A Review of Potential Geological Hazards and Precautions in the Mining of Submarine Natural Gas Hydrate

Abstract

1. Introduction

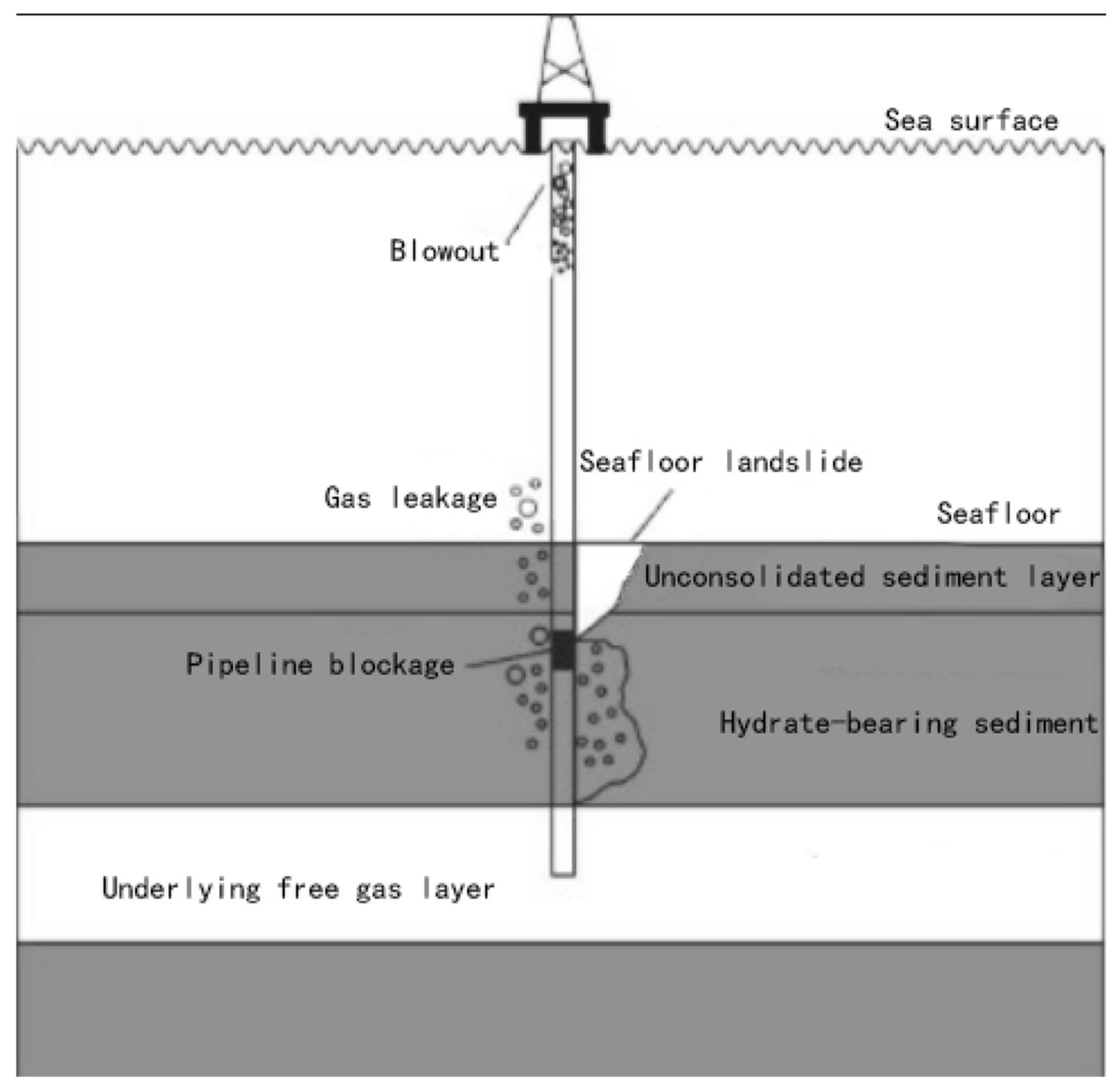

2. Potential Geological Hazards in NGH Mining

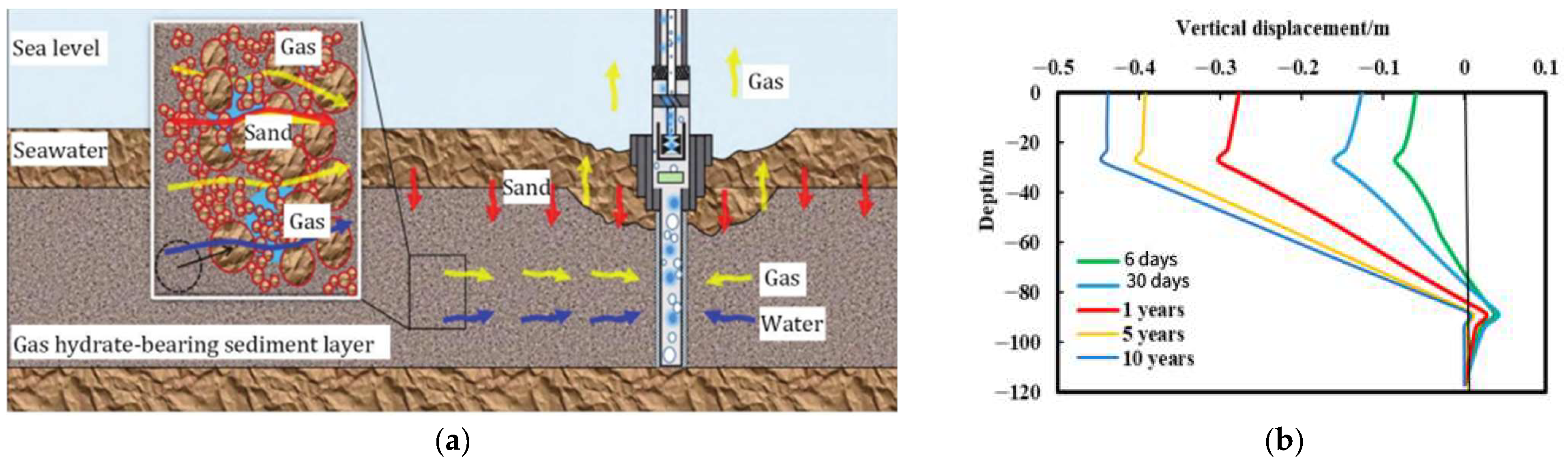

2.1. Stratum Subsidence

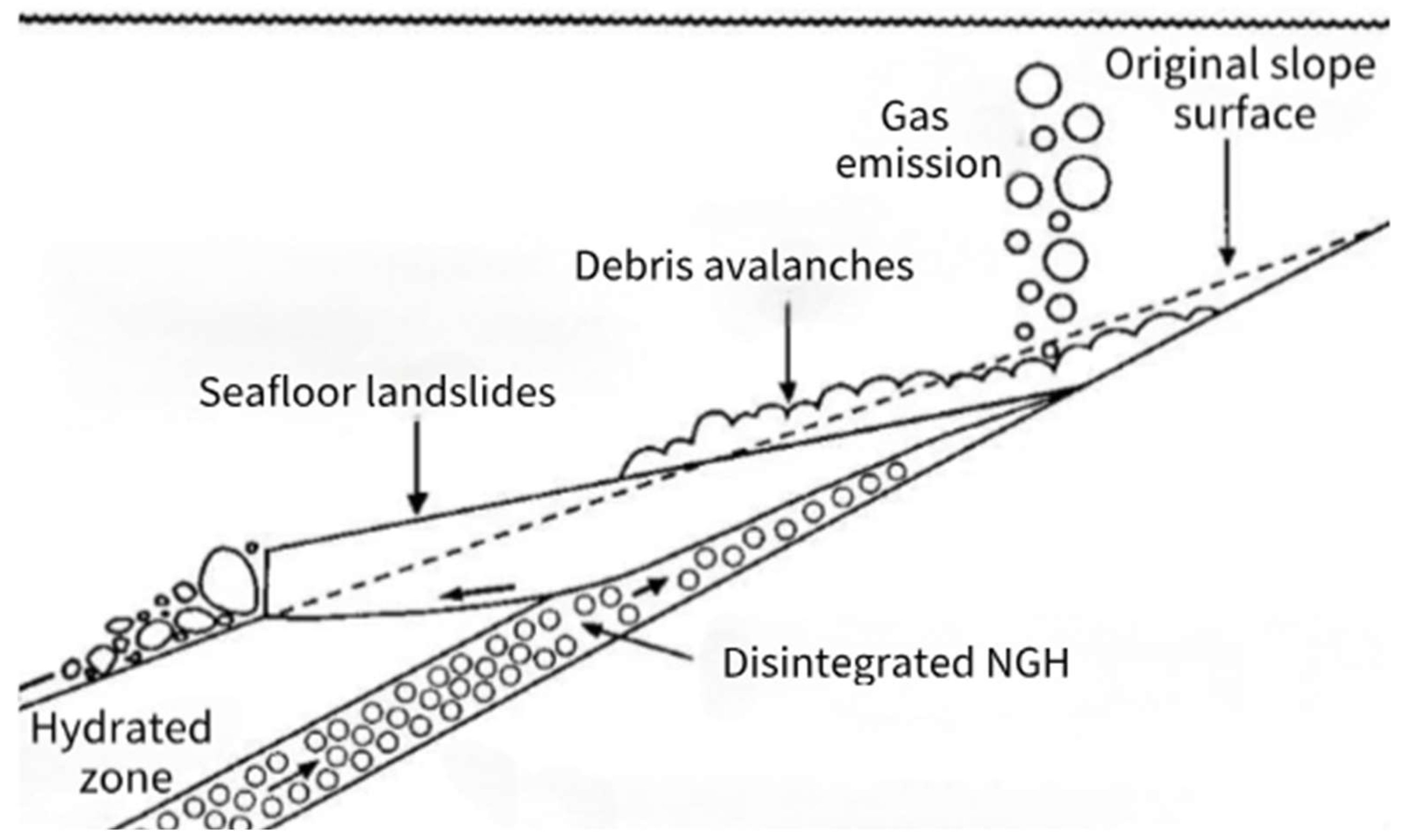

2.2. Seafloor Landslide

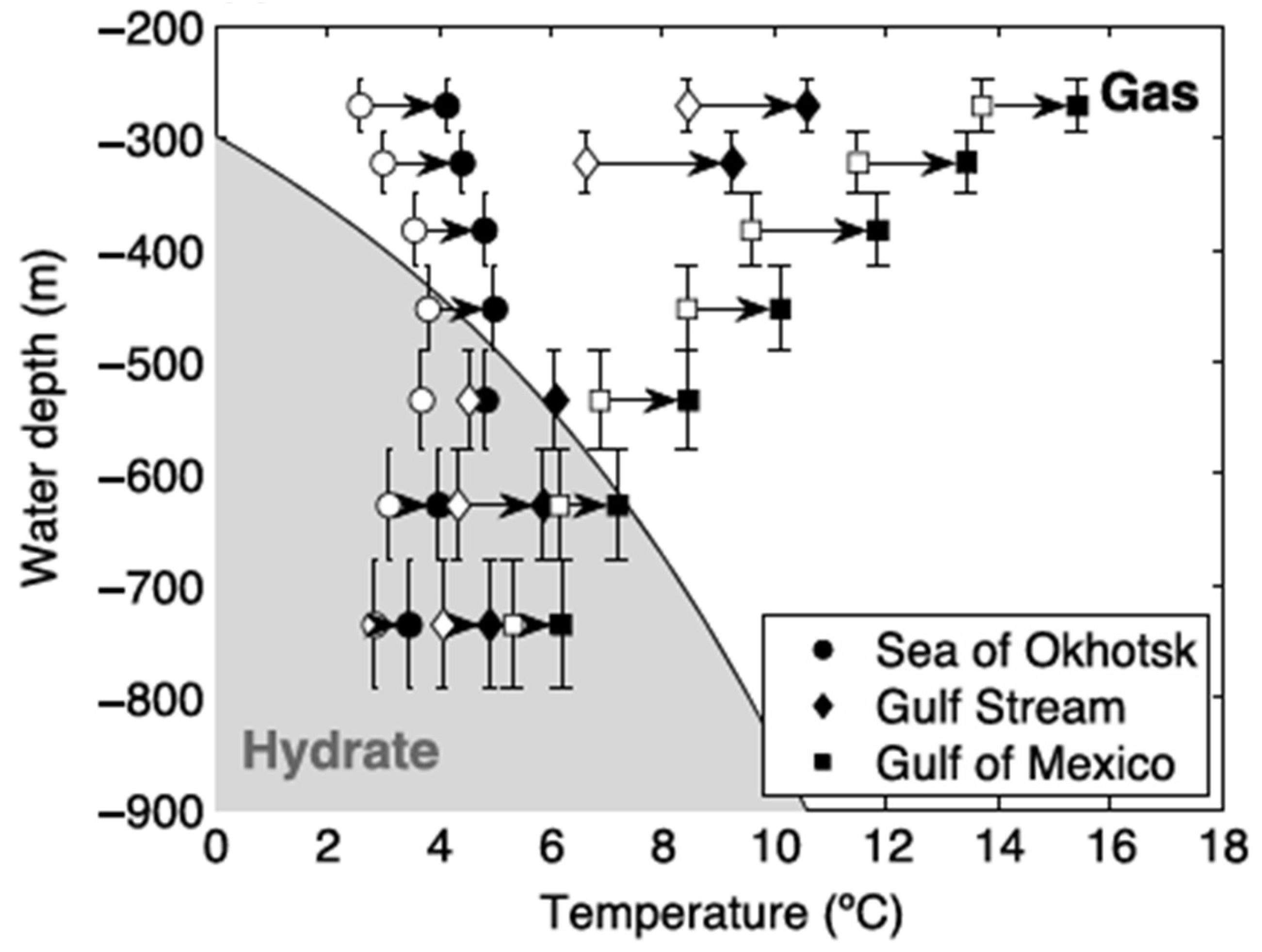

2.3. Greenhouse Effect

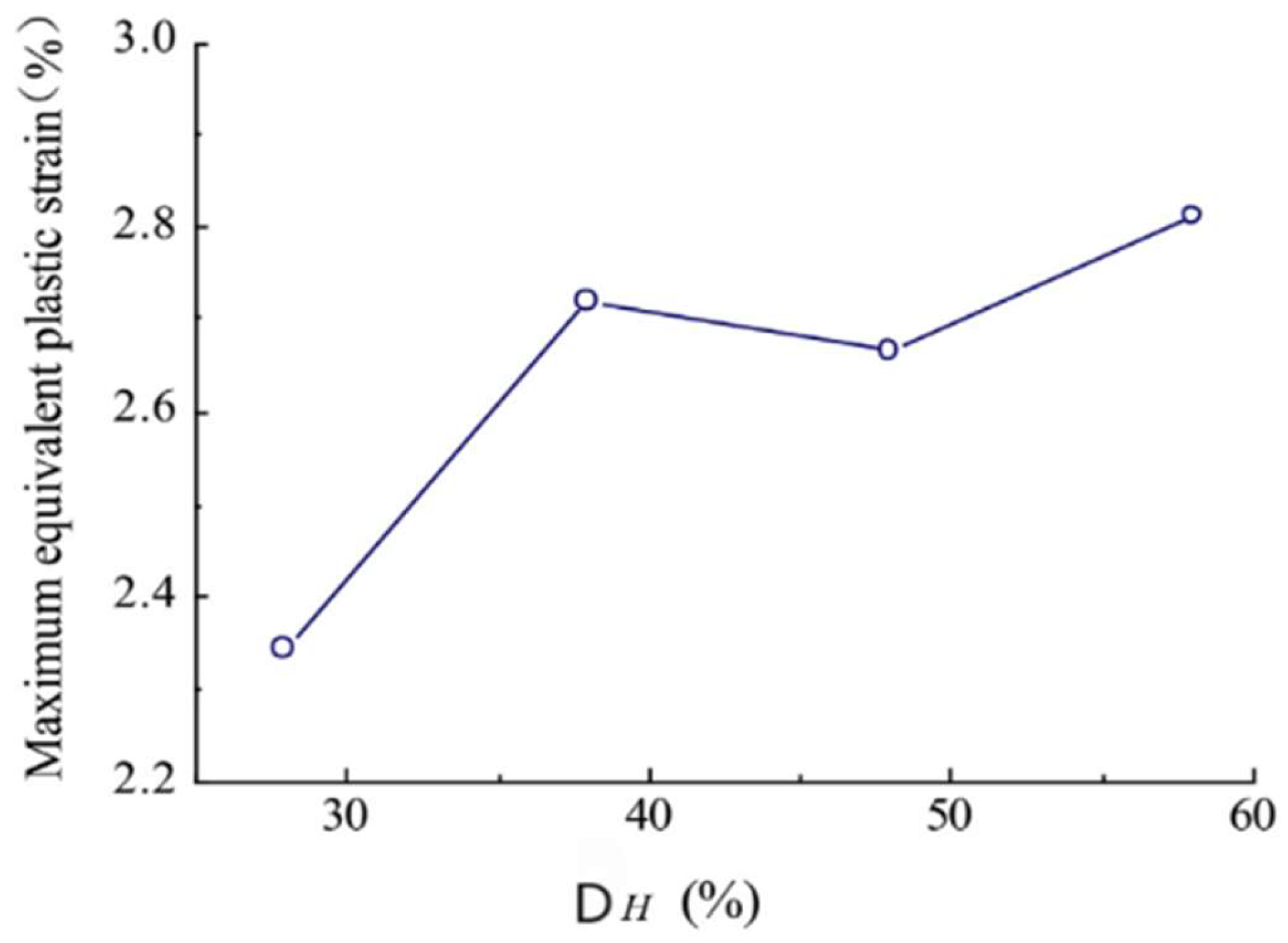

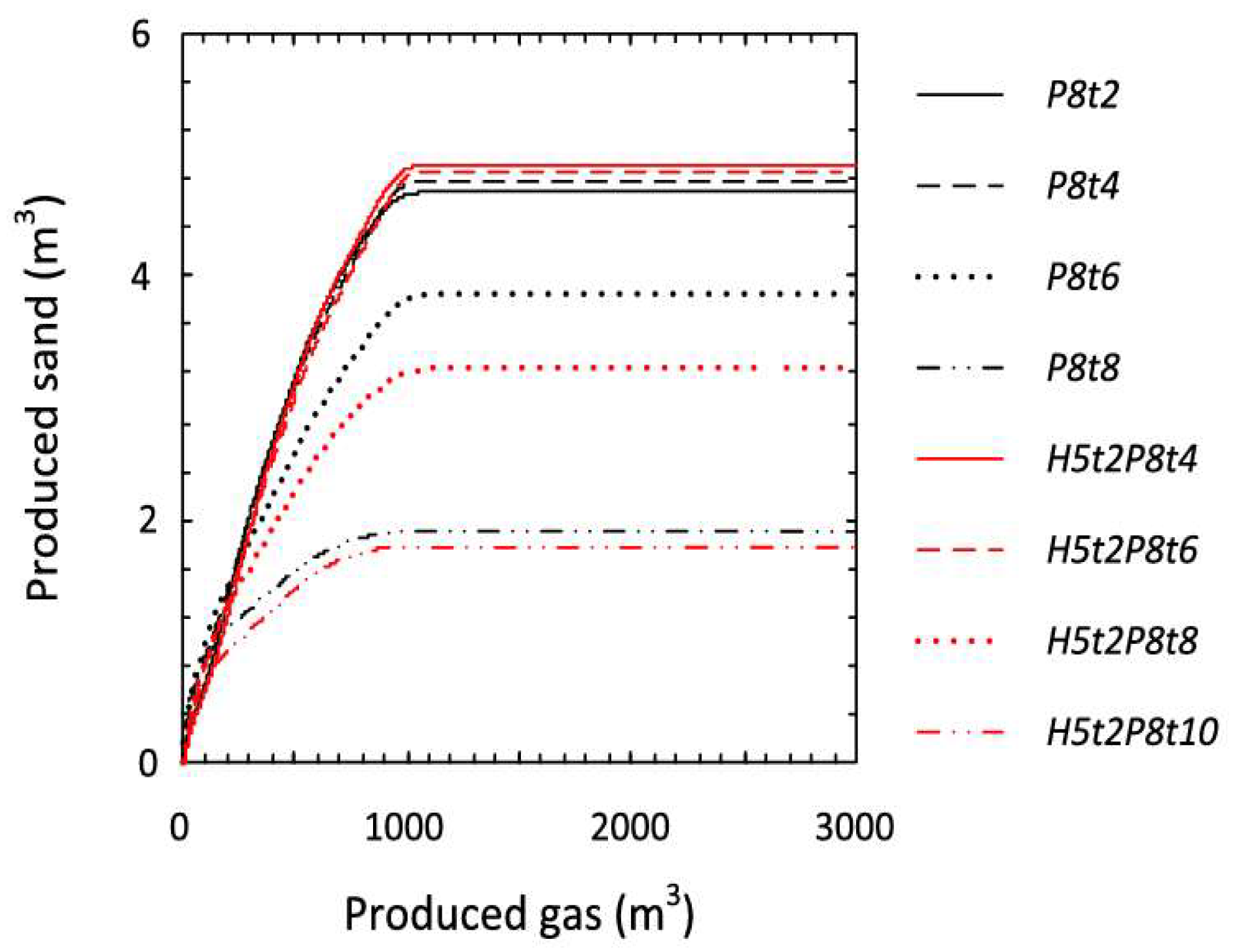

2.4. Sand Piping

2.5. Well Blowout

2.6. Wellbore Instability

3. Technical Precautions

3.1. Optimize the CO2-EGR Method to Alleviate Stratum Subsidence

3.2. Fill Foamed Cement to Control Seafloor Landslides

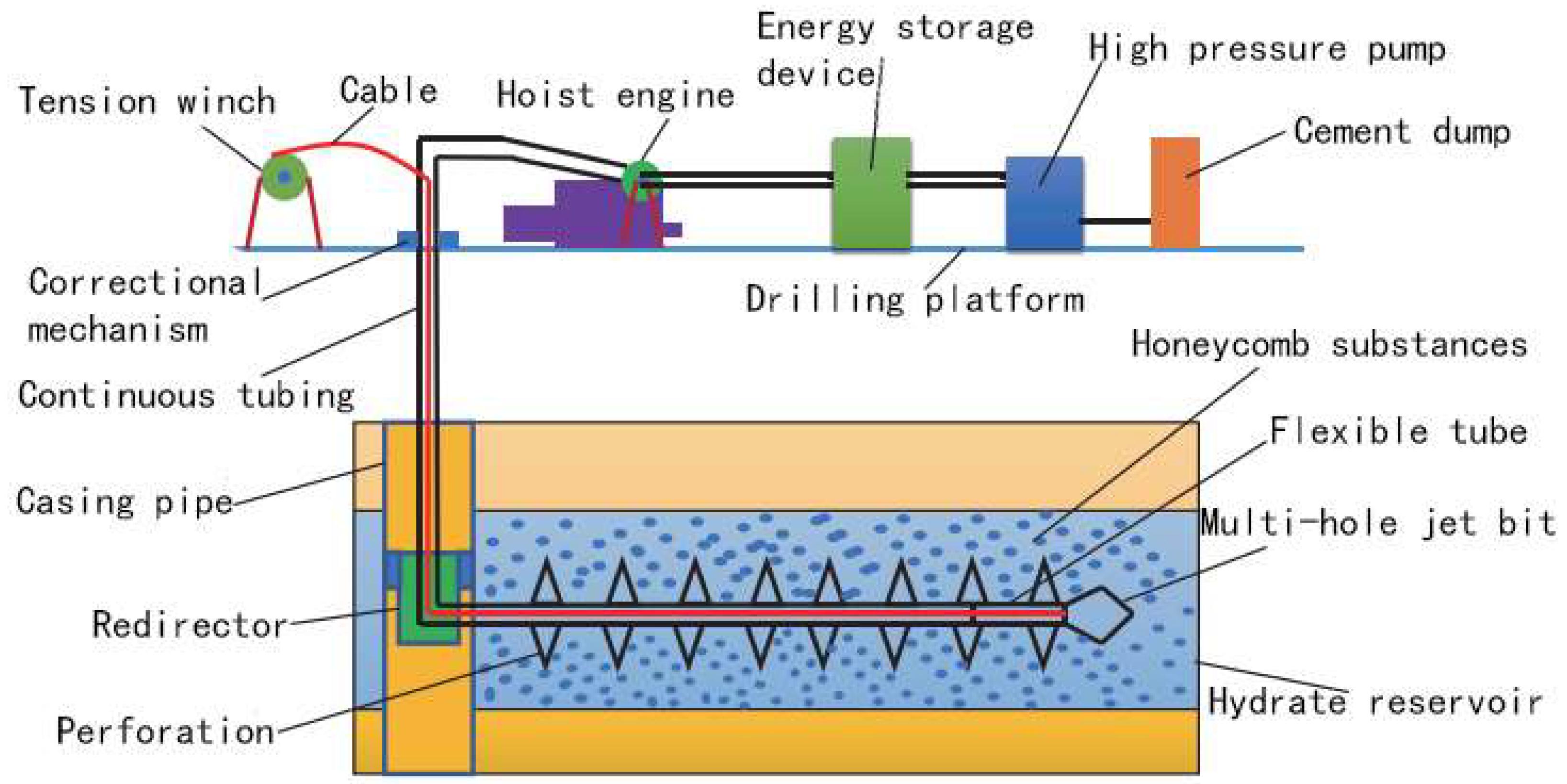

3.3. Improve Drilling Technology to Mitigate the Greenhouse Effect

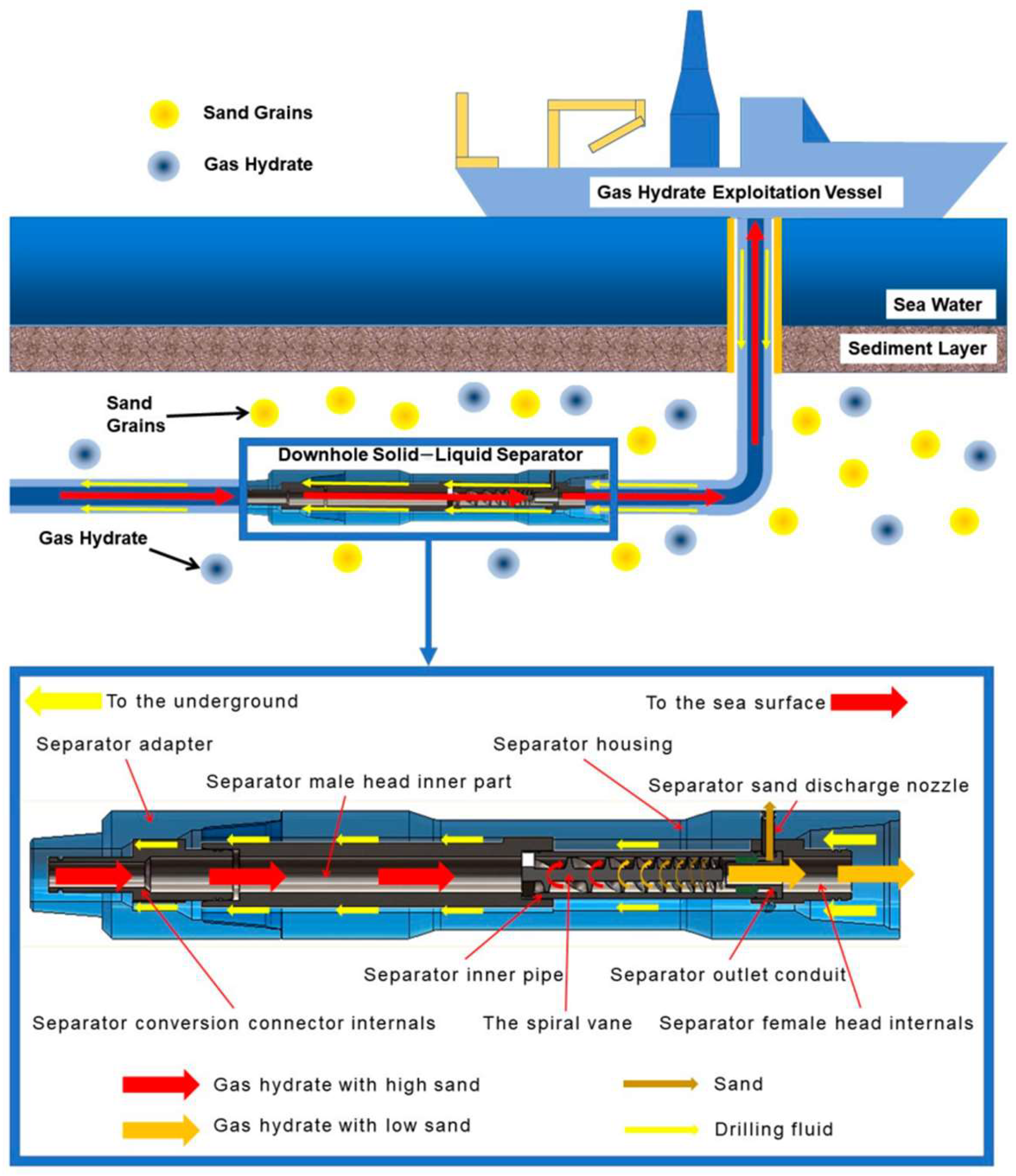

3.4. Install a New Solid–Liquid Separator to Reduce Sand Piping

3.5. Adopt New Inhibitor to Lower Well Blockage

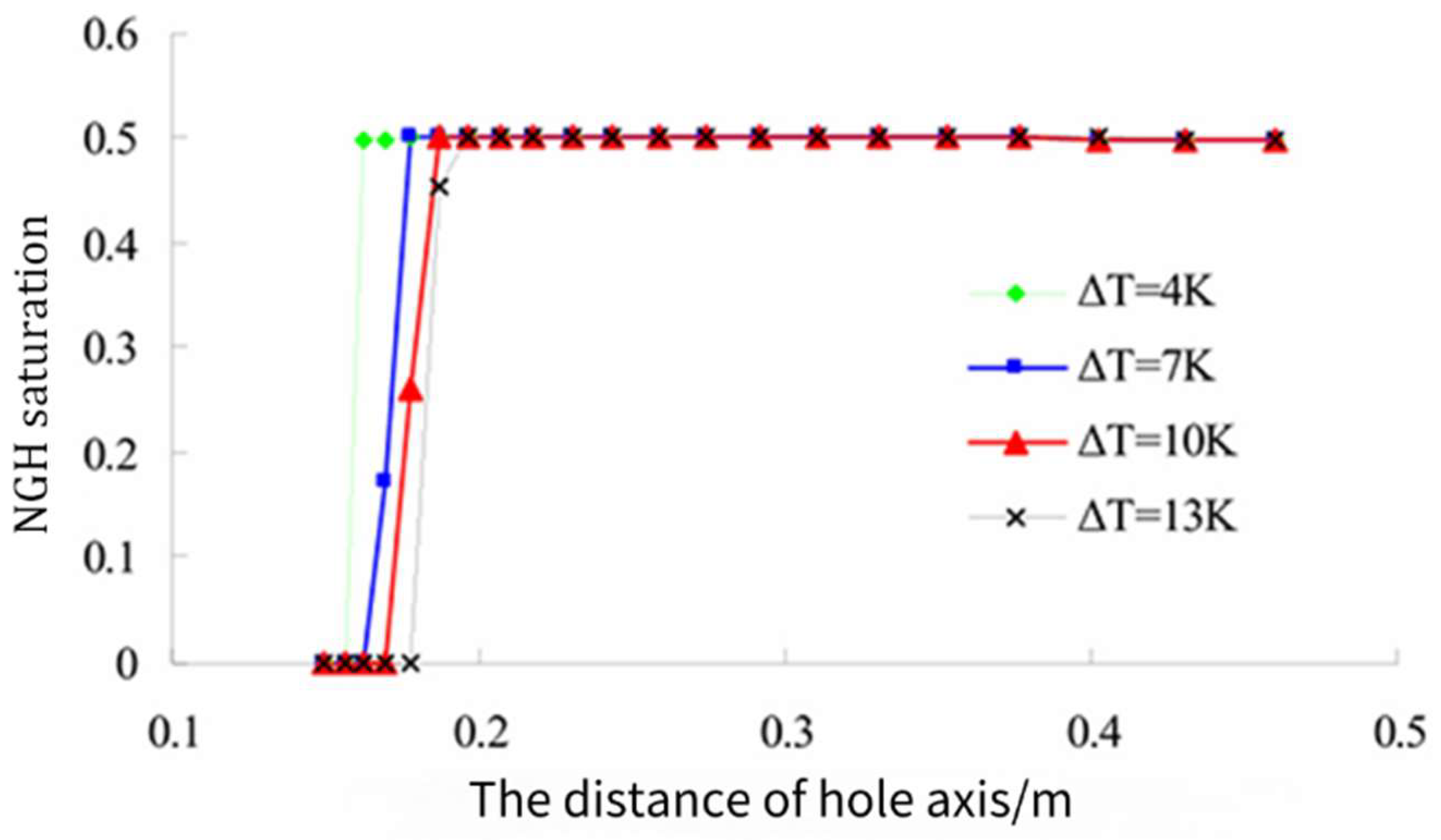

3.6. Use a Low-Temperature Drilling Fluid to Keep Wellbore Stable

4. Policy Suggestions

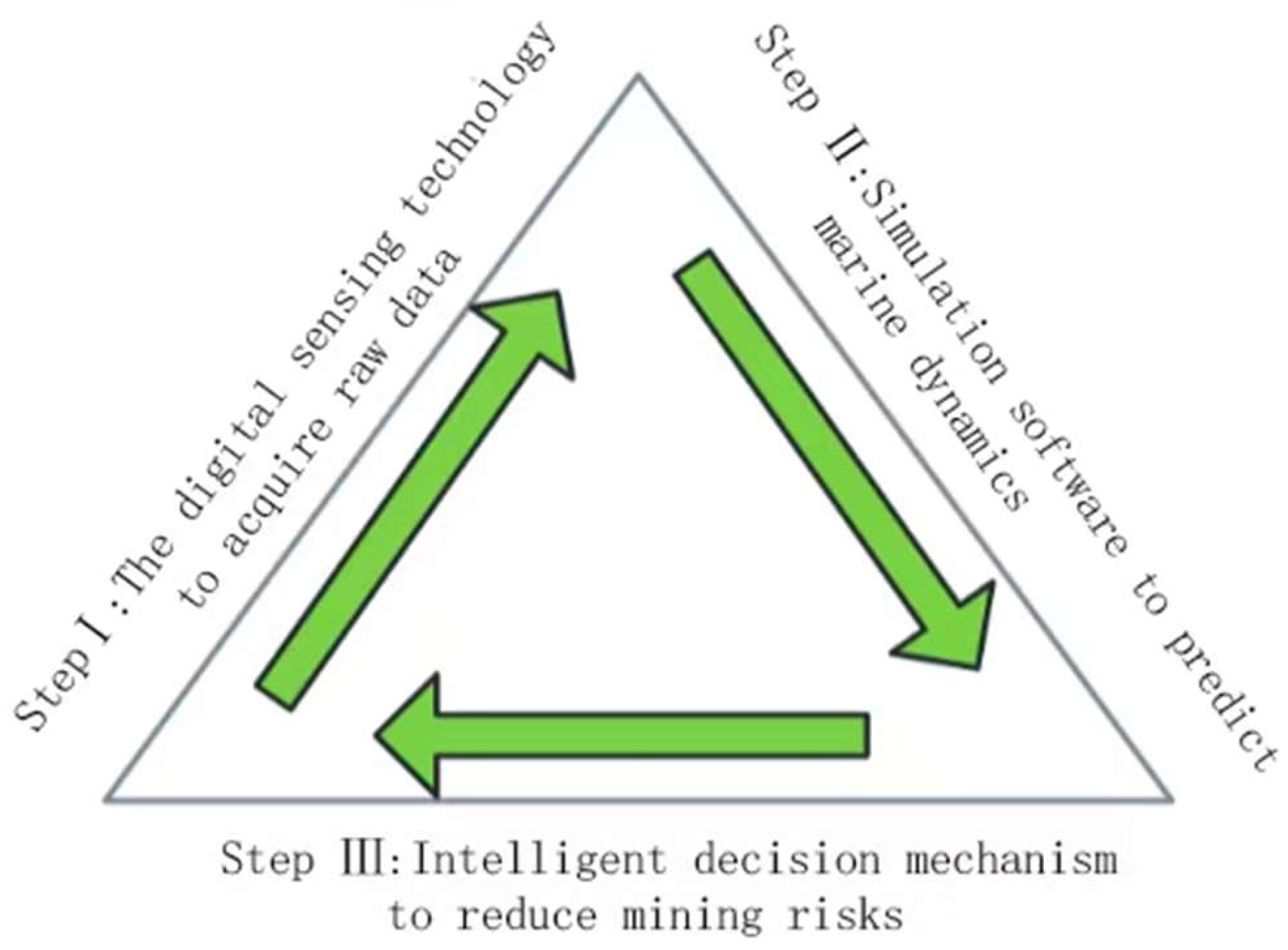

4.1. Founding a Risk Identification Mechanism Through Marine Science and Technology Research

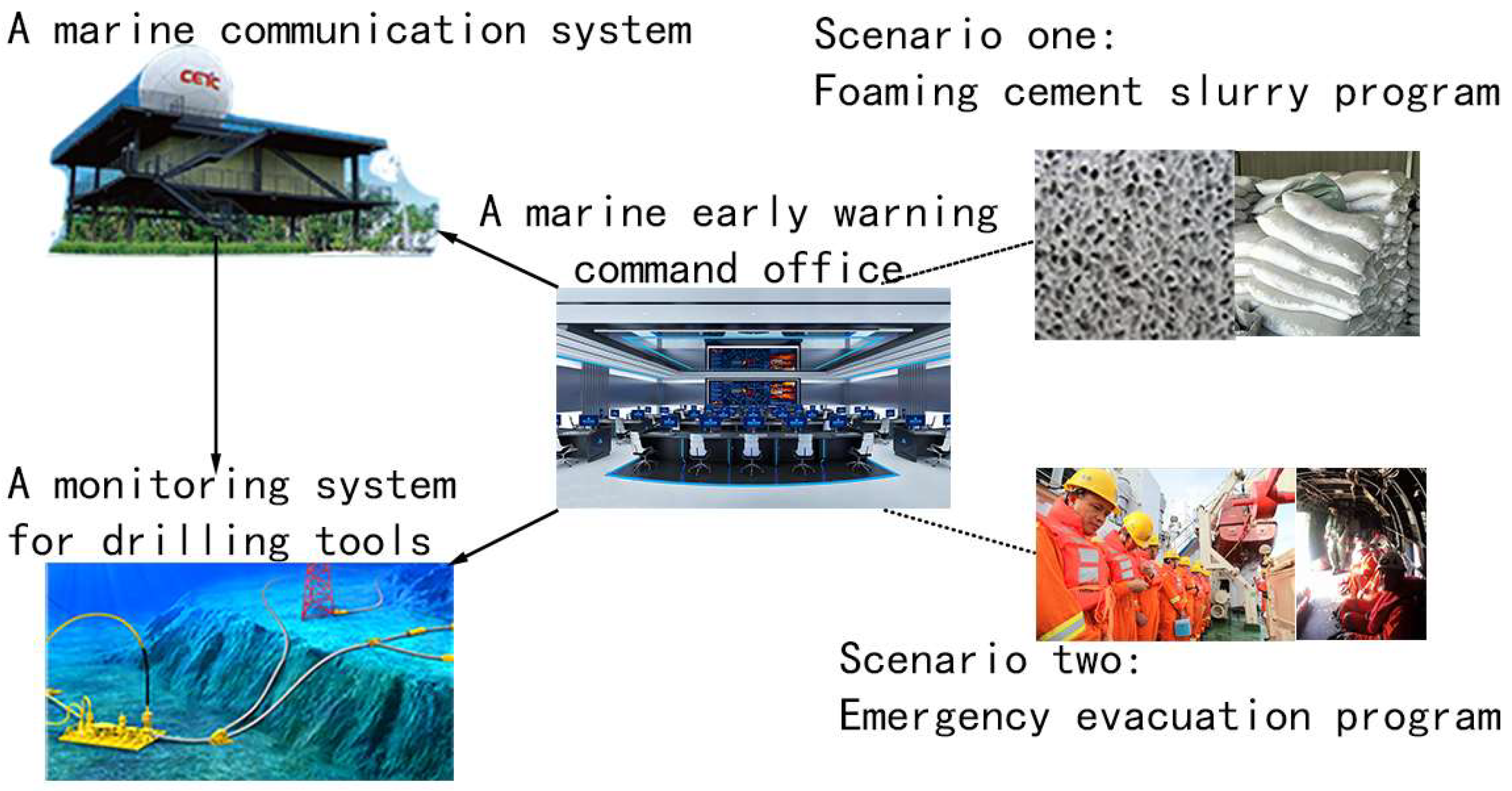

4.2. Establishing a Risk Warning Mechanism Through International Cooperation

4.3. Improving Safety Regulations Through Legal Supervision

5. Conclusions

- (1)

- There are two types of potential geological risks in commercial mining: natural geological hazards, including stratum subsidence, seafloor landslides, and the greenhouse effect; and secondary geological accidents, including sand piping, well blowout, and wellbore instability.

- (2)

- Technical precautions include optimizing the CO2-EGR method to alleviate stratum subsidence; filling with foamed cement to control seafloor landslides; improving drilling technology to mitigate the greenhouse effect; installing a new solid–liquid separator to reduce sand piping; adopting a new inhibitor to lower well blockage; and using a low-temperature drilling fluid to keep the wellbore stable.

- (3)

- Policy suggestions include founding a risk identification mechanism through marine science and technology research; establishing a risk warning mechanism through international cooperation; and improving safety regulations through legal supervision.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Dong, X.C. Distribution of global proven oil reserves: Historical evolution and data analysis. China Pet. Enterp. 2024, 41, 13–15. [Google Scholar]

- Dai, R.; Huang, H.L.; Luo, M.; Li, W.T.; Wu, Y.H.; Li, X.; Zhou, S.Q. Applicability analysis of thermodynamic model of gas hydrate phase equilibrium. Energy Chem. Ind. 2025, 46, 42–50. [Google Scholar]

- Ma, X.; Sun, Y.; Guo, W.; Jia, R.; Li, B. Numerical simulation of horizontal well hydraulic fracturing technology for gas production from hydrate reservoir. Appl. Ocean Res. 2021, 112, 102674. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, Z.; Li, P.; Song, Y.; Wang, D. Numerical modeling of coupled behavior of gas production and mechanical deformation of gas hydrate reservoir in Shenhu area, South China Sea: Enlightenments for field monitoring and model verification. Energy 2022, 254, 124406. [Google Scholar] [CrossRef]

- Yang, Y.; Li, Q.; Xu, Y.; Huang, J. Dynamics study of self-pulling & self-rotating jet drill bit in natural gas hydrate reservoirs radial horizontal well drilling. Geoenergy Sci. Eng. 2025, 244, 213490. [Google Scholar]

- Faramawy, S.; Zaki, T.; Sakr, A.E. Natural gas origin, composition, and processing: A review. J. Nat. Gas Sci. Eng. 2016, 34, 34–54. [Google Scholar] [CrossRef]

- Ansari, U.; Cheng, Y.; Li, Q.; Mawaipopo, G.G.; Wei, J. Simulating the effect of subsurface stresses and transient pore pressure on wellbore stability in subsea horizontal wells. Energy Sources Part A Recovery Util. Environ. Eff. 2019, 41, 2028–2038. [Google Scholar] [CrossRef]

- Wang, F.; Shen, K.; Zhang, Z.; Zhang, D.; Wang, Z.; Wang, Z. Numerical simulation of natural gas hydrate development with radial horizontal wells based on thermo-hydrochemistry coupling. Energy 2023, 272, 127098. [Google Scholar] [CrossRef]

- Wang, Z.; Lei, X.; Zhou, W.; Wang, Y.; Cao, J.; Wang, C. Numerical simulation of the damage process of rock containing cracks by impacts of steel-particle water jet. Powder Technol. 2023, 422, 118465. [Google Scholar] [CrossRef]

- Boswell, R.; Collett, T. Current perspectives on gas hydrate resources. Energy Environ. Sci. 2011, 4, 1206–1215. [Google Scholar] [CrossRef]

- Liu, H.; Liu, H.; Zhang, Q.; Fan, M.; Yin, B.; Wang, X.; Sun, X.; Wang, Z. Effect of liquid viscosity on the gas-liquid two phase countercurrent flow in the wellbore of bullheading killing. Geoenergy Sci. Eng. 2023, 221, 111274. [Google Scholar] [CrossRef]

- Onwukwe, S.I.; Duru, U.I. Prospect of harnessing associated gas through natural gas hydrate (NGH) technology in Nigeria. J. Pet. Gas Eng. 2015, 6, 38–44. [Google Scholar] [CrossRef]

- Konno, Y.; Masuda, Y.; Hariguchi, Y.; Kurihara, M.; Ouchi, H. Key factors for depressurization-induced gas production from oceanic methane hydrates. Energy Fuels 2010, 24, 1736–1744. [Google Scholar] [CrossRef]

- Yamamoto, K.; Kanno, T.; Wang, X.; Tamaki, M.; Fujii, T.; Wang, X.; Pimenov, V.; Shako, V. Thermal responses of a gas hydrate-bearing sediment to a depressurization operation. RSC Adv. 2017, 10, 5554. [Google Scholar] [CrossRef]

- Wang, B.; Dong, H.; Liu, Y.; Lv, X.; Liu, Y.; Zhao, J.; Song, Y. Evaluation of thermal stimulation on gas production from depressurized methane hydrate deposits. Appl. Energy 2018, 227, 710–718. [Google Scholar] [CrossRef]

- Chen, C.; Meng, Y.; Zhong, X.; Nie, S.; Ma, Y.; Pan, D.; Liu, K.; Li, X.; Gao, S. Research on the influence of injection-production parameters on challenging natural gas hydrate exploitation using depressurization combined with thermal injection stimulated by hydraulic fracturing. Energy Fuels 2021, 35, 15589–15606. [Google Scholar] [CrossRef]

- Li, Q.; Wang, F.; Wang, Y.; Zhou, C.; Chen, J.; Forson, K.; Zhang, J. Effect of reservoir characteristics and chemicals on filtration property of water-based drilling fluid in unconventional reservoir and mechanism disclosure. Environ. Sci. Pollut. Res. 2023, 30, 55034–55043. [Google Scholar] [CrossRef]

- Liu, F.; Tun, S.; Sun, Y. A quantitative analysis for submarine slope instability of the northern South China Sea due to gas hydrate dissociation. Chin. J. Geophys. 2010, 53, 946–953. [Google Scholar]

- Li, J.; Ye, J.; Qin, X.; Qiu, H.; Wu, N.; Lu, H.; Xie, W.; Lu, J.; Peng, F.; Xu, Z.; et al. The first offshore natural gas hydrate production test in South China Sea. China Geol. 2018, 1, 5–16. [Google Scholar] [CrossRef]

- Song, B.; Cheng, Y.; Yan, C.; Lyu, Y.; Wei, J.; Ding, J.; Li, Y. Seafloor subsidence response and submarine slope stability evaluation in response to hydrate dissociation. J. Nat. Gas Sci. Eng. 2019, 65, 197–211. [Google Scholar] [CrossRef]

- Song, B.; Cheng, Y.; Yan, C.; Han, Z.; Ding, J.; Li, Y.; Wei, J. Influences of hydrate decomposition on submarine landslide. Landslides 2019, 16, 2127–2150. [Google Scholar] [CrossRef]

- Yan, C.; Ren, X.; Cheng, Y.; Song, B.; Li, Y.; Tian, W. Geomechanical issues in the exploitation of natural gas hydrate. Gondwana Res. 2020, 81, 403–422. [Google Scholar] [CrossRef]

- Ding, J.; Cheng, Y.; Deng, F.; Yan, C.; Sun, H.; Li, Q.; Song, B. Experimental study on dynamic acoustic characteristics of natural gas hydrate sediments at different depths. Int. J. Hydrogen Energy 2020, 45, 26877–26889. [Google Scholar] [CrossRef]

- Li, Q.; Wang, F.; Wang, Y.; Bai, B.; Zhang, J.; Lili, C.; Sun, Q.; Wang, Y.; Forson, K. Adsorption behavior and mechanism analysis of siloxane thickener for CO2 fracturing fluid on shallow shale soil. J. Mol. Liq. 2023, 376, 121394. [Google Scholar] [CrossRef]

- Liang, H.; Song, Y.; Chen, Y. Numerical simulation for laboratory-scale methane hydrate dissociation by depressurization. Energy Convers. Manag. 2010, 51, 1883–1890. [Google Scholar] [CrossRef]

- Zhong, X.; Pan, D.; Zhai, L.; Zhu, Y.; Zhang, H.; Zhang, Y.; Wang, Y.; Li, X.; Chen, C. Evaluation of the gas production enhancement effect of hydraulic fracturing on combining depressurization with thermal stimulation from challenging ocean hydrate reservoirs. J. Nat. Gas Sci. Eng. 2020, 83, 103621. [Google Scholar] [CrossRef]

- Wan, Y.; Wu, N.; Hu, G.; Xin, X.; Jin, G.; Liu, C.; Chen, Q. Reservoir stability in the process of natural gas hydrate production by depressurization in the Shenhu area of the South China Sea. Nat. Gas Ind. B 2018, 5, 631–643. [Google Scholar] [CrossRef]

- Jin, G.; Lei, H.; Xu, T.; Liu, L.; Xin, X.; Zhai, H.; Liu, C. Seafloor subsidence induced by gas recovery from a hydratebearing sediment using multiple well system. Mar. Pet. Geol. 2019, 107, 438–450. [Google Scholar] [CrossRef]

- Huang, L.; Xu, C.; Xu, J.; Zhao, Y. Hydrate dissociation evaluation and stratum subsidence response induced by depressurization in hydrate-bearing permafrost. Energy Fuels 2022, 36, 11077–11088. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, R.; Ye, R.; Zhou, K.; Gong, B.; Golsanami, N. Mechanical properties of nodular natural gas hydratebearing sediment. Adv. Geo-Energy Res. 2024, 11, 41–53. [Google Scholar] [CrossRef]

- He, Y.; Song, B.; Li, Q. Coupling submarine slope stability and wellbore stability analysis with natural gas hydrate drilling and production in submarine slope strata in the South China Sea. J. Mar. Sci. Eng. 2023, 11, 2069. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, Y.J.; Cai, N.; Liu, H.X.; Ma, C.H.; Liang, J.W. The effect of decomposition of natural gas hydrate on deep-water drilling. Pet. Sci. Technol. 2024, 42, 1701–1721. [Google Scholar] [CrossRef]

- Luo, T.; Li, Y.; Madhusudhan, B.N.; Sun, X.; Song, Y. Deformation behaviors of hydrate-bearing silty sediment induced by depressurization and thermal recovery. Appl. Energy 2020, 276, 115468. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, J.; Li, X.; Zhang, Y.; Han, H. Methane hydrate decomposition and sediment deformation in unconfined sediment with different types of concentrated hydrate accumulations by innovative experimental system. Appl. Energy 2018, 226, 916–923. [Google Scholar] [CrossRef]

- Zhang, X.; Xia, F.; Xu, C.; Han, Y. Stability analysis of near-wellbore reservoirs considering the damage of hydratebearing sediments. J. Mar. Sci. Eng. 2019, 7, 102. [Google Scholar] [CrossRef]

- Zhou, M.; Soga, K.; Yamamoto, K.; Huang, H. Geomechanical responses during depressurization of hydrate-bearing sediment formation over a long methane gas production period. Geomech. Energy Environ. 2020, 23, 100111. [Google Scholar] [CrossRef]

- Xue, K.; Liu, Y.; Yu, T.; Yang, L.; Zhao, J.; Song, Y. Numerical simulation of gas hydrate production in Shenhu area using depressurization: The effect of reservoir permeability heterogeneity. Energy 2023, 271, 126948. [Google Scholar] [CrossRef]

- Ye, J.; Qin, X.; Xie, W.; Lu, H.; Ma, B.; Qiu, H.; Liang, J.; Lu, J.; Kuang, Z.; Lu, C.; et al. The second natural gas hydrate production test in the South China Sea. China Geol. 2020, 3, 197–209. [Google Scholar] [CrossRef]

- Yu, T.; Guan, G.; Wang, D.; Song, Y.; Abudula, A. Numerical evaluation on the effect of horizontal-well systems on the long-term gas hydrate production behavior at the second Shenhu test site. J. Nat. Gas Sci. Eng. 2021, 95, 104200. [Google Scholar] [CrossRef]

- Xiao, C.W.; Li, X.S.; Li, G.; Yu, Y.; Yu, J.X.; Lv, Q.N. Numerical analysis of production behaviors and permeability characteristics on the second gas hydrate production test in the South China Sea. Energy Fuels 2022, 36, 10960–10974. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, P.; Pang, S.; Zhang, S.; Xiao, R. A review of the resource and test production of natural gas hydrates in China. Energy Fuels 2021, 35, 9137–9150. [Google Scholar] [CrossRef]

- Sun, J.; Ning, F.; Zhang, L.; Liu, T.; Peng, L.; Liu, Z.; Li, C.; Jiang, G. Numerical simulation on gas production from hydrate reservoir at the 1st offshore test site in the eastern Nankai Trough. J. Nat. Gas Sci. Eng. 2016, 30, 64–76. [Google Scholar] [CrossRef]

- Chen, L.; Feng, Y.; Kogawa, T.; Okajima, J.; Komiya, A.; Maruyama, S. Construction and simulation of reservoir scale layered model for production and utilization of methane hydrate: The case of Nankai Trough Japan. Energy 2018, 143, 128–140. [Google Scholar] [CrossRef]

- Yu, T.; Guan, G.; Wang, D.; Song, Y.; Abudula, A. Numerical investigation on the long-term gas production behavior at the 2017 Shenhu methane hydrate production site. Appl. Energy 2021, 285, 116466. [Google Scholar] [CrossRef]

- Yin, F.; Gao, Y.; Chen, Y.; Sun, B.; Li, S.; Zhao, D. Numerical investigation on the long-term production behavior of horizontal well at the gas hydrate production site in South China Sea. Appl. Energy 2022, 311, 118603. [Google Scholar] [CrossRef]

- Ma, Y.Y. Study on Sealing Transformation and Injection Inhibitor Mining of Permeable Cap Rock in Marine Hydrate Reservoir; Jilin University: Jilin, China, 2023. [Google Scholar]

- Ma, S.; Li, H.; Jia, H. Influence of Natural Gas Hydrate’s Property Weakening from Dissociation on Subsidence of Seabed Sediments: A Simulation Study. Adv. Civ. Eng. 2022, 15, 6159470. [Google Scholar] [CrossRef]

- Li, S.X.; Ding, S.Y.; Wu, D.D.; Wang, X.P.; Hao, Y.M.; Li, Q.P.; Pang, W.X. Analysis of Stratum Subsidence Induced by Depressurization at an Offshore Hydrate-Bearing Sediment. Energy Fuels 2021, 35, 1381–1388. [Google Scholar] [CrossRef]

- Zhou, S.W.; Li, Q.P.; Zhu, J.L.; Pang, W.X.; He, Y.F. Challenges and reflections on the development of gas hydrate in the South China Sea. Nat. Gas Ind. 2023, 43, 152–163. [Google Scholar]

- Huang, Y.; Cheng, J.; Wang, M.; Wang, S.; Yan, W. Gas hydrate dissociation events during LGM and their potential trigger of submarine landslides: Foraminifera and geochemical records from two cores in the northern South China sea. Front. Earth Sci. 2022, 10, 876913. [Google Scholar] [CrossRef]

- Ma, X.; Jiang, Y.; Yan, P.; Luan, H.; Wang, C.; Shan, Q.; Cheng, X. A review on submarine geological risks and secondary disaster issues during natural gas hydrate depressurization production. J. Mar. Sci. Eng. 2024, 12, 840. [Google Scholar] [CrossRef]

- Fell, R. Landslide risk assessment and acceptable risk. Can. Geotech. J. 1994, 31, 261–272. [Google Scholar] [CrossRef]

- Fell, R.; Corominas, J.; Bonnard, C.; Cascini, L.; Leroie, E.; Savage, W.Z. Guidelines for landslide susceptibility, hazard and risk zoning for land use planning. Eng. Geol. 2008, 102, 85–98. [Google Scholar] [CrossRef]

- McAdoo, B.G.; Watts, P. Tsunami hazard from submarine landslides on the Oregon continental slope. Mar. Geol. 2004, 203, 235–245. [Google Scholar] [CrossRef]

- Masson, D.G.; Harbitz, C.B.; Wynn, R.B.; Pedersen, G.; Lovholt, F. Submarine landslides: Processes, triggers and hazard prediction. Philos. Trans. R. Soc. A Mathematical. Phys. Eng. Sci. 2006, 364, 2009–2039. [Google Scholar] [CrossRef] [PubMed]

- Kvenvolden, K.A. Potential effects of gas hydrate on human welfare. Proc. Natl. Acad. Sci. USA 1999, 96, 3420–3426. [Google Scholar] [CrossRef] [PubMed]

- Pape, T.; Bahr, A.; Klapp, S.A.; Abegg, F.; Bohrmann, G. High-intensity gas seepage causes rafting of shallow gas hydrates in the southeastern Black Sea. Earth Planet Sci. Lett. 2011, 307, 35–46. [Google Scholar] [CrossRef]

- Zou, H.; Li, Q.X.; Chen, A.Q.; Xiao, B.; Jiang, X.W.; Huang, C.C.; Hu, C.H.; Li, D. The Formation and Disappearance of the Neoproterozoic “Snowball Earth” and the Records from the South China Plate. J. Sediment. 2022, 40, 1043–1058. [Google Scholar]

- Zhang, Z.G.; Wang, Y.; Gao, L.F.; Zhang, Y.; Liu, C.S. Marine gas hydrates: Future energy or environmental killer? Energy Procedia 2012, 16, 933–938. [Google Scholar] [CrossRef]

- Sun, M.Q.; Wang, Y.Q.; Fu, P. Relationship between natural gas hydrate and global climate change. Environ. Sci. Manag. 2012, 37, 80–84. [Google Scholar]

- Kretschmer, K.; Biastoch, A.; Rüpke, L.; Burwicz, E. Modeling the fate of methane hydrates under global warming. Glob. Biogeochem. Cycles 2015, 29, 610–625. [Google Scholar] [CrossRef]

- Yan, C.; Li, Y.; Cheng, Y.; Wang, W.; Song, B.; Deng, F.; Feng, Y. Sand production evaluation during gas production from natural gas hydrates. J. Nat. Gas Sci. Eng. 2018, 57, 77–88. [Google Scholar] [CrossRef]

- Zhu, N. Analysis of environmental impact factors and monitoring status of test mining of combustible ice. Mech. Electr. Eng. Technol. 2019, 48, 134–135+214. [Google Scholar]

- Chen, K.; Wei, X.; Li, H.; Lin, H.; Khan, F. Operational risk analysis of blowout scenario in offshore drilling operation. Process Saf. Environ. Prot. 2021, 149, 422–431. [Google Scholar] [CrossRef]

- Johansen, Ø. Development and verification of deep-water blowout models. Mar. Pollut. Bull. 2003, 47, 360–368. [Google Scholar] [CrossRef]

- Yapa, P.D.; Chen, F. Behavior of oil and gas from deepwater blowouts. J. Hydraul. Eng. 2004, 130, 540–553. [Google Scholar] [CrossRef]

- Sun, B.W.; Song, R. Application of a seven-component multiphase flow model to deepwater well control. Acta Petrolei Sinica 2011, 32, 1042. [Google Scholar]

- Chen, Y.J.; Deng, C.G.; Ma, T.S. Reliability theory evaluation method for wellbore instability risk. Nat. Gas Ind. 2019, 39, 97–104. [Google Scholar]

- Zhang, Z.W. Quantitative Evaluation of Wellbore Instability Risk in High Temperature and High Pressure Wells. Master’s Thesis, Xi’an University of Petroleum, Xi’an, China, 2023. [Google Scholar]

- Huang, Y.; Yang, J.; Shi, S.S.; Luo, M.; Yin, Q.S.; Xu, D.S. Application of managed pressure drilling technology in offshore ultra-high temperature and high pressure wells. Pet. Drill. Process 2018, 40, 699–705. [Google Scholar]

- Chen, G.; Ewy, R.T. Investigation of the undrained loading effect and chemical effect on shale stability. In Proceedings of the SPE/ISRM Rock Mechanics Conference 2002, Irving, TX, USA, 20–23 October 2022; SPE: Calgary, AB, Canada, 2022; p. SPE-78164. [Google Scholar]

- Bradley, W.B. Failure of inclined boreholes. J. Energy Resour. Technol. 1979, 101, 232–239. [Google Scholar] [CrossRef]

- Chukwuemeka, A.O.; Amede, G.; Alfazazi, U. A Review of wellbore instability during well construction: Types, causes, prevention and control. Pet. Coal 2017, 7, 590–610. [Google Scholar]

- Medhi, N.; Borthakur, P.P. An Extensive Review on Gas Hydrates: Recent Patents, Properties, Formation, Detection, Production, Importance, and Challenges. Recent Pat. Eng. 2025, 19, E080524229746. [Google Scholar] [CrossRef]

- Yang, Y.T. Research on Accidental Catastrophe Evolution and Early Warning Method for NGH Test Mining Operation; China University of Petroleum (East China): Dongying, China, 2022. [Google Scholar]

- Chen, J. Methods and risk control of NGH mining in the sea. Sci. Technol. Wind. 2020, 33, 109–110. [Google Scholar]

- Zhao, B. Analysis of NGH Mining Activities in the Sea Area and Potential Disaster Prevention and Control; China University of Mining and Technology: Xuzhou, China, 2019. [Google Scholar]

- Xin, X.; Wang, H.; Luo, J.; Yu, H.; Yuan, Y.; Xia, Y.; Chen, Q. Simulation–optimization coupling model for the depressurization production of marine natural gas hydrate in horizontal wells based on machine learning method. Nat. Gas Ind. 2020, 40, 149–158. [Google Scholar]

- Lin, T.K.; Hsieh, B.Z. Prevention of seabed subsidence of class-1 gas hydrate deposits via CO2-EGR: A numerical study with coupled geomechanics-hydrate reaction-multiphase fluid flow model. Energies 2020, 13, 1579. [Google Scholar] [CrossRef]

- Wang, Z.G.; Li, X.Y.; Zhang, Y.B.; Yin, H.; Hu, C.; Liang, J.Q.; Huang, W. Analysis of the stimulation methods for marine non-diagenetic natural gas hydrate reservoirs. Drill. Eng. 2021, 48, 32–38. [Google Scholar]

- Yang, Y.; He, Y.; Zheng, Q. An analysis of the key safety technologies for natural gas hydrate exploitation. Adv. Geo-Energy Res. 2017, 1, 100–104. [Google Scholar] [CrossRef]

- Tian, H.; Yu, Z.; Xu, T.; Xiao, T.; Shang, S. Evaluating the recovery potential of CH4 by injecting CO2 mixture into marine hydrate-bearing reservoirs with a new multi-gas hydrate simulator. J. Clean. Prod. 2022, 361, 132270. [Google Scholar] [CrossRef]

- Nie, Q.; Zhang, S.; Huang, Y.; Yi, X.; Wu, J. Numerical and Experimental Investigation on Safety of Downhole Solid–Liquid Separator for Natural Gas Hydrate Exploitation. Energies 2022, 15, 5649. [Google Scholar] [CrossRef]

- Uchida, S.; Klar, A.; Yamamoto, K. Sand production model in gas hydrate-bearing sediments. Int. J. Rock Mech. Min. Sci. 2016, 86, 303–316. [Google Scholar] [CrossRef]

- Cha, M.J.; Hu, Y.; Sum, A.K. Methane hydrate phase equilibria for systems containing NaCl, KCl, and NH4Cl. Fluid Phase Equilib. 2016, 413, 2–9. [Google Scholar] [CrossRef]

- Chong, Z.R.; Chan, A.H.M.; Babu, P.; Yang, M.J.; Linga, P. Effect of NaCl on methane hydrate formation and dissociation in porous media. J. Nat. Gas Sci. Eng. 2015, 27, 178–189. [Google Scholar] [CrossRef]

- Cha, M.; Shin, K.; Kim, J.; Chang, D.; Seo, Y.; Lee, H.; Kang, S.P. Thermodynamic and kinetic hydrate inhibition performance of aqueous ethylene glycol solutions for natural gas. Chem. Eng. Sci. 2013, 99, 184–190. [Google Scholar] [CrossRef]

- Kwak, G.H.; Lee, K.H.; Hong, S.Y.; Seo, S.D.; Lee, J.D.; Lee, B.R.; Sum, A.K. Phase Behavior and Raman Spectroscopic Analysis for CH4 and CH4/C3H8 Hydrates Formed from NaCl Brine and Monoethylene Glycol Mixtures. J. Chem. Eng. Data 2018, 63, 2179–2184. [Google Scholar] [CrossRef]

- Yang, L.M.; Gao, F.M.; Gao, X.; Yan, Z.J.; Xu, D.D. Development and performance evaluation of a new hydrate inhibitor HAY. Liaoning Chem. 2025, 54, 248–251. [Google Scholar]

- Qin, H.B. Research on Hydrate Kinetic Inhibition Mechanism and Development of Efficient Hydrate Kinetic Inhibitors; China University of Petroleum: Beijing, China, 2016. [Google Scholar]

- Jager, M.; Peters, C.; Sloan, E. Experimental determination of methane hydrate stability in methanol and electrolyte solutions. Fluid Phase Equilib. 2002, 193, 17–28. [Google Scholar] [CrossRef]

- Jinhao, S.; Zhi, W.; Xuanji, L.; Xuanwei, Z.; Yumo, Z.; Shangfei, S.; Bohui, S.; Jing, G.; Xia, L. Paired KHI-MEG for synergistic inhibition of methane hydrate reformation. Chem. Ind. Eng. Prog. 2022, 41, 5373–5380. [Google Scholar]

- Kelland, M.A.; Pomicpic, J.; Ghosh, R. Maleic and Methacrylic Homopolymers with Pendant Dibutylamine or Dibutylamine Oxide Groups as Kinetic Hydrate Inhibitors. ACS Omega 2022, 7, 42505–42514. [Google Scholar] [CrossRef]

- Olabisi, O.T.; John, C.U.; Udim, M.C. Experimental investigation of modified starch from white corn as a kinetic inhibitor of gas hydrate. Pet. Coal 2019, 9, 1487–1493. [Google Scholar]

- Longinos, S.N.; Longinou, D.D. Examination of different amino acids as methane-propane gas hydrate kinetic inhibitors in upstream industry. In Proceedings of the 13th Panhellenic Scientific Conference in Chemical Engineering (PESXM), Patra, Greece, 2–4 June 2022. [Google Scholar]

- Li, B.B.; Sun, Q.; Gao, W.W. Experimental study on the effect of diethylene glycol butyl ether on the performance of kinetic hydrate inhibitors. Sci. Technol. Eng. 2014, 14, 141–144. [Google Scholar]

- Luan, H.; Liu, M.; Shan, Q.; Jiang, Y.; Yan, P.; Du, X. Experimental Study on the Effect of Mixed Thermodynamic Inhibitors with Different Concentrations on Natural Gas Hydrate Synthesis. Energies 2024, 17, 2078. [Google Scholar] [CrossRef]

- Bu, Y.; Du, W.; Du, J.; Zhou, A.; Lu, C.; Liu, H.; Guo, S. The potential utilization of lecithin as natural gas hydrate decomposition inhibitor in oil well cement at low temperatures. Constr. Build. Mater. 2021, 269, 121274. [Google Scholar] [CrossRef]

- Li, L.; Cheng, Y.; Zhang, Y.; Cui, Q.; Zhao, F. A fluid-solid coupling model of wellbore stability for hydrate bearing sediments. Procedia Eng. 2011, 18, 363–368. [Google Scholar] [CrossRef]

| NGH Mining Area | Time | Reservoir Characterization | Mode of Mining | The Total Gas Output of NGH |

|---|---|---|---|---|

| Nankai, Japan | March 2013 | Water depth: 1000 m Burial depth: 300–360 m Type: Sand layer Average initial permeability: 20 mD | Depressurization production | Cumulative: 11.9 × 104 m3 Average: 2.0 × 104 m3/d |

| Nankai, Japan | May 2017 | Water depth: 1000 m Burial depth: 300–360 m Type: Sand layer Average initial permeability: 20 mD | Depressurization production | Cumulative: 26.2 × 104 m3 Average: 0.73 × 104 m3/d |

| Shenhu Sea, China | July 2017 | Water depth: 1266 m Burial depth: 203–277 m Type: Muddy chalk Average initial permeability: 2.9 mD | Depressurization production | Cumulative: 30.9 × 104 m3 Average: 0.5 × 104 m3/d |

| Shenhu Sea, China | April 2020 | Water depth: 1225 m Burial depth: 207–253 m Type: Muddy chalk Average initial permeability: 2.38 mD | Depressurization production | Cumulative: 8614 × 104 m3 Average: 2.87 × 104 m3/d |

| Alaska, USA | May 2012 | - | CO2 displacement production | Cumulative: 30 × 104 m3 |

| Type | Occurrence Conditions | Typical Examples | Causes | Instability Symptoms |

|---|---|---|---|---|

| Tensile failure (stress failure) | When the strain created by borehole pressure exceeds the internal stress of the rock formation | Wellbore fracturing, hole enlargement |

|

|

| Shear failure | When the strain created by borehole pressure is less than the internal stress of the rock formation | Wellbore collapse, tight holes |

| Inhibitor Type | Experiment Method | Experimental Result | Inhibitor Mechanism | Inhibitor Effect |

|---|---|---|---|---|

| Thermodynamic inhibitors |

| Sodium chloride is more effective | By adjusting the thermodynamic conditions of NGH, the gas production is inhibited | Strong stability; versatility; not limited by other mechanical conditions |

| Only under the condition of pure water is the sodium chloride solution effective | |||

| When the concentration of ethylene glycol is 30wt %, the hydrate inhibition effect is better | |||

| Mixed inhibitors |

| The result of mixed inhibitors is more effective than that of a single sodium chloride inhibitor | By using a mixed inhibitor of sodium chloride and ethylene glycol, the hydrate formation rate and wellbore blockage are slowed down | Strong inhibition effect; high economic type and adaptation to various environments |

| The effect of mixed inhibitors is better than the sum of single inhibitors | |||

| The mixing suppression effect is stronger | |||

| The mixed inhibitor of Tetrahydrofuran and N-butenyl pyrrolidone is more effective than a single inhibitor | |||

| Kinetic hydrate inhibitor |

| Polymers containing dibutylamine groups are more potent inhibitors than polymers containing dimethylamine or diethylamine groups | It is economical and effective, environmentally friendly, and has little impact on the production process | The suppression effect is affected by many factors such as temperature and pressure, and there are differences between the laboratory evaluation method and the actual scene |

| The results showed that, when the dosage of modified starch was 0.04wt %, the inhibition effect was the best | |||

| Aspartic acid and threonine showed inhibitory effects, while the latter two amino acids played a promoting role | |||

| Diethylene glycol butyl ether can significantly improve the efficiency of inhibitors |

| Geological Hazards | Technical Precautions | Policy Suggestions | |

|---|---|---|---|

| Natural geological hazards | Stratum subsidence | Optimize CO2-EGR method to alleviate stratum subsidence |

|

| Seafloor landslide | Fill foamed cement to control seafloor landslides | ||

| Greenhouse effect | Improve drilling technology to mitigate greenhouse effect | ||

| Secondary geological accidents | Sand piping | Install new solid–liquid separator to reduce sand piping | |

| Well blowout | Adopt new inhibitor to lower well blockage | ||

| Wellbore instability | Use a low-temperature drilling fluid to keep wellbore stable | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, Z.; Hu, W.; Yan, Q. A Review of Potential Geological Hazards and Precautions in the Mining of Submarine Natural Gas Hydrate. Processes 2025, 13, 1669. https://doi.org/10.3390/pr13061669

Ye Z, Hu W, Yan Q. A Review of Potential Geological Hazards and Precautions in the Mining of Submarine Natural Gas Hydrate. Processes. 2025; 13(6):1669. https://doi.org/10.3390/pr13061669

Chicago/Turabian StyleYe, Zhanghuang, Wenqi Hu, and Qiang Yan. 2025. "A Review of Potential Geological Hazards and Precautions in the Mining of Submarine Natural Gas Hydrate" Processes 13, no. 6: 1669. https://doi.org/10.3390/pr13061669

APA StyleYe, Z., Hu, W., & Yan, Q. (2025). A Review of Potential Geological Hazards and Precautions in the Mining of Submarine Natural Gas Hydrate. Processes, 13(6), 1669. https://doi.org/10.3390/pr13061669