Research on Cuttings Transport Behavior in the 32-Inch Borehole of a 10,000-Meter-Deep Well

Abstract

1. Introduction

2. Materials and Methods

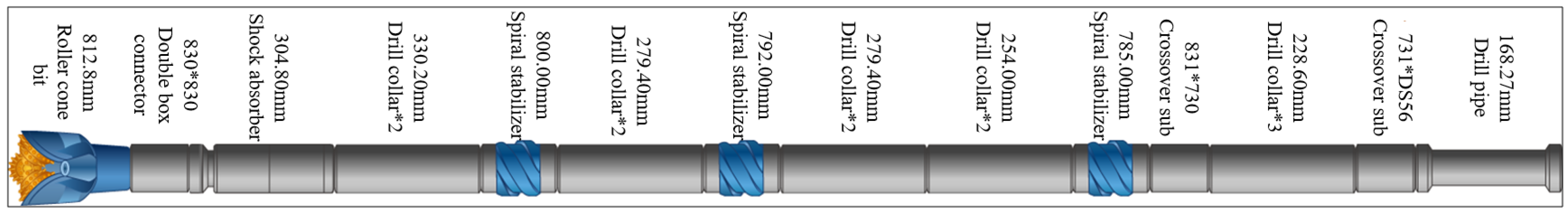

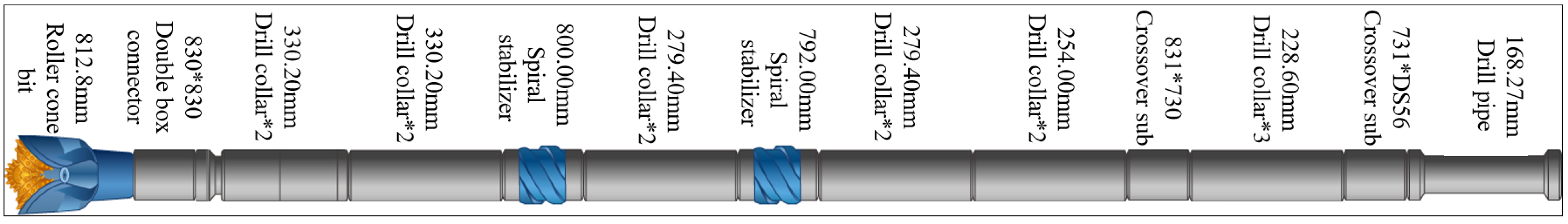

2.1. Description and Basic Parameters of Wellbore Cleaning in the 32-Inch Borehole

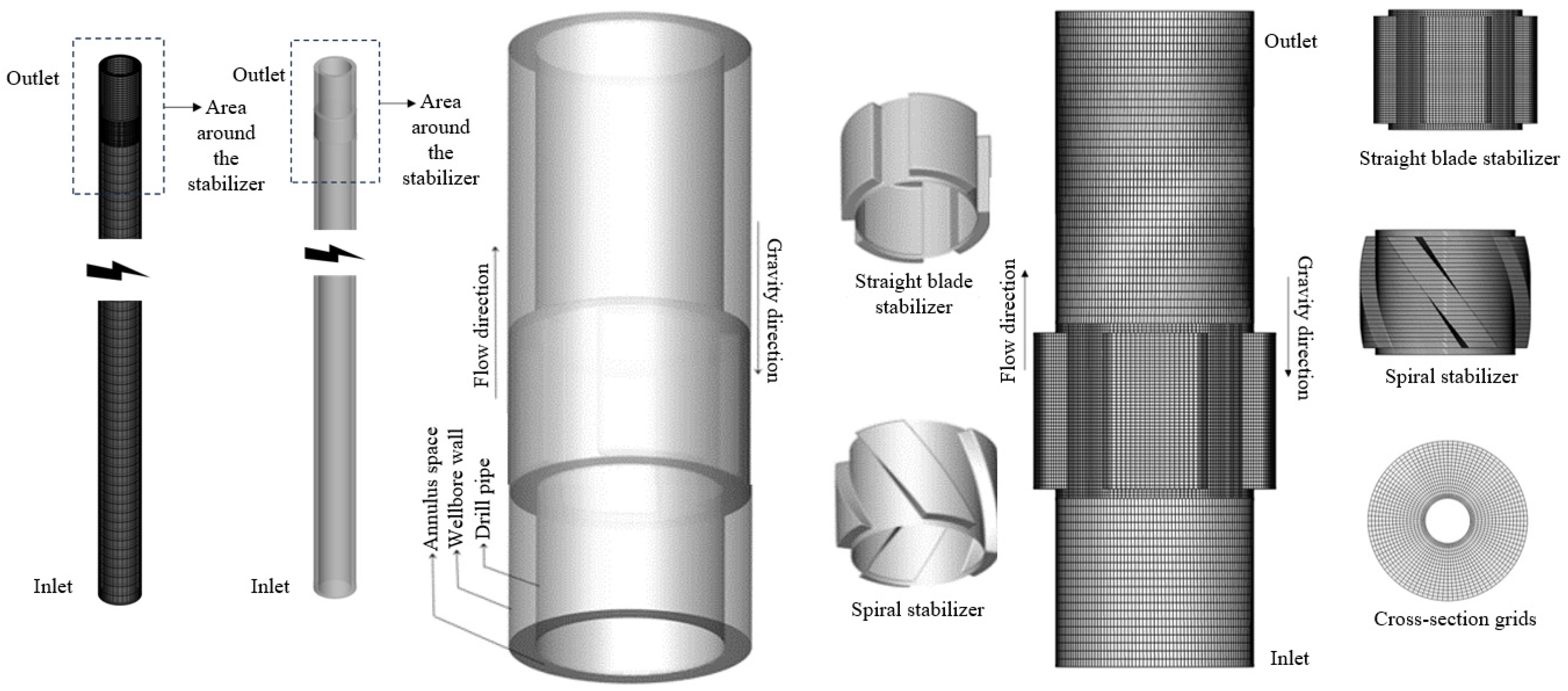

2.2. Geometric Model, Boundary Conditions, and Mesh Generation

2.3. Governing Equations

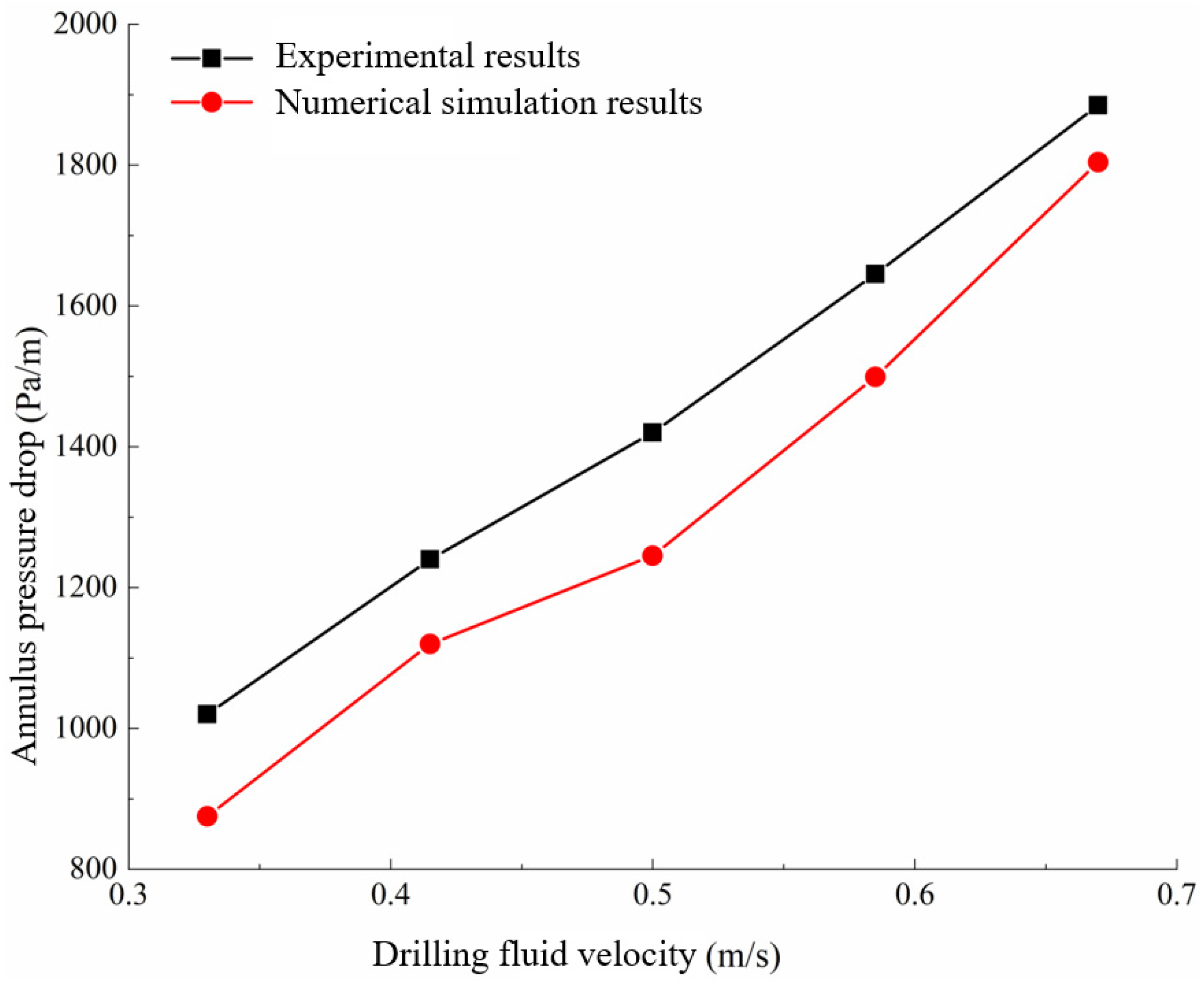

2.4. Model Validation

3. Results and Discussion

3.1. Actual Annular Return Velocity and Critical Rock Carrying Return Velocity

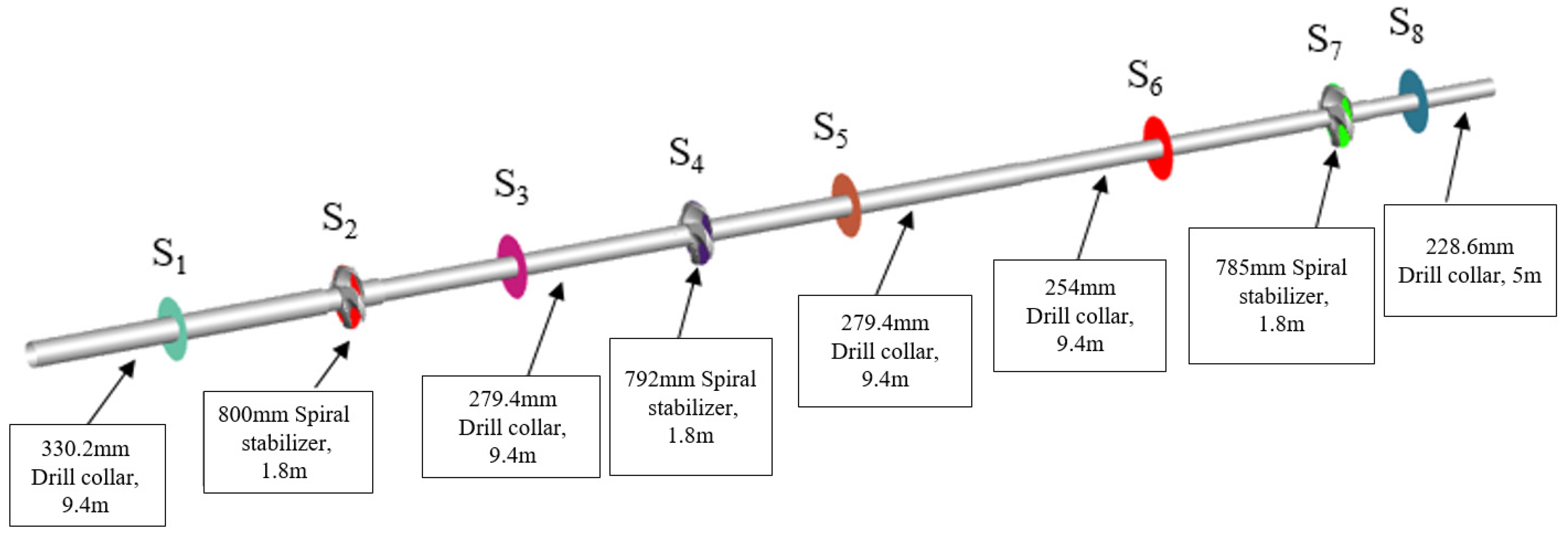

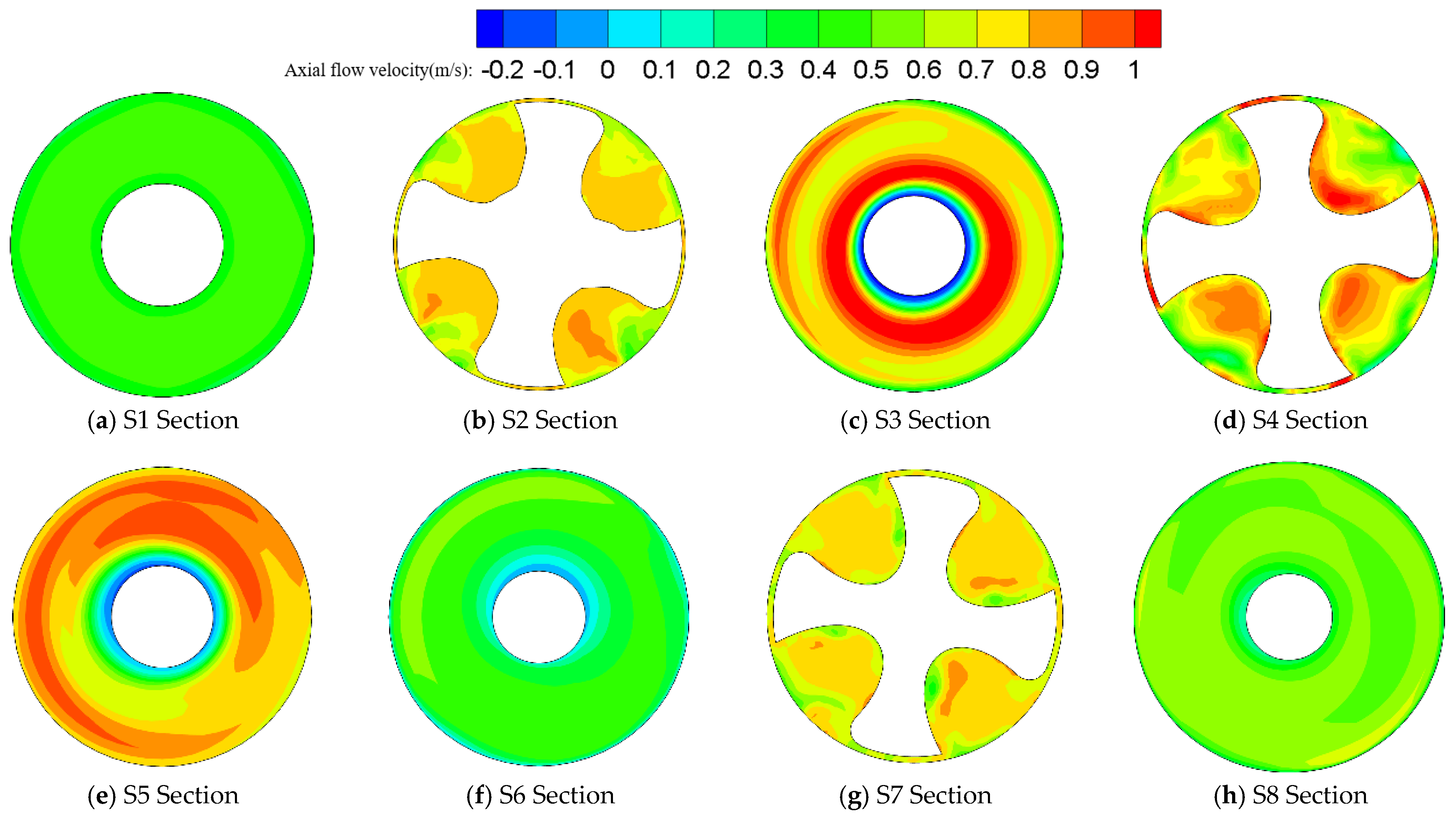

3.2. Cuttings Transport Characteristics near the Wellbore Bottom with a Three-Stabilizer BHA Configuration

3.3. Cuttings Transport Characteristics near the Wellbore Bottom with a Two-Stabilizer BHA Configuration

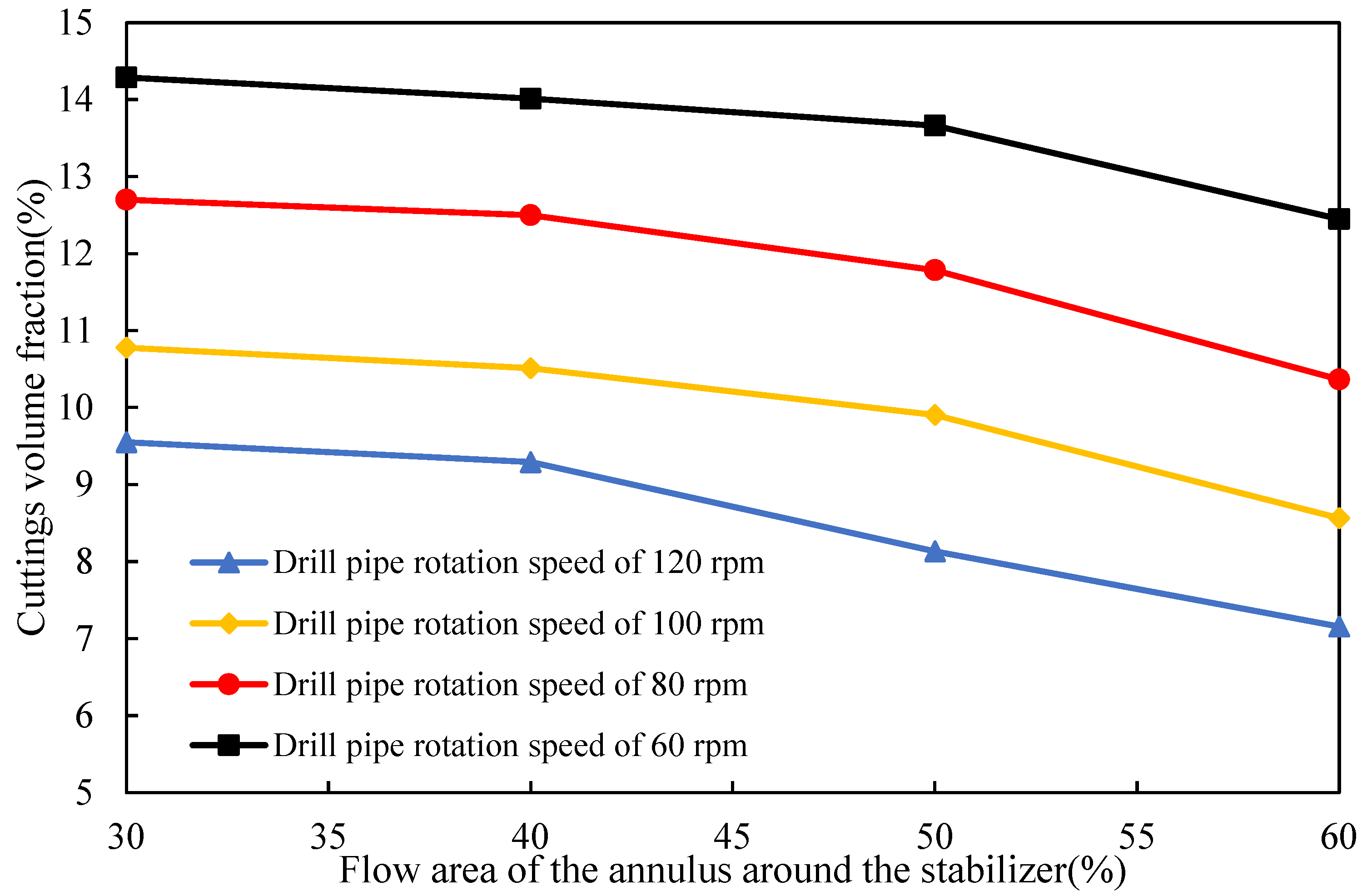

3.4. Impact of Stabilizers with Different Flow Areas

4. Conclusions

- (1)

- A 32″ large-diameter borehole was used in the upper section of a 10,000-meter-deep well. During the drilling processes, severe hole-cleaning challenges emerged, significantly increasing the risks of pipe stuck and circulation lost. A numerical simulation method for cuttings transport in ultra-large boreholes was developed based on the Eulerian two-fluid model. This method effectively reproduces the cuttings transport process in a 32″ borehole of a 10,000-meter-deep well.

- (2)

- One of the primary reasons for inefficient cuttings transport in the 32″ borehole annulus is that the actual annular return velocity is lower than the critical velocity required for cuttings transport. The large-diameter stabilizers in the 32″ borehole annulus significantly alter the drilling fluid flow field, inducing fluid recirculation and causing cuttings accumulation near the wellbore bottom. This recirculation effect is more pronounced in the dual-stabilizer BHA configuration compared to the triple-stabilizer configuration.

- (3)

- To improve the cuttings transport efficiency in the 32″ wellbore, measures should be implemented simultaneously in three aspects: enhancing drilling parameters, optimizing drilling fluid properties, and refining the structure of helical stabilizers. At the same time, increasing the top drive speed can improve cuttings transport efficiency. The helical stabilizer alters the drilling fluid flow field, which is a major cause of cuttings accumulation near the wellbore bottom.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, H.-L.; Xiang, S.-L.; Pei, D.-D.; Wu, X.-D.; Zhang, Z. Transient Collapse Failure Prediction of Production Casing After Packer Unsetting in High-Pressure and High-Temperature Deep Oil Wells. Processes 2025, 13, 839. [Google Scholar] [CrossRef]

- Shen, W.; Ma, T.; Li, X.; Sun, B.; Hu, Y.; Xu, J. Fully coupled modeling of two-phase fluid flow and geomechanics in ultra-deep natural gas reservoirs. Phys. Fluids 2022, 34, 043101. [Google Scholar] [CrossRef]

- Xie, R.; Zhang, L. A New Prediction Model of Annular Pressure Buildup for Offshore Wells. Appl. Sci. 2024, 14, 9768. [Google Scholar] [CrossRef]

- Wang, C.; Cai, B.; Shao, X.; Zhao, L.; Sui, Z.; Liu, K.; Khan, J.A.; Gao, L. Dynamic risk assessment methodology of operation process for deepwater oil and gas equipment. Reliab. Eng. Syst. Saf. 2023, 239, 109538. [Google Scholar] [CrossRef]

- Chen, Y.; Li, W.; Wang, X.; Wang, Y.; Fu, L.; Wu, P.; Wang, Z. Research and Application of Geomechanics Using 3D Model of Deep Shale Gas in Luzhou Block, Sichuan Basin, Southwest China. Geosciences 2025, 15, 65. [Google Scholar] [CrossRef]

- Sheng, J.J. Critical review of field EOR projects in shale and tight reservoirs. J. Petrol. Sci. Eng. 2017, 159, 654–665. [Google Scholar] [CrossRef]

- Jiao, S.; Li, W.; Li, Z.; Gai, J.; Zou, L.; Su, Y. Hybrid physics-machine learning models for predicting rate of penetration in the Halahatang oil field, Tarim Basin. Sci. Rep. 2024, 14, 5957. [Google Scholar] [CrossRef]

- Jing, Y.; Wang, T.; Zhang, B.; Zheng, Y.; Li, X.; Lu, N. Safety Risk Analysis of Well Control for wellbore with sustained annular pressure and Prospects for Technological Development. Chem. Tech. Fuels Oil 2025, 61, 1676–1685. [Google Scholar] [CrossRef]

- Zhang, D. Development prospect of natural gas industry in the Sichuan Basin in the next decade. Nat. Gas. Ind. B 2022, 9, 119–131. [Google Scholar] [CrossRef]

- Wang, C.; Ming, C.; Chen, J.; Qu, H.; Wang, W.; Di, Q. Analysis of secondary makeup characteristics of drill collar joint and prediction of downhole equivalent impact torque of Well SDTK1. Petrol. Explor. Devel 2024, 51, 697–705. [Google Scholar] [CrossRef]

- Zhu, X.; Li, K.; Li, W.; He, M.; She, C.; Tan, B. Drill string mechanical behaviors of large-size borehole in the upper section of a 10,000 m deep well. Nat. Gas. Ind. 2024, 44, 49–57. [Google Scholar]

- Ou, C.; Li, C.; Huang, S.; Sheng, J.J. Remigration and leakage from continuous shale reservoirs: Insights from the Sichuan Basin and its periphery, China. AAPG Bull. 2019, 103, 2009–2030. [Google Scholar] [CrossRef]

- Song, D.; Luo, X.; He, M. Development and Application of 812.8 mm PDC Bit for Myriameter Ultradeep Wells. China Petrol. Mach. 2025, 53, 31–36. [Google Scholar]

- Mohammadzadeh, K.; Akbari, S.; Hashemabadi, S.H. Parametric study of cutting transport in vertical, deviated, and horizontal wellbore using CFD simulations. Pet. Sci. Technol. 2021, 39, 31–48. [Google Scholar] [CrossRef]

- Erge, O.; Ozbayoglu, E.M.; Miska, S.Z.; Yu, M.; Takach, N.; Saasen, A.; May, R. Laminar to turbulent transition of yield power law fluids in annuli. J. Petrol. Sci. Eng. 2015, 128, 128–139. [Google Scholar] [CrossRef]

- Cai, M.; He, M.; Tan, L.; Mao, D.; Xiao, J. Failure analysis of large-size drilling tools in the oil and gas industry. J. Energy Resour. Technol. 2024, 146, 073201. [Google Scholar]

- Zhu, N.; Huang, W.; Gao, D. Numerical analysis of the stuck pipe mechanism related to the cutting bed under various drilling operations. J. Petrol. Sci. Eng. 2022, 208, 109783. [Google Scholar] [CrossRef]

- Dehvedar, M.; Moarefvand, P.; Kiyani, A.R.; Mansouri, A.R. Using an experimental drilling simulator to study operational parameters in drilled-cutting transport efficiency. J. Min. Environ. 2019, 10, 417–428. [Google Scholar]

- Mansoury, A.; Kiani, A.; Dehvedar, M.; Ameri, H. Well annulus cleaning while using stabilizer with an experimental flow loop and its cfd model. Arab. J. Sci. Eng. 2023, 48, 9413–9427. [Google Scholar] [CrossRef]

- Sun, X.; Yan, T.; Li, W.; Wu, Y. Study on Cuttings Transport Efficiency Affected by Stabilizer’s Blade Shape in Vertical Wells. Open Petrol. Eng. J. 2013, 6, 7–11. [Google Scholar]

- Li, X.; Gao, D.; Zhou, Y.; Zhang, H. Study on open-hole extended-reach limit model analysis for horizontal drilling in shales. J. Nat. Gas. Sci. Eng. 2016, 34, 520–533. [Google Scholar] [CrossRef]

- Li, Z.; Yao, C.; Hu, K. Research and practice of horizontal wellbore cleaning technology. Xinjiang Oil Gas. 2022, 18, 48–53. [Google Scholar]

- Chen, Y.F.; Zhang, H.; Wu, W.X.; Li, J.; Ouyang, Y.; Lu, Z.Y.; Dong, Z.X. Simulation study on cuttings transport of the backreaming operation for long horizontal section wells. Petrol. Sci. 2024, 21, 1149–1170. [Google Scholar] [CrossRef]

- Nguyen, D.; Rahman, S.S. A three-layer hydraulic program for effective cuttings transport and hole cleaning in highly deviated and horizontal wells. SPE Drill. Complet. 1998, 13, 182–189. [Google Scholar] [CrossRef]

- Guan, Z.; Liu, Y.M.; Liu, Y.W.; Xu, Y. Hole cleaning optimization of horizontal wells with the multi-dimensional ant colony algorithm. J. Nat. Gas. Sci. Eng. 2016, 28, 347–355. [Google Scholar] [CrossRef]

- Lu, N.; Zhang, B.; Wang, T.; Fu, Q. Modeling research on the extreme hydraulic extension length of horizontal well: Impact of formation properties, drilling bit and cutting parameters. J. Pet. Explor. Prod. Tech. 2021, 11, 1211–1222. [Google Scholar] [CrossRef]

- Zhang, F.; Islam, A. A pressure-driven hole cleaning model and its application in real-time monitoring with along-string pressure measurements. SPE J. 2023, 28, 1–18. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, J.; Bi, C.; Liu, X.; Ji, G.; Yu, J. Study on settling characteristics of rock cuttings from terrestrial high clay shale in power-law fluid. Front. Energy Res. 2024, 12, 1370803. [Google Scholar] [CrossRef]

- Yao, D.; Sun, X.; Zhang, H.; Qu, J. Experimental Study on Blocky Cuttings Transport in Shale Gas Horizontal Wells. Water 2025, 17, 1016. [Google Scholar] [CrossRef]

- Xu, Z.; Song, X.; Zhu, Z. Development of elastic drag coefficient model and explicit terminal settling velocity equation for particles in viscoelastic fluids. SPE J. 2020, 25, 2962–2983. [Google Scholar] [CrossRef]

- Sun, X.; Tao, L.; Qu, J.; Yao, D.; Hu, Q. Evaluating the effectiveness of cleaning tools for enhanced efficiency in reamed wellbore operations. Geoenergy Sci. Eng. 2025, 246, 213620. [Google Scholar] [CrossRef]

- Yan, T.; Qu, J.; Sun, X.; Chen, Y.; Hu, Q.; Li, W.; Zhang, H. Numerical investigation on horizontal wellbore hole cleaning with a four-lobed drill pipe using CFD-DEM method. Powder Technol. 2020, 375, 249–261. [Google Scholar] [CrossRef]

- Pang, B.; Wang, S.; Wang, Q.; Yang, K.; Lu, H.; Hassan, M.; Jiang, X. Numerical prediction of cuttings transport behavior in well drilling using kinetic theory of granular flow. J. Pet. Sci. Eng. 2018, 161, 190–203. [Google Scholar] [CrossRef]

- Pang, B.; Wang, S.; Liu, G.; Jiang, X.; Lu, H.; Li, Z. Numerical prediction of flow behavior of cuttings carried by Herschel-Bulkley fluids in horizontal well using kinetic theory of granular flow. Powder Technol. 2018, 329, 386–398. [Google Scholar] [CrossRef]

- Minakov, A.V.; Zhigarev, V.A.; Mikhienkova, E.I.; Neverov, A.L.; Buryukin, F.A.; Guzei, D.V. The effect of nanoparticles additives in the drilling fluid on pressure loss and cutting transport efficiency in the vertical boreholes. J. Pet. Sci. Eng. 2018, 171, 1149–1158. [Google Scholar] [CrossRef]

- Yan, T.; Qu, J.; Sun, X.; Li, Z.; Li, W. Investigation on horizontal and deviated wellbore cleanout by hole cleaning device using CFD approach. Energy Sci. Eng. 2019, 7, 1292–1305. [Google Scholar] [CrossRef]

- Lun, C.K.; Savage, S.B.; Jeffrey, D.J.; Chepurniy, N. Kinetic theories for granular flow: Inelastic particles in Couette flow and slightly inelastic particles in a general flowfield. J. Fluid. Mech. 1984, 140, 223–256. [Google Scholar] [CrossRef]

- Ding, J.; Gidaspow, D. A Bubbling Fluidization Model Using Kinetic Theory of Granular Flow. AIChE J. 1990, 36, 523–538. [Google Scholar] [CrossRef]

- Wolfshtein, M. The velocity and temperature distribution in one-dimensional flow with turbulence augmentation and pressure gradient. Int. J. Heat Mass Transfe 1969, 12, 301–318. [Google Scholar] [CrossRef]

- Huilin, L.; Gidaspow, D.; Bouillard, J.; Wentie, L. Hydrodynamic simulation of gas–solid flow in a riser using kinetic theory of granular flow. Chem. Eng. J. 2003, 95, 1–13. [Google Scholar] [CrossRef]

- Ergun, S. Fluid flow through packed columns. Chem. Eng. Prog. 1952, 48, 89–94. [Google Scholar]

- Wen, C.Y. Mechanics of fluidization. Chem. Eng. Prog. 1966, 62, 100–111. [Google Scholar]

- Han, S.M.; Hwang, Y.K.; Woo, N.S.; Kim, Y.J. Solid–liquid hydrodynamics in a slim hole drilling annulus. J. Petro Sci. Eng. 2010, 70, 308–319. [Google Scholar] [CrossRef]

- Epelle, E.I.; Gerogiorgis, D.I. Transient and steady state analysis of drill cuttings transport phenomena under turbulent conditions. Chem. Eng. Res. Des. 2018, 131, 520–544. [Google Scholar] [CrossRef]

| Cylinder Liner Diameter, mm | Max Stroke Rate, r/min | Maximum Discharge Pressure, MPa | Maximum Displacement, L/s |

|---|---|---|---|

| φ130 | 166 | 51.9 | 55.08 |

| φ140 | 154 | 44.7 | 59.27 |

| φ150 | 144 | 39.0 | 63.62 |

| φ160 | 135 | 34.2 | 67.86 |

| φ170 | 127 | 30.3 | 72.07 |

| φ180 | 120 | 27.0 | 76.34 |

| No | Parameters | Value |

|---|---|---|

| 1 | Stabilizer Outer Diameter, mm | 800/792 |

| 2 | Well deviation angle, deg | 0 |

| 3 | Outer diameter of the drill string, mm | 168.3 |

| 4 | Inner diameter of the wellbore, mm | 812.8/819.2 |

| 5 | Drilling fluid density, kg/m3 | 1270 |

| 6 | Fluid inlet velocity, m/s | 0.20/0.26/0.32/0.38 |

| 7 | Cuttings particle size, mm | 2.0 |

| 8 | Drilling fluid flow rate, L/s | 100/130/160/190 |

| 9 | Cuttings density, kg/m3 | 2500 |

| 10 | Length of a single stabilizer, m | 1.8 |

| 11 | Stabilizer flow area, % | 30/40/50/60 |

| 12 | Apparent viscosity of drilling fluid, mPa·s | 20 |

| 13 | Inlet cuttings volume fraction % (corresponding to ROP 1.3 m/h) | 3.6 |

| No | Model Grid Number | Rock Cuttings Volume Fraction | Relative Error |

|---|---|---|---|

| 1 | 219,852 | 11.83% | - |

| 2 | 294,195 | 10.99% | 7.10% |

| 3 | 347,340 | 10.51% | 4.37% |

| 4 | 467,512 | 10.43% | 0.76% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Liu, L.; Xia, L.; Zhang, J.; He, X.; Liu, X.; Yu, J.; Zhang, B. Research on Cuttings Transport Behavior in the 32-Inch Borehole of a 10,000-Meter-Deep Well. Processes 2025, 13, 2003. https://doi.org/10.3390/pr13072003

Wang Q, Liu L, Xia L, Zhang J, He X, Liu X, Yu J, Zhang B. Research on Cuttings Transport Behavior in the 32-Inch Borehole of a 10,000-Meter-Deep Well. Processes. 2025; 13(7):2003. https://doi.org/10.3390/pr13072003

Chicago/Turabian StyleWang, Qing, Li Liu, Lianbin Xia, Jiawei Zhang, Xusheng He, Xiaoao Liu, Jinping Yu, and Bo Zhang. 2025. "Research on Cuttings Transport Behavior in the 32-Inch Borehole of a 10,000-Meter-Deep Well" Processes 13, no. 7: 2003. https://doi.org/10.3390/pr13072003

APA StyleWang, Q., Liu, L., Xia, L., Zhang, J., He, X., Liu, X., Yu, J., & Zhang, B. (2025). Research on Cuttings Transport Behavior in the 32-Inch Borehole of a 10,000-Meter-Deep Well. Processes, 13(7), 2003. https://doi.org/10.3390/pr13072003