Investigation of the Convective Mass Transfer Characteristics in a Parallel-Plate Channel Flow Disturbed by Using a Selenoid Pulse Generator

Abstract

1. Introduction

2. Materials and Methods

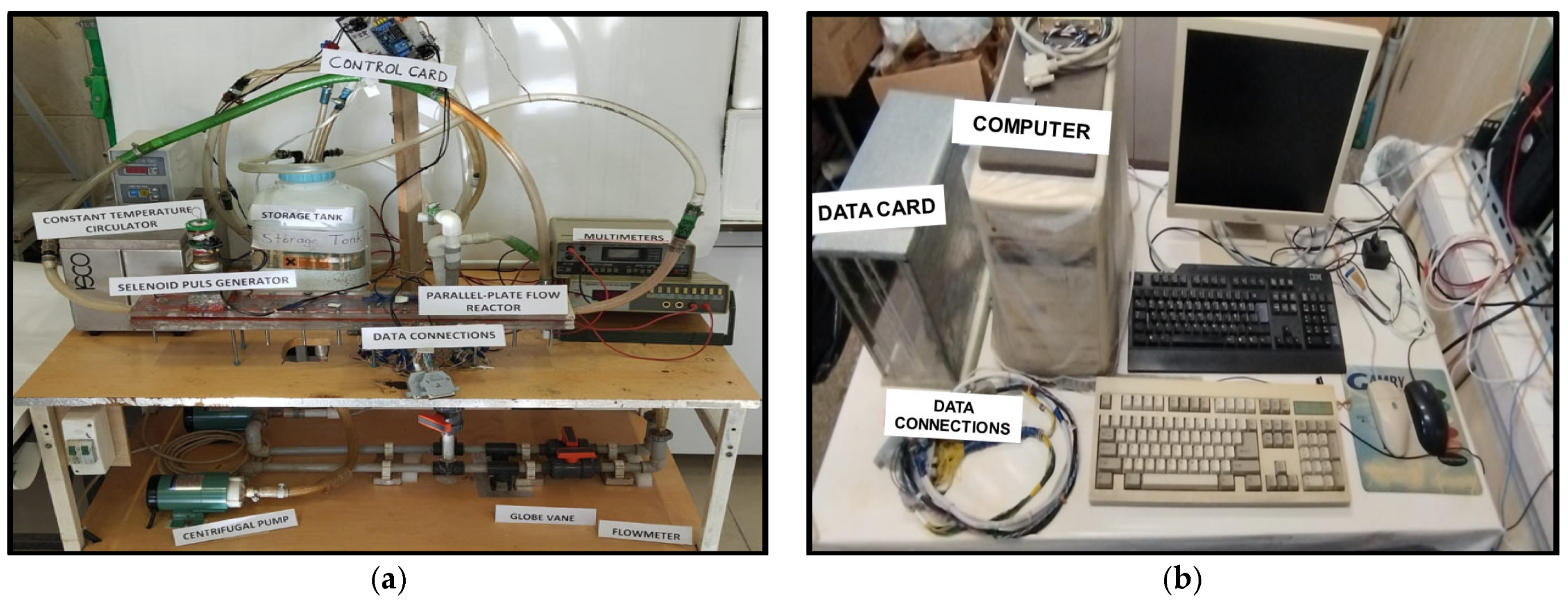

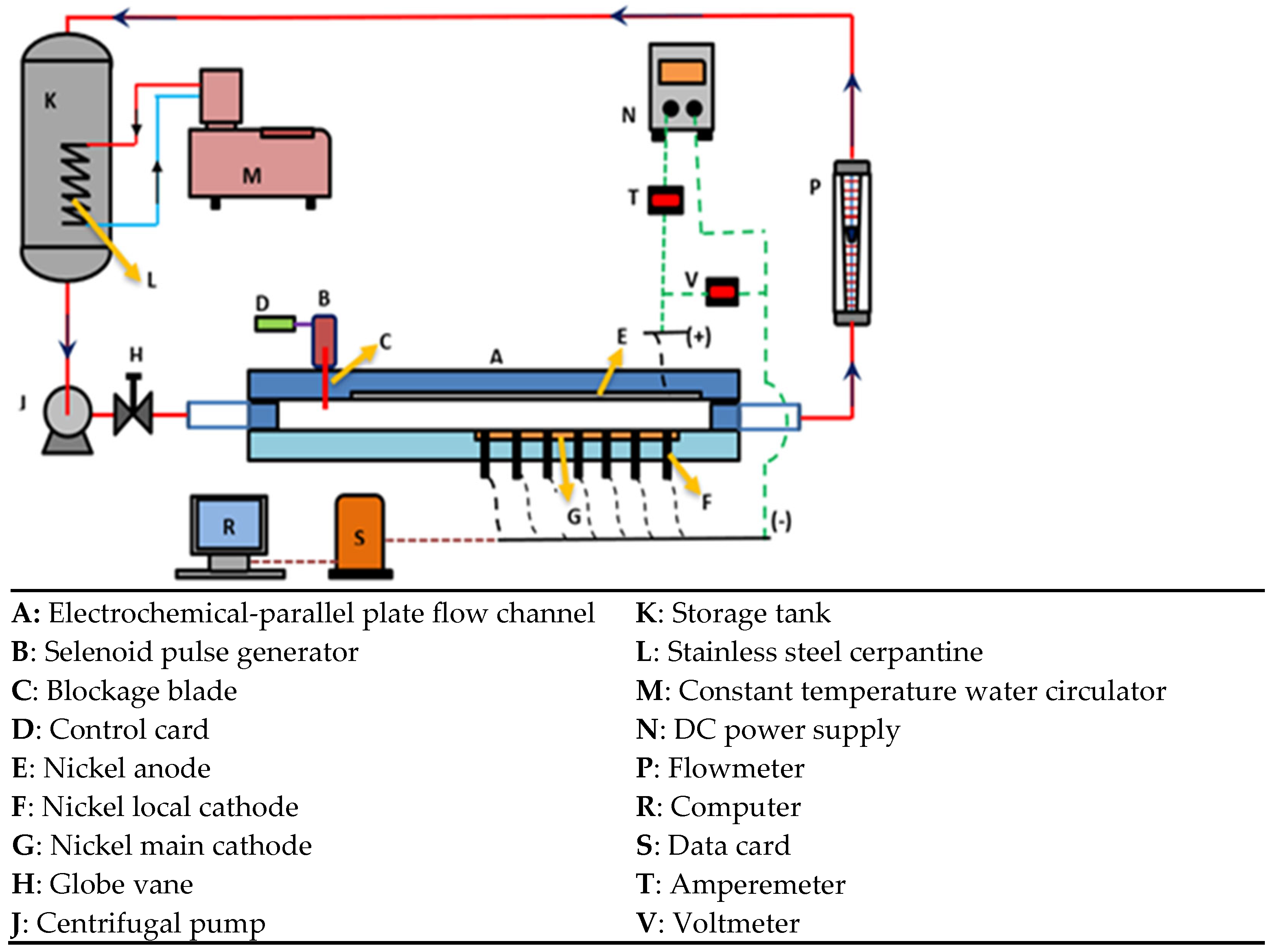

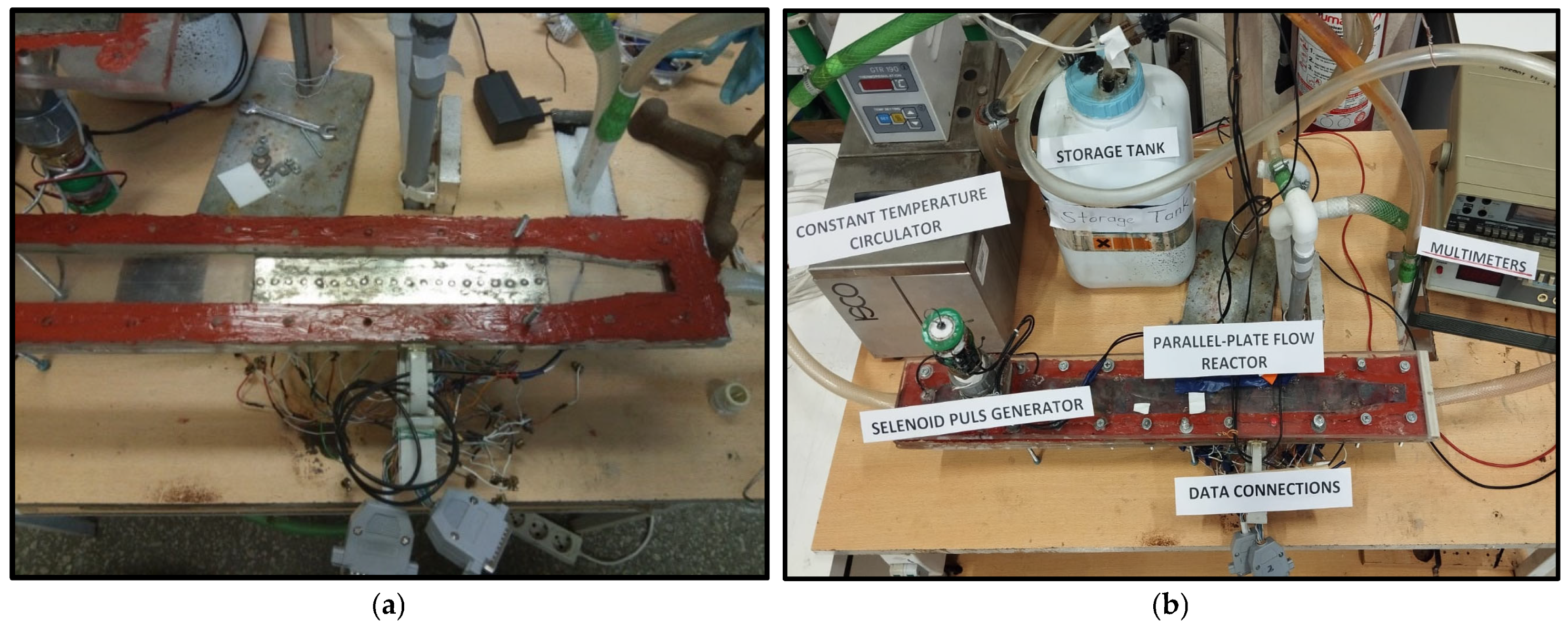

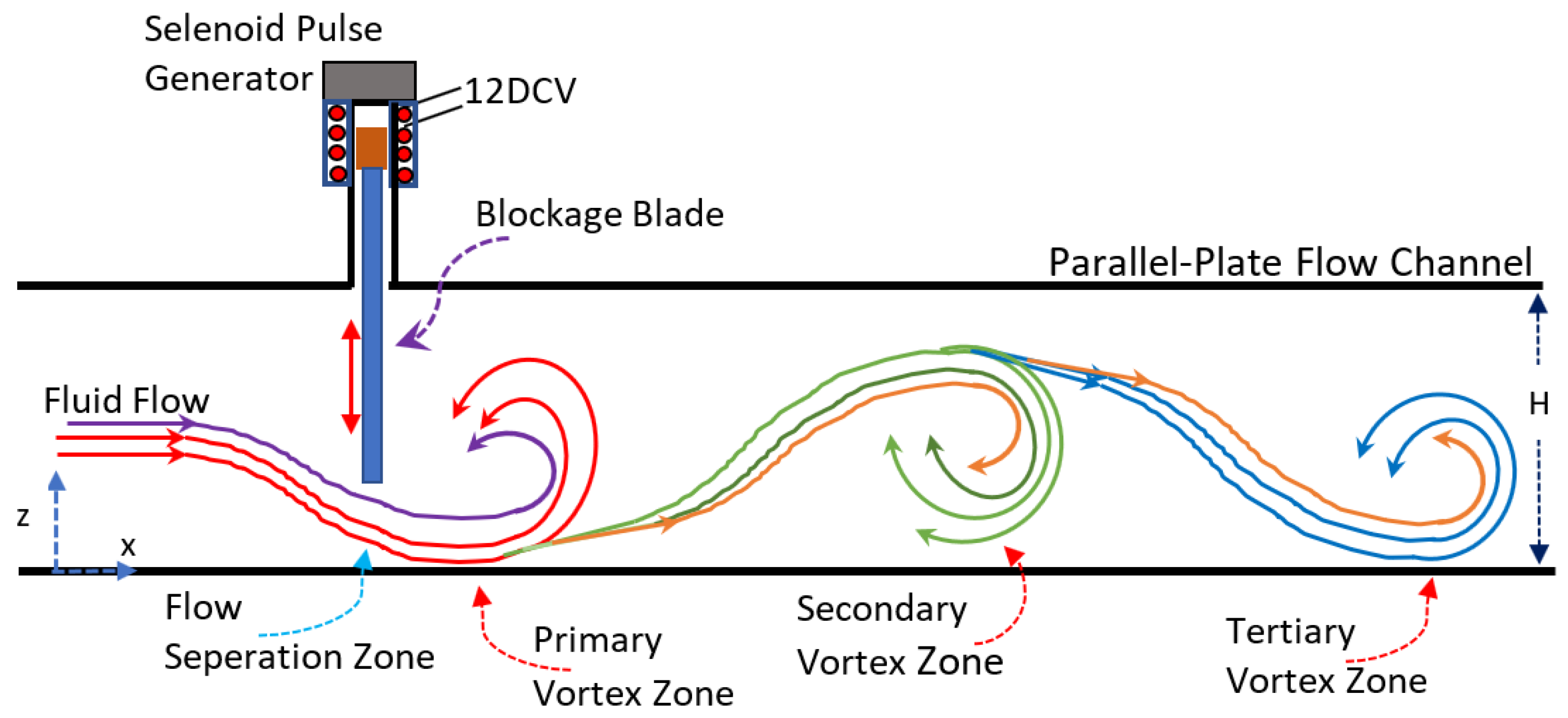

2.1. Experimental Set-Up

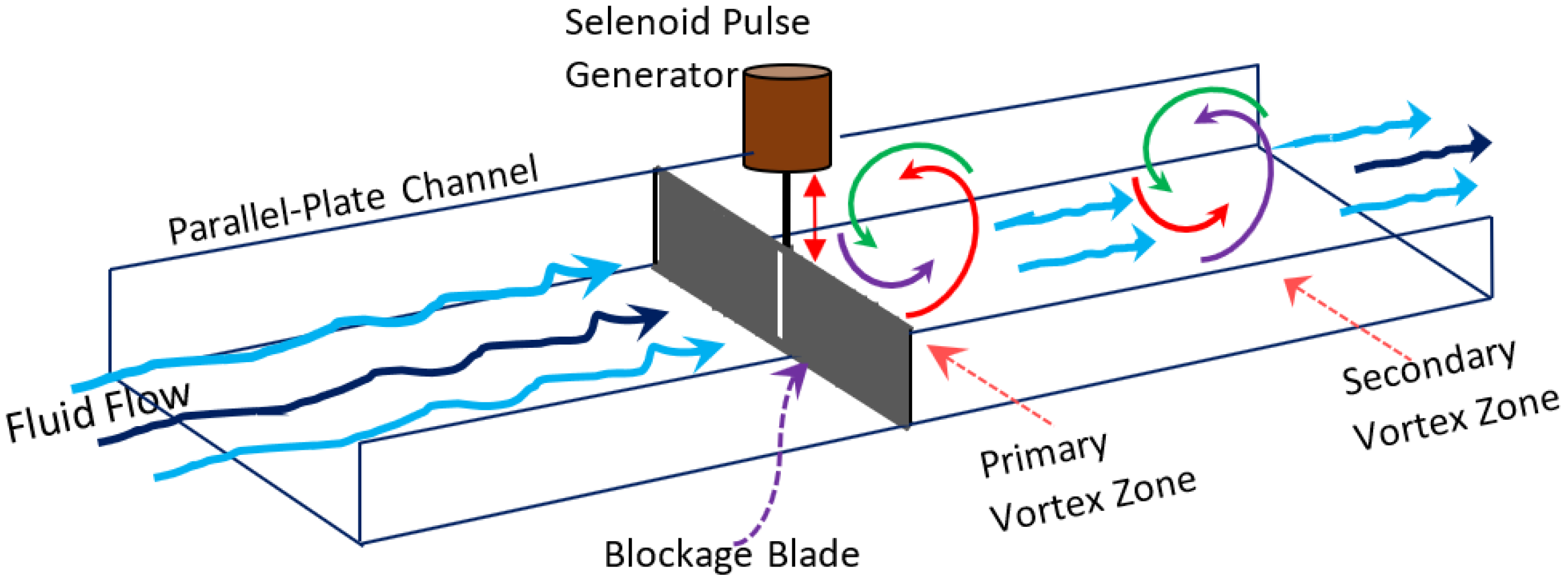

2.2. Selenoid Pulse Generator and Its Location in the Channel

2.3. Parallel-Plate Flow Channel

2.4. Parameters and Levels Used in the Study

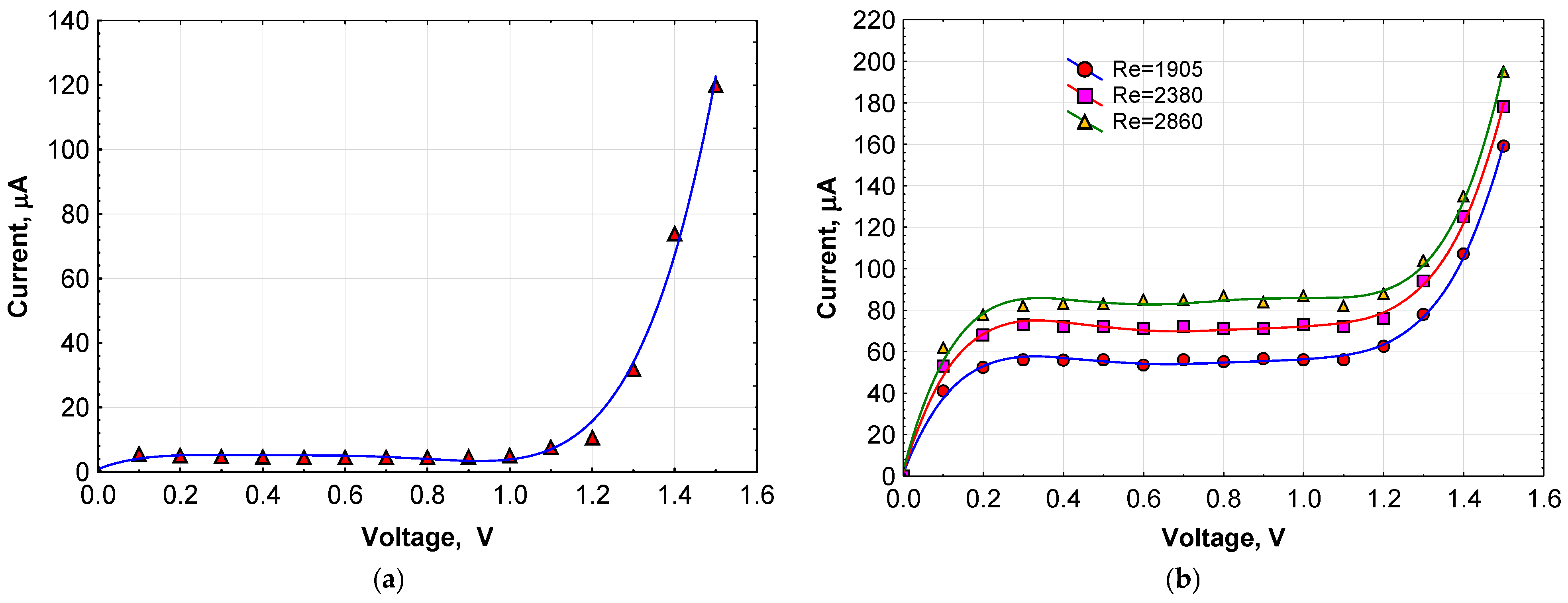

2.5. Measurement Technique and Test Bench

2.6. Uncertainty Analysis

3. Results and Discussion

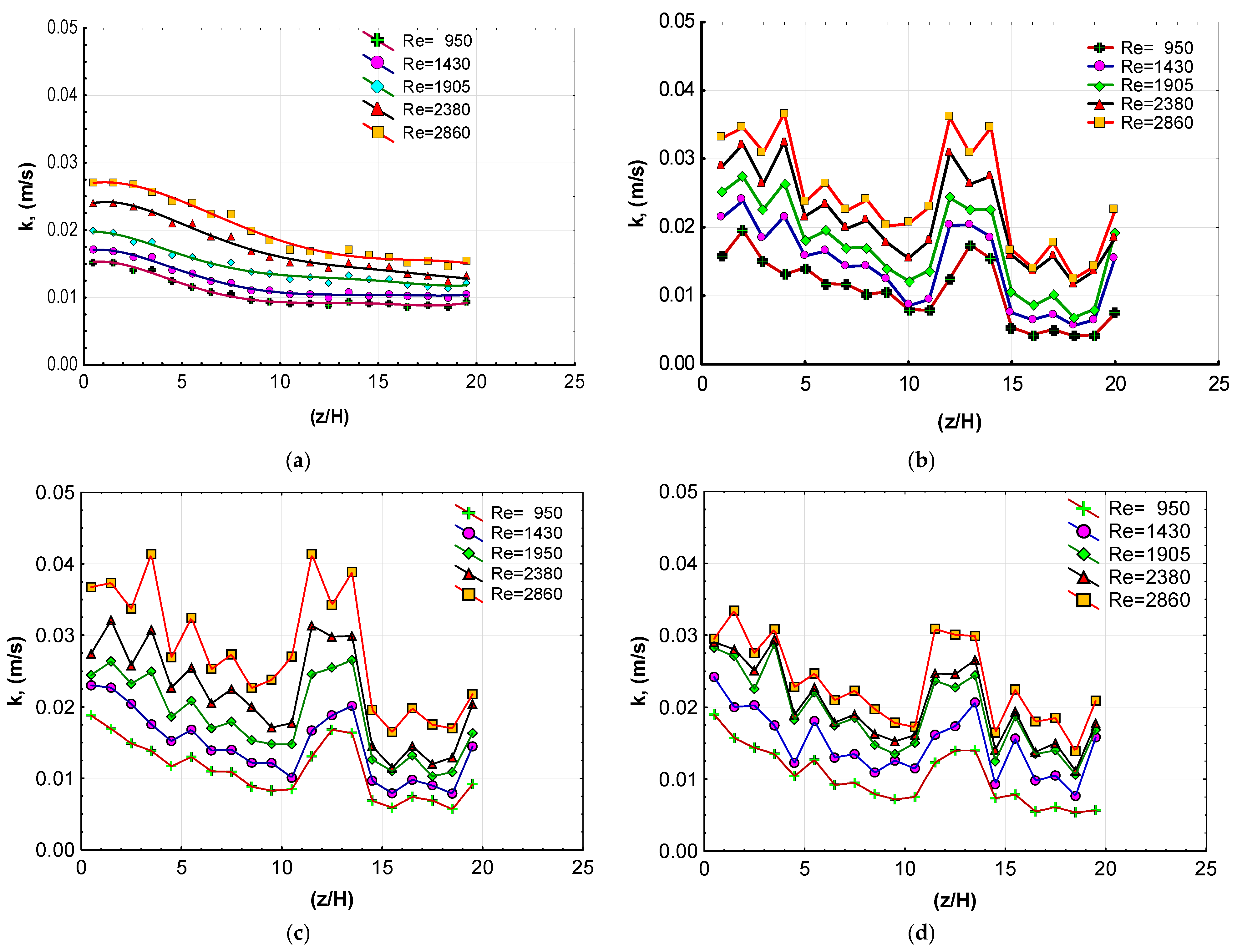

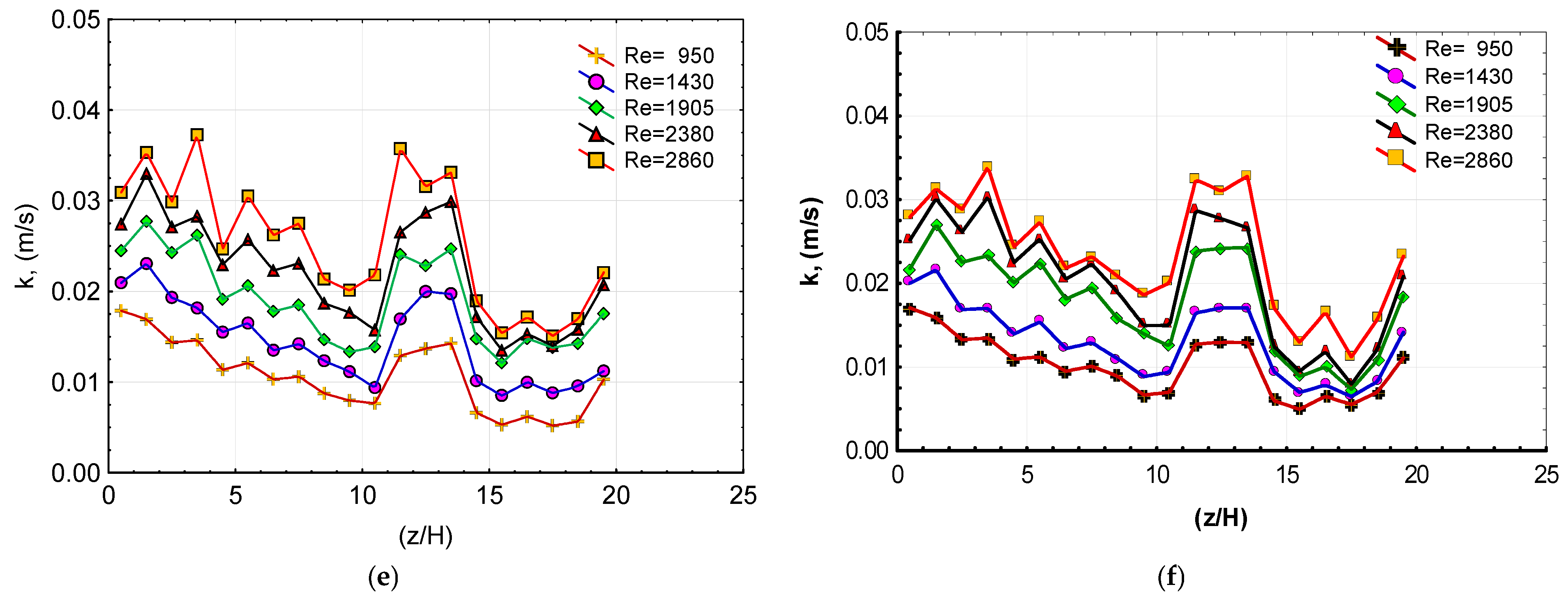

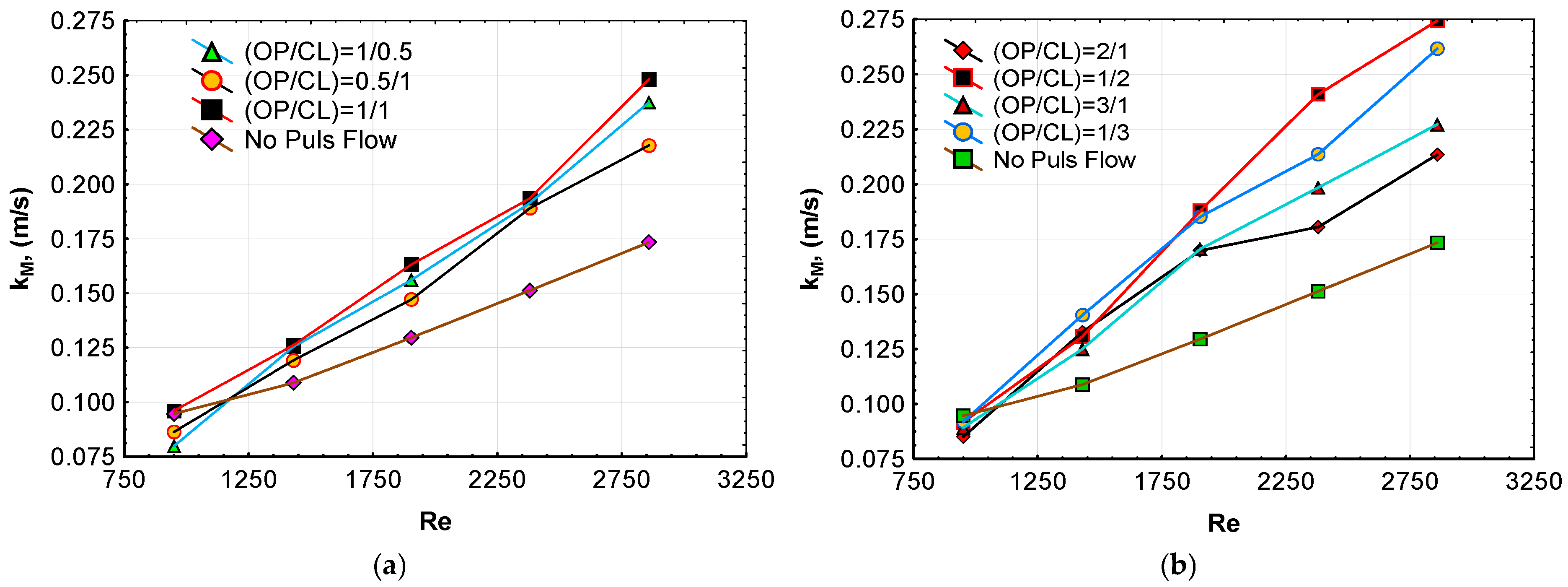

3.1. Effect of the Flow Re Number on the Distribution of Mass Transfer Coefficients

3.2. Effect of the (OP/CL) Ratio on the Distribution of Mass Transfer Coefficients

3.3. The Effect of Pulse Number on the Distribution of the Mass Transfer Coefficients

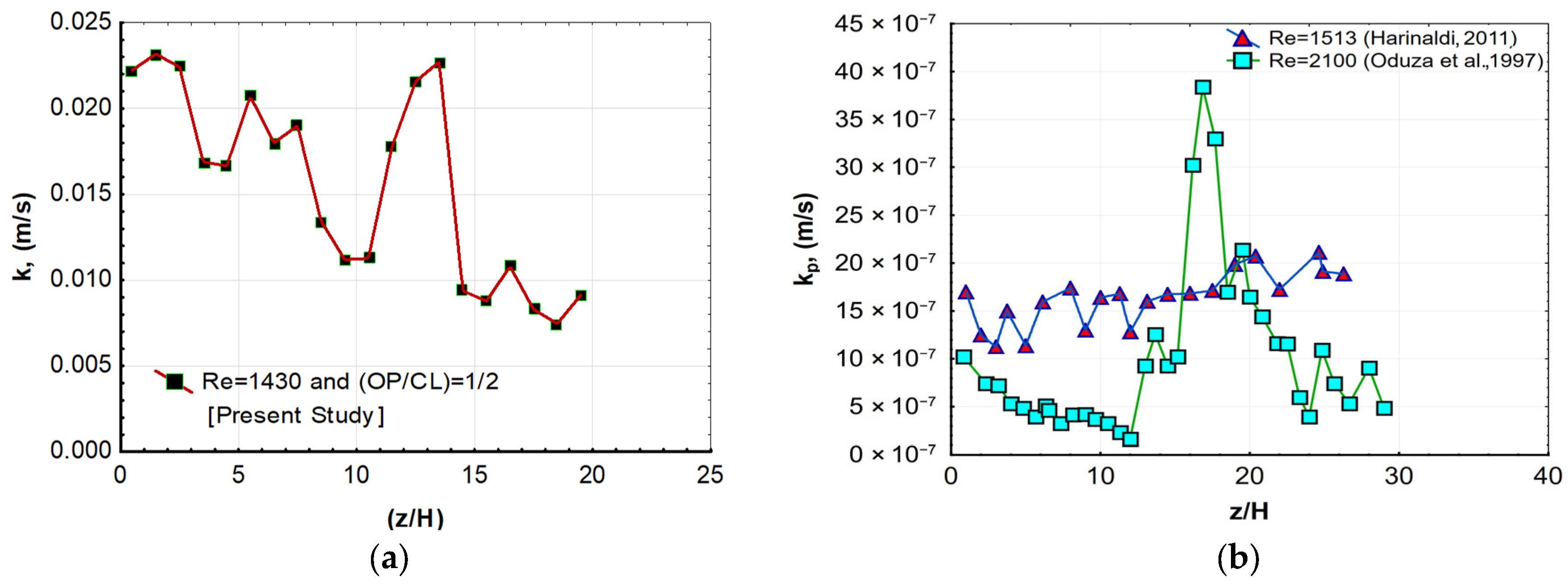

3.4. The Comparison of the Peak Mass Transfer Coefficient Values (kp) with the Literature Data

3.5. The Turbulent Kinetic Energy Level for Channel Flow

3.6. Sherwood Correlation

4. Conclusions

- (1)

- An attempt was made to determine the effect of Re by considering the Mode-1 values in Table 6. The highest k distribution was obtained at Re = 2860 at the (1/1) situation. It was found that the distributions of k versus (z/H) increased as the Re values were increased from 950 to 2860;

- (2)

- The effect of the second parameter, the (OP/CL) ratio, was evaluated on the mass transfer coefficient (k) across the entire range of Reynolds numbers studied. The results indicated that the highest mass transfer coefficients, up to Re = 1905, were achieved at an (OP/CL) of (1/5). In contrast, for Reynolds values greater than 1905, the highest mass transfer coefficients were attained at an (OP/CL) of (1/2). Conversely, the lowest mass transfer coefficients were recorded for an (OP/CL) of (1/0.5) across the entire range of Re numbers;

- (3)

- Additionally, an investigation into the effect of the pulse number on mass transfer coefficients at Re = 2860 revealed that the Mode-2 flow produced higher average mass transfer coefficient (kM) values compared to Mode-1 within the 10–45 pulse range;

- (4)

- Inserting one or more selenoid pulse generators in a parallel-plate flow channel (reactor) has increased the convective mass transfer rate significantly. Although only the laminar flow conditions have been supplied in the parallel-plate flow channel, the convective mass transfer rate has increased because of vortices produced by a selenoid pulse generator;

- (5)

- It was concluded that the flow kinetic energy measured using an active technique in the present study was approximately 27 times greater than that recorded in Harinaldi’s study [9], which utilized a passive technique;

- (6)

- In the literature [5], it has been observed that the convective peak mass transfer coefficients increased by 25.5% for a Reynolds value of 2856 compared to the no-flow condition. In the present study, for a Reynolds number of 2860, the mass transfer coefficients for the pulsed flow with (OP/CL) equals (1/2) increased by 159% compared to the no pulsed flow.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ELDCT | Electrochemical limiting diffusion current technique |

| OP/CL | Open/closed ratio |

| z/H | Dimensionless distance along the channel |

| H | The channel height, m |

| z | Length of measurement area in flow direction, (m) |

| L | Length of test zone |

| DC | Direct Current |

| PC | Personal computer |

| k | Local convective mass transfer coefficient, (m/s) |

| kp | Peak convective mass transfer coefficient, (m/s) |

| kM | Mean convective mass transfer coefficient, (m/s) |

| ILC | The limiting current, A |

| A | Electrode active surface area, m2 |

| n | Number of transferred electrons in redox reaction |

| F | Faraday coefficient, 96,487 C mol−1 |

| C∞ | Bulk concentration of ferricyanide in the electrolyte, (mol m−3) |

References

- Seetharama Rajua, D.S.; Gangadharb, M.; Nageswara Raoa, V.; Chitti Babua, N.; Raoa, P.J. Mass Transfer with Equilateral Triangular Plate as Turbulence Promoter in Circular Pipe. Int. J. Mod. Eng. Res. (IJMER) 2012, 2, 3281–3288. [Google Scholar]

- Turgut, O.; Khastar, F.; Gültekin, A.M. Dikdörtgen Kesitli Kanallarda Laminer Akış ve Isı Transferinin Sayısal Olarak İncelenmesi. Suleyman Demirel Univ. J. Nat. Appl. Sci. 2014, 18, 22–29. [Google Scholar]

- Geankoplis, C.J. Principles of Unsteady-state and convective mass transfer. In Transport Processes and Unit Operations, 3rd ed.; Prentice-Hall International Inc.: Englewood Cliffs, NJ, USA, 1993; pp. 432–475. [Google Scholar]

- Oduoza, C.F.; Wragg, A.A.; Patrick, M.A. The effects of a variety of wall obstructions on local mass transfer in a parallel plate electrochemical flow cell. J. Chem. Eng. 1997, 68, 145. [Google Scholar] [CrossRef]

- Harinaldi, H.; Rhakasywi, D.; Akrom, H. Characteristics of convective mass transfer under influence of turbulence control with wall-recess in a parallel plate electrochemical flow cell. Technol. World 2012, 3, 25–30. [Google Scholar]

- Ibrahim, M.H.; Najim, S.T. Determination of Mass Transfer Coefficient for Copper Electrodeposition by Limiting Current Technique. Al-Nahrain J. Eng. Sci. 2012, 20, 666–672. [Google Scholar]

- Frias-Ferrer, A.; Gonzalez-Garcia, J.; Saez, V.; Ponce de Leo´n, C.; Walsh, F.C. The Effects of Manifold Flow on Mass Transport in Electrochemical Filter-Press Reactors. AIChE J. 2008, 54, 811–823. [Google Scholar] [CrossRef]

- Harinaldi, H. Control of turbulent mass transfer in backward-facing step flow using acoustic excitation. J. Mek. 2011, 32, 86–95. [Google Scholar]

- Harinaldi, H. On the Hydrodynamics Turbulent Control of Mass Transfer in Electrodeposition Process. Int. J. Mech. Mechatron. Eng. 2011, 11, 1–8. [Google Scholar]

- Çengel, Y.A.; Cımbala, J.M. External fluids: Resistance and buoyancy. In Fluid Mechanics, 1st ed.; Engin, T., Ed.; Guven Publishing: İzmir, Türkiye, 2008; pp. 569–580. [Google Scholar]

- Arzutug, M.E. Design of a CPU Heat Sink with Minichannel-Fins & Its Thermal Analysis. Pol. J. Chem. Technol. 2023, 25, 89–100. [Google Scholar] [CrossRef]

- Cheng, C.H.; Chen, H.N.; Aung, W. Experimental Study of the effect of transverse oscillation on convection heat transfer from a circular cylinder. J. Heat Transf. 1997, 119, 474–482. [Google Scholar] [CrossRef]

- Berger, F.P.; Ziai, A. Optimisation of experimental conditions for electrochemical mass transfer measurements. Chem. Eng. Res. Des. 1983, 61, 377–382. [Google Scholar]

- Rieger, P.H. Electrochemistry; Chapman & Hall: New York, NY, USA, 1994; pp. 152–156. [Google Scholar] [CrossRef]

- Venkatraman, M.; Van Zee, J.W. Effect of a net on the limiting current distribution in a parallel plate electrochemical reactor: Part II: Combined effects. J. Appl. Electrochem. 2009, 39, 1437–1442. [Google Scholar] [CrossRef]

- Arzutug, M.E.; Yapıcı, S. Electrochemical Mass Transfer in Impinging Swirl Jets. Ind. Eng. Chem. Res. 2009, 48, 1593–1602. [Google Scholar] [CrossRef]

- Selman, R.J.; Tobias, C.W. Mass transfer measurements by the limiting current technique. Adv. Chem. Eng. 1978, 10, 211. [Google Scholar] [CrossRef]

- Öztürk, A.E. Determination of Selected Physicochemical Properties of Some Electrolytes Used in Ionic Mass Transfer Measurements. Ph.D. Thesis, Ataturk University, Institute of Science and Technology, Erzurum, Türkiye, 1996; pp. 12–13. [Google Scholar]

- Szanto, D.A.; Cleghorn, S.; Ponce-de-Leon, C.; Walsh, F.C. The Limiting Current for Reduction of Ferricyanide Ion at Nickel: The Importance of Experimental Conditions. AIChE J. 2008, 54, 802–810. [Google Scholar] [CrossRef]

- Zhang, W.; Stone, H.A.; Sherwood, J.D. Mass Transfer at a microelectrode in channel flow. J. Phys. Chem. 1996, 100, 9462–9464. [Google Scholar] [CrossRef]

- Quiroz, M.A.; Martínez Huitle, U.A.; Martínez Huitle, C.A. Mass Transfer Measurements in A Parallel Disk Cell Using the Limiting Current Technique. J. Mex. Chem. Soc. 2005, 49, 279–283. [Google Scholar]

- Kessler, D.P.; Greenkorn, R.A. Essentials: Averages. In Momentum Heat and Mass Transfer Fundamentals; Marcel Dekker Inc.: New York, NY, USA, 1999; pp. 33–57. [Google Scholar]

- Convective Mass Transfer. FDE312-Part-II. University of Anbar, Collage of Engineering, Petrochemical Engineering—Stage-2. 2020. Available online: https://www.yumpu.com/en/document/view/50591540/convective-mass-transfer (accessed on 2 May 2025).

- Eroglu, E.; Yapici, S.; Şara, O.N. Some Transport Properties of Potassium Ferri/Ferro-Cyanide Solutions in a Wide Range of Schmidt Numbers. J. Chem. Eng. Data 2011, 56, 3312–3317. [Google Scholar] [CrossRef]

- Genceli, O. Deneysel bulguların analizi. In Ölçme Tekniği (Boyut, Basınç, Akış ve Sıcaklık ölçümleri); Birsen Yayınevi: İstanbul, Türkiye, 2005; pp. 23–29. [Google Scholar]

- Kline, S.J.; McClintock, F.A. Describing Uncertain ties in Single-Sample Experiments. Mech. Eng. 1953, 75, 3–8. [Google Scholar]

- Sethuraman, V.; Khan, S.A. Base pressure control using micro-jets in supersonic flow regimes. Int. J. Aviat. Aeronaut. Aerosp. 2018, 5, 1–24. [Google Scholar] [CrossRef]

- Chen, L.; Asai, K.; Nonomura, T.; Xi, G.; Liu, T. A review of backward-facing step (BFS) flow mechanisms, Heat transfer and Control. Therm. Sci. Eng. Prog. 2018, 6, 194–216. [Google Scholar] [CrossRef]

- Sethuraman, V.; Rajendran, P.; Khan, S.A. Base and Wall Pressure Control using Cavities and Ribs in Suddenly Expanded Flows—An Overview. J. Adv. Res. Fluid Mech. Therm. Sci. 2020, 66, 120–134. [Google Scholar]

- Tagg, D.J.; Patrick, M.A.; Wragg, A.A. Heat and mass transfer downstream of abrupt nozzle expansions in turbulent flow. Trans. Inst. Chem. Eng. 1979, 57, 176–181. [Google Scholar]

- Yu, M.; Guo, Q.; Tang, Z.; Li, B.; Yuan, X. Turbulent kinetic energy transport in high-speed turbulence subject to wall disturbances. Int. J. Heat Fluid Flow 2024, 106, 1–14. [Google Scholar] [CrossRef]

| Parameters | |||||||

|---|---|---|---|---|---|---|---|

| Reynolds Number | 950 | 1430 | 1905 | 2380 | 2860 | ||

| (OP/CL) ratios | Mode-1 | 0.5/1 | 1/1 | 2/1 | 3/1 | 4/1 | 5/1 |

| Mode-2 | 1/0.5 | 1/1 | 1/2 | 1/3 | 1/4 | 1/5 | |

| Pulse numbers in 60 s | 45 | 30 | 20 | 15 | 12 | 10 | |

| Residence Times for Each (OP/CL) Ratios | |||||||

|---|---|---|---|---|---|---|---|

| Mode-1 | OP/CL | 0.5/1 | 1/1 | 2/1 | 3/1 | 4/1 | 5/1 |

| Open residence time, (s) | 0.5 | 1 | 2 | 3 | 4 | 5 | |

| Closed residence time, (s) | 1 | 1 | 1 | 1 | 1 | 1 | |

| Mode-2 | OP/CL | 1/0.5 | 1/1 | 1/2 | 1/3 | 1/4 | 1/5 |

| Open residence time, (s) | 1 | 1 | 1 | 1 | 1 | 1 | |

| Closed residence time, (s) | 0.5 | 1 | 2 | 3 | 4 | 5 | |

| Property | Value | Unit |

|---|---|---|

| Density, ρ | 1025.9 | kg/m3 |

| Viscosity, µ | 866.3 | kg/ms |

| Concentration of ferricyanide | 5 | mol/m3 |

| Schmidth number | 1583 | |

| Channel cross-sectional area | 4 × 10−4 | m2 |

| The height of blockage blade | 1 × 10−2 | m |

| Micro-electrode area | 7.07 × 10−6 | m2 |

| S. No. | Uncertainty Equation | Uncertainty % | |

|---|---|---|---|

| 1 | 6.4 | ||

| 2 | 5.7 | ||

| 3 | 10.5 |

| OP/CL | Percentage of Increment Ratio of the Peak k Values (%) | |

|---|---|---|

| No pulsed flow | - | 179 |

| Pulsed flow | 0.5/1 | 206 |

| 1/1 | 244 | |

| 2/1 | 222 | |

| 3/1 | 252 | |

| 5/1 | 260 |

| (OP/CL) ratios | Mode-1 | 0.5/1 | 1/1 | 2/1 | 3/1 | 4/1 | 5/1 |

| Mode-2 | 1/0.5 | 1/1 | 1/2 | 1/3 | 1/4 | 1/5 | |

| Pulse numbers in 60 s. | 45 | 30 | 20 | 15 | 12 | 10 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arzutuğ, M.E. Investigation of the Convective Mass Transfer Characteristics in a Parallel-Plate Channel Flow Disturbed by Using a Selenoid Pulse Generator. Processes 2025, 13, 1700. https://doi.org/10.3390/pr13061700

Arzutuğ ME. Investigation of the Convective Mass Transfer Characteristics in a Parallel-Plate Channel Flow Disturbed by Using a Selenoid Pulse Generator. Processes. 2025; 13(6):1700. https://doi.org/10.3390/pr13061700

Chicago/Turabian StyleArzutuğ, Mehmet Emin. 2025. "Investigation of the Convective Mass Transfer Characteristics in a Parallel-Plate Channel Flow Disturbed by Using a Selenoid Pulse Generator" Processes 13, no. 6: 1700. https://doi.org/10.3390/pr13061700

APA StyleArzutuğ, M. E. (2025). Investigation of the Convective Mass Transfer Characteristics in a Parallel-Plate Channel Flow Disturbed by Using a Selenoid Pulse Generator. Processes, 13(6), 1700. https://doi.org/10.3390/pr13061700