Abstract

Polymer residues can be reused in civil construction by partially replacing mineral aggregates in concrete, thereby reducing the extraction of natural resources. This study aimed to evaluate the use of powdered poly (ethylene terephthalate) (PET) and polyethylene (PE) residues, accumulated in shaving-mill filters during the extrusion of multilayer films used in food packaging, in the production of sealing masonry blocks. The PET/PE residues were characterized by Fourier Transform Infrared Spectroscopy (FTIR), thermogravimetric analysis (TGA) and scanning electron microscopy (SEM). Cylindrical specimens were produced in which part of the sand, by volume, was replaced with 10, 20, 30, 40 and 50% polymer residue. The cylindrical specimens were evaluated for specific mass, water absorption and axial and diametral compressive strengths. The 10% content provided the highest compressive strength. This formulation was selected for the manufacture of concrete blocks, which were evaluated and compared with the specifications of ABNT NBR 6136:2014. The concrete blocks showed potential for applications without structural function and were classified as Class C. The results, in line with previous investigations on the incorporation of plastic waste in concrete, underscore the promising application potential of this strategy.

1. Introduction

In the industrial sector, searching for alternatives for appreciation of by-products confers a company greater economic income, minimization of costs related to the destination of by-products and a commitment for the environment. Plastic waste (plastic bottles, bags and sheets) is not readily biodegradable, which makes it one of the most challenging sources of pollution. According to previous studies [1,2], plastic waste generation increased from 156 million tonnes in 2000 to 353 million tonnes in 2019. According to OECD projections (2024) [3], by 2040, recycled plastics will account for just 6% of total production. One possibility would be inserting the industrial residues of a certain sector into another, so that it closes cycles and opens revenue opportunities for the entire productive chain, by way of a circular economy. According to Preston [4], what has already been thought of as a circular economy (CE) model is one in which the industrial system is restoring or regenerative by design. Within this perspective, new business models are developed in order to decrease the need for virgin raw materials. This is done by rethinking how production chains can become closed cycles. A possible solution for the destination problem consists in the incorporation of polymer residues as aggregates in the preparation of concrete [5,6]. It is important to reuse and recycle these wastes as construction material for better conservation of natural resources and reduce embodied energy [7]. The circular economy presents an alternative to the linear “take, make, use, dispose” system. It attempts to keep resources in use for as long as possible, maximize their value while they are in use, and recover and regenerate products at the end of their useful lives [8].

The production and use of plastic sand bricks and blocks is a good example of the innovation required to establish a circular economy [9]. Over the last decades, many studies [10,11] have been conducted on the usage of different types and sizes of polymer fragments in the substitution of part of the amount in volume or mass of aggregates in concrete. Such factors influence the features and physical and chemical properties of the compounds formed, in addition to the structure and mechanical performance.

Foti [12] analyzed reinforced concrete with fibers of PET bottle residues and verified that they can have a great influence on the post-fissured material through the execution of simple concrete elements. In addition, the study emphasized that these fibers improve the tenacity of samples and increase concrete plasticity. Additionally, Wattanavichien et al. [13] developed concrete formulations in which PET derived from municipal plastic waste was used as an aggregate. The authors observed a decrease in both compressive and tensile strength. However, an increase in chloride resistance was also reported.

Rahmani et al. [14] evaluated the effects of 5, 10 and 15% substitution of sand with PET particles, presenting different gradations in the concrete; more pores would be formed in the concrete because of the plate and narrow format of the polymer particles. In addition, excess water in the concrete specimens, corresponding to the amount that did not react with cement, created some miniscule channels in the concrete, resulting in more pores after drying.

Saikia and Brito [5] described the effect of the shape of the PET particles on concrete workability. Three plastic particles of different shapes, fragmented fractions with a thin strip, fragmented fractions with thick strips and pellets in a spherical/cylindrical shape. The results indicated that the consistency of fresh concrete slightly increases with the incorporation of spherical/cylindrical aggregates and the inclusion of fragments with fine granulometry, and that coarse aggregate decreases drastically the consistency.

Barreto et al. [15] analyzed pressed concrete blocks with the incorporation of recycled PET replacing the fine aggregates, in volume, at content ratios of 15, 30 and 45%. The 15% ratio presented better results in regard to compression resistance; water absorption, which is probably related to a greater packing degree; and the homogeneity of the composite obtained, when compared to other content ratios of PET replacement.

Kassa et al. [16] studied the environmental and economic benefits of the partial replacement of cement by fly ash, a residue from wood combustion, and the addition of PET fibers to reinforce concrete. According to the composition of the material, the production of 1.0 m3 of modified concrete requires 5.51 kg of PET fibers and 100.95 kg of fly ash, and the cost with binder, cement and fly ashes decreased by 19.25% in relation to control concrete.

Zéhil and Assaad [17] conducted studies with post-consumption cross-linked polyethylene (XLPE) residues, which presents difficulties in being recycled due to covalent cross-links between polymer chains. However, the incorporation of this class of residues into concrete, which occurred in up to 8% of cement mass, was advantageous. The results of the tests showed that the workability and empty spaces in the concrete were not affected with the incorporation of XLPE, while the specific mass decreased due to the difference in density amongst aggregates and the polymer. In addition, it was reported that the performance of concrete with substitution for polymer material was greater in terms of water permeability, and the size or particles moderately influenced its resistance to compression and retraction.

Halim et al. [18], in an experimental analysis, measured thermal conductivity parameters of concrete blocks with PET ratios of 0, 5, 15 and 25%; the results obtained emphasized an improvement in mechanical, thermal and thermal insulation properties, compared to a traditional concrete mixture. Ashok et al. [19] studied the substitution rate of recycled plastics in concrete and considered that it is feasible to prepare concrete with 5% non-activated and 15% activated recycled plastics, by alkali activation using NaOH solution, as fine aggregate.

Xiong et al. [20] investigated the high-strain rate compressive behavior substitution of concrete with two different types and morphology of recycled plastic aggregates, namely, recycled PET powder and recycled mixed plastic granules composed of polypropylene (PP) and polyethylene (PE). Scanning electron microscopy revealed observations of interfacial transition zones between the different plastic aggregates and the cement paste. More micropores and micro-cracks are generally observed with the presence of PET and mix–plastic aggregate.

In light of previous studies and the authors’ recognition of the potential of using plastic in concrete, it is evident that while this approach is promising, identifying an optimal mix design is essential to preserve the material’s mechanical properties. This presents a promising opportunity to introduce residues from the packaging industry into the civil construction sector. The packaging industry generates around 250 kg of this powdered polymer residue each month. Due to the fine granulometry and lightness of the material, the producing company itself is not able to recycle it, and it is necessary for the residue to be transported to industrial landfills, generating costs and impacting the environment. The incorporation of this residue into concrete not only offers a sustainable alternative for its disposal but also contributes to circular economy practices by reintegrating industrial residues into new construction materials. Furthermore, this study proposes the use of an industrial residue, which is difficult to recycle and presents specific physical characteristics. In this context, the study stands out by investigating the feasibility of applying this specific residue, contributing to the valorization of an industrial by-product. Therefore, the objective of this study was to incorporate poly (ethylene terephthalate)/polyethylene (PET/PE) powder residue into concrete by partially replacing the volume of natural sand. This strategy represents a promising opportunity to introduce packaging industry waste into the civil construction sector.

2. Materials and Methods

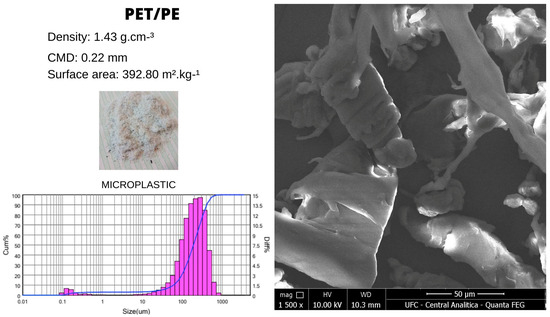

To carry out this study, the following materials were used: CP V Portland cement; powdered poly (ethylene terephthalate)/polyethylene (PET/PE) residue with a density of 1.43 g.cm−3; natural quartz sand with a density of 2.66 g.cm−3 as fine aggregate; gravel with a fineness modulus of 5.85 and a density of 2.82 g.cm−3; and water from the municipal supply system.

2.1. Characterization of Aggregates

The powdered poly (ethylene terephthalate)/polyethylene residue (PET/PE), generated through grinding the shavings from the process of extrusion of multilayered films for food packaging, underwent analysis in the Fourier Transform Infrared Spectroscopy (FTIR) in an spectrophotometer from Biorad Laboratories, Excalibur Series FTS 3500 GX model (Cambridge, MA, USA), in the 4000 to 600 cm−1 scope, with 4.0 cm−1 resolution and 128 scans min−1. Thermal stability of the PET/PE samples was evaluated by a TA Instruments TGA Q500 V20.10 Build 36 thermal analyzer (New Castle, DE, USA), in a nitrogen atmosphere at 50 mL min−1, with a warming rate of 10 °C min−1, with a 30 to 900 °C scan. Verification of the powdered PET/PE morphology was performed scanning electron microscopy (SEM) analysis, employing a high-resolution electronic microscope (Zeiss, EVO MA15, Oberkochen, Germany), with a power of 20 kV.

In order to compare the morphology of fine aggregates, scanning electron microscopy (SEM) on the natural quartz sand as well, employing a field emission scanning electron microscope (FE) model Mira 3, Tescan, with a power of 15 kV. Both aggregates underwent laser granulometry analysis on a BETTERSIZE/S3 PLUS laser particle analyzer granulometer, with analysis ranging from 0.01 to 3500 µm—Laser Diffraction: DLOIOS, liquid dispersion system, employing ISO 13320 [21] as the essay parameter for verification and comparison of the sizes of both PET/PE particles and natural sand. Additionally, the coarse aggregates were characterized only by their density and granulometric curve.

2.2. Manufacture and Characterization of Cylindrical Samples of Concrete

The ratio of materials for the manufacture of conventional concrete in relation to cement was of 1:2.4:2.9:0.5, respectively, for cement, sand, gravel and water. For each replacement content, the amount in mass (g) of PET/PE was determined, taking into account contents of 10, 20, 30, 40 and 50% from the calculation of the corresponding volume of sand and according to the density of these materials. These formulations were designated as 10PET/PE, 20PET/PE, 30PET/PE, 40PET/PE and 50PET/PE, respectively.

The preparation of the cylindrical samples followed the NBR 12821 standard [22]. An automatic concrete mixer was employed (Figure 1a) to prepare fresh concrete, which was molded in cylindrical metal molds measuring 50 mm × 100 mm after the application of a releasing agent and submitted to compression with a vibrating table for 90 s (Figure 1b). After 24 h, the samples were demolded. The specific mass of the formulations was determined based on the weighing and volume of samples, following the guidelines set by NBR 5738 [23]. Then a water absorption essay was performed according to the specifications listed on NBR 12118 [24], which consisted in the determination of the mass (g) of a water-saturated sample on an analytical scale divided by the dry mass (g) and multiplied by 100, calculating water absorption percentage by the concrete cylindrical samples [19].

Figure 1.

Equipment used in the manufacture of cylindrical samples and concrete blocks: (a) mortar mixer; (b) vibrating table; (c) manual rectifier; (d) Emic DL 30000 N model press.

After a period of seven days for curing, a surface finishing was performed on the samples using a manual rectifier (Figure 1c); then, an axial compression strength analysis was performed, which followed the NBR 5739 [25] standard, in which a uniform pressure was applied on the circular surface until rupture. The analysis was performed using an Emic DL30000 N model compression machine, Figure 1d.

After the evaluation of the sand substitution content presenting best performance and the reference formulation for comparison, specimens were once again manufactured, and the analyses described in item 2.2 were undertaken again after 28 days. Afterward, five samples also manufactured in all the stages, and the results of the analyses were submitted to Analysis of Variance (ANOVA) with a 95% confidence level, complemented by Levene’s test for variance homogeneity and Welch’s test.

2.3. Manufacturing and Characterization of Concrete Blocks

After a careful evaluation of the data obtained from the specimens over 28 days, five concrete blocks measuring 390 mm × 145 mm × 190 mm were manufactured. For the preparation of the concrete, a concrete mixer was employed, and molding was performed with a vibro-press concrete block machine. The concrete blocks were submitted to water absorption analysis and axial compression tests, according to NBR 12118 [24], after a curing period of 28 days. The results obtained were compared to the classification established on NBR 6136 [26], as being or not being of structural function.

3. Results

3.1. Characterization of Fine Aggregates

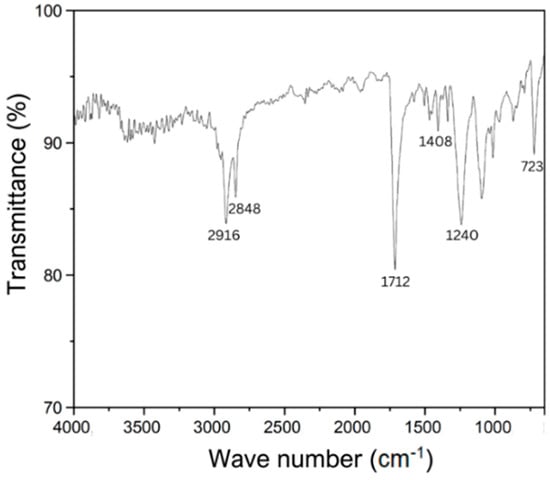

In the FTIR analysis (Figure 2), the bands in the range 2916 to 2848 cm−1 are attributed to symmetric stretches of the bonds (CH2); the band at 1712 cm−1 is related to bond stretching (C=O) of the ester; the bands at 1450 to 1375 cm−1 are associated with angular deformation of the group (CH3) the bands at 1275 to 1200 cm−1 are characteristic of bond stretching (C=O)-C. The band at 723 cm−1 is typical of the deformation of the aromatic ring (C=C) outside the frame. Based on this analysis and in literature reports [27,28], it was possible to confirm that the powdered residue is made up of PET/PE.

Figure 2.

FTIR spectrum of powdered PET/PE residues.

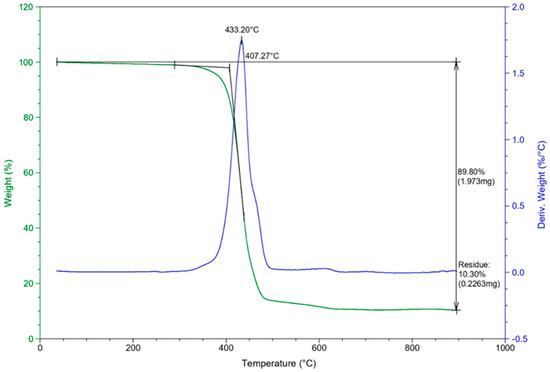

The thermogravimetric curve obtained by the pyrolysis of powdered PET/PE (Figure 3) shows Posteriorly initial temperature and maximum degradation temperature with mass loss of 407.27 °C and 433.20 °C, respectively. Stabilization of the residual mass was observed from 620 °C; the mass loss was 89.9% of the initial mass, PET/PE presented a residual mass of 10.1%, which, according to Singh et al. [29], is a value normally found in the thermal degradation of PET in an inert atmosphere, while LDPE has practically no significant residual mass at the end of pyrolysis process.

Figure 3.

Thermogravimetric analysis (TGA) spectrum of powdered PET/PE residues.

It is possible to attribute the formation of the residual mass in the pyrolysis of this sample due to the by-product formation resulting from the condensation of the polymeric chain of PET [30], since during its thermal degradation, the C-H group of the chain undergoes a transition state, whose hydrogen migrates to oxygen of the ester bond (C=O), resulting in the release of CO and CO2 with increasing temperature. Thus, the C=C double bond and the O-H bonds are formed by the partial dissociation of the C-H bond and the alkoxy bonds (C-O) [31,32]. The thermal degradation curve for pure PET and pure LDPE shows one single peak, while in the case of the PET/LDPE mixture, two degradation peaks are observed in dTG [30].

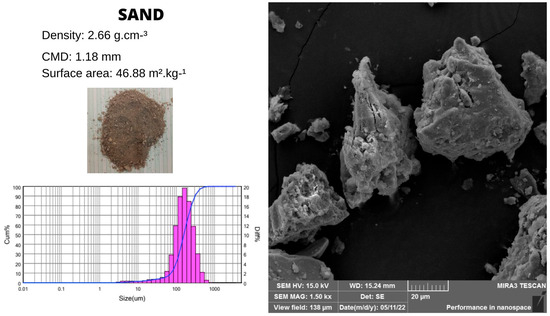

According to Figure 4, PET/PE powder residue visually presents an aspect of fiber, which was confirmed during SEM analysis, with an increase of 1500×. This feature of the irregular format of polymer particles might be a result of the grounding process of the multilayer films. On the other hand, in the case of sand morphology, it was verified that the format of the grains is more regular. On the granulometry of PET/PE and sand, which is apparently similar, it was possible to observe, during laser analysis, that the maximum characteristic dimension (MCD) of PET/PE was 0.22 mm, and for sand it was 1.18 mm, which represents a size five times greater. Within this perspective, powdered PET/PE can be classified as microplastic, since it presents a size of less than 5.00 mm. It is thus potentially an environmental pollutant, and it might generate direct impact on marine life and transference via the food chain [33,34].

Figure 4.

Illustration of the comparison of small aggregates of natural sand and powdered PET/PE residues.

Through surface analysis of PET/PE fibers, it was verified that it presented a 392.80 m2 kg−1 size while sand presented a 46.88 m2 kg−1 size, which indicates that polymer residues have a surface that is eight times greater; in other words, its very fine granulometry reflects the size of surface area of the particles, and this factor might affect its behavior in relation to concrete, since the area of interaction with water, which is part of the composition, will be significantly greater. Studies on surface area, particle morphology in comparison to sand, and hygroscopic features have already been conducted by Rahmani et al. [14], Awaja et al. [35] and Sharma [36].

3.2. Characterization of Concrete Cylindrical Samples

Figure 5 shows concrete samples with a curing period of 7 days. The concrete cylindrical samples were manufactured according to the amounts of water and PET/PE described on Table 1. For formulations with PET/PE content of 40 and 50%, it was necessary to add 20.0 g more than the amount applied in other tests so that it was possible to perform the molding of the samples, because the cement paste was too dry, due to the possible absorbing action by the polymer matter. The increase in the water/cement ratio might have negatively influenced the performance of the mechanical properties of the concrete for greater replacement contents.

Figure 5.

Concrete samples with a curing period of 7 days.

Table 1.

Amount of water and PET/PE and the water/cement ratio of the manufactured concrete compositions.

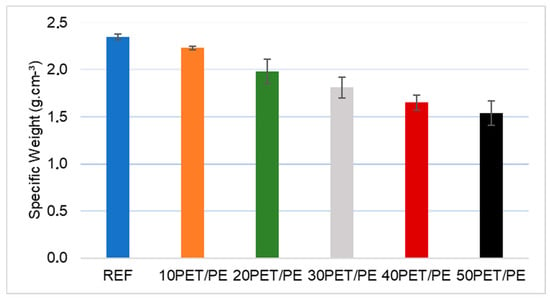

The manufactured concrete cylindrical samples were submitted to tests of specific weight, water absorption content and axial compression over a period of seven days. Figure 6 shows the specific weight of the concrete samples. It can be observed that, with the increasing amount of PET/PE and the corresponding decrease in sand content, the specific weight of the formulations also decreased. This trend can be explained by the difference in density between the natural fine aggregates and the PET/PE residue [34], as the density of powdered PET/PE is 1.43 g·cm−3, compared to 2.66 g·cm−3 for sand. As a result, the use of plastic aggregates leads to a reduction in the density of fresh concrete. This effect was also observed by Sharma and Bansal [36]. The authors reported that the addition of PET particles resulted in less unitary mass in concrete formulations that replaced part of the volume with natural sand.

Figure 6.

Specific weight of concrete samples with a curing period of 7 days.

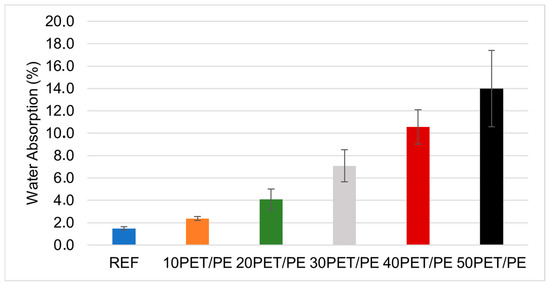

Figure 7 shows the water absorption with a curing period of 7 days. In relation to water absorption analyses, it was observed that with increased amounts of PET/PE in concrete, there was an increase in this parameter in the samples, for a 10(PET/PE) content; absorption was (2.4 ± 0.2)%, while for the reference, it was (1.5 ± 0.1)%, which, according to the Analysis of Variance (ANOVA), is statistically equal to a confidence level of 95%. The 20, 30, 40 and 50(PET/PE) contents presented increased water absorption contents, which might attributed to the weak bond between the polymer residues and the cement paste, which allows water absorption by capillarity, through the existing gaps between the PET/PE residues and cement paste, as well as the interaction between water and residues, keeping it absorbed on the surface of the particle. The addition of plastic residues affects the effect of distribution of the water available in the paste and, consequently, the workability of the concrete [36].

Figure 7.

Water absorption graphic with a curing period of 7 days.

Thus, when a natural sand content was replaced with PET particles in the concrete, more pores would be formed due to the narrow format of polymer particles. In addition, excess water in the samples resulted from the amount that does not take part in the reaction with concrete, forming some small canals in the concrete, resulting in more pores after drying. Therefore, the addition of PET particles caused an increase in the ratio of water and cement in the concrete [14,36].

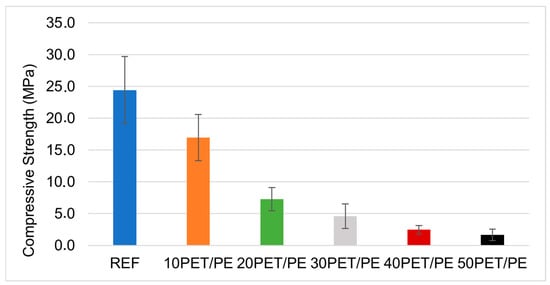

Figure 8 shows the compressive strength of concrete samples with a curing period of 7 days. In relation to axial compressive strength, it was verified that an increase in PET/PE quality resulted in decreased resistance to compression of the concrete cylindrical bodies, which might be explained, in part, by the fact that natural sand is more mechanically resistant than polymers, due to its mineral composition, features of chemical bonds and crystalline structures. The formulation with powdered residues that presented the best performance was the one with a 10(PET/PE) content, which presented a 16.9 ± 3.6 MPa compression. In general, the use of PET partially replacing the fine aggregate in concrete resulted in a loss of strength, but it also provided an adequate discharge of this residue, which would otherwise be discharged in sanitary landfills or be incorrectly disposed [4]. Thus, less chemical interaction was observed between the polymer and the cement matrix when compared to light aggregates, generating residual porosity, a fact that causes an increase in water absorption and decreased resistance to compression of the concrete [34].

Figure 8.

Compressive strength of concrete samples with a curing period of 7 days.

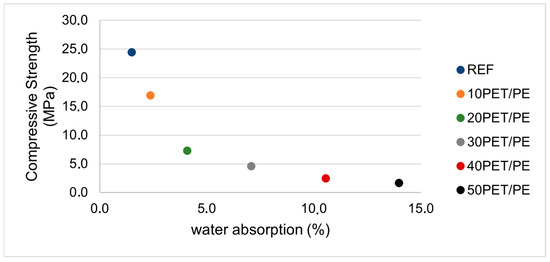

Figure 9 shows the relationship between mechanical and physical properties, compressive strength versus water absorption, of concrete samples with a curing period of 7 days. It was observed that increased PET/PE favors absorption of water and decreases compressive strength. According to Rahmani et al. [14], with an increase of PET content to 10 and 15%, resistance to compression by the concrete decreased, because the PET particles acted as barriers and prevented the cement paste remained adhered to the aggregates, gradually decreasing the concrete’s resistance.

Figure 9.

Relationship between of mechanical and physical properties compressive strength versus water absorption with a curing period of 7 days.

Statistical Analysis

As shown in Table 2, the incorporation of waste significantly affected the specific mass, water absorption and compressive strength of the specimens after 7 days of curing. The one-way ANOVA revealed highly significant differences between mixtures for all variables (p < 0.0001). While the addition of 10% PET/PE did not alter specific mass or water absorption compared to the control, it led to a notable decrease in compressive strength. Higher PET/PE contents (≥20%) resulted in progressive reductions in a specific mass and strength, along with increased absorption. Levene’s test indicated heteroscedasticity for all parameters, which was confirmed by Welch’s test, supporting the robustness of the observed effects. These results reinforce the need to balance environmental benefits with mechanical performance when defining optimal waste content in cementitious composites.

Table 2.

Physical and mechanical characterization of cylindrical specimens after 7 days of curing (mean ± standard deviation; n = 5).

3.3. Cylindrical Specimens (28 Days)

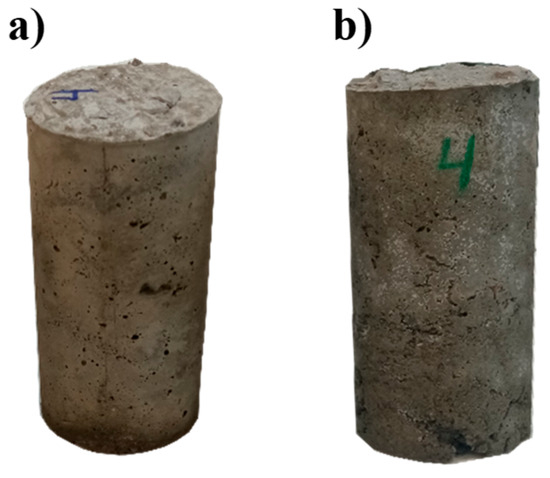

Since the 10(PET/PE) content presented the best result in resistance to compression, this composition was chosen for the repetition of analysis, with a curing period of 28 days (Figure 10), and verified the potential of application as sealing concrete blocks, without any structural function. It was possible to verify the visual similarity of the reference concrete cylindrical samples to those with 10(PET/PE); however, the greater the water/cement relation, the greater the porosity of the concrete [37].

Figure 10.

Cylindrical specimens with a curing period of 28 days: reference sample (a), and 10(PET/PE) (b).

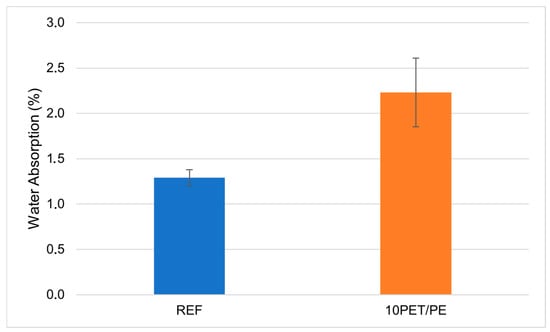

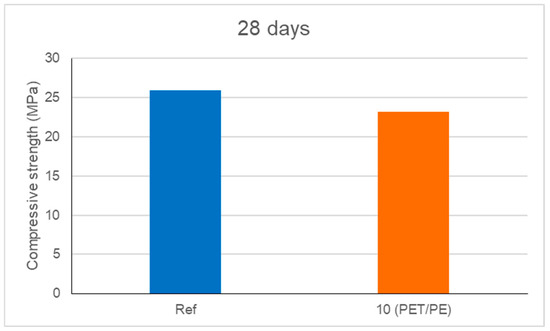

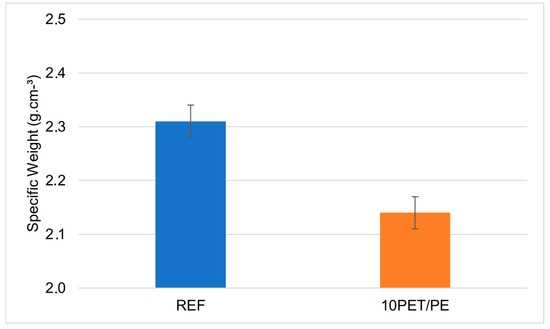

In the water absorption tests, it was verified that the concrete cylindrical samples with 10(PET/PE) content presented absorption an ratio (Figure 11) of 2.2 ± 0.2%, while the reference sample presented 1.3 ± 0.1%. In the axial compressive strength test with a curing period of 28 days, (Figure 12), it was verified that the 10% PET/PE (23.2 ± 2.2 MPa) formulation presented a result that is statistically similar to the reference sample 25.9 ± 1.9 MPa. In this period the constituents of Portland cement, 90% is composed of tricalcium silicate (C3S), dicalcium silicate (C2S), tricalcium aluminate (C3A) and tetra-calcium aluminon ferrite (C4AF), which chemically reacts with water [38], and the formation of these crystals is what might confer resistance to concrete, which in the case of the 10(PET/PE) formulation was not significantly affected. When the specific weight (Figure 13), of reference is compared to the 10(PET/PE) content, it is observed that this parameter decreases as the amount of polymers increases.

Figure 11.

Water absorption with a curing period of 28 days.

Figure 12.

Compressive strength of concrete samples with a curing period of 28 days.

Figure 13.

Specific weight of concrete samples with a curing period of 28 days.

When comparing the results of compression tests of concrete cylindrical samples with curing periods of 7 and 28 days, it was verified that there was an increase in resistance to compression (Figure 14). The reference formulation presented an increase in resistance to compression of 6.2%, while 10(PET/PE) concrete content reached 37.3%; within this perspective, with the passing of time, crystallization of oxides comprising the concrete were successful. Although preliminary results suggested that powdered PET/PE did not affect cement hydration, further analyses should be carried out to substantiate this claim. Additionally, the homogeneity of the cement paste might have contributed to the reduction in the presence of pores. Therefore, it was possible to consider that the formulation with 10% sand replacement presented potential for being used as alternative raw material in civil construction, in accordance with the principles of a circular economy.

Figure 14.

Comparative chart of resistance to compression of the reference samples and a 10PET/PE with curing periods of 7 and 28 days.

In general, reference concrete increases compressive strength with curing periods, while plastic concrete decreases it. Sadrmomtazi et al. [38] analyzed, at the ages of 7, 28, 60, and 90 days, reference concrete and concrete with a ratio of plastic, and in the two cases, the plastic increased the proprieties. In this study, an increase in resistance was also observed in both cases.

3.4. Characterization of Concrete Blocks

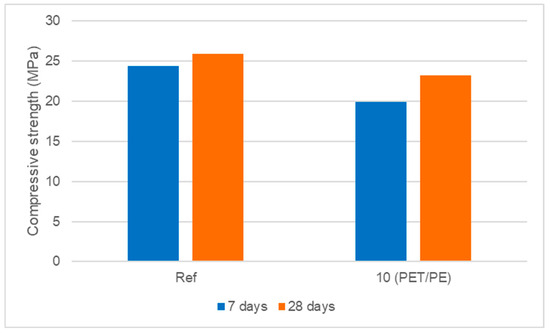

The reference concrete blocks and those with a 10(PET/PE) content were compared according to the visual and morphological aspects from the SEM analysis with a 2500× increase. It can be considered that the sample with 10% powdered PET/PE content presented homogeneity in the cement paste (Figure 15), with little difference when compared with the reference and, when analyzing the chemical elements identified in the reference EDS mapping, the presence of chemical elements calcium, oxygen, silicon, aluminum and iron was observed, while the EDS for 10(PET/PE) differentiated itself by the presence of carbon, an element that is characteristic of the composition of this polymer, which was also verified in the FTIR analysis to which the residue was submitted, which found the presence of functional carbonyl groups (C=O), aromatic rings (C=C), esters (C=O) and aliphatic C-H2. Thus, such presence of carbon, calcium and oxygen in 10(PET/PE) concrete confirms the presence of elements comprising the crystalline structures of concrete, which corresponds to the four main cement compounds that react with water to form C3S, C2S, C3A and C4AF, which confer concrete proprieties [39] and the satisfactory distribution of polymer residue, showing its potential for being used as a substitute for fine aggregates. The manufactured concrete blocks were submitted to tests of resistance to compression and water absorption, and the results obtained (Table 3) were compared to the NBR 6136 [26] rule and classified as not presenting or presenting structural function.

Figure 15.

Illustration of the results of the mapping analyses of EDS, SEM and EDS of the reference concrete samples and a 10(PET/PE) with a curing period of 28 days.

Table 3.

Analysis of the results of the tests of resistance to compression and water absorption for 28 days.

For tests of axial compressive strength, the reference concrete blocks (4.3 MPa) and 10(PET/PE) (3.9 MPa) presented similar results; the same behavior was observed in the performance verified with concrete cylindrical samples with curing of 7 and 28 days. It was expected that axial compressive strength presented a lesser result for the formulation with sand replacement, since the chemical composition is different when compared to PET/PE. For reference blocks presenting resistance to axial compression of 4.3 MPa (fbk ≥ 3.0) and normal aggregate water absorption of 1.4% (≤10.0%/average and ≤13.0%/individual), blocks were classified as class C: not presenting structural function. On the other hand, the 10(PET/PE) formulation presented resistance to axial compression of 3.9 (fbk ≥ 3.0) and normal aggregate water absorption of 2.5% (≤8.0%/average and ≤16.0%/individual), classified as class C: not presenting structural function.

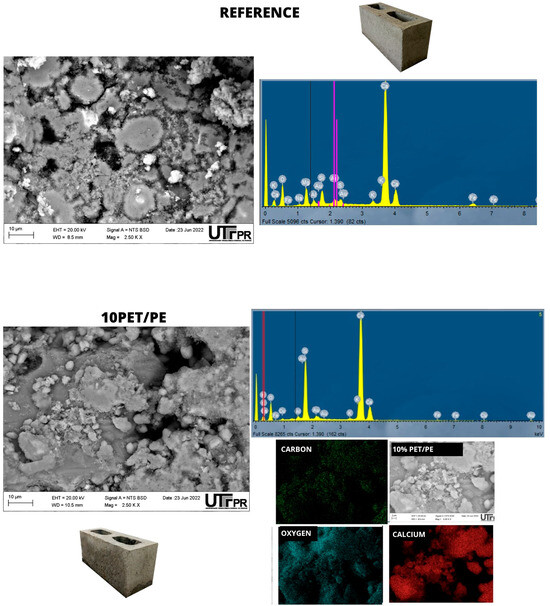

When the potential of application of this study was evaluated (Figure 16), it was found that in the production of 1.0 m3 of 10(PET/PE) concrete, 42.4 kg of residue is necessary, and, in order to manufacture 1000 concrete blocks weighing 12.0 kg each, the consumption of 229.0 kg of PET/PE would be necessary. Therefore, the alternative of reinserting industrial polymer residues in the civil construction sector presents itself with the potential to close the PET/PE productive chain, in accordance with the circular economy principles.

Figure 16.

Illustration of the amount of powdered PET/PE residues used in the concrete.

Within this perspective, it is important to emphasize the environmental impact generated in the extraction of sand for the production of natural fine aggregates. In spite of all the measures put on by public policies, aiming at controlling the impacts from sand mining, the activity is environmentally degrading and one of the greatest modifiers of land surface, affecting the ecosystem in general [40].

4. Conclusions

In evaluating the potential use of powdered PET/PE residues as a volumetric replacement for sand in concrete formulations, it was observed that, despite the polymer having a particle size 5 times smaller and a surface area 8 times greater than that of sand, it shows promising potential as an alternative raw material to natural fine aggregates. The analyses conducted after 7 and 28 days of curing showed that the concrete cylindrical samples with 10(PET/PE) presented satisfactory results in terms of resistance to compression when compared to the reference formulation. In addition, the presence of the polymer did not affect the homogeneity of the cement paste. The use of PET/PE also reduced the demand for natural aggregates, added value to polymer residues, and showed potential for application in Class C concrete blocks that do not present structural function. Therefore, the use of PET/PE as an alternative raw material in concrete can help reduce environmental impacts by decreasing the consumption of natural fine aggregates. It also promotes the reuse of powdered residues from multilayer films used in food packages, fostering collaboration between different sectors in the development of a more sustainable and responsible economic model.

Author Contributions

Investigation, A.P.K. and W.M.; data curation, A.P.K.; formal analysis, A.P.K., R.F. and W.M.; writing—original draft, A.P.K., R.F., R.M.B.R. and P.I.M.; writing—review and editing, A.P.K., R.F., R.M.B.R., P.I.M., W.M. and J.R.K.; conceptualization, A.P.K., W.M. and J.R.K.; visualization, R.F., R.M.B.R., P.I.M., W.M. and J.R.K.; project administration, J.R.K.; supervision, W.M. and J.R.K.; methodology, A.P.K.; funding acquisition, J.R.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no funding.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Acknowledgments

To the Federal University of Technology—Paraná (UTFPR) for institutional and financial support, to the Polymeric Materials Laboratory, Civil Construction Research Laboratory, Multiuser Center for Materials Characterization and the Multiuser Laboratory for Chemical Analysis of UTFPR—Curitiba. To The Institute of Macromolecules Professora Eloisa Mano (IMA-UFRJ), to the Multiuser Laboratory Complex of the State University of Ponta Grossa, to the Analytical Center of the Federal University of Ceará and to Evertis Packaging Solutions Company.

Conflicts of Interest

All authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- OCDE. Global Plastics Outlook Economic Drivers, Environmental; OCDE: Paris, France, 2022. [Google Scholar]

- Ryou, H.; Byun, J.; Bae, J.; Kim, D.; Han, J. Energy-efficient and environmentally friendly upcycling of waste plastic into fuels, chemicals, and polymer. Eng. J. 2025, 511, 162256. [Google Scholar] [CrossRef]

- OCDE. Scénarios d’Action Pour l’Elimination de la Pollution Plastique à L’horizon 2040; OCDE: Paris, France, 2024. [Google Scholar]

- Preston, F. A Global Redesign? Shaping the Circular Economy; Chatham House: London, UK, 2012. [Google Scholar]

- Saikia, N.; Brito, J. Mechanical properties and abrasion behaviour of concrete containing shredded PET bottle waste as a partial substitution of natural aggregate. Constr. Build. Mater. 2014, 52, 236–244. [Google Scholar] [CrossRef]

- Baruzdin, A.; Zakrevskaya, L. Prospects for the use of polymer waste as concrete aggregates. Tech. Technol. Silic. 2024, 31, 3. [Google Scholar] [CrossRef]

- Rathnam, P.M.; Ram, S. Imbibing Energy Efficiency in Buildings Through Sustainable Materials—A Review. In Advances in Sustainable Materials and Resilient Infrastructure; Springer: New York, NY, USA, 2022; pp. 399–414. [Google Scholar] [CrossRef]

- United Nations Development Programme. Plastics and Circular Economy: Community Solutions; UNDP: New York, NY, USA, 2019; Available online: https://www.undp.org/publications/plastics-and-circular-economy-community-solutions (accessed on 24 June 2025).

- Al-Sinan, M.; Bubshait, A.A. Using plastic sand as a construction material toward a circular economy: A review. Sustainability 2022, 14, 6446. [Google Scholar] [CrossRef]

- Babu, D.S.; Babu, K.G.; Huan, W.T. Effect of polystyrene aggregate size on strength and moisture migration characteristics of lightweight concrete. Cem. Concr. Compos. 2006, 28, 520–527. [Google Scholar] [CrossRef]

- Debska, B. 10—Modification of Polymer Composites by Polyethylene Terephthalate Waste. In Poly(Ethylene Terephthalate) Based Blends, Composites and Nanocomposites; Visakh, P.M., Liang, M., Eds.; William Andrew Publishing: Norwich, UK, 2015; pp. 195–212. ISBN 9780323313063. [Google Scholar] [CrossRef]

- Foti, D. Preliminary analysis of concrete reinforced with waste bottles PET fibers. Constr. Build. Mater. 2011, 25, 1906–1915. [Google Scholar] [CrossRef]

- Wattanavichien, P.; Iwanami, M. Investigation of the mechanical, microstructure, and durability properties of concrete with fine uniform and non-uniform polyethylene terephthalate (PET). Clean. Mater. 2024, 13, 100267. [Google Scholar] [CrossRef]

- Rahmani, E.E.; Dehestani, M.; Beygi, M.H.A.; Allahyari, H.; Nikbin, I.M. On the mechanical properties of concrete containing waste PET particles. Constr. Build. Mater. 2013, 47, 1302–1308. [Google Scholar] [CrossRef]

- Barreto, J.M.L.; da Costa, H.N.; Candido, L.F.; Correio, A.E.B.C. Análise das propriedades físicas e mecânicas de blocos de concreto prensados sem função estrutural com incorporação de PET reciclado. Rev. Matéria 2019, 24, e12357. [Google Scholar] [CrossRef]

- Kassa, R.B.; Kanali, C.; Ambassah, N. Environmental and Cost Advantages of Using Polyethylene Terephthalate Fibre Reinforced Concrete with Fly Ash as a Partial Cement Replacement. Open J. Civ. Eng. 2019, 9, 281–290. [Google Scholar] [CrossRef]

- Zehil, G.P.; Assaad, J.J. Feasibility of concrete mixtures containing cross-linked polyethylene waste materials. Constr. Build. Mater. 2019, 226, 1–10. [Google Scholar] [CrossRef]

- Halim, N.F.A.; Taib, N.; Aziz, Z.A. The performance of thermal property in concrete containing waste pet (polyethylene terephthalate) as an alternative sustainable building material. IOP Conf. Ser. Earth Environ. Sci. 2020, 452, 012108. [Google Scholar] [CrossRef]

- Ashok, M.; Jayabalan, P.; Saraswathy, V.; Muralidharan, S. A study on mechanical properties of concrete including activated recycled plastic waste. Adv. Concr. Constr. 2020, 9, 207–215. [Google Scholar] [CrossRef]

- Xiong, B.; Falliano, D.; Restuccia, L.; Di Trapani, F.; Demartino, C.; Marano, G.C. High-strain rate compressive behavior of concrete with two different substituted recycled plastic aggregates: Experimental characterization and probabilistic modeling. Constr. Build. Mater. 2023, 368, 130279. [Google Scholar] [CrossRef]

- ISO 13320; Particle Size Analysis—Laser Diffraction Methods. International Organization for Standardization: Geneva, Switzerland, 2009.

- NBR 12821; Preparation of Concrete in the Laboratory—Procedure. Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2009.

- NBR 5738; Procedure for Molding and Curing Specimens. Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2008.

- NBR 12118; Plain Concrete Hollow Blocks for Masonry—Test Methods. Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2013.

- NBR 5739; Concrete—Compression Test of Cylindrical Specimens. Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2018.

- NBR 6136; Plain Concrete Hollow Blocks for Masonry—Requirements. Brazilian Association of Technical Standards (ABNT): Rio de Janeiro, Brazil, 2014.

- Barbosa, L.C.A. Espectroscopia no Infravermelho: Na Caracterização de Compostos Orgânicos; UFV: Viçosa, MG, Brazil, 2007. [Google Scholar]

- Chen, Z.; Hay, J.N.; Jenkins, M.J. FTIR spectroscopic analysis of poly (ethylene terephthalate) on crystallization. Eur. Polym. J. 2012, 48, 1586–1610. [Google Scholar] [CrossRef]

- Singh, R.K.; Ruj, B.; Sadhukhan, A.K.; Gupta, P. Thermal degradation of waste plastics under non-sweeping atmosphere: Part 1: Effect of temperature, product optimization, and degradation mechanism. J. Environ. Manag. 2019, 239, 395–406. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, Y.; Song, H.; Wang, Y.; Deng, T.; Hou, X. Zinc-catalyzed ester bond cleavage: Chemical degradation of polyethylene terephthalate. J. Clean. Prod. 2019, 208, 1469–1475. [Google Scholar] [CrossRef]

- Grause, G.; Handa, T.; Kameda, T.; Mizoguchi, T.; Yoshioka, T. Effect of temperature management on the hydrolytic degradation of PET in a calcium oxide filled tube reactor. Chem. Eng. J. 2011, 166, 523–528. [Google Scholar] [CrossRef]

- Xue, Y.; Johnston, P.; Bai, X. Effect of catalyst contact mode and gas atmosphere during catalytic pyrolysis of waste plastics. Energy Convers. Manag. 2017, 142, 441–451. [Google Scholar] [CrossRef]

- Turner, A. In situ elemental characterisation of marine microplastics by portable XRF. Mar. Pollut. Bull. 2017, 124, 286–291. [Google Scholar] [CrossRef]

- Abbasi, S.; Keshavarzi, B.; Moore, F.; Delshab, H.; Soltani, N.; Sorooshian, A. Investigation of microrubbers, microplastics and heavy metals in street dust: A study in Bushehr city, Iran. Environ. Earth Sci. 2017, 76, 798. [Google Scholar] [CrossRef]

- Awaja, F.; Pavel, D. Recycling of PET. Eur. Polym. J. 2005, 41, 1453–1477. [Google Scholar] [CrossRef]

- Sharma, R.; Bansal, P.P. Use of different forms of waste plastic in concrete—A review. J. Clean. Prod. 2016, 112, 473–482. [Google Scholar] [CrossRef]

- Mendonça, A.M.G.D.; Souza, L.M.C.; Lira, Y.C.; Neto, V.F.S.; Luz, T.E.B.; Nunes, C.G.L.; Pereira, P.H.S.; Diniz, M.I.L. Physical and mechanical characterization of concrete incorporated with Polymer. Braz. J. Dev. 2021, 7, 26860–26876. [Google Scholar] [CrossRef]

- Sadrmomtazi, A.; Dolati-Milehsara, S.; Lotfi-Omran, O.; Sadeghi-Nik, A. The combined effects of waste Polyethylene Terephthalate (PET) particles and pozzolanic materials on the properties of self-compacting concrete. J. Clean. Prod. 2016, 112, 2363–2373. [Google Scholar] [CrossRef]

- Sousa, V.C.M. Pathology, Recovery and Reinforcement of Concrete Structures; PINI: São Paulo, Brasil, 2018. [Google Scholar]

- Marcondes, E.F.; Batista, G.T.; Targa, M.S.; Soares, P.V. The Future Use of Sand Mining Areas in the Subsection Between Jacareí and Pindamonhangaba, SP and Its Insertion in the Local and Regional Dynamics. Annals of the Seminar on Water Resources in the Paraíba do Sul Hydrographic Basin: Eucalyptus and the Hydrological Cycle, Taubaté-SP, 1:139-146. 2007. Available online: https://ipabhi.org/serhidro/doc/@indice.htm (accessed on 24 June 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).