Investigating the Impact of Organic Loading Rates and Magnetic Nanoparticles on the Performance and Stability of Continuous Stirred Tank Reactors

Abstract

1. Introduction

2. Materials and Methods

2.1. List of Materials and Instruments

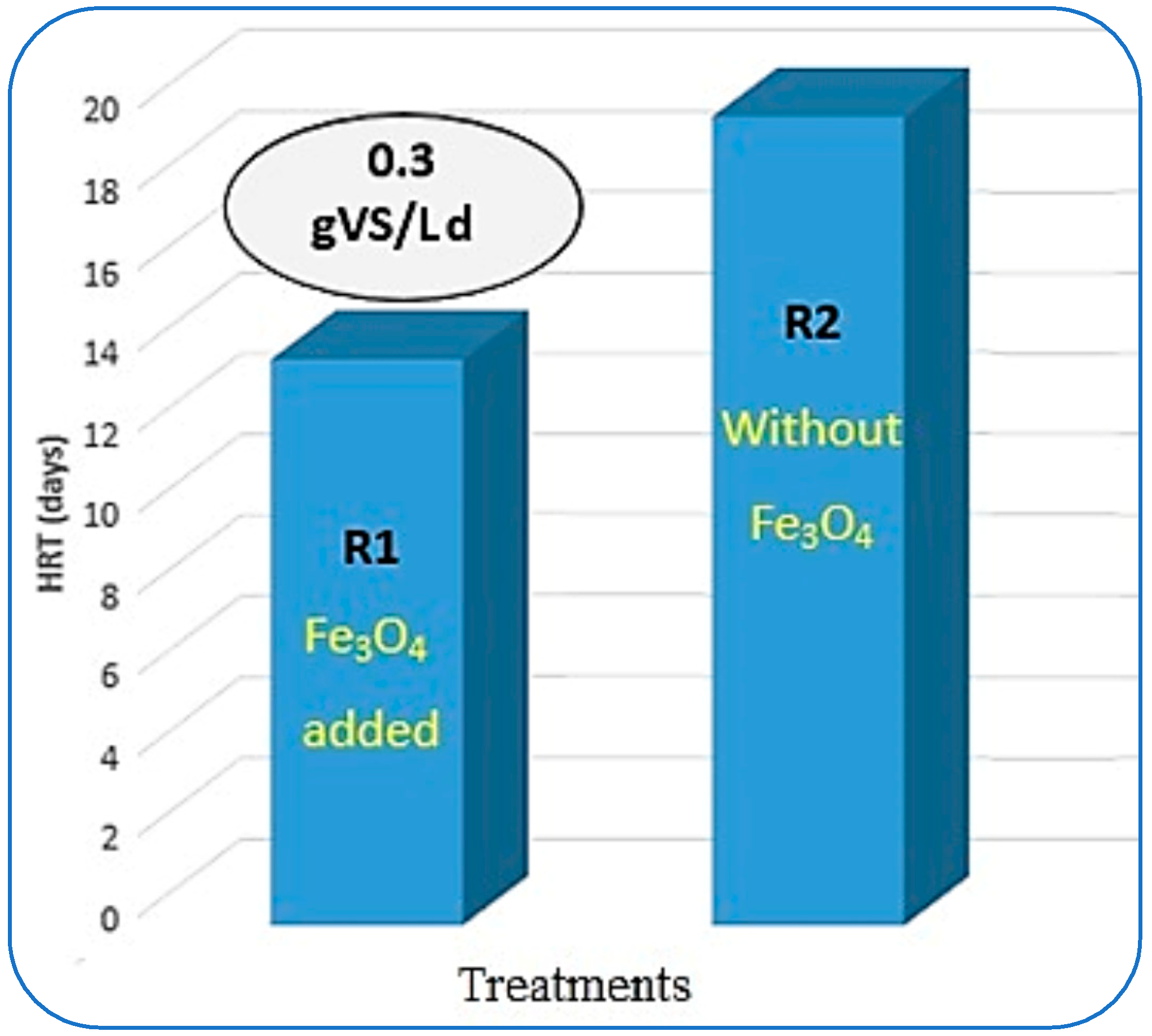

2.2. Optimization Methods for AD Reactors

2.3. Synthesis of Fe3O4 NPs

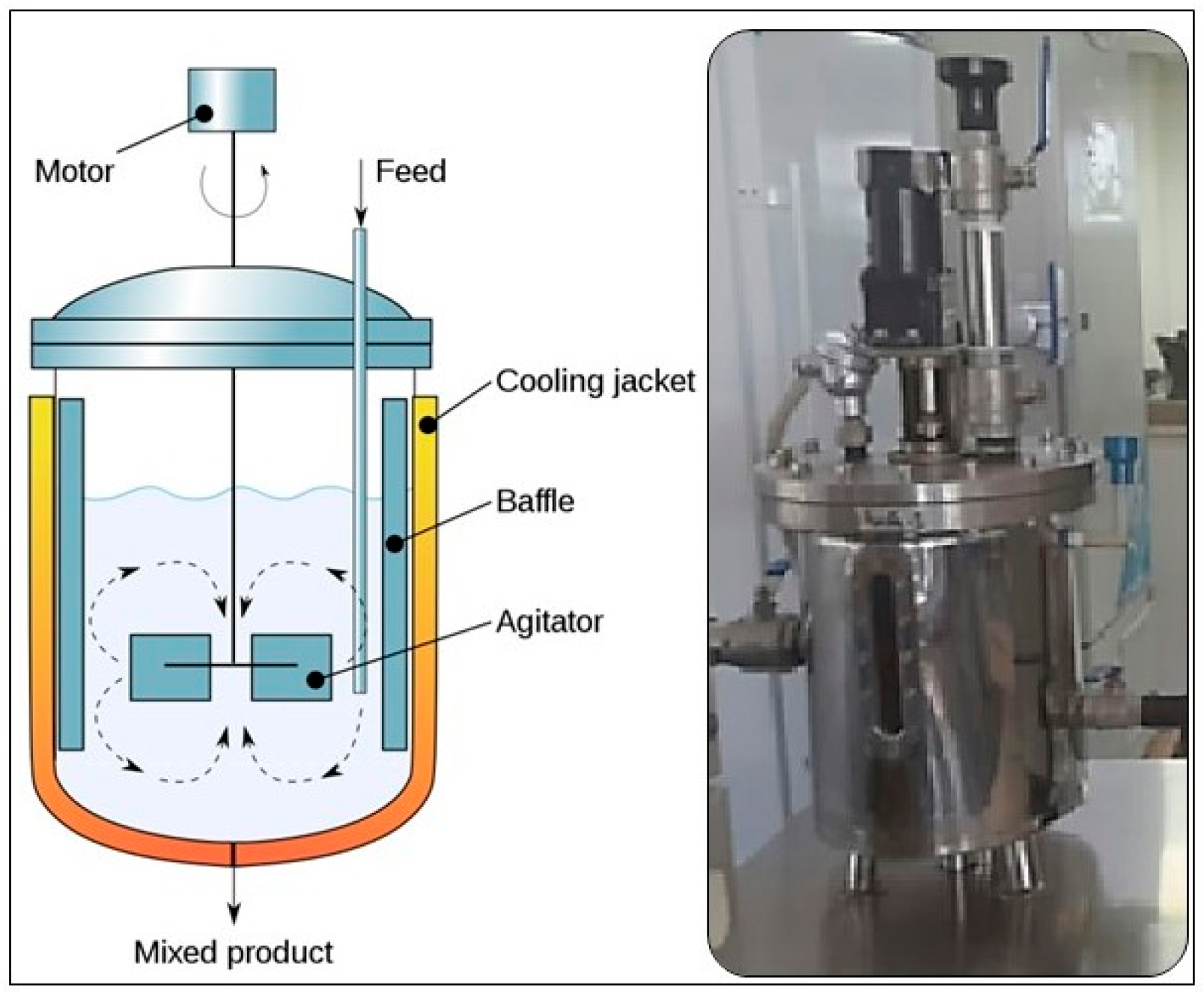

2.4. Reactors Working Mechanism

2.5. Statistical Analysis

3. Results and Discussion

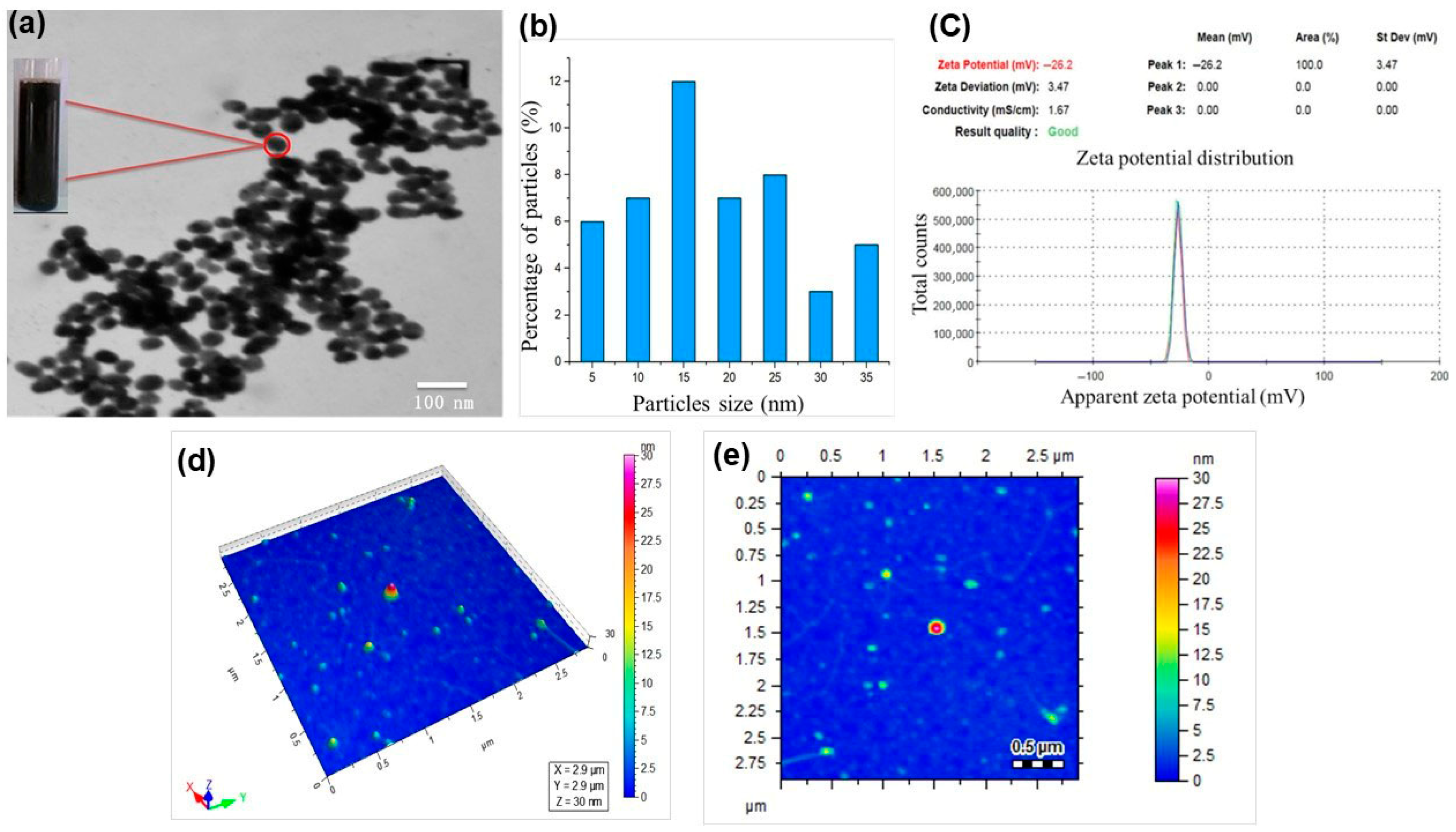

3.1. Characterization of Fe3O4 Nanoparticles

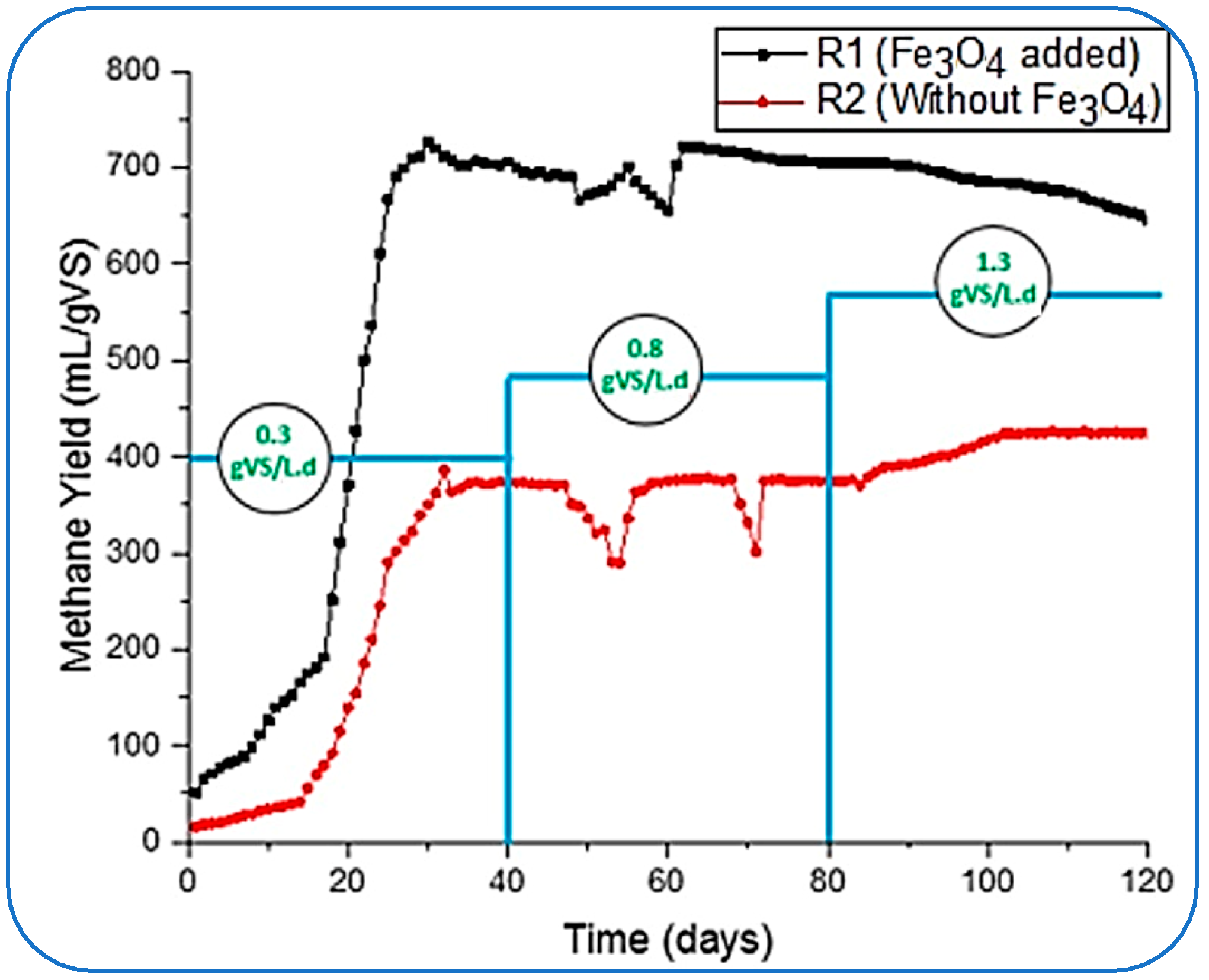

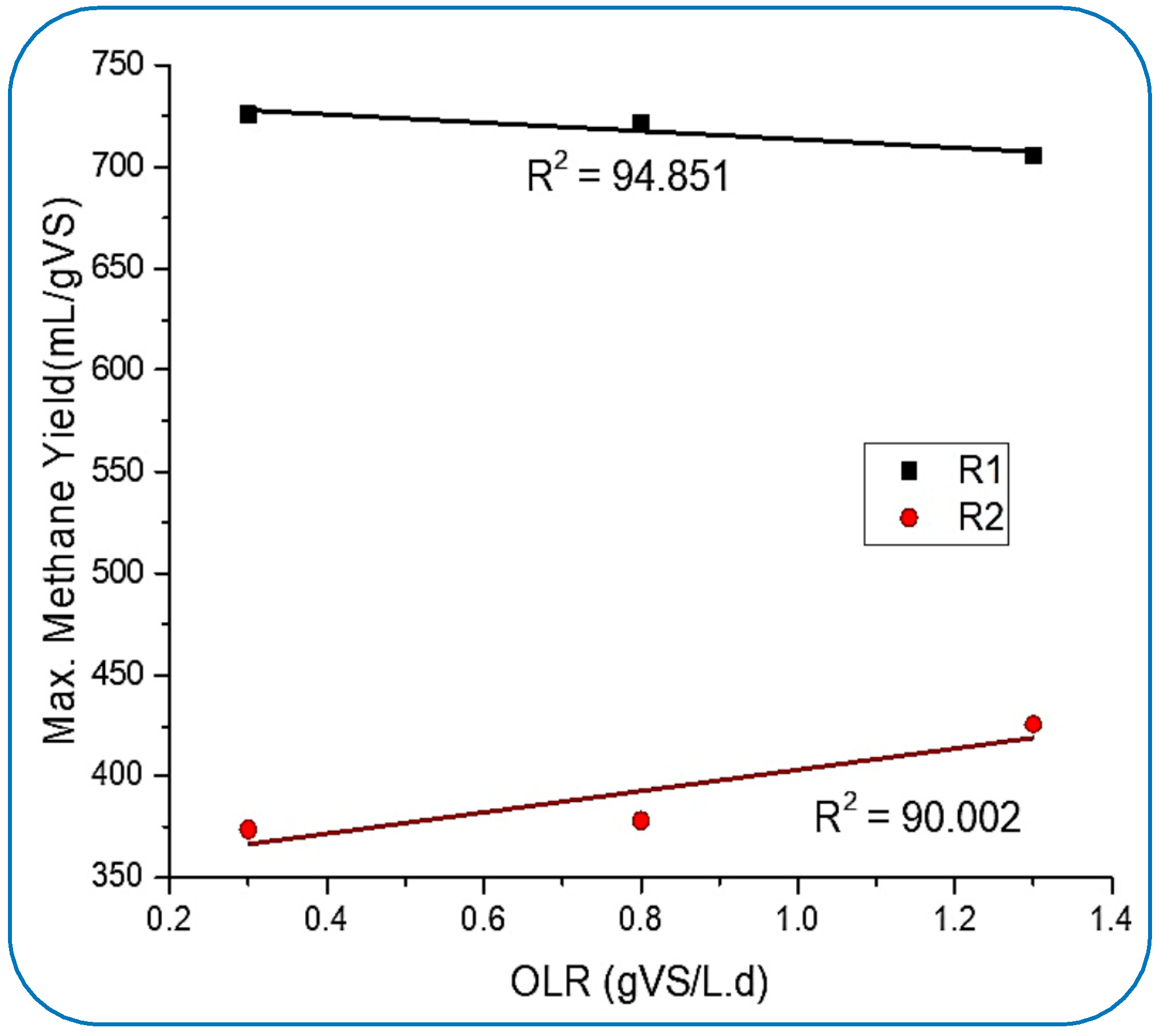

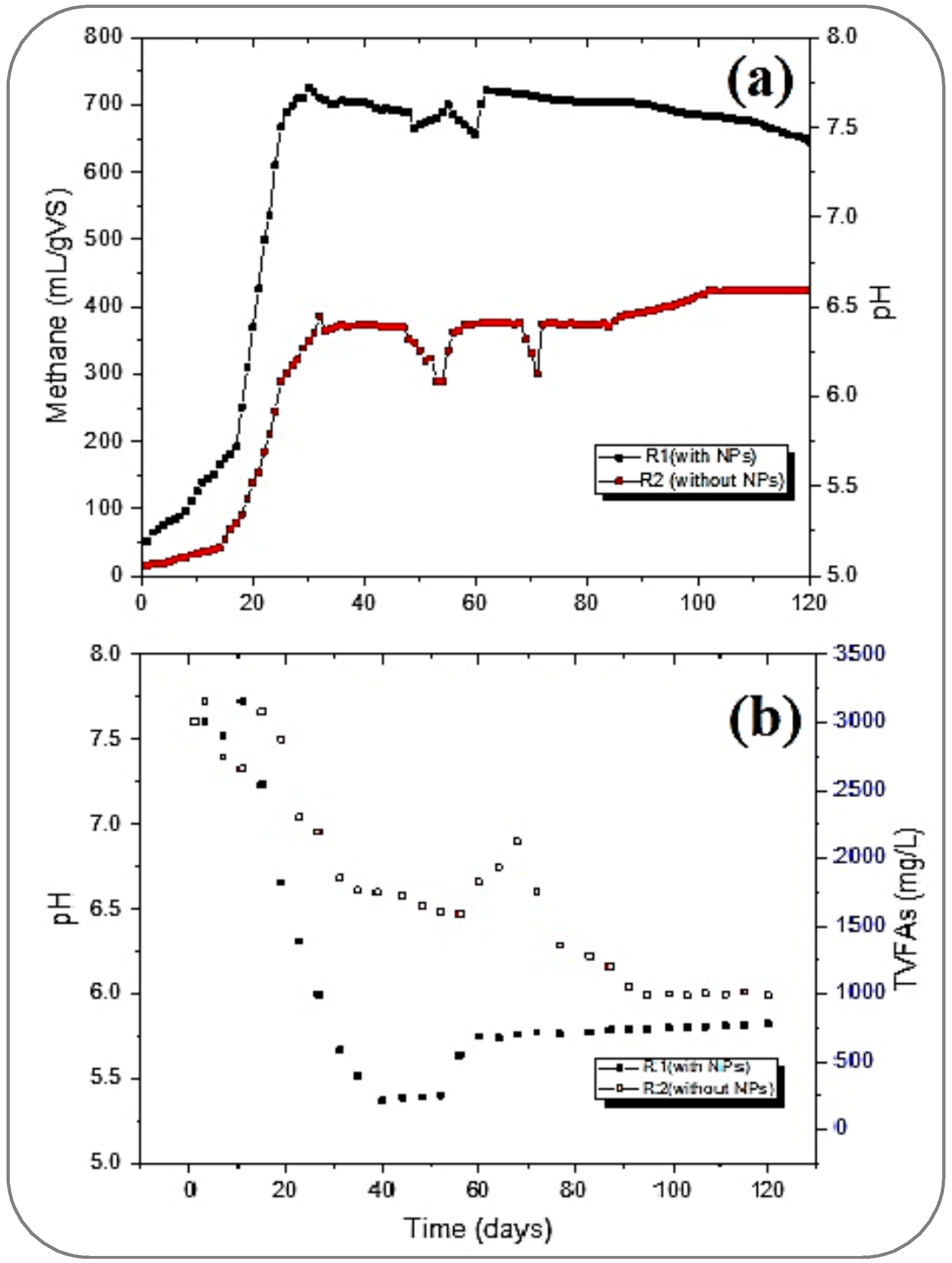

3.2. Impact of OLR on Methane Generation

3.3. Impact of pH on CH4 and TVFAs Generation

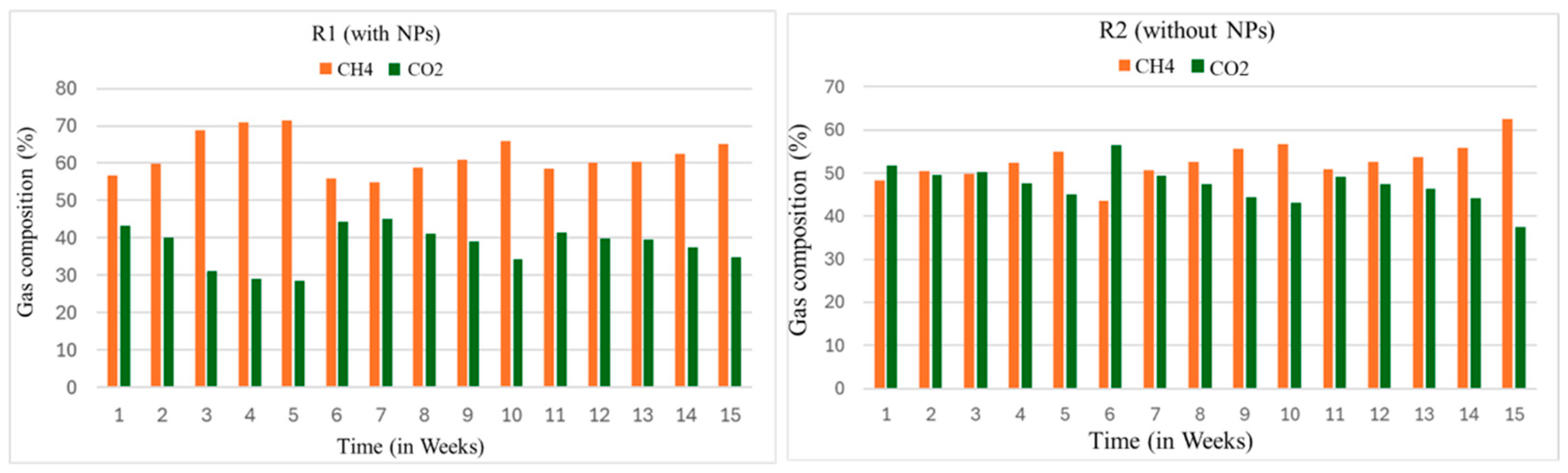

3.4. CH4 vs. Biogas Content

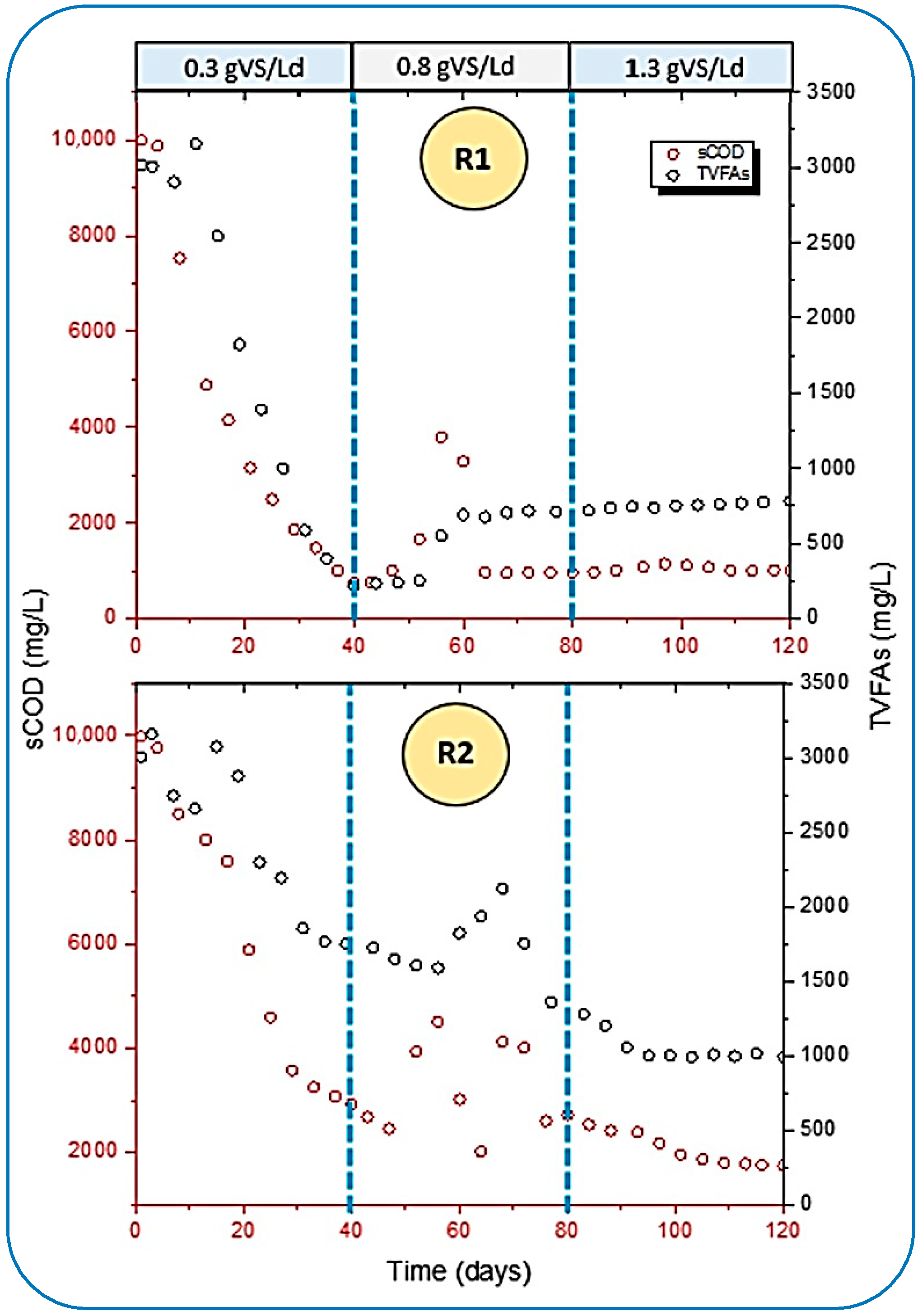

3.5. Behavior of sCOD Removal and TVFAs

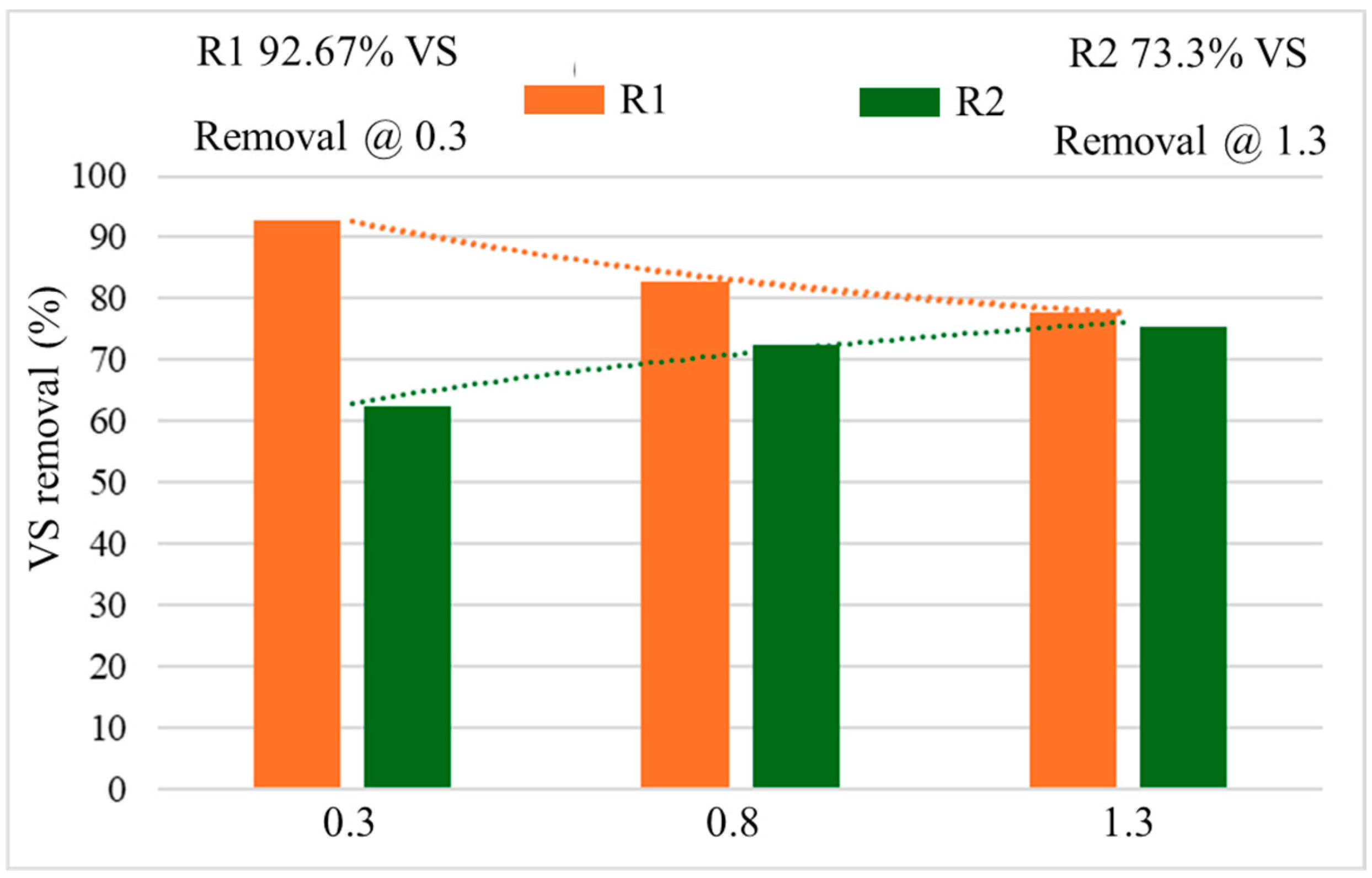

3.6. TS, VS, TS/VS Disintegration

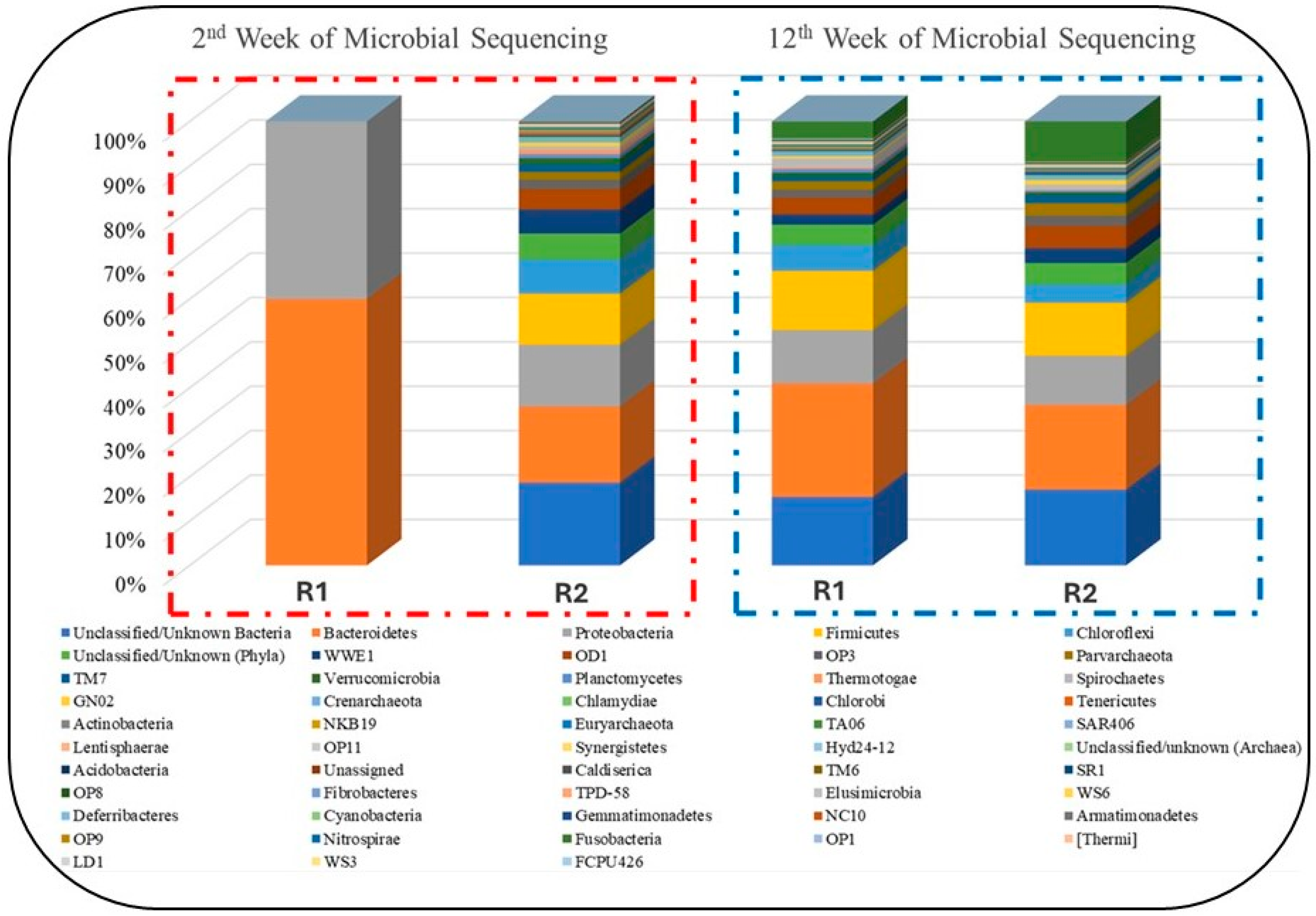

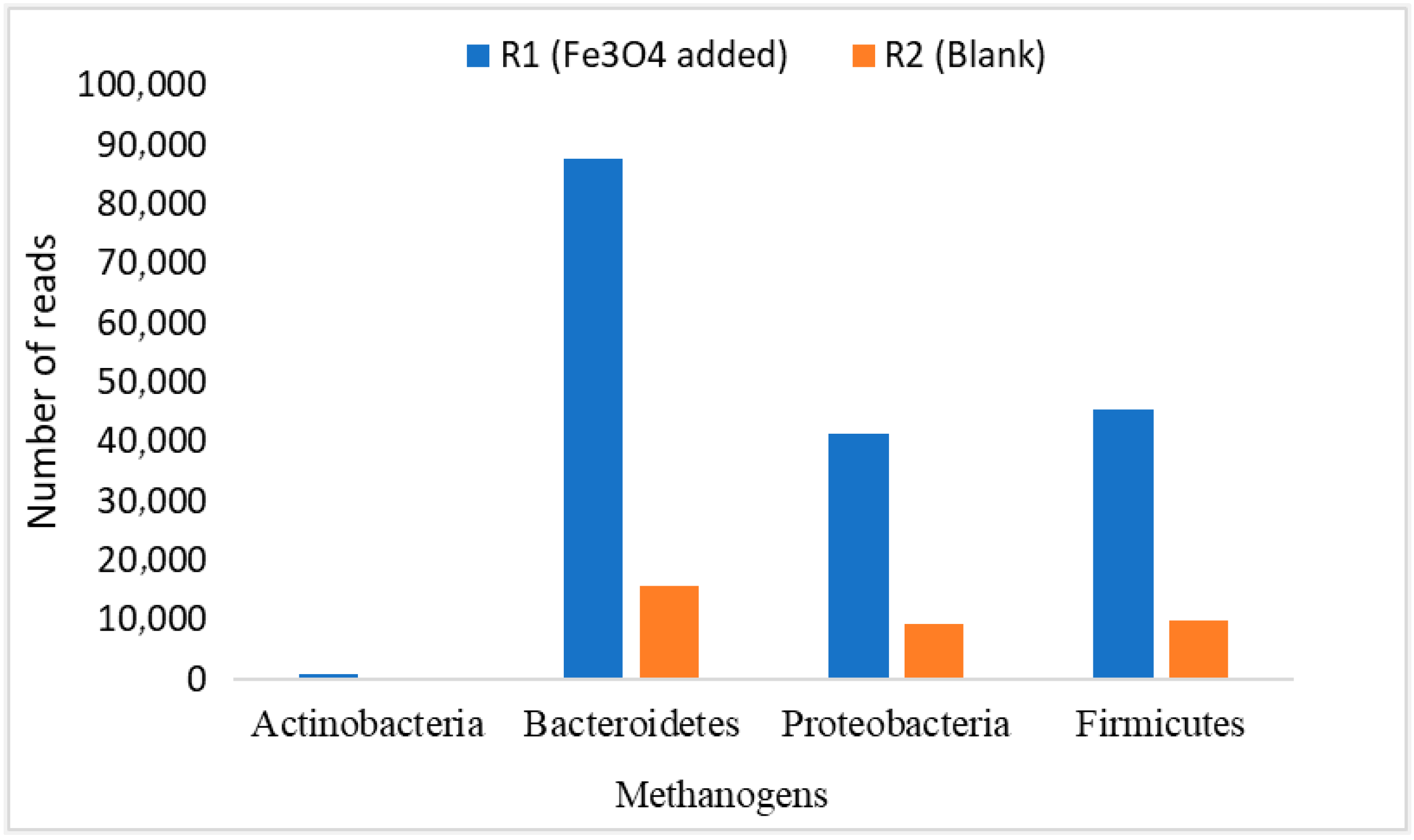

3.7. Effect of Fe3O4-NPs on Microbial Communities

3.8. Kinetic Modeling

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ferguson, R.M.; Coulon, F.; Villa, R. Organic loading rate: A promising microbial management tool in anaerobic digestion. Water Res. 2016, 100, 348–356. [Google Scholar] [CrossRef] [PubMed]

- Ali, A.; Mahar, R.B.; Sheerazi, S.T.H. Renewable electricity generation from food waste through anaerobic digestion in Pakistan: A mini-review. Earth Syst. Environ. 2019, 3, 95–100. [Google Scholar] [CrossRef]

- Zhu, X.; Blanco, E.; Bhatti, M.; Borrion, A. Impact of metallic nanoparticles on anaerobic digestion: A systematic review. Sci. Total Environ. 2021, 757, 143747. [Google Scholar] [CrossRef] [PubMed]

- Ye, M.; Liu, J.; Ma, C.; Li, Y.Y.; Zou, L.; Qian, G.; Xu, Z.P. Improving the stability and efficiency of anaerobic digestion of food waste using additives: A critical review. J. Clean. Prod. 2018, 192, 316–326. [Google Scholar] [CrossRef]

- Thi, N.B.D.; Lin, C.Y.; Kumar, G. Waste-to-wealth for valorization of food waste to hydrogen and methane towards creating a sustainable ideal source of bioenergy. J. Clean. Prod. 2016, 122, 29–41. [Google Scholar] [CrossRef]

- Pellera, F.M.; Gidarakos, E. Chemical pretreatment of lignocellulosic agroindustrial waste for methane production. Waste Manag. 2018, 71, 689–703. [Google Scholar] [CrossRef]

- Fei, X.; Jia, W.; Chen, T.; Ling, Y. Life cycle assessment of food waste anaerobic digestion with hydrothermal and ionizing radiation pretreatment. J. Clean. Prod. 2022, 338, 130611. [Google Scholar] [CrossRef]

- Ariunbaatar, J.; Panico, A.; Esposito, G.; Pirozzi, F.; Lens, P.N. Pretreatment methods to enhance anaerobic digestion of organic solid waste. Appl. Energy 2014, 123, 143–156. [Google Scholar] [CrossRef]

- Wagner, A.O.; Lackner, N.; Mutschlechner, M.; Prem, E.M.; Markt, R.; Illmer, P. Biological pretreatment strategies for second-generation lignocellulosic resources to enhance biogas production. Energies 2018, 11, 1797. [Google Scholar] [CrossRef]

- Lohani, S.P.; Havukainen, J. Anaerobic digestion: Factors affecting anaerobic digestion process. In Waste Bioremediation; Springer: Singapore, 2018; pp. 343–359. [Google Scholar] [CrossRef]

- Chae, K.J.; Jang, A.M.; Yim, S.K.; Kim, I.S. The effects of digestion temperature and temperature shock on the biogas yields from the mesophilic anaerobic digestion of swine manure. Bioresour. Technol. 2008, 99, 1–6. [Google Scholar] [CrossRef]

- Ryue, J.; Lin, L.; Kakar, F.L.; Elbeshbishy, E.; Al-Mamun, A.; Dhar, B.R. A critical review of conventional and emerging methods for improving process stability in thermophilic anaerobic digestion. Energy Sustain. Dev. 2020, 54, 72–84. [Google Scholar] [CrossRef]

- Vandevivere, P.; De Baere, L.; Verstraete, W. Types of anaerobic digester for solid wastes. In Biomethanization of the Organic Fraction of Municipal Solid Wastes; Iwa Publishing: London, UK, 2003; pp. 111–140. [Google Scholar]

- Ali, A.; Keerio, H.A.; Panhwar, S.; Ahad, M.Z. Experimental Investigation of Methane Generation in the Presence of Surface and Un-Surface Nanoparticles of Iron Oxide. AgriEngineering 2022, 4, 134–140. [Google Scholar] [CrossRef]

- Ali, A.; Mahar, R.B.; Panhwar, S.; Keerio, H.A.; Khokhar, N.H.; Suja, F.; Rundong, L. Generation of green renewable energy through anaerobic digestion technology (ADT): Technical insights review. Waste Biomass Valorization 2023, 14, 663–686. [Google Scholar] [CrossRef]

- Abdelsalam, E.; Samer, M.; Attia, Y.A.; Abdel-Hadi, M.A.; Hassan, H.E.; Badr, Y. Influence of zero valent iron nanoparticles and magnetic iron oxide nanoparticles on biogas and methane production from anaerobic digestion of manure. Energy 2017, 120, 842–853. [Google Scholar] [CrossRef]

- Lee, Y.J.; Lee, D.J. Impact of adding metal nanoparticles on anaerobic digestion performance—A review. Bioresour. Technol. 2019, 292, 121926. [Google Scholar] [CrossRef]

- Casals, E.; Barrena, R.; García, A.; González, E.; Delgado, L.; Busquets-Fité, M.; Font, X.; Arbiol, J.; Glatzel, P.; Kvashnina, K.; et al. Programmed iron oxide nanoparticles disintegration in anaerobic digesters boosts biogas production. Small 2014, 10, 2801–2808. [Google Scholar] [CrossRef]

- Ali, A.; Mahar, R.B.; Soomro, R.A.; Sherazi, S.T.H. Fe3O4 nanoparticles facilitated anaerobic digestion of organic fraction of municipal solid waste for enhancement of methane production. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 1815–1822. [Google Scholar] [CrossRef]

- Tratnyek, P.G.; Johnson, R.L. Nanotechnologies for environmental cleanup. Nano Today 2006, 1, 44–48. [Google Scholar] [CrossRef]

- Ali, A.; Mahar, R.B.; Sherazi, S.T.H. Methane augmentation of anaerobic digestion of food waste in the presence of Fe3O4 and carbamide capped Fe3O4 nanoparticles. Waste Biomass Valorization 2020, 11, 4093–4107. [Google Scholar] [CrossRef]

- Dalla Vecchia, C.; Mattioli, A.; Bolzonella, D.; Palma, E.; Viggi, C.C.; Aulenta, F. Impact of magnetite nanoparticles supplementation on the anaerobic digestion of food wastes: Batch and continuous-flow investigations. Chem. Eng. Trans. 2016, 49, 1–6. [Google Scholar] [CrossRef]

- Ugwu, S.N.; Biscoff, R.K.; Enweremadu, C.C. A meta-analysis of iron-based additives on enhancements of biogas yields during anaerobic digestion of organic wastes. J. Clean. Prod. 2020, 269, 122449. [Google Scholar] [CrossRef]

- Wo, D.; Bi, G.; Li, L.; Kong, X.; Jiang, E.; Xie, J. Iron-fortified Anaerobic Co-digestion Performance of Kitchen Waste and Pennisetum Hybrid. BioEnergy Res. 2022, 16, 651–659. [Google Scholar] [CrossRef]

- Alavi-Borazjani, S.A.; da Cruz Tarelho, L.A.; Capela, M.I. Biohythane production via anaerobic digestion process: Fundamentals, scale-up challenges, and techno-economic and environmental aspects. Environ. Sci. Pollut. Res. 2024, 31, 49935–49984. [Google Scholar] [CrossRef] [PubMed]

- Popp, J.; Lakner, Z.; Harangi-Rákos, M.; Fari, M. The effect of bioenergy expansion: Food, energy, and environment. Renew. Sustain. Energy Rev. 2014, 32, 559–578. [Google Scholar] [CrossRef]

- Young, J.C.; Clesceri, L.S.; Kamhawy, S.M. Changes in the biochemical oxygen demand procedure in the 21st edition of Standard Methods for the Examination of Water and Wastewater. Water Environ. Res. 2005, 77, 404–410. [Google Scholar] [CrossRef]

- Wang, Q.; Noguchi, C.; Hara, Y.; Sharon, C.; Kakimoto, K.; Kato, Y. Studies on anaerobic digestion mechanism: Influence of pretreatment temperature on biodegradation of waste activated sludge. Environ. Technol. 1997, 18, 999–1008. [Google Scholar] [CrossRef]

- Kalia, V.C.; Sonakya, V.; Raizada, N. Anaerobic digestion of banana stem waste. Bioresour. Technol. 2000, 73, 191–193. [Google Scholar] [CrossRef]

- Zamanzadeh, M.; Hagen, L.H.; Svensson, K.; Linjordet, R.; Horn, S.J. Anaerobic digestion of food waste—Effect of recirculation and temperature on performance and microbiology. Water Res. 2016, 96, 246–254. [Google Scholar] [CrossRef]

- Panhwar, S.; Keerio, H.A.; Khokhar, N.H.; Muqeet, M.; Ali, Z.; Bilal, M.; Ul Rehman, A. Magnetic nanomaterials as an effective absorbent material for removal of fluoride concentration in water: A review. J. Water Health 2024, 22, 123–137. [Google Scholar] [CrossRef]

- Panhwar, S.; Keerio, H.A.; Ali, A.; Aftab, A.; Chang, M.A.; Khokhar, N.H.; Khokhar, H. Synthesis and characterization approaches of silver nano particles for various novel applications. Adv. Mater. Process. Technol. 2022, 8, 4106–4121. [Google Scholar] [CrossRef]

- Mata-Alvarez, J.; Llabrés, P.; Cecchi, F.; Pavan, P. Anaerobic digestion of the Barcelona central food market organic wastes: Experimental study. Bioresour. Technol. 1992, 39, 39–48. [Google Scholar] [CrossRef]

- Fagundes, D.S.; Orrico Junior, M.A.P.; Orrico, A.C.A.; Seno, L.O. Mathematical models of anaerobic digestion for the treatment of swine effluents. Pesqui. Agropecu. Trop. 2015, 45, 172–179. [Google Scholar] [CrossRef]

- Karidio Daouda Idrissa, O.K.; Tsuanyo, D.; Kouakou, R.A.; Konaté, Y.; Sawadogo, B.; Yao, K.B. Analysis of the criteria for improving biogas production: Focus on anaerobic digestion. Environ. Dev. Sustain. 2023, 26, 27083–27110. [Google Scholar] [CrossRef]

- Panhwar, S.; Hassan, S.S.; Mahar, R.B.; Carlson, K.; Talpur, M.Y. Highly sensitive and selective electrochemical sensor for detection of escherichia coli by using L-cysteine functionalized iron nanoparticles. J. Electrochem. Soc. 2019, 166, B227. [Google Scholar] [CrossRef]

- Yew, Y.P.; Shameli, K.; Miyake, M.; Khairudin, N.B.B.A.; Mohamad, S.E.B.; Naiki, T.; Lee, K.X. Green biosynthesis of superparamagnetic magnetite Fe3O4 nanoparticles and biomedical applications in targeted anticancer drug delivery system: A review. Arab. J. Chem. 2020, 13, 2287–2308. [Google Scholar] [CrossRef]

- Lee, J.H.; Park, S.Y.; Choi, I.G.; Choi, J.W. Investigation of molecular size effect on the formation of lignin nanoparticles by nanoprecipitation. Appl. Sci. 2020, 10, 4910. [Google Scholar] [CrossRef]

- Batstone, D.J. Mathematical modelling of anaerobic reactors treating domestic wastewater: Rational criteria for model use. Rev. Environ. Sci. Bio/Technol. 2006, 5, 57–71. [Google Scholar] [CrossRef]

- Adebayo, A.O.; Jekayinfa, S.O.; Linke, B. Effects of organic loading rate on biogas yield in a continuously stirred tank reactor experiment at mesophilic temperature. Br. J. Appl. Sci. Technol. 2015, 11, 1–9. [Google Scholar] [CrossRef]

- Fitamo, T.; Boldrin, A.; Boe, K.; Angelidaki, I.; Scheutz, C. Co-digestion of food and garden waste with mixed sludge from wastewater treatment in continuously stirred tank reactors. Bioresour. Technol. 2016, 206, 245–254. [Google Scholar] [CrossRef]

- Wang, W.; Yin, F.; Sun, Y.; Yu, Q.; Wang, X. Effects of carbon-based materials on methane production during anaerobic digestion: A review. J. Hazard. Mater. 2018, 350, 21–30. [Google Scholar] [CrossRef]

- Nagao, N.; Tajima, N.; Kawai, M.; Niwa, C.; Kurosawa, N.; Matsuyama, T.; Toda, T. Maximum organic loading rate for the single-stage wet anaerobic digestion of food waste. Bioresour. Technol. 2012, 118, 210–218. [Google Scholar] [CrossRef] [PubMed]

- Akturk, A.S.; Demirer, G.N. Petroleum Coke Supplementation Improves Biogas Production from Food Waste at a Level Comparable to Commercial Carbon-based Conductive Materials. BioEnergy Res. 2022, 15, 1482–1490. [Google Scholar] [CrossRef]

- Facchin, V.; Cavinato, C.; Fatone, F.; Pavan, P.; Cecchi, F.; Bolzonella, D. Effect of trace element supplementation on the mesophilic anaerobic digestion of foodwaste in batch trials: The influence of inoculum origin. Biochem. Eng. J. 2013, 70, 71–77. [Google Scholar] [CrossRef]

- Keerio, H.A.; Bae, W.; Park, J.; Kim, M. Substrate uptake, loss, and reserve in ammonia-oxidizing bacteria (AOB) under different substrate availabilities. Process Biochem. 2020, 91, 303–310. [Google Scholar] [CrossRef]

- Keerio, H.A.; Bae, W.; Panhwar, S. Nitrite Accumulation at Low Ammonia Concentrations in Wastewater Treatment Plants. Sustainability 2022, 14, 16449. [Google Scholar] [CrossRef]

- Kumari, D.; Singh, R. Pretreatment of lignocellulosic wastes for biofuel production: A critical review. Renew. Sustain. Energy Rev. 2018, 90, 877–891. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, R.; Liu, F.; Yong, X.; Wu, X.; Zheng, T.; Jiang, M.; Jia, H. Biogas production and microbial community shift through neutral pH control during the anaerobic digestion of pig manure. Bioresour. Technol. 2016, 217, 44–49. [Google Scholar] [CrossRef]

- Cai, C.; Leu, A.O.; Xie, G.J.; Guo, J.; Feng, Y.; Zhao, J.X.; Tyson, G.W.; Yuan, Z.; Hu, S. A methanotrophic archaeon couples anaerobic oxidation of methane to Fe (III) reduction. ISME J. 2018, 12, 1929–1939. [Google Scholar] [CrossRef]

- Kim, J.; Baek, G.; Lee, C. Inhibition of methanogenesis by metal and metal oxide nanoparticles. Environ. Sci. Nano 2015, 2, 632–646. [Google Scholar]

- Pavlostathis, S.G.; Giraldo-Gomez, E. Kinetics of anaerobic treatment: A critical review. Crit. Rev. Environ. Sci. Technol. 1991, 21, 411–490. [Google Scholar] [CrossRef]

- Agyeman, F.O.; Han, Y.; Tao, W. Elucidating the kinetics of ammonia inhibition to anaerobic digestion through extended batch experiments and stimulation-inhibition modeling. Bioresour. Technol. 2021, 340, 125744. [Google Scholar] [CrossRef] [PubMed]

- De Bere, L. Anaerobic digestion of solid waste: State-of-the-art. Water Sci. Technol. 2000, 41, 283–290. [Google Scholar] [CrossRef]

- Zeb, I.; Ma, J.; Mehboob, F.; Kafle, G.K.; Amin, B.A.Z.; Nazir, R.; Ndegwa, P.; Frear, C. Kinetic and microbial analysis of methane production from dairy wastewater anaerobic digester under ammonia and salinity stresses. J. Clean. Prod. 2019, 219, 797–808. [Google Scholar] [CrossRef]

- Li, D.; Liu, S.; Mi, L.; Li, Z.; Yuan, Y.; Yan, Z.; Liu, X. Effects of feedstock ratio and organic loading rate on the anaerobic mesophilic co-digestion of rice straw and cow manure. Bioresour. Technol. 2015, 189, 319–326. [Google Scholar] [CrossRef]

- Jang, H.M.; Kim, J.H.; Ha, J.H.; Park, J.M. Bacterial and methanogenic archaeal communities during the single-stage anaerobic digestion of high-strength food wastewater. Bioresour. Technol. 2014, 165, 174–182. [Google Scholar] [CrossRef]

- Guo, J.; Liu, W.; Zhu, C.; Luo, G.; Kong, Y.; Ling, N.; Wang, M.; Dai, J.; Shen, Q.; Guo, S. Bacterial rather than fungal community composition is associated with microbial activities and nutrient-use efficiencies in a paddy soil with short-term organic amendments. Plant Soil 2018, 424, 335–349. [Google Scholar] [CrossRef]

- Garcia-Peña, E.I.; Parameswaran, P.; Kang, D.W.; Canul-Chan, M.; Krajmalnik-Brown, R. Anaerobic digestion and co-digestion processes of vegetable and fruit residues: Process and microbial ecology. Bioresour. Technol. 2011, 102, 9447–9455. [Google Scholar] [CrossRef]

- Duan, N.; Zhang, D.; Lin, C.; Zhang, Y.; Zhao, L.; Liu, H.; Liu, Z. Effect of organic loading rate on anaerobic digestion of pig manure: Methane production, mass flow, reactor scale and heating scenarios. J. Environ. Manag. 2019, 231, 646–652. [Google Scholar] [CrossRef]

- Mähnert, P.; Linke, B. Kinetic study of biogas production from energy crops and animal waste slurry: Effect of organic loading rate and reactor size. Environ. Technol. 2009, 30, 93–99. [Google Scholar] [CrossRef]

- Lin, Y.; Wang, D.; Li, Q.; Huang, L. Kinetic study of mesophilic anaerobic digestion of pulp & paper sludge. Biomass Bioenergy 2011, 35, 4862–4867. [Google Scholar] [CrossRef]

- Ali, A.; Keerio, H.A.; Abro, O.A.; Noor, M.; Panhwar, S.; Mahar, R.B. A Study of Mathematical Models Used in Anaerobic Digestion of Organic Refuse. VFAST Trans. Math. 2024, 12, 150–163. [Google Scholar] [CrossRef]

| Parameters. | R1 (With F3O4·NPs) | R2 (Control) |

|---|---|---|

| TS (%) | 25.13 ± 1.21 | 29.67 ± 1.67 |

| VS (%) | 21.91 ± 1.09 | 24.73 ± 1.25 |

| VS/TS (%) | 87.19 ± 4.45 | 83.35 ± 4.05 |

| sCOD (mg/L) | 996.59 ± 20.25 | 1749.7 ± 29.87 |

| TVFAs (mg/L) | 780.56 ± 16.19 | 990.5 ± 21.08 |

| pH | 6.23 ± 0.912 | 7.45 ± 0.512 |

| Organic carbon (% from VS) | 50.6 ± 2.78 | 48.35 ± 1.89 |

| Total nitrogen (%) | 3.06 ± 0.178 | 2.7 ± 0.65 |

| C:N ratio | 16.55:1 | 17.90:1 |

| Bioreactor | Exp (Mt) (mL/gVS) | Model (Mt) (mL/gVS) | Kc (d−1) | R2 | rMSE (%) |

|---|---|---|---|---|---|

| R1 (with Fe3O4 NPs) | 725.901 | 724.611 | 0.057 | 0.833 | 0.317 |

| R2 (control) | 425.721 | 419.352 | 0.021 | 0.872 | 0.238 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, A.; Alnadish, A.M.; Panhwar, S.; Keerio, H.A.; Waheed, A.; Mahar, R.B. Investigating the Impact of Organic Loading Rates and Magnetic Nanoparticles on the Performance and Stability of Continuous Stirred Tank Reactors. Processes 2025, 13, 2126. https://doi.org/10.3390/pr13072126

Ali A, Alnadish AM, Panhwar S, Keerio HA, Waheed A, Mahar RB. Investigating the Impact of Organic Loading Rates and Magnetic Nanoparticles on the Performance and Stability of Continuous Stirred Tank Reactors. Processes. 2025; 13(7):2126. https://doi.org/10.3390/pr13072126

Chicago/Turabian StyleAli, Asim, Adham Mohammed Alnadish, Sallahuddin Panhwar, Hareef Ahmed Keerio, Abdul Waheed, and Rasool Bux Mahar. 2025. "Investigating the Impact of Organic Loading Rates and Magnetic Nanoparticles on the Performance and Stability of Continuous Stirred Tank Reactors" Processes 13, no. 7: 2126. https://doi.org/10.3390/pr13072126

APA StyleAli, A., Alnadish, A. M., Panhwar, S., Keerio, H. A., Waheed, A., & Mahar, R. B. (2025). Investigating the Impact of Organic Loading Rates and Magnetic Nanoparticles on the Performance and Stability of Continuous Stirred Tank Reactors. Processes, 13(7), 2126. https://doi.org/10.3390/pr13072126