Abstract

The digital transformation of port infrastructure is a key element in the evolution towards Smart Ports and Industry 4.0. This paper presents an optimized port asset management system based on Digital Twin technology and BIM/GIS integration, aiming to enhance efficiency, sustainability, and decision-making in port operations. The proposed system leverages real-time data acquisition, predictive maintenance, and resource optimization, addressing critical challenges in port asset lifecycle management. By integrating Digital Twin models with Internet of Things (IoT) sensors, cloud computing, and machine learning algorithms, this approach enables data-driven decision-making, which improves operational performance and minimizes costs. The Frankenstein Strategy is introduced as an innovative methodology for port digitalization, allowing incremental integration of digital twins into existing infrastructures. The results demonstrate that this system provides enhanced asset monitoring, optimized maintenance planning, and increased operational resilience, contributing to the automation and optimization of production processes in Industry 4.0. This research highlights the potential of Digital Twin technology to revolutionize port asset management, establishing a framework for smart, data-driven, and sustainable port operations.

1. Introduction

Industry 4.0 refers to the fourth industrial revolution, characterized by the integration of advanced digital technologies such as the Internet of Things (IoT), Artificial Intelligence (AI), cloud computing, and cyber-physical systems to optimize industrial processes [1]. This digital transformation enhances automation, real-time data processing, and intelligent decision-making in production environments, including port operations. Industry 4.0 is driving the digital transformation of production systems, integrating advanced technologies to optimize efficiency, cost reduction, and sustainability. In the port sector, asset management remains a challenge, requiring innovative solutions for predictive maintenance, process optimization, and real-time decision-making. This research presents a novel approach to optimize port operations using Digital Twin and BIM/GIS methodologies, integrating Industry 4.0 concepts such as IoT, big data, and artificial intelligence [1].

The developed world in the twenty-first century is constantly changing and evolving. This is a consequence of digital evolution. The port sector is actively transitioning towards digitalization. The transversal digital transformation of all its services triggers an improvement in resource dedication, process optimization, reduction of operational risks of failure, etc. [2]. This generates a new way of working to which the same sector has to adapt such as new jobs, training for the organization, acquisition of new equipment [3].

In the case of Spain, the Port Authorities (Spanish Port Authorities (SPAs)) have to define their own Digital Implementation and Adaptation Road Map. This is reflected in numerous initiatives that are valued year after year. This digital change has become a reality and is here to stay. The Government of Spain is committed to development linked to digitalization for the achievement of Smart Cities, Industry 4.0, and the concept of Smart Port [4]. In Spain, the transition towards Industry 4.0 in port management has been supported by initiatives such as the Ports 4.0 program, which promotes the adoption of smart technologies in logistics–port operations. According to Puertos del Estado (2023), more than 60% of Spanish Port Authorities (Spanish Port Authorities (SPAs)) are in the process of implementing digital asset management strategies using BIM and GIS. Furthermore, studies such as [5] (2020) indicate that the digitalization of Spanish ports has led to a 15% increase in operational efficiency and a 10% reduction in maintenance costs over the past five years [5].

This research is aligned with current organizational needs and in turn highlights the value of the ‘Ports 4.0’ program, since it highlights and shares the same objectives [5]. From port technology and digitalization, external factors are born that determine the need for Public Administrations to work with certain pre-established work methodologies.

Both Spain and the European Union promote the modernization of engineering practices through the implementation of digitalization strategies. This commitment is reflected in the development of specific regulations that establish mandatory requirements for infrastructure projects and service tenders, ensuring the adoption of innovative technologies such as BIM and GIS in public procurement processes [5].

Since 2018, Puertos del Estado has been directly monitoring initiatives for the improvement of port infrastructures. The need to identify policies and asset management models that were not implemented in the system that required covering all phases of the asset life cycle was identified, with special interest in preventive demands for maintenance and maintenance that was not part of previous models [6].

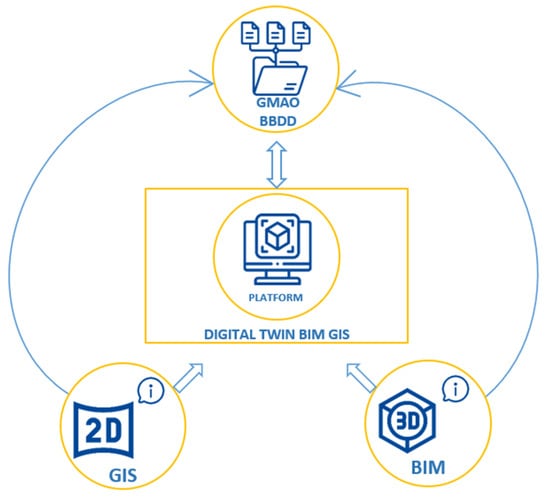

Once these precedents were set many of them were imposed; what this work seeks to achieve is to be able to add value to the newly imposed methodologies of BIM and GIS and provide continuity to these requirements (as-built 2D/3D) by providing digital tools to improve the management of the ports. In other words, what is sought is to be able to use the BIM and GIS methodology as a basis to implement a new form of asset management and build a twin system as a result of these BIM/GIS deliverables to implement such a new asset management system. See Figure 1 for the list of phases and activities that are taken into account in this work with respect to BIM and GIS.

Figure 1.

BIM/GIS relationship. Source: own elaboration.

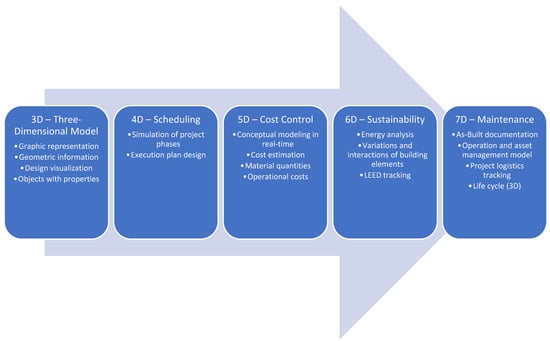

Port assets go through different phases within their life cycle. Administrations that implement BIM and/or GIS methodologies focus only on the design and construction phase; what happens once the works are received and the BIM and GIS models are obtained? Do we keep them on a pen drive and put them in a closet? These are the driving questions of this work. The following Figure 2 shows the different BIM dimensions. This work focuses on 7D.

Figure 2.

BIM dimensions. Source: own elaboration.

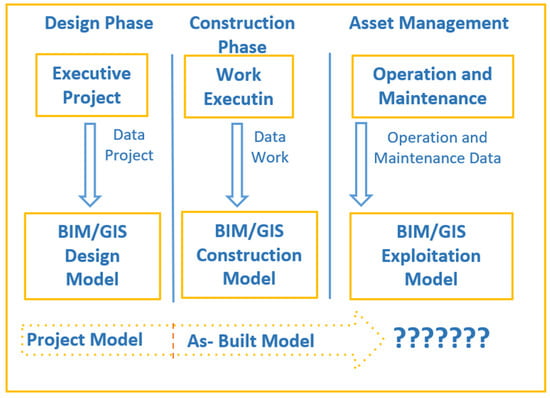

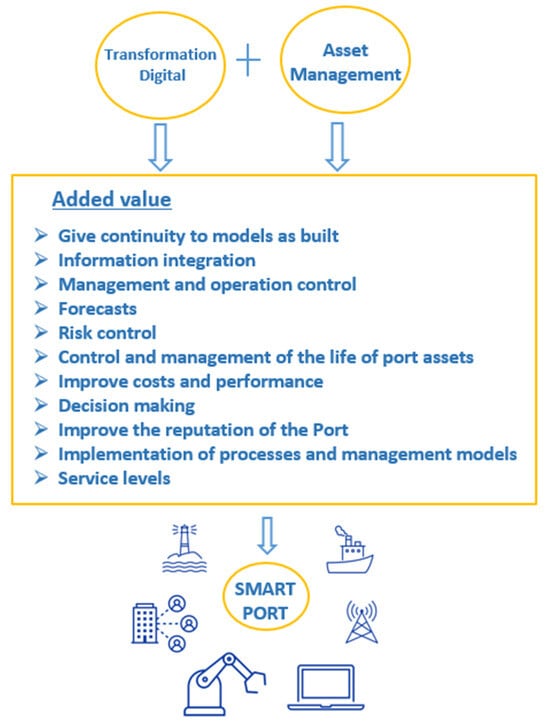

Another reason why we decided to carry out this research is the intention to implement an asset management system that is capable of optimizing resources, improving services, avoiding the risks of system failure by increasing costs, etc. (Figure 3).

Figure 3.

Scheme asset management system. Source: own elaboration.

This research aligns with the principles of Industry 4.0 by focusing on the optimization of port asset management through digitalization. The proposed Digital Twin framework enhances the efficiency of production processes by enabling real-time monitoring, predictive maintenance, and optimized decision-making. By leveraging BIM/GIS integration, the system improves resource allocation, reduces maintenance costs, and enhances operational reliability [7].

The implementation of Digital Twin technology in port asset management not only enhances operational efficiency but also contributes to sustainability objectives [8]. By optimizing predictive maintenance and resource allocation, the system minimizes energy consumption, extends asset lifespan, and reduces operational costs, aligning with global sustainability goals such as the UN’s Agenda 2030.

Digital Twin technology has been successfully implemented in Smart Factories to optimize production and maintenance processes [9]. This research extends this concept to the port industry, demonstrating how similar optimization techniques can enhance port efficiency, predictive maintenance, and process automation in an Industry 4.0 framework.

This paper thoroughly examines and delves into the technological and innovation sector within the port sector to X-ray the state of technological maturity in the port sector, approaches and vision of the Ports 4.0 revolution, and the maturity of the Spanish Port Authorities (SPAs).

This study focuses on the optimization of port asset management in Spanish ports, leveraging Digital Twin technology and BIM/GIS integration to enhance efficiency, sustainability, and decision-making. The proposed system aligns with Spain’s digital transformation policies, including the Ports 4.0 program, and aims to provide a replicable model for other port authorities worldwide.

This study contributes to the academic discourse by proposing a structured and scalable framework for integrating Digital Twin technology into port asset management. Unlike previous works that focus solely on the visualization and modeling capabilities of BIM and GIS, this research presents a methodological approach that incorporates predictive analytics, real-time monitoring, and strategic decision-making within a single asset management system. The novelty of this work lies in its ability to bridge the gap between theoretical asset management models and their practical implementation in dynamic port environments.

2. State-of-the-Art

2.1. Introduction: Industry 4.0 and Its Impact on Port Optimization and Smart Ports

Industry 4.0 is revolutionizing industrial operations by integrating advanced technologies such as Artificial Intelligence (AI), Internet of Things (IoT), and Digital Twin models. These innovations enable the optimization of production processes, predictive maintenance, and real-time decision-making. The port sector, as a crucial link in the global supply chain, is undergoing a transformation towards Smart Ports that leverage data-driven asset management for increased efficiency, reduced operational costs, and sustainability [10].

The ‘Ports 4.0’ capital fund is the corporate open innovation model adopted by Puertos del Estado and the Spanish Port Authorities to attract, support and facilitate the application of talent and entrepreneurship to the Spanish public and private logistic–port systems in the context of the fourth industrial revolution [11].

The main objective of Ports 4.0 is to actively promote and incorporate disruptive or incremental innovation as an element of competitiveness, efficiency, sustainability, safety and protection in the Spanish logistics–port sector, both public and private, to facilitate its transition towards the 4.0 economy [11].

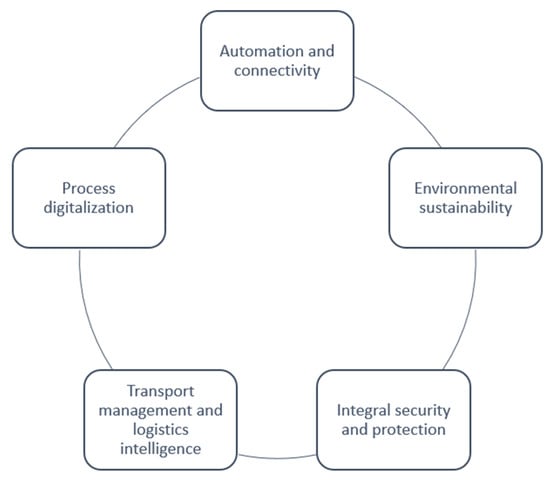

Smart Ports represent the next generation of port infrastructure, acting as key drivers and enablers of the transition towards the Industry 4.0 economy. They serve as innovation hubs, enhancing efficiency, safety, and sustainability within the logistics and maritime sectors. Note that the first line of change, see Figure 4, highlights the relationship of digitalization, automation, decarbonization, connectivity, monitoring or artificial intelligence in transport and logistics management [5].

Figure 4.

Smart Ports. Source: own elaboration.

Smart Ports are emerging as a response to the increasing demand for efficiency, automation, and sustainability in the logistics and maritime industry. Ports 4.0 is an example of an initiative that promotes the integration of cutting-edge technologies such as IoT, big data, and AI into port operations [5]. The transition towards Smart Ports is driven by the need to optimize operational workflows, enhance security, and reduce environmental impact. This evolution highlights the role of automation, decarbonization, and real-time monitoring as essential elements of modern port infrastructure.

2.2. Industry 4.0 and Smart Port Digitalization

Industry 4.0 is transforming global logistics by incorporating IoT, AI, and big data analytics into supply chain management [12]. Research by [13,14] emphasizes the shift from traditional infrastructure management to intelligent, interconnected systems, where predictive maintenance and automated decision-making reduce downtime and operational costs [15].

In ports, these advancements support the transition to Smart Ports, characterized by real-time traffic optimization, environmental sustainability, and enhanced operational resilience. The papers [16,17] investigated the impact of IoT and AI-driven asset tracking in port operations, demonstrating a 15% increase in efficiency and a 10% reduction in maintenance costs. This aligns with the objectives of the present research, which aims to establish a scalable, data-driven port management strategy [18].

2.3. Digital Twin and Its Application in Port Optimization

Digital twins are a virtual representation of objects or systems throughout their lifecycle designed to accurately reflect and provide vital information from the different areas of functionality of the twins [19]. They present information on different aspects at the physical level, such as performance, technical characteristics, historical characteristics, services, etc. These data give us the information to carry out simulations, analysis of improvements, creation or increase business value, and above all to have technical support for decision making [20].

Digital twins are used in many distinct types of industries with different objectives. They are used to carry out simulations to test hypotheses and observe how these models respond, to know the result that a decision on real assets will have consequences, risks involved, time of inactivity involved, etc. (Figure 5) [21].

Figure 5.

Added value of digital twins. Source: own elaboration.

Another function of the digital twins is the application of IOT to make predictions to avoid reaching fault service states and their new commissioning, reduce costs in corrections, and offer a greater understanding of the possible operational risks of the system [22].

In short, virtual gems make it possible to see the process as a series of interconnected elements dependent on each other. In addition, problems that are detected early can be corrected more quickly and allow for greater experimentation. Development times and production costs are reduced, while innovation accelerates. Virtual twins make us more efficient and sustainable, resulting in more and better designs [23].

This study is focused on managing port assets through digital twins. The only reference to this type of management is found in the BIM Guide of the State-owned Port System (2019) but this focuses only on the management of the maintenance of a specific project. It does not present any methodology to try to work in a preventive environment (see Figure 5—Cost Relationship and Maintenance Model). Thus, due to this lack of knowledge and management model in Spain, an analysis is made on mature institutions that have implemented management systems for many years with the aim of finding an approach that fits with this work.

Depending on the sector in which we are speaking, the definition of asset management can vary, yielding several approaches ranging from the relationship of investment management and finance, as well as the management of physical assets in an environment of engineering and economics [24]. ISO 55000 develops a clear definition for asset management: “the coordinated activity of an organization to derive value from assets”, and as in [25]:

- An asset is an “item, object or entity that has actual or potential value to an organization”;

- The definition of asset management states that: “the realization of value will generally involve a balance of costs, risks, opportunities and performance benefits; and the term ’activity’ has a broad meaning and may include, for example, approach, planning, plans, and implementation”.

Asset management is more than doing things for assets, it is about using assets to obtain value and achieve the business objectives of the organization; it also offers a different approach, a way of thinking and a transformation of organizational alignment and culture [26]. Each organization must determine what the value is and choose how to manage its assets for the best total value. Asset management is relevant to all types of organizations, whether large, small, private, public, governmental, or not-for-profit. There is growing evidence in the world that effective asset management can improve an organization’s reputation and ability to [27]:

- Operate safely;

- Comply with its regulatory and regulatory obligations;

- Evaluate future business strategies for the realization of different profiles of performance, cost and tolerable risk.

Significantly reduce the cost of managing assets during their life.

Regulation 2.4.2. of ISO 55000 [28] states that asset management is based on four fundamentals: value, food, leadership and assurance; in addition, two characteristics of asset management that differentiate it from other disciplines and management systems are its approach to the entire life cycle of the asset and its approach to decision making [25].

For many organizations, asset management is the next frontier in value generation and risk reduction. This asset management model is a new organizational policy. Within the organization, it impacts from organizational objectives/strategic plans to the corresponding activities of the asset life cycle. So that this can be carried out, everything starts and turns in the information of the assets [29].

No business can plan, structure, manage, decide, evaluate or estimate resources for its operation without knowing the volume of assets, value, status, service levels, history of failures, repairs, costs, etc. No organizational policy can be established or be accountable to customers [30].

The basis of good asset management is to have a deep knowledge of them, turning them into information; graphic data (digital twin) and technical data of the asset is transformed into added value [31]. This is the first step for the organization to define objectives and a corporate strategy, the form of management, and the operational, exploitation and management of assets. For this to happen, as stated above, we have to know our assets, without this, we cannot size corporate resources nor the level of risk tolerance or make decisions that affect the organization [32].

Clause 2.2 of ISO 55000 states that benefits may include but may not be limited to the following [33]:

- Improved financial performance;

- Informed decisions in asset investment;

- Risk management;

- Improved services and products;

- Proven social responsibility;

- Demonstrated compliance;

- Improved reputation;

- Improved organizational sustainability;

- Improved efficiency and effectiveness.

Some benefits can be directly assessed and quantified, for example, the reduction in capital and maintenance costs, the increase in the availability of assets and the reduction of risk exposure. Other benefits can be much harder to measure, such as reputation and customer satisfaction. Also, while many benefits are realized in the short term, cost savings over the entire life of the asset may not occur for several years [34].

The traditional economic case for asset management has focused on cost savings through the optimization of operations and maintenance costs, along with improved productivity through increased reliability and availability.

These are important benefits, but there are many other potential elements that may be equally or more important such as the following [35]:

- Effective management of value, risk and obligations is also part of a standard economic justification;

- Effective asset management improves processes;

- Assets contribute to the reputation and image of the organization;

- Asset management allows for some help in standardization;

- Improved understanding of asset performance through improved data and analytics;

- Analysis of the definition of CAPEX and OPEX allocations;

- Service levels;

- Return on Investment (ROI) or Return on Net Assets (RONA);

- The expected profitability, the loss account and the cash flow statement.

The development of this study is based on fundamental technical principles and key contextual factors as previously described. The implementation of this port work ecosystem requires that the Spanish Port Authorities (SPAs) be at least involved in the implementation phase and work with BIM and GIS methodologies.

2.4. Predictive Maintenance Based on AI and Machine Learning

Predictive maintenance is a crucial component of Industry 4.0, leveraging Artificial Intelligence (AI) and Machine Learning (ML) to anticipate failures before they occur. By analyzing real-time data from IoT sensors, historical performance records, and operational conditions, AI-driven predictive models can identify patterns and anomalies that signal potential breakdowns. This proactive approach minimizes unexpected downtime, extends the lifespan of assets, and reduces maintenance costs. Unlike traditional preventive maintenance, which follows fixed schedules, predictive maintenance adapts dynamically to the actual condition of equipment, ensuring more efficient resource allocation and improved operational reliability [36].

In the port industry, integrating AI-powered predictive maintenance into Digital Twin models enhances real-time monitoring and decision-making. By simulating potential failure scenarios and predicting asset degradation, ports can schedule maintenance activities only when necessary, optimizing logistics and minimizing disruptions. Additionally, ML algorithms can continuously learn and improve their predictions, increasing accuracy over time. This approach not only reduces the risk of costly repairs but also supports sustainability goals by reducing waste, energy consumption, and unnecessary component replacements [37].

2.5. Data-Driven Optimization and Simulation for Decision-Making

Industry 4.0 is transforming decision-making processes through data-driven optimization and simulation techniques, enabling organizations to make informed choices based on real-time insights. By leveraging big data analytics, machine learning models, and Digital Twin simulations, businesses can analyze complex operational scenarios, predict outcomes, and test strategies before implementation. These technologies help optimize supply chain logistics, resource allocation, and production workflows, improving efficiency and reducing costs. Simulation tools also allow stakeholders to evaluate the impact of different variables in a controlled digital environment, minimizing risks and maximizing operational effectiveness [37].

In the context of Smart Ports, data-driven decision-making enhances asset management, cargo handling, and energy consumption efficiency. Digital Twin models, integrated with real-time sensor data, enable predictive analytics for demand forecasting, traffic flow optimization, and port infrastructure resilience. By simulating alternative operational strategies, port authorities can anticipate bottlenecks, optimize scheduling, and improve throughput capacity. This integration of data intelligence, AI, and simulation ultimately leads to more agile, responsive, and sustainable port operations, aligning with the broader goals of Industry 4.0 [6].

Despite significant advances in Industry 4.0 and the increasing adoption of Digital Twin, BIM, and GIS technologies in port infrastructure management, there remains a critical gap in their integration and practical application beyond the design and construction phases. Current implementations primarily focus on static digital models, without leveraging real-time data analytics, AI-driven predictive maintenance, and dynamic asset optimization. Moreover, there is a lack of a standardized methodology for the continuous exploitation of digital twins post-construction, leading to fragmented management strategies and underutilized digital assets.

This research aims to bridge this gap by proposing a comprehensive asset management system that integrates Digital Twin technology with AI, IoT, and machine learning to enhance real-time decision-making, predictive maintenance, and lifecycle optimization of port assets. The proposed Frankenstein Strategy introduces a scalable approach to gradually integrating digital twins into existing infrastructure while ensuring long-term data continuity and operational efficiency. This work contributes to the development of Smart Ports by offering a data-driven, intelligent, and sustainable framework for port asset management in the context of Industry 4.0.

2.6. Challenges and Research Gaps

Despite the growing adoption of Digital Twin and BIM/GIS methodologies, several challenges persist. The paper of [38] highlights the lack of interoperability between legacy systems and modern digital platforms, while [39] stresses the need for standardized protocols to ensure seamless data integration. Moreover, the fragmented approach to port asset digitalization often results in underutilized datasets and inefficient maintenance strategies [40].

This study aims to address these gaps by proposing a comprehensive asset management framework based on the Frankenstein Strategy, allowing incremental Digital Twin integration in Spanish ports. The proposed model builds upon existing research by providing a scalable and cost-effective solution for long-term infrastructure optimization.

3. Methodology

This study aims to develop and validate an optimized port asset management system integrating Digital Twin technology, BIM/GIS, and IoT, with a specific focus on Spanish ports. The proposed framework enhances predictive maintenance, data-driven decision-making, and real-time asset monitoring, contributing to the transformation toward Smart Ports within the Industry 4.0 framework.

The optimization objectives of this research include enhancing predictive maintenance accuracy, improving asset lifecycle assessment, and streamlining decision-making processes through real-time data analytics. To achieve these objectives, this study employs BIM/GIS-based data integration, AI-driven failure prediction models, and IoT-enabled monitoring tools, ensuring a comprehensive and scalable approach to asset management in port environments.

This work proposes a port asset management system based on the exploitation of a 2D and 3D digital twin developed from the BIM and GIS projects that the SPANISH PORT AUTHORITIES (SPAs) are forced to incorporate into their tenders.

Added value is provided to the product required by specifications by simulating all port assets. It is a plus with respect to traditional CAD and Excel solutions since they lack associated information and interoperability between different databases and systems.

Thus, it is claimed that this management system revolves around the main component of both alphanumeric and graphical information.

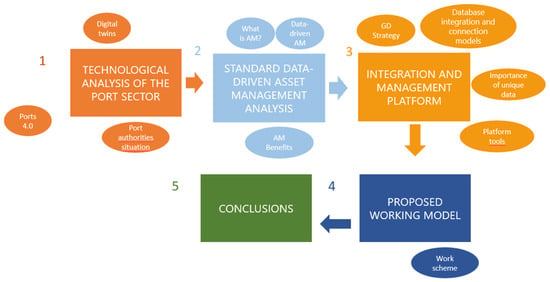

The following phases are presented in Figure 6:

Figure 6.

Phases of the methodology. Source: own elaboration.

To ensure the reliability of the AI and Machine Learning models integrated into the asset management system, this study follows a structured approach consisting of data preprocessing, model training, validation, and continuous improvement. Historical maintenance records, sensor data from IoT devices, and environmental variables are used to train predictive models based on supervised learning techniques. Model performance is evaluated using standard metrics such as Mean Absolute Error (MAE), Root Mean Squared Error (RMSE), and accuracy rates, ensuring that only validated models are deployed for decision-making in port operations.

Within this flowchart, two stages are identified that are composed of four phases:

Phase 1: State of technology in the port sector.

It is essential to analyze the current state of the technology market, know what kind of technology the port industry consumes, and understand what benefits they provide. This phase is fundamental as it will help identify the most successful technological tools to carry out this work under the premises of BIM and GIS methodologies that are imposed by regulations.

This radiographic will serve as technical support on how to approach this work. Here, reference is made to the analysis of the importance of the PoE commitment to technology, see Ports 4.0, which analyzes the benefits and functionalities of digital twins.

Phase 2: A current vision of how the asset management model is applied in the Spanish port sector and what the strengths and options are that can be implemented from other international asset management systems (see Section 3 and Section 4).

Phase 3: Proposal phase of definition of the integration and management platform

In this phase, the development and connection strategy of the proposed platform is defined to work based on the digital twins of each port.

- The evolution strategy of the digital twin “Frankenstein” is proposed in order to integrate the digital twin within the work system;

- The integration and work connection scheme of the platform is defined so that it is interoperable with BIM/GIS and CMMS;

- A set of functionalities to be granted to the platform are identified and proposed so that it can be exploited intelligently, and optimal asset management can be made.

Phase 4: Proposal phase of defining the work model or that adds value to this work.

The Frankenstein Strategy was chosen over other digital twin implementation approaches due to its flexibility and incremental integration capability. Unlike full-scale digital twin deployment, which requires extensive upfront investment, this method allows for a progressive adaptation to existing infrastructure, reducing initial costs and operational disruption. Alternative strategies, such as the direct adoption of pre-modeled digital twins, often fail to account for legacy infrastructure, making the Frankenstein Strategy more suitable for Spanish ports.

4. Results and Discussion

The scheme of the work system is defined, which includes the integration of the new BIM and GIS models into the system, the management of existing assets that are part of the CMMS database, the critical activities of auditing, stakeholders that are part of the system of the SPANISH PORT AUTHORITIES (SPAs), and the relationship of the functionalities of the platform and the vision of asset management. The core of this scheme is the work platform.

4.1. Phase 1: Analysis of Technology in the Port Sector

This section analyzes the maturity of the port system, State Ports (PoE) and Public Administrations in terms of digital maturity. In addition, separately the Spanish Port Authorities (SPAs) are analyzed in terms of implementation of BIM methodologies. This analysis is essential to address the working model to be proposed in the document.

Below is a SWOT matrix of the Port System Maturity Analysis, State Ports (PoE) and Spanish Port Authorities (SPAs) (see Table 1) Reconstruction of market borders.

Table 1.

SWOT analysis of port system maturity, Puertos del Estado (PdE), and Public Administrations (Spanish Port Authorities (SPAs)).

Table 1 SWOT analysis: Analysis of the maturity of the port system, State Ports (PoE) and Public Administrations. Source: own source.

To know the relationship of and its level of BIM implementation, an analysis of the Public Administrations in terms of implementation of BIM methodologies is carried out (see Table 2).

Table 2.

Analysis of BIM GIS implementation level in Spanish Port Authorities (SPAs).

Note that the analysis has identified seven Spanish Port Authorities (SPAs) that are in an advanced state of maturity in terms of BIM implementation and digital twins.

- Barcelona, Bilbao, Balearic Islands, Cartagena, Málaga, Tenerife and Valencia.

4.2. Phase 2: Asset Management

This section is developed at the point of state of knowledge. It can be summarized as:

The coordinated activity of an organization to derive value from assets (ISO 55000).

The implementation of Digital Twin technology in port asset management represents a shift from traditional, reactive strategies to a proactive, data-driven approach. Traditional asset management methods often rely on fixed maintenance schedules, fragmented data sources, and high operational costs, limiting their adaptability and scalability. In contrast, Digital Twin-based management integrates real-time data analytics, AI-driven predictive maintenance, and centralized information systems, optimizing both operational efficiency and sustainability. The following table provides a comparative analysis of these two approaches, highlighting key differences in cost efficiency, real-time adaptability, data integration, predictive maintenance, scalability, and sustainability impact (Table 3).

Table 3.

Comparative: traditional vs. digital twin-based asset management.

An asset is an “item, object, or entity that has actual or potential value to an organization”.

Here are some key benefits of asset management [41]:

- Maximizing the useful life of assets: Asset management allows companies to maximize the useful life of their assets through timely and scheduled maintenance. This reduces the need to replace assets frequently, which in turn reduces costs and increases profitability;

- Improving Asset Performance: Asset management helps companies identify the underlying causes of asset performance problems. By addressing these issues, companies can improve the performance of their assets, which translates into greater efficiency and productivity;

- Reduced operating costs: Asset management helps companies reduce their operating costs by minimizing downtime and maintenance costs. By maximizing the useful life of assets, companies also reduce the need to replace assets frequently, which in turn reduces long-term costs;

- Improved decision-making: Asset management provides companies with valuable information about the performance of their assets. By using this information, companies can make more informed decisions about buying, maintaining and retiring assets;

- Regulatory compliance: Asset management helps companies comply with applicable rules and regulations. By keeping a record of assets and their maintenance histories, companies can demonstrate that they comply with legal and regulatory requirements.

In short, asset management can help companies maximize the useful life of their assets, improve their performance, reduce operating costs, make more informed decisions, and comply with applicable rules and regulations.

4.3. Phase 3: Development of the Integration and Management Platform

This research tries to establish a WEB space “platform” to centralize the 2D/3D digital twins and the information of the assets allowing them to be exploited and managed intelligently obtaining an improvement in yields, analysis of failure forecasts (thus avoiding supply cuts, production, etc.), real and accounting value, depreciation, and technical supports for decision making the maximum benefit.

4.3.1. Phase 3.1 Digital Twin Strategy

This work proposes a constant evolution of digital support due to the continuous changes in work and services that ports suffer.

So that the strategy of the digital twin work can be developed in the future, several minimum requirements are raised to take into account:

- Ports often have a large area of public domain;

- The high cost and time to develop a 3D digital model with a LOD 400;

- Short-term functionality and operability;

- Risk of using base information for development with little precision (inventories and cartography).

Due to all this, a logical work strategy is proposed that guarantees the operability of the system from the beginning and allows for high flexibility to incorporate and modify areas where large amounts of assets are experienced significantly. Thus the “Frankenstein Strategy” was born.

This strategy is based on developing for BIM a 3D digital twin with a very basic LOD; LOD 100. This twin will be quick to build and functional to be able to connect with the CMMS and with the GIS digital model.

Once this basic model has been developed, numerous works, projects, services, facilities, networks, etc. They will be discharged, replaced or modified. When these variations with respect to the base model LOD 100 occur, the as-builts from these projects will have to be received and validated by the SPANISH PORT AUTHORITY (SPA). Once this happens, the area of the new model is ready to be replaced in the base model, creating a Frankenstein strategy. The strategy is that the SPANISH PORT AUTHORITY (SPA), according to its investment plan, can define areas to be modified and potentially unmodified areas. The Public Administration should focus on spending resources on modifying the unforeseen areas of modification since the planned modification areas will be incorporated into the basic model in the short and medium term.

Below is an example of this strategy in a private port.

Initial port

Example of an initial port state, see Figure 7.

Figure 7.

Initial port. Source: Google Maps.

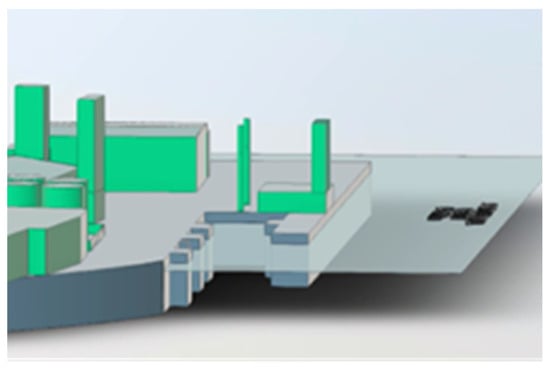

Basic Port Modeling ready to be integrated into the platform and be operational and functional.

For an example of a basic model in the same area, see Figure 8.

Figure 8.

Example of actions for investment plan. Source: own elaboration.

Identified areas subject to modification by the IPA’s investment plan.

An example of an investment plan in the same initial zone is shown in Figure 9.

Figure 9.

Example of action of investment plan. Source: Google Maps.

- Blue: Docking dock refurbishment;

- Red: Rehabilitation of the SPANISH PORT AUTHORITY (SPA) commercial building;

- Pink: New system of surface drainage and paving of the road.

In these three areas, the SPANISH PORT AUTHORITY (SPA) should not spend resources on modeling because, by law, the tenders of these projects must be through the BIM methodology and will bring their own 3D model.

High LOD modeling port.

Next, we see an example in Figure 10 of the same area as the digital twin after applying the Frankenstein strategy.

Figure 10.

Digital twin. Source: own elaboration.

Regarding the GIS model, the strategy is simpler. It is assumed that the Public Administrations have a consistent inventory and have updated and highly accurate CAD base drawings.

With this information, it is digitized using any free software and SHP files are created.

These SHP files are published via postgis/geoserver to the integration web platform.

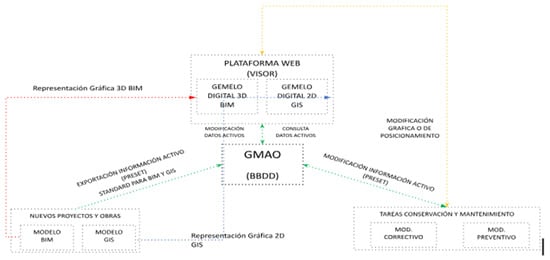

4.3.2. Phase 3.2. Integration of Models and Databases

This work is approached from the point of view of a global scheme.

This work does not include the design and development of computer science, programming languages, codes, etc., since they would be very specific and personalized activities for each SPANISH PORT AUTHORITY (SPA).

That said, this chapter proposes where the 3D BIM graphic information, the 2D GIS graphic information and the data information of the asset are housed being managed through the CMMS software of the SPANISH PORT AUTHORITY (SPA). In addition, this work defines how these models are understood and how they connect with the CMMS database.

Accommodation:

- DIGITAL TWIN 3D BIM(Only the Graphic Part): BBDD CLOUD BIM

- Digital Twin 2D GIS(Only the Graphic part): BBDD GIS //POSTGIS//GEOSERVER

- PSET standards for both twins (data information, “Technical characteristics”): CMMS database

Connection: through calls through a unique Asset Code.

The proposed system is designed to be scalable and adaptable to different Port Authorities (PAs) by incorporating a modular integration strategy. Ports with higher digital maturity can fully implement the Digital Twin framework, while ports with limited digital infrastructure can adopt a phased approach, starting with basic BIM/GIS visualization and gradually integrating AI-driven predictive maintenance. The system’s architecture allows for custom API connections with existing databases, ensuring compatibility with various legacy asset management platforms.

The core of this work is to obtain that from any 2D or 3D digital twin, when selecting any asset the information that the web platform offers is the one that is hosted in the database of the CMMS; the scheme of connection operation is the one shown in Figure 11 (integration scheme).

Figure 11.

Integration scheme. Source: Own source.

The benefit that this approach guarantees is that there is only one unique asset with its unique information and two sources of representation. The option of duplication of information on two different platforms is avoided since the data are separated from the models as built and integrated into the CMMS database and the data are modified as a result of conservation and maintenance activities on the database through the web platform. On the one hand, centralizing, absorbing and integrating all the works that are received into a DB is achieved and on the other hand, each activity that is carried out on that particular asset is centralized, creating history and updates. This is the basis where value is achieved: the creation of the data and the exploitation of the data that is obliged to be developed by the regulations mentioned above.

Continuing with the introduction on the importance of the single data and the unique asset code that is made in the previous point, it is described below how the understanding between the different systems is raised and what is the point of union to be able to exploited so as to manage port assets intelligently.

The link is the unique asset code. Regardless of the system you are working on, each element (active) either in 3D or 2D, has a unique code. This code is used so that the call that is made between systems shows the database information of that unique code. This DB, as mentioned above, lives in the CMMS.

To complete the ecosystem by assembling this paper, a series of minimum digital functionalities are proposed for the integration platform that guarantees the capacity of exploitation, operation and management of both graphic and alphanumeric data hosted in BIM-GIS-BBDD CMMS.

Thus, the digital functionalities to be achieved in the integration platform are the following:

- Business intelligence. Bulk queries with N variables combined (technical data of the asset, positioning, costs, historical corrective PDS, historical preventive PDS, zones, contracts and time);

- Dashboard for decision-making;

- Data visualization and connected devices;

- Extracting information from queries;

- Extracting inventory by delimiting a polygon on GIS;

- Consultation of plans in as-built information;

- Consultation of administrative information;

- Field check using a data validation WEB form (tablet support);

- Exporting a delimited area in BIM to IFC;

- Exporting a delimited area in GIS to SHP;

- Geometric check against point cloud;

- Connecting with cameras;

- Preventive maintenance management in the field, highlighting assets on the platform (tablet support);

- Management corrective maintenance in the field highlighting assets on the platform. (tablet support).

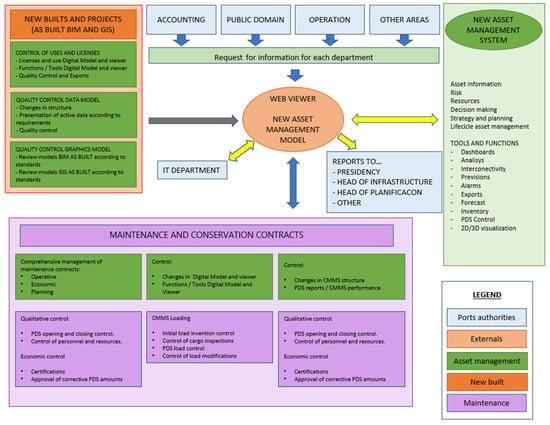

4.4. Phase 4: Work Model “Integration Platform—Asset Management for an Spanish Port Authority (SPA)”

The proposed scheme of Work Model, see Figure 12, demonstrates the process and the way of working in the scenario where the projects are received in BIM/GIS and in the scenario where the different port assets in the maintenance phase are modified (exploited and operated). This process describes the following:

Figure 12.

Proposed working model. Source: own source.

- The corresponding activities in each scenario to be able to integrate into the platform;

- Stakeholders;

- Platform features and tools.

This working model is governed by the integration conditions described in Figure 11 (schema of integration of this work).

With this work model and the digital functionalities in the previous section, it is guaranteed to be able to implement the management of assets in an intelligent way, enabling the implementation of the following:

- Have truthful, updated and centralized information (graphic and alphanumeric) of all the assets of the Ports Authorities. Thus, achieving optimal asset management of data information;

- Be able to identify and analyze operational risks accurately. This will allow us to define and know the Company’s real risk tolerance policy. Thus, achieving optimal asset risk management;

- To be able to size adequate resources (human and economic) through the outputs arrogated by the functionalities of the viewer, such as the analyzed returns, planned activities of action on the assets, and replacement of assets after analyzing the optimal point according to the WLC of each asset, see Figure 6 Whole Life Cost (WLC). Thus, achieving optimal asset management;

- Improve decision-making capacity thus increasing the quality of the definition of a strategy and planning that offers the guarantees of achieving the organizational objectives proposed by the SPANISH PORT AUTHORITY (SPA). Optimal asset management of Decision Making, Strategy and Planning is thus achieved;

- Finally, this model, by guaranteeing the four previous points, gives us the opportunity to be able to accompany and know the real state of the asset in all its phases of life. In addition, it enables us to be able to operate, exploit and manage it in an optimal way moving from the reactive management model to the preventive management model.

The integrated asset management system identifies and analyzes operational risks through a real-time data-driven approach, leveraging sensor-based condition monitoring, historical failure pattern analysis, and AI-powered anomaly detection. Risk assessment is conducted using Failure Mode and Effect Analysis (FMEA) techniques, prioritizing assets based on criticality, failure probability, and maintenance urgency. To ensure data integrity and accessibility across different project phases, the system implements cloud-based redundant storage, encrypted data transmission protocols, and role-based access control mechanisms. These measures guarantee that all stakeholders have reliable and secure access to asset information throughout its lifecycle.

The implementation of Digital Twin and predictive maintenance in port asset management has been shown to reduce maintenance costs by approximately 20%, as demonstrated in similar applications in manufacturing and smart city projects [23]. Furthermore, operational efficiency in Spanish ports adopting BIM/GIS frameworks has increased by 15–20%, according to Puertos del Estado (2023). These improvements highlight the economic and logistical benefits of transitioning to data-driven asset management [6].

Our findings align with those of González-Cancelas et al. (2024) [6], who analyzed the digital transformation of Spanish ports and found that the integration of BIM and GIS improves asset monitoring and operational planning. While their study focused primarily on infrastructure modeling, our research extends this approach by incorporating Digital Twin technology and predictive analytics, resulting in a more comprehensive asset management framework. The increased flexibility and automation provided by our proposed system further support the transition to Smart Ports.

5. Conclusions

This study demonstrates that the integration of Digital Twin technology with BIM/GIS enhances port asset management by enabling real-time monitoring, predictive maintenance, and improved decision-making. The proposed Frankenstein strategy provides a scalable solution for the gradual implementation of digital twins in Spanish ports. While this research highlights significant benefits, future work should focus on refining AI-driven predictive models, expanding real-time data applications, and developing standardized protocols for seamless adoption in the port sector

This study confirms that Digital Twin integration with BIM/GIS significantly improves port asset management, enabling predictive maintenance, real-time monitoring, and optimized resource allocation. The proposed Frankenstein strategy provides a scalable and cost-effective approach for Spanish ports, facilitating their transition towards Industry 4.0. Future research should focus on refining AI-driven maintenance models and expanding interoperability standards for broader industry adoption.

This study highlights significant gaps in the implementation of BIM and GIS methodologies in Spanish port asset management. The current approach, adopted by the Spanish government and Puertos del Estado (PdE), lacks adequate preparation, training, and a long-term operational vision, resulting in inefficiencies in asset monitoring, maintenance, and strategic decision-making. Additionally, the absence of standardized BIM protocols for the port sector and a well-defined asset management strategy limits the effective utilization of digital models after construction.

Moreover, there is a lack of asset management culture at all hierarchical levels of Spanish Port Authorities, leading to poor inventory accuracy, data fragmentation, and insufficient maintenance strategies. This study addresses these issues by proposing a data-driven asset management framework, leveraging Digital Twin technology, BIM/GIS integration, and predictive maintenance models to enhance port operations.

The main contribution of this research is the development of a continuous and scalable asset management system that extends BIM and GIS utilization beyond infrastructure project completion. The Frankenstein strategy introduced in this work offers an incremental approach to Digital Twin integration, enabling Port Authorities to gradually adapt to digital asset management while ensuring long-term operational sustainability.

This study emphasizes that investing in high-resolution BIM/GIS models without a clear management and exploitation strategy leads to the underutilization of digital assets and inefficient decision-making. By integrating AI, IoT, and big data analytics, this research provides a replicable model for Smart Port transformation, ensuring optimized asset performance, predictive maintenance, and cost efficiency.

This research provides port planners and asset managers with a data-driven decision-making framework that enhances operational efficiency and long-term asset sustainability. The proposed system allows for real-time monitoring, predictive analytics, and optimized resource allocation, reducing operational costs and minimizing risks. The Frankenstein strategy ensures a flexible and scalable transition towards Smart Ports, fostering proactive asset management, sustainability, and resilience within the Industry 4.0 landscape.

Future research should focus on refining AI-driven predictive maintenance models to enhance fault detection and anomaly prediction, improving interoperability between BIM, GIS, and Digital Twin platforms for seamless data integration. Additionally, developing standardized BIM/GIS protocols will facilitate the widespread adoption of digital asset management in ports. Further studies should also assess the economic and environmental impact of Digital Twin implementation through case studies and simulations. These advancements will contribute to the scalability and adaptability of this framework, ensuring its applicability to ports worldwide.

Author Contributions

Conceptualization, N.G.-C., A.C.-O., J.V.-C. and P.M.M.; methodology, N.G.-C., A.C.-O., J.V.-C. and P.M.M.; validation, N.G.-C., A.C.-O., J.V.-C. and P.M.M.; formal analysis, N.G.-C., A.C.-O., J.V.-C. and P.M.M.; investigation, N.G.-C., A.C.-O., J.V.-C. and P.M.M.; resources, N.G.-C., A.C.-O., J.V.-C. and P.M.M.; data curation, N.G.-C., A.C.-O., J.V.-C. and P.M.M.; writing—original draft preparation, N.G.-C., A.C.-O. and J.V.-C.; writing—review and editing, N.G.-C., A.C.-O., J.V.-C. and P.M.M.; supervision, N.G.-C., A.C.-O. and J.V.-C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author due to restriction.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Abiodun, T.; Rampersad, G.; Brinkworth, R. Driving Industrial Digital Transformation. J. Comput. Inf. Syst. 2023, 63, 1345–1361. [Google Scholar] [CrossRef]

- Sanchis, R.; García-Perales, Ó.; Fraile, F.; Poler, R. Low-code as enabler of digital transformation in manufacturing industry. Appl. Sci. 2019, 10, 12. [Google Scholar] [CrossRef]

- Leignel, J.-L.; Ungaro, T.; Staar, A. Digital Transformation: Information System Governance; John Wiley & Sons: Hoboken, NJ, USA, 2016. [Google Scholar]

- Othman, A.; El Gazzar, S.; Knez, M. Investigating the influences of smart port practices and technology employment on port sustainable performance: The Egypt case. Sustainability 2022, 14, 14014. [Google Scholar] [CrossRef]

- González-Cancelas, N.; Serrano, B.M.; Soler-Flores, F.; Camarero-Orive, A. Using the SWOT Methodology to Know the Scope of the Digitalization of the Spanish Ports. Logistics 2020, 4, 20. [Google Scholar] [CrossRef]

- González-Cancelas, N.; Orive, A.C.; Cabrero, J.V.; Flores, F.S. Digital Transformation in Spanish Port System; IntechOpen: London, UK, 2024. [Google Scholar]

- Abideen, D.K.; Yunusa-Kaltungo, A.; Manu, P.; Cheung, C. A systematic review of the extent to which BIM is integrated into operation and maintenance. Sustainability 2022, 14, 8692. [Google Scholar] [CrossRef]

- Demir, S.; Yomralioglu, T. Bridging Geo-Data and Natural Gas Pipeline Design Standards: A Systematic Review of BIM-GIS Integration for Natural Gas Pipeline Asset Management. Energies 2024, 17, 2306. [Google Scholar] [CrossRef]

- Soori, M.; Arezoo, B.; Dastres, R. Digital twin for smart manufacturing, A review. Sustain. Manuf. Serv. Econ. 2023, 2, 100017. [Google Scholar] [CrossRef]

- Rana, R.; Bhambri, P. Artificial Intelligence and Internet of Things (IoT) Facilitated Digital Twin for Industry 4.0 Application Domains. In AI-Driven Digital Twin and Industry 4.0; CRC Press: Boca Raton, FL, USA, 2024; pp. 168–181. Available online: https://www.taylorfrancis.com/chapters/edit/10.1201/9781003395416-11/artificial-intelligence-internet-things-iot-facilitated-digital-twin-industry-4-0-application-domains-rachna-rana-pankaj-bhambri (accessed on 11 February 2025).

- Molina, B.; Ortiz-Rey, N.; González-Cancelas, N.; Soler-Flores, F.; Camarero-Orive, A. Use of the Blue Ocean Strategy to obtain ports 4.0. Ing. Compet. 2021, 23, e9466. [Google Scholar]

- Pullagura, L.; Brahma, B.; Kumari, N.V.; Ravikumar, L.; Katta, S.K.G.; Chiwariro, R. Industry 4.0 Design Principles, Technologies, and Applications. In Computational Intelligence in Industry 4.0 and 5.0 Applications; Auerbach Publications: Boca Raton, FL, USA, 2025; pp. 357–388. Available online: https://www.taylorfrancis.com/chapters/edit/10.1201/9781003581963-11/industry-4-0-design-principles-technologies-applications-lokaiah-pullagura-biswajit-brahma-vinaya-kumari-ravikumar-siva-kumar-gowda-katta-ronald-chiwariro (accessed on 23 February 2025).

- Hofmann, E.; Sternberg, H.; Chen, H.; Pflaum, A.; Prockl, G. Supply chain management and Industry 4.0: Conducting research in the digital age. Int. J. Phys. Distrib. Logist. Manag. 2019, 49, 945–955. [Google Scholar] [CrossRef]

- Dehghan, S.; Karganroudi, S.S.; Echchakoui, S.; Barka, N. The Integration of Additive Manufacturing into Industry 4.0 and Industry 5.0: A Bibliometric Analysis (Trends, Opportunities, and Challenges). Machines 2025, 13, 62. [Google Scholar] [CrossRef]

- Valaskova, K.; Nagy, M.; Zabojnik, S.; Lăzăroiu, G. Industry 4.0 wireless networks and cyber-physical smart manufacturing systems as accelerators of value-added growth in Slovak exports. Mathematics 2022, 10, 2452. [Google Scholar] [CrossRef]

- Ziemba, E.W.; Duong, C.D.; Ejdys, J.; Gonzalez-Perez, M.A.; Kazlauskaitė, R.; Korzyn-ski, P.; Mazurek, G.; Paliszkiewicz, J.; Stankevičienė, J.; Wach, K. Leveraging artificial intelligence to meet the sustainable development goals. J. Econ. Manag. 2024, 46, 508–583. [Google Scholar] [CrossRef]

- Almehdhar, M.; Albaseer, A.; Khan, M.A.; Abdallah, M.; Menouar, H.; Al-Kuwari, S. Deep learning in the fast lane: A survey on advanced intrusion detection systems for intelligent vehicle networks. IEEE Open J. Veh. Technol. 2024, 5, 869–906. Available online: https://ieeexplore.ieee.org/abstract/document/10582439/ (accessed on 23 February 2025). [CrossRef]

- Kumar, C.; Ansari, M.S.A. An explainable nature-inspired cyber attack detection system in Software-Defined IoT applications. Expert Syst. Appl. 2024, 250, 123853. [Google Scholar] [CrossRef]

- Verdouw, C.; Tekinerdogan, B.; Beulens, A.; Wolfert, S. Digital twins in smart farming. Agric. Syst. 2021, 189, 103046. [Google Scholar] [CrossRef]

- Magalhães, L.C.; Magalhães, L.C.; Ramos, J.B.; Moura, L.R.; de Moraes, R.E.N.; Gonçalves, J.B.; Hisatugu, W.H.; Souza, M.T.; de Lacalle, L.N.L.; Ferreira, J.C.E. Conceiving a Digital Twin for a Flexible Manufacturing System. Appl. Sci. 2022, 12, 9864. [Google Scholar] [CrossRef]

- Alizadehsalehi, S.; Yitmen, I. Digital twin-based progress monitoring management model through reality capture to extended reality technologies (DRX). Smart Sustain. Built Environ. 2023, 12, 200–236. [Google Scholar] [CrossRef]

- Hosamo, H.H.; Svennevig, P.R.; Svidt, K.; Han, D.; Nielsen, H.K. A Digital Twin predictive maintenance framework of air handling units based on automatic fault detection and diagnostics. Energy Build. 2022, 261, 111988. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, K.; Zhang, Y. Digital twin networks: A survey. IEEE Internet Things J. 2021, 8, 13789–13804. [Google Scholar] [CrossRef]

- Aminu, Y.; Zainudin, N. A review of anatomy of working capital management theories and the relevant linkages to working capital components: A theoretical building approach. Eur. J. Bus. Manag. 2015, 7, 10–18. [Google Scholar]

- Konstantakos, P.; Chountalas, P.; Magoutas, A. The contemporary landscape of asset management systems. Qual.-Access Success 2019, 20, 10–17. [Google Scholar]

- Van Der Lei, T.; Herder, P.; Wijnia, Y. (Eds.) Asset Management: The State of the Art in Europe from a Life Cycle Perspective; Springer: Dordrecht, The Netherlands, 2012. [Google Scholar] [CrossRef]

- Nocco, B.W.; Stulz, R.M. Enterprise Risk Management: Theory and Practice. J. Appl. Corp. Financ. 2022, 34, 81–94. [Google Scholar] [CrossRef]

- Cahyo, I.W.N. Engineering Asset Management:(Pengantar Manajemen Aset Industri Berbasis ISO 55000); Universitas Islam Indonesia: Yogyakarta, Indonesia, 2019; Available online: https://books.google.es/books?hl=es&lr=&id=LTlCEAAAQBAJ&oi=fnd&pg=PA1&dq=I.+W.+N.+Cahyo,+%E2%80%9CEngineering+Asset+Management:(Penganga+Manajemen+Aset+Industri+berbasis+ISO+55000),%E2%80%9D+Univ.+Islam+Indones.,+2019.&ots=vXPVTXt5_5&sig=aHB4UWS1pn3Li58yV-3ELhaBb3M (accessed on 11 February 2025).

- Prahalad, C.K.; Ramaswamy, V. The new frontier of experience innovation. MIT Sloan Manag. Rev. 2003. Available online: https://sloanreview.mit.edu/article/the-new-frontier-of-experience-innovation/ (accessed on 11 February 2025).

- Halfawy, M.R.; Dridi, L.; Baker, S. Integrated Decision Support System for Optimal Renewal Planning of Sewer Networks. J. Comput. Civ. Eng. 2008, 22, 360–372. [Google Scholar] [CrossRef]

- Wiig, K.M. Knowledge management: Where did it come from and where will it go? Expert Syst. Appl. 1997, 13, 1–14. [Google Scholar] [CrossRef]

- Tsang, Y.P.; Yang, T.; Chen, Z.S.; Wu, C.H.; Tan, K.H. How is extended reality bridging human and cyber-physical systems in the IoT-empowered logistics and supply chain management? Internet Things 2022, 20, 100623. [Google Scholar] [CrossRef]

- Alsyouf, I.; Alsuwaidi, M.; Hamdan, S.; Shamsuzzaman, M. Impact of ISO 55000 on organisational performance: Evidence from certified UAE firms. Total Qual. Manag. Bus. Excell. 2021, 32, 134–152. [Google Scholar] [CrossRef]

- De Villiers, J.-M. A Framework for Implementing Lean Practices and Tools to Support ISO 55000 Compliance for Physical Asset Management. Ph.D. Thesis, Stellenbosch University, Stellenbosch, South Africa, 2018. Available online: https://scholar.sun.ac.za/bitstream/handle/10019.1/103424/devilliers_framework_2018.pdf?sequence=1 (accessed on 11 February 2025).

- Rangu, S.K.; Lolla, P.R.; Dhenuvakonda, K.R.; Singh, A.R. Recent trends in power management strategies for optimal operation of distributed energy resources in microgrids: A comprehensive review. Int. J. Energy Res. 2020, 44, 9889–9911. [Google Scholar] [CrossRef]

- Atzeni, D.; Ramjattan, R.; Figliè, R.; Baldi, G.; Mazzei, D. Data-driven insights through industrial retrofitting: An anonymized dataset with machine learning use cases. Sensors 2023, 23, 6078. [Google Scholar] [CrossRef]

- Khan, P.W.; Byun, Y.-C. A Review of machine learning techniques for wind turbine’s fault detection, diagnosis, and prognosis. Int. J. Green Energy 2024, 21, 771–786. [Google Scholar] [CrossRef]

- Kalantari, M.; Clemen, C.; Jadidi, M. BIM and 3D GIS Integration for Digital Twins: An Introduction; CRC Press: Boca Raton, FL, USA, 2024; Available online: https://books.google.es/books?hl=es&lr=&id=o9cuEQAAQBAJ&oi=fnd&pg=PP1&dq=Kalantari,+M.,+Clemen,+C.,+%26+Jadidi,+M.+(2024).+BIM+and+3D+GIS+Integration+for+Digital+Twins:+An+Introduction.+CRC+Press.+&ots=XIUAmM4GXI&sig=ibYMiwn7oitg7iHgqsQROrfUZxc (accessed on 23 February 2025).

- Park, C.; Rahimian, F.P.; Dawood, N.; Pedro, A.; Dongmin, L.; Hussain, R.; Soltani, M. Digitalization in Construction; Routledge: London, UK, 2023; p. 11. [Google Scholar]

- Mohamed, A.G.; Alqahtani, F.K.; Ismail, E.R.; Nabawy, M. Synergizing BIM and Value Engineering in the Construction of Residential Projects: A Novel Integration Framework. Buildings 2024, 14, 2515. [Google Scholar] [CrossRef]

- Lu, Q.; Xie, X.; Heaton, J.; Parlikad, A.K.; Schooling, J. From BIM Towards Digital Twin: Strategy and Future Development for Smart Asset Management. In Service Oriented, Holonic and Multi-Agent Manufacturing Systems for Industry of the Future; Borangiu, T., Trentesaux, D., Leitão, P., Boggino, A.G., Botti, V., Eds.; Studies in Computational Intelligence; Springer International Publishing: Cham, Switzerland, 2020; Volume 853, pp. 392–404. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).