Abstract

When an engine burns methanol, which has a high latent heat of vaporization, if the injection parameters are not set reasonably, the engine will exhibit high combustion instability at low speeds. Therefore, in this study, two pre-injections are set up in an electric-plug-assisted compression ignition methanol engine to investigate the effects of the pre-injection ratio and pre-injection timing on combustion stability and to provide a theoretical basis for the calibration of the injection of the engine at low speeds. The test results show that, at low speeds, the pre-injection ratio and pre-injection timing have a significant effect on combustion stability. They also show that, at low speeds and high loads, by regulating the pre-injection strategy, the bimodal phenomenon observed in the cylinder pressure of the compression ignition methanol engine can be weakened, and the cylinder pressure fluctuation caused by afterburning can be improved. Specifically, the maximum cyclic fluctuation of cylinder pressure was improved by 32.8%, the maximum cyclic fluctuation of the engine’s indicated average effective pressure was improved by 8.12%, and the maximum cyclic fluctuation of engine peak pressure was improved by 16.96%. The start point and combustion center of gravity data were centralized. The concentration of the start point and combustion center of gravity data improved by 6 °CA and 5.87 °CA, respectively.

1. Introduction

Methanol is a high-quality alternative fuel that is liquid at room temperature and atmospheric pressure, making it easy to transport. However, due to the current low number of methanol refueling stations, its transportation cost is relatively high. The main technical routes for the combustion of methanol in conventional engines include (1) blending conventional fuels with methanol for combustion: this technical route has a small engine modification workload, but the proportion of methanol combustion is low; (2) using traditional fuels to ignite methanol: this technical route is flexible in the methanol combustion mode, but the engine modification workload is large, and at the same time, it needs to be equipped with a number of fuel tanks to reserve different fuels, which is less practical; (3) using electric plugs to assist the compression ignition of methanol in engines with high compression ratios: this technical route has a small engine modification workload and a high methanol substitution ratio, but it has higher requirements for the quality of electric heat plugs. Driven by the goal of global energy transition, the unsustainability of traditional fossil fuels and the energy problems they cause are becoming increasingly prominent. Methanol, as a renewable fuel with high oxygen content and a wide range of sources, is regarded as one of the key paths to solving the energy crisis due to its high combustion efficiency, low carbon footprint, and environmental sustainability. It is also widely used as an alternative fuel for engines [1]. However, due to characteristics such as a high ignition point and low-temperature vaporization and heat absorption, methanol has long faced technical bottlenecks such as ignition difficulties and unstable combustion in compression ignition engines, which have limited its large-scale promotion [2,3]. In contrast, electric-plug-assisted compression ignition combustion technology provides a new approach to solving the problem of methanol’s spontaneous combustion by precisely controlling the temperature of the combustion chamber. The electric plug compression ignition engine breaks through the low-temperature ignition barrier of methanol and does not require significant modification in the engine structure, which significantly reduces the application cost [4,5]. In summary, research on the electric plug compression ignition methanol engine provides not only a technological breakthrough to cope with the energy crisis and climate challenges but also a core driving force to promote the green transformation of transportation, shipping, and other fields.

Combustion stability is crucial for enhancing the performance of methanol engines. A pre-injection strategy can create a more stable environment for the complete combustion of fuel by pre-injecting it before the main combustion, thus improving the stability of the whole combustion process. The authors of [6] investigated the possibility of using biodiesel as a pre-injection agent and found that it could not only improve combustion stability but also increase overall engine efficiency and reduce NOx emissions. Reference [7] showed that stable biofuel suspensions can be prepared by mixing animal fats with water and methanol and that they exhibit good combustion stability in diesel engines. In addition, reference [8] focused on combustion stability in ignition engines using blended fuels (a mixture of ethanol and methanol). The authors of [9] utilized a plasma-assisted ignition (PAI) system in conjunction with methanol M100 fuel to improve the combustion stability of a single-cylinder engine under extreme conditions. The authors of [10] found that no misfires occurred in methanol when the temperature of the electric plug was raised to 900 °C. In [11], the cycle volatility of a methanol engine was improved by increasing the temperature of the electric heat plug.

The effect of the pre-injection strategy on combustion stability is an important aspect according to the literature. The uniformity of the combustion process can be improved, and the risk of unstable combustion can be reduced by adopting appropriate pre-injection strategies, thus improving the overall engine performance and reliability [12,13,14,15,16]. In reference [17], it was found that the pre-injection strategy can help solve the combustion stability problem due to the low reactivity of methanol when using bio-methanol. The authors of [18] investigated the combustion characteristics of a mixture of pure methanol plus EHN in a compression combustion engine through 3D CFD simulation and found that the pre-injection strategy can significantly improve combustion stability. The authors of [19] investigated the effect of pre-injection strategies on the combustion process by conducting experimental studies on a diesel/methanol dual-fuel direct-injection engine. Reference [20] investigated the effect of pre-injection timing on the combustion and emission performance of a methanol/diesel dual-fuel high-compression ignition engine under low-load conditions through three-dimensional numerical simulations. Reference [21] found that premature pre-injection timing leads to the wet-wall phenomenon, while delayed timing may lead to insufficient mixing and affect combustion stability. Therefore, selecting the optimal pre-injection timing is essential to improving combustion efficiency and reducing emissions. The authors of [22] pointed out that under low-oxygen conditions, a pre-injection strategy may reduce the combustion efficiency and decrease unburned hydrocarbon emissions, which suggests that the selection of the pre-injection strategy needs to be optimized according to the specific operating conditions and combustion mode. Reference [4] experimentally investigated the combustion stability of n-butanol/diesel fuel blends in a partially premixed combustion engine, and waveform analysis was used to investigate cyclic variability. It was found that pre-injection strategies significantly reduce the cyclic variability of combustion and thus improve its overall stability. The authors of [23] also pointed out that pre-injection strategies can significantly affect combustion stability, and unburned NH3 emissions in a multi-fuel system can be reduced by using an appropriate amount of pre-injected fuel; at the same time, the combustion efficiency of the engine is improved. This indicates that the application of the pre-injection strategy in a multi-fuel co-combustion system has a wide range of prospects. Reference [24] explored the optimization of the combustion characteristics of pure methanol fuel by adjusting the injection parameters and EHN addition through CFD simulation and experimental studies.

In summary, using pre-injection strategies is an important research direction that can enhance the performance and environmental friendliness of compression ignition methanol engines by improving the physical and chemical properties of the fuel, as well as modulating combustion in the early stages of the combustion process. The results of different studies have shown that optimizing the timing and amount of pre-injection is essential to achieving the best combustion results.

2. Test Platform and Test Program

2.1. Modification of the Engine

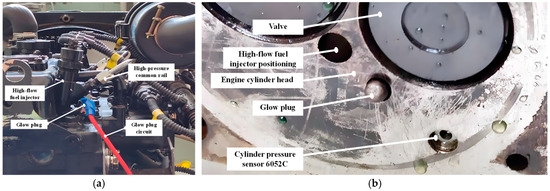

A three-cylinder machine equipped with electric plugs for transformation has a transformation program for 1. the electric plugs’ access to an independent power supply so that they remain in a red-hot state; 2. the use of special high-flow injectors to ensure that the methanol injection volume can meet the test requirements; 3. the transformation of the engine’s low-pressure oil system to ensure that the engine has an oil supply. Figure 1 shows a schematic diagram of engine modification, and Table 1 provides a comparison of the engine’s technical parameters before and after transformation.

Figure 1.

Schematic diagram of engine modification: (a) cylinder head exterior close-up; (b) cylinder head interior close-up.

Table 1.

Comparison of engine’s technical parameters.

2.2. Introduction of Engine Test Bench

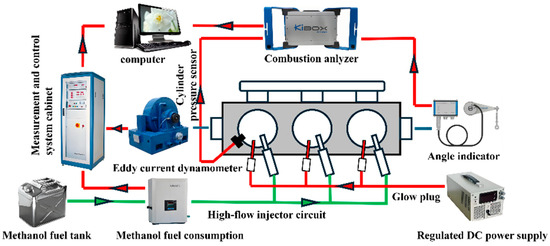

Figure 2 presents a schematic diagram of the engine test bench. The DW100 eddy current dynamometer in the test stand was used to control the engine load, and the real-time pressure in the cylinder was measured with a Kistler 6052C pressure sensor (Kistler Group, Winterthur, Switzerland) (installed in the third cylinder). The measurement interval of the Kistler 6052C pressure sensor was 0.1 °CA, and the signal was displayed in real time and analyzed using the KiBox software (Software version number: KiBoxCockpit3.2.3.9757).

Figure 2.

Engine test stand.

The main data acquisition devices in the Kistler combustion analyzer included cylinder pressure sensors and angle gauges. Details of these devices are shown in Table 2.

Table 2.

Combustion analyzer’s data acquisition equipment information.

During this test study, the maximum pressure in the engine cylinders was below 10 MPa. Table 3 shows the calibration instructions for the Kistler model 6052C pressure sensor. It can be seen that the linearity error of the cylinder pressure sensors used in the test is less than 0.2%, which meets the test requirements. The data acquisition equipment configured in the Kistler combustion analyzer has a reliable resistance to interfering signals, which ensures the reliability of the measured data.

Table 3.

Kistler model 6052C pressure transducer’s calibration instructions.

2.3. Test Program

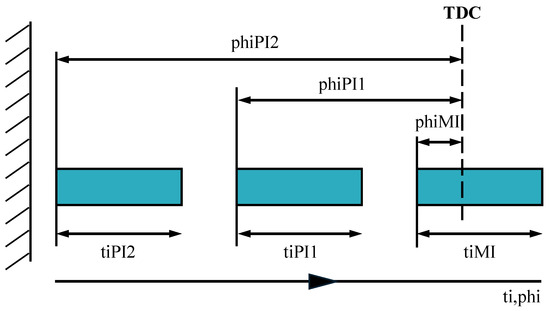

Figure 3 shows a schematic diagram of the crankshaft position for setting the injection parameters during the test. The engine was adjusted for two pre-injections during the test, defining the one close to the main injection (phiMI) as pre-injection 1 (phiPI1) and the one far from the main injection as pre-injection 2 (phiPI2). In addition, the pulse widths of pre-injection 2 (phiPI2), pre-injection 1 (phiPI1), and the main injection (phiMI) and the position principle of the top dead center (TDC) are defined in the diagram.

Figure 3.

Schematic diagram of each injector parameter.

Because, in low-speed conditions, the engine’s cylinder combustion temperature and pressure are low, and methanol has a high latent heat of vaporization, shortly after a large amount of methanol is sprayed into the cylinder, the combustion environment will deteriorate, which causes the combustion stability to deteriorate. Thus, the test conditions selected were 1200 r/min medium/high load, and a pre-spray was used to form a segmented combustion to improve the combustion instability due to the aforementioned problems.

Table 4 shows the set values of injection parameters. Among them, the main injection timing refers to the original diesel engine’s main injection timing (3 °CA BTDC). The main injection pulse width was set to 10 °CA to keep the engine at a medium/high load. The pre-injection timing was set according to the pre-bench experience so that the pre-injected methanol would have a good mixing quality. The ratio of the pulse width of pre-injection 1 to that of pre-injection 2 is defined as the pre-injection proportioning ratio (rPI). Since it takes some time for the injector control system to complete the opening and closing actions, the pre-injection pulse width was set to a minimum of 2 °CA, and the detailed setting values are shown in Table 3. During the test, an open-source ECU control system was used to accurately control the relevant injection parameters. The test study adopted the full test program, and each group of test parameters was collected for 211 cycles after the engine was running stably to reduce the influence of test errors on the test results.

Table 4.

Injector parameter setting.

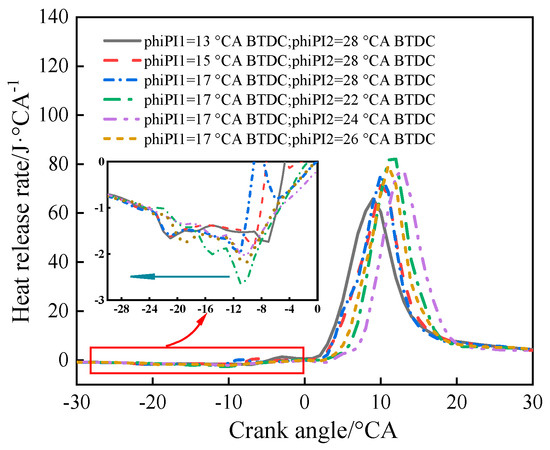

When the pre-injected methanol enters the cylinder, the temperature and pressure inside the cylinder will decrease to a certain extent, which can be verified by using the exothermic rate measured using the combustion analyzer. To visualize the exothermic rate under different pre-injection parameters, the pre-injection parameters shown in Table 5 were used to verify pre-injection control. Figure 4 shows the exothermic rate under different pre-injection timings. The green line represents the direction of the prejet away from the main jet. The results indicate that delaying the pre-injection timing (away from the main injection) causes the peak exothermic rate location to shift away from the main injection.

Table 5.

Pre-spray parameterization.

Figure 4.

Schematic of exothermic rate.

3. Results and Discussion

The cyclic coefficient of variation () value is an important indicator of the combustion instability of the engine, which is calculated with the following formula:

where is the mean value of the studied parameter x; is the standard deviation of the studied parameter x. Parameter x includes a cyclic variation in in-cylinder pressure at each crankshaft corner, indicated mean effective pressure (IMEP), and peak cylinder pressure (PMAX).

In Equation (1), when the denominator is small, small changes in the numerator will cause large changes in the COV value, which is a disadvantage of using the cyclic coefficient of variation to analyze combustion instability. Therefore, in the research process, when key combustion parameters with small average values—such as the combustion initiation point (AI05) and combustion center of gravity (AI50)—are analyzed, the interquartile range (IQR) method can be used to quantify their fluctuation degree.

The interquartile range (IQR) is obtained by calculating the difference between the upper quartile (Q3) and the lower quartile (Q1) of the data. The statistical method analyzing the impact of extreme values shows that they have better anti-interference properties. The IQR is calculated as follows:

where Q1 is equal to the 25th percentile of all the values in the sample from small to large, and Q3 is equal to the 75th percentile of all the values in the sample from small to large. The interquartile range gives the range of the middle 50% portion of the data, which can be visualized by constructing a box plot; the smaller the range, the more concentrated and less volatile the data.

3.1. Analysis of Combustion Pressure Cycle Fluctuations

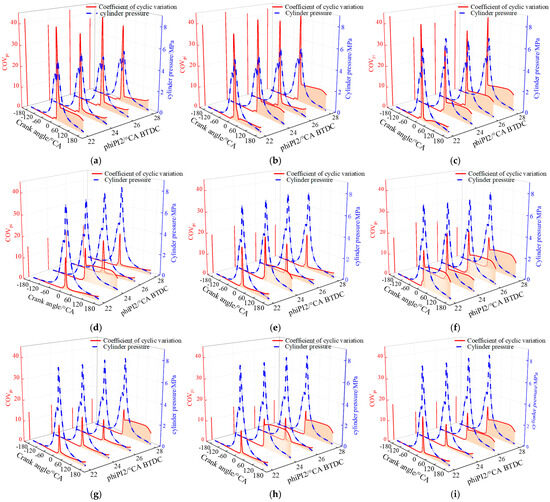

Figure 5 shows the cylinder pressure (pi) curve of the compression ignition methanol engine and the cyclic fluctuation value of the cylinder pressure (COVpi) curve at each crankshaft angle under the full test program. When rPI = 2:4, the engine cylinder pressure had an obvious bimodal peak phenomenon, and at the same time, the cylinder pressure fluctuated more, with a maximum cyclic fluctuation rate value of 43.58% (phiPI1 = 15 °CA BTDC, phiPI2 = 24 °CA BTDC); the greater the pulse width of pre-injection 1, the closer the crankshaft angle corresponding to the peak cylinder pressure of the engine was to the upper stop; the phenomenon of double peaks of the cylinder pressure gradually weakened, and the peak cyclic fluctuation of the cylinder pressure at each crankshaft angle was significantly reduced, with a minimum cyclic fluctuation rate value of 10.78% (rPI = 4:2, phiPI1 = 13 °CA BTDC, phiPI2 = 26 °CA BTDC). The above data indicate that the cylinder pressure cycle fluctuation of the compression ignition methanol engine can be significantly improved by adjusting the pre-injection parameters, with the maximum improvement reaching 32.8% in this test program. The reasons for the above phenomenon are that (1) with the increase in the pulse width of pre-injection 1, the heat generated in the pre-injection stage is closer to that in the main injection stage, and the stagnation period of the main injection is shortened, which reduces the effect of fuel aggregation during the stagnation period and makes the ignition more stable; (2) the closer the peak cylinder pressure is to the upper stopping point, the lower the rate of change in the volume of combustion and the more centralized the pressure release; moreover, the combustion is affected by the reflections of the pressure wave, so the cyclic fluctuation rate is lower. In summary, the cylinder pressure cyclic fluctuation of the compression ignition methanol engine can be significantly improved by adjusting the pre-spray parameters; the maximum improvement reached 32.8% in this test program.

Figure 5.

COV curves of in-cylinder pressure time series at each crankshaft angle: (a) rPI = 2:4; phiPI1 = 13 °CA BTDC; (b) rPI = 2:4; phiPI1 = 15 °CA BTDC; (c) rPI = 2:4; phiPI1 = 17 °CA BTDC; (d) rPI = 3:3; phiPI1 = 13 °CA BTDC; (e) rPI = 3:3; phiPI1 = 15 °CA BTDC; (f) rPI = 3:3; phiPI1 = 17 °CA BTDC; (g) rPI = 4:2; phiPI1 = 13 °CA BTDC; (h) rPI = 4:2; phiPI1 = 15 °CA BTDC; (i) rPI = 4:2; phiPI1 = 17 °CA BTDC.

At each pre-injection ratio, there was no clear pattern of influence between tiPI1 and tiPI2 on the cylinder pressure cycle fluctuation. As the pre-injection gradually moved away from the main injection, the influence of the heat generated by pre-injection on the main combustion stage weakened, and the formation of aggregates of the main injection fuel due to insufficient combustion led to an increase in the value of the back section of the COVpi curve in more test groups, i.e., an increase in afterburning in the combustion process.

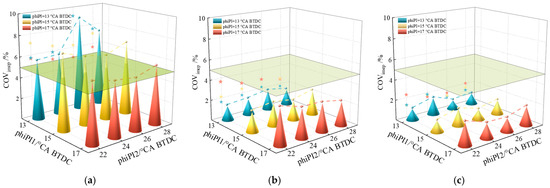

3.2. Analysis of Cyclic Fluctuations in Indicated Average Effective Pressure

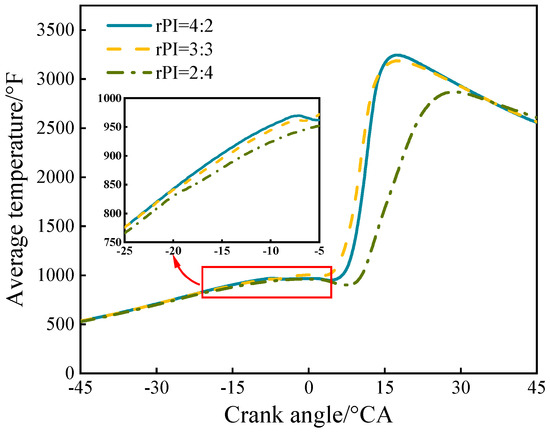

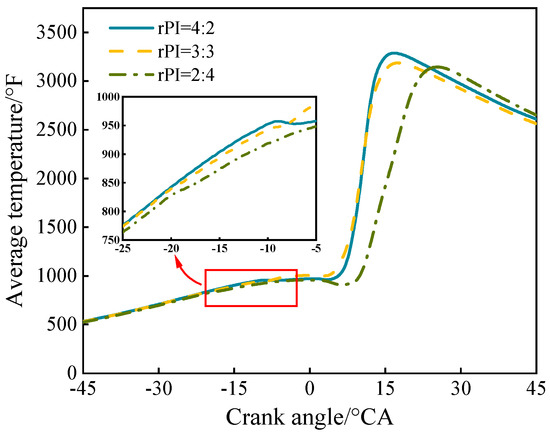

Figure 6 shows the cyclic fluctuation rate of the indicated average effective pressure. The dotted line represents the trend of the test results as the pre-spraying time changes, and the asterisk indicates the projection of the test results. The cyclic fluctuation rate of the indicated average effective pressure is often used to reflect the stability of the engine’s work. A value of less than 5% can be considered to be stable combustion; the figure is labeled with the cross-section of COVimep = 5% (Green plates in the figure). When the pulse width of pre-injection 1 increased above 3 °CA, the COVimep value of the engine was significantly reduced, by up to 8.12%. The reason for the reduction in COVimep is that pre-injection 1 ignition can significantly increase the cylinder temperature when the main injection of methanol enters the cylinder, which effectively reduces the risk of a misfire in the main combustion stage while advancing the start of combustion, which improves the effect on the quality of the main combustion due to the weakening of the air movement during the downward movement of the piston. The pre-spray 1 pulse width increased from 3 °CA to 4 °CA, and the heat generated by the pre-sprayed fuel had a reduced effect on the main combustion stage, while the decrease in the COVimep value was reduced. Figure 7 shows a schematic of the average in-cylinder temperatures for each pre-injection ratio at the pre-injection timing with optimal COVimep values (phiPI1 = 13 °CA BTDC, phiPI2 = 26 °CA BTDC).

Figure 6.

Schematic diagram of cyclic fluctuations indicating mean effective pressure: (a) rPI = 2:4; (b) rPI = 3:3; (c) rPI = 4:2.

Figure 7.

Average temperature vs. crank angle of the cylinder.

There was no clear pattern of the influence of pre-jet timing on the indicated mean effective pressure cycle fluctuation rate at each pre-jet ratio. At reasonable pre-spray ratios (COVimep < 5%), larger main pre-spray intervals (phiPI1 = 17 °CA ATDC) reduced the improvement effect of pre-spraying on the main combustion quality, and the fluctuation between the retarded and afterburning phases had a greater effect on the calculation of the indicated mean effective pressure. When rPI = 4:2, the engine combustion was stable; the COVimep values of the different experimental groups were concentrated at ±0.63%, and the effect of pre-injection timing on the COVimep value reached a negligible level.

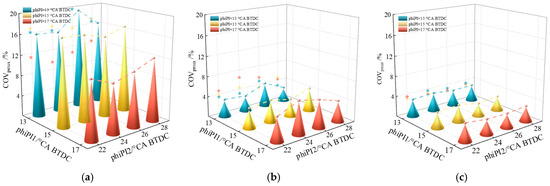

3.3. Cyclic Variation Analysis of Peak In-Cylinder Pressure

Because the peak cylinder pressure (PMAX) is easy to measure and sensitive to cyclic variations, it is also commonly used to characterize the combustion stability of the engine [25]. Figure 8 shows the effect of the pre-injection parameters on the cyclic variation coefficient of the peak cylinder pressure (COVpmax) of the methanol engine. The dotted line represents the trend of the test results as the pre-spraying time changes, and the asterisk indicates the projection of the test results. From this, it can be seen that increasing the pulse width of pre-injection 1 can effectively reduce the cyclic fluctuation rate of the peak cylinder pressure of the engine by up to 16.96%. As the interval between pre-injection 2 and the main injection was large, the in-cylinder pressure was low during injection, and increasing the pre-injection 2 pulse width increased the wet-wall rate of the engine, which in turn affected the combustion quality in the main combustion stage. Peak cylinder pressure was more sensitive to its phase and the ignition moment of the main combustion, and increasing the pulse width of pre-spray 1 could weaken the double-peak phenomenon of the in-cylinder pressure, which in turn improved the cyclic fluctuation of the peak cylinder pressure. Figure 9 shows a schematic diagram of the average in-cylinder temperatures for each pre-injection ratio at pre-injection timing with optimal COVpmax values (phiPI1 = 15 °CA BTDC, phiPI2 = 26 °CA BTDC).

Figure 8.

Schematic diagram of cyclic fluctuation of peak pressure in the cylinder: (a) rPI = 2:4; (b) rPI = 3:3; (c) rPI = 4:2.

Figure 9.

Average temperature of the cylinder.

The pre-spray timing had no clear law of influence on the cyclic fluctuation rate of peak cylinder pressure according to each pre-spray ratio. When pre-injection 1 had better combustion quality, the peak cylinder pressure was not sensitive to the fluctuations in the retarded and afterburning periods, so a larger main pre-injection interval did not provide the worst fluctuation results in scenarios with lower peak cylinder pressure fluctuation rates (rPI = 3:3, rPI = 4:2). When rPI = 4:2, the bimodal phenomenon of the cylinder pressure was significantly weakened; the values of the COVpmax of the different experimental groups were concentrated at ±0.56%, and the effect of pre-injection timing on COVpmax values reached a negligible level.

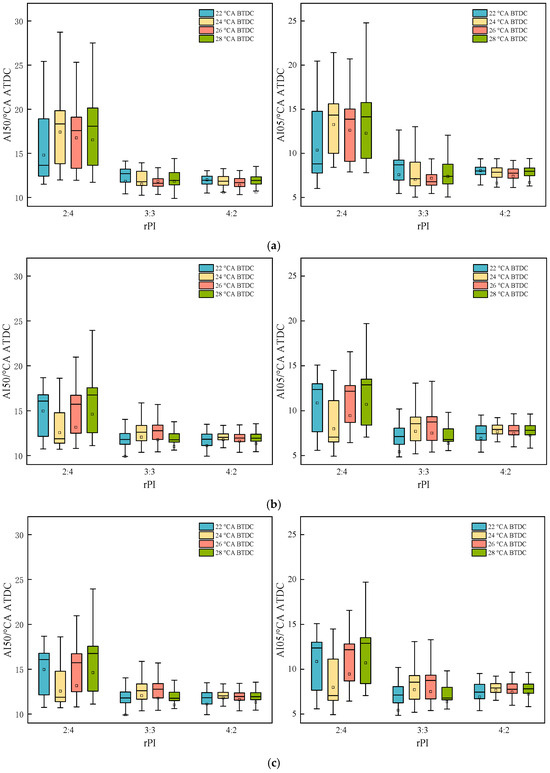

3.4. Analysis of Fluctuation of Combustion Start Point and Combustion Center of Gravity

During the stagnant combustion period, fuel aggregation and mixing directly affect the combustion onset moment, exothermic rate, and methanol mixing, which in turn directly influences combustion stability. The position of the crankshaft where the center of gravity of combustion is located directly reflects the timing consistency of the combustion process and energy controllability, which is the core index in combustion control. In this test, the main injection timing was fixed (3 °CA BTDC), and the fluctuation of the stagnation period was reflected by the fluctuation of the combustion start point. The Kistler combustion analyzer used the crankshaft angle (AI05) corresponding to 5% of the cumulative heat release as the combustion start point and the crankshaft angle (AI50) corresponding to 50% of the cumulative heat release as the combustion center of gravity.

The average value of the phase (AI05) of the combustion start point is small, and it can be seen from Equation (1) that when the denominator is small, a small change in the numerator can cause a large change in the COV value, which affects the analysis of the results. Therefore, the stability of the combustion start point was investigated using the quartile spacing statistical method. The same method was used to study the phase of the combustion center of gravity (AI50), which is conducive to analyzing the connection between the two fluctuations.

From Figure 10, it can be seen that when rPI = 2:4, the amount of pre-injection 2 fuel increased and entered the cylinder at a position far away from the upper stop, which means that it was easily diluted by the surrounding air and thus led to insufficient combustion. Pre-injection 1 had a small amount of fuel, which could not provide a good combustion environment for the main injection fuel, causing the ratio of methanol premixed combustion in the main injection stage to increase and greatly fluctuate. When the pre-injection ratio was adjusted to rPI = 3:3 and rPI = 4:2, the quality of the main combustion was improved, the proportion of the diffusion combustion in the main injection combustion process increased, and the fluctuation of the combustion center of gravity was greatly improved compared with that of rPI = 2:4. The fluctuations in the center of gravity of combustion and the fluctuations in the combustion initiation point showed significant consistency, which was attributed to the fast combustion rate of methanol and the weak influence of the piston’s downward movement on the combustion stability of the main combustion stage during the rapid combustion phase.

Figure 10.

Schematic diagram of fluctuation of combustion start point and combustion center of gravity: (a) phiPI1 = 13 °CA BTDC; (b) phiPI1 = 15 °CA BTDC; (c) phiPI1 = 17 °CA BTDC.

4. Conclusions

- (1)

- The reasonable regulation of the ratio of the two pre-injection pulse widths can enhance the degree to which the pre-injection improves the main combustion stage, which is an effective way to reduce fluctuations in parameters such as the engine’s in-cylinder pressure, the indicated average effective pressure, the peak cylinder pressure, and the combustion start point. This comprehensive study shows that the combustion stability of the electric-plug-assisted compression ignition methanol engine can be improved by choosing a pre-injection pulse width ratio of rPI = 4:2 at 1200 r/min medium/high loads, and the best stability is obtained at phiPI1 = 15° CA BTDC and phiPI1 = 26 °CA BTDC.

- (2)

- With electric-plug-assisted compression ignition technology, the ignition of pre-injected methanol significantly affects the combustion start point of the main injection of methanol, which in turn affects the diffusion combustion ratio of methanol in the main combustion stage. In this stage, the greater the diffusion combustion ratio, the weaker the double-peak phenomenon of in-cylinder pressure, and the smaller the cyclic fluctuation in each parameter of the methanol engine. Therefore, in the process of calibrating the engine injection parameters, the position of the combustion start point should be as far as possible in the main injection period.

- (3)

- At low speeds and high loads, the impact of the pre-injection ratio strategy on the combustion stability of methanol engines is significantly higher than that of the pre-injection timing strategy. If the technical method of adjusting the injection parameters is used to improve the combustion stability, the appropriate pre-injection ratio should be determined first.

- (4)

- The combustion of methanol in the cylinder is a complex chaotic process. The pre-injection parameters set during the test cannot completely cover the entire combustion process under a medium–high load of 1200 rpm. Therefore, in future work, a machine learning model should be constructed using the setup parameters and results of this experiment as training data. This model will enable accurate prediction of combustion stability, thereby enhancing the research and analysis of combustion stability using the pre-injection strategy throughout the entire combustion process.

Author Contributions

Experiments, M.J. and S.G.; methodology, C.Z.; validation, M.J. and H.H.; writing—original draft preparation, M.J. Supervision, X.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the decomposition characteristics of natural gas hydrate in porous media based on the LBM method (ZY-2023019), Shanxi Institute of Energy; a study on the influence of multiple combustion modes on the combustion characteristics and emissions of M100 methanol engine (ZY-2023013), Shanxi Institute of Energy; and a study on the carbon emission pattern of electric vehicles based on the carbon peaking background (ZY-2023015), Shanxi Institute of Energy.

Data Availability Statement

The data are contained within the article.

Conflicts of Interest

All authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Bharath, B.K.; Selvan, V.A.M. Influence of Higher Alcohol Additives in Methanol–Gasoline Blends on the Performance and Emissions of an Unmodified Automotive SI Engine: A Review. Arab. J. Sci. Eng. 2021, 46, 7057–7085. [Google Scholar] [CrossRef]

- No, S.Y. Application of biomethanol to advanced CI engines: A review. J. Fundam. Renew. Energy Appl. 2018, 8. [Google Scholar] [CrossRef]

- Pandey, S. A critical review: Application of methanol as a fuel for internal combustion engines and effects of blending methanol with diesel/biodiesel/ethanol on performance, emission, and combustion characteristics of engines. Heat Transf. 2022, 51, 3334–3352. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Singh, A.P.; Kumar, V. Effect of pilot injection strategy on the methanol-mineral diesel fueled reactivity controlled compression ignition combustion engine. Fuel 2023, 338, 127115. [Google Scholar] [CrossRef]

- Cheng, C.; Faurskov, C.R.; Dyhr, P.T.; Winther, K.; Langballe, F.N.; Schramm, J. Investigation of combustion characteristics, physical and chemical ignition delay of methanol fuel in a heavy-duty turbo-charged compression ignition engine. Fuel 2023, 348, 128536. [Google Scholar] [CrossRef]

- Jamrozik, A.; Tutak, W.; GrabRogaliński, K. Combustion Stability, Performance and Emission Characteristics of a CI Engine Fueled with Diesel/n-Butanol Blends. Energies 2021, 14, 2817. [Google Scholar] [CrossRef]

- Kerihuel, A.; Senthilkumar, M.; Bellettre, J.; Tazerout, M. Use of animal fats as CI engine fuel by making stable emulsions with water and methanol. Fuel 2005, 84, 1713–1716. [Google Scholar] [CrossRef]

- Agama, A.A.; Sugiarto, B.; Mokhtar; Kurniawan, A.; Auzani, A.S.; Wisnugraha, M.A.; Rahatwan, Z.B.; Prasetyo, D. Evaluating Lean Combustion Cycle Stability and Emissions in Spark Ignition Engines with Gasoline, Ethanol, and Methanol Blends. IOP Conf. Ser. Earth Environ. Sci. 2024, 1372, 012042. [Google Scholar] [CrossRef]

- Ricci, F.; Mariani, F.; Papi, S.; Zembi, J.; Battistoni, M.; Grimaldi, C.N. The Synergy between Methanol M100 and Plasma-Assisted Ignition System PAI to Achieve Increasingly Leaner Mixtures in a Single-Cylinder Engine. Energies 2024, 17, 1659. [Google Scholar] [CrossRef]

- Kusaka, J.; Daisho, Y.; Kihara, R.; Saito, T. Combustion and ignition characteristics in a glow assisted methanol DI engine (Optimization of slit geometries and glow-plug temperature). JSAE Rev. 1997, 18, 64–66. [Google Scholar] [CrossRef]

- Liu, X.; Zhu, J.; Li, Z.; Gong, S.; Long, Y.; Zheng, Y. Combustion and Emission of Compression Ignition Methanol Engine Assisted by Controllable Temperature Glow Plug. Veh. Engine 2024, 1, 8–15. [Google Scholar]

- Xu, M.; Cheng, W.; Zhang, H.; An, T.; Zhang, S. Effect of diesel pre-injection timing on combustion and emission characteristics of compression ignited natural gas engine. Energy Convers. Manag. 2016, 117, 86–94. [Google Scholar] [CrossRef]

- Hadadpour, A.; Xu, S.; Pang, K.M.; Bai, X.-S.; Jangi, M. Effects of pre-injection on ignition, combustion and emissions of spray under engine-like conditions. Combust. Flame 2022, 241, 112082. [Google Scholar] [CrossRef]

- Punov, P.; Evtimov, T. Combustion optimization in a modern diesel engine by means of pre-injection strategy. Mach. Technol. Mater. 2015, 4, 41–44. [Google Scholar]

- Shibata, G.; Ogawa, H.; Okamoto, Y.; Amanuma, Y.; Kobashi, Y. Combustion Noise Reduction with High Thermal Efficiency by the Control of Multiple Fuel Injections in Premixed Diesel Engines. SAE Int. J. Engines 2017, 10, 1128–1142. [Google Scholar] [CrossRef]

- Li, Z.; Wang, Y.; Yin, Z.; Geng, H.; Zhu, R.; Zheng, X. Effect of injection strategy on a diesel/methanol dual-fuel direct-injection engine. Appl. Therm. Eng. 2021, 189, 116691. [Google Scholar] [CrossRef]

- García, A.; Monsalve-Serrano, J.; Guzmán-Mendoza, M.G.; Iñiguez, E. Comparison of the transient response of a compression ignition engine running with gasoline, naphtha, and methanol as fuels. Fuel 2024, 367, 131454. [Google Scholar] [CrossRef]

- Liu, H.; Li, M.; Wei, H.; Wang, C.; Song, T.; Huang, Z.; Zhang, Z.; Cui, Y.; Jin, C. Effects of Injection Parameters and EHN Mixing on the Combustion Characteristics of Fueling Pure Methanol in a Compression Ignition Engine. Processes 2024, 12, 48. [Google Scholar] [CrossRef]

- Duan, H.; Hu, W.; Wang, J.; Yin, X.; Hu, E.; Zeng, K. Effects of diesel pilot-injection strategy on a methanol/diesel dual-direct injection engine. Appl. Therm. Eng. 2025, 261, 125106. [Google Scholar] [CrossRef]

- Liu, J.; Wu, P.; Wang, L.; Jia, D.; Ji, Q.; Li, J.; Rashed, G.; Kheshti, M. Effects of pre-injection strategy on combustion performance of methanol/diesel dual fuel engine at low load. E3S Web Conf. 2021, 252, 02027. [Google Scholar] [CrossRef]

- Yu, Y.; Wen, H. Investigation on efficient and clean combustion pre-injection strategy of a diesel/methanol dual direct-injection marine engine under full load. Case Stud. Therm. Eng. 2024, 59, 104472. [Google Scholar] [CrossRef]

- Treacy, M.; Xu, L.; Fatehi, H.; Kaario, O.; Bai, X.-S. Performance of a Methanol-Fueled Direct-Injection Compression-Ignition Heavy-Duty Engine under Low-Temperature Combustion Conditions. Energies 2024, 17, 4307. [Google Scholar] [CrossRef]

- Cheng, Q.; Kaario, O.; Ahmad, Z.; Vuorinen, V.; Larmi, M. Effect of pilot fuel properties on engine performance and combustion stability in a tri-fuel engine powered by premixed methane-hydrogen and diesel pilot. Int. J. Hydrogen Energy 2021, 46, 37469–37486. [Google Scholar] [CrossRef]

- Yang, D.; Wei, S.; Ma, Y.; E, J.; Zhao, J. Influence of critical parameters on combustion and emission characteristics of methanol/diesel dual fuel compression combustion engine. Fuel 2024, 368, 131647. [Google Scholar] [CrossRef]

- Yao, B.; Li, G. Analysis of combustion cycle variation characteristics parameters of natural gas engines. Chin. Intern. Combust. Engine Eng. 2007, 28, 1–5. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).