1. Introduction

The environmental problems caused by the massive use of fossil energy have increasingly attracted people’s attention. As people’s voices on environmental protection are raised, the utilization of clean and renewable energy sources has become the focus of people’s attention. In order to realize the sustainable development of society and reduce the dependence on fossil energy, solar energy, wind energy, tidal energy, geothermal energy and many other green and clean energies began to ascend to the stage of history and become the mainstream direction of future energy development in the world. In 2024, China’s domestic installed capacity will increase by 14,388 units, with a capacity of 86.99 million kW, an increase of 9.6% year-on-year; in the same year, the total installed capacity was more than 209,000 units, with a total installed capacity of 561.26 million kW [

1]. As the main form of wind energy utilization, the wind power generation industry has been widely emphasized in China.

As the core component of the generator set, the stable operation of the generator set is affected to a large extent by the performance of the blade. Its manufacturing cost accounts for 15% to 20% of the wind turbine equipment, and a large part of wind farm accidents is due to the unstable operation of the blade. Ensuring the quality of the blade is an important factor in ensuring the stable operation of the wind turbine and the safety of the wind farm. Wind turbine blades in operation will be subjected to extreme load and fatigue load; the actual situation is greater than the material strength limit of the extreme load and seldom leads to blade failure; the fatigue load amplitude is lower than the strength limit of the material, but due to the significantly higher number of cycles, it is usually the leading cause of fatigue damage to the blade. Research shows that the blade service life depends mainly on the fatigue life; therefore, the prediction of the blade’s fatigue life is of great significance. Based on the fracture mechanics theory, Aghajani et al. proposed a new multiaxial fatigue damage prediction model for wind turbine blades; interfiber characteristics and fatigue reduction of fiber are separately treated and simulated in this research, and the mechanism of composite blade damage generation and accumulation under multiaxial fatigue load conditions are analyzed [

2]. According to the fatigue failure criterion, Kou selects blade stiffness as the characteristic quantity of the blade performance and proposes the blade acceleration model (AM). Then, the model of the blade stiffness attenuation path is established by using the Gamma process. Finally, the life of the full-size megawatt blade is predicted to be about 20 years by combining the proposed acceleration model and the blade stiffness degradation model [

3]. Based on the measured wind speed and direction data at the hub of the wind turbine, Zhao Qin uses the research ideas of ‘non-Gaussian characteristics analysis of wind‘ and ’fatigue life analysis of blades‘ to systematically study the joint distribution probability model of non-Gaussian wind speed and direction and the life calculation model of blades in the whole wind direction range [

4]. After obtaining the fatigue load of each section of the blade under different working wind speeds using GH Bladed software, Han Tongtong carried out a transient analysis with a remote point. Simplifying the section load into a remote point load can significantly improve the calculation efficiency. NCode compiles the stress load spectrum, and the fatigue life is predicted by fuzzy mathematics theory [

5]. Zhang Zhewei carried out damage identification and location of small wind turbine blades with damage through experiments and carried out fluid–solid coupling simulation using finite element analysis software. The obtained data were used to study the residual fatigue life of wind turbine blades under four damage conditions [

6]. Ma proposed a model to describe the constant life fatigue limit of typical glass fiber-reinforced plastic (GRP) composites. Compared with the classical model, it is pointed out that there are differences in the damage accumulation mode of GRP in the tensile and compressive stages. It is proved that the constant life fatigue limit curve is asymmetric and bell-shaped. The prediction effect of the model in stress–life data is compared and analyzed [

7]. Yu takes the 1.5 MW blade as the research object and uses the fatigue load spectrum of the actual 1.5 MW blade during service. Based on the generalized stress–life curve of the blade material, the fatigue damage accumulation model of the blade under random load is used to calculate the total fatigue damage of the blade and predict the fatigue life. The prediction results of blade life are close to the field test results, which proves the correctness of the proposed blade fatigue life evaluation method [

8]. According to the condition that the initial static strength of the composite material obeys the two-parameter Weibull distribution, Zhao assumed the relationship between the residual strength decay rate and the residual strength and constructed the initial static strength [

9].

In summary, in past research, the key to predicting the fatigue life is to calculate the fatigue damage of the blade, so choosing a suitable method to solve the fatigue damage of the blade is the key to estimating the life of the blade and the premise of calculating the fatigue damage of the blade is to obtain the blade response and then obtain the stress spectrum. Some scholars measured the stress spectrum of the blade by installing a strain gauge at the root of the blade. However, determining the installation position of the strain gauge is a problem. In addition, due to the difficulty in obtaining measured load data for large wind turbines, most scholars primarily obtain relevant load data through analysis and simulation for the fatigue analysis of wind turbine blades. Some scholars calculate the static load of the dangerous part of the blade under each working wind speed using the fluid–solid coupling method and then obtain the stress spectrum by combining the annual distribution of wind speeds. In this paper, a fluid–solid coupling method is proposed to obtain the corresponding instantaneous static response sequence by combining the static load and the dynamic wind speed sequence. The instantaneous static response results are used to calculate the damage generated during the blade working process. Considering that the calculation results of this method will be affected by the randomness of wind speed when the wind speed data is insufficient, in order to make up for this, the wind speed prediction is used to simulate enough reasonable wind speed data to eliminate this effect. The test data in Reference [

10] show that the dynamic response of the blade is closely related to the change in wind speed, and the transient response of the blade is not entirely consistent with the instantaneous change in wind speed. If the transient response of the blade is entirely consistent with the change in the corresponding wind speed, that is, the instantaneous dynamic response of the blade with the change of wind speed is approximated to the corresponding instantaneous static response, the vibration of the strain signal is much more severe than the original [

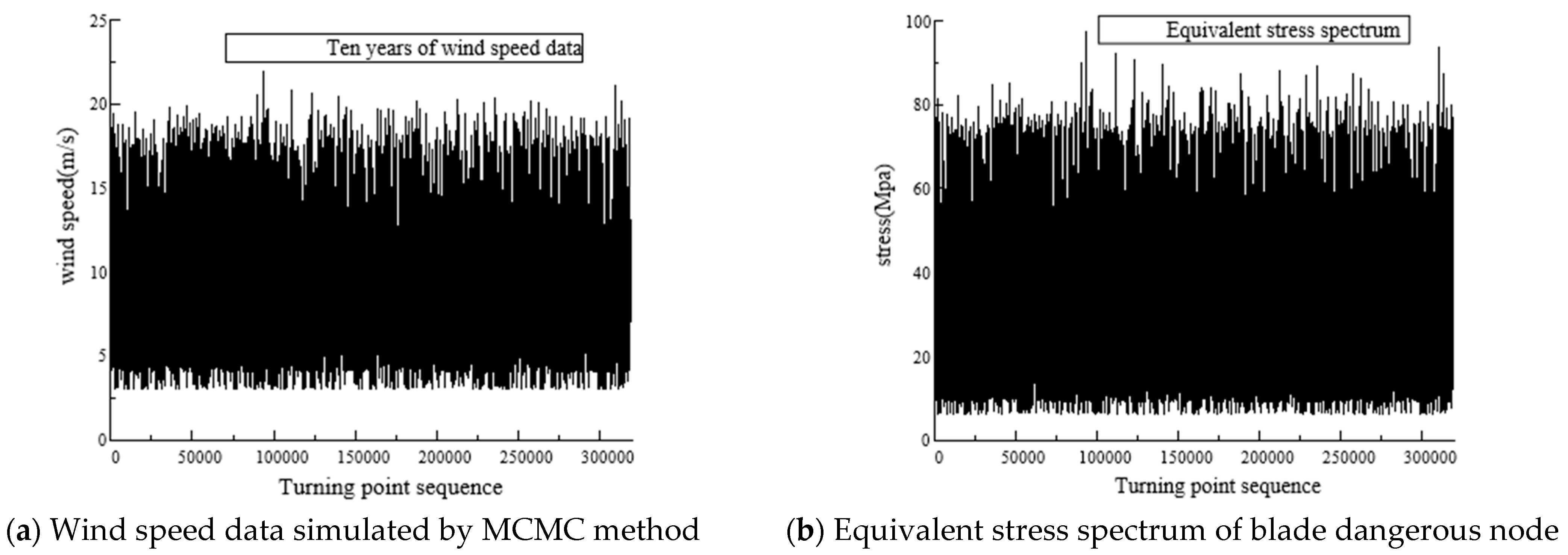

11]. From the perspective of fatigue, it can be considered that this assumption will cause more damage to the blade; that is to say, calculating the fatigue life of the blade under this assumption is a more conservative and feasible engineering estimation method. Considering that this method is not enough to cover all cases of blade service life in wind speed data, the estimated fatigue life will also have a lot of discreteness. This paper proposes a fatigue life prediction method considering long-term wind speed simulation to reduce the influence of wind speed randomness on the prediction results. In this paper, the wind speed prediction model is required to predict as much instantaneous wind speed data as possible. When evaluating the reliability of offshore wind power, Chao uses the time series properties of wind speed series to predict the wind speed for a long time by using the MCMC model and ARMA model, respectively. The final results show that the prediction results of the ARMA model contain negative values, while the MCMC model is more in line with the actual situation [

12]. Based on statistical methods and neural network methods, Li designed a multi-neural network data fusion algorithm to predict the hourly wind speed in the following year. The results show that the average absolute error is small, and the wind speed trend is close to the actual results [

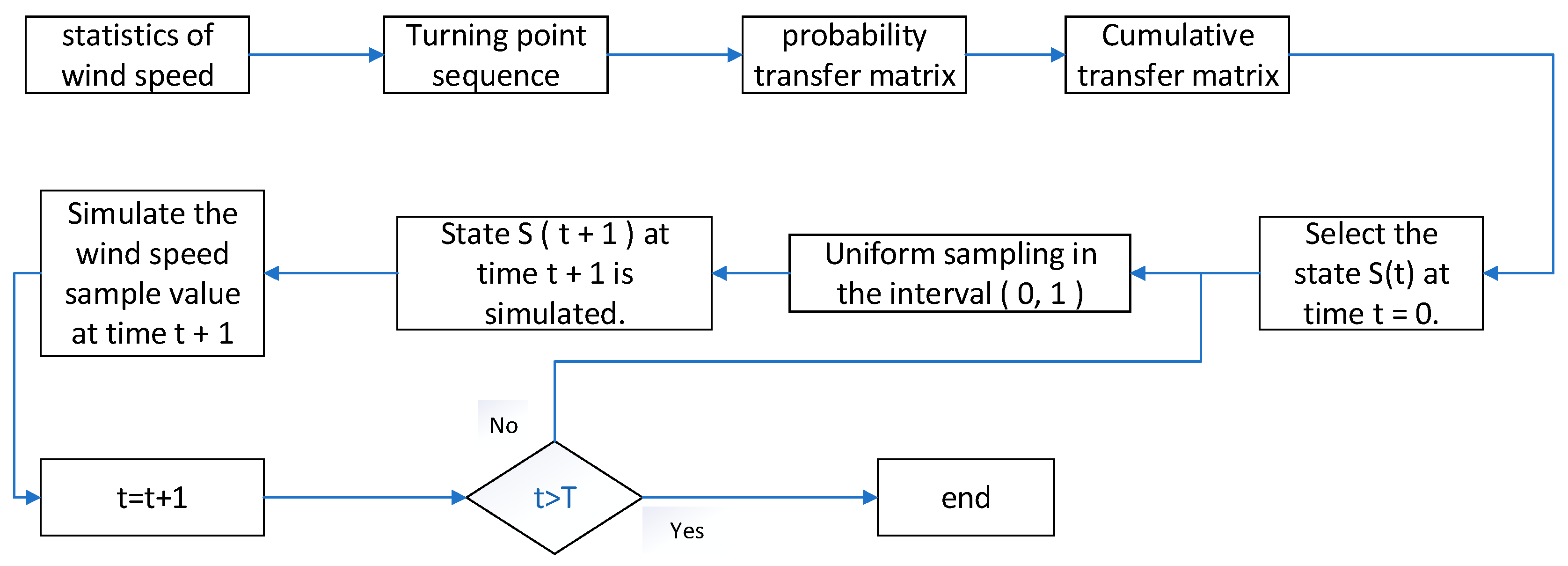

13]. Under comprehensive consideration, this paper uses the MCMC model as the wind speed prediction model. The technical roadmap of this paper is shown in

Figure 1:

4. Material Stress–Life Curve (S–N Curve) and Fatigue Damage Criterion

4.1. S–N Curve of Composite Material

The S–N curve describes the relationship between the stress level and the number of cycles N of the standard part under a specific cyclic symmetrical load loading condition. The general S–N curve obtains the corresponding data through the fatigue test of the standard part, to draw the S–N curve. Another way is to obtain the S-N curve according to the material parameters combined with the empirical formula. Since composite materials have no apparent fatigue limit, the stress when the number of cycles increases to 10

8 is generally used as its conditional fatigue limit. The exponential function formula is used instead of the measured curve:

In the formula, a and b are material constants, which are dimensionless, (b is approximately equal to 10), is the static strength of the material; a = 1/B; σi represents the stress of the ith level, and Ni represents the maximum number of cycles corresponding to the stress of the ith level.

The above calculation is obtained under symmetrical cyclic stress loading. In reality, the stress ratio of the component under load is generally not −1. Some scholars estimate the fatigue limit through empirical models. In this paper, the conditional fatigue limit under random cyclic characteristics is calculated by the Goodman curve model:

In the formula, is the average stress, and is the fatigue limit when the stress ratio is −1.

4.2. Fuzzy Miner Linear Fatigue Damage Theory

The fatigue damage theory commonly used in current engineering is the Miner theory. This theory holds that the fatigue damage

D of the material can be expressed as the ratio of the number of cycles of stress

n to the fatigue limit N of the material under this stress:

D =

n/

N. Under the action of stress cycles with different amplitudes, when the fatigue failure of the component occurs, there are

The linear Miner theory holds that damage cannot be generated when the stress amplitude is lower than the fatigue limit. However, the stress of the material under random load is lower than the fatigue limit, which means there is an intermediate transition fuzzy state where the stress can cause damage to the component. In view of fatigue damage’s fuzziness, some scholars have proposed the discrete Miner fatigue damage accumulation rule of fuzzy theory (hereinafter referred to as the “fuzzy Miner method”).

Many experiments have shown no obvious fatigue limit for composite materials such as fiber glass-reinforced plastics and synthetic resin. For the crack propagation stage, the stress below the fatigue limit will also affect the fatigue damage to a certain extent [

17]. A fatigue damage threshold lower than the fatigue limit is defined. When the stress amplitude is lower than the threshold, it is considered that no damage will occur, the fuzzy damage degree is 0, and the stress amplitude in this interval does not affect the fatigue life. When the stress is between the fatigue limit and the fatigue damage threshold, it is considered that damage may occur, and the membership function determines the degree of fatigue damage. When the stress amplitude is greater than the fatigue limit, it is considered that there will be damage, and the fuzzy damage degree is 1.

The membership function is the key to describing the uncertainty of the research object. Only from the membership function can the ambiguity of the research object be described. The fatigue damage caused by random load on the blade is cumulatively increased. Generally, the large membership function is used for analysis and calculation, and the normal distribution membership function is used to describe the ambiguity of the damage caused by wind load on the wind turbine blade.

According to the fuzzy uncertainty of the damage of a large number of fatigue test materials under different stresses, it is most reasonable to take the fatigue damage threshold

as the boundary of the fuzzy characteristics of the material. Through the fitting observation of multiple sets of data, it can be seen that the value of

b in the formula is inversely proportional to the stress level, and the value range is (0.05–0.4)

. If the stress above the fatigue limit in the load history of the component has j levels, the fatigue damage of the component under the load history is

In the formula, is the base number of stress cycles. In this paper, .

6. Conclusions

Based on past research on the life of wind turbines at home and abroad, this paper proposes a method to calculate the blade load spectrum by combining the blade’s transient response with the wind speed value and uses the fuzzy Miner method to estimate the fatigue life of the 5 MW wind turbine. The main conclusions are as follows:

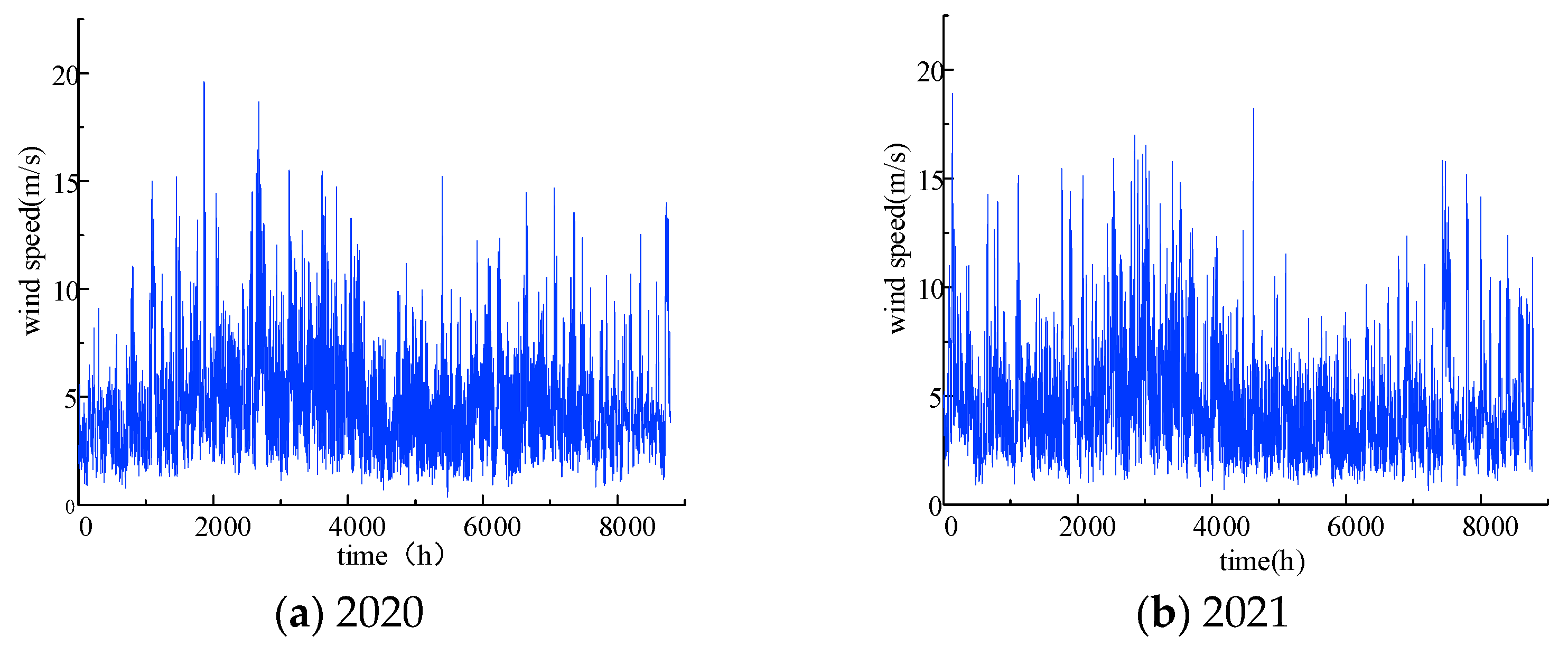

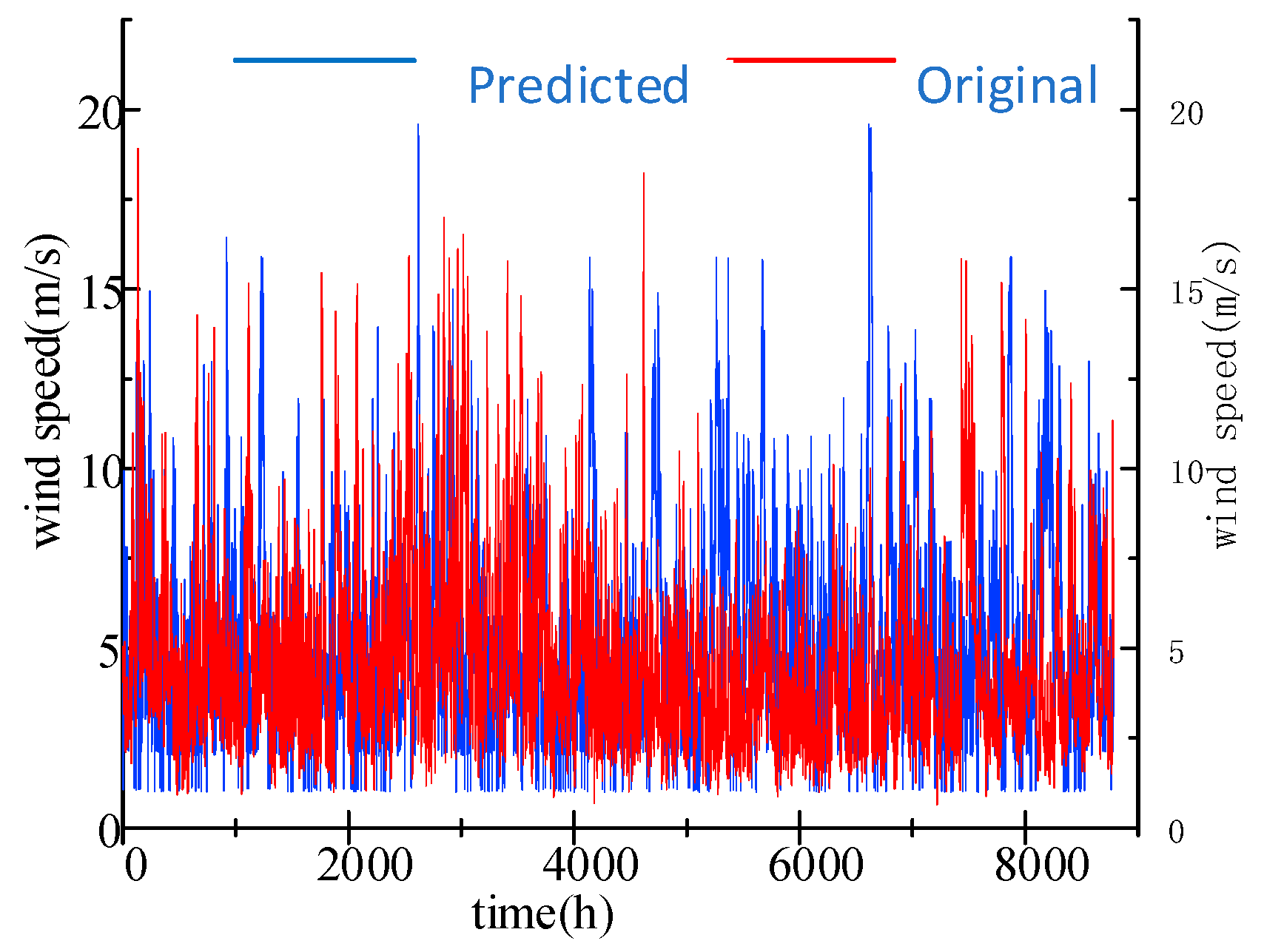

(1) In this paper, the significance of long-term wind speed simulation for fatigue life estimation of wind turbine blades is analyzed. Taking the wind speed data of the Xihe platform for two years as an example, the MCMC method establishes a reliable wind speed prediction model. The prediction results show that the simulation effect is good, and it is an effective method.

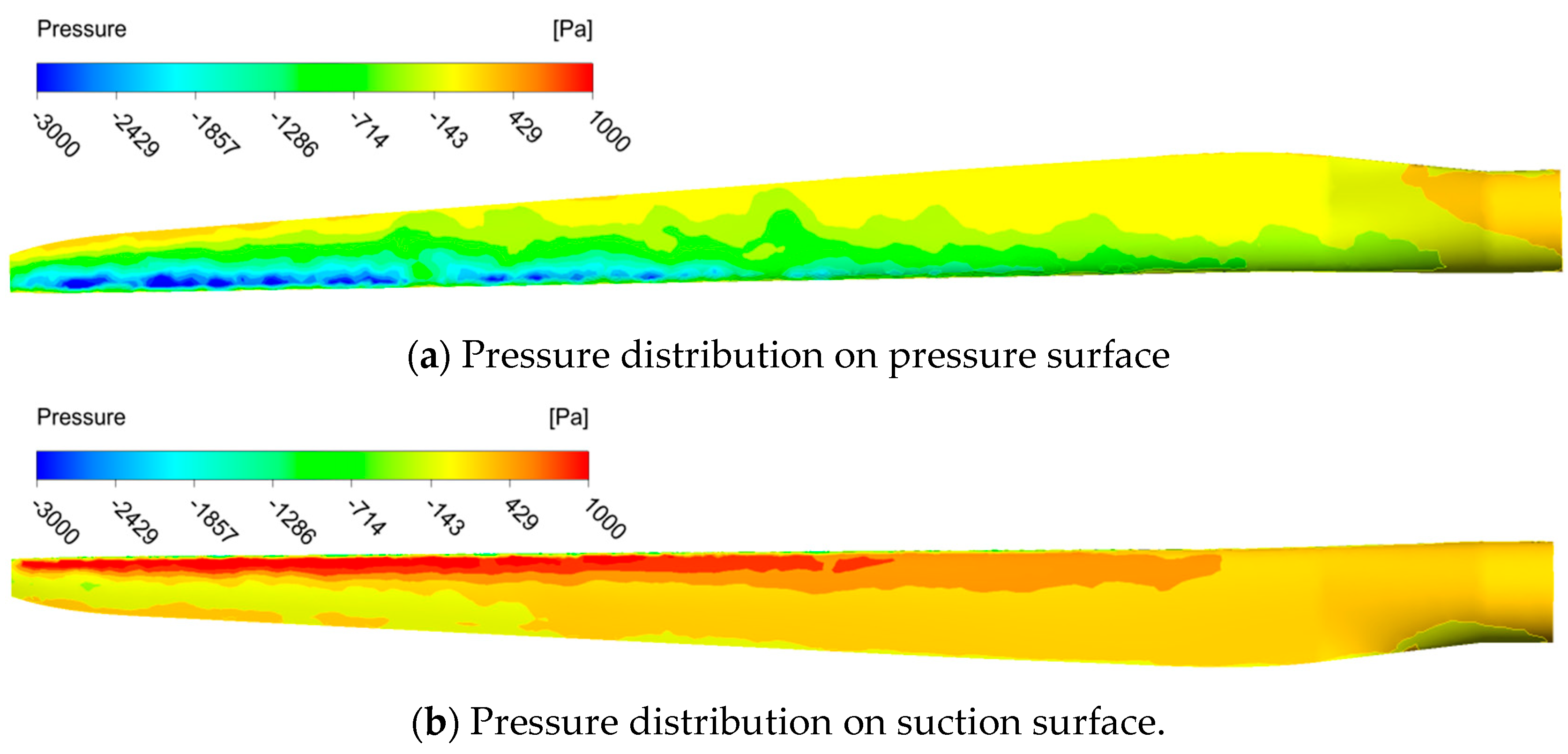

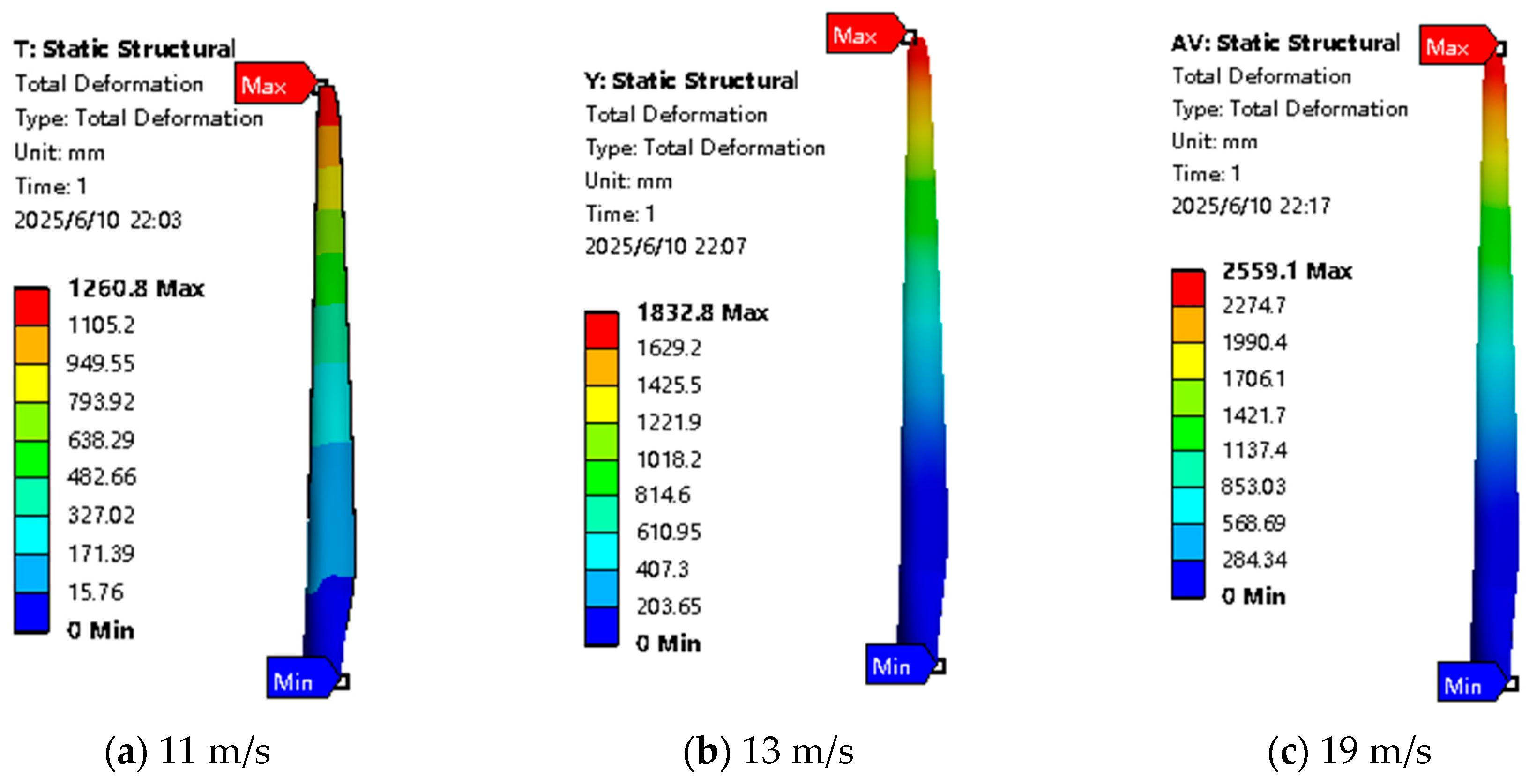

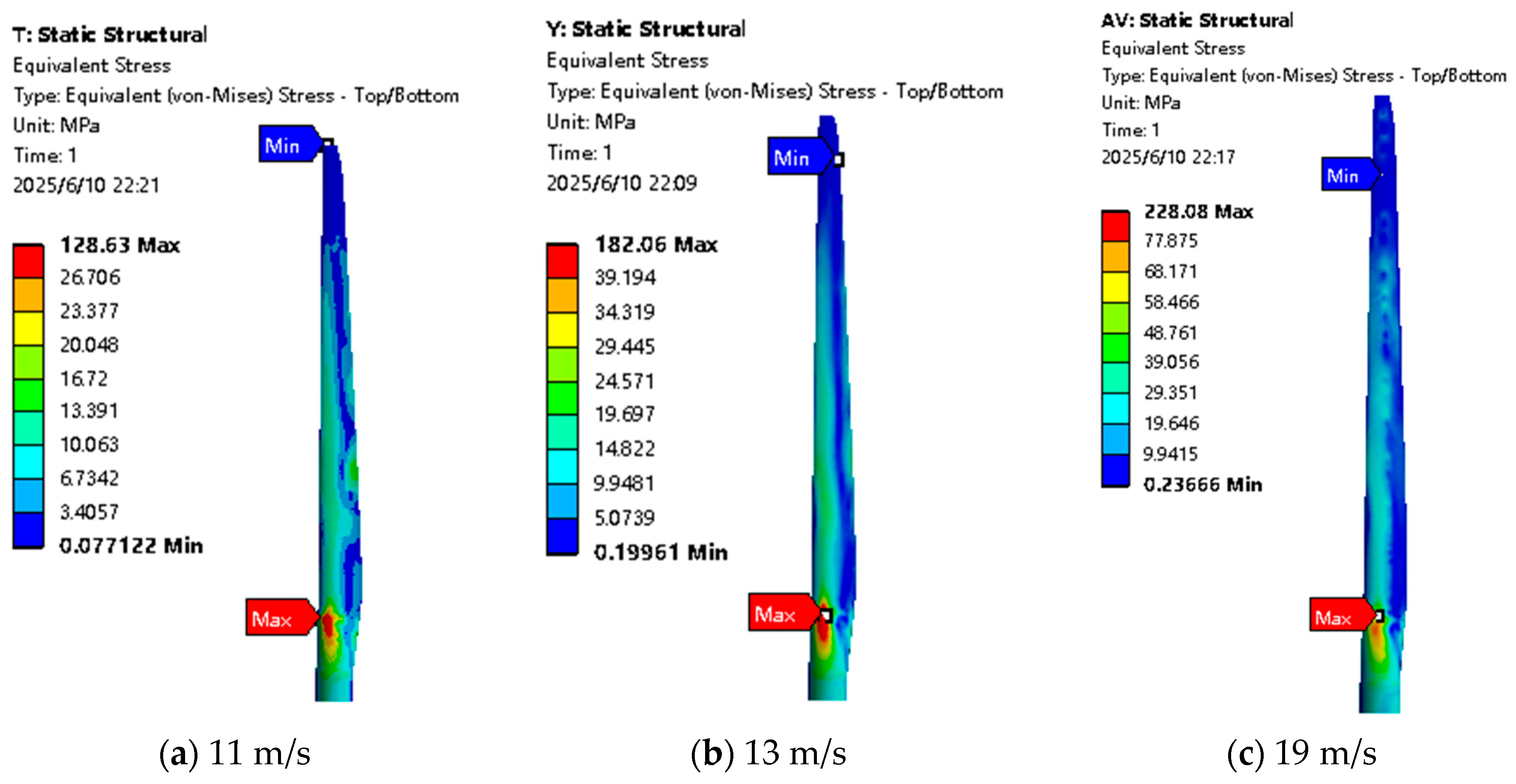

(2) The pressure difference between the suction surface and the pressure surface of the blade drives the fan blade to rotate. Through analysis, the maximum pressure of the blade is located at the transition position between the blade root and the aerodynamic part, and the maximum deformation is situated at the tip of the blade.

(3) The fatigue life of the wind turbine blade estimated based on the fuzzy theory is closer to the actual value than the estimation results of the classical theory, and the life estimation results show that the wind turbine blade can reach its design life.

In this paper, when predicting the fatigue life of the blade, only the normal operating conditions of the wind turbine are considered, and the influence of special conditions such as normal shutdown and emergency shutdown on the fatigue life of the blade is not considered. In future research, the proportion of various working conditions per unit time should be counted, and the damage under the corresponding working conditions should be calculated to make the estimated fatigue life closer to the real situation. Additionally, due to the computer’s performance, the model preprocessing used in this case is not sufficiently fine. In future research, it will be necessary to utilize a composite material layer model that closely resembles the real blade.