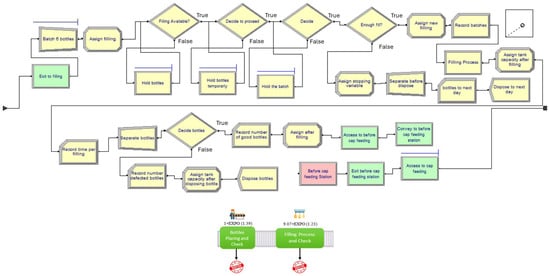

2.1.2. Filling Process Sub-Model

The detergent material is stored, as shown in Figure 4, in a tank with a 10,000 L capacity. The filling machine has six nozzles to fill six bottles concurrently. The processing time data for filling bottles is modeled as 9.07 + Exponential (1.23) seconds. A sensor failure occurs every 24 h and requires a 10-min fix.

Figure 4.

Filling sub-model.

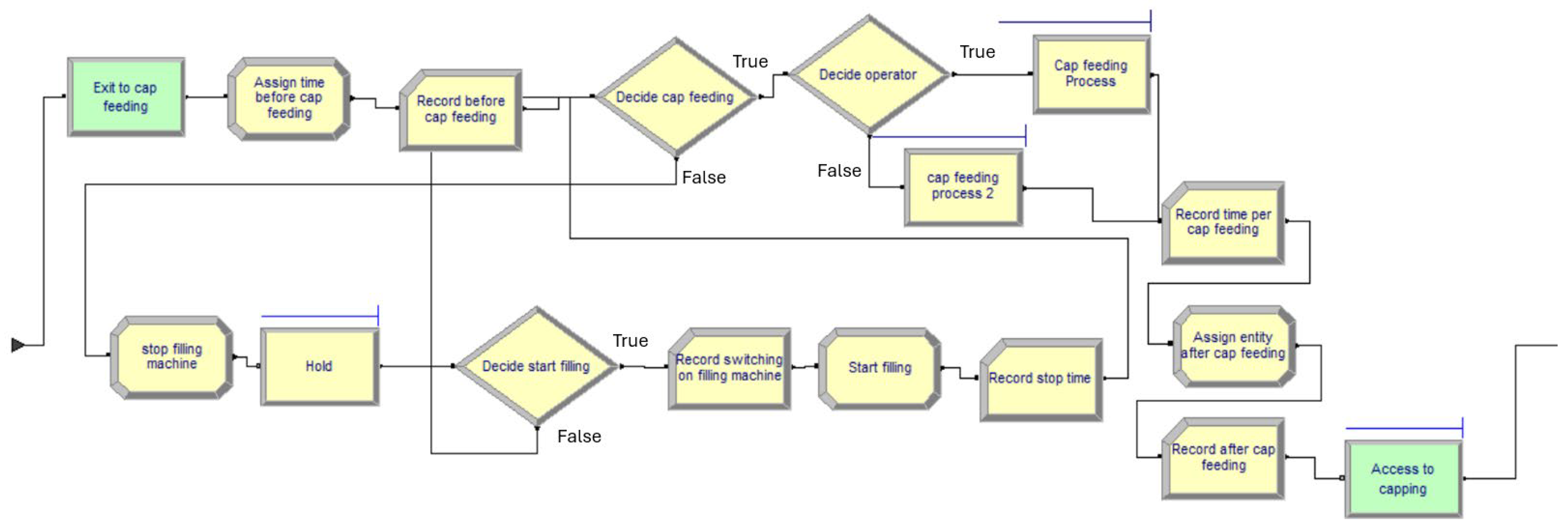

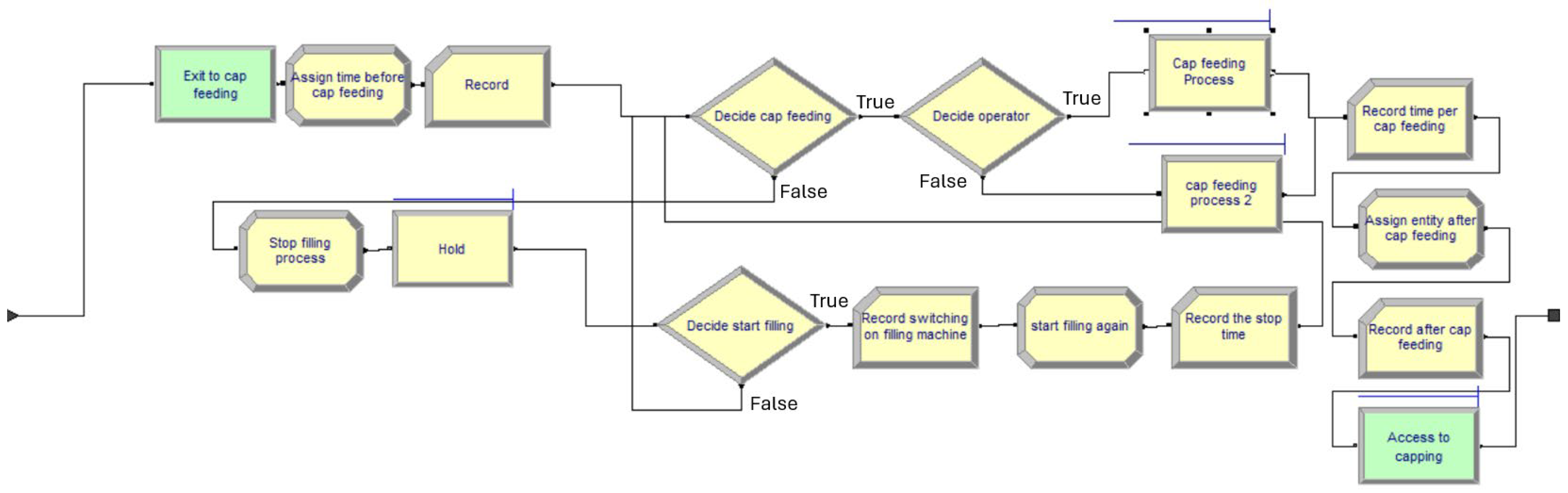

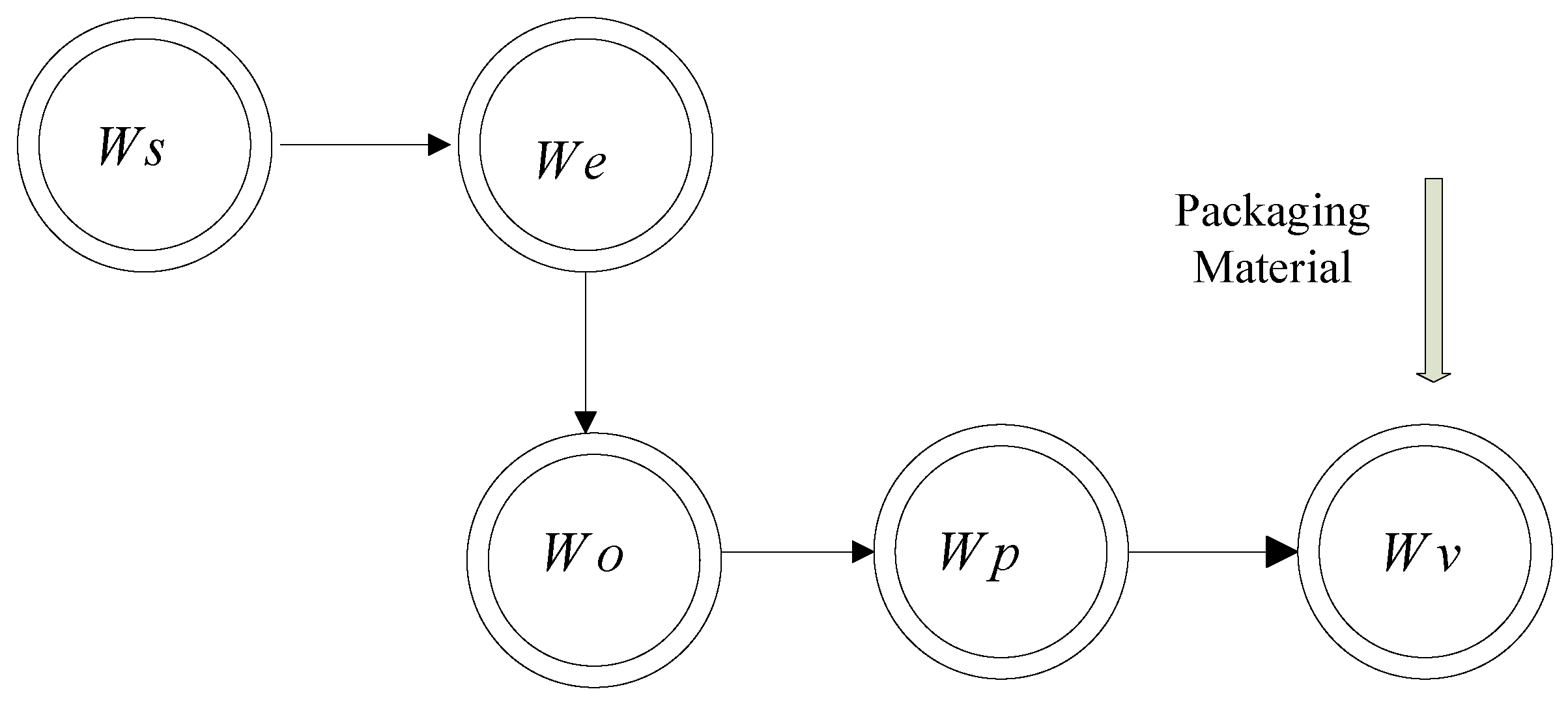

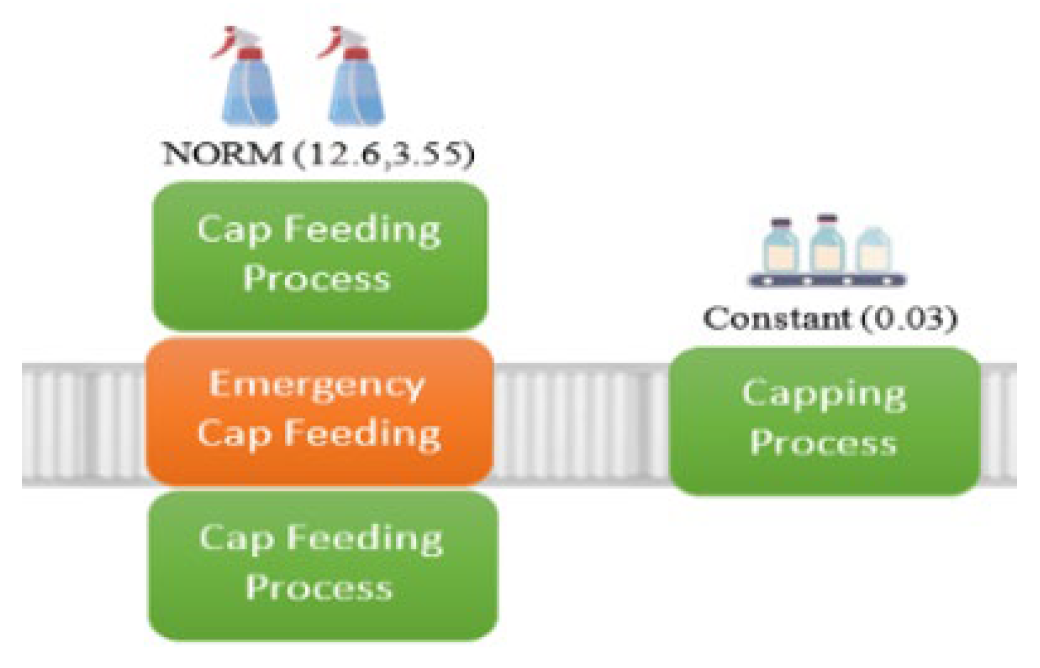

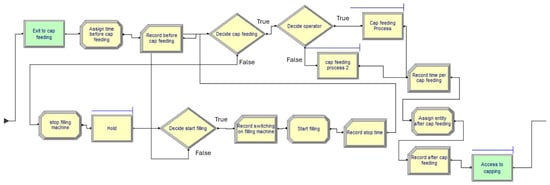

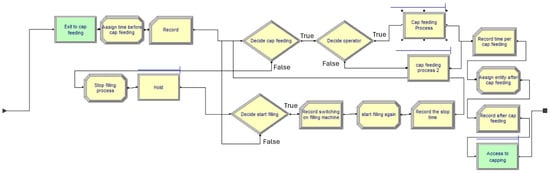

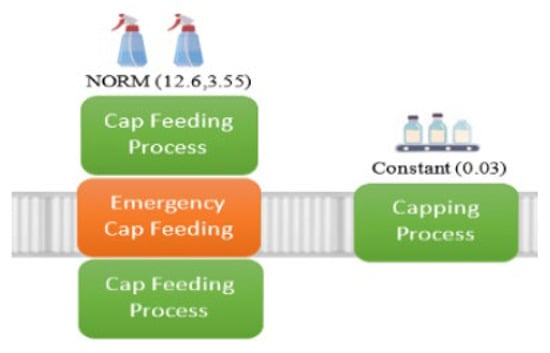

2.1.3. Cap-Feeding Sub-Model

The cap-feeding process is shown in Figure 5 and requires two operators who place and screw caps. The processing time follows a normal distribution NORM (12.6, 3.55). For every 396 bottles, the process stops temporarily for 40 s while a new box of caps is bought. When the process queue reaches 18 bottles, the filling machine stops.

Figure 5.

Cap-feeding sub-model.

2.1.4. Capping Sub-Model

The filled bottles are moved, as shown in Figure 6, to the capping process for closing, which takes 0.3 s.

Figure 6.

Capping Sub-model.

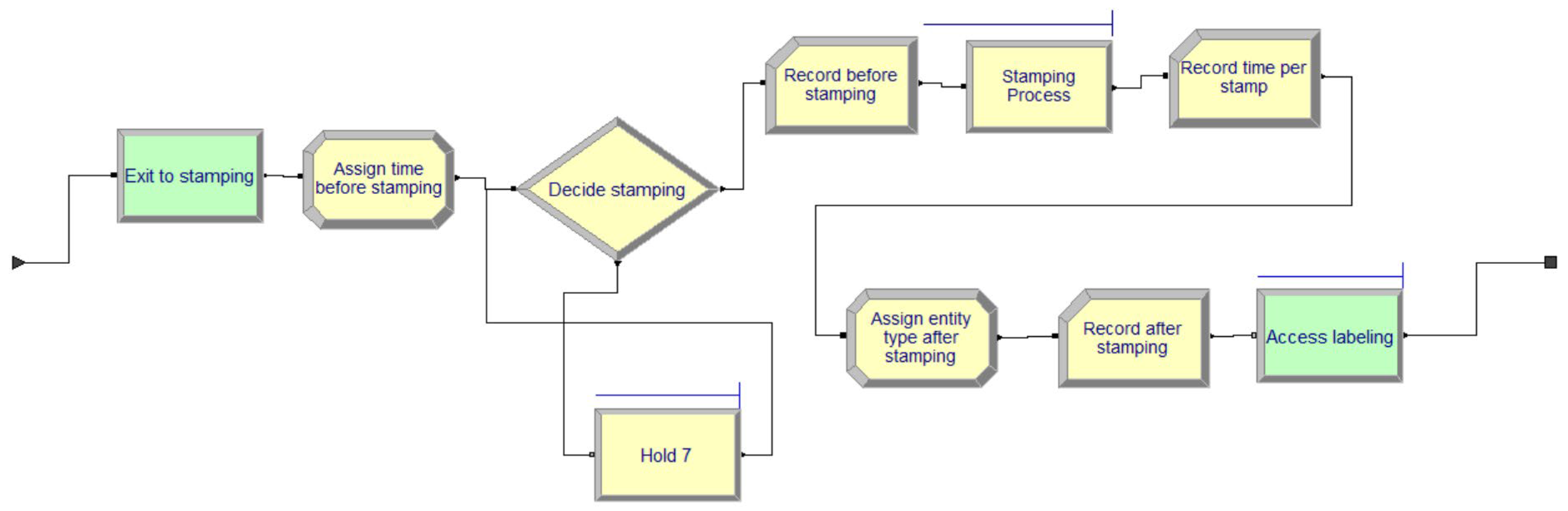

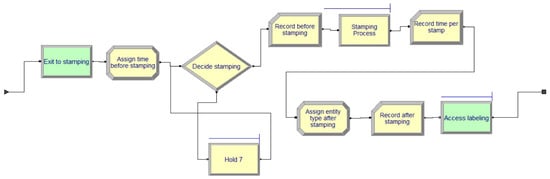

2.1.5. Stamping Sub-Model

The sealed bottles are moved automatically, as shown in Figure 7, to the stamping station. The processing time is 0.47 s.

Figure 7.

Stamping sub-model.

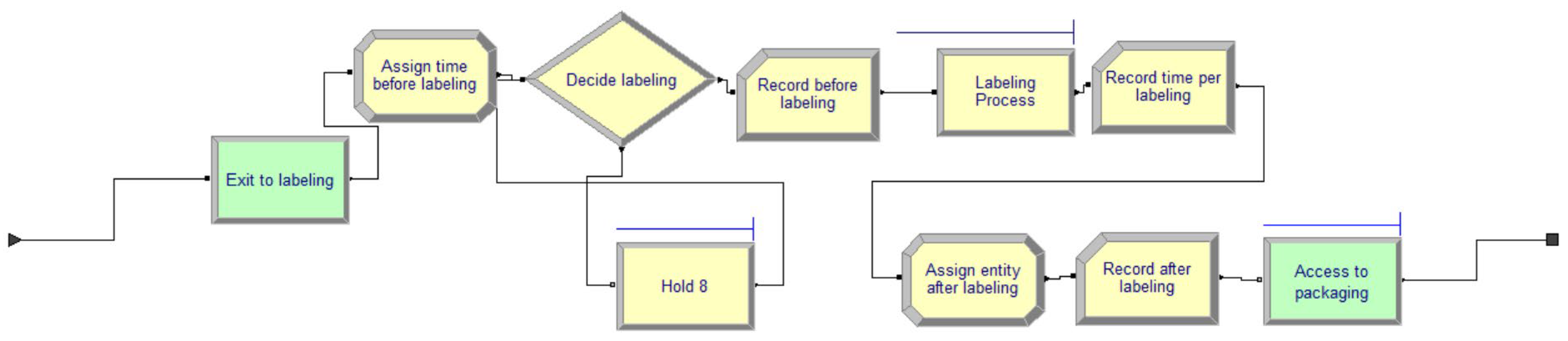

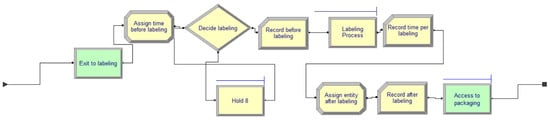

2.1.6. Labeling Sub-Model

The simulation model for the labeling process is depicted in Figure 8. Two stoppages occur as the label roll must be changed every 3456 bottles. The process mean time to failure and downtime are 2 h and 5 min, respectively.

Figure 8.

Labeling sub-model.

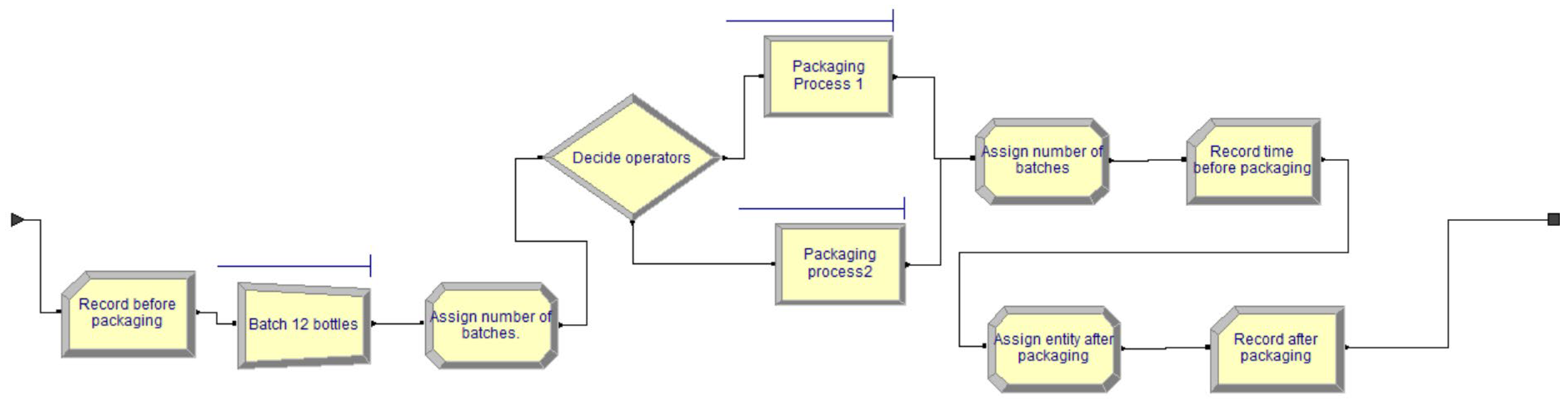

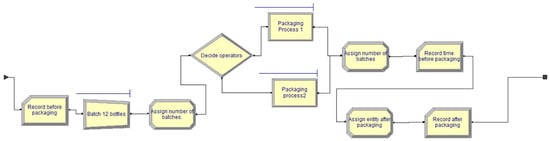

2.1.7. Packaging Sub-Model

The labeled bottles, as shown in Figure 9, are batched into boxes of 12 bottles. At the packaging station, two operators package bottles following a processing time defined as 13 + WEIB (40.4, 1.19) seconds. An inspection is conducted to detect misalignments of the label position on the bottle.

Figure 9.

Packaging sub-model.

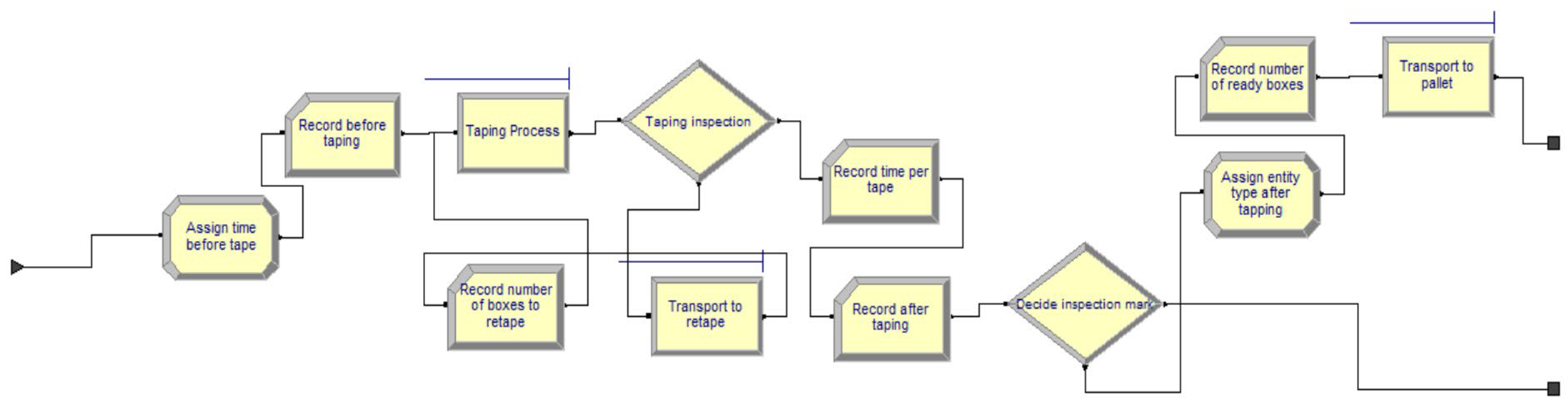

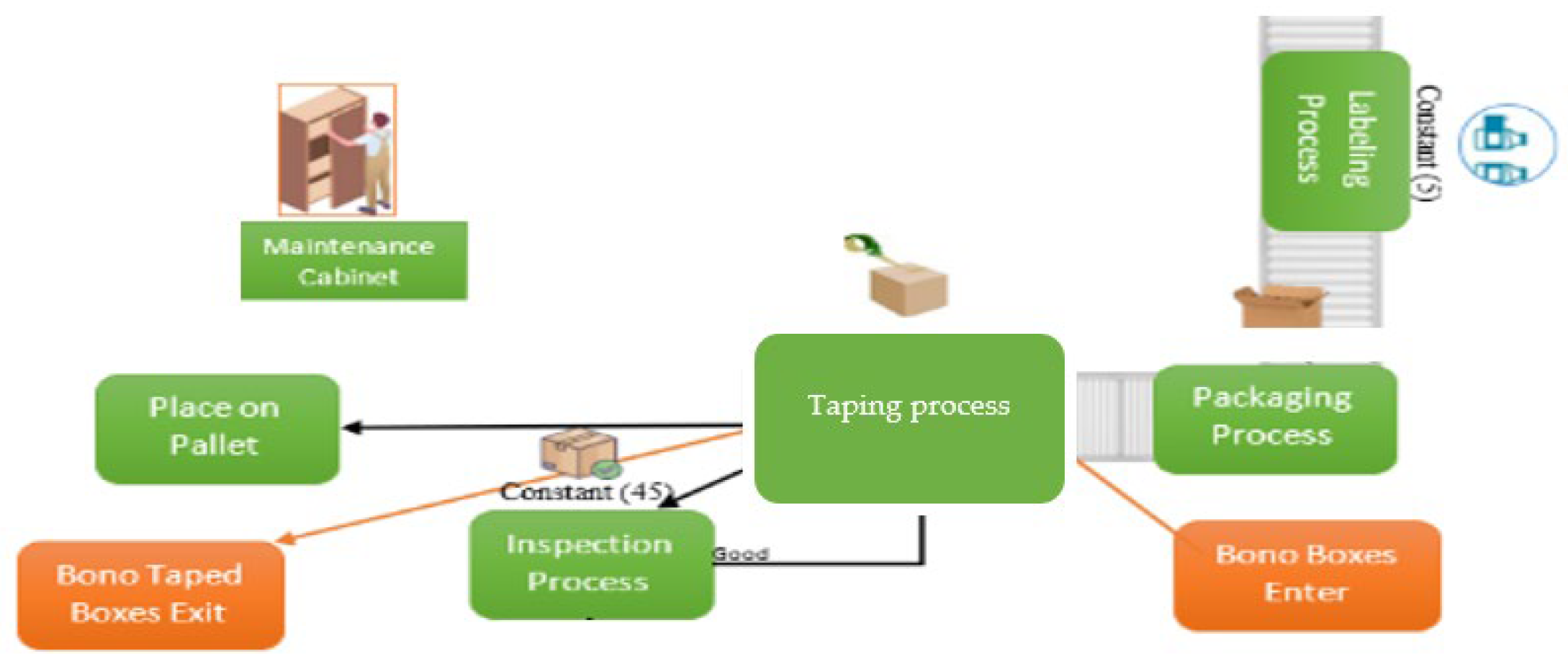

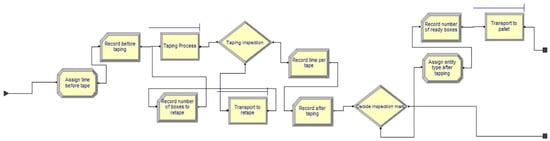

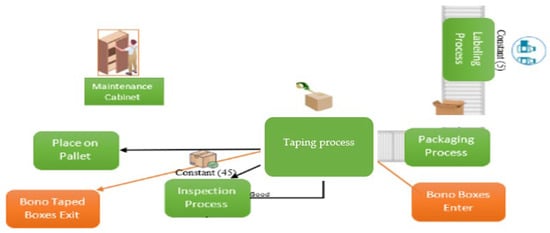

2.1.8. Taping Sub-Model

The taping process is shown in Figure 10. The machine requires lubrication every 2 h.

Figure 10.

Taping sub-model.

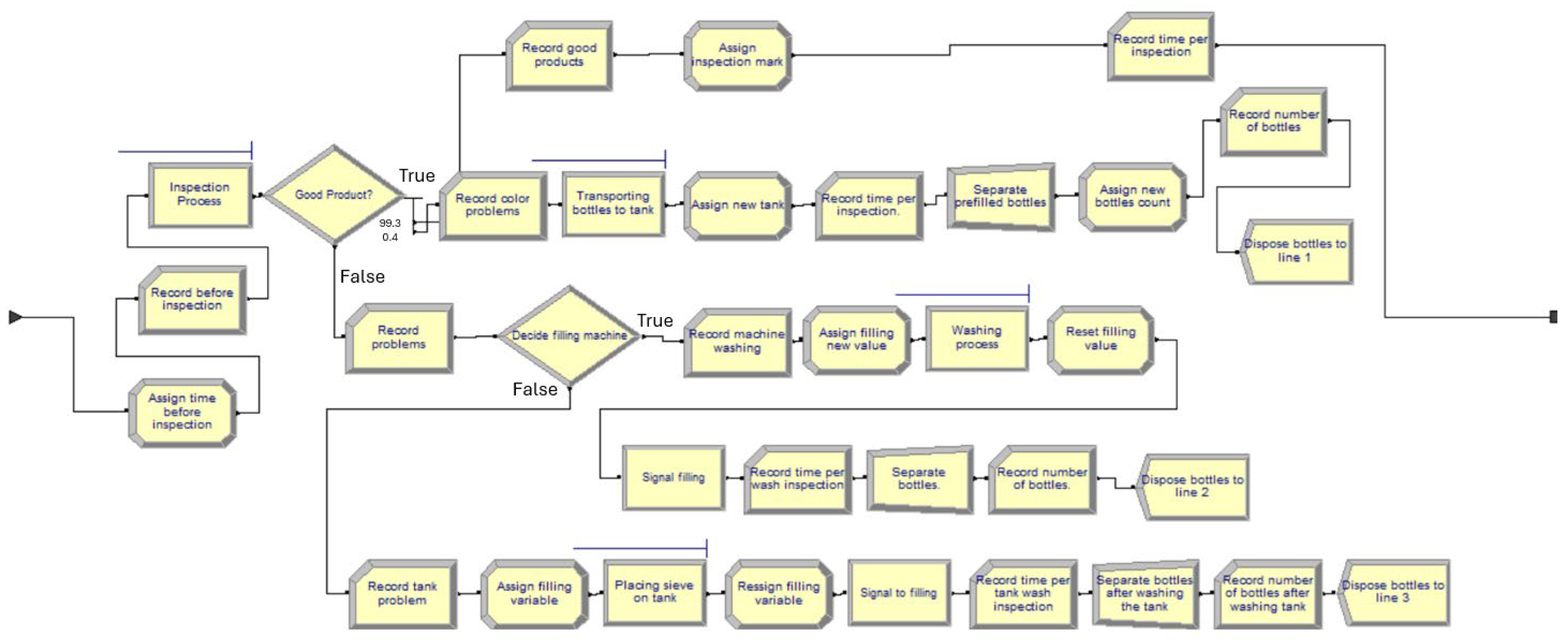

2.1.9. Inspection Sub-Model

The inspection sub-model is constructed, as shown in Figure 11. The box inspection is performed by one inspector every 20 min with an inspection time of 45 s.

Figure 11.

Inspection sub-model.

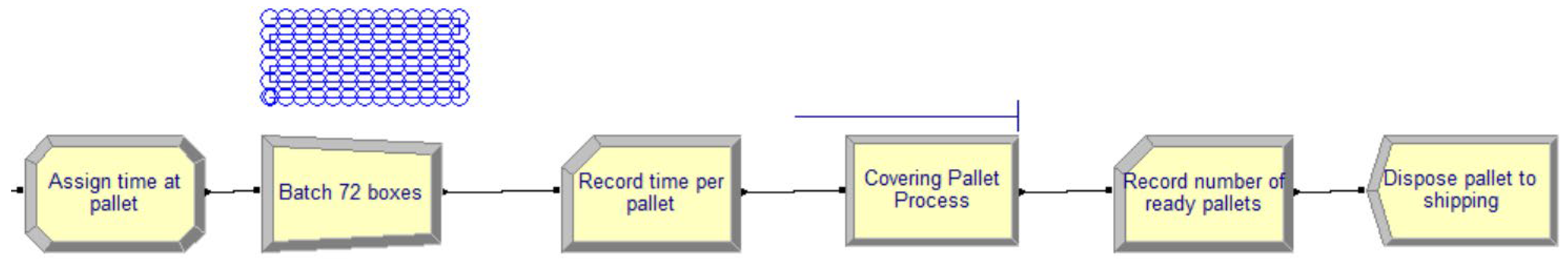

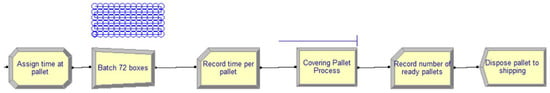

2.1.10. Palletizing Process

After the boxes are taped and inspected, they proceed as shown in Figure 12 to the pallet at the end of the production line with a transfer time defined as TRI (2, 3, 5) seconds. Each pallet contains 72 boxes wrapped securely. This process is performed manually and takes 3 s. Completed pallets are then transported to the finished goods warehouse.

Figure 12.

Palletizing process.

Simulation for the production line was run for a two-shift working day of 11.5 h/shift and replicated 50 times. Simulation results were then compared to the actual output to assess the model’s validity and reliability, as shown in Table 3. The maximum error between the simulated output and actual observed data is 2.79% for the transportation to the retaping process. Consequently, the simulation model is considered valid because the error is less than 5%.

Table 3.

Model validation.

Overall Equipment Effectiveness (OEE) is commonly used to measure three critical manufacturing performance indicators (availability %, quality %, and performance %). Measuring OEE provides a valuable indication of how to systematically improve production line processes and provides an accurate picture of how effectively a process runs over time. OEE is calculated as follows [33]:

Availability (%) considers all unplanned and planned events that stop planned production and result in machine downtime. Availability is calculated using Equation (2).

where Planned Production Time (PPT) is calculated as follows:

and

PPT = Shift Working Hours − Breaks

According to the simulation results, the Availability for each process is calculated and presented in Table 4. Furthermore, quality (%) considers quality losses, which encompass manufactured parts that fail to meet quality requirements and standards. Quality can be measured as follows:

Table 4.

Availability (%) of the AS-IS model.

The calculated quality (%) for each process is presented in Table 5. Finally, performance (%) considers anything that causes the manufacturing process to run at less than the maximum possible speed when it is running. Performance can be measured as follows [34]:

where the ideal cycle time (ICT) represents the minimum time to produce one part. The performance of each process is calculated and presented in Table 6.

Table 5.

Quality (%) of the AS-IS model.

Table 6.

Performance (%) of the AS-IS model.

Table 7 displays the calculated OEE for the production line. It is noted that the bottle placing, filling process, labeling process, and taping correspond to OEE values below the targeted world-class level (=85%). Consequently, improvement actions are needed to enhance the OEE level for these processes.

Table 7.

OEE (%) of the AS-IS model.

2.2. Environmental Assessment

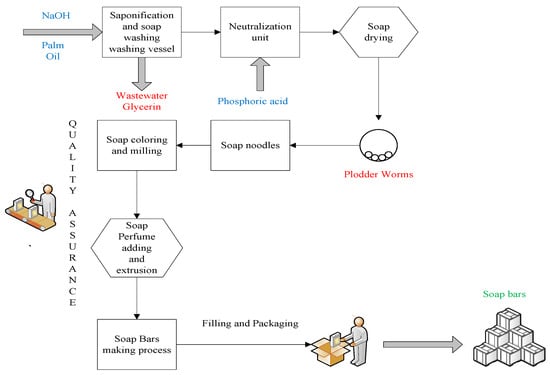

The environmental assessment for the soap production line is conducted as follows [17]. The basic components of the soap bar are as follows: (1) fats and oils, including palm oil, palm stearine oil, palm kernel oil, and coconut fatty acids; (2) sodium hydroxide (NaOH), also known as caustic soda; and (3) sodium chloride (NaCl). The basic formulations of soap are as follows:

Fats/Oils + Water --------> Fatty Acids + Glycerin

Fatty Acids + Caustic Soda --------> Soaps + Water

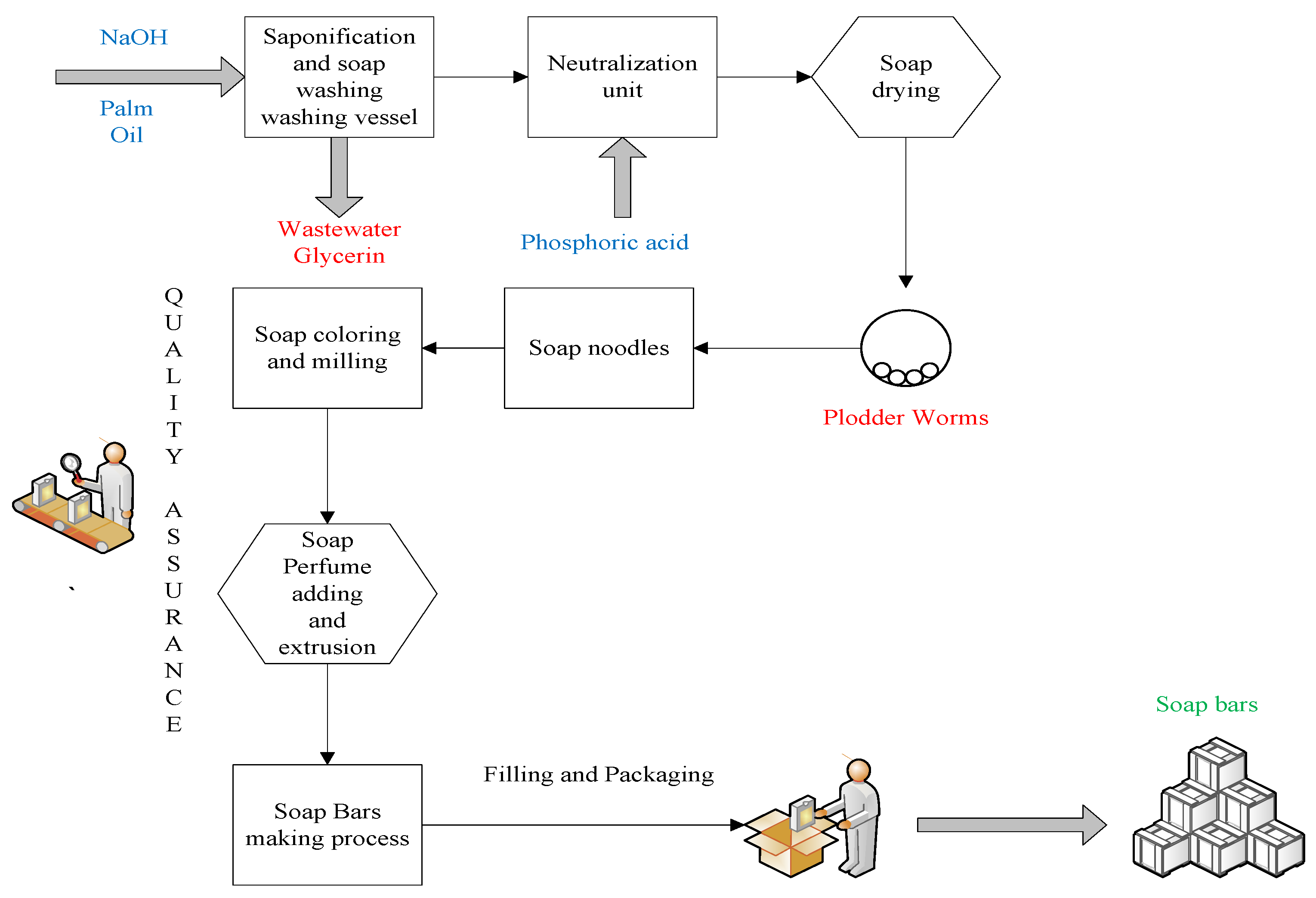

Figure 13 illustrates the soap production processes; it usually goes through saponification and toilet soap production processes, where palm oil and other raw fats are thermally treated with steam in the presence of caustic soda (NaOH), forming soap and water with traces of glycerin and salt by-products. The neutralization process is important, as the caustic levels are unacceptably high for toilet soap.

Figure 13.

Soap production processes.

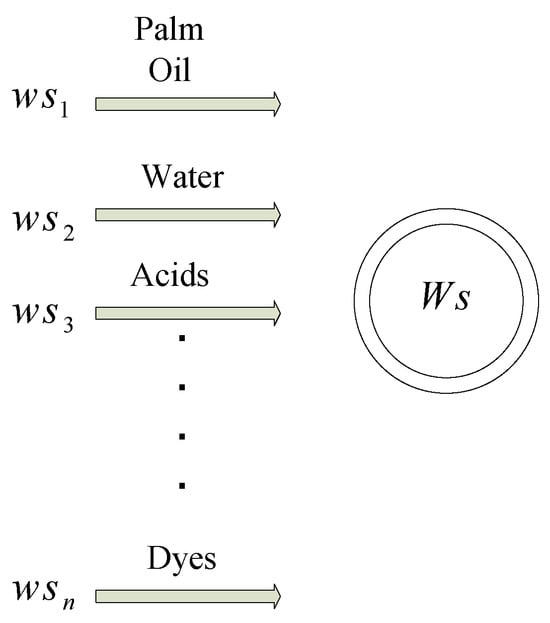

Five profiles are considered when preparing the environmental characteristics, including the following:

- (i)

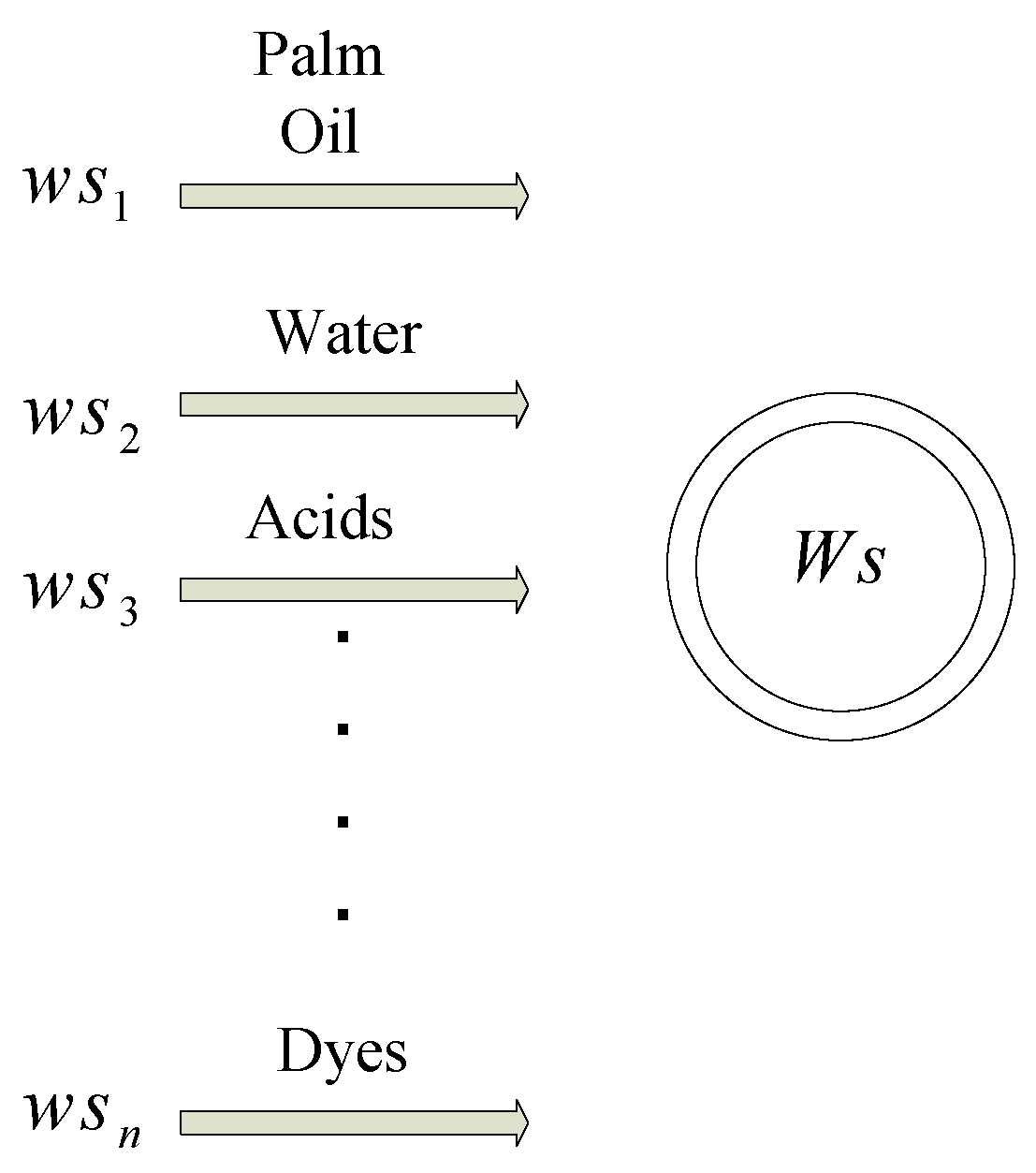

- Raw material unit index

The raw material profile for the soap product, as shown in Figure 14, comprises quantitative data related to all raw material flows, including primary raw materials, auxiliary raw materials, and water used in technological processes. Let Ws and wsi denote the raw material unit index and the partial raw material unit index for the primary raw material i, respectively.

where msi denotes the weight of the primary raw material i used in the technological process, and mcp denotes the total weight of all products manufactured in the technological process.

Figure 14.

Raw material unit indices.

- (ii)

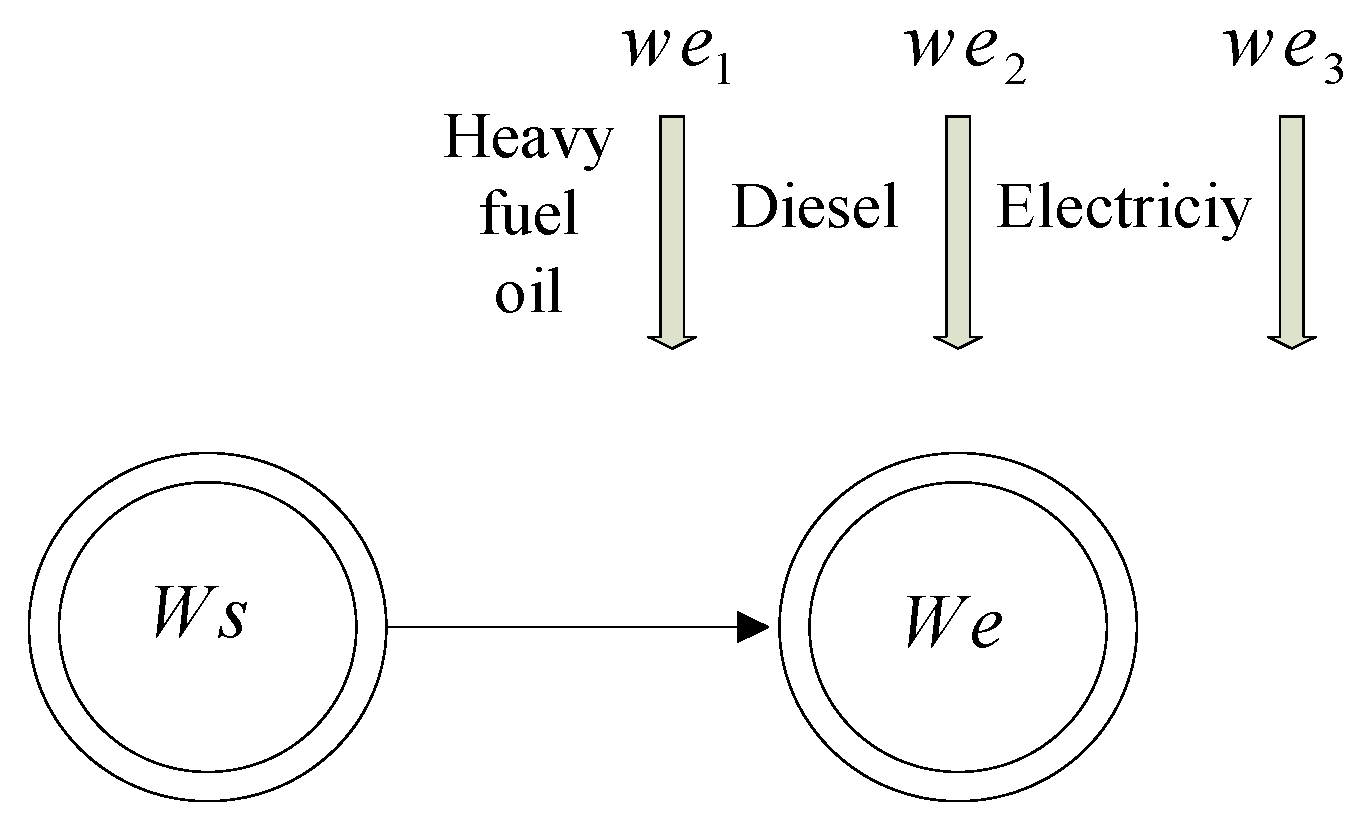

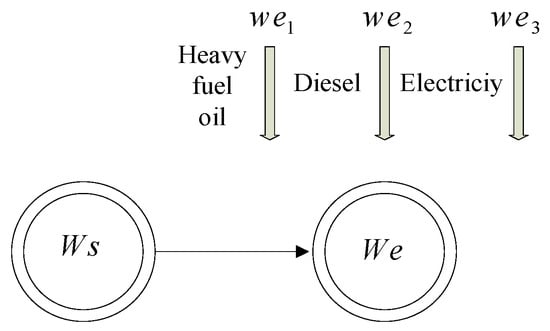

- Energy unit index

The energy profile, as shown in Figure 15, covers quantitative data related to the consumption of all power raw material flows (solid, liquid, and gaseous fuels) and any kind of energy (heat, electricity) used in the process. Let wej denote the partial energy unit index for the power raw material j, calculated as follows:

where zej denotes the consumption of power raw material j, expressed in weight of standard fuel.

Figure 15.

Energy unit indices.

- (iii)

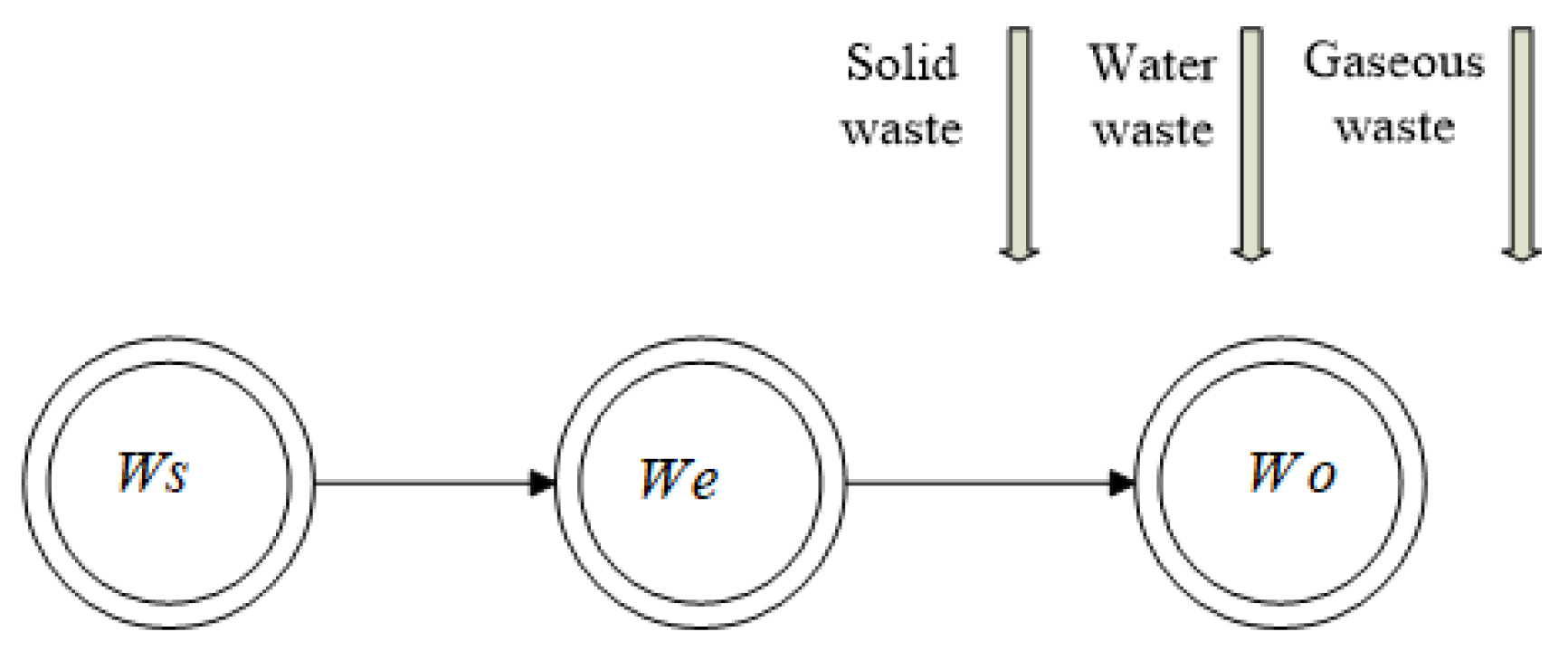

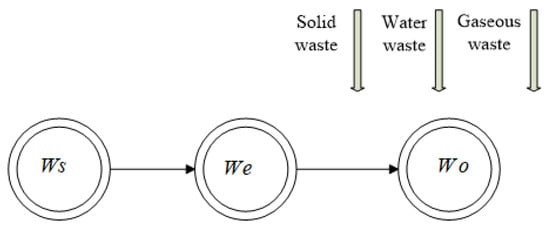

- Waste unit index

The waste profile, as shown in Figure 16, consists of quantitative data related to all waste flows, including solid, liquid, and gaseous wastes generated during the process. Let and denote the partial solid waste generation unit index and the relative solid toxicity index, respectively. Let mosk denote the weight of solid waste generated. Then,

Figure 16.

Waste unit indices.

Let wocl and kocl denote the partial liquid waste generation unit index and the relative liquid toxicity index, respectively. Then,

where mocl denotes the weight of liquid waste generated.

Let wogg and kogg denote the partial gaseous waste generation unit index and the relative gaseous toxicity index, respectively. Then,

where denotes the weight of gaseous waste generated.

- (iv)

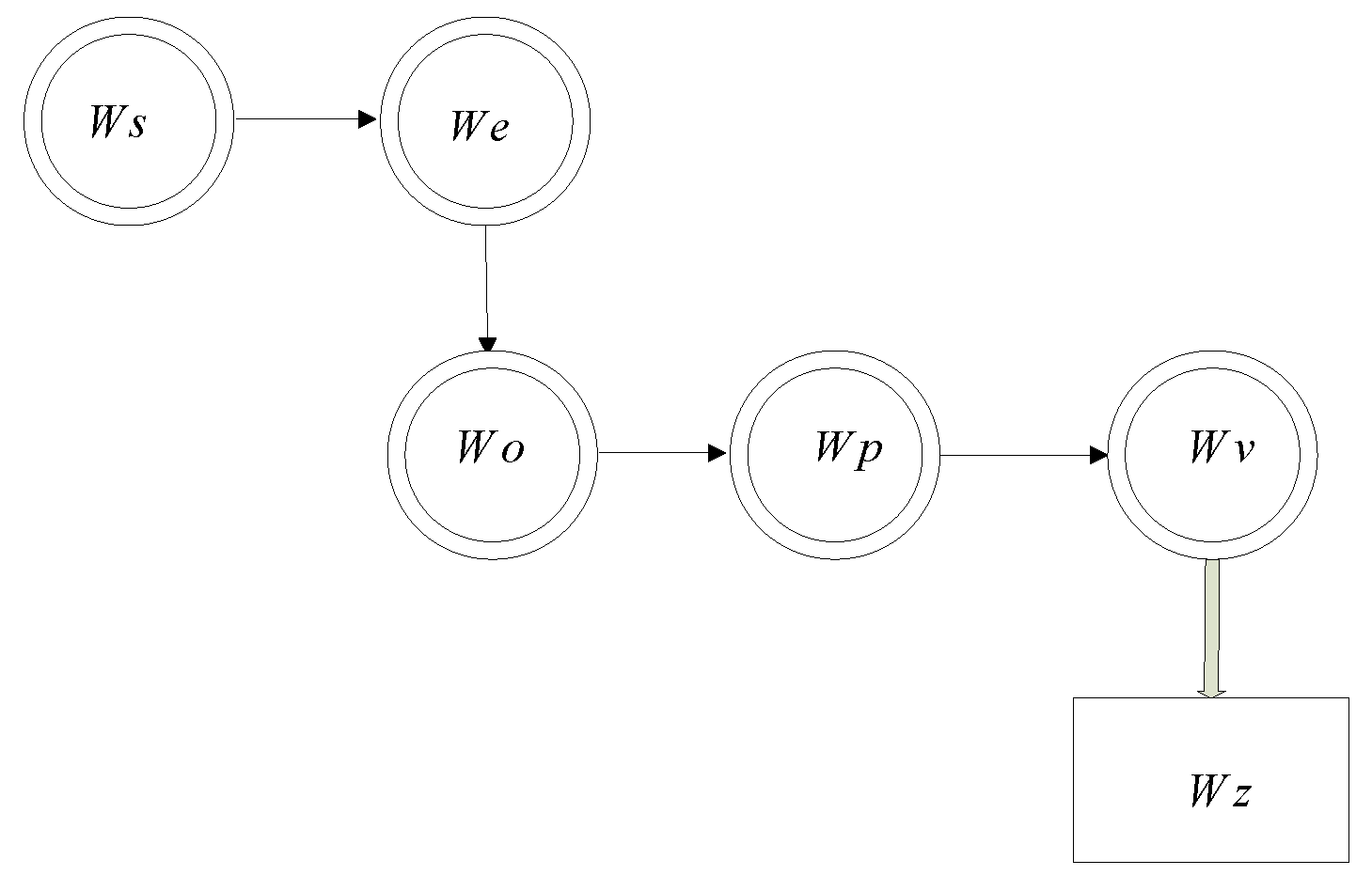

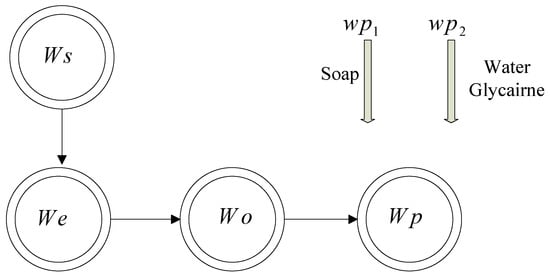

- Product unit index

The product profile, as shown in Figure 17, comprises quantitative data related to product flows that have adverse environmental impacts resulting from the technological process. Let wpp denote the partial product unit index for product p, calculated as follows:

where msp denotes the weight of the manufactured product p by the technological process. Let

where mse denotes the weight of environmentally hazardous components of the unit product p.

Figure 17.

Product unit indices.

- (v)

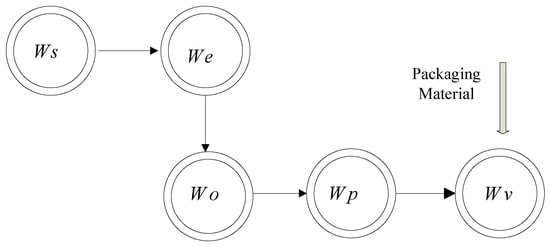

- Packaging unit index

The packaging profile, as shown in Figure 18, comprises the environmental characteristics of the packaging materials used in the technological process, including quantitative data related to all types of packaging, while considering their negative environmental impact. Let wvh be the partial packaging unit index for packaging material h, calculated as follows:

Figure 18.

Packaging unit indices.

That mvh denotes the weight of the kind of packaging material h. Let

where kvs and kvs max denote the total environmental loading index for the given packaging material and the maximum value of the total environmental loading index for packaging materials, respectively.

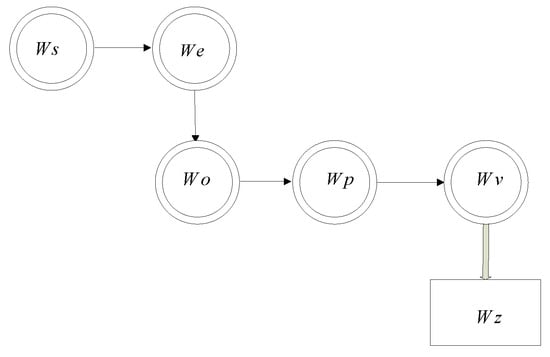

The integrated index is a mathematical expression describing the developed model for the overall environmental assessment of the technological process, while considering the environmental quality of the manufactured products. The integrated environmental assessment index, Wz, for cleaner production technologies, as shown in Figure 19, is estimated using Equation (16).

Figure 19.

Integrated environmental assessment indices.

The environmental nuisance for any analyzed technological process is classified according to Table 8.

Table 8.

Environmental nuisance classification scheme.

The Wz was calculated to determine the degree of environmental nuisance related to the technological processes at the soap factory and is presented as follows:

- (i)

- Raw material unit index

The raw material unit index, Ws, for the soap production was calculated for the raw materials, and the results are displayed in Table 9. For illustration, the unit index for palm oil is calculated as follows. The weight of palm oil used in the process is 1960 metric tons, and the total weight of all soap manufactured in the process is 3605 tons. The partial palm oil unit index, ws1, is calculated as 0.544 (=1960/3605). Knowing that the mass of one unit of soap produced is 0.1 kg, which gives 10 units in 1 kg, ws1 in terms of units produced is 5.44.

Table 9.

Summary of raw material unit indices.

From Table 9, the raw material unit index (Ws) is 10.763, where the largest partial raw material unit index (=5.44) corresponds to the palm oil.

- (ii)

- Energy unit index

Let be the calorific value of the heat amount produced by the complete combustion of a material or fuel, measured in units of energy per amount of material, as shown in Table 10. The energy unit index, We, is estimated for three raw energy materials as shown in Table 11. Knowing that 1 (ton per standard fuel) equals 1 Mt of hard coal and 29.3 MJ/kg. Also, the for heavy fuel oil (HFO) is 43.5 MJ/kg. Then, the tpu of HFO, tupHFO, is calculated as follows:

Table 10.

Consumption of raw energy materials.

Table 11.

Summary of energy unit indices.

The annual heavy fuel oil consumption is 1705 Mt. The annual tupHFO is 2530.66 tons/year. The is 3605 tons. Then, the partial energy unit index, we1, is 0.702 (=2530.66/3605). For 10 units of product, we1 is 7.02. The partial energy unit indices for diesel and electricity are estimated similarly.

In Table 11, the We is estimated to be 15.889, where the partial energy indices for heavy fuel oil (=7.11) and diesel (=7.61) contribute significantly to We. An insignificant partial energy index is found for electricity.

- (iii)

- Waste unit index

The technological process generates no solid waste. Thus, the waste material unit index, Wo, is calculated from the partial waste indices for the liquid and gaseous wastes as shown in Table 12. For liquid waste, for example, given the volume of water waste is 29,481 m3 (mass = 29,481 tons). The partial waste generation unit index for water waste, woc1, is 8.1778. The relative toxicity (kt = 0.9) and (=0.9) give k of 1.0.

Table 12.

Summary of waste unit indices.

In Table 12, it is observed that the partial liquid waste index (=8.1778) constitutes the largest portion of the waste unit index (10.6181).

- (iv)

- Product unit index

The product unit index is calculated from the partial product indices of soap and byproducts. First, the partial unit indices of the hazardous components, such as NaOH, fragrances, titanium dioxide, and phosphoric acid, are calculated as shown in Table 13. Then, the product unit index is estimated as shown in Table 14. The primary product is soap (wp1 = 1) is calculated as follows. Taking NaOH of mass 710 tons results in an environmental nuisance index, kp1, of 0.196948 (=710/3605). The partial product unit index is 0.196948 (=0.196948 × 1). The total index for hazardous components of soap is 0.225.

Table 13.

Summary of product unit indices.

Table 14.

Hazardous components of soap.

In Table 14, the components NaOH and fragrances of the primary product (soap) contribute significantly to the environmental nuisance index.

- (v)

- Packaging unit index

The packaging material unit index for cartons is obtained as follows. Each packaging carton weighs 0.5 kg and contains 100 units. A total production of 36,050,000 units needs 180,250 kg of packaging cartons. Then, the partial packaging unit index, , for the packaging carton is 0.05 (=180,250/3,605,000).

Table 15 summarizes the profile indices, where the integrated environmental assessment index, Wz, for cleaner production technologies is calculated as 107.93.

Table 15.

Summary of profile indices.

According to Table 15, the Wz (=107.93) indicates a high degree of environmental nuisance related to its technological process.

3. Improvement Actions on the Production Line

To-Be Simulation Models

Several lean, agile, and resilient practices were deployed to enhance the performance of the production line and are presented as follows:

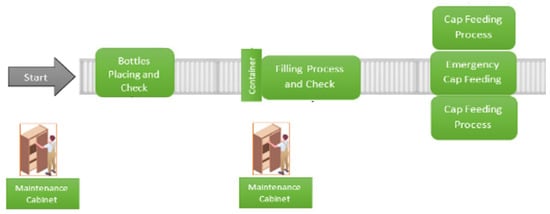

Action 1: Lean practice involving the addition of a container to collect waste from the filling process, as shown in Figure 20. The action collects an average waste of 10.32 mL per fill or 20 L/day.

Figure 20.

Improvement action 1.

Action 2: Resilient and lean practices by sharing the operator of bottle placing with the cap feeding station when the conveyor is full, as shown in Figure 21. The cap feeding process undergoes a problem that causes disturbances to the production line flow. The speed of two cap-feeding operators may not match the fast flow of six bottles dispatched. As a result, the conveyor and the filling machine should be stopped to cap all the bottles before proceeding to the capping machine. This action reduces the idle time of the bottle placing operator (lean) and enhances the performance of the cap feeding process under emergency conditions (resilient). Table 16 shows the OEE results for actions 1 and 2, where the OEE of bottle placing significantly increased from 20.05% to 81.31%. Moreover, the filling and cap feeding processes improved from 82.68% and 95.37% to 84.47% and 97.17%, respectively. Consequently, the capping process increased from 98% to 98.7%.

Figure 21.

Operator sharing.

Table 16.

OEE results for actions 1 and 2.

Action 3: Adopting resilient maintenance practices by placing common replacement parts, tools, and lubricants close to the production line, as shown in Figure 22. Failures, changeovers, and errors cause the production line to stop temporarily. This action results in reducing the downtimes for filling, labeling, and taping due to the shorter distance traveled to assess the failure. It thereby enhances machine availability, as shown in Table 17, where the availability of the filling, labeling, and taping processes is improved from 99.23%, 95.81%, and 99.08% to 99.5%, 97.47%, and 99.54%, respectively.

Figure 22.

Improvement in maintenance.

Table 17.

OEE results for actions 1 to 3.

Action 4: Agile practice by sharing the taping machine with two production lines, as shown in Figure 23, to increase its performance. The arrival rate of boxes is TRIA (25,60,120) seconds. Table 18 displays the obtained OEE for actions 1 to 4, where the performance of the taping machine improved from 82.19% to 100%. Consequently, the OEE of the taping process increased from 82.19% to 99.92%.

Figure 23.

Sharing the tape machine.

Table 18.

OEE results for actions 1 to 4.

4. Research Results

The results of this research are summarized as follows.

4.1. Simulation Results

The adoption of lean, agile, and resilient actions in the production line resulted in the OEE improvements shown in Table 18. Generally, relative improvements of more than 20% indicate significant improvement. In Table 18, the OEE values of the bottle placing and taping processes increased significantly compared to the as-is condition by 237.53% and 26.02%, respectively. Moreover, the filling and labeling processes were enhanced slightly by 4.67% and 5.41%, respectively. Furthermore, the smallest percentages of availability, quality, and performance are 97.46%, 99.82%, and 81.56%, respectively. These improvements can result in reduced waiting time and average number of units in the queue, and improved performance of the production line.

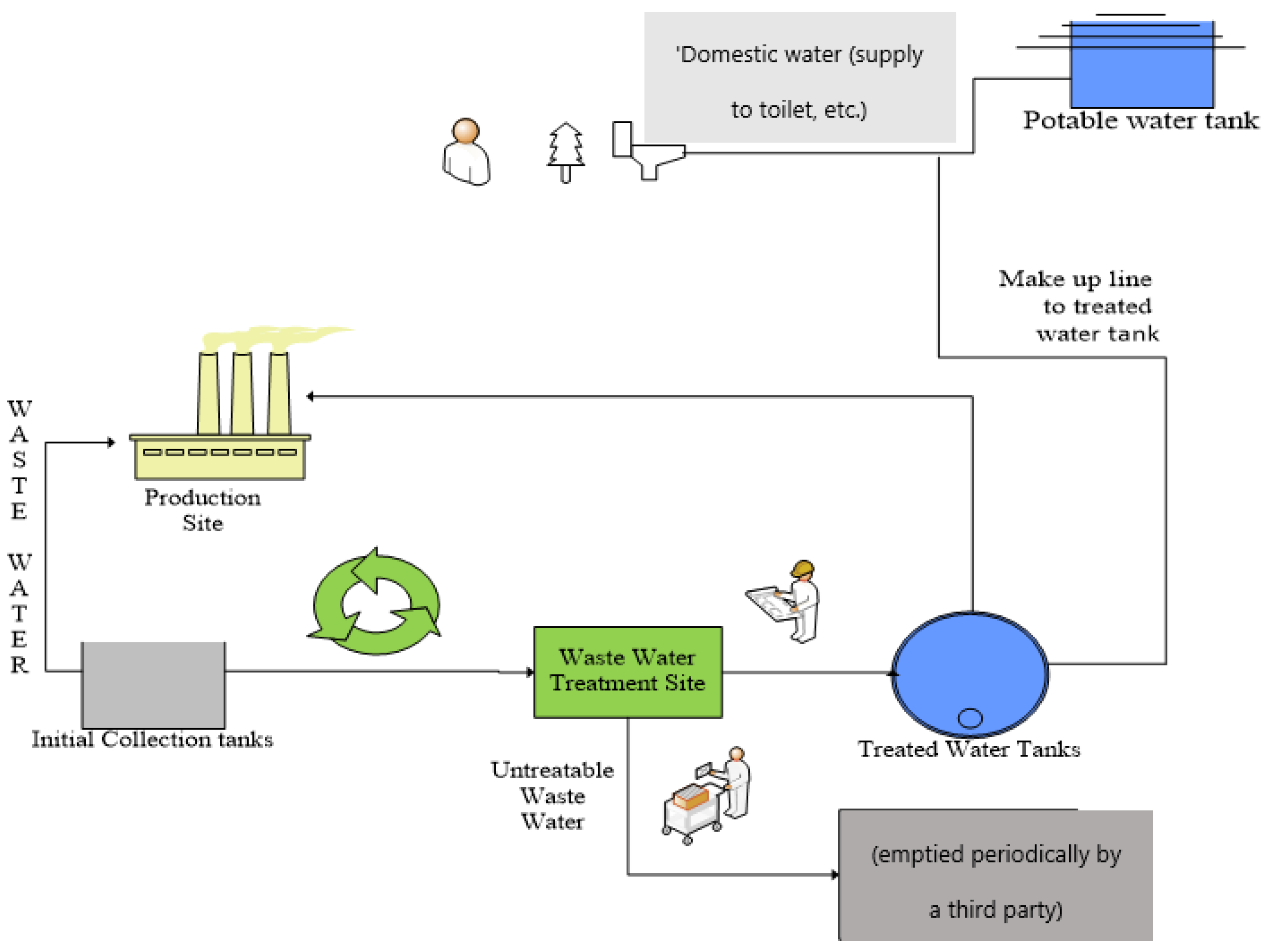

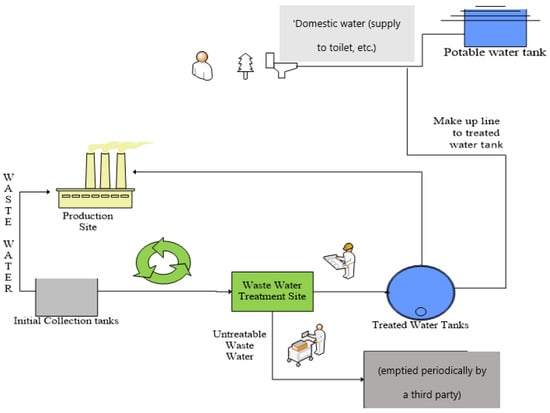

4.2. Waste Treatment

Environmental assessments showed that water waste is the most significant environmental problem. Figure 24 represents the proposed waste treatment system. Water is treated physically, chemically, and biologically to meet a minimum level of quality needed for the process. The treated water passes through pipes back to the production site, while the sludge is collected and emptied periodically.

Figure 24.

Proposed system (with water treatment).

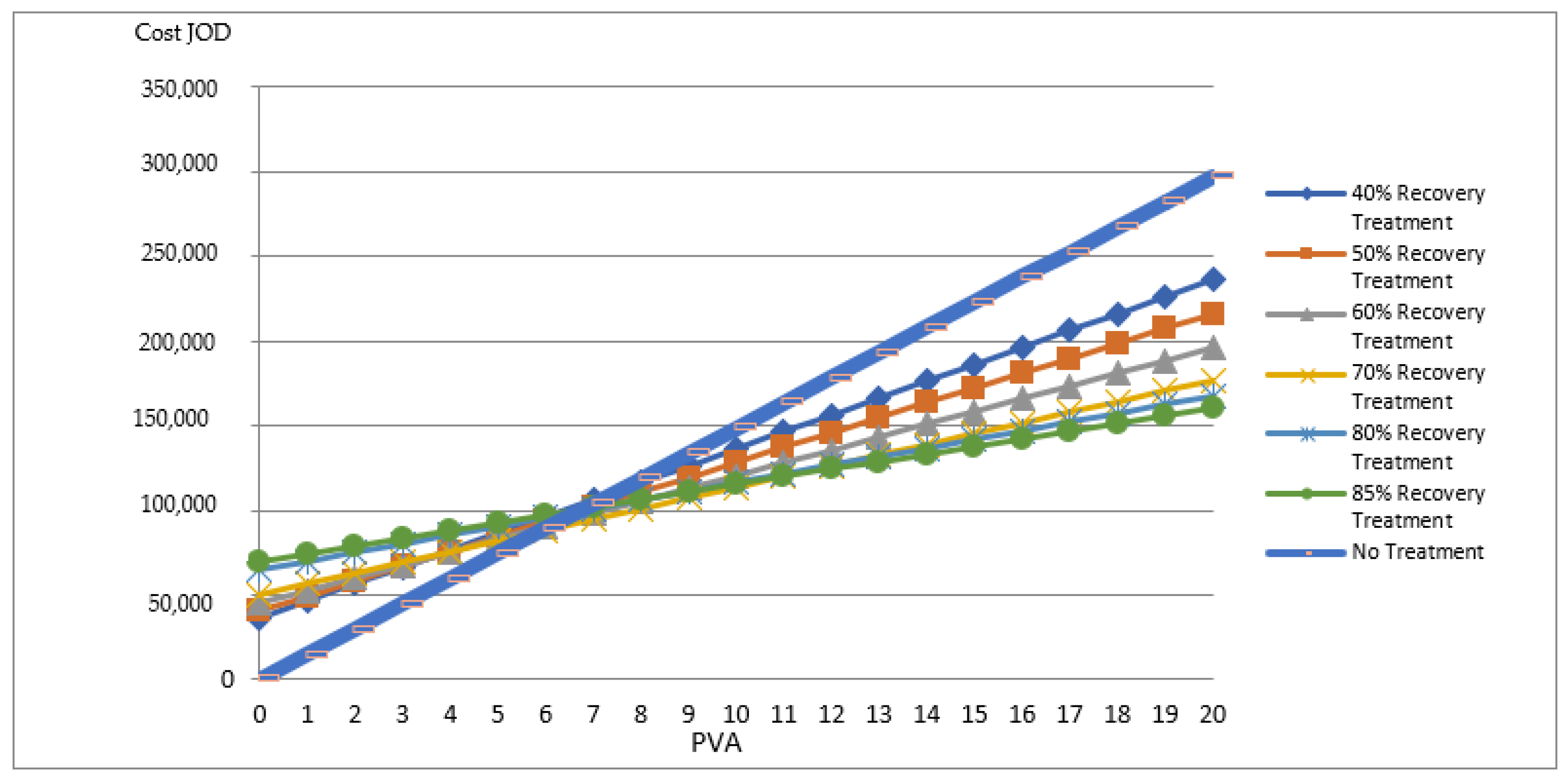

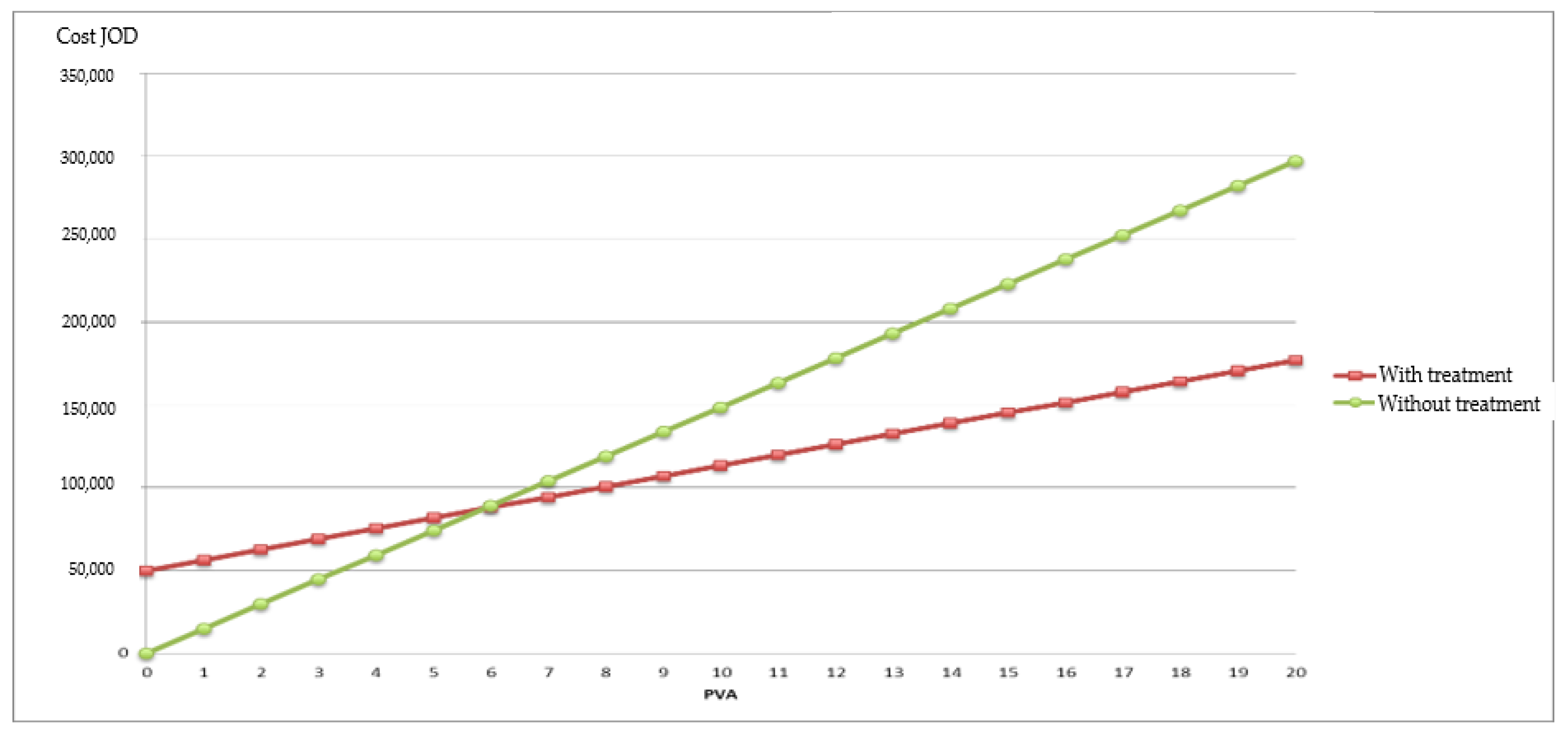

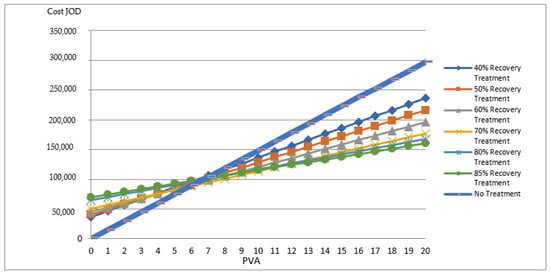

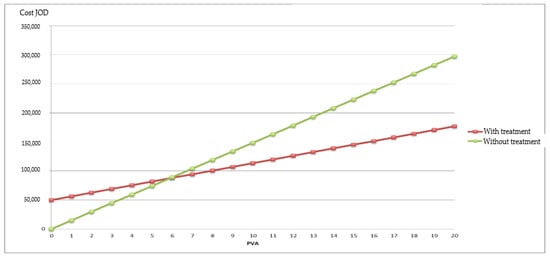

The feasibility of applying a treatment solution to the wastewater generated by the saponification process is assessed through a comparison between a system that operates without wastewater treatment (Case 1) and a system that includes wastewater treatment with a specified recovery rate (Case 2). The payback period for the treatment system is defined as the period necessary to cover the cost of installing and operating the treatment system through the savings acquired from the usage of the treated water. For Case 1, the clean water consumption is 44 m3 per day, and the waste discharge is 36 m3. For Case 2, the treatment system recovers a specified percentage of the waste discharge and reuses it. Knowing that the daily water consumption cost for Case 1 is (JOD 1.1/m3 × 44 m3/day) = JOD 48.4/day, which is equal to JOD 14,858.8/year. On the other hand, Case 2 indicates a considerable reduction in the purchasing cost of clean water, due to the different water recovery rates from the treatment center, as shown in Figure 25. For example, a 40% recovery rate produces 14.4 m3 of treated water, and the cost of the purchased water will be (JOD 1.1/m3 × 29.6 m3/day) = JOD 32.56/day. The yearly water consumption cost for Case 2 is (32.56/day × 307 days) = JOD 9995.92/year. Figure 26 displays the annual cost versus present value of an annuity (PVA) at a recovery rate of 70%, where a significant reduction in annual cost will be gained by installing the proposed water treatment system.

Figure 25.

Cost vs. PVA for different treatment recovery rates.

Figure 26.

Annual cost vs. PVA at a recovery rate of 70%.

The treatment system (cost: JOD 50,000; effective rate: 5%) with a 70% recovery rate, which corresponds to the system with the shortest payback period of 7 years, is considered. For case 1, the freshwater consumption is 44 m3 per day, and the waste discharge is 36 m3. For case 2, the treatment system recovers 70% of the waste discharge, equivalent to (0.70 × 36 m3/day = 25.2 m3/day), and reuses it. Hence, the freshwater consumption for case 2 is (44 − 25.2 = 18.8 m3/day). The daily water consumption cost for case 1 is (JOD 1.1m3 × 44 m3/day) = JOD 48.4/day. However, for case 2, due to the recovery of 25.2 m3 by the treatment unit, the cost of water is (JOD 1.1 m3 × 18.8 m3/day) = JOD 20.68/day. Table 19 summarizes the amounts and costs of purchased local water before and after applying the treatment.

Table 19.

Cost comparison between two cases.

5. Conclusions

This research aimed to enhance the performance of the detergent production line by implementing lean, agile, and resilient practices. Firstly, the AS-IS simulation model was developed and assessed utilizing OEE. Some processes required improvement in quality, availability, and performance percentages. Lean, agile, and resilient actions were utilized to enhance the OEE of the bottle placing, filling, labeling, and taping processes, which were enhanced by 237%, 4.67%, 5.41%, and 26.02%, respectively. Further, cleaner production assessments for soap production were used to estimate five indices, including raw material, energy, product, waste, and packaging. The estimated cleaner production index was 107.93, with liquid waste contributing the largest partial waste index. Consequently, a water treatment system was suggested and evaluated. A feasibility analysis showed that the payback period would be 7 years at a 5% rate of return. In conclusion, lean, agile, and resilient actions can result in significant savings in production and quality costs. Moreover, the adopted assessment for cleaner production can support decision makers in taking appropriate actions to reduce the environmental impact of their production lines. Future research will consider developing a combined OEEE index to assess OEE and the environmental impact of manufacturing processes.

Author Contributions

Conceptualization and methodology, A.A.-R.; software, A.A.-R.; validation, A.A.-R. and N.L.; formal analysis, A.A.-R. and N.L.; investigation, A.A.-R. and N.L.; resources, A.A.-R. and N.L.; data curation, A.A.-R., writing—original draft preparation, A.A.-R. and N.L.; writing—review and editing, A.A.-R.; visualization, A.A.-R.; supervision, A.A.-R. and N.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Jadoon, G.; Din, I.U.; Almogren, A.; Almajed, H. Smart and agile manufacturing framework, a case study for automotive industry. Energies 2020, 13, 5766. [Google Scholar] [CrossRef]

- Santos, D.M.C.D.; Santos, B.K.D.; Santos, C.G.D. Implementation of a standard work routine using Lean Manufacturing tools: A case Study. Gestão Produção 2021, 28, e4823. [Google Scholar] [CrossRef]

- Kaeo-Tad, N.; Jeenanunta, C.; Chumnumporn, K.; Nitisahakul, T.; Sanprasert, V. Resilient manufacturing: Case studies in Thai automotive industries during the COVID-19 pandemic. Eng. Manag. Prod. Serv. 2021, 13, 99–113. [Google Scholar] [CrossRef]

- Pattanaik, L.N.; Sharma, B.P. Implementing lean manufacturing with cellular layout: A case study. Int. J. Adv. Manuf. Technol. 2009, 42, 772–779. [Google Scholar] [CrossRef]

- Muslimen, R.; Yusof, S.M.; Abidin, A.Z. Lean manufacturing implementation in Malaysian automotive components manufacturer: A case study. In Proceedings of the World Congress on Engineering, London, UK, 6–8 July 2011; Volume 1, No. 1. pp. 6–8. [Google Scholar]

- Helleno, A.L.; de Moraes, A.J.I.; Simon, A.T. Integrating sustainability indicators and Lean Manufacturing to assess manufacturing processes: Application case studies in Brazilian industry. J. Clean. Prod. 2017, 153, 405–416. [Google Scholar] [CrossRef]

- Singh, J.; Singh, H.; Singh, G. Productivity improvement using lean manufacturing in manufacturing industry of Northern India: A case study. Int. J. Product. Perform. Manag. 2018, 67, 1394–1415. [Google Scholar] [CrossRef]

- Jimenez, G.; Santos, G.; Sá, J.C.; Ricardo, S.; Pulido, J.; Pizarro, A.; Hernández, H. Improvement of Productivity and Quality in the Value Chain through Lean Manufacturing—A case study. Procedia Manuf. 2019, 41, 882–889. [Google Scholar] [CrossRef]

- Potdar, P.K.; Routroy, S. Performance analysis of agile manufacturing: A case study on an Indian auto component manufacturer. Meas. Bus. Excell. 2017, 21, 117–135. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, K.; Jain, S.K. Agility enhancement through agile manufacturing implementation: A case study. TQM J. 2022, 34, 1527–1546. [Google Scholar] [CrossRef]

- Zhang, W.J.; Van Luttervelt, C.A. Toward a resilient manufacturing system. CIRP Ann. 2011, 60, 469–472. [Google Scholar] [CrossRef]

- Kusiak, A. Fundamentals of Smart Manufacturing: A Multi-Thread Perspective. Annu. Rev. Control. 2019, 47, 214–220. [Google Scholar] [CrossRef]

- Lee, J.; Siahpour, S.; Jia, X.; Brown, P. Introduction to resilient manufacturing systems. Manuf. Lett. 2022, 32, 24–27. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. Robust engineering for the design of resilient manufacturing systems. Appl. Sci. 2021, 11, 3067. [Google Scholar] [CrossRef]

- Dittfeld, H.; van Donk, D.P.; van Huet, S. The effect of production system characteristics on resilience capabilities: A multiple case study. Int. J. Oper. Prod. Manag. 2022, 42, 103–127. [Google Scholar] [CrossRef]

- Fowler, D.S.; Epiphaniou, G.; Higgins, M.D.; Maple, C. Aspects of resilience for smart manufacturing systems. Strateg. Change 2023, 32, 183–193. [Google Scholar] [CrossRef]

- Fijal, T. An environmental assessment method for cleaner production technologies. J. Clean. Prod. 2007, 15, 914–919. [Google Scholar] [CrossRef]

- Gong, Q.; Wu, J.; Jiang, Z.; Hu, M.; Chen, J.; Cao, Z. An integrated design method for remanufacturing scheme 19. considering carbon emission and customer demands. J. Clean. Prod. 2024, 476, 143681. [Google Scholar] [CrossRef]

- Ding, C.; Li, C.; Xiong, Z.; Li, Z. Computer big data technology in additive manufacturing and product design in sustainable manufacturing. Int. J. Adv. Manuf. Technol. 2024, 135, 4855–4863. [Google Scholar] [CrossRef]

- Alkaya, E.; Demirer, G.N. Sectoral assessment of the Turkish textile industry for the diffusion of sustainable production approach. J. Text. Inst. 2015, 106, 1212–1225. [Google Scholar] [CrossRef]

- Giannetti, B.F.; Agostinho, F.; Eras, J.C.; Yang, Z.; Almeida, C.M.V.B. Cleaner production for achieving the sustainable development goals. J. Clean. Prod. 2020, 271, 122127. [Google Scholar] [CrossRef]

- Ghazinoory, S. Cleaner production in Iran: Necessities and priorities. J. Clean. Prod. 2005, 13, 755–762. [Google Scholar] [CrossRef]

- Van Berkel, R. Cleaner production for process industries. In Proceedings of the Plenary Lecture—CHEMECA 2000, Perth, WA, USA, 9–12 July 2000. [Google Scholar]

- Bai, S.W.; Zhang, J.S.; Wang, Z. A methodology for evaluating cleaner production in the stone processing industry: Case study of a Shandong stone processing firm. J. Clean. Prod. 2015, 102, 461–476. [Google Scholar] [CrossRef]

- Ramos, A.R.; Ferreira, J.C.E.; Kumar, V.; Garza-Reyes, J.A.; Cherrafi, A. A lean and cleaner production benchmarking method for sustainability assessment: A study of manufacturing companies in Brazil. J. Clean. Prod. 2018, 177, 218–231. [Google Scholar] [CrossRef]

- de Oliveira Neto, G.C.; Correia, J.M.F.; Silva, P.C.; de Oliveira Sanches, A.G.; Lucato, W.C. Cleaner Production in the textile industry and its relationship to sustainable development goals. J. Clean. Prod. 2019, 228, 1514–1525. [Google Scholar] [CrossRef]

- Dai, N.; Li, L.; Xu, K.; Lu, Z.; Hu, X.; Yuan, Y. Development of a standardized data collection and intelligent fabric quality prediction system for the weaving department. J. Eng. Fibers Fabr. 2025, 20, 15589250241312778. [Google Scholar] [CrossRef]

- Li, T.; Li, Y. Artificial intelligence for reducing the carbon emissions of 5G networks in China. Nat. Sustain. 2023, 6, 1522–1523. [Google Scholar] [CrossRef]

- Al-Refaie, A.; Lepkova, N. A Fuzzy LARG Index for Assessing the Lean, Agile, Resilience, and Green Paradigms in Industrial Companies. Sustainability 2025, 17, 1863. [Google Scholar] [CrossRef]

- Al-Refaie, A.; Al-Tahat, M.; Lepkova, N. Modelling relationships between agility, lean, resilient, green practices in cold supply chains using ISM approach. Technol. Econ. Dev. Econ. 2020, 26, 675–694. [Google Scholar] [CrossRef]

- Al-Refaie, A.; Lepkova, N.; Camlibel, M.E. The relationships between the pillars of TPM and TQM and manufacturing performance using structural equation modeling. Sustainability 2022, 14, 1497. [Google Scholar] [CrossRef]

- Al-Refaie, A.; Kokash, T. Optimization of sustainable reverse logistics network with multi-objectives under uncertainty. J. Remanufacturing 2023, 13, 1–23. [Google Scholar] [CrossRef]

- Al-Refaie, A.; Jararweh, A. Adoption of quality management 4.0 to enhance the overall effectiveness of vehicle licence renewal services. Int. J. Electron. Gov. 2024, 16, 406–427. [Google Scholar]

- Al-Refaie, A.; Abbasi, G.; Al-shalaldeh, H. Lean and agile practices to improve the performance of filling process via simulation and data envelopment analysis. SN Appl. Sci. 2019, 1, 1131. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).