Abstract

Factory automation (FA) is a vital technology that enhances manufacturing efficiency, reduces defect rates, and maximizes productivity in response to evolving market demands. This study analyzes global research and development (R&D) trends in FA based on patent information from major manufacturing countries. It also proposes growth directions for FA technology in South Korea, applying latent Dirichlet allocation (LDA) to identify key technologies for the Korean market. Specifically, FA-related technology is classified into five topics, with documents less likely to belong to a single topic being reclassified and analyzed as hybrid topics. Furthermore, this study analyzes the growth rate of FA-related technologies and the current level of technological emergence through a four-quadrant analysis, providing valuable insights into global R&D trends. The results demonstrate that artificial intelligence-related patents are important for FA. Further R&D is necessary, as the development of wireless communication technology suitable for industrial environments has become crucial and is a competitive technology for FA in terms of infrastructure and maintenance. Visual processing technology, which enables accurate decision making using artificial intelligence in a precise and constantly changing operating environment through FA, requires more attention to secure international competitiveness in the Korean market.

1. Introduction

Modern manufacturing must become more efficient, adapt quickly to global market changes, and build closer connections with customers. This requires constant adjustments to physical infrastructure and intellectual resources to keep up with changes and fully exploit technological advancements [1]. Factory automation (FA) is a key technology in modern production that enhances the efficiency of manufacturing processes, reduces defect rates, and maximizes productivity [2]. In particular, FA plays a crucial role in smart factory operations. Smart factories can be classified into various stages of development, ranging from basic to advanced, with each stage requiring FA as a key technology [3,4,5]. For example, in the basic stage, the goal of smart factories is to reduce reliance on labor and enhance efficiency through the automation of production processes [6]. In the intermediate stage, the focus shifts to strengthening real-time data collection and process management through sensor networks and the Industrial Internet of Things (IIoT) [7]. In the advanced stage, artificial intelligence (AI)-driven predictive analytics and autonomous decision making are employed to optimize processes and maximize productivity [8]. Recent studies have emphasized the technological integration of IoT, IIoT, and Industry 4.0 as the core enabler for smart manufacturing. Qiu et al. [9] reviewed the technological convergence between IoT, IIoT, and Industry 4.0, highlighting their collective role in enabling smart manufacturing, with an emphasis on connectivity, real-time data, and system interoperability. Thus, FA technology plays an essential role in each stage of smart factory development, necessitating effective strategies for its adoption and utilization.

Governments and companies in advanced manufacturing countries are also implementing national-level manufacturing strategies, such as Hightech Strategy 2025 and Industry 4.0 (Germany), Advanced Manufacturing 2.0 (United States), Made in China 2025 (China), Society 5.0 (Japan), and Manufacturing Innovation 3.0 (South Korea). These strategies aim to increase production, lower defect rates, shorten delivery times, and manage lead times through the use of IIoT and cyber–physical system (CPS) technologies [10,11,12,13].

South Korea, a leader in manufacturing, has a well-developed information technology (IT) infrastructure, and some large companies, such as those in the semiconductor and automobile industries, have implemented advanced AI-based manufacturing processes. However, several small and medium-sized enterprises (SMEs) in South Korea are still in the early stages of implementing AI-based manufacturing processes. Considering that SMEs account for 99% of all industries and supply key components of finished goods to large companies in the supply chain industry, improving the level of FA in SMEs is critical for maintaining the overall manufacturing competitiveness of the nation [14,15].

Previous studies have explored patent-based topic modeling to identify technology trends in manufacturing domains [16,17]. However, most of these works focused on broad categorizations of smart manufacturing and offered only high-level overviews of emerging technologies. There remains a lack of research that analyzes FA technologies with finer granularity, particularly through the lens of comparative national trends and their implications for SMEs. Additionally, while prior studies utilizing patent data have primarily focused on categorizing topics or identifying trends through topic modeling, few have distinguished between documents that are strongly associated with a single topic and those that exhibit mixed thematic distributions [18,19]. As these studies relied on theoretical classifications without adequately reflecting technological convergence and strategic insights, their practical applicability may be limited. Therefore, a complementary methodological approach is required.

Given this gap, there is a critical need for research that takes a more detailed and comparative approach to analyzing FA technology trends, especially from the perspective of SMEs. Accordingly, this study proposes the following research direction and objectives. First, we identify the core technological topics related to FA based on patent data from major manufacturing countries and evaluate the growth potential and innovation status of each technology. Second, we derive strategic implications for facilitating FA adoption in South Korean SMEs by considering their unique technological and resource limitations.

To achieve these purposes, this paper introduces a novel classification framework that categorizes patents into specific and hybrid topics based on the results of latent Dirichlet allocation (LDA) analysis. This allows for a more nuanced understanding of the technological landscape of FA. Furthermore, we integrate a four-quadrant analysis using a nested Poisson regression model to quantitatively evaluate the growth trajectories of each topic. This combined approach enables the identification of both emerging and mature technologies, offering more practical and actionable insights, particularly for SMEs considering FA adoption.

The findings of this study can guide the development of FA technology and contribute to the effective implementation and operation of smart factories. It can also provide policymakers with a basis for designing support measures to enhance the levels of automation in SMEs. The remainder of this paper is organized as follows. Section 2 summarizes the conceptual backgrounds of FA, technology trend analysis, and text mining. Section 3 discusses the research methods and procedures. Section 4 presents the empirical analysis, and Section 5 discusses the results and implications. Finally, Section 6 presents the conclusions.

2. Conceptual Background

2.1. Factory Automation

Smart factories utilize innovative manufacturing technology, such as cloud storage, big data, and IoT, to enhance a company’s competitiveness [20]. FA involves using IT to control and advance mechanized production as opposed to simply replacing human labor with machines [21]. FA includes technologies such as robotic automation devices, computerized numerical control (CNC) machines, and flexible manufacturing systems (FMS) that can perform production processes on their own, without human intervention, according to a predetermined schedule [22].

In addition to these systems, factory automation is commonly supported by software and devices that facilitate real-time control and monitoring within the physical production environment. These include programmable logic controllers (PLCs) for machine-level automation [23], human–machine interfaces (HMIs) for operator interaction [24], and manufacturing execution systems (MESs) to oversee shop-floor operations and coordinate production workflows [25]. These elements serve as the operational backbone of FA and enable seamless integration of machines, operators, and enterprise systems.

The implementation of FA is often considered a requirement for companies to achieve innovation, boost productivity and flexibility, and reduce costs by producing high-quality products at a low cost [26,27,28]. In this study, we define FA as the use of software and hardware technologies to facilitate manufacturing innovation, improve productivity, create flexible production factories, and reduce energy consumption by overcoming the limitations of manual labor. Research shows that FA is an effective method to enhance the productivity and efficiency of companies. However, SMEs may not easily adopt basic FA owing to a lack of internal resources to introduce and operate these technologies [15]. This can pose a challenge for SMEs in the manufacturing industry as they strive to improve their competitiveness.

In South Korea, most manufacturing companies are SMEs, and these enterprises play a crucial role in enhancing the competitiveness of the national manufacturing industry. To address this issue, we propose analyzing patent-based FA technologies and extracting key insights from them to improve the FA levels of SMEs.

2.2. Technology Trend Analysis Based on Patents

A patent specification is a document that outlines the technical details of an invention and protects the inventor’s rights [29]. This information is particularly useful for analyzing technological competitiveness and trends over time. Patents can provide insights into technology strategies for companies that may not be visible from the outside. Consequently, patents are often used to predict technological trends, create technology roadmaps, identify promising technologies, and gather general technological information.

Several studies have utilized patents to forecast technological trends and identify promising technologies. For example, Chen, Wan, Shu, Li, Mukherjee and Yin [7] analyzed data from 13,910 Australian patents from the United States Patent and Trademark Office from 2000 to 2014 using a technology prediction methodology based on the latent Dirichlet allocation (LDA) model. Gerrish and Blei [30] used a dynamic topic model to track changes in research paper topics over time and measured the impact of individual papers. Momeni and Rost [31] employed k-core analysis and LDA to monitor technology trends and identify promising technologies, whereas Suominen, Toivanen and Seppänen [16] applied LDA to 155,718 patents from leading companies, such as Samsung, Microsoft, and Google, from 2001 to 2014 to predict future trends in industrial patents. Ju and Sohn [32] used patent network analysis and the House of Quality to suggest promising technologies, and Choi, et al. [33] developed a technology roadmap by extracting the subject–action–object structure from patent abstracts and claims. Tseng, Lin and Lin [29] studied the use of keyword analysis and clustering techniques in the text mining of patent data. Previous studies have demonstrated that patents can be used to identify promising technologies and technological trends.

2.3. Topic Modeling for Patent Analysis

Text mining is a method for extracting patterns or relationships from unstructured text data, such as natural language, to uncover meaningful information. Text mining involves more complex data collection and preprocessing steps than machine-learning techniques, which utilize structured data. However, it has been used as an unsupervised learning method by many researchers because it enables the analysis of users’ emotions or intentions through their text [34,35]. In parallel, several studies on Industry 4.0 have underscored the importance of assessing the current level of technological adoption within organizations. Such assessments are often used as a foundation for planning digital transformation strategies [36].

Topic modeling is a text-mining technique used for discovering topics within unstructured documents by analyzing vector values related to the context of a document [37]. This method infers abstract structures and variables between documents and words, and is commonly used in semantic analysis because it can determine the proportion of keywords that make up a particular topic and the probability that keywords will be included in a specific topic [38,39]. To perform topic modeling, a corpus referring to a set of words and natural language samples is extracted and preprocessed. A document term matrix is then created by converting the frequency of words appearing in each document into a matrix form, providing information on the relationships between topics, documents, and words. In the past, latent semantic allocation (LSA) was the main methodology used for topic modeling; however, more recently, LDA has become the most widely used method [4,40]. LDA generates a combination of keywords in each group and allows the generation of topics within the collected documents.

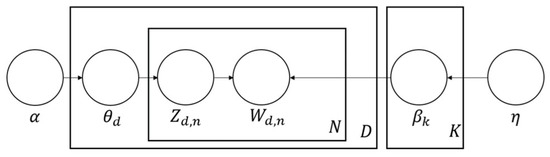

The LDA process is illustrated in Figure 1. In this figure, represents the parameter for the Dirichlet prior weight of the topic in each document, represents the parameter for the Dirichlet prior weight of the word in each topic, represnts the ratio of topics within technology documents (d), represents the probability of word appearance within topics (k), represents the topic of the nth word in document (d), represents the nth word in document (d), and K represents the number of topics.

Figure 1.

Document creation process of LDA (Tong & Zhang [41]).

Various text-mining studies have used patent data. Hu, et al. [42] proposed a method for automating the knowledge-organization system of patent data using term clamping, LDA, and k-means clustering. Choi and Song [43] used LDA to classify topics and explore R&D trends in logistics patents at USTPO. Lee and Sohn [44] applied LDA to financial business patterns, classifying patent specifications as hot and cold topics depending on whether the exponential weighted moving average exceeded a threshold. They suggested that short-granted periods and highly forward-cited topics may become hot.

2.4. Four-Quadrant Analysis for Strategy Mapping

We conduct a classification analysis of topic information based on the results of a prior LDA model and linear predictive model. Research on technological strategies that use patent data has been conducted using various methods. We focus on performing a four-quadrant analysis of each topic’s growth rate, measured by the number of registered patents. This analytical approach is frequently applied in technology management and patent metric studies [45].

Related previous research includes the following. Wang and Hsu [17] used LDA and a generalized linear mixed model to classify patent data in the smart manufacturing field into 14 topics, presenting the major R&D topics in that field. In their study, the authors distinguished four quadrants using the topic’s growth rate (slope) and patent filed status (intercept). Kim and Lee [46] constructed a patent portfolio map for business method patents in the mobile service field. They formed four quadrants using “importance” and “increase rate”, with the position of each mobile service on the map derived from data envelopment analysis results. Liu and Chang [47] conducted a patent portfolio analysis of competing firms using light detection and ranging (LiDAR) systems by applying patent maps and linear regression. Their study formed four quadrants based on the total number of claims and the number of citations of patents held by multiple competing firms. Moreover, Charmanas, et al. [48] analyzed home automation-related patents to distinguish between technologies leading the market and those in decline, employing an annual growth rate and patent share as the axes for their four-quadrant analysis, and labelling the quadrants as “emerging”, “dominant”, “declining”, and “saturated”.

Similar to previous studies, we also perform an LDA analysis of patent specifications and apply a four-quadrant analysis based on the topic information assigned to each patent. To do this, we employ a nested Poisson regression model. Poisson regression is well suited for a dependent variable measured by the number of occurrences, such as patents. To estimate the effect of each topic’s patent count more precisely, we incorporate a nested (hierarchical) analysis structure that accounts for topic-specific quarterly effects. The model used in this study is as follows:

where denotes the number of patents registered in the j-th quarter for the i-th LDA topic. Here, is the intercept (overall mean), is the effect of the i-th topic, and indicates the growth rate for the j-th quarter within the i-th topic. is the error term, and in the actual estimation process, we consider the mean–variance relationship of the Poisson distribution.

3. Research Framework

This study uses patent specifications to identify emerging technologies related to FA. Specifically, we analyze the technical content of these patents to understand the characteristics of FA in South Korea compared to other countries. We extract patent information related to FA from a summary of patent specifications in the United States, Europe, Japan, and South Korea. To quantitatively analyze the information in the patent specifications, we use topic modeling, a type of text mining, to extract and define specific technologies related to FA. We then conduct a trend analysis of these technologies over time using time-series analysis. Our aim is to determine the future direction of FA technologies.

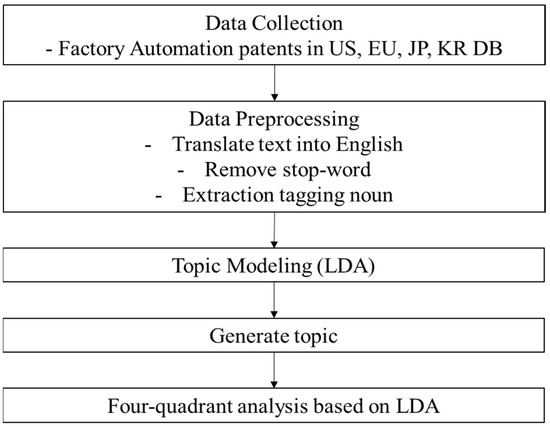

To identify specific trends in FA, we propose the research procedure depicted in Figure 2. First, we acquire patent data related to FA in the United States, Europe, Japan, and South Korea, which are considered advanced manufacturing countries. We then translate the data into a common language (English), remove stop words, and extract the tagging nouns. Next, we conduct topic modeling and define each topic.

Figure 2.

Text-mining process for FA technology.

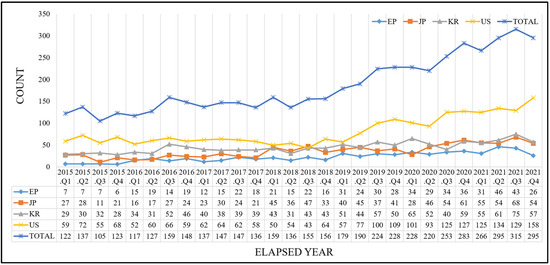

To analyze FA R&D trends, we collected 5994 patent documents filed between 1 January 2015, and 31 December 2021, from major patent databases in the United States, Europe, Japan, and South Korea. This timeframe was intentionally selected to emphasize technologies that are sufficiently mature and realistically applicable for SMEs, particularly within the South Korean industrial context. While patents filed after 2022 increasingly feature advanced innovations in artificial intelligence (AI) and generative AI, such technologies often require substantial investment and infrastructure, posing significant barriers to adoption for SMEs [49,50]. Accordingly, the selected timeframe enables a more grounded and practical analysis of FA technologies that are both accessible and actionable for SMEs. These data were obtained through keyword searches using patent information search services, such as the Korea Intellectual Property Rights Information Service and Application Program Interface for patents from the United States, Europe, Japan, and South Korea. Patent data included the name, application number, date, registration number, International Patent Classification (IPC), summary, and abstract of the invention. As shown in Figure 3, the number of patents has steadily increased each year, with a particularly higher number of FA patents in the United States than in other countries. This may be because many start-up companies in the United States use AI.

Figure 3.

Number of FA patents by country.

In this study, we used abstracts of patent specifications for topic modeling. To prepare the data for this analysis, we first divided the summary of the patent data into individual words based on spaces. We then designated and deleted unnecessary special characters, postpositions, and articles in the document (referred to as stop words), and only extracted nouns. The resulting keywords were labelled using lemmatization, a process that groups the inflected forms of a word such that they can be analyzed as a single term. After preprocessing the patent information, an LDA analysis was performed.

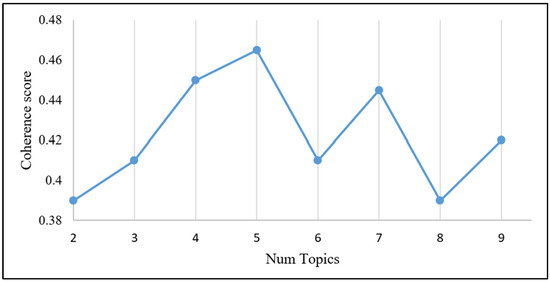

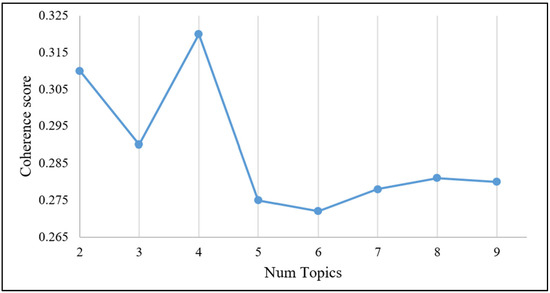

The number of topics must be specified in advance for LDA topic modeling because the results may vary depending on this parameter. We set the number of topics based on coherence scores, which measure the similarity of the top words within each topic derived from topic modeling [51]. A high coherence score indicates that each topic is composed of semantically similar words [52,53].

4. Empirical Result

In this study, we applied the LDA algorithm to generate topics through topic modeling using the final data after preprocessing. We used the Gensim, pyLDAvis, and nltk packages in Python 3.6. As discussed in Section 3, the number of topics must be determined before implementing topic modeling. We set the number of topics from two to nine and calculated the coherence score, as shown in Figure 4. The coherence score was highest when the number of topics was set to five, indicating a high similarity between the top words for each topic in this setting. Therefore, we set the optimal number of topics to five for the LDA analysis. Each document (in this case, the abstract of a patent specification) was assigned a probability of belonging to each topic. If a document had a probability of 50% or greater of belonging to one topic, we defined it as a “specific topic”, whereas documents that did not meet this criterion were defined as “hybrid topics”. The patent specifications were classified as “hybrid topics”, and we performed the LDA analysis once again.

Figure 4.

Coherence scores based on number of topics.

The results of the text mining based on LDA are presented in Table 1. The five specific topics are as follows:

Table 1.

LDA results for specific topics.

Topic 1: Systems for signal detection and control. This topic includes technologies related to the generation and detection of signals and the collection of data for process control through FA. Control systems that specialize in minimizing process fluctuations by collecting and analyzing various signals and environmental data can promote high quality and production stability.

Topic 2: Industrial robot design methods for improving business performance. This topic includes technologies related to the design of industrial robots used in manufacturing processes and classified as either collaborative or industrial robots. The main difference between these two robot types is the presence or absence of humans. Industrial robots are designed to operate independently, whereas collaborative robots work alongside humans and are capable of flexible and precise movements, making them suitable for a variety of tasks.

Topic 3: Automated process control systems. This topic includes technologies related to the design of automated process control systems that have gained attention in the context of smart factories. Designing systems that utilize information and communication technologies (ICT) systems for FA, such as enterprise resource planning, manufacturing execution systems, process lifetime management, and supply chain management has gained interest.

Topic 4: Wireless communication and data control. This topic includes technologies related to the construction of networks for data communication between heterogeneous equipment and flexible production in manufacturing firms. These networks include Wi-Fi, frequency-hopping spread spectrum, 5G, and long-range wide-area networks. Considerations for wireless communication include the communication area, stability, security, scalability, and maintenance, which are configured based on the characteristics of each plant.

Topic 5: Pattern (image) recognition and processing. This topic includes technologies related to image recognition and processing and is characterized by a concentration of words related to visual processing. Image analysis techniques, such as deep learning, can be combined with the ICT infrastructure to develop automatic analysis systems with low inspection errors and high reliability. Recently, many factories have implemented automatic inspection functions using image analysis technology to inspect finished products owing to a lack of manpower.

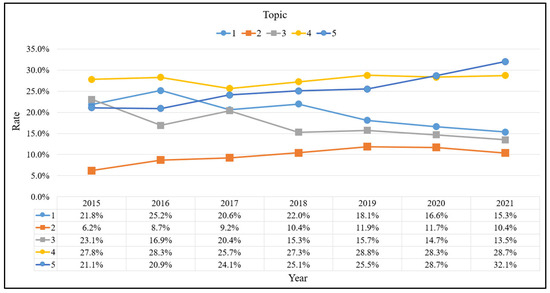

This trend is confirmed in Figure 5. When analyzing the time series of topics, the proportion of patents decreases over time for Topics 1 and 3, whereas the proportion of patents for Topics 4 and 5 continues to rise. This suggests that the importance of FA technologies in wireless communication and image analysis is increasing, reflecting their growing connection to technologies that can create added value, such as autonomous driving. As FA technologies continue to advance and become more prevalent, they may play a significant role in shaping the future of manufacturing and other industries.

Figure 5.

Patent rates by specific topic.

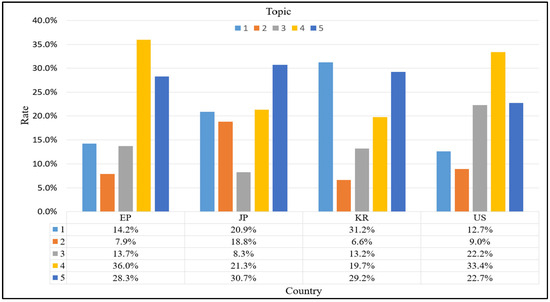

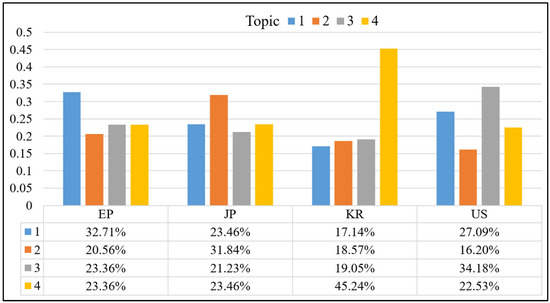

The proportion of patents by country for each topic is shown in Figure 6. Most countries have a significant number of patents related to Topic 5. In South Korea and Japan, the ratio of patents for traditional industrial robots (Topic 1) is relatively high. In contrast, patents from the United States and Europe tend to focus on Topic 4. Based on these results, the next-generation FA technology of South Korea may face challenges in terms of competitiveness compared with other countries.

Figure 6.

Specific patent rates by country.

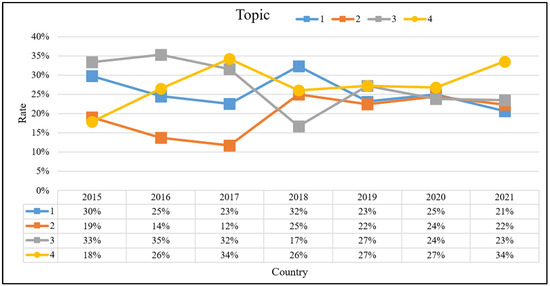

The hybrid topics were classified into four categories based on their coherence scores, as shown in Figure 7. Pattern (image) recognition and processing, which is Topic 5 of the specific topics, was classified into Topic 1 (light signal detection and control system) and Topic 3 (image signal detection and control system) of the hybrid topics. The results for the hybrid topics are shown in Table 2 and Figure 8 and Figure 9.

Figure 7.

Coherence scores for the hybrid topics.

Table 2.

LDA results for hybrid topics.

Figure 8.

Patent rates by hybrid topic.

Figure 9.

Hybrid patent rates by country.

Topic 2 was related to information processing systems. FA relies heavily on IT; therefore, information processing technology that can create a real-time environment must be highly developed. While continuously pursuing process stabilization, technologies that reduce malfunctions and defects are of significant interest as fusion technologies.

Topic 4 refers to an anomaly detection system. This topic is related to the technology used to detect abnormal operations outside the average yield range and identify factors contributing to quality deterioration through the detection of abnormalities in manufacturing facilities.

A strong relationship exists between hybrid topics and AI technologies, particularly in image processing. Our results indicate that many factories are developing and implementing technologies related to image recognition and processing in their automation processes. Interestingly, South Korea had a particularly high concentration of hybrid Topic 4, which is related to traditional FA. This suggests that South Korea, a major manufacturing powerhouse, focuses more on technological security than other countries.

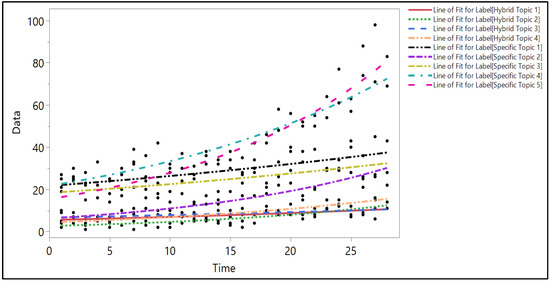

Next, a nested Poisson regression analysis was conducted for both specific and hybrid topics, in preparation for a four-quadrant analysis. The results are shown in Table 3 and Table 4 as well as in Figure 10. For the regression model, the data were collected by categorizing the patents by topic and quarter, and the explanatory variables were set as time (in quarterly units) and LDA topic classification. Time represents the growth rate, which can vary by topic and is thus defined as a nested effect.

Table 3.

Results for whole model test.

Table 4.

Results for effect test.

Figure 10.

Regression plot.

The results in Table 3 and Table 4 confirm that both explanatory variables are statistically significant. The overdispersion value was 1.1508, which was acceptable. The correlation coefficient between the actual number of patents and the predicted number of patents from the regression model was 0.957, which was notably high. Figure 10 illustrates the actual data values by quarter (points) and the predicted values (lines).

5. Discussion and Implications

This study examines the trends in FA patent technology in the United States, Europe, Japan, and South Korea using text mining and topic modeling. We used time-series analysis with LDA to identify the optimal number of topics and distinguish between specific and hybrid topics using coherence scores.

Our results reveal the latest R&D trends in FA. Pattern (image) recognition and processing technologies are becoming increasingly popular. This area has been identified as an important topic in all the countries analyzed. Recently, advancements in sensor technology, including high-resolution cameras, LiDAR, and other sensor technologies, have provided more accurate and detailed image data. In addition, deep-learning technologies have significantly improved image recognition and processing capabilities. For example, advanced convolutional neural networks and other deep-learning algorithms are used to detect and process complex patterns and shapes.

Moreover, systems for signal detection, control, and automated process control have received less attention. Traditionally, these technologies are critical for process stability. However, rapid progress in AI and machine-learning technologies has shifted towards more intelligent and adaptive control systems, reducing reliance on traditional control systems. Although automated process control systems have been effective in improving efficiency, they can be costly to implement and maintain. Therefore, recent manufacturing firms may invest in more cost-effective alternative technologies, such as AI-driven or data-driven process control systems.

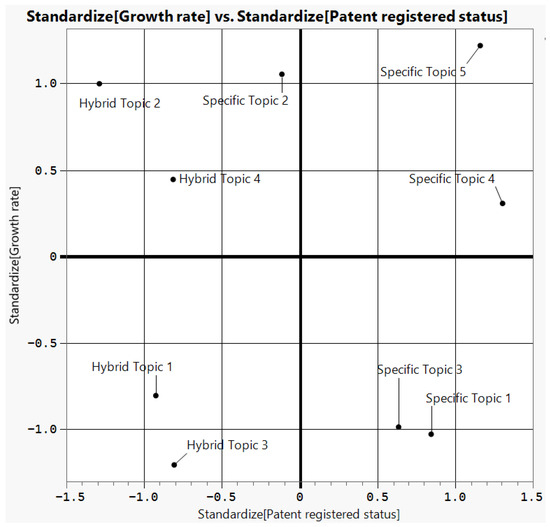

Next, we discuss the direction for establishing an R&D roadmap for FA technology based on the patent resistant status (intercept) and growth rate (slope) of the topic. We applied a four-quadrat analysis and derived specific and hybrid topic positions on a two-dimensional plane, as shown in Figure 11.

Figure 11.

Four-quadrant analysis for FA-related patents.

These nine topics can be positioned within a two-dimensional topic matrix based on their intercepts and slopes. This matrix serves as a tool for visualizing the relative emergence of various technological topics. The x-axis, as the intercept, represents the relative quantity of granted patents, and the y-axis, as the slope, indicates the relative growth rate of patent registrations.

In the four-quadrant analysis, specific Topic 4 (wireless communication and control of data) and specific Topic 5 (pattern/image recognition and processing) are located in the first quadrant. The first quadrant represents competitive technological topics with above-average granted patents and growth rates, indicating technologies that have already captured a significant market share and exhibit strong growth potential. Specific Topic 4 is a core technology in smart manufacturing that enables data communication and control among IoT sensors and equipment. The development of high-performance networks and low-latency communication systems is critical in this domain [54]. Owing to the intense competition for this topic, establishing intellectual property (IP) strategies through extensive patent filings is crucial for maintaining technological leadership. For example, Bosch implemented 5G networks in its German factories to enable real-time communication between autonomous robots and IoT devices, enhancing data transmission and system efficiency. Specific Topic 5 is another essential technology that underpins machine vision and AI-based automation systems. It is widely applied in process monitoring, defect detection, and robotic vision [55]. R&D is focused on improving image recognition accuracy using deep and machine learning, with potential extensions to other industries, such as medical imaging, logistics automation, and autonomous vehicles. For instance, KUKA Robotics adopted AI-based image processing in its industrial robots to detect and handle components with high precision, improving assembly line accuracy and reducing positional errors in production lines [56].

The second quadrant includes emerging technologies in their early developmental stages with below-average patent volumes but high growth rates. These topics have a significant growth potential and investment opportunities, necessitating proactive IP protection and market entry to secure future advantages. Specific Topic 2 (industrial robot design method for business performance), hybrid Topic 2 (information processing system), and hybrid Topic 4 (anomaly detection system) fall within this category. Specific Topic 2 focuses on robot performance enhancement, lightweighting, precision improvement, and multipurpose usability. This technology supports precision manufacturing processes and optimizes robot design to improve business outcomes [57]. Early investment and market strategies, such as customized robot designs for differentiation, are vital. Hybrid Topic 2 focuses on real-time data processing from various machines and processes with the aim of extracting actionable insights related to operations and equipment. R&D trends in this area emphasize the integration of cloud and edge infrastructures for efficient data management [58]. For example, Siemens’ MindSphere provides a cloud-based operating system for real-time data collection and analysis in manufacturing environments via IoT and edge computing (https://www.prolim.com/wp-content/uploads/2019/04/Siemens-MindSphere-Whitepaper.pdf (accessed on 17 February 2025)). In addition to such software platforms, commercial R&D trends also include the development of physical devices that support industrial IoT, such as edge controllers and protocol gateways compatible with message queuing telemetry transport (MQTT) and open platform communications unified architecture (OPC UA) [59]. These innovations enhance connectivity and interoperability among FA systems. Hybrid Topic 4 focuses on identifying errors or abnormal states in manufacturing processes to minimize productivity losses. This technology has been widely applied to AI-driven predictive maintenance and automated quality control. For example, Hitachi has implemented AI-based anomaly detection systems in its manufacturing processes to reduce process disruptions and improve product quality. Machine learning boosts detection accuracy and enables smarter workflows when combined with process monitoring. Therefore, industry-specific solutions offer competitive advantages.

The third quadrant in the topic strategy matrix represents technological topics with below-average granted patents and growth rates, which reflect technological uncertainty and market stagnation. Despite these challenges, the potential for technological development and market opportunities still exists. Hybrid Topics 1 (light signal detection and control system) and 3 (image signal detection and control system) are positioned in this quadrant. Hybrid Topic 1 can be applied to areas such as smart lighting, optical sensors, and manufacturing process monitoring, but currently faces stagnation in technological development. Overcoming this requires improvements in precision, energy efficiency, and cost effectiveness, as well as expansion into new applications. For example, General Electric (GE) uses optical sensors in its manufacturing processes to detect product dimensions and surface conditions. By introducing AI-based analysis, GE improved sensor precision and successfully reduced error rates, addressing the challenges posed by stagnant technology [60]. Hybrid Topic 3 is used in industrial automation and smart manufacturing, but its growth is hindered by technical barriers and high costs. Integrating machine learning or deep learning can boost image analysis performance. Targeted investments in functional upgrades are essential to revive this technology [61].

The fourth quadrant includes topics with above-average granted patents and below-average growth rates, indicating technologies that have reached maturity. This often reflects market saturation or a limited room for further innovation. Specific Topics 1 (system for signal detection and control) and 3 (automated process control system) are located in this quadrant. Specific Topic 1 exemplifies such maturity, having been extensively deployed in manufacturing environments for equipment monitoring and process control. For instance, Honeywell’s distributed control systems leverage sensor data to stabilize operations in smart factories [62]. Although innovation in this area has plateaued, opportunities remain through the exploration of niche applications, the adoption of cost-reducing licensing strategies, and the integration of emerging technologies, such as AI and IoT, to enhance system functionality. Specific Topic 3 supports the automation of manufacturing processes and is widely adopted in large-scale operations owing to its advanced maturity. Future efforts should focus on incorporating AI-based predictive control into existing systems to develop intelligent process control solutions, drive further innovation, and extend the lifecycle of these technologies.

After the FA technology trend analysis, this study suggests a specific recommendation for the manufacturing industry in South Korea by linking the research purposes—whether clusters of technologies related to FA may be delineated for Korean SMEs based on patents—with the analysis revealing distinctive features compared with other countries. Interestingly, South Korea shows very strong interest in systems for signal detection and control (specific Topic 1). This is related to the focus of R&D on microprocesses, such as the semiconductor and display industries. Currently, memory semiconductors focus on planning high-efficiency products, such as high bandwidth memory, and South Korean SMEs need to pay attention to FA technology that can be combined with these high-value-added products and packaging technology. However, considering the results of the quadrant analysis, specific Topic 1 shows a high level of technological maturity but a low growth rate in global trends. Therefore, R&D efforts must be increased in other topics to ensure sustained innovation and competitiveness. For example, the topics of wireless communication and data control (specific Topic 2) are less prominent in South Korea and Japan than in Europe and the United States. Reflecting on the quadrant analysis results in the FA market, wireless communication technology is being developed to enable decision making through communication between edge computing and IoT-based equipment. The development of wireless communication technology for use at manufacturing sites is important, and is currently being researched worldwide. Wireless communication is used in voice, cloud technology, data, scheduling management, and budget accounting. In particular, cloud technology enables the easy introduction and operation of smart factories or FA without the need for infrastructure, making it a popular choice for SMEs because of its low maintenance costs. Although wireless communication technology has been developed in South Korea, further support and attention are required to ensure its technological competitiveness in the global market. To prepare for a decrease in the labor force, comprehensive FA based on the IoT environment is necessary, which involves the mutual communication and coordination of each process machine. For this purpose, the development of wireless communication and monitoring technology as well as early warning systems must attract more attention.

Another specific topic that South Korea should focus on is pattern (image) recognition and processing technologies. They combine the accuracy of visual inspection with the benefits of IT, such as reliability, consistency, and speed, leading to ongoing R&D in this area. These technologies are used for product identification and defect inspection, particularly in situations where operating conditions change in real time or when a worker’s skill has a significant impact on product quality. In South Korea, where the labor force is declining rapidly, industrial robots are needed to replace human labor, and the fastest area to replace robots is one where humans can make distinctions with their eyes. Process-stage inspection work and FA for security and identification should be applied first.

For hybrid topics, South Korea is most interested in anomaly detection, which is related to active investment in technology to stabilize the manufacturing process for nano-manufacturing technologies such as semiconductors and displays, and SMEs also need to make bold investments in these areas. However, quadrant analysis also indicates a high growth potential for anomaly detection technologies for the control and processing of outliers. To achieve such technological advancement, intelligent patent recommendation systems are required to strategically filter relevant external patent information from the global technology ecosystem and align it with a firm’s internal technological capabilities. Liu et al. [63] proposed a firm-specific patent recommendation method that, by leveraging a firm’s existing technological strengths, effectively identifies latent innovation linkages and has been shown to enhance technological competitiveness in international markets.

The proposed methodology, which integrates LDA-based topic modeling with a four-quadrant analysis, offers practical value for both firms and policymakers seeking to navigate the increasingly complex landscape of FA technologies.

For manufacturing firms, particularly SMEs, the proposed framework enables a data-driven assessment of both the maturity and growth trajectory of FA technologies across subdomains. By mapping technologies into four strategic quadrants, firms can make informed R&D decisions based on their resource availability and innovation objectives. For instance, Quadrant I technologies, such as wireless communication and image recognition, are characterized by high market activity and rapid growth, making them ideal targets for SMEs seeking short-term ROI through technology licensing, integration, or incremental innovation. In contrast, Quadrant II technologies, such as anomaly detection and industrial robot design, present long-term innovation opportunities. These areas typically require higher upfront investment and collaborative R&D efforts but offer significant competitive advantages if adopted early. SMEs with limited R&D capacity can mitigate risk by leveraging this study’s network-based recommendations to identify optimal R&D partners, such as public research institutes or large firms with complementary capabilities [64].

For innovation policymakers and support institutions, the results can be used to tailor technology support programs. Policies may be designed to incentivize investment in underdeveloped but high-growth areas (such as anomaly detection and edge communication) or to build collaboration platforms between SMEs and technology leaders in specific quadrants. Given the limitations in the internal capabilities of SMEs, it is crucial to identify and select appropriate R&D partners. By integrating both horizontal (peer-level) and vertical (supply chain) relationships, SMEs can predict suitable collaborators and design cooperative structures that support more effective R&D strategies. Hybrid topic analysis can further support customized policy interventions for technology convergence. For innovation policymakers and support institutions, the results of this study can be leveraged to develop more targeted and effective technology support programs. The four-quadrant mapping of FA technologies offers a clear framework for identifying areas that require policy intervention. For example, technologies in Quadrant II, such as anomaly detection and edge communication, exhibit strong growth potential despite currently low adoption rates. Policymakers can prioritize these areas by offering tax incentives, matching grants, or pilot project funding to stimulate early-stage R&D and commercialization activities.

In addition, this framework can inform the design of structured collaboration platforms that connect SMEs with technology leaders, research institutions, and integrators based on technological complementarity. Rather than generic innovation hubs, support programs can be quadrant-specific, encouraging partnerships between firms positioned in complementary quadrants. For instance, an SME active in Quadrant II could be strategically matched with a larger firm already established in Quadrant I to accelerate technology transfer and joint development.

In summary, this methodological framework transforms abstract patent data into actionable strategic insights, improving the operability and decision-making precision of industrial technology roadmaps.

However, this study has some limitations. First, it only analyzed patent data from the United States, Europe, Japan, and South Korea and did not include data from China and India, where the manufacturing industry is rapidly developing. Particularly in the case of China, the field of wireless communications has greatly advanced, which is associated with Topic 4 in the results of the topic-modeling analysis. Further examinations of this aspect and research analyzing global trends and specific technologies are necessary. Including data from other countries in future studies may provide a more comprehensive and reliable perspective of the technological trends. Second, this study excluded post-2021 patent data. While this aligns with the research goal of focusing on technologies implementable by SMEs, it may have limited the inclusion of the latest innovations, such as generative AI and advanced smart manufacturing systems. Future research should consider extending the timeframe and incorporating filtering methods to distinguish between scalable and resource-intensive technologies. Second, this study used the abstracts of patent specifications for analysis. To reflect technology protection through patents more accurately, future studies should use the claims section of the specifications in the original language. Finally, a trend analysis was conducted on the broad scope of FA technology. Therefore, a more detailed topical analysis is required to understand the characteristics of these technologies.

6. Conclusions

This study uses text-mining techniques and patent data to identify methods to improve the competitiveness of FA technologies and suggests directions for future research based on specific and hybrid topics. This study contributes to the literature by conducting research based on patents registered in Europe, the United States, Japan, and South Korea and analyzing patents that have demonstrated technological value. In addition, we introduce a new classification method that defines hybrid topics when the subject matter of a patent is not clearly distinguished. This provides a more empirical approach for analyzing and proposing technologies in the field of FA. In addition, this study is one of the few to empirically identify FA trends by analyzing the time series of FA-related technologies in each country. SMEs that cannot implement technology roadmaps or determine the direction of investment in new technologies are expected to benefit from the ability to choose the direction of their technology investments on a country-by-country and topic-by-topic basis.

Author Contributions

Conceptualization, I.C. and Y.J.; Methodology, I.C. and Y.J.; Software, Y.J.; Validation, I.C. and Y.J.; Formal analysis, I.C.; Investigation, I.C. and Y.J.; Resources, I.C. and Y.J.; Data curation, Y.J.; Writing—original draft, I.C. and Y.J.; Writing—review & editing, I.C. and Y.J.; Visualization, Y.J.; Supervision, Y.J.; Project administration, Y.J. All authors have read and agreed to the published version of the manuscript.

Funding

The work of Insu Cho was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT) (NRF-2022R1G1A1009419). The work of Yonghan Ju was supported by the National Research Foundation of Korea (NRF) grant funded by the Korean Government (MSIT, NRF-2022R1G1A1008344).

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors upon reasonable request.

Conflicts of Interest

The authors declare that they have no conflicts of interest.

References

- Dotoli, M.; Fay, A.; Miśkowicz, M.; Seatzu, C. An overview of current technologies and emerging trends in factory automation. Int. J. Prod. Res. 2019, 57, 5047–5067. [Google Scholar] [CrossRef]

- Gurav, V.S.; Gugnani, A.; Meena, Y.; Marathe, V.; Vijay, S.A.A.; Nanda, S. The Impact of Industrial Automation on the Manufacturing Industry in the Era of Industry 4.0. In Proceedings of the 2024 15th International Conference on Computing Communication and Networking Technologies (ICCCNT), Kamand, India, 24–28 June 2024; pp. 1–6. [Google Scholar]

- Herrmann, F. The smart factory and its risks. Systems 2018, 6, 38. [Google Scholar] [CrossRef]

- Lee, G.-Y.; Kim, M.; Quan, Y.-J.; Kim, M.-S.; Kim, T.J.Y.; Yoon, H.-S.; Min, S.; Kim, D.-H.; Mun, J.-W.; Oh, J.W. Machine health management in smart factory: A review. J. Mech. Sci. Technol. 2018, 32, 987–1009. [Google Scholar] [CrossRef]

- Mabkhot, M.M.; Al-Ahmari, A.M.; Salah, B.; Alkhalefah, H. Requirements of the smart factory system: A survey and perspective. Machines 2018, 6, 23. [Google Scholar] [CrossRef]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The future of productivity and growth in manufacturing industries. Boston Consult. Group 2015, 9, 54–89. [Google Scholar]

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart factory of industry 4.0: Key technologies, application case, and challenges. IEEE Access 2017, 6, 6505–6519. [Google Scholar] [CrossRef]

- Yadav, N.; Gupta, V.; Garg, A. Industrial Automation Through AI-Powered Intelligent Machines—Enabling Real-Time Decision-Making. In Recent Trends in Artificial Intelligence Towards a Smart World: Applications in Industries and Sectors; Springer: Berlin/Heidelberg, Germany, 2024; pp. 145–178. [Google Scholar]

- Qiu, F.; Kumar, A.; Hu, J.; Sharma, P.; Tang, Y.B.; Xiang, Y.X.; Hong, J. A Review on Integrating IoT, IIoT, and Industry 4.0: A Pathway to Smart Manufacturing and Digital Transformation. IET Inf. Secur. 2025, 2025, 9275962. [Google Scholar] [CrossRef]

- Holroyd, C. Technological innovation and building a ‘super smart’ society: Japan’s vision of society 5.0. J. Asian Public Policy 2022, 15, 18–31. [Google Scholar] [CrossRef]

- Lasi, H.; Fettke, P.; Kemper, H.-G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Li, L. China’s manufacturing locus in 2025: With a comparison of “Made-in-China 2025” and “Industry 4.0”. Technol. Forecast. Soc. Chang. 2018, 135, 66–74. [Google Scholar] [CrossRef]

- Li, Y.; He, Y.; Liao, R.; Zheng, X.; Dai, W. Integrated predictive maintenance approach for multistate manufacturing system considering geometric and non-geometric defects of products. Reliab. Eng. Syst. Saf. 2022, 228, 108793. [Google Scholar] [CrossRef]

- Jang, S.; Chung, Y.; Son, H. Are smart manufacturing systems beneficial for all SMEs? Evidence from Korea. Manag. Decis. 2022, 60, 1719–1743. [Google Scholar] [CrossRef]

- Won, J.Y.; Park, M.J. Smart factory adoption in small and medium-sized enterprises: Empirical evidence of manufacturing industry in Korea. Technol. Forecast. Soc. Chang. 2020, 157, 120117. [Google Scholar] [CrossRef]

- Suominen, A.; Toivanen, H.; Seppänen, M. Firms’ knowledge profiles: Mapping patent data with unsupervised learning. Technol. Forecast. Soc. Chang. 2017, 115, 131–142. [Google Scholar] [CrossRef]

- Wang, J.; Hsu, C.-C. A topic-based patent analytics approach for exploring technological trends in smart manufacturing. J. Manuf. Technol. Manag. 2021, 32, 110–135. [Google Scholar] [CrossRef]

- Venugopalan, S.; Rai, V. Topic based classification and pattern identification in patents. Technol. Forecast. Soc. Chang. 2015, 94, 236–250. [Google Scholar] [CrossRef]

- Yun, J.; Geum, Y. Automated classification of patents: A topic modeling approach. Comput. Ind. Eng. 2020, 147, 106636. [Google Scholar]

- Strozzi, F.; Colicchia, C.; Creazza, A.; Noè, C. Literature review on the ‘Smart Factory’ concept using bibliometric tools. Int. J. Prod. Res. 2017, 55, 6572–6591. [Google Scholar]

- Hitomi, K. Automation—Its concept and a short history. Technovation 1994, 14, 121–128. [Google Scholar] [CrossRef]

- Wallén, J. The History of the Industrial Robot; Linköping University Electronic Press: Linköping, Sweden, 2008. [Google Scholar]

- Folgado, F.J.; Calderón, D.; González, I.; Calderón, A.J. Review of Industry 4.0 from the perspective of automation and supervision systems: Definitions, architectures and recent trends. Electronics 2024, 13, 782. [Google Scholar] [CrossRef]

- Kumar, N.; Lee, S.C. Human-machine interface in smart factory: A systematic literature review. Technol. Forecast. Soc. Chang. 2022, 174, 121284. [Google Scholar] [CrossRef]

- Bianchini, A.; Savini, I.; Andreoni, A.; Morolli, M.; Solfrini, V. Manufacturing execution system application within manufacturing small–medium enterprises towards key performance indicators development and their implementation in the production line. Sustainability 2024, 16, 2974. [Google Scholar] [CrossRef]

- Han, X.; Wang, Z.; Xie, M.; He, Y.; Li, Y.; Wang, W. Remaining useful life prediction and predictive maintenance strategies for multi-state manufacturing systems considering functional dependence. Reliab. Eng. Syst. Saf. 2021, 210, 107560. [Google Scholar] [CrossRef]

- Martins, N.; Silva, F.; Campilho, R.; Ferreira, L.P. A novel concept of Bowden cables flexible and full-automated manufacturing process improving quality and productivity. Procedia Manuf. 2020, 51, 438–445. [Google Scholar] [CrossRef]

- Ryalat, M.; ElMoaqet, H.; AlFaouri, M. Design of a smart factory based on cyber-physical systems and Internet of Things towards Industry 4.0. Appl. Sci. 2023, 13, 2156. [Google Scholar] [CrossRef]

- Tseng, Y.-H.; Lin, C.-J.; Lin, Y.-I. Text mining techniques for patent analysis. Inf. Process. Manag. 2007, 43, 1216–1247. [Google Scholar] [CrossRef]

- Gerrish, S.; Blei, D.M. A language-based approach to measuring scholarly impact. In Proceedings of the 27th International Conference on Machine Learning (ICML), Haifa, Israel, 21–24 June 2010; pp. 375–382. [Google Scholar]

- Momeni, A.; Rost, K. Identification and monitoring of possible disruptive technologies by patent-development paths and topic modeling. Technol. Forecast. Soc. Chang. 2016, 104, 16–29. [Google Scholar] [CrossRef]

- Ju, Y.; Sohn, S.Y. Patent-based QFD framework development for identification of emerging technologies and related business models: A case of robot technology in Korea. Technol. Forecast. Soc. Chang. 2015, 94, 44–64. [Google Scholar] [CrossRef]

- Choi, S.; Kim, H.; Yoon, J.; Kim, K.; Lee, J.Y. An SAO-based text-mining approach for technology roadmapping using patent information. RD Manag. 2013, 43, 52–74. [Google Scholar]

- Niemann, H.; Moehrle, M.G.; Frischkorn, J. Use of a new patent text-mining and visualization method for identifying patenting patterns over time: Concept, method and test application. Technol. Forecast. Soc. Chang. 2017, 115, 210–220. [Google Scholar] [CrossRef]

- Yoon, B.; Park, Y. A text-mining-based patent network: Analytical tool for high-technology trend. J. High Technol. Manag. Res. 2004, 15, 37–50. [Google Scholar] [CrossRef]

- Zamora Iribarren, M.; Garay-Rondero, C.L.; Lemus-Aguilar, I.; Peimbert-García, R.E. A Review of Industry 4.0 Assessment Instruments for Digital Transformation. Appl. Sci. 2024, 14, 1693. [Google Scholar] [CrossRef]

- Steyvers, M.; Griffiths, T. Probabilistic topic models. In Handbook of Latent Semantic Analysis; Psychology Press: London, UK, 2007; pp. 439–460. [Google Scholar]

- Chang, J.; Gerrish, S.; Wang, C.; Boyd-Graber, J.; Blei, D. Reading tea leaves: How humans interpret topic models. Adv. Neural Inf. Process. Syst. 2009, 22, 288–296. [Google Scholar]

- Cho, I.; Ju, Y. Text mining method to identify artificial intelligence technologies for the semiconductor industry in Korea. World Pat. Inf. 2023, 74, 102212. [Google Scholar] [CrossRef]

- Petrakis, K.; Georgiou, K.; Mittas, N.; Angelis, L. PatentInspector: An Open-Source Tool for Applied Patent Analysis and Information Extraction. Appl. Sci. 2023, 13, 13147. [Google Scholar] [CrossRef]

- Tong, Z.; Zhang, H. A text mining research based on LDA topic modeling. In Proceedings of the International Conference on Computer Science, Engineering and Information Technology, Vienna, Austria, 21–22 May 2016; pp. 201–210. [Google Scholar]

- Hu, Z.; Fang, S.; Liang, T. Empirical study of constructing a knowledge organization system of patent documents using topic modeling. Scientometrics 2014, 100, 787–799. [Google Scholar] [CrossRef]

- Choi, D.; Song, B. Exploring technological trends in logistics: Topic modeling-based patent analysis. Sustainability 2018, 10, 2810. [Google Scholar] [CrossRef]

- Lee, W.S.; Sohn, S.Y. Identifying emerging trends of financial business method patents. Sustainability 2017, 9, 1670. [Google Scholar] [CrossRef]

- Kwon, K.; Jun, S.; Lee, Y.-J.; Choi, S.; Lee, C. Logistics technology forecasting framework using patent analysis for technology roadmap. Sustainability 2022, 14, 5430. [Google Scholar] [CrossRef]

- Kim, C.; Lee, H. A patent-based approach for the identification of technology-based service opportunities. Comput. Ind. Eng. 2020, 144, 106464. [Google Scholar] [CrossRef]

- Liu, K.; Chang, C. Patent Portfolio Strength Analysis of LiDAR by Patent Map and Linear Regression. J. Multidiscip. Eng. Sci. Technol. 2022, 9, 15156–15165. [Google Scholar]

- Charmanas, K.; Georgiou, K.; Mittas, N.; Angelis, L. Classifying the Main Technology Clusters and Assignees of Home Automation Networks Using Patent Classifications. Computers 2023, 12, 211. [Google Scholar] [CrossRef]

- Khan, S.A.R.; Sheikh, A.A.; Shamsi, I.R.A.; Yu, Z. The Implications of Artificial Intelligence for Small and Medium-Sized Enterprises’ Sustainable Development in the Areas of Blockchain Technology, Supply Chain Resilience, and Closed-Loop Supply Chains. Sustainability 2025, 17, 334. [Google Scholar] [CrossRef]

- Schwaeke, J.; Peters, A.; Kanbach, D.K.; Kraus, S.; Jones, P. The new normal: The status quo of AI adoption in SMEs. J. Small Bus. Manag. 2025, 63, 1297–1331. [Google Scholar] [CrossRef]

- Newman, D.; Lau, J.H.; Grieser, K.; Baldwin, T. Automatic evaluation of topic coherence. In Proceedings of the Human Language Technologies: The 2010 Annual Conference of the North American Chapter of the Association for Computational Linguistics, Los Angeles, CA, USA, 2 June 2010; pp. 100–108. [Google Scholar]

- Stevens, K.; Kegelmeyer, P.; Andrzejewski, D.; Buttler, D. Exploring topic coherence over many models and many topics. In Proceedings of the 2012 Joint Conference on Empirical Methods in Natural Language Processing and Computational Natural Language Learning, Jeju Island, Republic of Korea, 12–14 July 2012; pp. 952–961. [Google Scholar]

- Syed, S.; Spruit, M. Full-text or abstract? examining topic coherence scores using latent dirichlet allocation. In Proceedings of the 2017 IEEE International Conference on Data Science and Advanced Analytics (DSAA), Tokyo, Japan, 19–21 October 2017; pp. 165–174. [Google Scholar]

- Noor-A-Rahim, M.; John, J.; Firyaguna, F.; Sherazi, H.H.R.; Kushch, S.; Vijayan, A.; O’Connell, E.; Pesch, D.; O’Flynn, B.; O’Brien, W. Wireless communications for smart manufacturing and industrial IoT: Existing technologies, 5G and beyond. Sensors 2022, 23, 73. [Google Scholar] [CrossRef]

- Palanikumar, K.; Natarajan, E.; Ponshanmugakumar, A. Application of machine vision technology in manufacturing industries—A study. In Machine Intelligence in Mechanical Engineering; Elsevier: Amsterdam, The Netherlands, 2024; pp. 91–122. [Google Scholar]

- Erdei, T.I.; Kapusi, T.P.; Hajdu, A.; Husi, G. Image-to-Image Translation-Based Deep Learning Application for Object Identification in Industrial Robot Systems. Robotics 2024, 13, 88. [Google Scholar] [CrossRef]

- Amiri, P.; Müller, M.; Southgate, M.; Theodoridis, T.; Wei, G.; Richards-Brown, M.; Holderbaum, W. A Statistical Analysis of Commercial Articulated Industrial Robots and Cobots. J. Manuf. Mater. Process. 2024, 8, 216. [Google Scholar] [CrossRef]

- Mittal, S.; Negi, N.; Chauhan, R. Integration of edge computing with cloud computing. In Proceedings of the 2017 International Conference on Emerging Trends in Computing and Communication Technologies (ICETCCT), Dehradun, India, 17–18 November 2017; pp. 1–6. [Google Scholar]

- Silva, D.; Carvalho, L.I.; Soares, J.; Sofia, R.C. A performance analysis of internet of things networking protocols: Evaluating MQTT, CoAP, OPC UA. Appl. Sci. 2021, 11, 4879. [Google Scholar] [CrossRef]

- Aggour, K.S.; Gupta, V.K.; Ruscitto, D.; Ajdelsztajn, L.; Bian, X.; Brosnan, K.H.; Chennimalai Kumar, N.; Dheeradhada, V.; Hanlon, T.; Iyer, N.; et al. Artificial intelligence/machine learning in manufacturing and inspection: A GE perspective. MRS Bull. 2019, 44, 545–558. [Google Scholar] [CrossRef]

- Kim, J.; Ko, J.; Choi, H.; Kim, H. Printed circuit board defect detection using deep learning via a skip-connected convolutional autoencoder. Sensors 2021, 21, 4968. [Google Scholar] [CrossRef]

- Yani, Z.; Maobin, T. Simulation of DCS control system for dimethyl ether plant. In Proceedings of the 2017 IEEE International Conference on Computational Science and Engineering (CSE) and IEEE International Conference on Embedded and Ubiquitous Computing (EUC), Guangzhou, China, 21–24 July 2017; pp. 58–62. [Google Scholar]

- Liu, Z.; Wang, X.; Feng, J. Firm-specific patent recommendation using topology-based link prediction and SAO embedding method. IEEE Trans. Eng. Manag. 2025, 72, 2097–2115. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Y.; Feng, J. Identifying supply chain R&D partners via multilayer institutional cooperation network and tailored link prediction. Comput. Ind. Eng. 2025, 201, 110887. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).