Production Reliability Technology Based on Vacuum Infusion Process Convergence to Design Strengthen Boat Safety

Abstract

1. Introduction

2. Vacuum Infusion Method and Hull Design

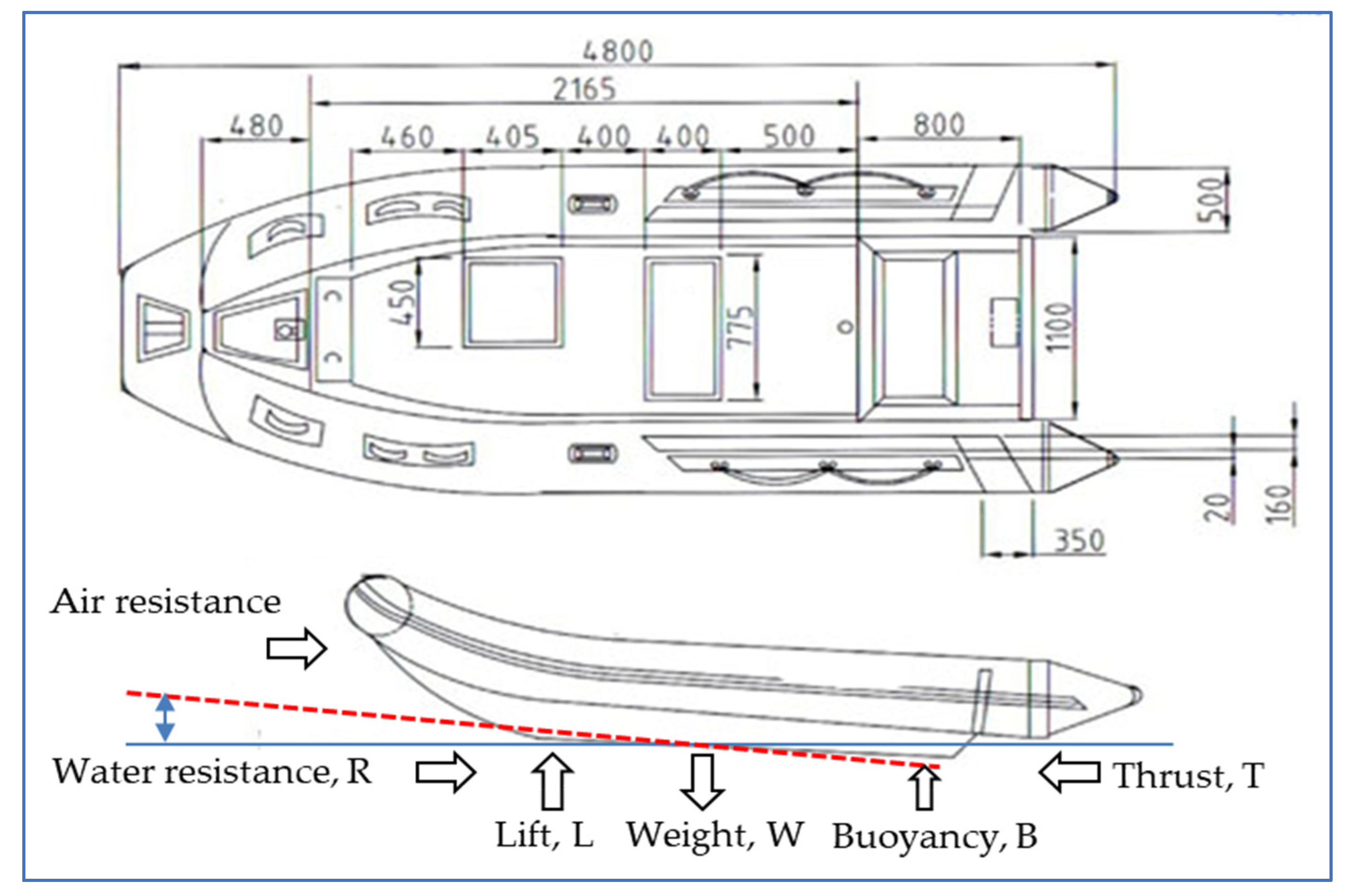

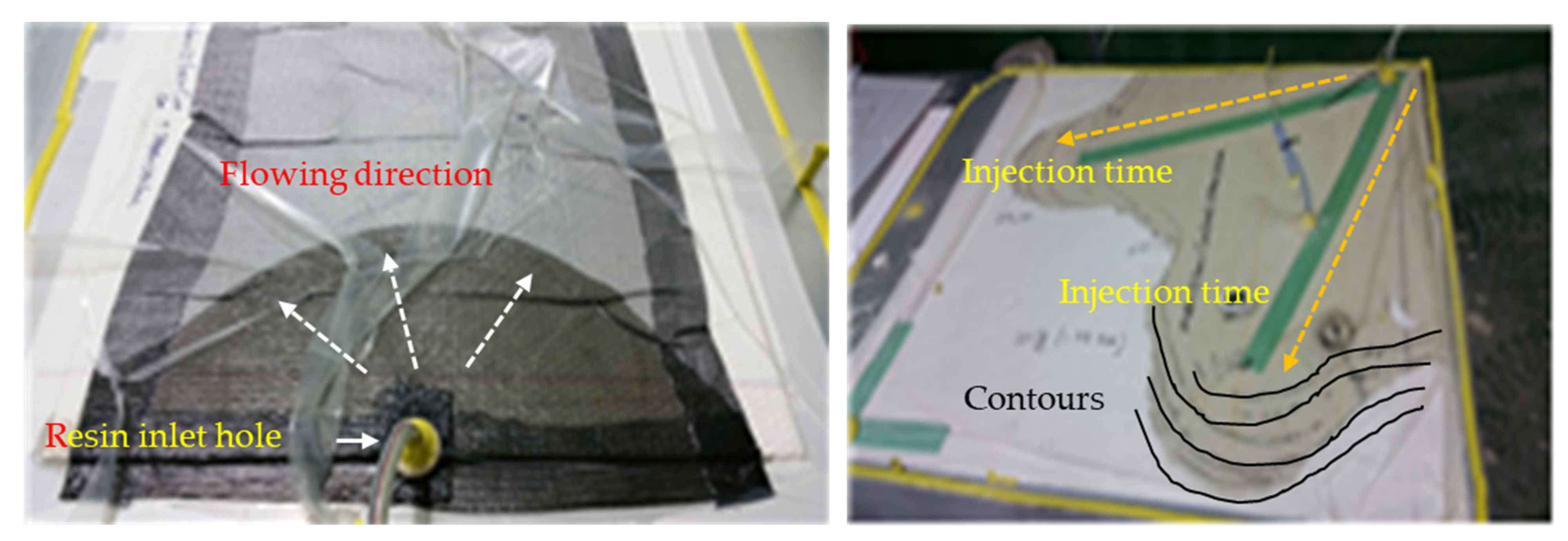

2.1. Analysis of 3D Liquidity of Boats

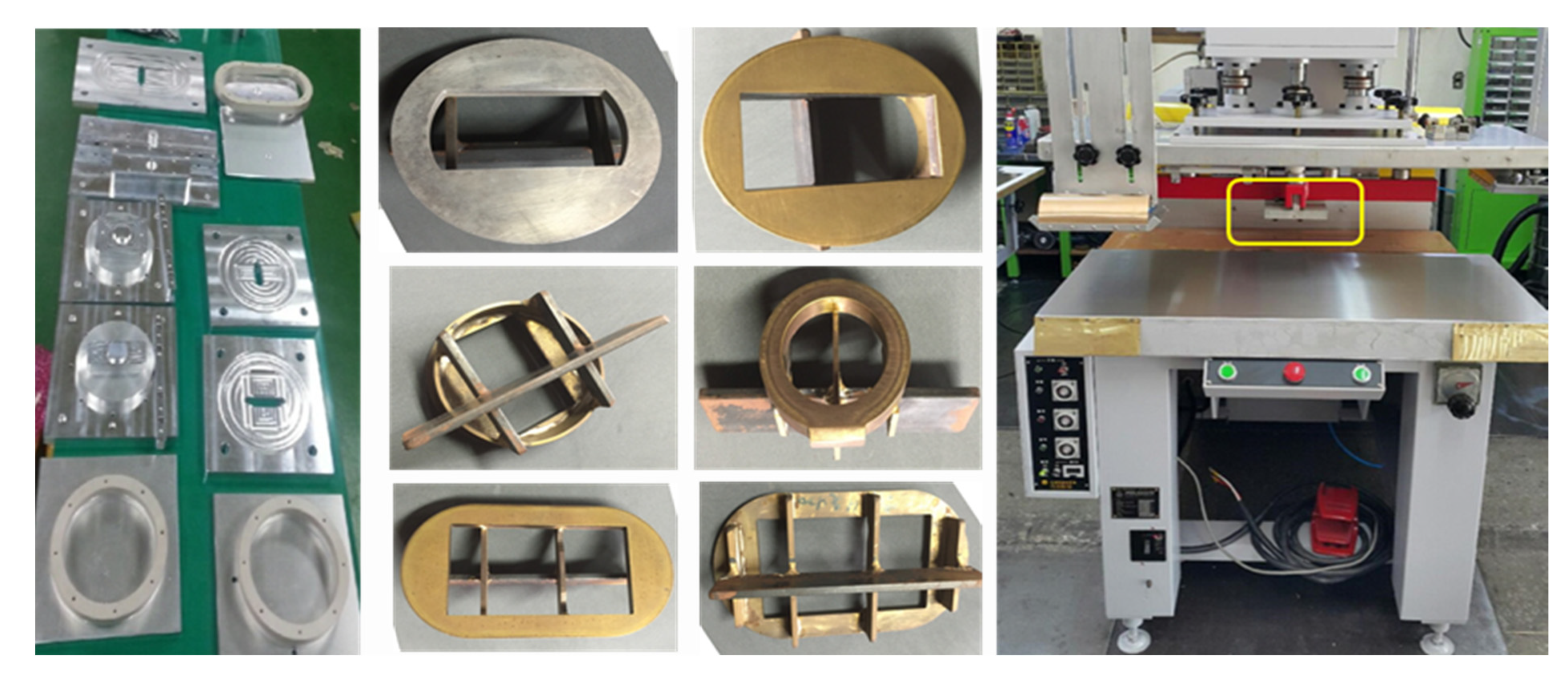

2.2. Air Boat Mold Design and Implementation

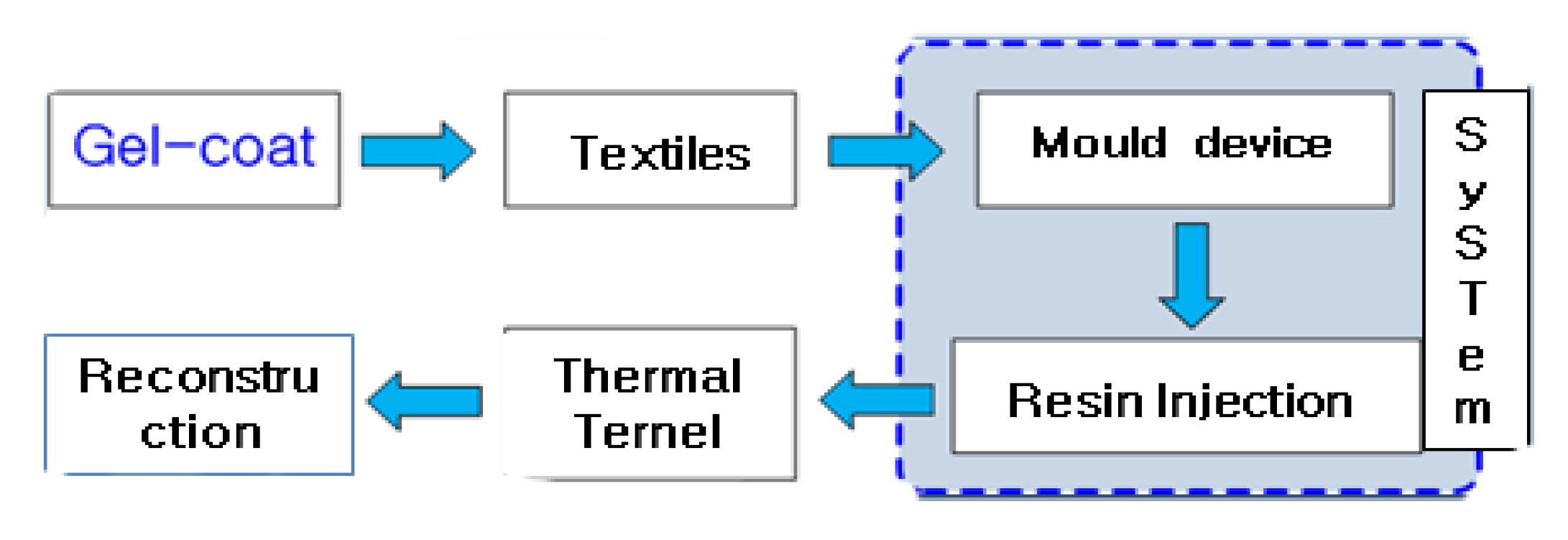

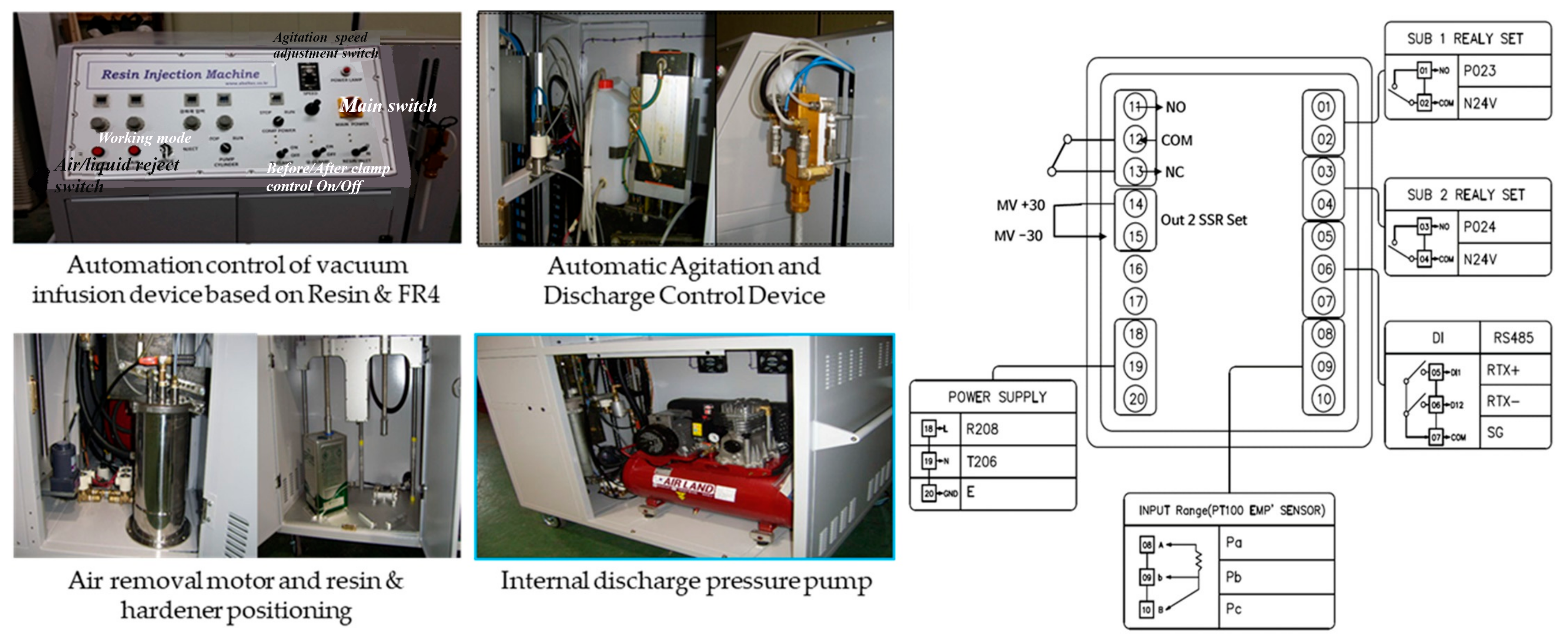

2.3. Vacuum Infusion Process Convergence Automation System

3. Manufacturing Convergence of Air Instrument and Boat Floor Molding

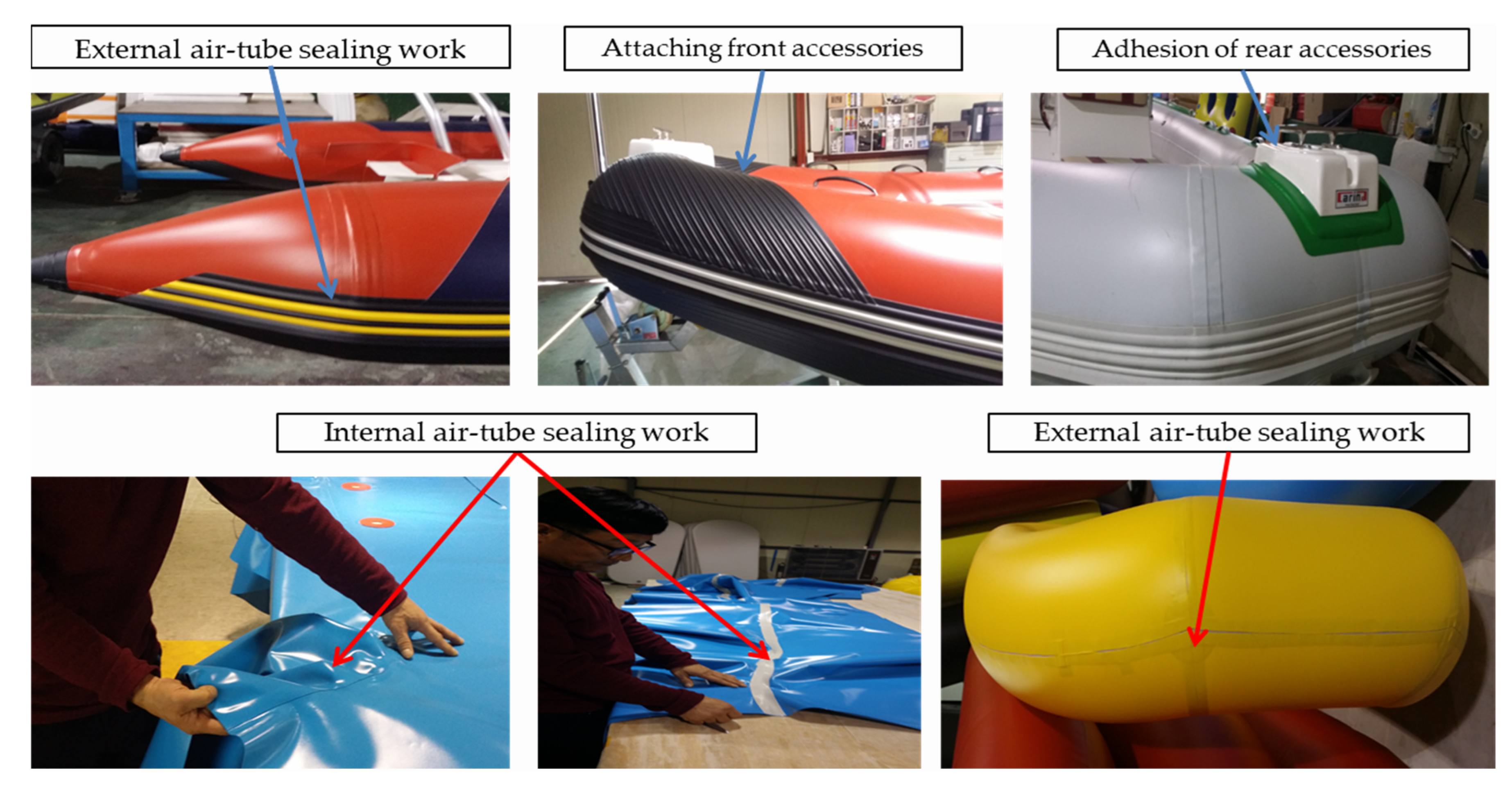

3.1. Air Instrument Implementation Technology

3.2. Manufacturing Convergence of Boat Floor Molding

4. Experimental Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Puls, J.; Fassbender, F.R. Method and Device for Detecting the Risk of a Person Drowning in Water. Patent Application No. WO2008055593A1, 15 May 2008. [Google Scholar]

- Oh, D.K.; Lee, K.W.; Lee, C.W. Basic Design of 40ft Class Pleasure Boat based on Digital Mock-up. J. Korean Soc. Mar. Environ. 2011, 17, 283–289. [Google Scholar] [CrossRef]

- Korean Society for Research and Research. A Study on the Status of Leisure Sports Industry. J. Korean Soc. Res. Res. 2023, 24, 33–79. [Google Scholar] [CrossRef]

- Available online: https://www.sports.re.kr/front/board/bs/boardList.do?board_seq=72&menu_seq=862 (accessed on 25 January 2025).

- Lee, S.W.; Kim, S.G.; Lee, J.H.; Hong, J.W.; Lee, Y.J.; Schwarzbach, H. A Study on Marine Tourism Policies to Upgrade the Marine and Pleasure Boat Industry of Korea; Korea Maritime Fisheries Development Institute: Busan, Republic of Korea, 2008. [Google Scholar]

- Shen, R.; Liu, T.; Liu, H.; Zou, X.; Gong, Y.; Guo, H. An Enhanced Vacuum-Assisted Resin Transfer Molding Process and Its Pressure Effect on Resin Infusion Behavior and Composite Material Performance. Polymers 2024, 16, 1386. [Google Scholar] [CrossRef]

- Yoon, D.H.; Kim, S.H.; Min, H.G. Development of Boat Aerostat for the Safety Strengthen based on the Manufacture Convergence. Korean J. Saf. Cult. 2020, 9, 25–32. [Google Scholar]

- Lee, D.K.; Jeong, Y.K.; Shin, J.G. Development of a Factory Layout Design System using Leisure-Boat Building Process. J. Soc. Nav. Archit. Korea 2013, 50, 14–24. [Google Scholar] [CrossRef]

- Choi, S.S. A Study on Hull Form Development of Polyethylene Boat. J. Korea Acad.-Ind. Coop. Soc. 2013, 14, 4726–4732. [Google Scholar]

- Khalaquzzaman, M.; Lee, S.J.; Hossen, M.M. Reliability Assessment of NPP Safety Class Equipment Considering the Manufacturing Quality Assurance Process. J. Nucl. Eng. 2023, 4, 421–435. [Google Scholar] [CrossRef]

- Jeong, U.C.; Kwon, S.Y.; Choi, J.H.; Kim, D.J.; Hong, K.S. Study of Hull Form Development and Resistance Performance of Catamaran-type High Speed Fishing Leisure Boat. J. Ocean Eng. Technol. 2013, 27, 1–6. [Google Scholar] [CrossRef]

- Kang, N.S.; Yoon, H.K. A Study for the Conceptual Design of a Small Leisure Boat Handling Simulator. J. Korea Soc. Simul. 2013, 22, 99–107. [Google Scholar] [CrossRef]

- Jaskowska, K.; Daily, J.; Budi, M.; Jordan, A.; Habicht, S. Port Security and Emergency Response Using Autonomous Systems: Virginia Pilot Program; CNA: Arlington, VA, USA, 2024. [Google Scholar]

- Yoon, J.H.; Yoon, D.H. Implementation of a GAS Injection Type Prefabricated Lifting Device for Underwater Rescue Based on Location Tracking. Adv. Sci. Technol. Eng. Syst. J. 2023, 8, 78–86. [Google Scholar] [CrossRef]

- Oh, G.H.; Yoo, J.H. Numerical Prediction of Running Attitude and Resistance of Planing Craft. J. Soc. Nav. Archit. Korea 2013, 50, 95–103. [Google Scholar] [CrossRef]

- Lin, J. Resin Molding Apparatus, Resin Molding Method and Resin Container. Patent No. KR101059936B1, 26 August 2011. [Google Scholar]

- Gokai, U. Laminate Modeling Device and Method. Patent Application No. PCT/JP2010/058649, 2 December 2010. [Google Scholar]

- Available online: https://www.sciencedirect.com/topics/materials-science/vacuum-infusion (accessed on 25 January 2025).

- Yoon, D.H.; Zhao, X.; Lee, C.H. Vacuum Infusion System for Manufacture Process Convergence and Automation of Boat. J. IKEEE 2018, 22, 274–280. [Google Scholar]

- An, S.; Kim, J.-S.; Roh, H.D.; Kim, W.-D.; Lee, J.; Um, M.-K. Effect of Peel Ply on Resin Flow during Vacuum Infusion. Materials 2023, 16, 4421. [Google Scholar] [CrossRef]

- Osipov, E.V.; Bugembe, D.; Ponikarov, S.I.; Ponikarov, A.S. Comprehensive Modeling of Vacuum Systems Using Process Simulation Software. ChemEngineering 2024, 8, 31. [Google Scholar] [CrossRef]

- Available online: https://alliedfibreglass.co.za/advantages-and-disadvantages-of-vacuum-infusion (accessed on 25 January 2025).

- Grisin, B.; Carosella, S.; Middendorf, P. Vacuum Chamber Infusion for Fiber-Reinforced Composites. Polymers 2024, 16, 2763. [Google Scholar] [CrossRef]

- Atake, H. Process and Apparatus for Effecting Injection-Molded in Foil Decoration. Patent No. KR100350582B1, 28 August 2002. [Google Scholar]

- Schagatay, E.; Aman, P.A. Repeated freediving—An efficient and safe method to rescue subjects trapped in cars underwater. Saf. Sci. 2019, 118, 752–756. [Google Scholar] [CrossRef]

- Yoon, D.-H.; Lee, J.-H. Boat Aerostat Production Apparatus and Method for Safety Strengthen Based on Manufacture Convergence. Patent No. 1020200137878, 22 October 2020. [Google Scholar]

- Bonfitto, A.; Amati, N. Mechanical Construction and Propulsion Analysis of a Rescue Underwater Robot in the case of Drowning Persons. Appl. Sci. 2018, 8, 693. [Google Scholar] [CrossRef]

- Korean Society for Research and Research Science and Technology. System Assessment and Validation for Emergency Responders (SAVER); U.S. Department of Homeland Security: Washington, DC, USA, 2021.

| Process Name | Unit Work | Major Facilities | Time/Day | Unit Weight | |

|---|---|---|---|---|---|

| 1 | Tailoring work | Drawing a fabric pattern | Hand cutting machine | More than 4 h | 20 Kg |

| Bottom drawing foundation | - | ||||

| 2 | Making and working with accessories | Making Accessory Membrane | Manual operation | More than 4 h | 3 Kg |

| Fabric adhesion | 3 Kg | ||||

| 3 | Width joint | Fabric piecxe adhesion | Manual operation | More than 4 h | 3 Kg |

| 4 | Addition width | Fabric cylindrical bonding | Drier, sharp knife, Scissors | More than 4 h | 5 Kg |

| Press to trim the adhesive area | - | ||||

| 5 | Make-up tape | Make-up tape gluing | Manual operation | More than 4 h | 5 Kg |

| Trim the adhesive area | - | ||||

| 6 | Bottom adhesion | Boat post adhesion | Cutter, Knife | More than 4 h | 5 Kg |

| Boat bottom adhesion | - | ||||

| 7 | Accesory adhesion | Rubbing and Bottom adhesion | Manual operation | More than 4 h | 5 Kg |

| Adhesion of accessories | - | ||||

| 8 | Packaging | Boat-folding box | Bending, Packaging, Boxing | More than 4 h | 25 Kg |

| Place movement after bending | 25 Kg | ||||

| Sortation | Exposure Time/Day | Body Parts | Working Posture Content | Weight/Exposue Frequency |

|---|---|---|---|---|

| Work 1 | More than 4 h | Hand, wrist, arm, shoulder | Data input | Frequency |

| Work 2 | More than 2 h | Wrist, elbow, shoulder | Repeat the same action | |

| Work 3 | More than 2 h | Arm, shoulder | Task in which the elbow is heard by the body | |

| Work 4 | More than 2 h | Neck, waist | Bending or twisting without changing posture | |

| Work 5 | More than 2 h | Knee, waist | Squatting knees | |

| Work 6 | More than 2 h | Finger | Finger-grabbing work | Carrying more than 1 kg Catch more than 2 kg |

| Work 7 | More than 2 h | Hand | Act of lifting or catching an object | Lift and hold objects greater than 4.5 kg |

| Work 8 | More than 2 h | Waist | Work of carrying things | 25 Kg/day at least 10 times |

| No. | Analysis Contents | Improvments |

|---|---|---|

| 1 | Prediction of boat position through 2D flow analysis | Prediction of boat posture by performing optimized flow analysis through 3D design |

| 2 | Rely on the operator’s skill by hand during the production of Air-Tube | Standardized automation process from experiential fabrication in tube fabrication |

| 3 | Boat performance based on the angle of the mold and operator’s experience in designing the mold | Secure the safety and reliability of the boat through the development of the proposed construction method |

| 4 | Production yield problems and boat performance depend on manual work and affect safety and reliability when making molds | Contribute to improved production yield, improved boat performance and stability through the development of convergence processes and automation of production lines |

| 5 | Insufficient production quality control | PC-based database and monitoring with daily, weekly, and monthly resource management |

| Sortation | Sample 1 | Sample 2 | Sample 3 | Sample 4 | Sample 5 | Average | |

|---|---|---|---|---|---|---|---|

| Manual Process 01 | Thickness (mm) | 11 | 9.2 | 9.5 | 10 | 11 | 10.1 |

| Weight (g) | 11.5 | 12 | 9.6 | 11 | 10 | 10.7 | |

| Manual Process 02 | Thickness (mm) | 10.8 | 12 | 9.2 | 10 | 10.5 | 10.5 |

| Weight (g) | 10.9 | 12.1 | 9.6 | 10.2 | 10.6 | 10.6 | |

| Vacuum infusion 01 | Thickness (mm) | 6 | 6.2 | 6 | 6 | 6.3 | 6.1 |

| Weight (g) | 5.8 | 6 | 6 | 5.8 | 6.1 | 5.9 | |

| Vacuum infusion 02 | Thickness (mm) | 6 | 5.6 | 5.8 | 6 | 5.9 | 5.6 |

| Weight (g) | 5.9 | 5.6 | 5.7 | 6 | 5.9 | 5.8 | |

| Sortation | Sample 1 | Sample 2 | Sample 3 | Sample 4 | Sample 5 | Average | |

|---|---|---|---|---|---|---|---|

| Manual | Thickness (mm) | 6.7 | 6.8 | 6.6 | 6.7 | 6.7 | 6.7 |

| Strengthen power | Ave. 18.46 (181 MPa) | ||||||

| Depression power | Ave. 20.40 (200 MPa) | ||||||

| Vacuum infusion | Thickness (mm) | 2.4 | 2.2 | 2.3 | 2.3 | 2.3 | 2.3 |

| Strengthen power | Ave. 27.44 (269 MPa) | ||||||

| Depression power | Temp. value (Thickness 6.7 mm)—Ave. 32.68 Real value (Thickness 2.3 mm)—Ave. 11.22 | ||||||

| No | Stacking Method | Resin | Tempered Glass Fiber | Number of Stacks and Order | Thickness (mm) | Weight (cm/g) | Flow Rate | Operation Mash |

|---|---|---|---|---|---|---|---|---|

| 01 | Manual | G-713BT | M450, ROVING570 | M. M. Rx2 (six sheets) | 4.9 | 5.7 | - | - |

| 02 | FH-123NHL | 4.9 | 5.9 | - | - | |||

| 03 | UV-R1 | 4.9 | 5.6 | - | - | |||

| 04 | Infusion-01 | G-713BT | 2.63 | 2.5 | 0.43 | Part Distribution | ||

| 05 | FH-123NHL | 2.61 | 2.3 | 0.42 | ||||

| 06 | UV-R1 | 2.6 | 2.1 | 0.46 | ||||

| 07 | Infusion-02 | G-713BT | M450, L T600, DB400, COER, DBL600 | M, LT, DB, CO, DBL (five sheets) | 6.1 | 5.94 | 0.27 | |

| 08 | FH-123NHL | 6.0 | 5.96 | 0.3 | ||||

| 09 | UV-R1 | 5.8 | 5.65 | 0.31 | ||||

| 10 | G-713BT | 6.1 | 6 | 0.7 | Entire Distribution | |||

| 11 | FH-123NHL | 6.15 | 5.9 | 0.75 | ||||

| 12 | UV-R1 | 6 | 5.8 | 0.78 |

| No | Terms | Manual | Vacuum | Note |

|---|---|---|---|---|

| 1 | Resin weight | 160 kg | 80 kg | 50% (⤓) |

| 2 | Glass fiber | 80 kg | 60 kg | 25% (⤓) |

| 3 | Ship weight | 240 kg | 140 kg | 42% (⤓) |

| 4 | Manufacture | 10 | 8 | 20% (⤓) |

| 5 | Intensity | 181 MPa | 269 MPa | 49% (⤒) |

| 6 | Pressure strength | 200 MPa | 320 MPa | 60% (⤒) |

| 7 | Ship edge effectiveness | Minimize the friction area between ship and water for the sharpened ship edge part | ||

| 8 | Ship out part | no bending the line and surface | ||

| 9 | Speed up | About 15% | ||

| 10 | Fuel efficiency | 10% | ||

| 11 | Safety | Safety sense for 7 estimated terms | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, J.-H.; Park, H.-M.; Yoon, D.-H. Production Reliability Technology Based on Vacuum Infusion Process Convergence to Design Strengthen Boat Safety. Processes 2025, 13, 2025. https://doi.org/10.3390/pr13072025

Yoon J-H, Park H-M, Yoon D-H. Production Reliability Technology Based on Vacuum Infusion Process Convergence to Design Strengthen Boat Safety. Processes. 2025; 13(7):2025. https://doi.org/10.3390/pr13072025

Chicago/Turabian StyleYoon, Jong-Hwa, Hoon-Min Park, and Dal-Hwan Yoon. 2025. "Production Reliability Technology Based on Vacuum Infusion Process Convergence to Design Strengthen Boat Safety" Processes 13, no. 7: 2025. https://doi.org/10.3390/pr13072025

APA StyleYoon, J.-H., Park, H.-M., & Yoon, D.-H. (2025). Production Reliability Technology Based on Vacuum Infusion Process Convergence to Design Strengthen Boat Safety. Processes, 13(7), 2025. https://doi.org/10.3390/pr13072025