Research Progress on Optimization Methods of Platform Well Fracturing in Unconventional Reservoirs

Abstract

1. Introduction

2. New Progress in Optimization Research of PWF for Unconventional Reservoirs

2.1. Determination of Optimization Parameters and Objective Functions

2.1.1. Design of Optimization Parameters

2.1.2. Design of Objective Functions

- (1)

- Production Capacity as the Objective Function

- (2)

- Net Present Value (NPV) as the Objective Function

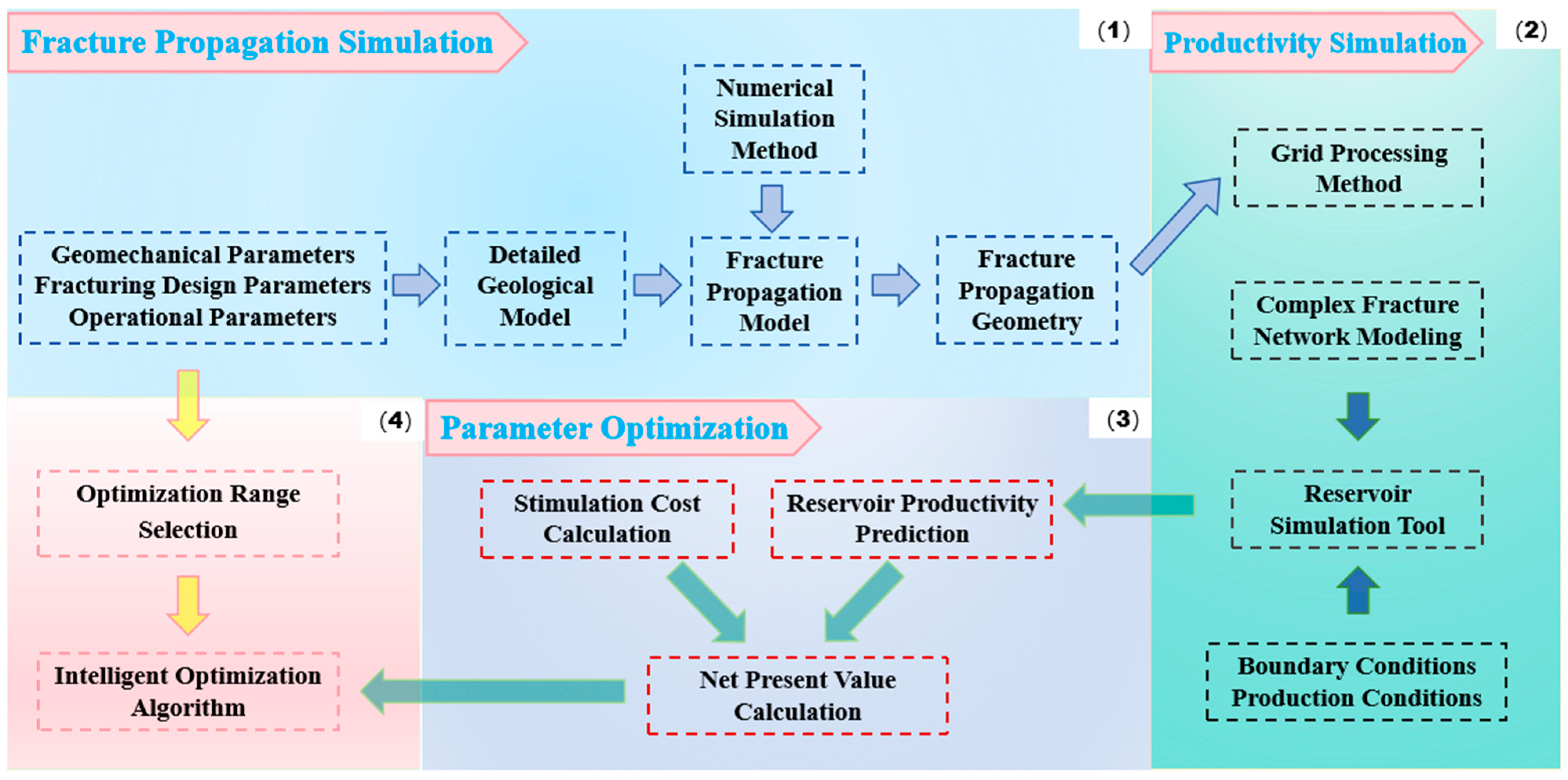

2.2. Integration of Fracture Propagation and Production Dynamics

2.3. PWF Optimization Method

2.3.1. Single-Factor Analysis

2.3.2. Orthogonal Testing Method

2.3.3. Intelligent Optimization Method

3. Challenges of PWF Technology in Unconventional Reservoirs

- (1)

- Complex Geological Conditions of Unconventional Reservoirs

- (2)

- Inability to Quantitatively Characterize Complex Fracture Networks

- (3)

- Lack of Accurate Geological and Production Data Support

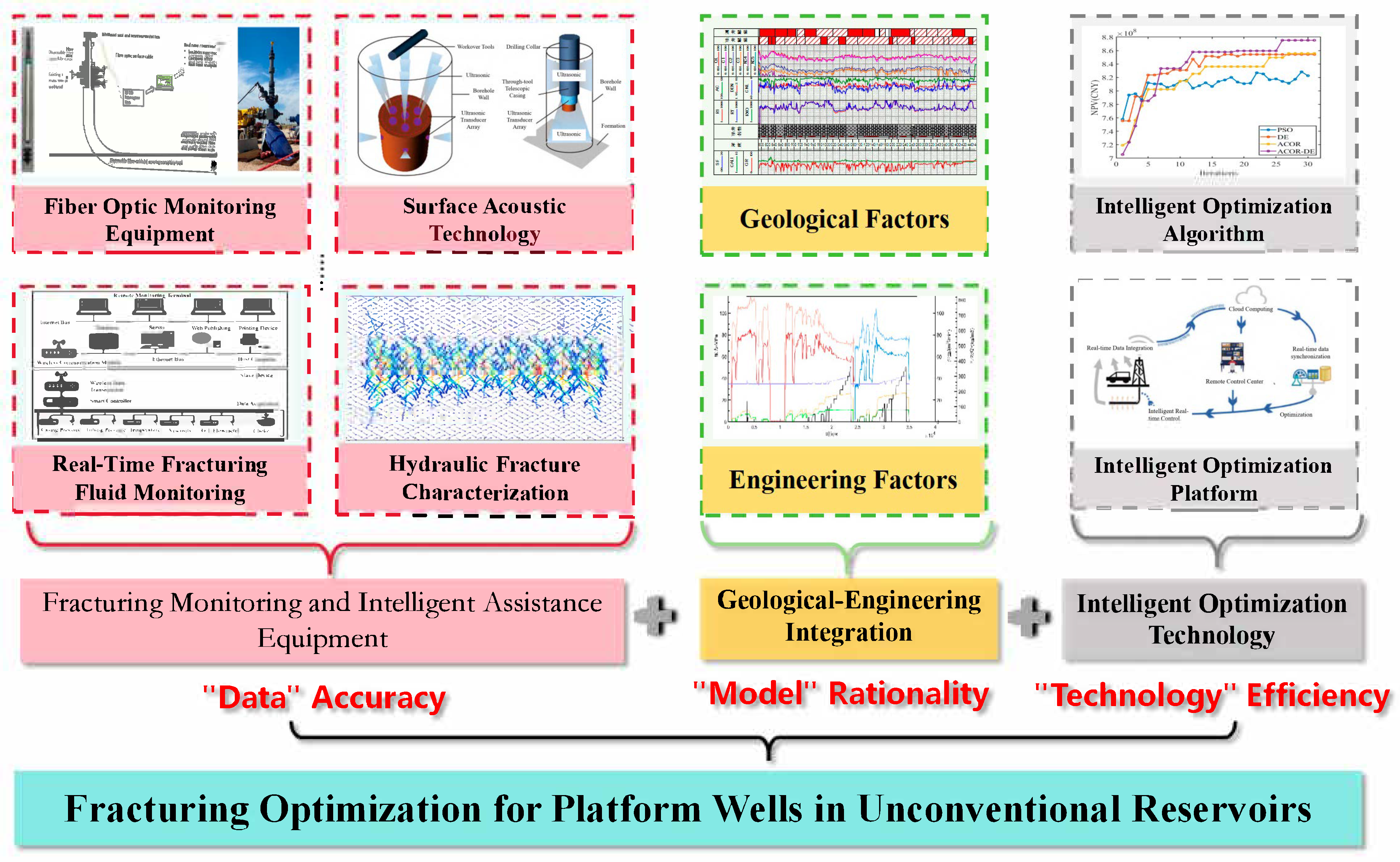

4. Development Direction of Fracturing Technology for Platform Wells in Unconventional Reservoirs

4.1. Strengthen the Integrated Research of Geology and Engineering and Scientifically Design the Fracturing Plan

4.2. Enhanced Fracturing Detection and Intelligent Auxiliary Equipment

4.2.1. Fiber Optic Monitoring Technology for Fracturing of Unconventional Oil and Gas Wells

4.2.2. Real-Time Friction Data Measurement Based on Downhole Sonic Technology

4.2.3. Fracturing Fluid Real-Time Tracking and Monitoring Equipment

4.2.4. Unconventional Hydraulic Fracture Diagnosis Technology

4.3. Develop Intelligent Optimization and Real-Time Control Technology for PWF

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Odgaard, O.; Delman, J. China׳ s energy security and its challenges towards 2035. Energy Policy 2014, 71, 107–117. [Google Scholar] [CrossRef]

- Fu, E.; He, W. The development and utilization of shale oil and gas resources in China and economic analysis of energy security under the background of global energy crisis. J. Pet. Explor. Prod. Technol. 2024, 14, 2315–2341. [Google Scholar] [CrossRef]

- Wang, Y.; Lu, Y.; Li, Y.; Wang, X.; Yan, X.; Zang, Z. Progress and application of unconventional reservoir fracturing technology. Acta Pet. Sin. 2012, 33, 149–158. [Google Scholar]

- Zhang, Y.; Ge, H.; Zhao, K.; Liu, S.; Zhou, D. Simulation of pressure response resulted from non-uniform fracture network communication and its application to interwell-fracturing interference in shale oil reservoirs. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 114. [Google Scholar] [CrossRef]

- Qun, L.E.I.; Yun, X.U.; Bo, C.A.I.; Baoshan, G.; Xin, W.; Guoqiang, B.I.; Tao, L. Progress and prospects of horizontal well fracturing technology for shale oil and gas reservoirs. Pet. Explor. Dev. 2022, 49, 191–199. [Google Scholar]

- Jiyong, Z.H.A.O.; Jianming, F.A.N.; Yonghong, H.E.; Ziqing, Y.A.N.G.; Wei, G.A.O.; Wubin, G.A.O. Optimization of horizontal well injection-production parameters for ultra-low permeable–tight oil production: A case from Changqing Oilfield, Ordos Basin, NW China. Pet. Explor. Dev. 2015, 42, 74–82. [Google Scholar]

- Yi, Y.; Wang, L.; Li, J.; Chen, S.; Tian, H.; Tian, G. Optimization of re-fracturing method and fracture parameters for horizontal well in Mahu conglomerate oil reservoir. Front. Energy Res. 2022, 10, 856524. [Google Scholar] [CrossRef]

- Li, J.; He, Y.; Yuan, C.; Zou, Q.; Qin, J.; Li, J. Practice and discussion on “factory-like” fracturing mode of horizontal well groups in shale gas reservoirs. Drill. Prod. Technol. 2017, 40, 47–50+7–8. [Google Scholar]

- Qun, L.E.I.; Dingwei, W.E.N.G.; Xiong, S.; Hanbin, L.I.U.; Baoshan, G.U.A.N.; Qiang, D.E.N.G.; Xuemei, Y.A.N.; Liang, H.; Zeyuan, M.A. Progress and development directions of shale oil reservoir stimulation technology of CNPC. Pet. Explor. Dev. 2021, 48, 1035–1042. [Google Scholar]

- Qian, B.; Zhang, J.; Zhu, J.; Fang, Z.; Kou, S.; Chen, R. Application of zipper-fracturing of horizontal cluster wells in the Changning shale gas pilot zone, Sichuan Basin. Nat. Gas Ind. B 2015, 2, 181–184. [Google Scholar] [CrossRef]

- Cheng, S.; Wu, B.; Zhang, M.; Zhang, X.; Han, Y.; Jeffrey, R.G. Surrogate modeling and global sensitivity analysis for the simultaneous growth of multiple hydraulic fractures. Comput. Geotech. 2023, 162, 105709. [Google Scholar] [CrossRef]

- Guo, C.; Wei, M.; Liu, H. Study of gas production from shale reservoirs with multi-stage hydraulic fracturing horizontal well considering multiple transport mechanisms. PLoS ONE 2018, 13, e0188480. [Google Scholar] [CrossRef] [PubMed]

- Guan, B.; Li, S.; Liu, J.; Zhang, L.; Chen, S. Analysis and optimization of multiple factors influencing fracturing induced stress field. J. Pet. Explor. Prod. Technol. 2020, 10, 171–181. [Google Scholar] [CrossRef]

- Pszonka, J.; Sala, D. Application of the mineral liberation analysis (MLA) for extraction of grain size and shape measurements in siliciclastic sedimentary rocks. E3S Web Conf. 2018, 66, 02002. [Google Scholar] [CrossRef]

- Yao, J.; Liu, L.; Yang, Y.; Sun, H.; Zhang, L. Characterizing multi-scale shale pore structure based on multi-experimental imaging and machine learning. Nat. Gas Ind. B 2023, 10, 361–371. [Google Scholar] [CrossRef]

- Khan, M.; Bery, A.A.; Ali, S.S.; Awfi, S.; Bashir, Y. Unlocking reservoir potential: Machine learning-driven prediction of reservoir properties and sweet spots identification. In Proceedings of the International Petroleum Technology Conference (IPTC), Dhahran, Saudi Arabia, 12 February 2024; p. D031S140R009. [Google Scholar]

- Wang, W.; Ma, X.; Zhang, W.; Zou, Y.; Zhang, S.; Wang, X.; Yang, L. Data-driven and unsupervised machine learning for comprehensive quality evaluation and intelligent optimization of multi-stage design in horizontal wells within shale reservoir. Geoenergy Sci. Eng. 2025, 253, 213991. [Google Scholar] [CrossRef]

- Yang, Y.; Shi, X.; Ji, C.; Yan, Y.; An, N.; Zhang, T. The hydraulic fracturing optimization for stacked tight gas reservoirs using multilayers and multiwells fracturing strategies. Energy Eng. 2024, 12, 121. [Google Scholar] [CrossRef]

- Swadesi, B.; Ahmad Muraji, S.; Kurniawan, A.; Widiyaningsih, I.; Widyaningsih, R.; Budiarto, A.; Aslam, B.M. Optimizing the development strategy of combined steam flooding & cyclic steam stimulation for enhanced heavy oil recovery through reservoir proxy modeling. J. Pet. Explor. Prod. Technol. 2021, 11, 4415–4427. [Google Scholar]

- Zhang, L.J.; Tan, X.H.; Jiao, Y.J.; Wang, S. Study on Influencing Factors and Prediction Methods of Initial Productivity of Volumetric Fracturing Wells. In Proceedings of the International Field Exploration and Development Conference, Qingdao, China, 20–22 October 2021; Springer Nature: Singapore; pp. 5546–5556. [Google Scholar]

- Zhang, H.; Sheng, J. Optimization of horizontal well fracturing in shale gas reservoir based on stimulated reservoir volume. J. Pet. Sci. Eng. 2020, 190, 107059. [Google Scholar] [CrossRef]

- Zhao, X.; Li, M.; Yan, K.; Yin, L. Revolutionizing Tight Reservoir Production: A Novel Dual-Medium Unsteady Seepage Model for Optimizing Volumetrically Fractured Horizontal Wells. Energy Eng. 2023, 120, 2933–2949. [Google Scholar] [CrossRef]

- Yu, Z.; Wang, Z.; Jiang, Q.; Wang, J.; Zheng, J.; Zhang, T. Analysis of factors of productivity of tight conglomerate reservoirs based on random forest algorithm. ACS Omega 2022, 7, 20390–20404. [Google Scholar] [CrossRef] [PubMed]

- Luo, S.; Zhao, Y.; Zhang, L.; Chen, Z.; Zhang, X. Integrated simulation for hydraulic fracturing, productivity prediction, and optimization in tight conglomerate reservoirs. Energy Fuels 2021, 35, 14658–14670. [Google Scholar] [CrossRef]

- Huang, L.; Lu, M.; Sheng, G.; Gong, J.; Ruan, J.; Billi, A. Research advance on prediction and optimization for fracture propagation in stimulated unconventional reservoirs. Lithosphere 2021, Special 1, 4442001. [Google Scholar] [CrossRef]

- Chen, J.; Xu, Z.; Leung, J.Y. Analysis of fracture interference–Coupling of flow and geomechanical computations with discrete fracture modeling using MRST. J. Pet. Sci. Eng. 2022, 219, 111134. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, L.; Gao, R.; Xu, G.; Liu, Z.; Mo, S.; Wang, X. Numerical analysis of zipper fracturing using a non-planar 3D fracture model. Front. Earth Sci. 2022, 10, 808183. [Google Scholar] [CrossRef]

- Fang, M.; Shi, H.; Li, H.; Liu, T. Application of machine learning for productivity prediction in tight gas reservoirs. Energies 2024, 17, 1916. [Google Scholar] [CrossRef]

- Yu, W.; Sepehrnoori, K. Optimization of multiple hydraulically fractured horizontal wells in unconventional gas reservoirs. In Proceedings of the SPE Oklahoma City Oil and Gas Symposium/Production and Operations Symposium, Oklahoma City, Oklahoma, 23–26 March 2013; p. SPE–164509. [Google Scholar]

- Li, N.; Lolon, E.; Mayerhofer, M.; Cordts, Y.; White, R.; Childers, A. Optimizing well spacing and well performance in the piceance basin niobrara formation. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 24 January 2017; p. D031S008R002. [Google Scholar]

- Xu, S.; Feng, Q.; Wang, S.; Javadpour, F.; Li, Y. Optimization of multistage fractured horizontal well in tight oil based on embedded discrete fracture model. Comput. Chem. Eng. 2018, 117, 291–308. [Google Scholar] [CrossRef]

- Jia, A.; Jia, C.; Wei, Y.; Qi, Y.; Wang, J.; Jin, Y.; Yuan, H. Optimization workflow for stimulation-well spacing design in a multiwell pad. Pet. Explor. Dev. 2019, 46, 981–992. [Google Scholar]

- Sheng, G.L.; Liu, H.L.; Li, L.L.; Zhao, H.; Zhou, Y.H. Automatic optimization method of fracture pattern and well pattern for fractured horizontal wells in unconventional gas reservoirs. Nat. Gas Geosci. 2020, 31. [Google Scholar]

- Li, W.; Zhang, T.; Liu, X.; Dong, Z.; Dong, G.; Qian, S.; Zhang, T. Machine learning-based fracturing parameter optimization for horizontal wells in Panke field shale oil. Sci. Rep. 2024, 14, 6046. [Google Scholar] [CrossRef]

- Deng, H.; Sheng, G.; Zhao, H.; Meng, F.; Zhang, H.; Ma, J.; Ruan, J. Integrated optimization of fracture parameters for subdivision cutting fractured horizontal wells in shale oil reservoirs. J. Pet. Sci. Eng. 2022, 212, 110205. [Google Scholar] [CrossRef]

- Xue, L.; Gu, S.H.; Jiang, X.E.; Liu, Y.T.; Yang, C. Ensemble-based optimization of hydraulically fractured horizontal well placement in shale gas reservoir through Hough transform parameterization. Pet. Sci. 2021, 18, 839–851. [Google Scholar] [CrossRef]

- Ding, S.; Lu, R.; Xi, Y.; Liu, G.; Ma, J. Efficient well placement optimization coupling hybrid objective function with particle swarm optimization algorithm. Appl. Soft Comput. 2020, 95, 106511. [Google Scholar] [CrossRef]

- Park, J.; Janova, C. Stimulated Reservoir Volume Characterization and Optimum Lateral Well Spacing Study of Two-Well Pad: Midland Basin Case Study. Geofluids 2020, 2020, 8829015. [Google Scholar] [CrossRef]

- Qun, L.E.I.; Lifeng, Y.A.N.G.; Yaoyao, D.U.A.N.; Dingwei, W.; Xin, W.; Baoshan, G.; Ying, G.U.O. The “fracture-controlled reserves” based stimulation technology for unconventional oil and gas reservoirs. Pet. Explor. Dev. 2018, 45, 770–778. [Google Scholar]

- Liang, C.; He, Y.; Zhu, D.; Chen, Y.; Hu, Y.; Cui, M.; Cai, W.; Li, X.; Wang, X.; Chen, H. Productivity simulation of hydraulically fractured wells based on hybrid local grid refinement and embedded discrete fracture model. Pet. Explor. Dev. 2020, 47, 341–348. [Google Scholar]

- Tang, J.; Wang, X.; Du, X.; Ma, B.; Zhang, F. Optimization of integrated geological-engineering design of volume fracturing with fan-shaped well pattern. Pet. Explor. Dev. 2023, 50, 845–852. [Google Scholar] [CrossRef]

- Wang, B.; Fang, Y.; Li, L.; Liu, Z. Automatic optimization of multi-well multi-stage fracturing treatments combining geomechanical simulation, reservoir simulation and intelligent algorithm. Processes 2023, 11, 1759. [Google Scholar] [CrossRef]

- Hu, S.; Wu, Y.; Yan, Y.; Huo, T.; Xu, Z.; Li, Y.; Wang, D. Parameter optimization study of three-dimensional well network-fracture network coupled fracturing in jimsar shale oil. Unconv. Resour. 2024, 4, 100102. [Google Scholar] [CrossRef]

- Zhai, M.; Wang, D.; Zhang, Z.; Zhang, L.; Yang, F.; Huang, B.; Li, L. Numerical simulation and multi-factor optimization of hydraulic fracturing in deep naturally fractured sandstones based on response surface method. Eng. Fract. Mech. 2022, 259, 108110. [Google Scholar] [CrossRef]

- Liu, X.; Li, D.; Jia, Y.; Liyong, Y.; Xiaoting, G.; Tao, Z.; Yu, Z. Optimizing construction parameters for fractured horizontal wells in shale oil. Front. Earth Sci. 2023, 10, 1015107. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, X.; Guo, J.; Wang, S.; Zhao, Z. Optimization method of fracture parameters in multistage fracturing of horizontal wells. Energy Sources Part A: Recovery Util. Environ. Eff. 2025, 47, 6743–6761. [Google Scholar] [CrossRef]

- Yao, J.; Li, Z.; Liu, L.; Fan, W.; Zhang, M.; Zhang, K. Optimization of fracturing parameters by modified variable-length particle-swarm optimization in shale-gas reservoir. SPE J. 2021, 26, 1032–1049. [Google Scholar] [CrossRef]

- Zhang, H.; Sheng, J.J. Complex fracture network simulation and optimization in naturally fractured shale reservoir based on modified neural network algorithm. J. Nat. Gas Sci. Eng. 2021, 95, 104232. [Google Scholar] [CrossRef]

- Wang, L.; Yao, Y.; Wang, W.; Adenutsi, C.D.; Zhao, G.; Lai, F. Integrated optimization design for horizontal well spacing and fracture stage placement in shale gas reservoir. J. Nat. Gas Sci. Eng. 2022, 105, 104706. [Google Scholar] [CrossRef]

- Lu, C.; Jiang, H.; Yang, J.; Wang, Z.; Zhang, M.; Li, J. Shale oil production prediction and fracturing optimization based on machine learning. J. Pet. Sci. Eng. 2022, 217, 110900. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, B.; Lv, Z.H.; Lv, B.; Li, L.; Zhou, H. Intelligent optimization of holistic fracturing in unconventional reservoirs. Xinjiang Pet. Nat. Gas 2024, 20, 36–43. [Google Scholar]

- Raiaan, M.A.K.; Sakib, S.; Fahad, N.M.; Al Mamun, A.; Rahman, M.A.; Shatabda, S.; Mukta, M.S.H. A systematic review of hyperparameter optimization techniques in Convolutional Neural Networks. Decis. Anal. J. 2024, 11, 100470. [Google Scholar] [CrossRef]

- Li, Q.; Xing, H.; Liu, J.; Liu, X. A review on hydraulic fracturing of unconventional reservoir. Petroleum 2015, 1, 8–15. [Google Scholar] [CrossRef]

- Xiaoxia, Z.; Jiajie, Y.; Nianyin, L.; Chao, W. Multi-scale fracture prediction and characterization method of a fractured carbonate reservoir. J. Pet. Explor. Prod. 2021, 11, 191–202. [Google Scholar] [CrossRef]

- Wang, H.; Sharma, M.M. Determine in-situ stress and characterize complex fractures in naturally fractured reservoirs from diagnostic fracture injection tests. Rock Mech. Rock Eng. 2019, 52, 5025–5045. [Google Scholar] [CrossRef]

- Turner, A.K. Challenges and trends for geological modelling and visualisation. Bull. Eng. Geol. Environ. 2006, 65, 109–127. [Google Scholar] [CrossRef]

- Feng, Q.; Li, R.; Jia, Y.; Liang, Z. Big data and artificial intelligence-based optimization of petroleum exploration and reservoir modeling: Intelligent pathways for enhancing efficiency and accuracy. Adv. Resour. Res. 2025, 5, 477–495. [Google Scholar]

- Dong, K.; Jiang, M.; Li, J.; Zhang, D. Research progresses in formation mechanism of complex fracture network for unconventional reservoir. Arab. J. Geosci. 2020, 13, 750. [Google Scholar] [CrossRef]

- Mantell, M.E.; Mercer, A.; Jackson, J.B.; Murphy, D.J.; Conaway, J.; Machovoe, S.R.; Elliott, M. (2022, January). Application of disposable fiber technology to evaluate far-field communication and fracture performance in the Marcellus Shale. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, Muscat, Oman, 11–13 January 2022; p. D011S002R004. [Google Scholar]

- Crawford, R.; Green, A.; Lynch, P.; Feherty, C. Disposable Fibre Optic Surveys Optimise Wells and Reduce CO2 Emissions in Unconventional Assets. In Proceedings of the SPE Asia Pacific Unconventional Resources Conference and Exhibition, Brisbane, Australia, 14–15 November 2023; p. D012S002R003. [Google Scholar]

- Mahue, V.; Jimenez, E.; Dawson, P.; Trujillo, K.; Hull, R. Repeat DAS and DTS production logs on a permanent fiber optic cable for evaluating production changes and interference with offset wells. In Proceedings of the Unconventional Resources Technology Conference, Houston, TX, USA, 20–22 June 2022; pp. 2697–2713. [Google Scholar]

- Srinivasan, A.; Liu, Y.; Wu, K.; Jin, G.; Moridis, G. Geomechanical modeling of fracture-induced vertical strain measured by distributed fiber-optic strain sensing. SPE Prod. Oper. 2023, 38, 537–551. [Google Scholar] [CrossRef]

- Xu, S.; Li, S.; Zou, Z. Hybrid Virtual Interferometry Technique Based on Stacking of Neighboring Virtual Traces to Enhance Acoustic Logging Data. Surv. Geophys. 2024, 45, 745–771. [Google Scholar] [CrossRef]

- Sheng, M.; Deng, C.; Li, J.; Gu, M.; Wang, T.; Tian, S. Mechanism and parameter optimization of balanced multi-cluster fracture propagation controlled by non-uniform perforation. Xinjiang Pet. Nat. Gas 2024, 20, 54–63. [Google Scholar]

- Sheng, M.; Jiang, F.M.; Hu, S.M.; Lv, Z.; Kong, M.; Si, L. Interpretation of in-situ stress and fracturing design optimization in heterogeneous conglomerate reservoirs. Xinjiang Pet. Nat. Gas 2024, 20, 1–10. [Google Scholar]

- Xiong, F.; Wang, X.Q.; Liu, Y.; Chen, L.; Zhao, Z.H.; Yang, H.; Li, D. Development and Application of Real-Time Monitoring System for Fracturing and Acidizing Flowback Fluid. In Proceedings of the International Field Exploration and Development Conference, Wuhan, China, 19–21 September 2023; Springer Nature: Singapore, 2023. [Google Scholar]

- Scott, E.; Young, S.; Ely, J.; Jones, D.; Vasquez, O. Lost in the shadows: Surviving fracturing hazards with fluid tracking. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 5 February 2020; p. D031S007R006. [Google Scholar]

- Pugh, T.; Stocking, R.; Greene, T.; Vasquez, O. Proper Parenting with Newborns-A Frac Fluid Tracking Case Study. In Proceedings of the Unconventional Resources Technology Conference, Online, 16–18 November 2020; p. D033S077R004. [Google Scholar]

- Zakhour, N.; Jones, M.; Zhao, Y.; Orsini, K.; Sahni, V. HFTS-2 Completions Design and State-of-the-Art Diagnostics Results. In Proceedings of the Unconventional Resources Technology Conference, Houston, TX, USA, 26–28 July 2021; pp. 1162–1185. [Google Scholar]

- Mahmoud, A.; Gowida, A.; Aljawad, M.S.; Al-Ramadan, M.; Ibrahim, A.F. Advancement of hydraulic fracture diagnostics in unconventional formations. Geofluids 2021, 2021, 4223858. [Google Scholar] [CrossRef]

- Wu, Y.; Cheng, L.; Killough, J.E.; Huang, S.; Fang, S.; Jia, P.; Xue, Y. Integrated characterization of the fracture network in fractured shale gas reservoirs—Stochastic fracture modeling, simulation and assisted history matching. In Proceedings of the SPE Annual Technical Conference and Exhibition, Calgary, AB, Canada, 30 September–2 October 2019; p. D011S006R00. [Google Scholar]

- Ren, L.; Zhan, S.; Zhou, D.; Su, Y.; Wang, W.; Chen, M.; Sun, J. Propagation simulation and structural characterization of multiple hydraulic fractures in naturally fractured unconventional hydrocarbon reservoirs. J. Nat. Gas Sci. Eng. 2020, 83, 103557. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Wang, B.; Hu, M.; Shi, X.; Yang, L.; Zhou, F. Research Progress on Optimization Methods of Platform Well Fracturing in Unconventional Reservoirs. Processes 2025, 13, 1887. https://doi.org/10.3390/pr13061887

Zhang L, Wang B, Hu M, Shi X, Yang L, Zhou F. Research Progress on Optimization Methods of Platform Well Fracturing in Unconventional Reservoirs. Processes. 2025; 13(6):1887. https://doi.org/10.3390/pr13061887

Chicago/Turabian StyleZhang, Li, Bo Wang, Minghao Hu, Xian Shi, Liu Yang, and Fujian Zhou. 2025. "Research Progress on Optimization Methods of Platform Well Fracturing in Unconventional Reservoirs" Processes 13, no. 6: 1887. https://doi.org/10.3390/pr13061887

APA StyleZhang, L., Wang, B., Hu, M., Shi, X., Yang, L., & Zhou, F. (2025). Research Progress on Optimization Methods of Platform Well Fracturing in Unconventional Reservoirs. Processes, 13(6), 1887. https://doi.org/10.3390/pr13061887