1. Introduction

At present and for at least the next 10 to 15 years, oil will continue to maintain its dominant position in the global energy system, and ensuring stable oil production is of profound significance for energy security [

1,

2]. Water injection is one of the most economical and effective measures for maintaining stable production in oil fields, and pipelines, as a common water transportation method, play a crucial role in the water injection process [

3]. Although water injection technology can significantly improve the recovery rate of oil wells, it also brings some challenges and problems, one of which is the corrosion and scaling issues caused by the complex fluid composition within pipelines [

4,

5,

6]. Corrosion and leakage of water injection pipelines will cause huge economic losses to oil fields and have serious impacts on their operations [

4,

5,

7].

In order to effectively prevent similar accidents, reduce economic losses, and improve oilfield development efficiency, scholars in China and abroad have conducted in-depth analysis of the factors affecting the corrosion of oilfield water injection pipelines and proposed a series of effective corrosion protection measures. Lou Liangjie comprehensively investigated the water quality of sewage, corrosion monitoring data, and the composition of corrosion products. Combined with the use of corrosion inhibitors on site, they studied the causes of corrosion and proposed corresponding solutions [

8]; Marí n-Cruz J conducted in-depth research on the corrosion and scale inhibition processes in cooling system media [

9]; Defang Z conducted a study on a new type of composite environmentally friendly corrosion and scale inhibitor for steel surfaces in cooling water, and developed an efficient and environmentally friendly scale inhibitor that can effectively reduce corrosion and scale inhibition on steel surfaces [

10]. Ying Xu synthesized polyaspartic acid/5-aminolactic acid graft copolymers and evaluated their scale and corrosion inhibition properties [

11].

Previous studies have gained a certain understanding of the corrosion and scaling characteristics, influencing factors and anti-corrosion measures of water injection pipelines. However, the research mainly focuses on indoor simulation experiments, with relatively simple experimental conditions and a lack of analysis based on corrosion and scaling data under real on-site service conditions. This article analyzes the corrosion and scaling morphology, service conditions, physical and chemical properties of a water injection pipeline in a particular oilfield based on the actual situation of variable working conditions during pipeline on-site service. The reasons for the corrosion of the water injection pipeline in the well are discussed, aiming to effectively prevent similar accidents from happening again.

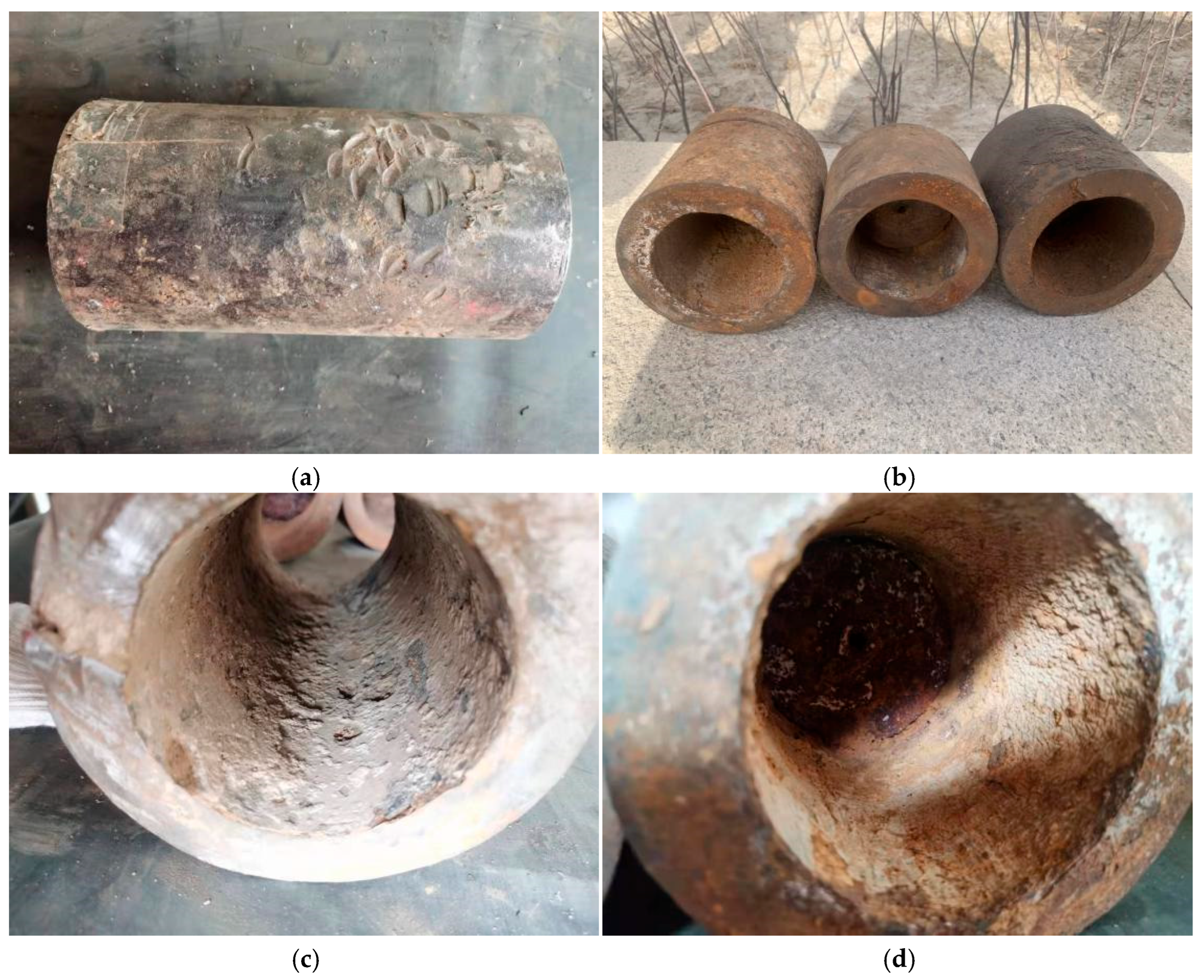

The water injection pipeline of a particular oilfield was completed and put into use in November 2001. The pipeline specification is Φ140 mm × 22 mm, made of 20# steel, with a design pressure of 40 MPa and a total length of 1.81 km. The conveying medium is sewage, and there are no internal anti-corrosion measures. The failed sample is shown in

Figure 1. The sample sent for inspection this time consists of two parts. One part is the pipe section cut in January 2022 (

Figure 1a), marked as Sample 1, which has undergone water injection, shutdown, and gas injection conditions, with a length of 255 mm. The other part is the pipe section cut after the pressure test in September 2020 (

Figure 1b), marked as Sample 2, divided into three sections with lengths of 145 mm, 87 mm, and 127 mm, which have undergone water injection and shutdown conditions. There are damage marks on the outer surface of Sample 1, and liquid accumulation marks can be seen at the 6 o’clock position on the inner wall, with multiple corrosion pits present (

Figure 1c). Sample 2 has a rust yellow outer surface and a yellow brown scale layer visible on the inner wall (

Figure 1d).

4. Discussion

From the macroscopic analysis and geometric dimension measurement of the pipe sample, it can be seen that there is a lot of scaling on the inner wall of the pipeline. The pipe section that has experienced water injection, shutdown, and gas injection conditions has local corrosion in the 6 o’clock direction, while the pipe section that has only experienced water injection and shutdown conditions has not shown significant corrosion thinning. Based on these characteristics and the service history of the pipeline, the reasons for local corrosion from the aspects of pipeline material and service conditions are analyzed below.

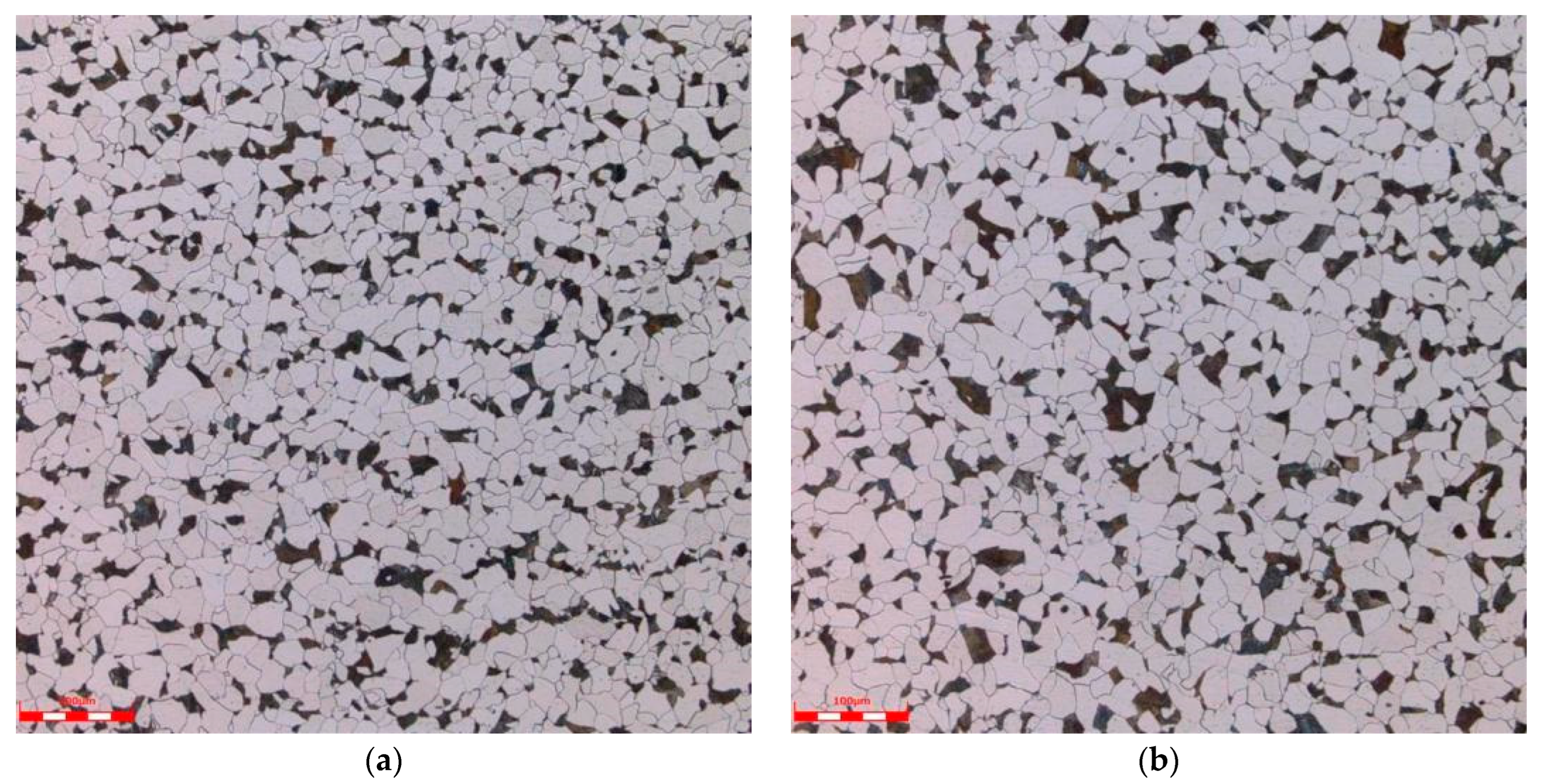

Firstly, from the perspective of pipeline material, its chemical composition meets the requirements of GB 6479-2013 for 20# steel; The metallographic structure consists of pearlite and ferrite, with non-metallic inclusions of A0.5, B0.5, and D0.5. Sample 1 has a grain size of 7.5, sample 2 has a grain size of 7.0, and no abnormalities are found in the metallographic structure. The tensile performance meets the requirements of GB 6479-2013 for 20# steel, but the impact performance does not meet the requirements of GB 6479-2013. The impact performance has a significant impact on the anti-cracking performance of pipelines, but has no direct effect on pipeline corrosion and scaling. It can be seen that a material problem in the pipeline is not the cause of local corrosion.

Secondly, from the perspective of pipeline service conditions, the pipeline was a water injection pipeline from November 2000 to April 2018, and the transport medium was treated wastewater from the joint station. There is a scaling phenomenon on the inner wall of the pipeline section that has only experienced water injection, shutdown, and gas injection conditions. According to the XRD analysis results of the scale samples, the chemical composition of the scale samples is the same, mainly barium sulfate, strontium scale, and a small amount of silicon dioxide. Combined with the analysis results of the injected water sample (

Table 8), the SO

42− content in the medium is 235.7 mg/L, the Ba

2+ content is 18.66 mg/L, and the Sr

2+ content is 496.2 mg/L, indicating that the scale layer on the inner wall of the pipeline was formed during the water injection condition. From the morphology of the inner wall of the pipeline section that only experienced water injection and shutdown conditions, no obvious corrosion was observed. XRD analysis of the scale layer on the inner wall showed that the corrosion product was mainly Fe

2O

3. However, there were corrosion pits in the 6 o’clock direction of the pipeline section that experienced water injection, shutdown, and gas injection conditions. The main corrosion products on the inner wall were FeCO

3 and Fe

2O

3. According to the analysis of the injected gas composition (

Table 9), the gas contained corrosive media such as CO

2 and trace amounts of hydrogen sulfide (H

2S), with CO

2 content of 1.332% and H

2S content of 0.0003%. The operating pressure of the pipeline was about 10 MPa. The calculated CO

2 partial pressure of the pipeline was about 0.1332 MPa and H

2S partial pressure was about 0.03 KPa. The corrosion caused by the low H

2S partial pressure can be ignored. Therefore, the pipeline section that experienced gas injection conditions was corroded mainly by CO

2. The partial pressure of carbon dioxide has a direct impact on the corrosion rate of pipelines. An increase in CO

2 partial pressure will lead to more CO

2 dissolution, lower pH, and decrease the concentration of CO

32−, thereby reducing the stability of FeCO

3. Especially under high flow rate conditions of multiphase flow, the scouring effect will further damage the protective film, leading to intensified corrosion. It is generally believed that moderate corrosion will occur in pipelines when the CO

2 partial pressure is between 0.021 MPa and 0.21 MPa [

19,

20]. In addition, a GLCC gas–liquid separator is installed at the injection gas source well site to perform simple separation of the produced raw gas. Due to the small size of the GLCC gas–liquid separation device and the large amount of plug flow in the gas source section, the gas–liquid separation effect is poor, which can lead to increased entrainment of liquid droplets in natural gas, exacerbating gas–liquid phase slip (increasing velocity difference) and result in a sustained high liquid content in the injection pipeline. High liquid holdup significantly increases the nucleation rate of FeCO

3 by elevating the interfacial concentrations of Fe

2+ and CO

32− while reducing mass transfer efficiency. Additionally, the pipeline operates at a pressure of 10 MPa, where the high pressure markedly enhances the solubility of CO

2 in the liquid phase. This promotes the hydration of CO₂ to form H₂CO₃, which subsequently dissociates into HCO

3− and CO

32−. The resulting increase in CO

32− concentration directly raises the supersaturation (S) of FeCO

3—a critical driving factor for nucleation kinetics.

However, dense FeCO3 corrosion product films typically form at temperatures above 60 °C. At the pipeline operating temperature of ~40 °C, the FeCO3 film tends to be porous and poorly adherent. When combined with Cl−-induced localized attack and flow fluctuations, the high nucleation rate may translate into localized corrosion risks rather than providing protective effects. This underscores the importance of mitigating factors such as chloride ingress, optimizing flow conditions, and considering material upgrades or corrosion inhibitors to address the compromised film integrity at lower temperatures.

In addition, the pipeline with local corrosion in this section is located in the cecum section. At the cecum section of the pipeline system, fluid stagnation may lead to a local increase in the concentration of Cl

− or other corrosive substances. Due to limited mass transfer, concentration batteries may form, exacerbating local corrosion. Meanwhile, the retention zone may experience pH changes due to poor material exchange, such as the accumulation of acidic substances, which further affects the corrosion process [

21]. The morphology of the inner wall of the pipeline also shows traces of liquid accumulation at the bottom of the pipeline. According to the test results of the produced water from the gas source well (

Table 10), the Cl

− content of the produced water is 94,800 mg/L, with a pH value of 6.12. Higher Cl

− content and an acidic environment will accelerate the occurrence of corrosion [

22,

23,

24]. This is because the presence of Cl

− usually accelerates the corrosion of carbon steel, especially at low pH levels. In a weakly acidic environment with a pH of 6.12, the corrosiveness of Cl

− further damages the passivation film, causing the corrosion potential to shift towards a more negative direction and accelerating the anodic reaction. In this case, as the corrosion rate increases, the driving force for electrochemical corrosion also increases. The pipeline was injected with gas from September 2020 until local corrosion was discovered in January 2022, a total of 16 months of gas injection operation. The maximum depth of the pipeline corrosion pit is about 3 mm, and the maximum corrosion rate is about 2.25 mm/a, which indicates an extremely severe degree of corrosion.

In summary, the Sample 1 pipeline sent for inspection is located in the cecum section. Under gas injection conditions, due to poor gas–liquid separation, the pipeline contains a high amount of liquid. There is liquid accumulation at the 6 o’clock position of the pipeline, which causes local corrosion under the action of CO

2 in the medium. The high Cl

- content and acidic environment in the medium accelerate the occurrence of corrosion. In addition, microbiologically influenced corrosion (MIC) may also be a potential factor that accelerates corrosion, especially in the relatively static environment of the cecal section of the pipeline, which is more conducive to the growth and metabolism of microorganisms. Fe

2O

3 is the result of oxidation of corrosion products on the inner wall of pipelines exposed to air, and is not the main cause of pipeline corrosion. In addition, the pipeline did not adopt anti-corrosion measures such as adding corrosion and scale inhibitors or using anti-corrosion and anti-scaling coatings on the inner wall, resulting in rapid corrosion and scaling of the pipeline [

25,

26,

27,

28].