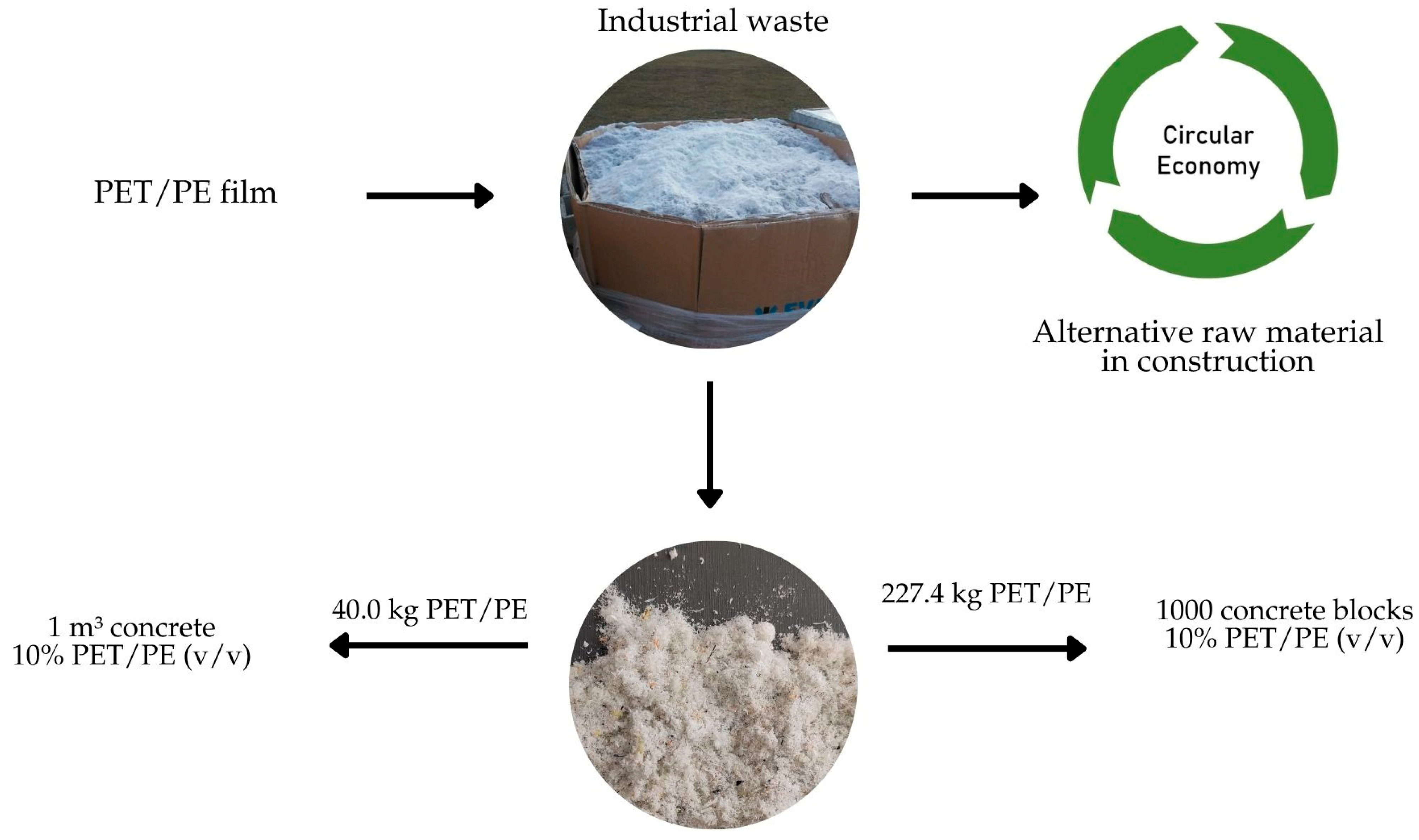

Incorporation of Poly (Ethylene Terephthalate)/Polyethylene Residue Powder in Obtaining Sealing Concrete Blocks

Abstract

1. Introduction

2. Materials and Methods

2.1. Characterization of Aggregates

2.2. Manufacture and Characterization of Cylindrical Samples of Concrete

2.3. Manufacturing and Characterization of Concrete Blocks

3. Results

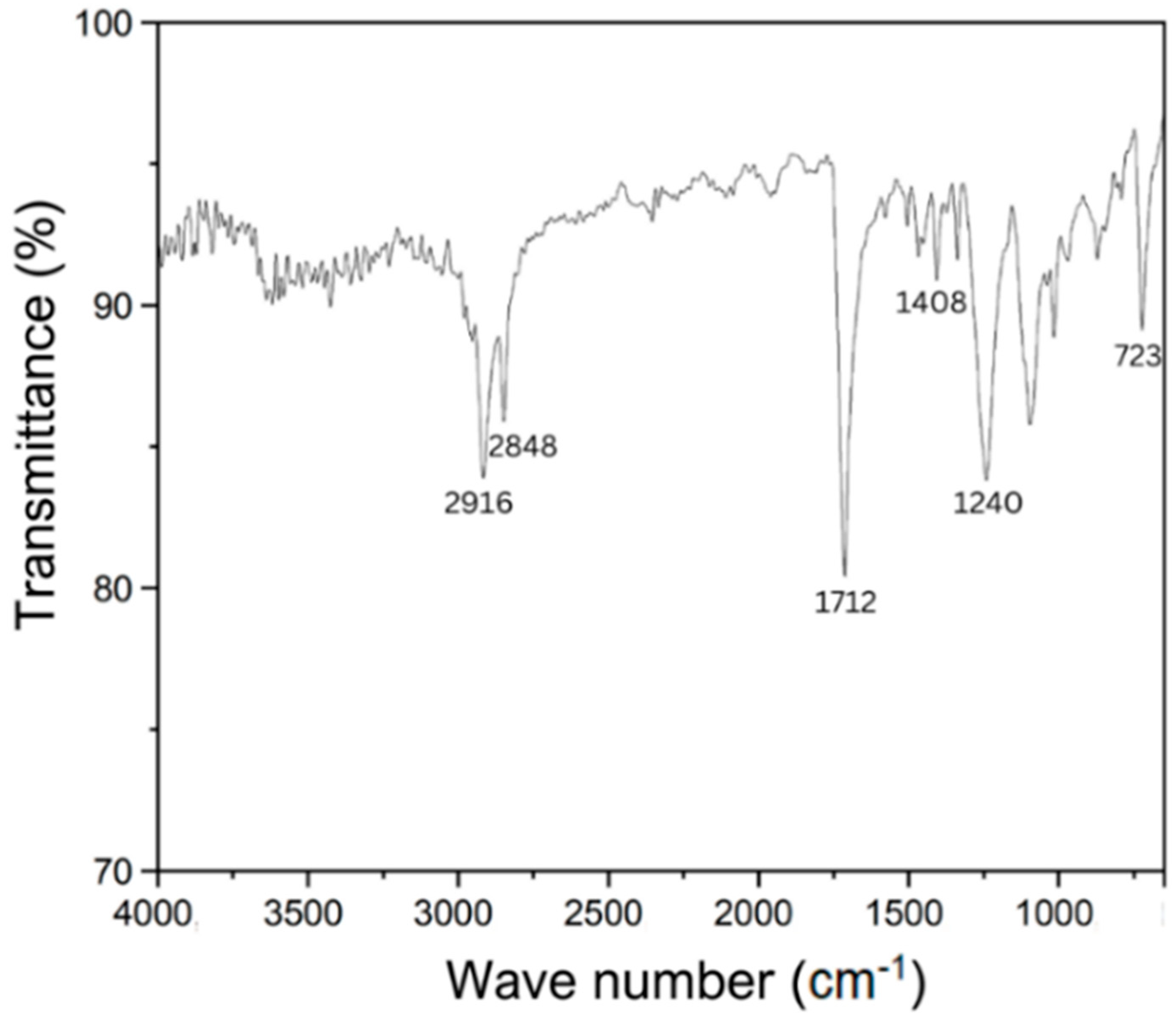

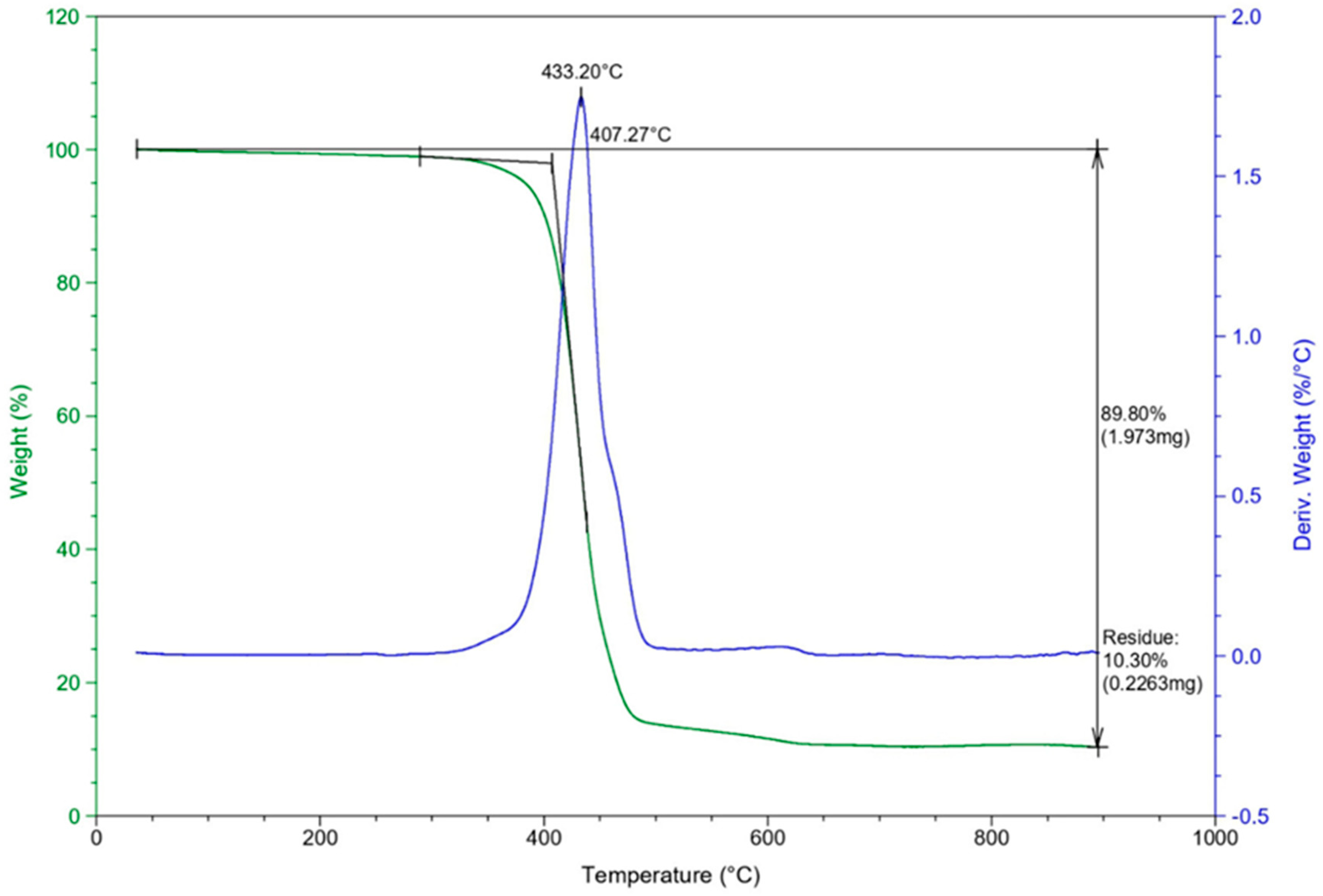

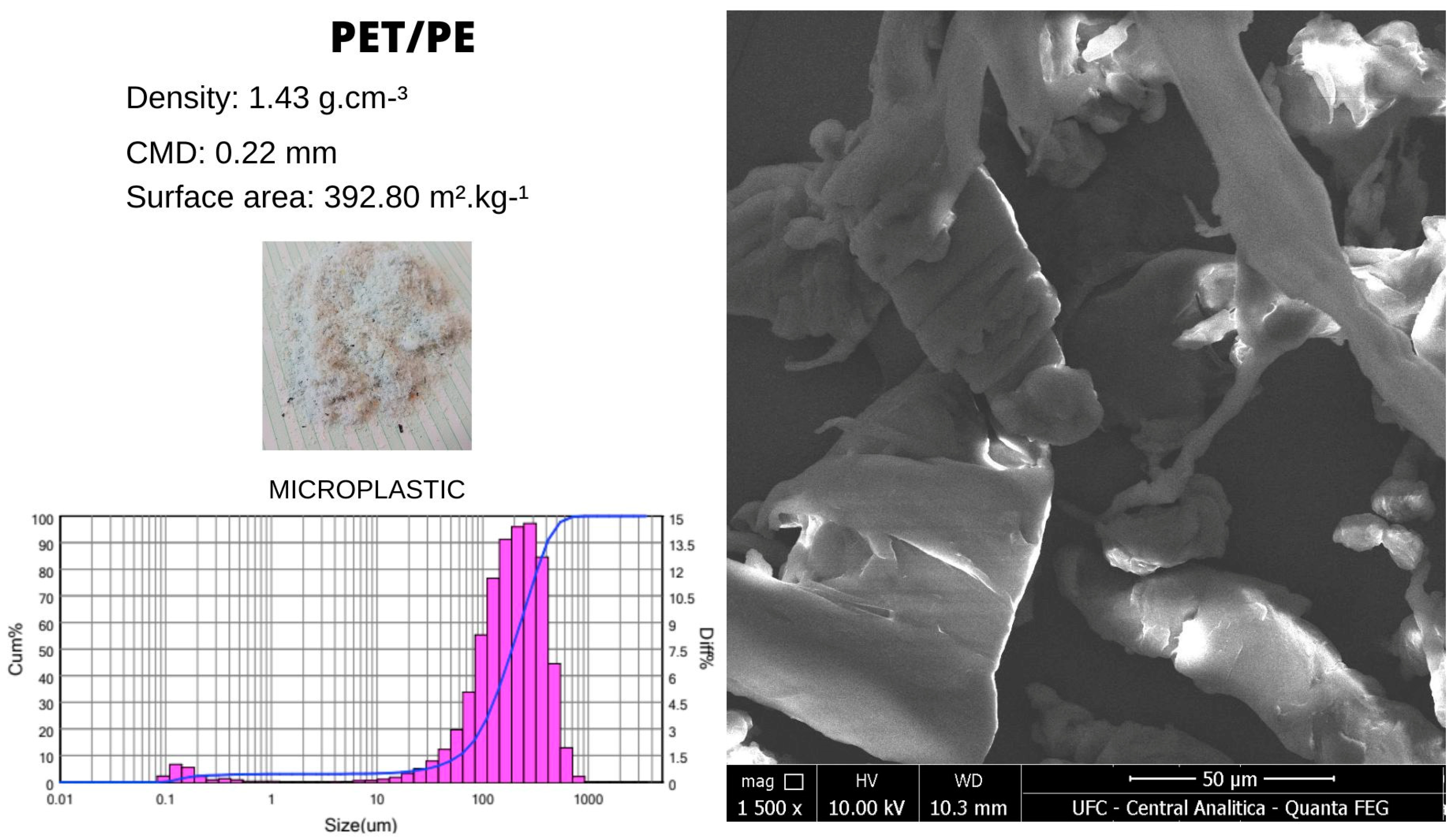

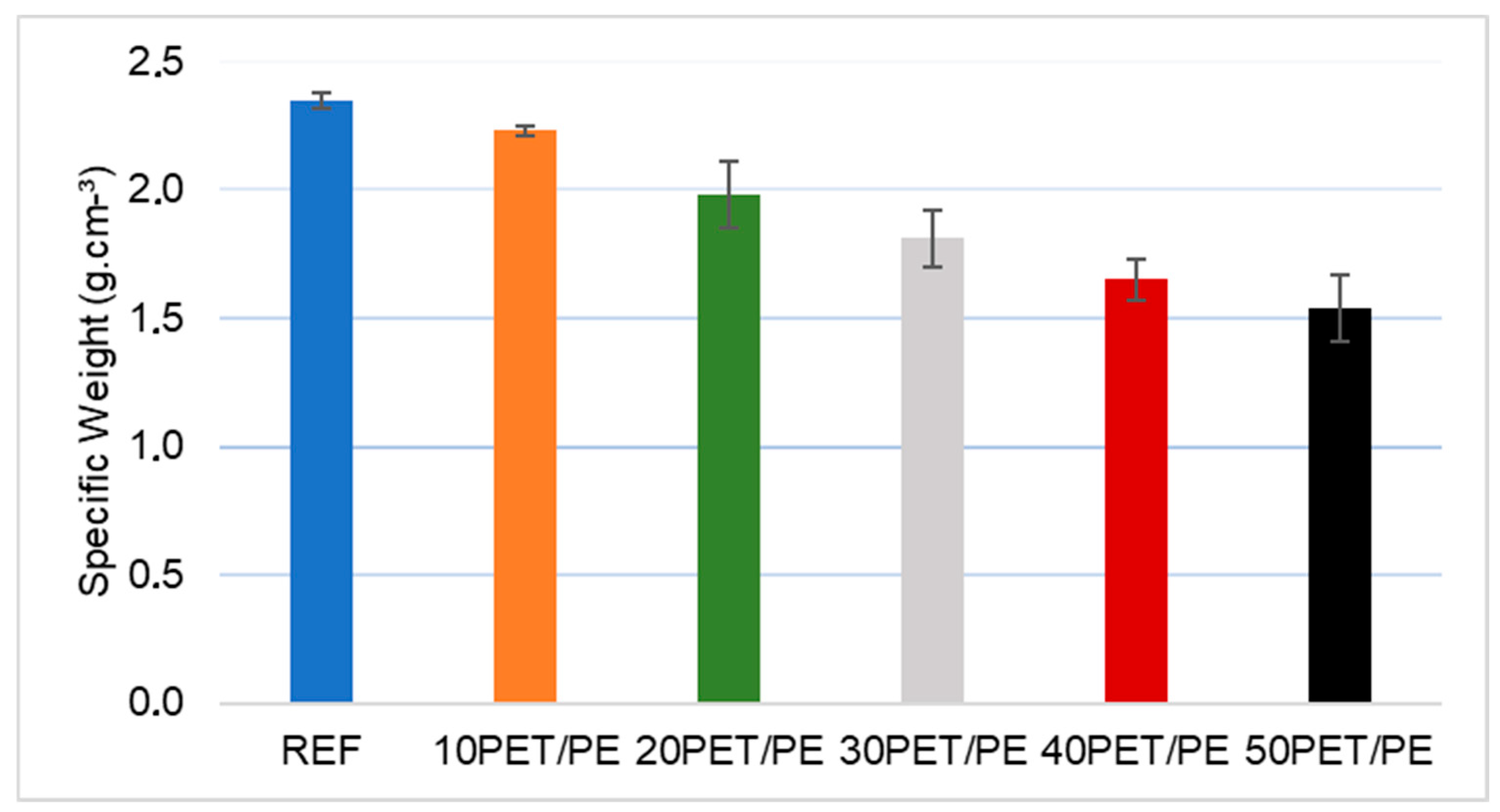

3.1. Characterization of Fine Aggregates

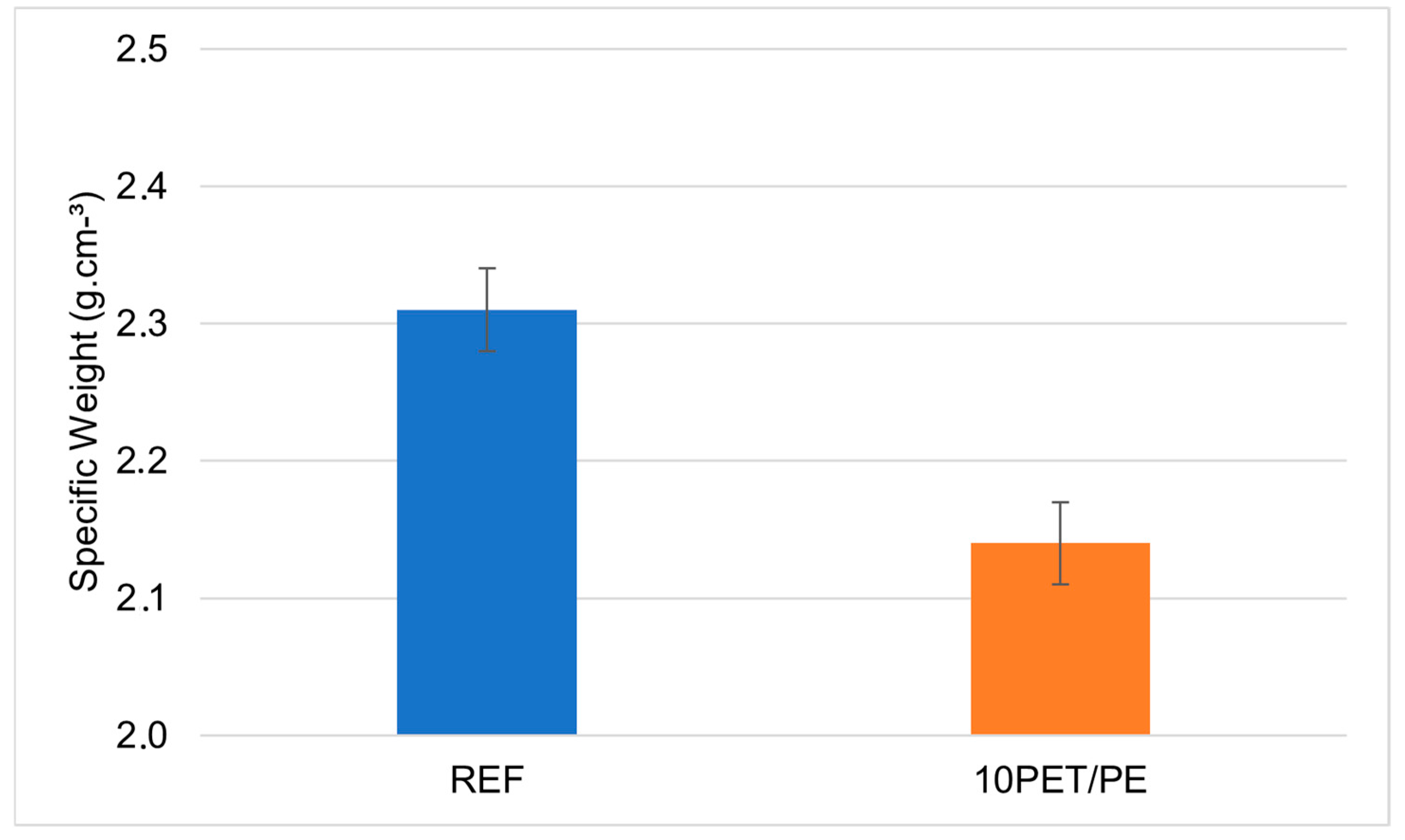

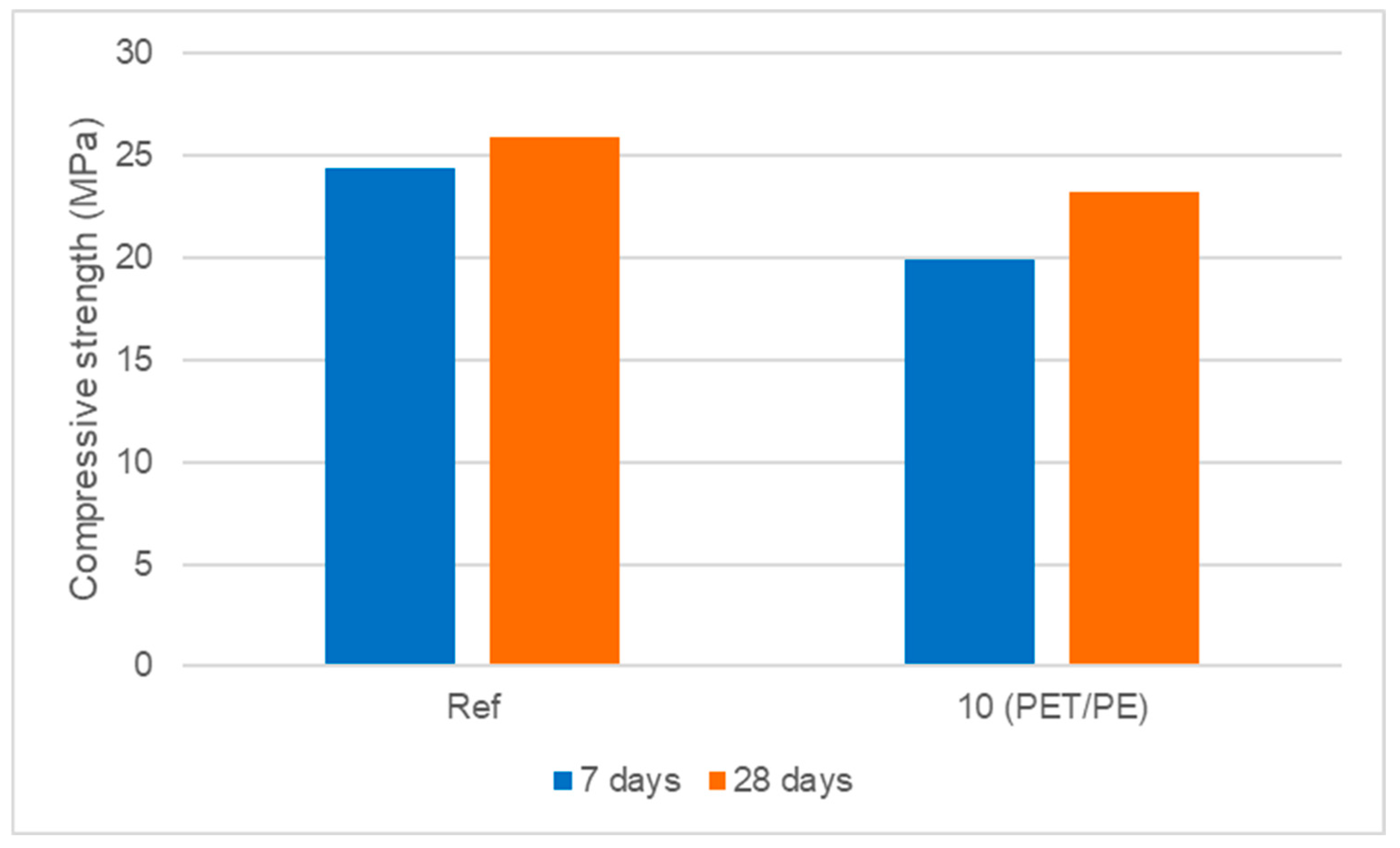

3.2. Characterization of Concrete Cylindrical Samples

Statistical Analysis

3.3. Cylindrical Specimens (28 Days)

3.4. Characterization of Concrete Blocks

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- OCDE. Global Plastics Outlook Economic Drivers, Environmental; OCDE: Paris, France, 2022. [Google Scholar]

- Ryou, H.; Byun, J.; Bae, J.; Kim, D.; Han, J. Energy-efficient and environmentally friendly upcycling of waste plastic into fuels, chemicals, and polymer. Eng. J. 2025, 511, 162256. [Google Scholar] [CrossRef]

- OCDE. Scénarios d’Action Pour l’Elimination de la Pollution Plastique à L’horizon 2040; OCDE: Paris, France, 2024. [Google Scholar]

- Preston, F. A Global Redesign? Shaping the Circular Economy; Chatham House: London, UK, 2012. [Google Scholar]

- Saikia, N.; Brito, J. Mechanical properties and abrasion behaviour of concrete containing shredded PET bottle waste as a partial substitution of natural aggregate. Constr. Build. Mater. 2014, 52, 236–244. [Google Scholar] [CrossRef]

- Baruzdin, A.; Zakrevskaya, L. Prospects for the use of polymer waste as concrete aggregates. Tech. Technol. Silic. 2024, 31, 3. [Google Scholar] [CrossRef]

- Rathnam, P.M.; Ram, S. Imbibing Energy Efficiency in Buildings Through Sustainable Materials—A Review. In Advances in Sustainable Materials and Resilient Infrastructure; Springer: New York, NY, USA, 2022; pp. 399–414. [Google Scholar] [CrossRef]

- United Nations Development Programme. Plastics and Circular Economy: Community Solutions; UNDP: New York, NY, USA, 2019; Available online: https://www.undp.org/publications/plastics-and-circular-economy-community-solutions (accessed on 24 June 2025).

- Al-Sinan, M.; Bubshait, A.A. Using plastic sand as a construction material toward a circular economy: A review. Sustainability 2022, 14, 6446. [Google Scholar] [CrossRef]

- Babu, D.S.; Babu, K.G.; Huan, W.T. Effect of polystyrene aggregate size on strength and moisture migration characteristics of lightweight concrete. Cem. Concr. Compos. 2006, 28, 520–527. [Google Scholar] [CrossRef]

- Debska, B. 10—Modification of Polymer Composites by Polyethylene Terephthalate Waste. In Poly(Ethylene Terephthalate) Based Blends, Composites and Nanocomposites; Visakh, P.M., Liang, M., Eds.; William Andrew Publishing: Norwich, UK, 2015; pp. 195–212. ISBN 9780323313063. [Google Scholar] [CrossRef]

- Foti, D. Preliminary analysis of concrete reinforced with waste bottles PET fibers. Constr. Build. Mater. 2011, 25, 1906–1915. [Google Scholar] [CrossRef]

- Wattanavichien, P.; Iwanami, M. Investigation of the mechanical, microstructure, and durability properties of concrete with fine uniform and non-uniform polyethylene terephthalate (PET). Clean. Mater. 2024, 13, 100267. [Google Scholar] [CrossRef]

- Rahmani, E.E.; Dehestani, M.; Beygi, M.H.A.; Allahyari, H.; Nikbin, I.M. On the mechanical properties of concrete containing waste PET particles. Constr. Build. Mater. 2013, 47, 1302–1308. [Google Scholar] [CrossRef]

- Barreto, J.M.L.; da Costa, H.N.; Candido, L.F.; Correio, A.E.B.C. Análise das propriedades físicas e mecânicas de blocos de concreto prensados sem função estrutural com incorporação de PET reciclado. Rev. Matéria 2019, 24, e12357. [Google Scholar] [CrossRef]

- Kassa, R.B.; Kanali, C.; Ambassah, N. Environmental and Cost Advantages of Using Polyethylene Terephthalate Fibre Reinforced Concrete with Fly Ash as a Partial Cement Replacement. Open J. Civ. Eng. 2019, 9, 281–290. [Google Scholar] [CrossRef]

- Zehil, G.P.; Assaad, J.J. Feasibility of concrete mixtures containing cross-linked polyethylene waste materials. Constr. Build. Mater. 2019, 226, 1–10. [Google Scholar] [CrossRef]

- Halim, N.F.A.; Taib, N.; Aziz, Z.A. The performance of thermal property in concrete containing waste pet (polyethylene terephthalate) as an alternative sustainable building material. IOP Conf. Ser. Earth Environ. Sci. 2020, 452, 012108. [Google Scholar] [CrossRef]

- Ashok, M.; Jayabalan, P.; Saraswathy, V.; Muralidharan, S. A study on mechanical properties of concrete including activated recycled plastic waste. Adv. Concr. Constr. 2020, 9, 207–215. [Google Scholar] [CrossRef]

- Xiong, B.; Falliano, D.; Restuccia, L.; Di Trapani, F.; Demartino, C.; Marano, G.C. High-strain rate compressive behavior of concrete with two different substituted recycled plastic aggregates: Experimental characterization and probabilistic modeling. Constr. Build. Mater. 2023, 368, 130279. [Google Scholar] [CrossRef]

- ISO 13320; Particle Size Analysis—Laser Diffraction Methods. International Organization for Standardization: Geneva, Switzerland, 2009.

- NBR 12821; Preparation of Concrete in the Laboratory—Procedure. Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2009.

- NBR 5738; Procedure for Molding and Curing Specimens. Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2008.

- NBR 12118; Plain Concrete Hollow Blocks for Masonry—Test Methods. Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2013.

- NBR 5739; Concrete—Compression Test of Cylindrical Specimens. Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2018.

- NBR 6136; Plain Concrete Hollow Blocks for Masonry—Requirements. Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2014.

- Barbosa, L.C.A. Espectroscopia no Infravermelho: Na Caracterização de Compostos Orgânicos; UFV: Viçosa, MG, Brazil, 2007. [Google Scholar]

- Chen, Z.; Hay, J.N.; Jenkins, M.J. FTIR spectroscopic analysis of poly (ethylene terephthalate) on crystallization. Eur. Polym. J. 2012, 48, 1586–1610. [Google Scholar] [CrossRef]

- Singh, R.K.; Ruj, B.; Sadhukhan, A.K.; Gupta, P. Thermal degradation of waste plastics under non-sweeping atmosphere: Part 1: Effect of temperature, product optimization, and degradation mechanism. J. Environ. Manag. 2019, 239, 395–406. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Song, H.; Wang, Y.; Deng, T.; Hou, X. Zinc-catalyzed ester bond cleavage: Chemical degradation of polyethylene terephthalate. J. Clean. Prod. 2019, 208, 1469–1475. [Google Scholar] [CrossRef]

- Grause, G.; Handa, T.; Kameda, T.; Mizoguchi, T.; Yoshioka, T. Effect of temperature management on the hydrolytic degradation of PET in a calcium oxide filled tube reactor. Chem. Eng. J. 2011, 166, 523–528. [Google Scholar] [CrossRef]

- Xue, Y.; Johnston, P.; Bai, X. Effect of catalyst contact mode and gas atmosphere during catalytic pyrolysis of waste plastics. Energy Convers. Manag. 2017, 142, 441–451. [Google Scholar] [CrossRef]

- Turner, A. In situ elemental characterisation of marine microplastics by portable XRF. Mar. Pollut. Bull. 2017, 124, 286–291. [Google Scholar] [CrossRef]

- Abbasi, S.; Keshavarzi, B.; Moore, F.; Delshab, H.; Soltani, N.; Sorooshian, A. Investigation of microrubbers, microplastics and heavy metals in street dust: A study in Bushehr city, Iran. Environ. Earth Sci. 2017, 76, 798. [Google Scholar] [CrossRef]

- Awaja, F.; Pavel, D. Recycling of PET. Eur. Polym. J. 2005, 41, 1453–1477. [Google Scholar] [CrossRef]

- Sharma, R.; Bansal, P.P. Use of different forms of waste plastic in concrete—A review. J. Clean. Prod. 2016, 112, 473–482. [Google Scholar] [CrossRef]

- Mendonça, A.M.G.D.; Souza, L.M.C.; Lira, Y.C.; Neto, V.F.S.; Luz, T.E.B.; Nunes, C.G.L.; Pereira, P.H.S.; Diniz, M.I.L. Physical and mechanical characterization of concrete incorporated with Polymer. Braz. J. Dev. 2021, 7, 26860–26876. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Dolati-Milehsara, S.; Lotfi-Omran, O.; Sadeghi-Nik, A. The combined effects of waste Polyethylene Terephthalate (PET) particles and pozzolanic materials on the properties of self-compacting concrete. J. Clean. Prod. 2016, 112, 2363–2373. [Google Scholar] [CrossRef]

- Sousa, V.C.M. Pathology, Recovery and Reinforcement of Concrete Structures; PINI: São Paulo, Brasil, 2018. [Google Scholar]

- Marcondes, E.F.; Batista, G.T.; Targa, M.S.; Soares, P.V. The Future Use of Sand Mining Areas in the Subsection Between Jacareí and Pindamonhangaba, SP and Its Insertion in the Local and Regional Dynamics. Annals of the Seminar on Water Resources in the Paraíba do Sul Hydrographic Basin: Eucalyptus and the Hydrological Cycle, Taubaté-SP, 1:139-146. 2007. Available online: https://ipabhi.org/serhidro/doc/@indice.htm (accessed on 24 June 2025).

| PET/PE (v/v) (%) | PET/PE (g) | Water (g) | Water/Cement |

|---|---|---|---|

| 0.0 | 0.0 | 210.0 | 0.50 |

| 10.0 | 54.0 | 210.0 | 0.50 |

| 20.0 | 109.0 | 210.0 | 0.50 |

| 30.0 | 163.0 | 210.0 | 0.50 |

| 40.0 | 217.0 | 230.0 | 0.55 |

| 50.0 | 272.0 | 230.0 | 0.55 |

| Mixture | Specific Mass (g cm−3) | Water Absorption (%) | Compressive Strength (MPa) |

|---|---|---|---|

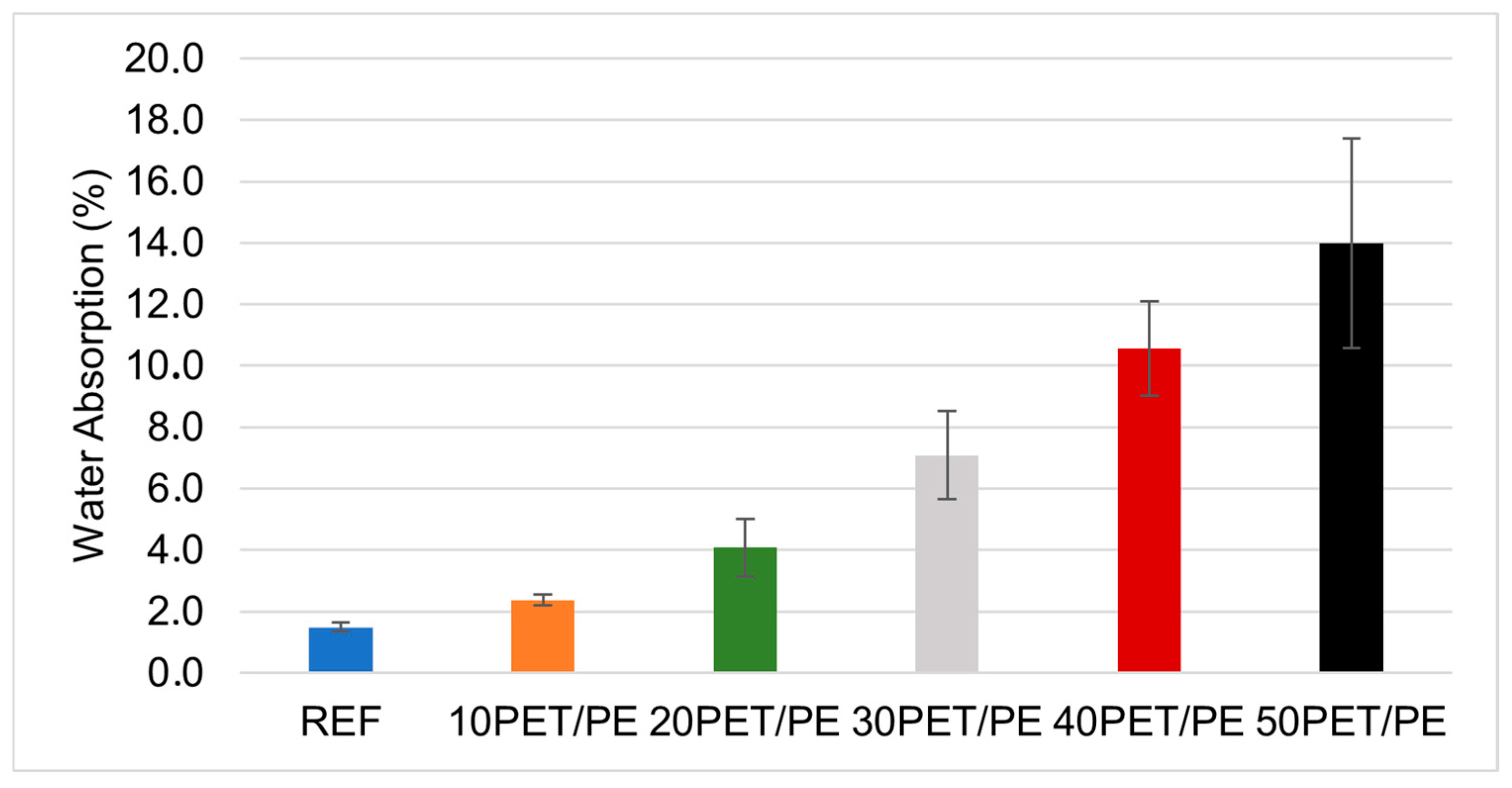

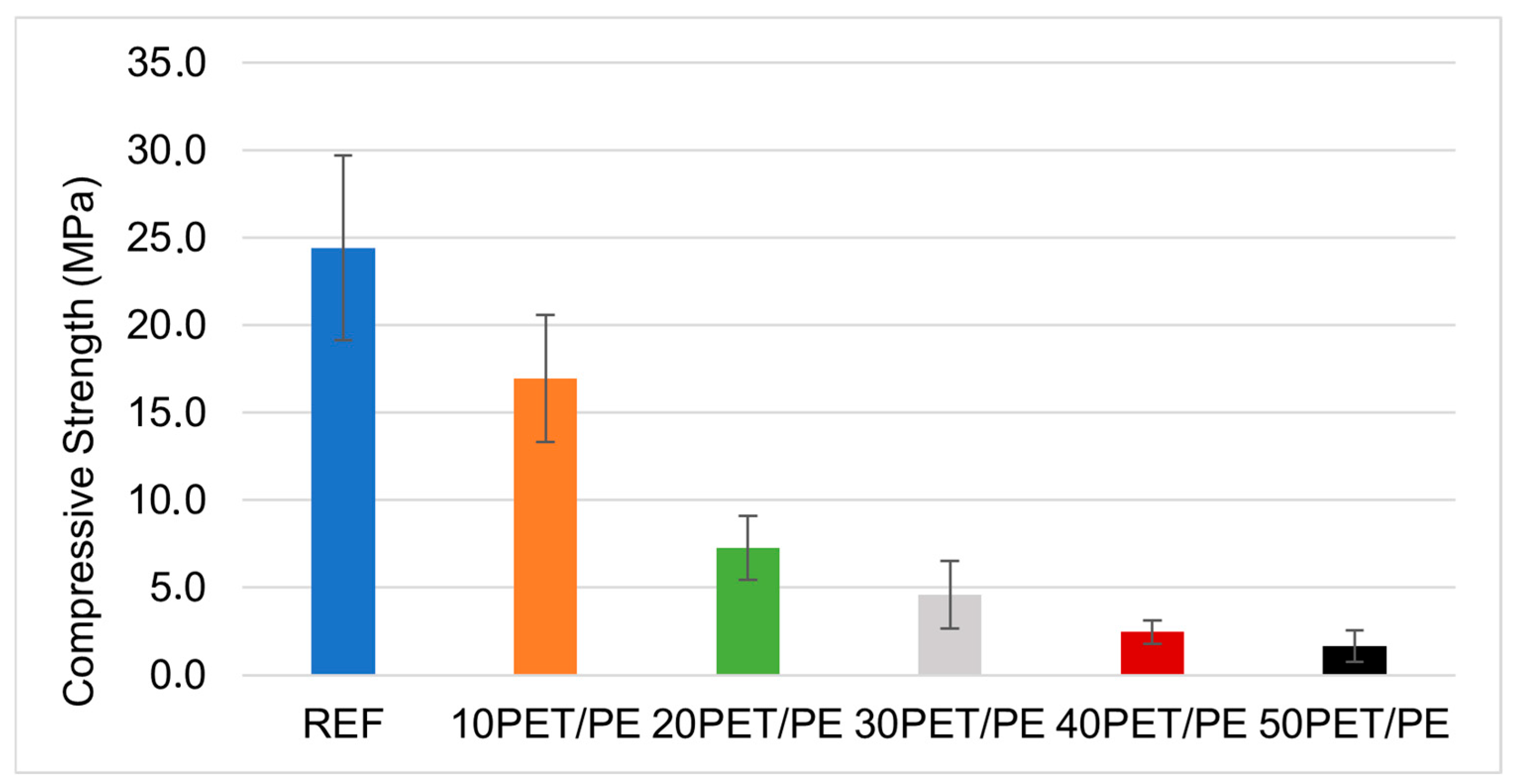

| REF | 2.35 ± 0.03 f | 1.49 ± 0.15 d | 24.4 ± 5.27 a |

| 10% | 2.23 ± 0.02 f | 2.37 ± 0.18 d | 16.9 ± 3.63 b |

| 20% | 1.98 ± 0.13 g | 4.08 ± 0.94 de | 7.26 ± 1.84 c |

| 30% | 1.81 ± 0.11 gh | 7.08 ± 1.43 e | 4.59 ± 1.94 c |

| 40% | 1.65 ± 0.08 hi | 10.55 ± 1.53 f | 2.45 ± 0.69 c |

| 50% | 1.54 ± 0.13 i | 13.98 ± 3.42 f | 1.65 ± 0.91 c |

| p-value (Levene’s test) | 0.020 | 0.012 | 0.024 |

| p-value (Welch’s test) | <0.001 | <0.001 | <0.001 |

| p-value (one-way ANOVA) | <0.001 | <0.001 | <0.001 |

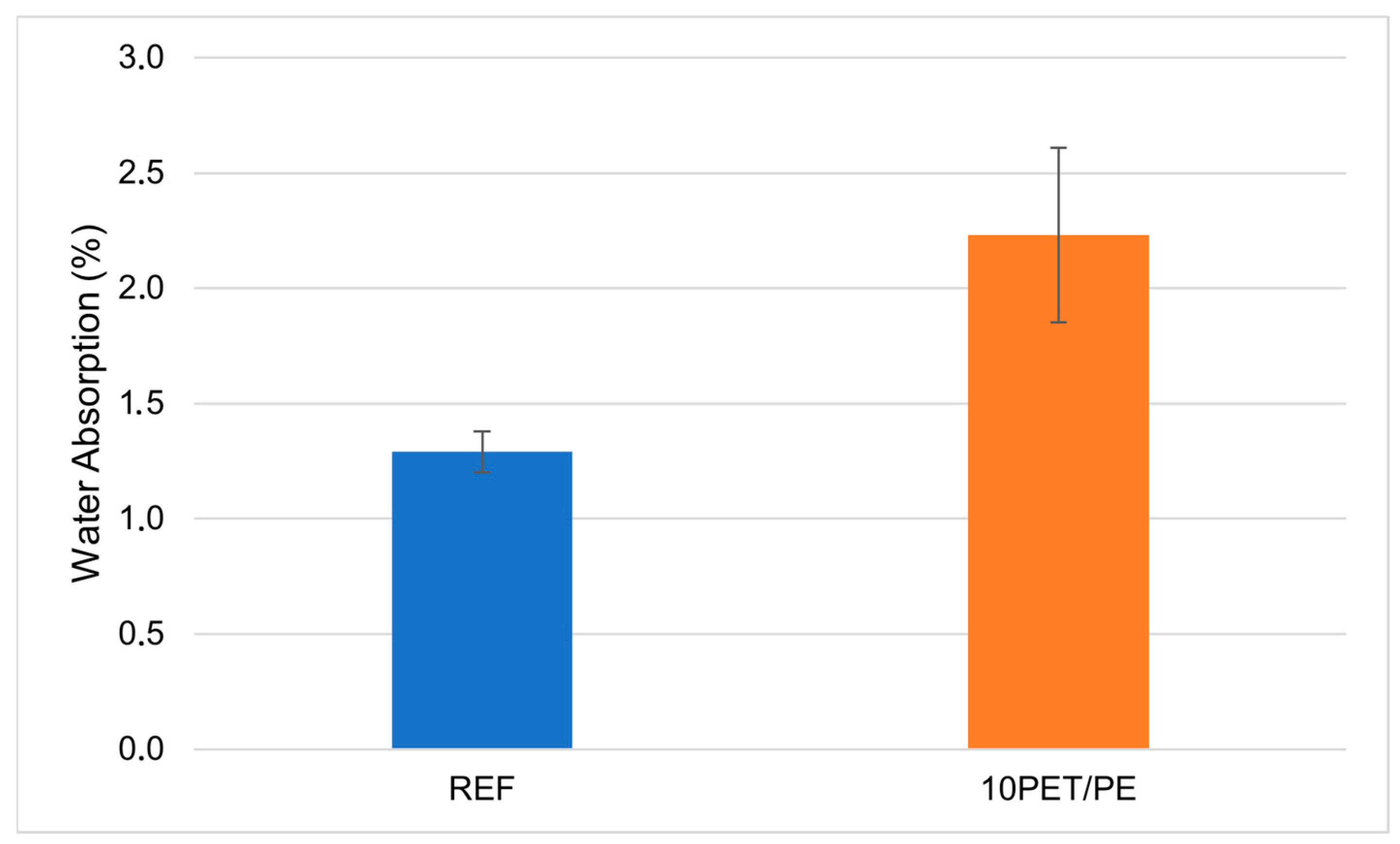

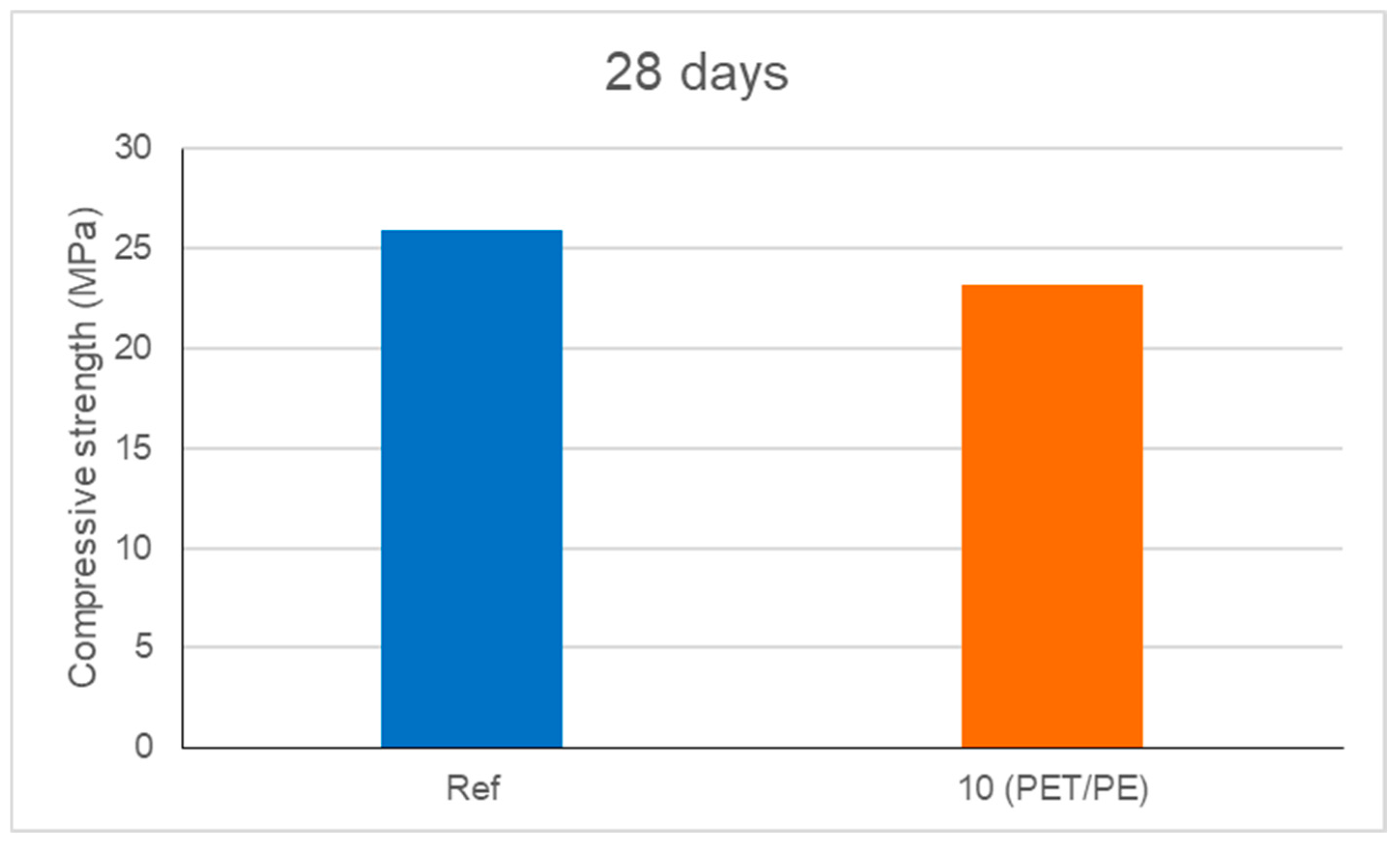

| PET/PE | Strength (MPa) | NBR 6136 (MPa) | Water Absorption (%) | Ordination | Group | |

|---|---|---|---|---|---|---|

| 0% | 4.3 | fbk ≥ 3.0 | 1.4 | ≤10.0 | no structural function | C |

| 10% | 3.9 | fbk ≥ 3.0 | 2.5 | ≤16.0 | no structural function | C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Knopik, A.P.; Fonseca, R.; Ramos, R.M.B.; Monteiro, P.I.; Mazer, W.; Kloss, J.R. Incorporation of Poly (Ethylene Terephthalate)/Polyethylene Residue Powder in Obtaining Sealing Concrete Blocks. Processes 2025, 13, 2050. https://doi.org/10.3390/pr13072050

Knopik AP, Fonseca R, Ramos RMB, Monteiro PI, Mazer W, Kloss JR. Incorporation of Poly (Ethylene Terephthalate)/Polyethylene Residue Powder in Obtaining Sealing Concrete Blocks. Processes. 2025; 13(7):2050. https://doi.org/10.3390/pr13072050

Chicago/Turabian StyleKnopik, Ana Paula, Roberta Fonseca, Rúbia Martins Bernardes Ramos, Pablo Inocêncio Monteiro, Wellington Mazer, and Juliana Regina Kloss. 2025. "Incorporation of Poly (Ethylene Terephthalate)/Polyethylene Residue Powder in Obtaining Sealing Concrete Blocks" Processes 13, no. 7: 2050. https://doi.org/10.3390/pr13072050

APA StyleKnopik, A. P., Fonseca, R., Ramos, R. M. B., Monteiro, P. I., Mazer, W., & Kloss, J. R. (2025). Incorporation of Poly (Ethylene Terephthalate)/Polyethylene Residue Powder in Obtaining Sealing Concrete Blocks. Processes, 13(7), 2050. https://doi.org/10.3390/pr13072050